Reaction system and method for preparing formic acid through carbon dioxide hydrogenation

A reaction system, carbon dioxide technology, applied in catalytic reactions, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

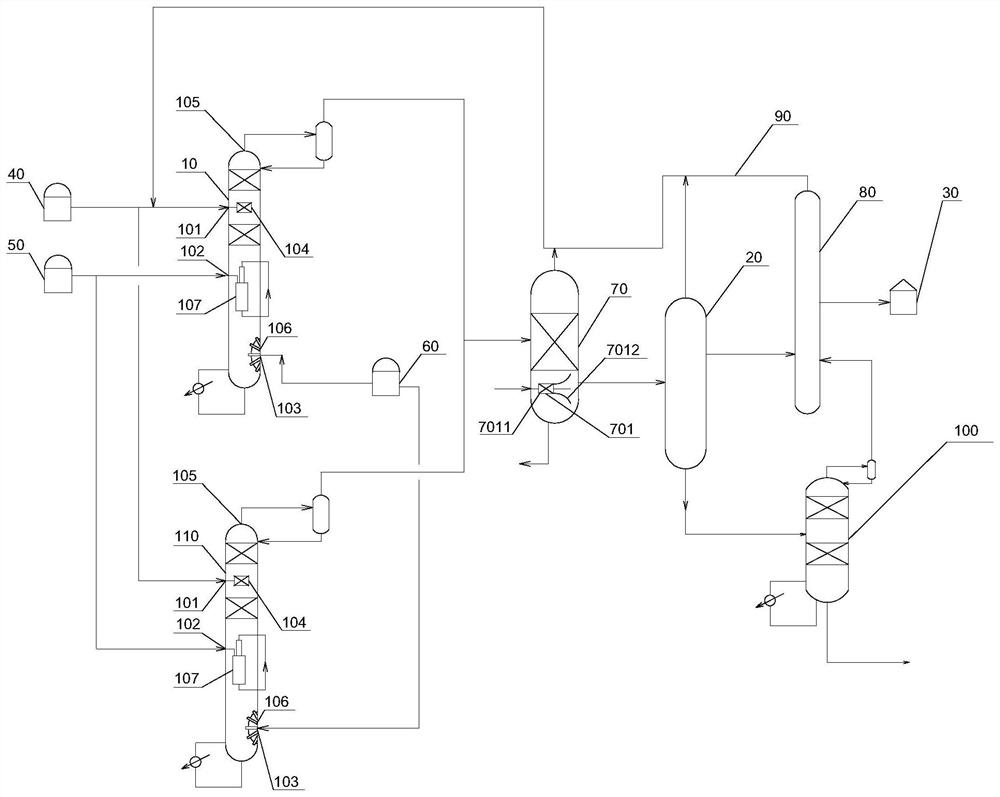

[0065] refer to figure 1 As shown, the reaction system for the production of formic acid by carbon dioxide hydrogenation provided by the embodiment of the present invention mainly includes the first reactive distillation column 10, the second reactive distillation column 110, the finishing reactor 70, the gas-liquid separation tank 20, the separation Tower 80 and purification tower 100; the side walls of the first reactive distillation tower 10 and the second reactive distillation tower 110 are successively provided with a hydrogen inlet 101, a carbon dioxide inlet 102 and a solvent and a catalyst mixing inlet 103 from top to bottom. 1. The catalyst mixing inlet 103 is arranged at the bottom of the first reactive distillation tower 10 and the second reactive distillation tower 110, so as to fill the whole first reactive distillation tower 10, the second reactive distillation tower 10, and the second reactive distillation tower with the solvent and catalyst that enter. Tower 11...

Embodiment 2-5

[0072] Other operation steps are consistent with embodiment 1, and difference is to adopt different catalysts to react, and the results are as shown in table 1:

[0073] Table 1. Reaction results using different catalysts

[0074] Example 2 3 4 5 catalyst Iron formate cobalt formate Manganese formate Nickel formate Liquid at the top of the tower (g) 2.8 4.4 1.6 2.0 Formic acid content (%) 98.5 98.3 98.8 98.9

Embodiment 6-10

[0076] Other operation steps are consistent with embodiment 1, and difference is to use different solvents to react, and the results are as shown in table 2:

[0077] Table 2. Reaction results using different solvents

[0078] Example 6 7 8 9 10 solvent n-decane Isododecane Tetradecane Isotetradecane n-hexadecane Liquid at the top of the tower (g) 3.4 3.8 3.7 3.7 3.9 Formic acid content (%) 96.6 98.7 98.6 98.6 98.9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com