Oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system

A technology of ebullating bed reactor and reaction system, which is applied in the field of oil-coal co-hydrogenation micro-interface enhanced ebullating bed reaction system, can solve the problem of high energy consumption in hydrogen process, achieve low cost per ton of products, reduce operating pressure, and reduce material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

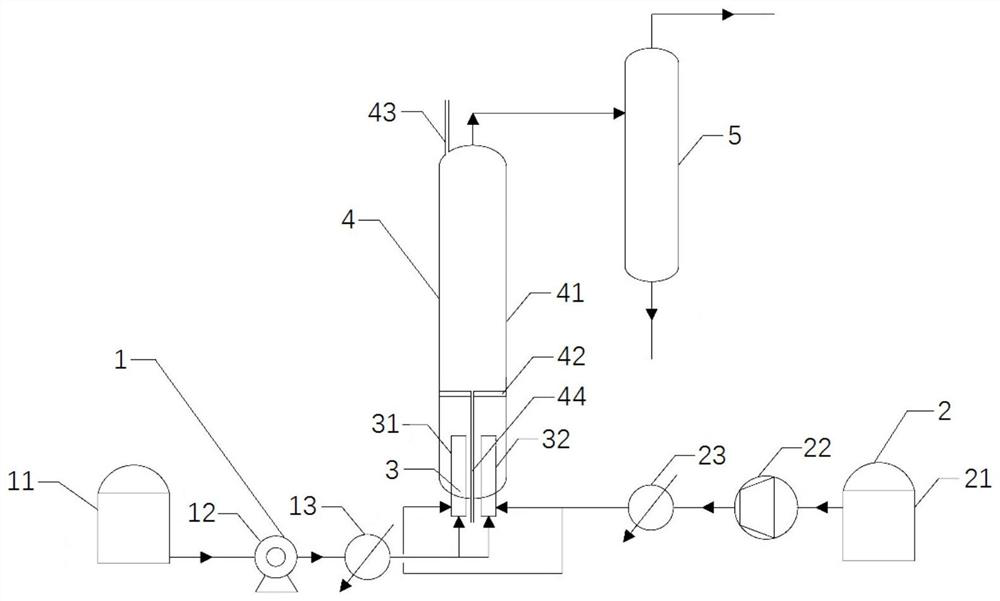

[0051] See figure 1 As shown, it is a schematic structural diagram of a bottom-mounted oil-coal co-hydrogenation micro-interface enhanced boiling bed reaction system according to an embodiment of the present invention, including a liquid feeding unit 1, a gas feeding unit 2, a micro-interface generator 3, and a boiling bed The reactor 4 and the separation tank 5; wherein the micro-interface generator 3 is connected to the liquid feeding unit 1 and the gas feeding unit 2 respectively, and is used to receive the mixed oil delivered by the liquid feeding unit 1 and The hydrogen delivered by the gas feed unit 2; the fluidized bed reactor 4 is connected to the micro-interface generator 3, and the output end of the micro-interface generator 3 is set inside the fluidized bed reactor 4 for the micro-interface generator The gas-liquid emulsion in 3 is output to the fluidized bed reactor; the separation tank 5 is connected to the fluidized bed reactor 4 to receive the mixture output from ...

Embodiment 2

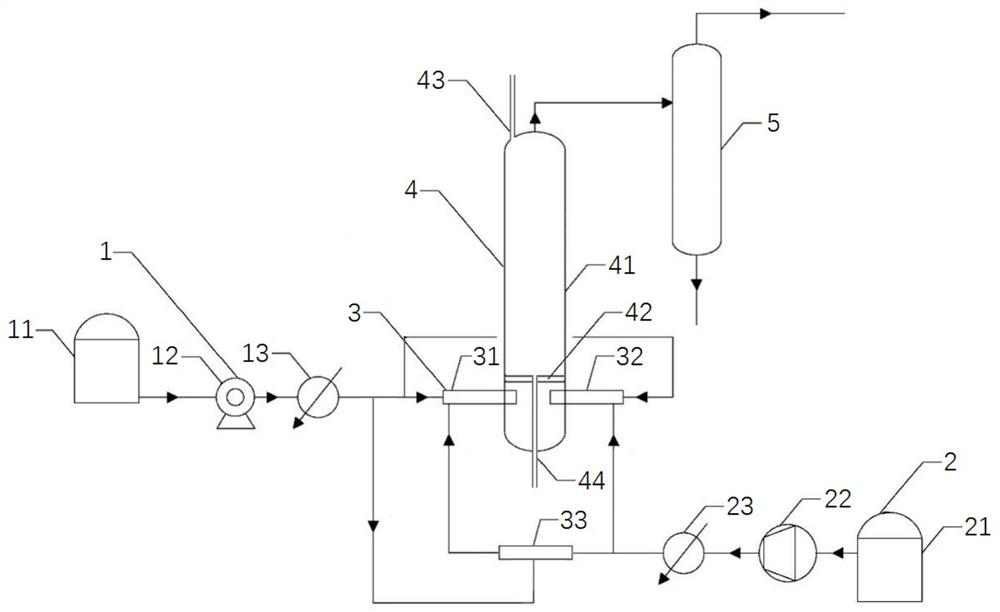

[0072] See figure 2 As shown, it is a schematic structural diagram of a side-mounted opposed oil-coal co-hydrogenation micro-interface enhanced fluidized bed reaction system according to an embodiment of the present invention, and the components of the system are the same as those in the first embodiment of the system.

[0073] The difference from Embodiment 1 of the above system is that in this embodiment, the micro-interface generator 3 is also provided with a third micro-interface generator 33, and the third micro-interface generator 33 is set in the gas feed At the exit of the heat exchanger 23, and the third micro-interface generator 33 is connected in parallel with the second micro-interface generator 32 to break a specified amount of hydrogen; the third micro-interface generator 33 is also connected to the first A micro-interface generator 31 is connected in series to break the hydrogen gas in multiple stages, thereby further reducing the diameter of the microbubbles.

[00...

experiment example 1

[0088] Use the above method and use the system in the first embodiment of the system to hydrodesulfurize the mixed oil, where:

[0089] The mixed oil product includes 100 mesh lignite and FCC gasoline, and the ratio of lignite to FCC gasoline is 1:1.

[0090] The standard volume ratio of hydrogen to mixed oil in the first micro-interface generator is 0.2:1; the standard volume ratio of hydrogen to mixed oil in the second micro-interface generator is 800:1.

[0091] In the step 6, the air pressure inside the fluidized bed reactor 4 is controlled at 8MPa, the reaction temperature is controlled at 380°C, and the space velocity is controlled at 0.5h -1 .

[0092] The catalyst in the step 7 is an iron-cobalt catalyst.

[0093] The mixed oil products before and after the operation of the system were tested. The test results are as follows:

[0094] The sulfur content in the raw material mixed oil is 120 ppm, which is reduced to 25 ppm after the process of this hydrodesulfurization reaction pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com