Lightweight graphite resistance reduction module and preparation method thereof

A graphite and resistance-reducing technology, applied in the field of lightweight graphite resistance-reducing modules and their preparation, can solve the problems of high resistance, heavy weight, and difficulty in handling, and achieve low resistivity, increased contact area, and superior electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

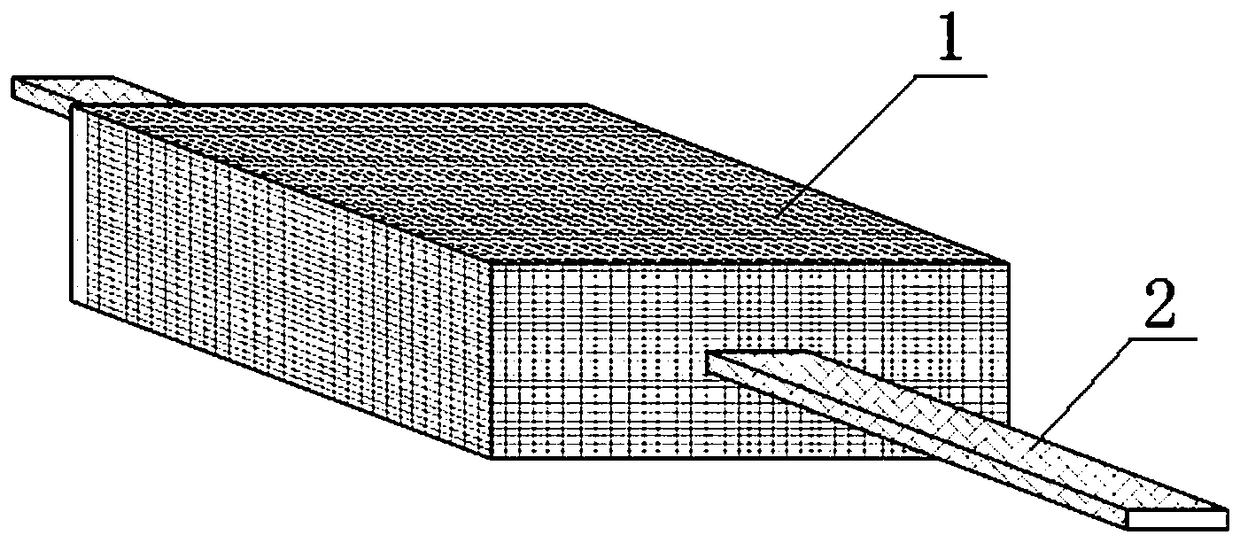

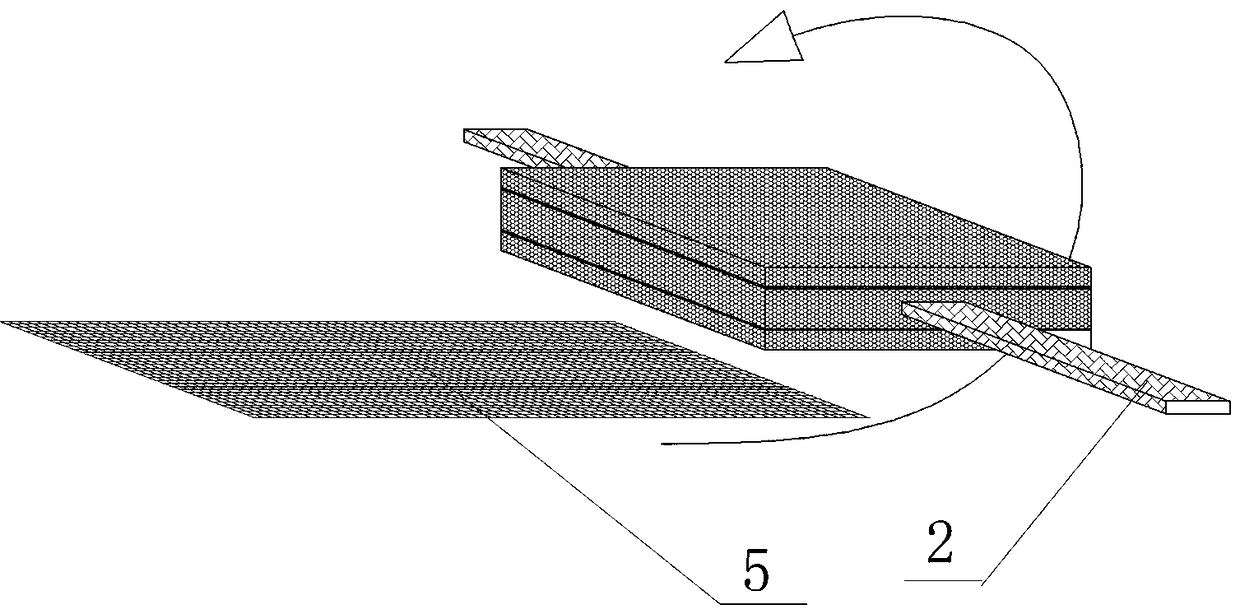

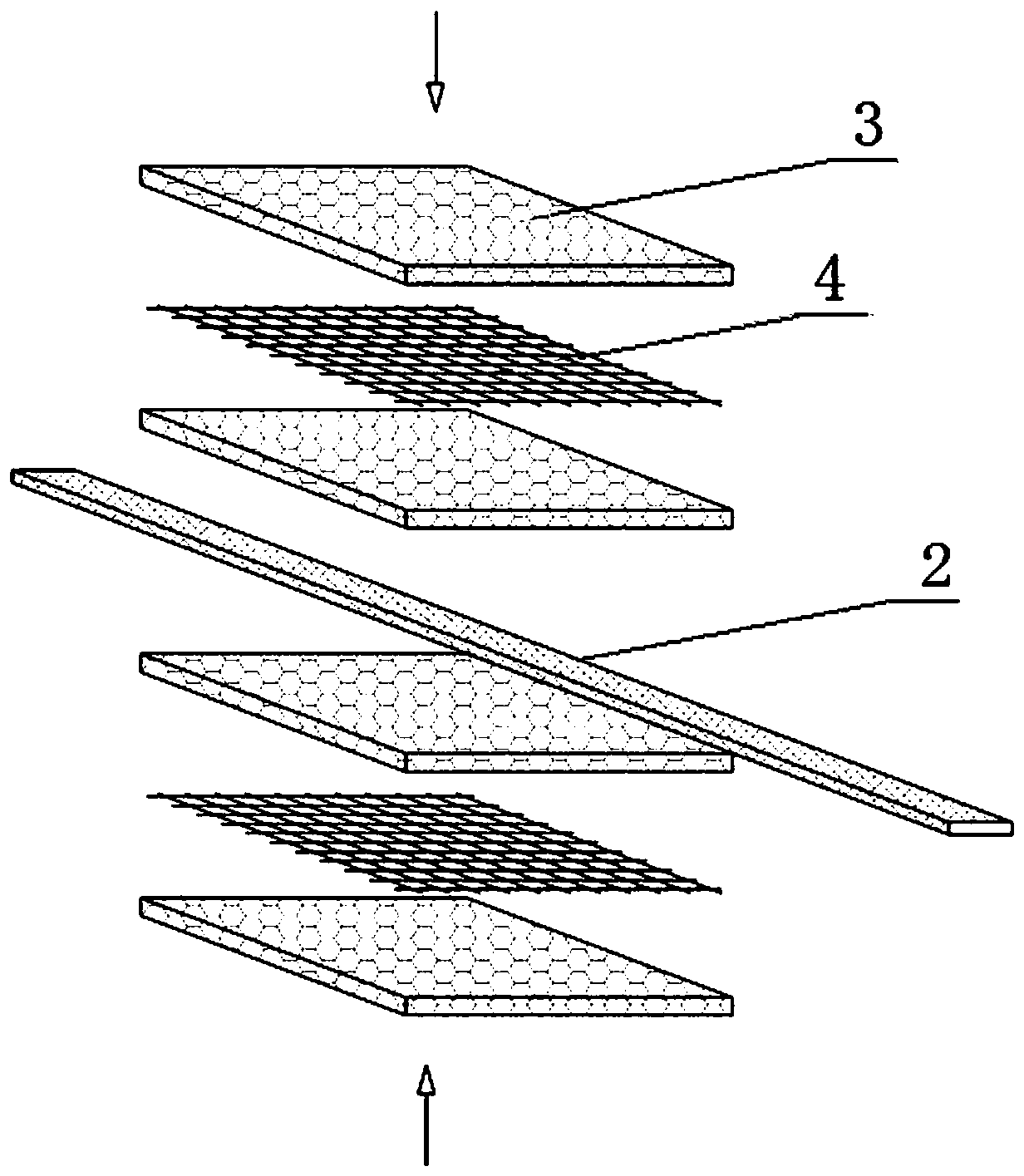

[0027] Such as figure 1 , 2 . The lightweight graphite resistance-reducing module shown in 3 has a grounding connection line 2, and the grounding connection line 2 runs through the grounding module 1, and the two sides of the grounding module 1 are laid with expanded graphite layers 3 layer by layer from the inside to the outside and glass fiber mesh cloth 4, the outermost layer of the grounding module is provided with a wrapping layer 5 that wraps the entire grounding module, and the grounding module is pressed into a fixed module by a mold.

[0028] The ground connection wire is a graphite braid or a metal or other graphite ground cable.

[0029] The shape of the ground connection wire is a flat block, a strip, a cylinder or an irregular cube.

[0030] The wrapping layer is graphite drag-reducing cloth, carbon fiber mesh cloth, glass fiber mesh cloth or metal braided mesh.

[0031] The size of the grounding module is 510mm*410mm*60mm.

[0032] The preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com