Caprolactam production wastewater treatment system and method

A technology for treatment system and production wastewater, applied in water/sewage treatment, natural water treatment, oxidized water/sewage treatment, etc. It can solve the problems of low COD elimination rate, increase follow-up work, and high equipment requirements, and increase the phase interface area. , the effect of saving costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

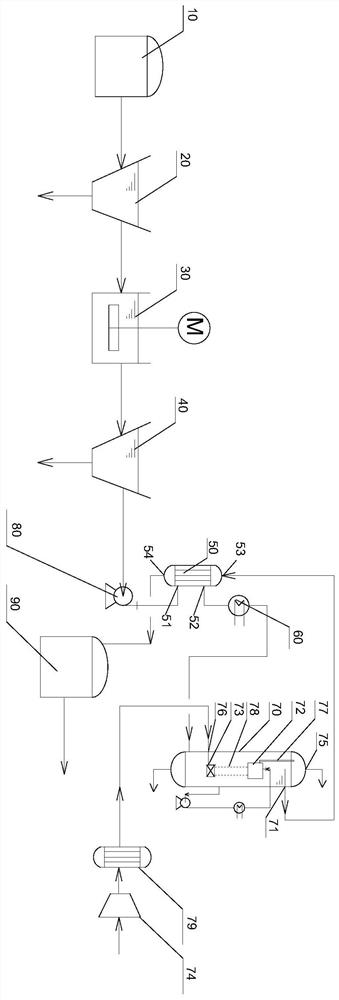

[0058] refer to figure 1 Shown is a caprolactam production wastewater treatment system according to an embodiment of the present invention, which includes a raw water tank 10 , a wastewater heat exchanger 50 , a wastewater heater 60 , an oxidation reactor 70 and an air compressor 74 connected in sequence.

[0059] Wherein, the waste water heat exchanger 50 has a material inlet 51, a material outlet 52, a heat source inlet 53, and a heat source outlet 54 respectively, and the oxidized water coming out of the oxidation reactor 70 enters the waste water heat exchanger 50 from the heat source inlet 53. The heat source outlet 54 is connected to the finished product tank 90, the material inlet 51 is connected to the raw water tank 10, and the material outlet 52 is connected to the waste water heater 60. In the waste water heat exchanger 50, the oxidized water after the oxidation reactor 70 is reacted and the The treated caprolactam production wastewater is heat-exchanged, so as to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com