Patents

Literature

40results about How to "Shorten blowing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

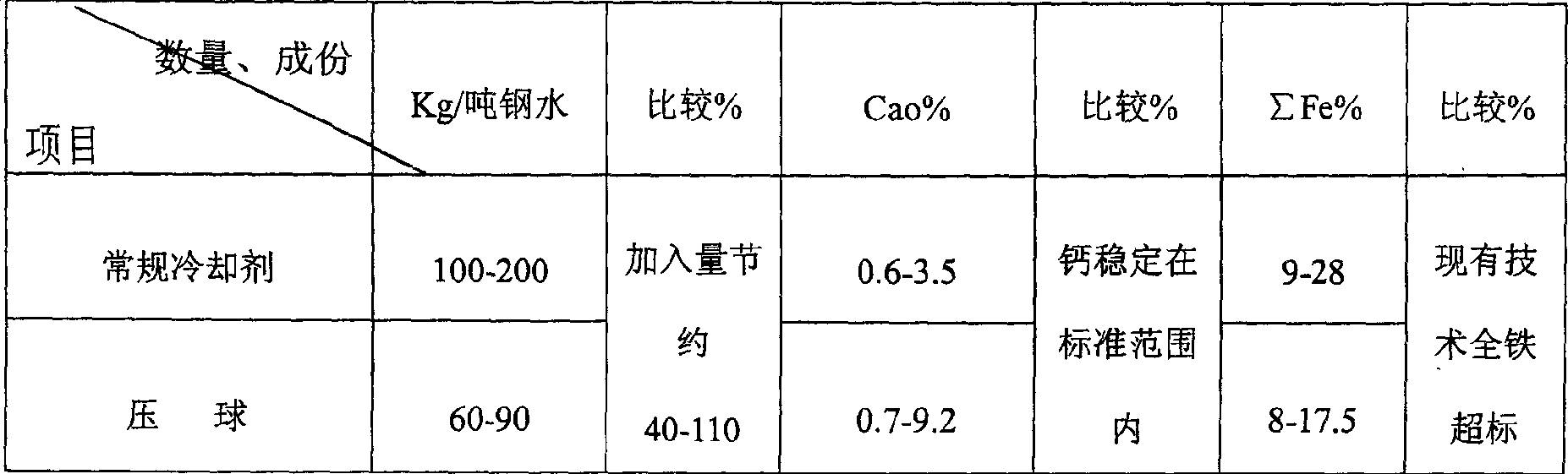

Molten iron vanadium-extracting calcium-controlling coolant and process therefor

The invention relates iron melt improving vanadium content and controlling calcium content cooling agent and the technology, specially relates the cooling agent of adjusting the proportion of cooling agent to stabilize calcium content in vanadium slag and the technology. The technology comprises the 56-60wt% iron scale, 30-40wt% iron concentrate powder containing vanadium, and 5-10wt% anchoring agent. The method stabilizes the calcium content and iron content in vanadium slag, and effectively solves the problems of great fluctuation of vanadium slag composition and superstandard calcium and iron. By controlling the thermoregulation material to meet the requirements of the improving vanadium temperature and calcium oxide content, the method improves the vanadium slag grade and extraction rate. The invention possesses the following characteristics: 1 shortening the converting time; 2 improving the vanadium slag grade and extraction rate, and stabilizing the calcium oxide content; 3 reducing the iron loss.

