Power socket demultiplexer

A technology for power sockets and splitters, applied in contact parts, riveted connections, etc., which can solve problems such as high assembly and material costs, affecting product continuity, and virtual soldering, so as to achieve stable quality, avoid virtual soldering, Easy assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

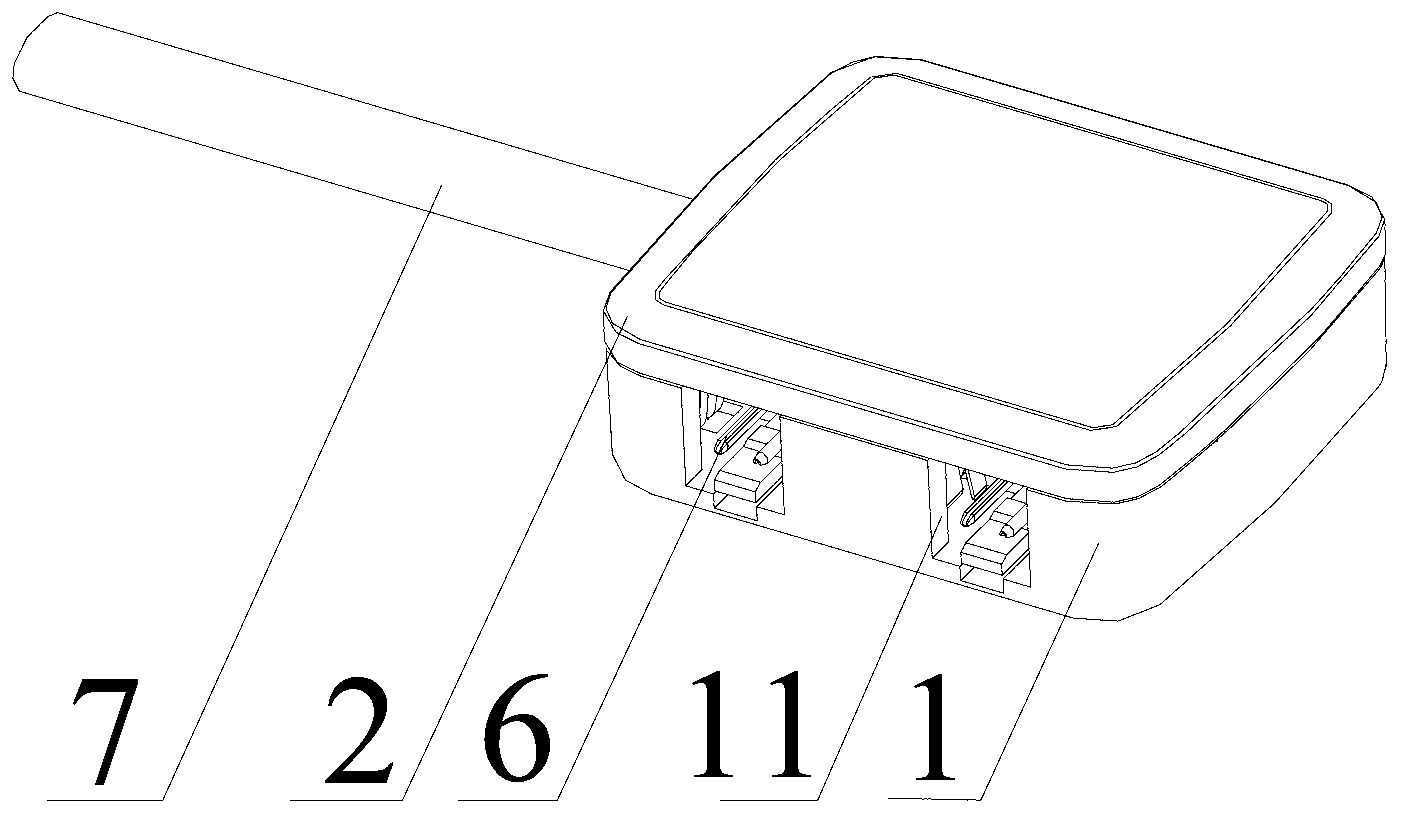

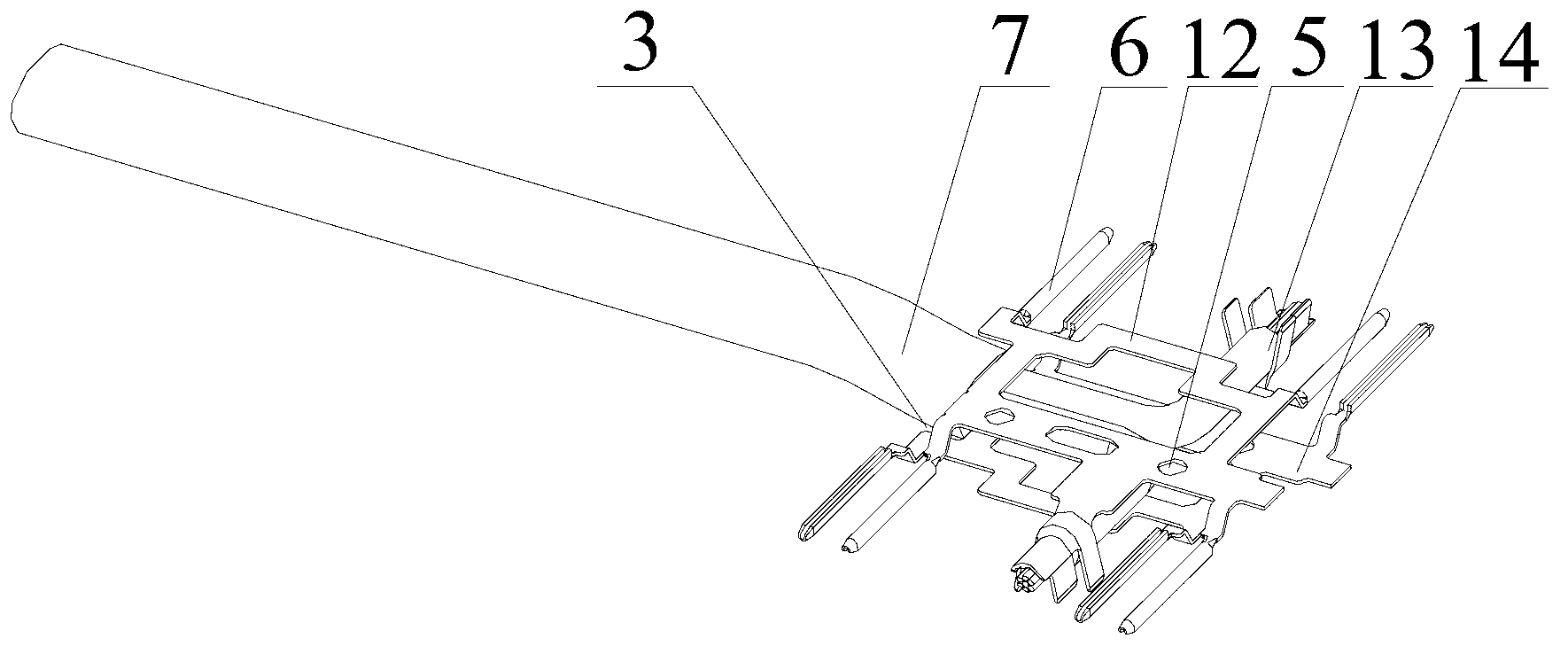

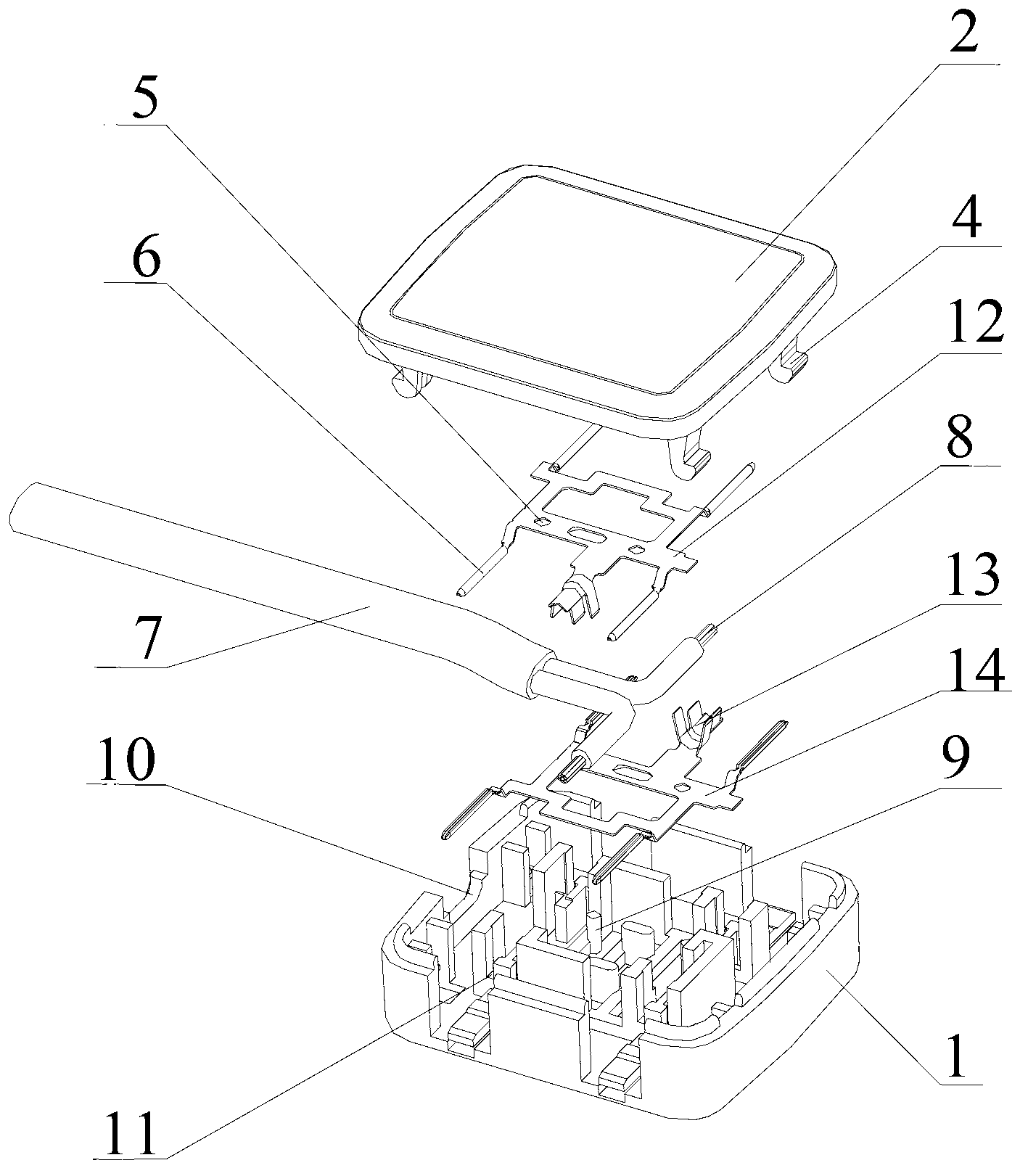

[0014] like Figure 1-3 As shown, a power socket splitter described in the embodiment of the present invention includes a base 1 and a cover 2, the cover 2 is provided with a hook 4, the upper end of the base 1 is provided with a card slot, and the base 1 passes through the card The cooperation between the hook 4 and the card slot is connected with the cover 2, the base 1 is provided with a terminal riveting wire assembly 3, the terminal riveting wire assembly 3 includes an upper terminal 12, a lower terminal 14 and a wire 7, and the lower terminal 14 is provided with The wire 7 is provided with an upper terminal 12, the front side and the rear side of the upper terminal 12 and the lower terminal 14 are respectively provided with several pairs of pins 6, and the upper terminal 12 and the lower terminal 14 are respectively provided with terminal riveting openings 13, Two peeled bare wires 8 are arranged on the wire 7, and the peeled bare wires 8 are respectively connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com