Gasification furnace chilling chamber containing flow-guiding cylinder and application method thereof

A technology of gasifier and chilling chamber, which is applied in gasification process, granular/powder fuel gasification, manufacture of combustible gas, etc., to achieve the effect of increasing contact area, reducing bubble size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

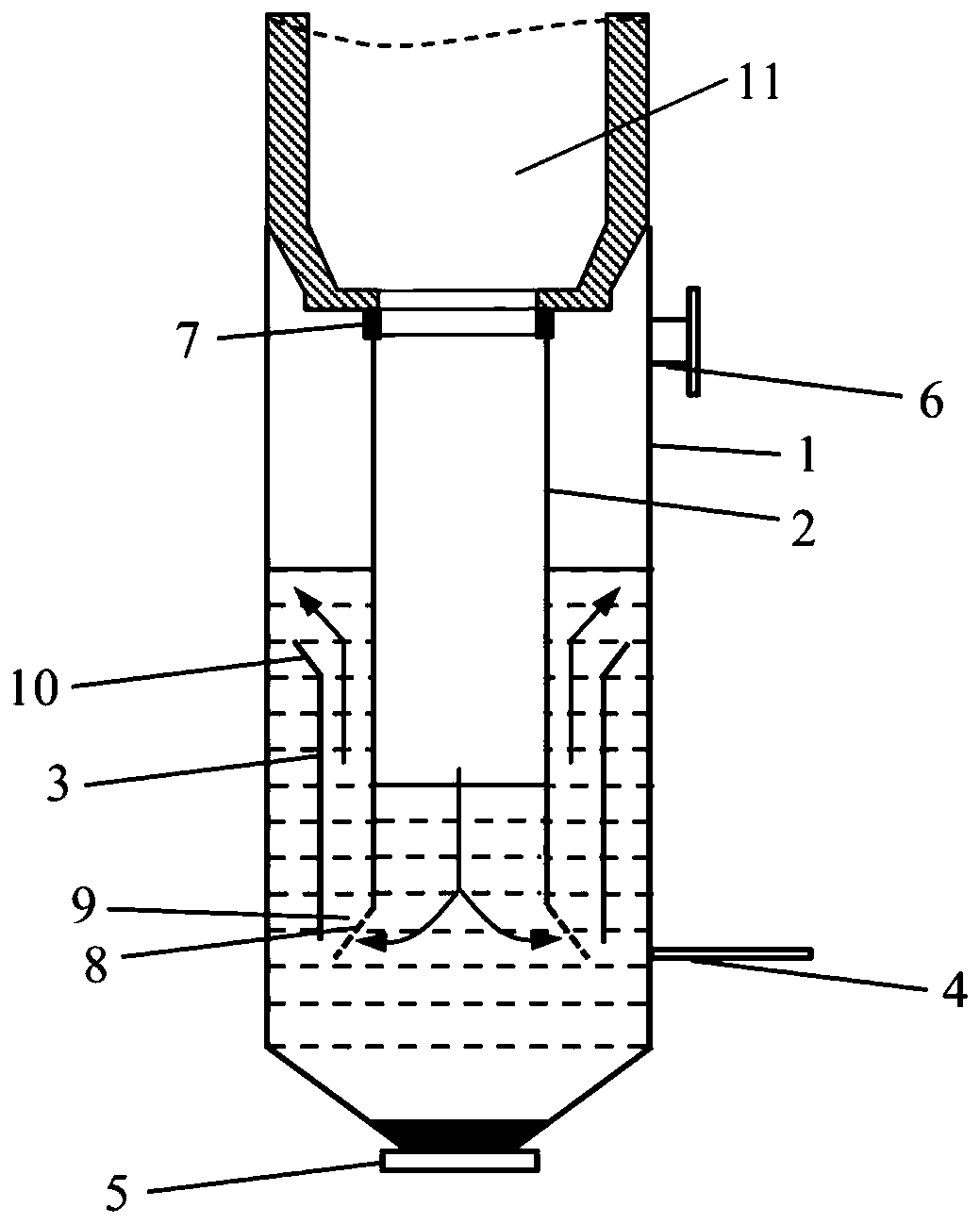

[0055] This embodiment provides a figure 1 The quenching chamber of the gasification furnace shown includes a shell 1 , a downcomer 2 is arranged inside the shell 1 , and a coaxial guide tube 3 is set on the outside of the downcomer 2 . An annular gap is formed between the guide tube 3 and the downcomer 2 . One end of the downcomer 2 is connected to the gasifier 11, and the other end is provided with a gas distribution device. The gas distribution device is a conical section 8 connected to the outer edge of the downcomer 2. The air hole 9 is set on the conical section 8, and the air hole 9 runs along the conical section. 8 is arranged in the circumferential direction, and the shape of the air hole 9 is circular. The synthesis gas produced by the gasifier 11 enters the downcomer 2 and then passes through the pores 9 on the conical section 8 to be introduced into the annular gap, and the diameter of the conical section 8 gradually increases along the direction of the syngas.

...