Owner:HEBEI LUANHE IND GROUP

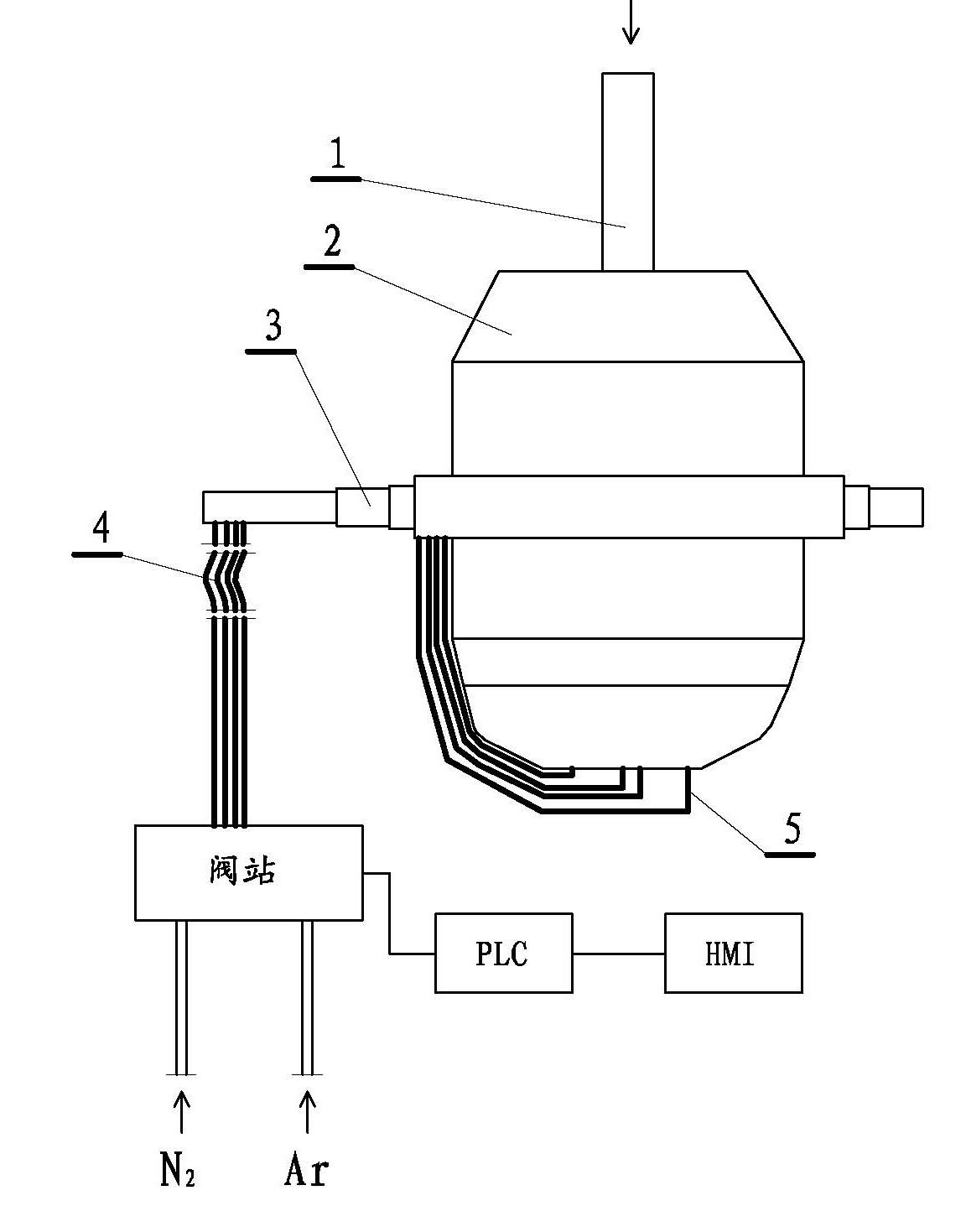

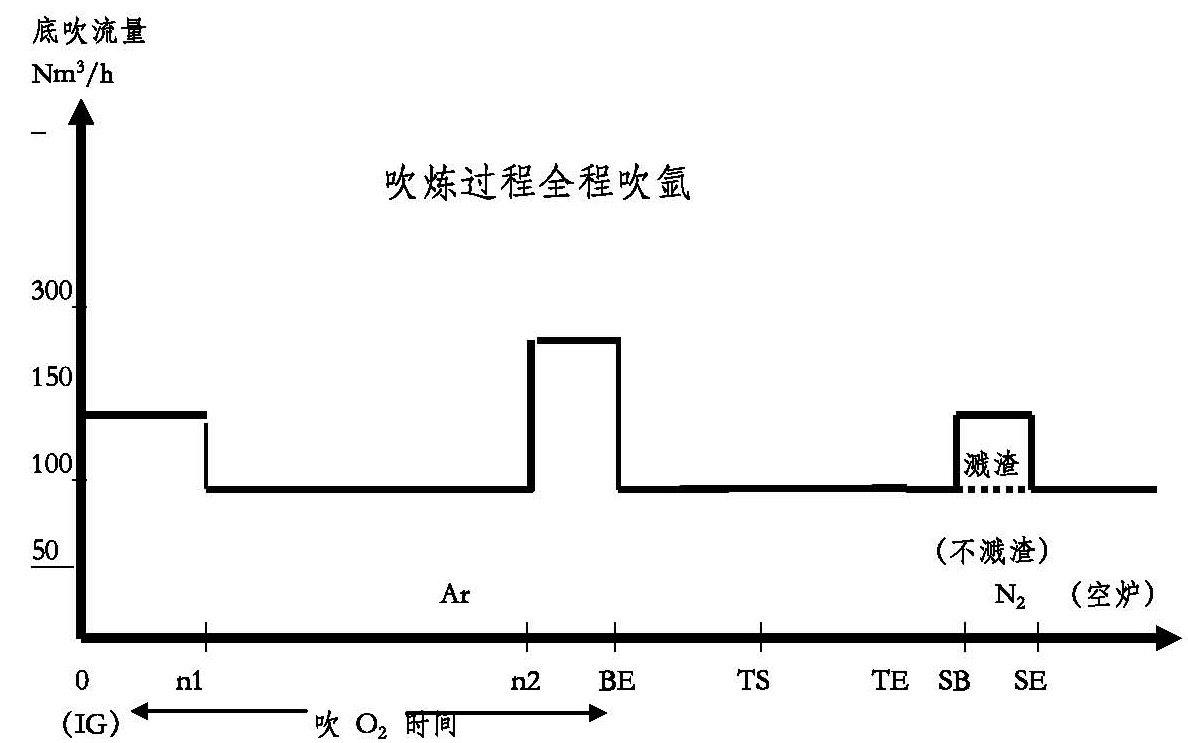

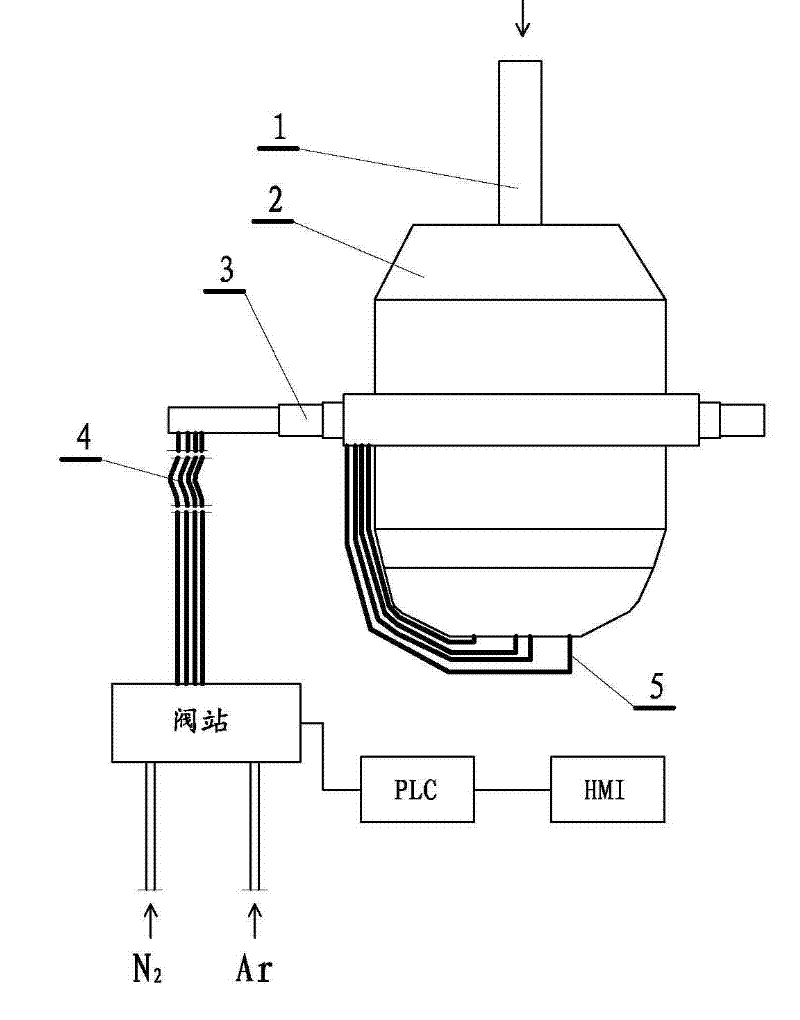

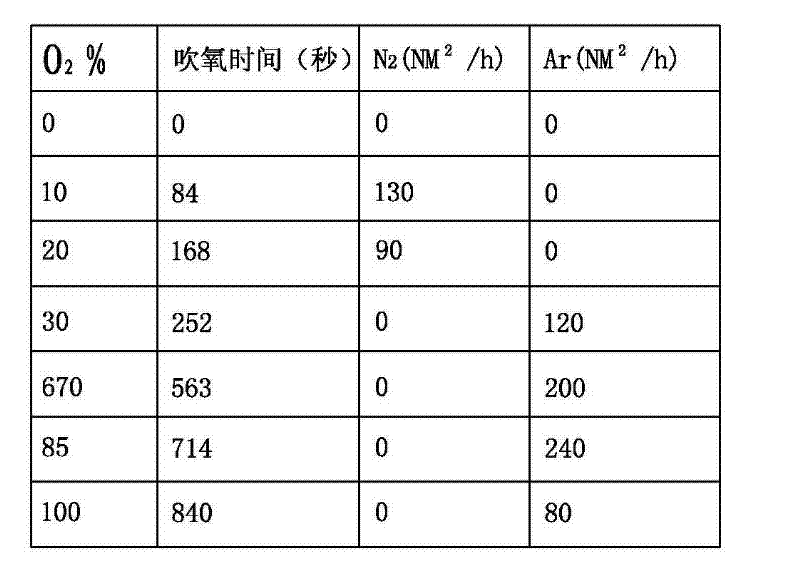

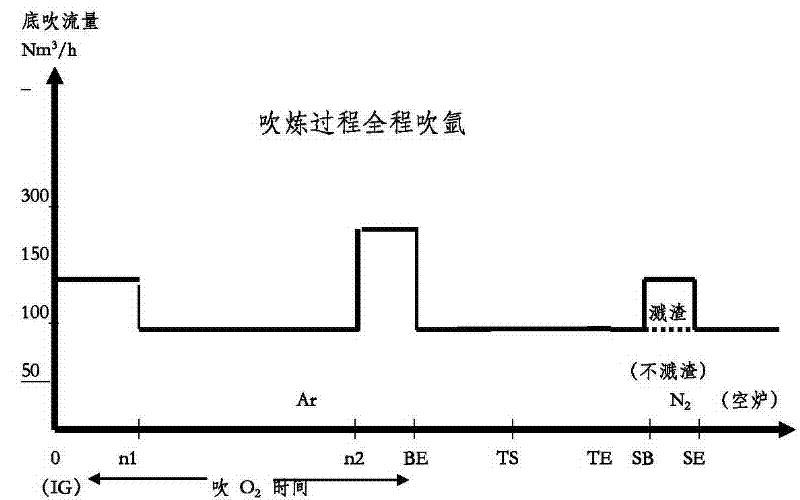

Method for automatic bottom blowing control of converter

InactiveCN102041346AQuality improvementShorten blowing timeManufacturing convertersHuman–machine interfaceSmelting process

The invention relates to a method for the automatic bottom blowing control of a converter. Hardware adopted by the method in the invention comprises a converter with a combined blowing function, a valve station for supplying argon and nitrogen and a PLC (programmable logic controller) with an HMI (human machine interface), wherein the PLC controls the valve station and stores a plurality of bottom blowing models. The method comprises the followings steps: selecting a bottom blowing model; confirming; loading a flow set value; transmitting the flow set value; and monitoring smelting process. According to different nitrogen contents and carbon contents of a target steel type, 9 models are combined in the invention, production operation personnel select a corresponding model code only according to a steel type to be smelted, and the parameter and the curve data of the model are automatically downloaded to the PLC. Thus, in the invention, the phenomenon that production operation personnel continuously and manually adjust valve opening in the conventional production step is reduced, thus the operation intensity is lightened. The PLC automatically switches nitrogen and argon, controls stable intake pressure and adjustable branch pipe flow, has high control precision and strong degree of automation and lowers production cost.

