Reaction system and process for preparing butyl octanol through propylene carbonylation based on micro-interface reinforcement

A propylene carbonyl and reaction system technology, applied in the field of carbonyl synthesis of butanol and octanol, can solve problems such as low reaction efficiency, and achieve the effects of ensuring reaction rate, saving costs, and strengthening mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

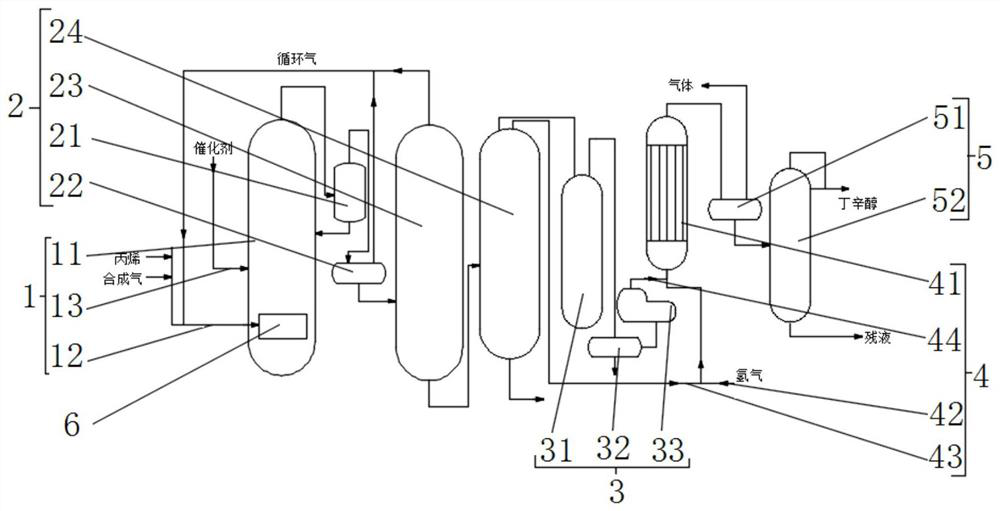

Method used

Image

Examples

Embodiment 1

[0102] Use the above-mentioned system and process to carry out carbonylation of propylene to prepare butanol, wherein:

[0103] In the process, the reaction temperature in the oxo reactor is 80°C, the reaction pressure is 0.8 MPa, the gas-liquid ratio in the micro-interface generator is 200:1, and the feed molar ratio of propylene to synthesis gas is 2 : 1, the syngas component carbon monoxide accounts for 48.2%, propane accounts for 1.2%, hydrogen accounts for 49.3%, and methane accounts for 1.3%.

[0104] After testing, after using the system and process, the conversion rate of propylene is 98.3%, the conversion rate of butyraldehyde is 97.7%, and the synthesis efficiency of the process is increased by 1.3%.

Embodiment 2

[0106] Use the above-mentioned system and process to carry out carbonylation of propylene to prepare butanol, wherein:

[0107] In the process, the reaction temperature in the oxo reactor is 83°C, the reaction pressure is 0.9MPa, the gas-liquid ratio in the micro-interface generator is 230:1, and the molar ratio of propylene to syngas is 3 : 2, the syngas component carbon monoxide accounts for 49.3%, propane accounts for 0.8%, hydrogen accounts for 48.5%, and methane accounts for 1.4%.

[0108] After testing, after using the system and process, the conversion rate of propylene is 98.5%, the conversion rate of butyraldehyde is 97.9%, and the synthesis efficiency of the process is increased by 1.4%.

Embodiment 3

[0110] Use the above-mentioned system and process to carry out carbonylation of propylene to prepare butanol, wherein:

[0111] In the process, the reaction temperature in the oxo reactor is 87°C, the reaction pressure is 1.0 MPa, the gas-liquid ratio in the micro-interface generator is 270:1, and the feed molar ratio of propylene to synthesis gas is 2 : 1, the syngas component carbon monoxide accounts for 49.7%, propane accounts for 1.2%, hydrogen accounts for 48.3%, and methane accounts for 0.8%.

[0112] After testing, after using the system and process, the conversion rate of propylene is 98.7%, the conversion rate of butyraldehyde is 98.0%, and the synthesis efficiency of the process is increased by 1.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com