Preparation method of phase change memory based on nano current channel

A phase change memory and current channel technology, applied in the field of phase change memory, can solve the problems of high process cost and difficulty, and achieve the effects of simple process, low total energy and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

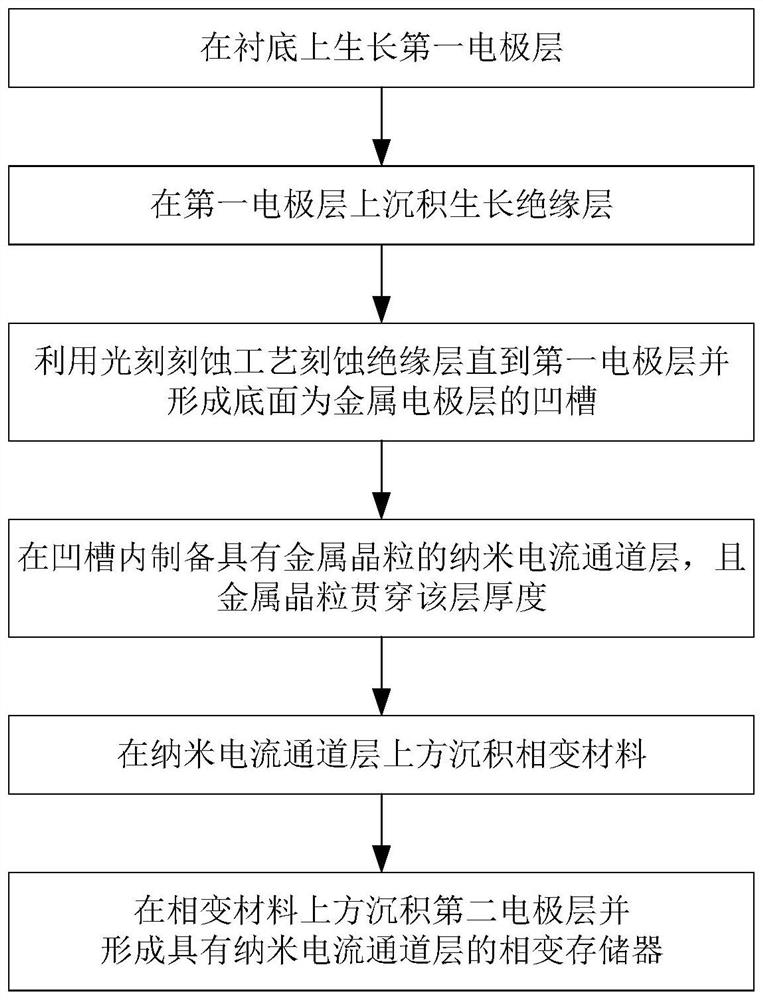

[0052] The preparation method of the phase-change memory based on the nano-current channel provided by the present invention includes:

[0053] (1) growing the first electrode layer on the substrate;

[0054] (2) depositing and growing an insulating layer on the first electrode layer;

[0055] (3) Etching the insulating layer up to the first electrode layer and forming a groove whose bottom surface is a metal electrode layer by using a photolithography etching process;

[0056] (4) preparing a nano current channel layer with metal grains in the groove, and the metal grains run through the thickness of the layer;

[0057] (5) Depositing a phase change material above the nano current channel layer;

[0058] (6) Depositing a second electrode layer on the phase change material to form a phase change memory with a nano current channel layer.

[0059] The present invention can adopt magnetron sputtering method, chemical vapor deposition method, plasma enhanced chemical vapor depo...

Embodiment 1

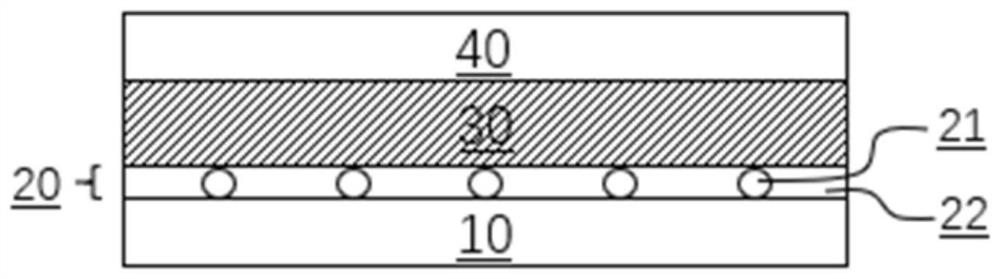

[0078] According to the first embodiment of the present invention, a cross-sectional view of an exemplary structure of a phase-change memory with a nanometer current channel layer and figure 2 show. The bottom electrode 10 is formed on SiO 2 On the substrate, the material of the bottom electrode 10 is selected from W, Pt, Au, Al, Cu, Ti, Ta and other metal materials and conductive materials of their alloys. The nano-current channel 20 is formed on the bottom electrode 10, the nano-current channel layer 20 is composed of an insulating and heat-insulating material 22 and conductive nano-crystal grains 21 embedded in the middle of the insulating and heat-insulating material layer, wherein the thickness of the nano-current channel layer 20 is between 1nm and 30nm . The size of the conductive nanoparticles in the insulating layer is 1nm-30nm, and the size of the conductive nanoparticles 21 in the direction perpendicular to the film is not less than the thickness of the nano curr...

Embodiment 2

[0081] According to the second embodiment of the present invention, the finite element simulation is performed on the phase-change memory structure with the nano current channel layer and the writing process of the traditional phase-change memory structure.

[0082] The simulation adopts the simplest three-layer phase-change memory cell structure in Embodiment 1. The material parameters used in the simulation are listed in Table 1 (the thermal and electrical parameters of various materials used in the finite element analysis). The upper and lower electrode materials of the two cell structures are Pt, and the insulating layer material is SiO 2 And the phase change layer material is Ge 2 Sb 2 Te 5 , the thickness of the upper and lower electrodes, insulating layer, and phase change layer are all 100nm, and the diameter of the unit device is 100nm. 2 Material, using Ag as the nano current channel, its diameter is 6nm. A RESET current pulse with an amplitude of 60uA and a puls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com