Owner:BEIJING JIANLONG HEAVY IND GROUP

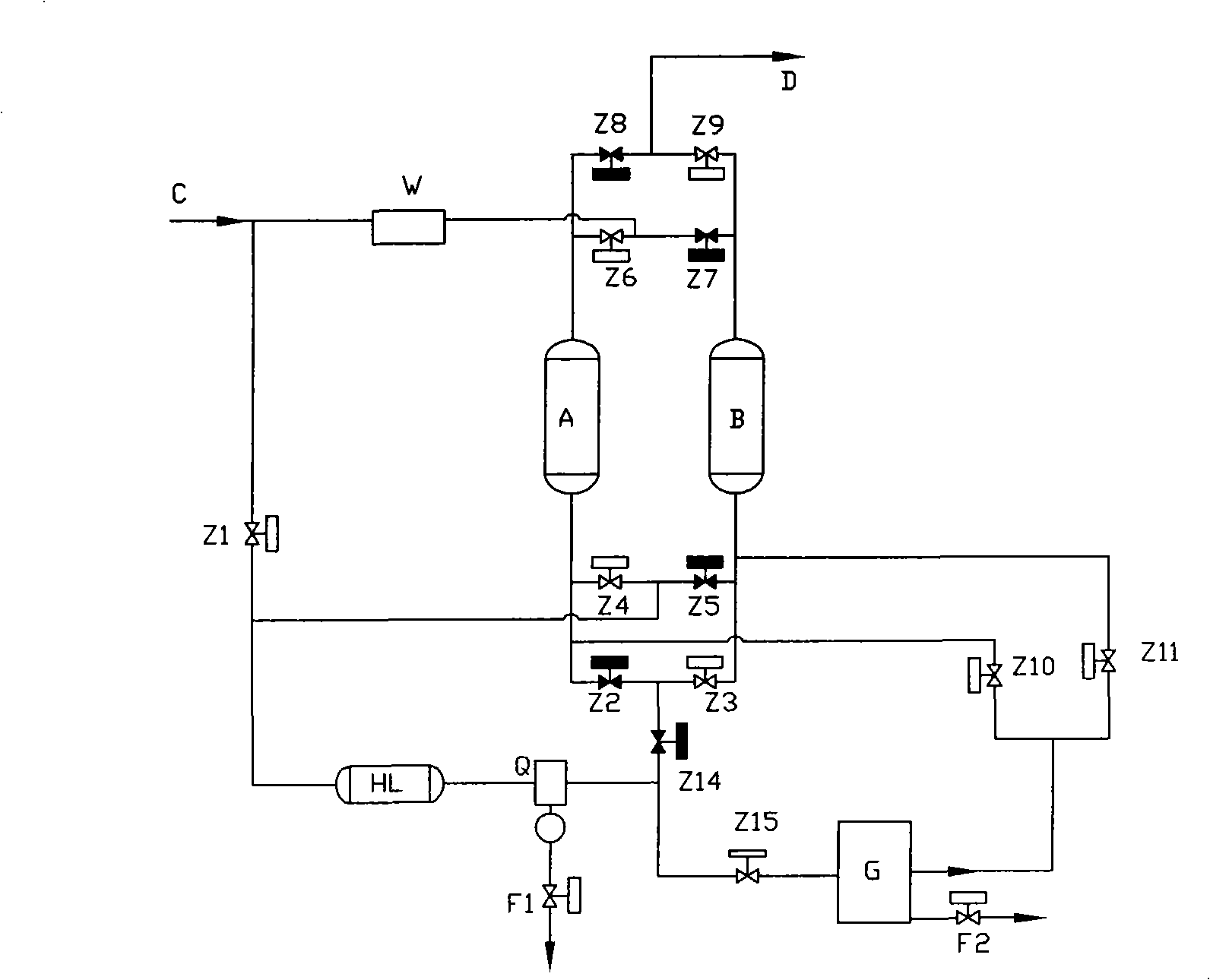

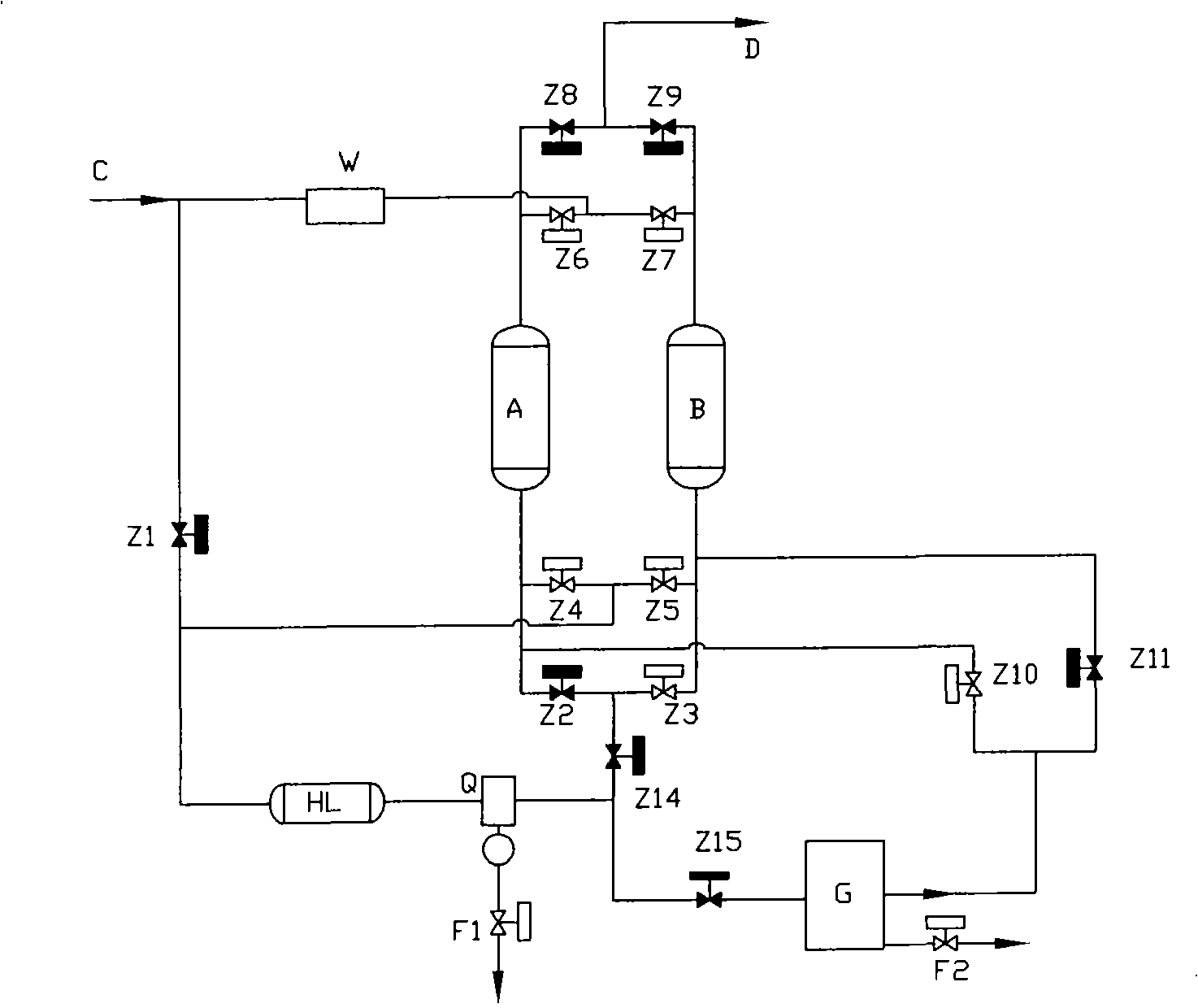

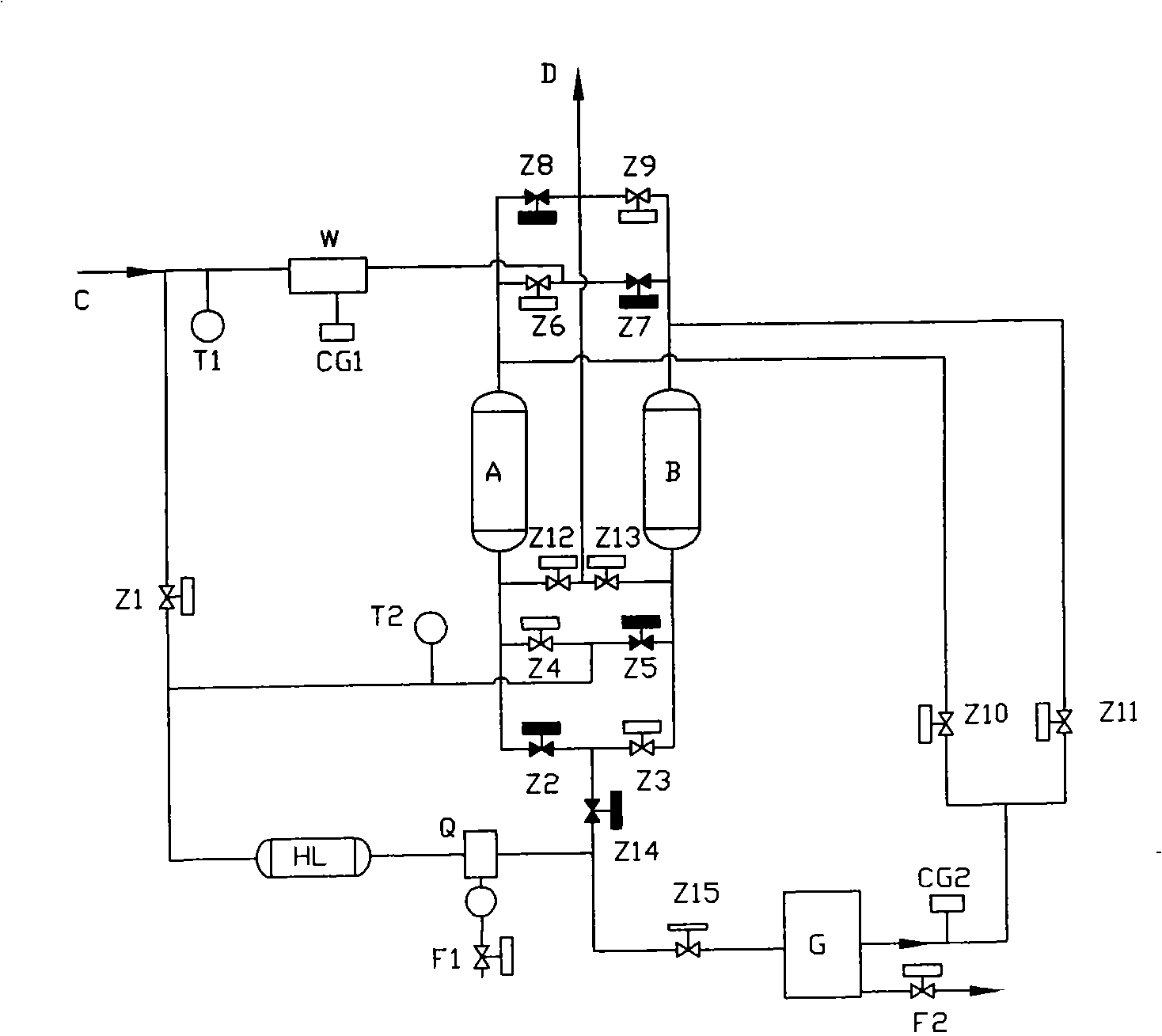

High-efficiency drying apparatus for regenerating exhaust heat of pressure gas

InactiveCN101314103AShorten blowing timeIncrease profitGas treatmentDispersed particle separationVapor–liquid separatorSorbent

The invention relates to a compressed gas drying device. The invention aims to provide the device with characteristics of complete regeneration of an adsorbent and lower outlet air pressure dew point. The invention adopts the technical proposal that: in a compressed gas waste heat regeneration high-efficiency drying device, a first path of pipeline is connected with at least two drying pipelines in parallel, and then is connected with an inlet of a freeze drier after the first path of pipelines is orderly connected with two adjusting valves in series; each drying pipeline is orderly connected with a valve and a forward inlet of a drying tower in series; a pipeline on an outlet of the freeze drier is divided into at least two branch paths, wherein, each branch path is connected with a valve, and then is connected to a reverse inlet of the drying tower; a second path of pipeline is divided into two branch paths; the first branch path is divided into at least two shunts; each shunt is connected with a valve, and then is connected with a reverse inlet of the drying tower; the second shunt is connected between the two adjusting valves through a water cooler and a gas-liquid separator in sequence; and the forward inlets of the drying towers are connected with a valve respectively, and then are connected with an air outlet in parallel.

