A cast polypropylene straight composite film

A technology of casting polypropylene and polypropylene, which is applied in the field of polypropylene film, can solve problems such as poor stiffness and heat resistance, high thermal shrinkage deformation rate, and unstable thermal viscosity, so as to improve stiffness and temperature resistance Sexuality, smooth unwinding and slitting, and the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

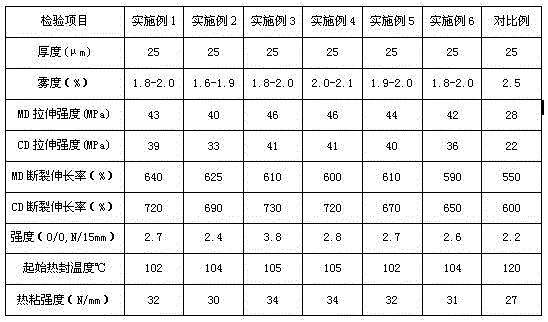

Examples

Embodiment 1

[0019] Embodiment 1: this casting polypropylene direct laminating film, its release layer is made of 100 parts of polypropylene binary random copolymer resins and synthetic wollastonite release agent (10% silicon dioxide or synthetic china clay or glass microspheres and 90% polypropylene blending and granulation, the same below) is composed of 0.002 parts; the core layer is composed of 100 parts of polypropylene homopolymer resin, 20 parts of ethylene-hexene copolymer, dibenzylidene sorbitol nucleating agent (DBS) 0.1 part and 0.0015 part of erucamide slip agent (95% polypropylene, 5% high-purity erucamide blended and granulated, the same below); the heat-sensitive functional layer is composed of ethylene-propylene copolymer (copolymer Composed of 100 parts of monomer content greater than 20%, ethylene content of 8%), 30 parts of maleic anhydride grafted ethylene-octene copolymer, and 30 parts of ethylene methyl acrylate copolymer (EMA). The above-mentioned three-layer materia...

Embodiment 2

[0020] Embodiment 2: The cast polypropylene direct laminating film, its anti-adhesive layer is composed of 100 parts of polypropylene binary random copolymer resin and 0.002 parts of synthetic silica; the core layer is made of 100 parts of polypropylene homopolymer resin, ethylene- 10 parts of hexene copolymer, 0.2 part of di-p-methyl-benzylidene sorbitol (MDBS) and 0.0015 parts of erucamide slip agent; the thermosensitive functional layer is composed of 100 parts of ethylene-propylene copolymer, grafted with maleic anhydride Composed of 35 parts of ethylene-octene copolymer and 35 parts of ethylene methyl acrylate copolymer (EMA). The above-mentioned three-layer materials are melted through their respective single-screw extruders, and then formed into a film through a batching block connector, a T-die co-extrusion and casting cooling. The product is subsequently cooled and shaped, thickness tested, corona treated, rolled, aged treated, cut and packaged to obtain the final pro...

Embodiment 3

[0021] Embodiment 3: The casting polypropylene direct laminating film, its anti-adhesive layer is made up of 100 parts of polypropylene binary random copolymer resin and 0.002 part of synthetic silicon dioxide; Core layer is made of 100 parts of polypropylene homopolymer resin, ethylene- Composed of 25 parts of hexene copolymer (comonomer content greater than 20%, ethylene content of 8%), 0.5 part of di-p-chlorobenzylidene sorbitol (CDBS) and 0.002 part of erucamide slip agent; the thermosensitive functional layer consists of Ethylene-propylene copolymer (comonomer content greater than 20%, ethylene content 8%) 100 parts, maleic anhydride grafted ethylene-octene copolymer 47 parts, ethylene methyl acrylate copolymer (EMA) 18 parts, ethylene Methacrylic acid (EMAA) 25 parts composition. The above-mentioned three-layer materials are melted through their respective single-screw extruders, and then formed into a film through a batching block connector, a T-die co-extrusion and cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com