Embodiment 2

[0061] This embodiment provides a method for using the quenching chamber of the gasifier described in Embodiment 1, and the method specifically includes the following steps:

[0062] (I) The synthesis gas and molten slag produced by the gasifier 11 enter the downcomer 2, and at the same time, quenching water is passed into the quenching ring 7, and the quenching water is sprayed out from the nozzle and descends along the inner wall of the downcomer 2 to form a liquid film;

[0063] (II) The synthesis gas passes through the downcomer 2 and is dispersed into small bubbles through the air holes 9 on the tapered section 8, and then enters the annulus, and the bubbles pass through the annulus and are discharged from the exhaust port 6;

[0064] (Ⅲ) The molten slag passed through the downcomer 2 settles and accumulates at the bottom of the quenching chamber of the gasifier, and is regularly discharged from the slag outlet 5 , and fine particles in the molten slag are discharged throu...

Embodiment 3

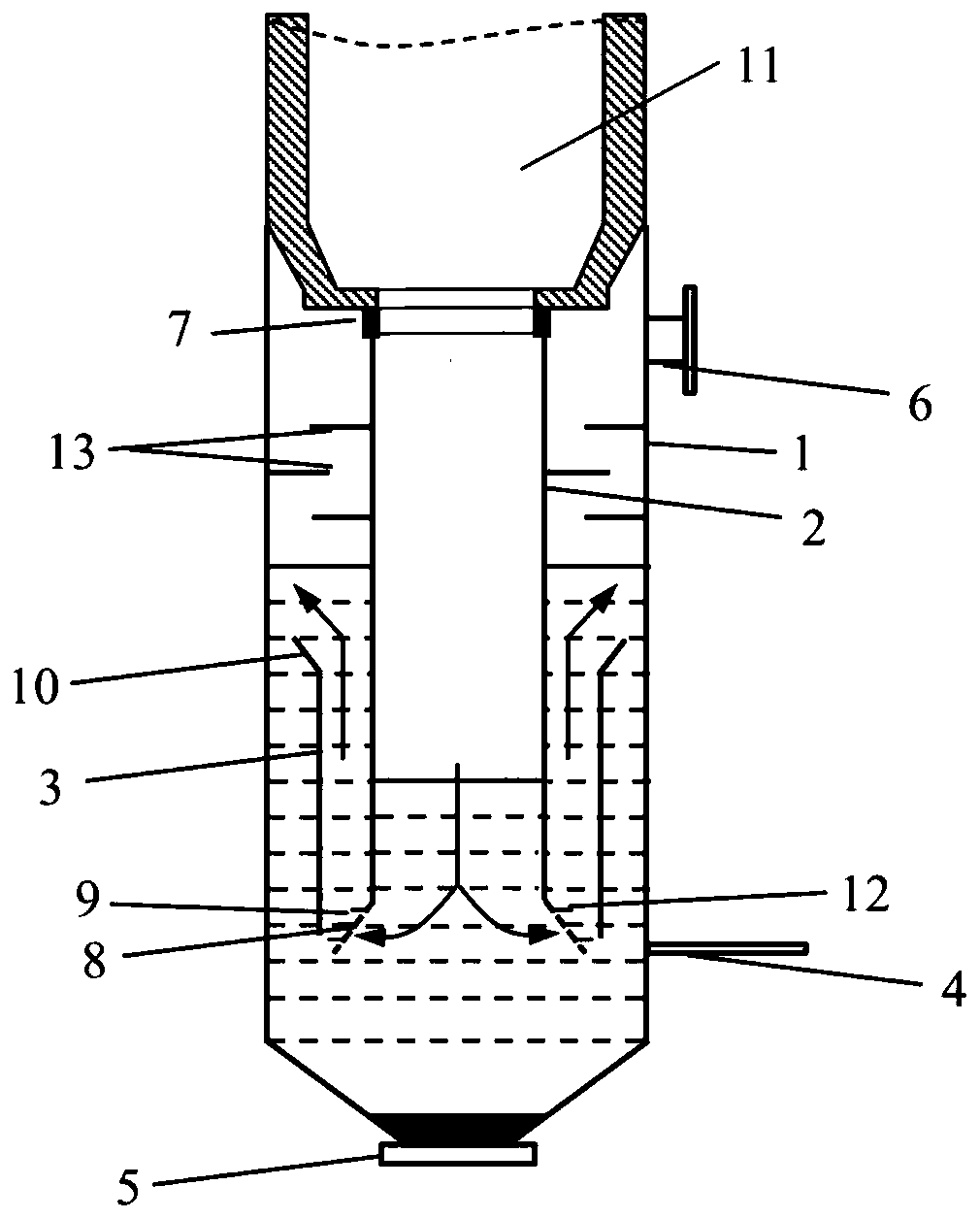

[0066] This embodiment provides a figure 2 The quenching chamber of the gasification furnace shown includes a casing 1, a downcomer 2 is arranged inside the casing 1, and a coaxial guide tube 3 is set on the outside of the downcomer 2, and a coaxial guide tube 3 is formed between the guide tube 3 and the downcomer 2. annulus. One end of the downcomer 2 is connected to the gasifier 11, and the other end is provided with a gas distribution device. The gas distribution device is a conical section 8 connected to the outer edge of the downcomer 2. The air hole 9 is set on the conical section 8, and the air hole 9 runs along the conical section. 8 is arranged in the circumferential direction, the shape of the air hole 9 is square, and the air hole 9 is provided with a deflector 12 . The synthesis gas produced by the gasifier 11 enters the downcomer 2 and then passes through the pores 9 on the conical section 8 to be introduced into the annular gap, and the diameter of the conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com