Owner:周才宝

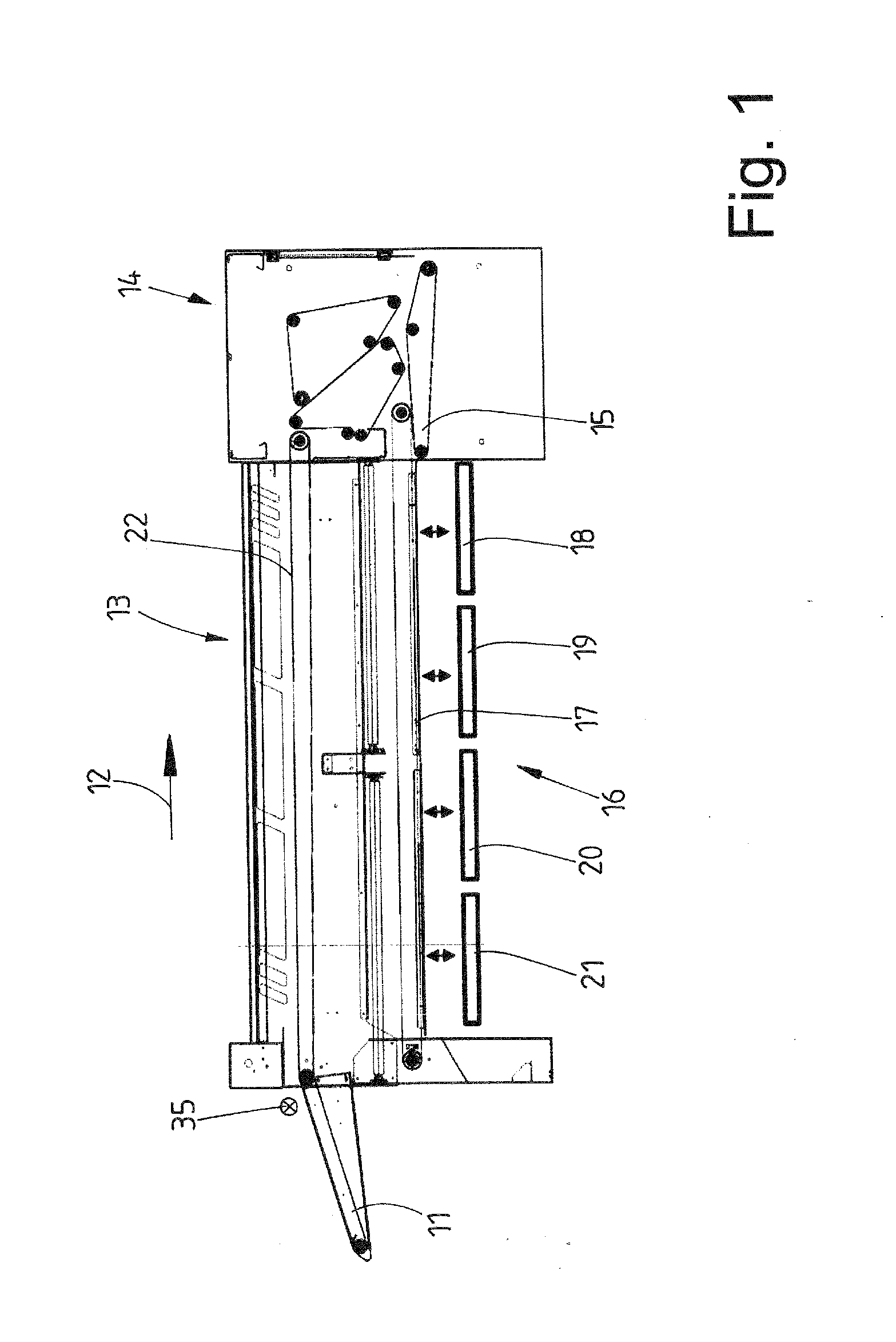

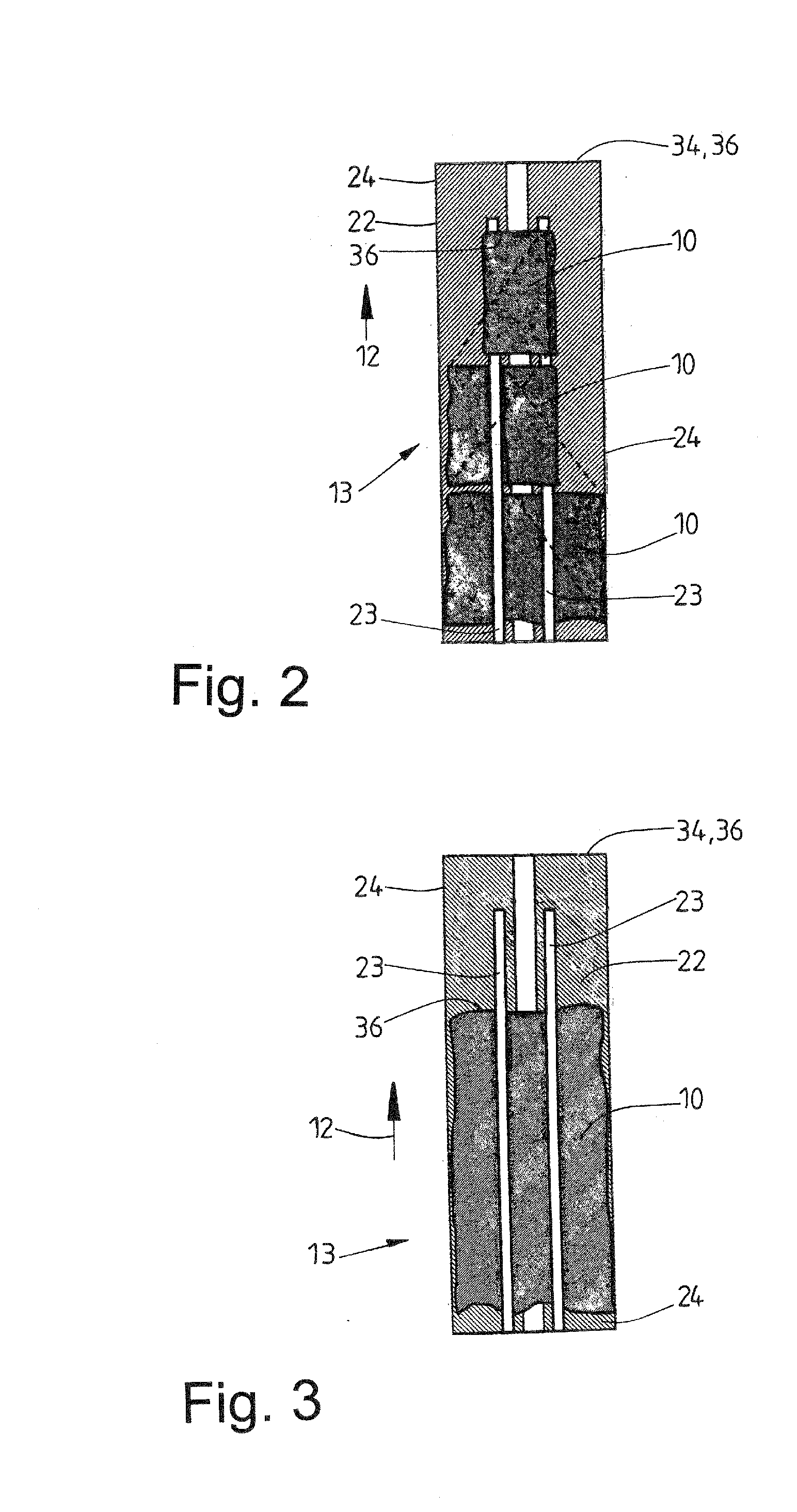

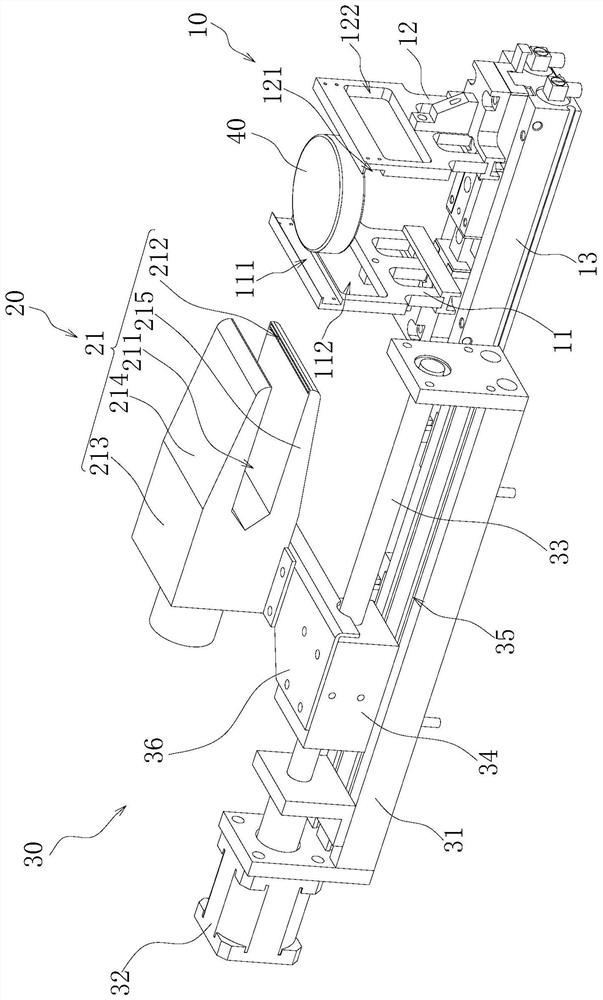

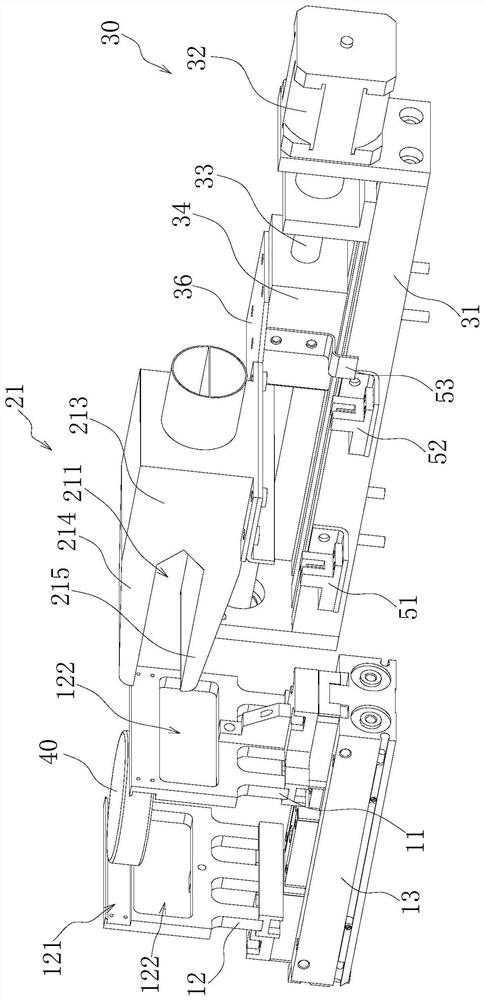

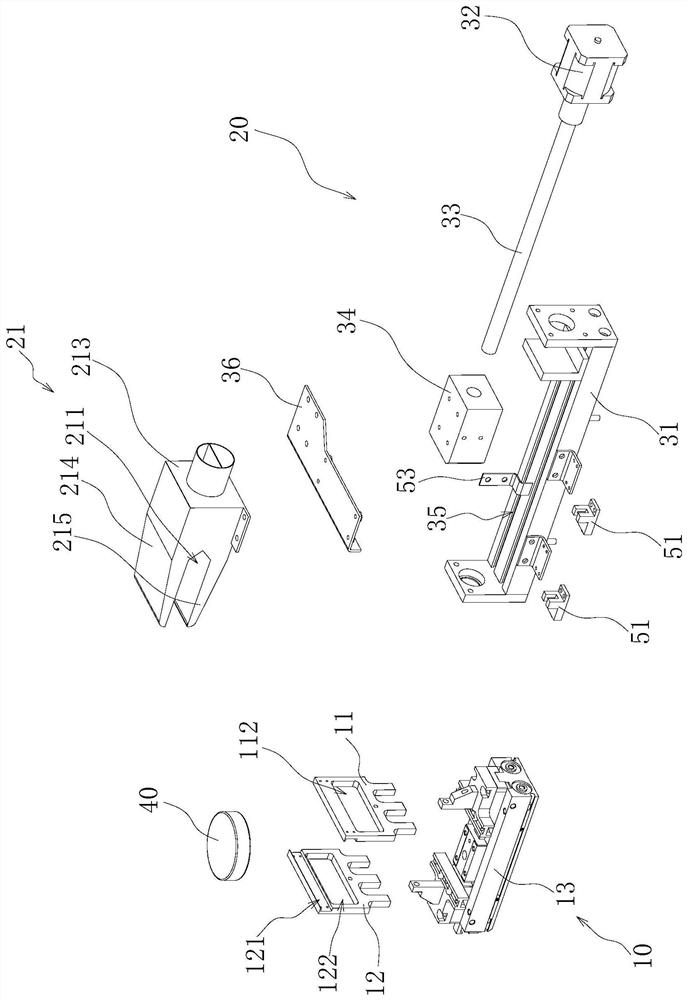

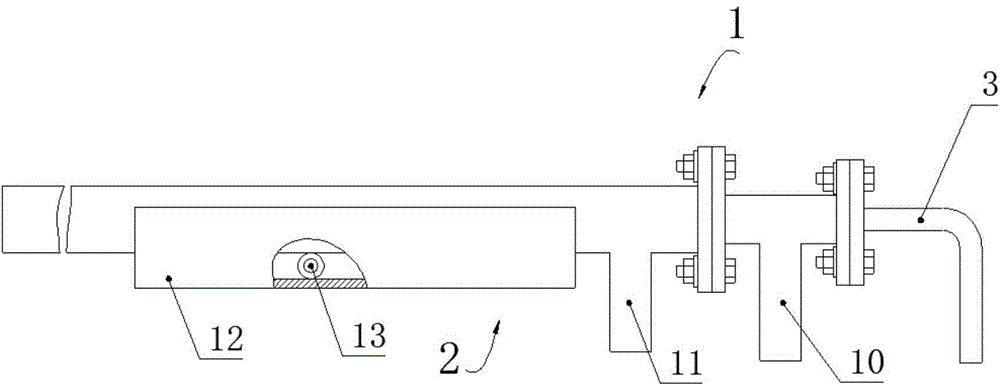

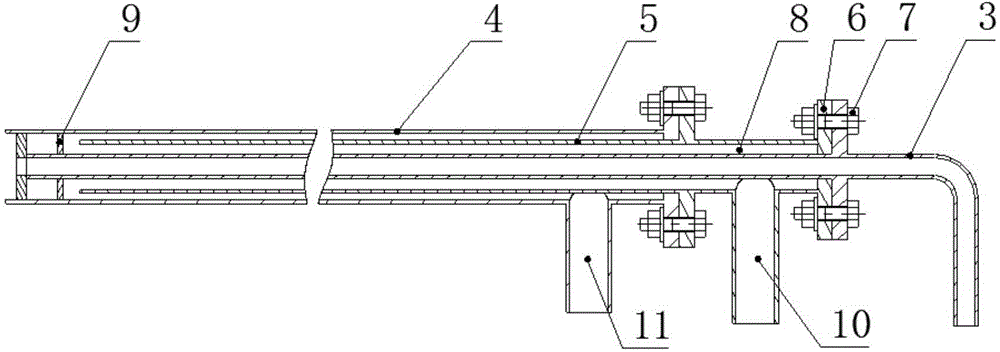

Mobile printing, positioning and conveying device

ActiveCN104692157AHigh speedShorten blowing timeArticle feedersPrinting press partsPaperboardEngineering

The invention relates to a printing device, in particular to a mobile printing, positioning and conveying device, and aims to provide a printing, positioning and conveying device which is long in positioning time, high in printing speed, high in overprinting accuracy and high in paper feeding speed. In order to solve the technical problem, the invention provides a mobile printing, positioning and conveying device which comprises a paper feeding device, a mobile front gauge positioning device, a circulation side gauge positioning device, an articulation tooth moving device, an electro-optical distance measurement device and a paper conveying roller. By virtue of the mobile printing, positioning and conveying device, the paper feeding efficiency can be improved; the paper moving distance can be accurately controlled by adjusting the distance between a movable cam and an annular fixed cam; the device is stable in structure, low in damage possibility and accurate to position; due to the cooperation of the circulation side gauge positioning device and a paper conveying plate, the paper positioning time can be prolonged; the printing speed is increased; the overprinting accuracy is ensured.

