Phase change memory based on nano current channel

A phase change memory and current channel technology, applied in the field of phase change memory, can solve the problems of high difficulty and high process cost, and achieve the effects of reducing device power consumption, simple process and improving current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] According to another aspect of the present invention, the present invention provides a nano current channel layer and a method for preparing a phase change memory containing a nano current channel layer, which is characterized in that magnetron sputtering, chemical vapor deposition, plasma enhanced chemical Any of vapor deposition, physical vapor deposition, laser pulse deposition, evaporation, electrochemical growth, ion implantation, molecular beam epitaxy, atomic vapor deposition, and atomic layer deposition.

[0055] The present invention also provides a preparation method of a phase-change memory based on a nano-current channel. power consumption purposes.

Embodiment 1

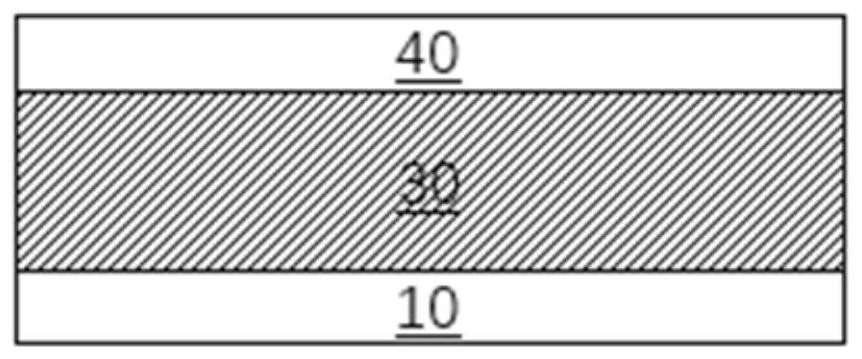

[0058] According to the first embodiment of the present invention, the sectional view of an exemplary structure of a conventional phase-change memory is as follows: figure 1 show.

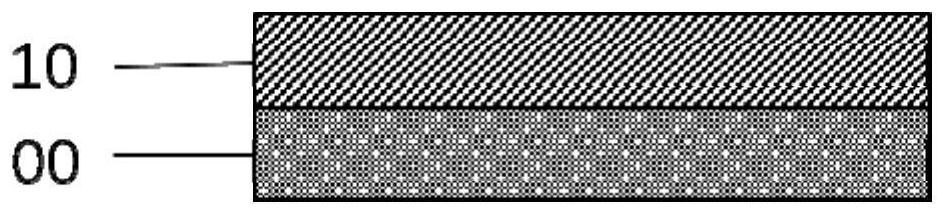

[0059] The bottom electrode 10 is formed on SiO 2 On the substrate, the material of the bottom electrode 10 is selected from W, Pt, Au, Al, Cu, Ti, Ta and other metal materials and conductive materials of their alloys. A phase change material layer 30 is formed on the bottom electrode 10, and the phase change layer material 30 includes a chalcogenide compound. Preferably, the chalcogenide compound includes an alloy compound formed by one of S, Se, Te and other non-chalcogenide materials, wherein the non-chalcogenide material includes Ge, Sb, Ga, Bi, In, Sn, Pb, Ag, N, One or more of O; preferably, the chalcogenides include GeTe, GeSb, Ge 2 Sb 2 Te 5 、 Ge 1 Sb 2 Te 4 , Sb 2 Te 3 , AgInSbTe; more preferably, the chalcogenide compound includes a compound formed by doping and modifying the ab...

Embodiment 2

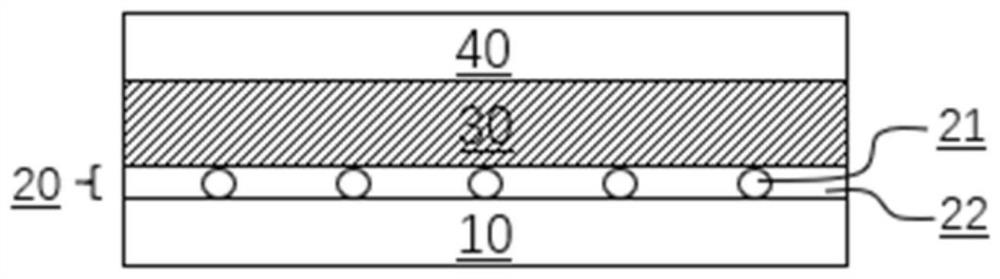

[0063] According to the second embodiment of the present invention, the finite element simulation is performed on the phase-change memory structure with the nano current channel layer and the writing process of the traditional phase-change memory structure.

[0064] The simulation adopts the simplest three-layer phase-change memory cell structure in Embodiment 1. The material parameters used in the simulation are listed in Table 1 (the thermal and electrical parameters of various materials used in the finite element analysis). The upper and lower electrodes of the two cell structures are made of Pt, and the insulating material between the cells is SiO 2 And the phase change layer material is Ge2 Sb 2 Te 5 , the thickness of the upper and lower electrodes, insulating layer, and phase change layer are all 100nm, and the diameter of the unit device is 100nm. In the structure with a nano-current channel layer, the thickness of the nano-current channel layer is set to 5nm. SiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com