Owner:郭石生

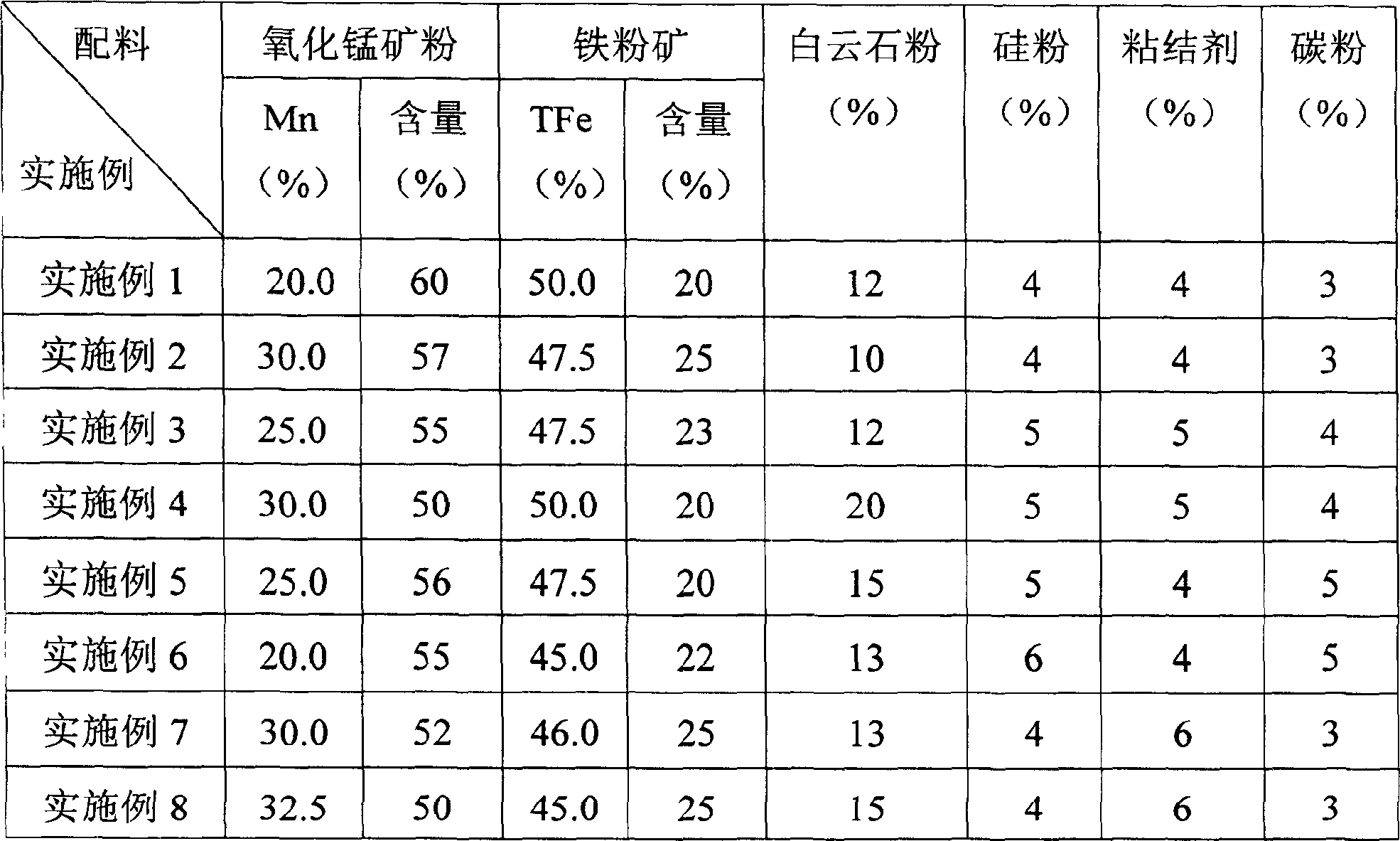

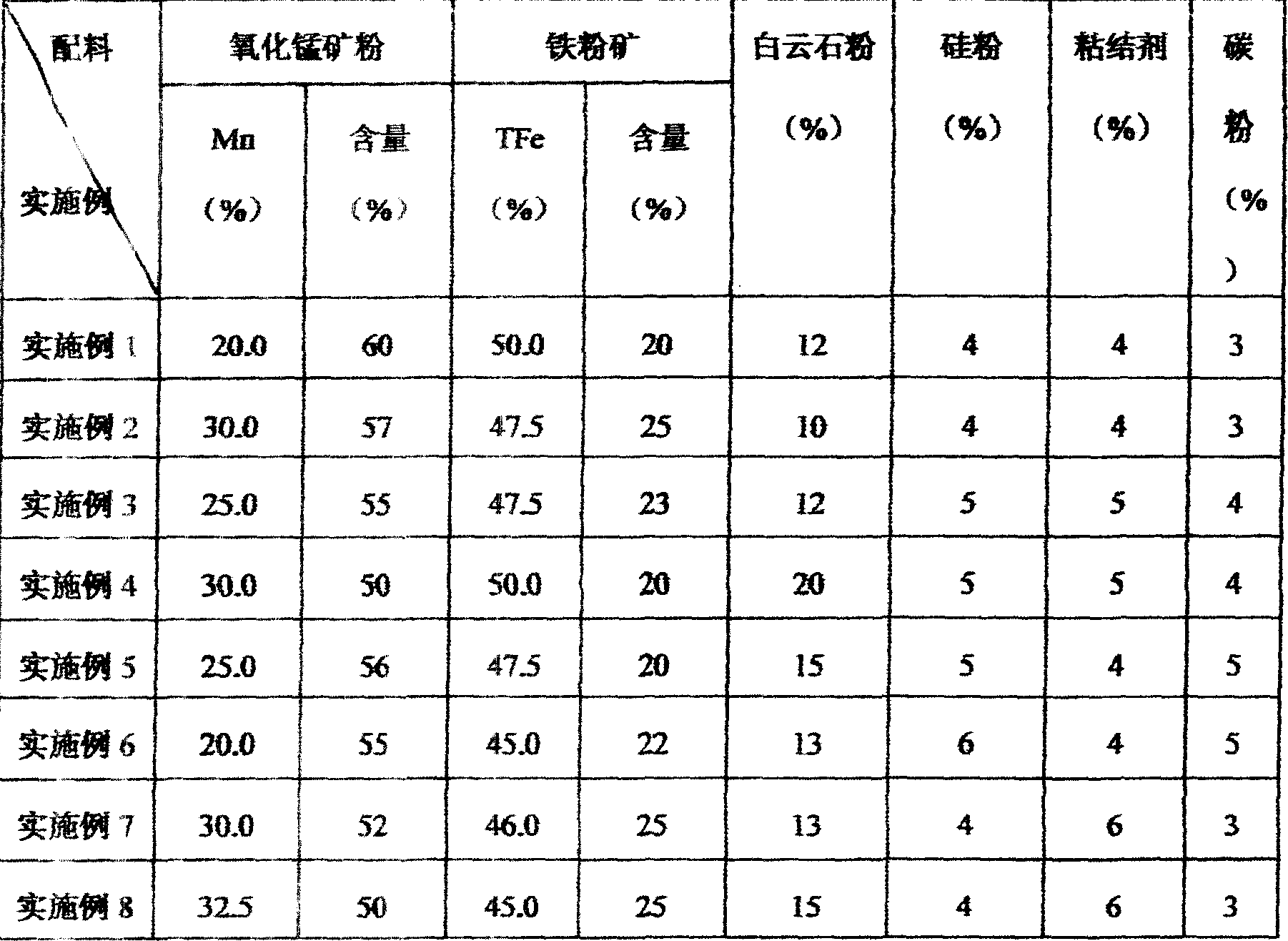

Highly effective metallurgical complexing agent for convertor (electric oven) and its preparation method and uses

The invention relates to an admixture removing foreign matter of converting process in the field of fusion alloy treatment. It is formed by (by weight ratio) manganese oxide powdered ore 40-50%, iron powdered ore20-25%, dolomitic limestone powder 10-20%, silicon powder 4-6%, carbon powder 3-5%, catalyst 4-6% and some water; the complex agent is made by preparing for the material, stirring, adding catalyst and water to mix them, extrusion molding drying and sieving and so on.

Owner:黄志勇

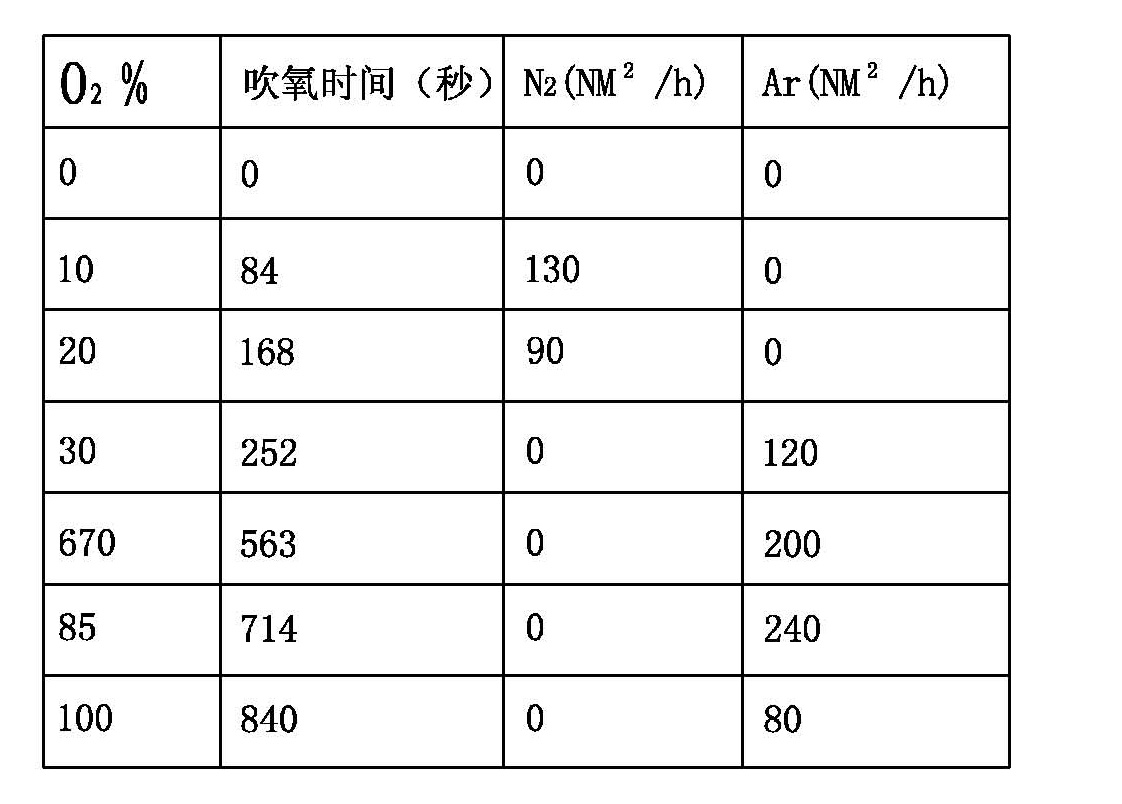

Phosphorus steel smelting method for a top-bottom combined blowing converter

ActiveCN105296703ARapid decarbonization and phosphorus conservationReduce stirringManufacturing convertersOxygen utilization rateSmelting process

The invention relates to a phosphorus steel smelting method for a top-bottom combined blowing converter. The method comprises the following steps that (1) the phosphorus content of molten iron is 0.08-0.12%, the oxygen supply pressure is 1-1.05 MPa, and the oxygen supply intensity is 3.5-3.8 m<3> / (t.min); (2) when converting is conducted for 1-3 min, and active lime and light burned dolomite are added; 1 min is delayed, and iron-containing material carbon balls are added; (3) an oxygen gun adopts a high-low-low gun position, and an automatic N / Ar switching mode is adopted for bottom blowing; (4) the nitrogen bottom-blowing mode is adopted for medium combined-blowing at the early stage and the medium stage, and the argon bottom blowing mode is adopted at the later stage of converting and 1-2 min before carbon catching; the converting final temperature is controlled within 1660-1680 DEG C, and the content of end point carbon is controlled within 0.04-0.06%; the content of end point phosphorus is controlled within 0.05-0.075%; and (5) the content of finished phosphorus is controlled within 0.06-0.09%. Compared with the prior art, the phosphorus steel smelting method has the beneficial effects that the converting time is shortened by improving the phosphorus steel smelting process for the top-bottom combined blowing converter, and the blowing converter can conduct decarbonization and phosphorus preservation rapidly; the oxygen utilization rate is increased, the smelting time is shortened, and the cost is reduced.

Owner:ANGANG STEEL CO LTD

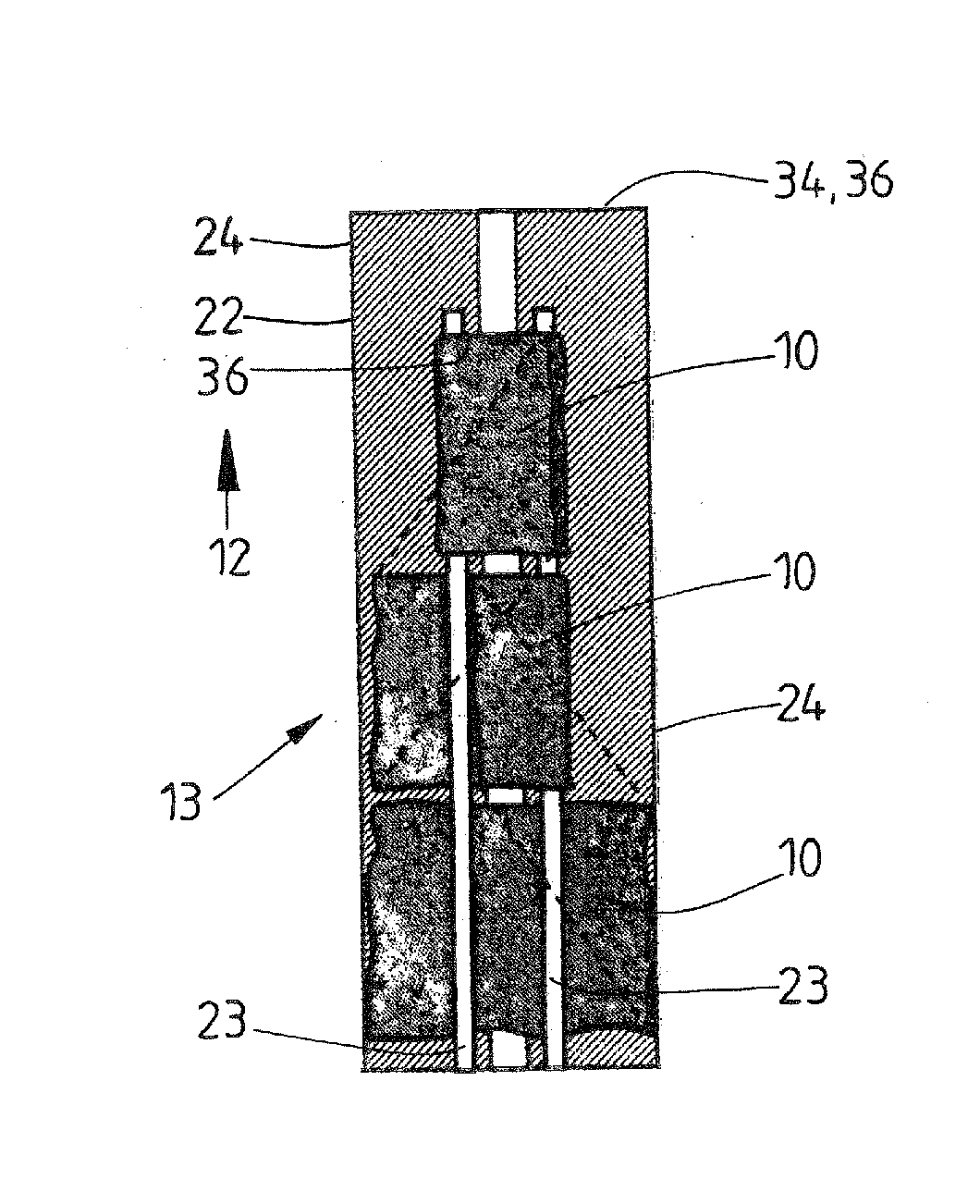

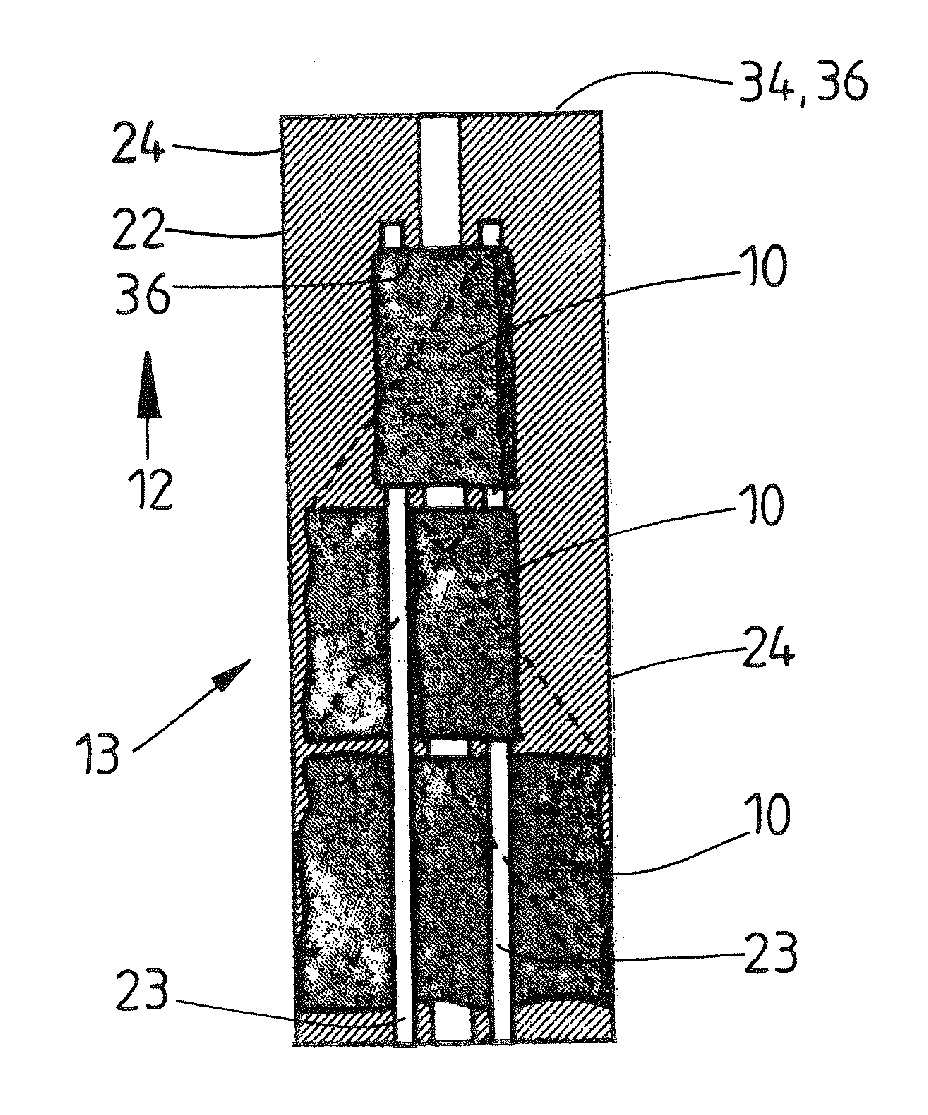

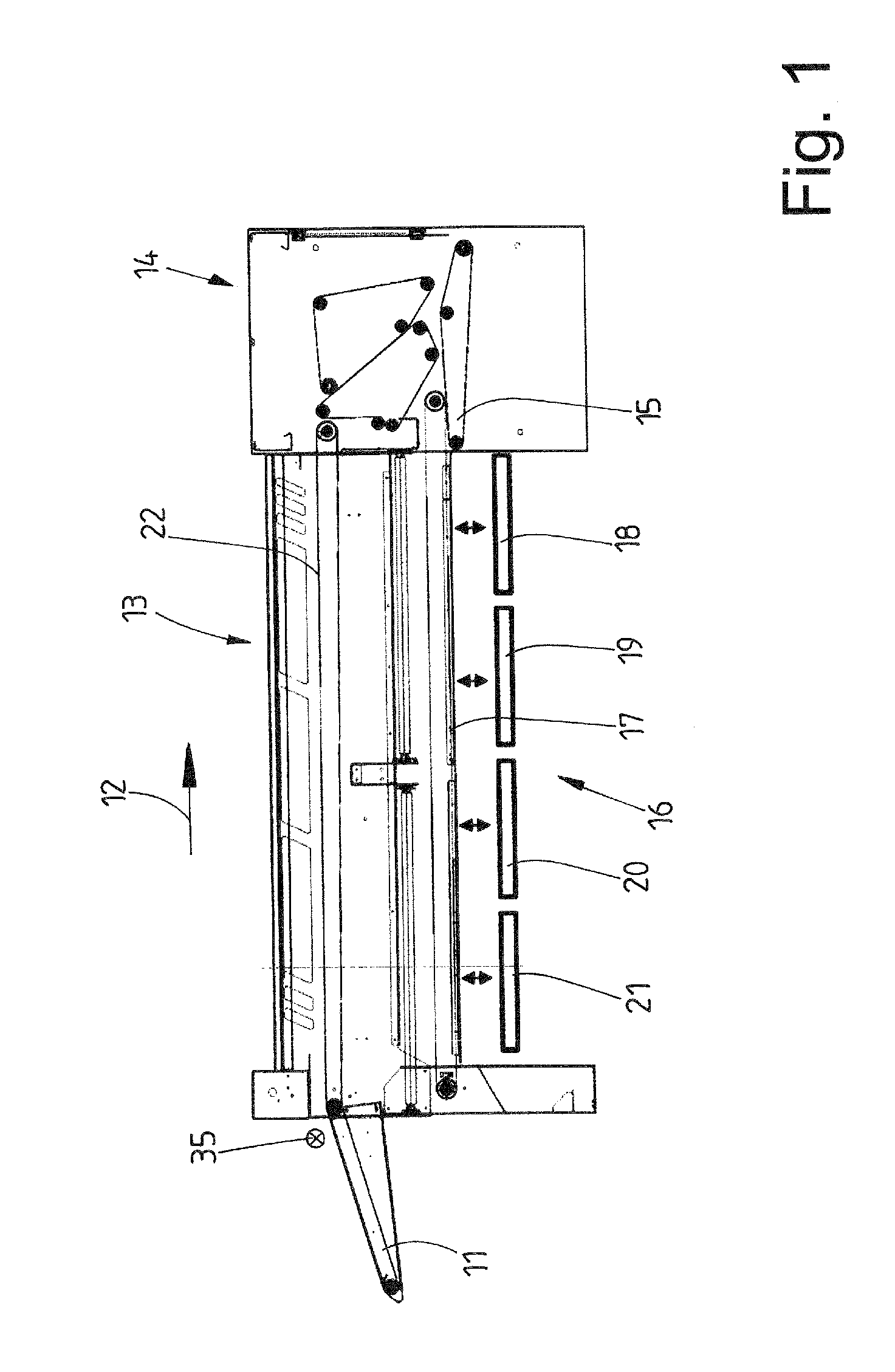

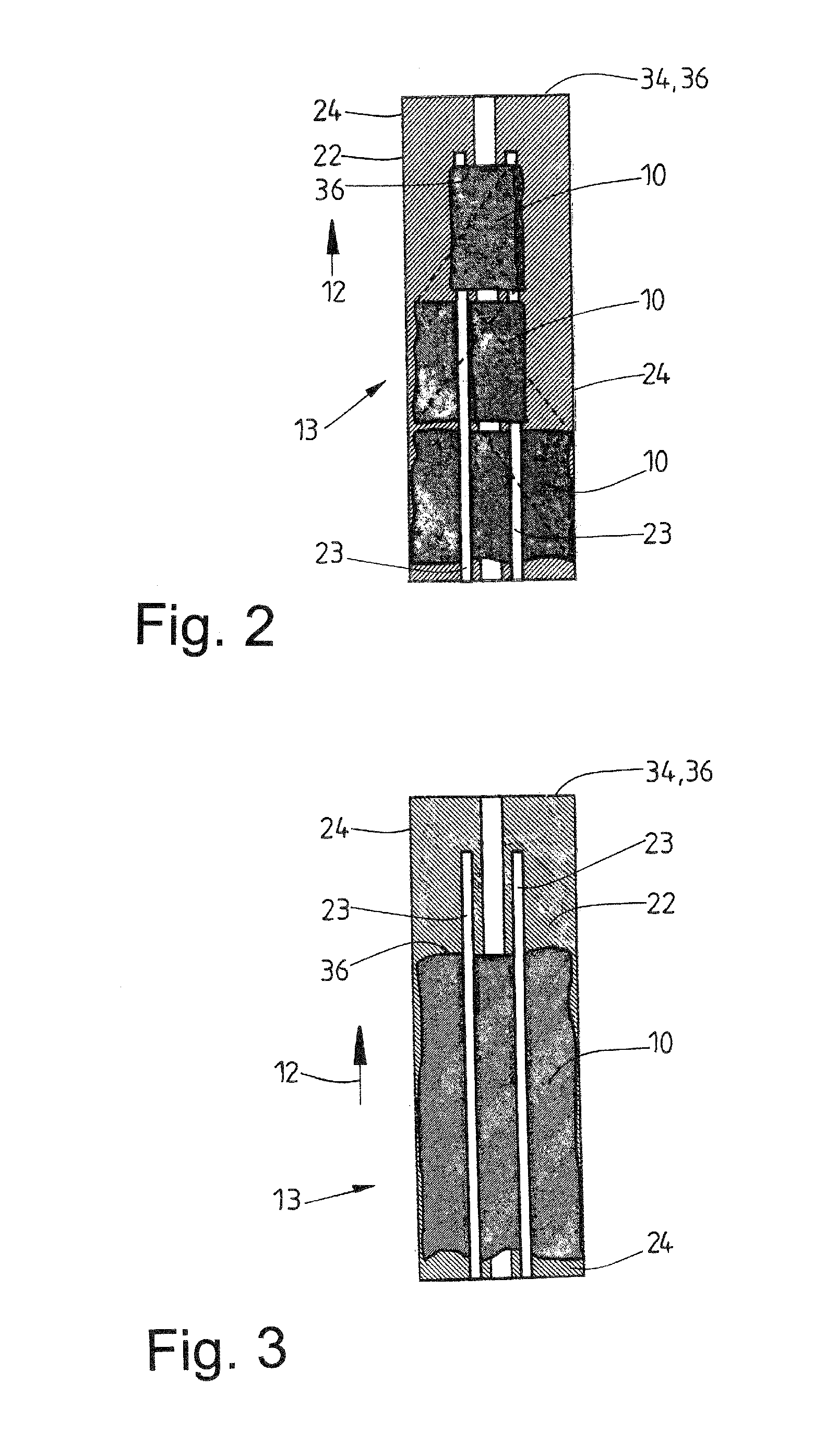

Method of folding items of laundry

ActiveUS20150094195A1Good folding effectShorten blowing timeMechanical working/deformationFolding thin materialsTelecommunicationsLaundry

In apparatuses for automatically folding items of laundry, items of laundry of different lengths usually are folded in an irregular sequence, resulting in idling and / or delays in particular in the longitudinal-folding station (13). The invention provides for determining the length of each item of laundry (10) upstream of the longitudinal-folding station (13) and for accelerating short items of laundry as they are transported through the longitudinal-folding station (13), whereas larger items of laundry are slowed down in the longitudinal-folding station (13). Following completion of the longitudinal-folding operation, the respectively folded item of laundry is located at the end of the longitudinal-folding station (13) and, immediately following completion of the longitudinal folding, is transported away out of the longitudinal-folding station (13). This avoids unnecessary idling times, and for relatively long items of laundry to be folded longitudinally during continuous, relatively slow onward transportation through the longitudinal-folding station (13).

Owner:KANNEGIESSER GMBH CO HERBERT

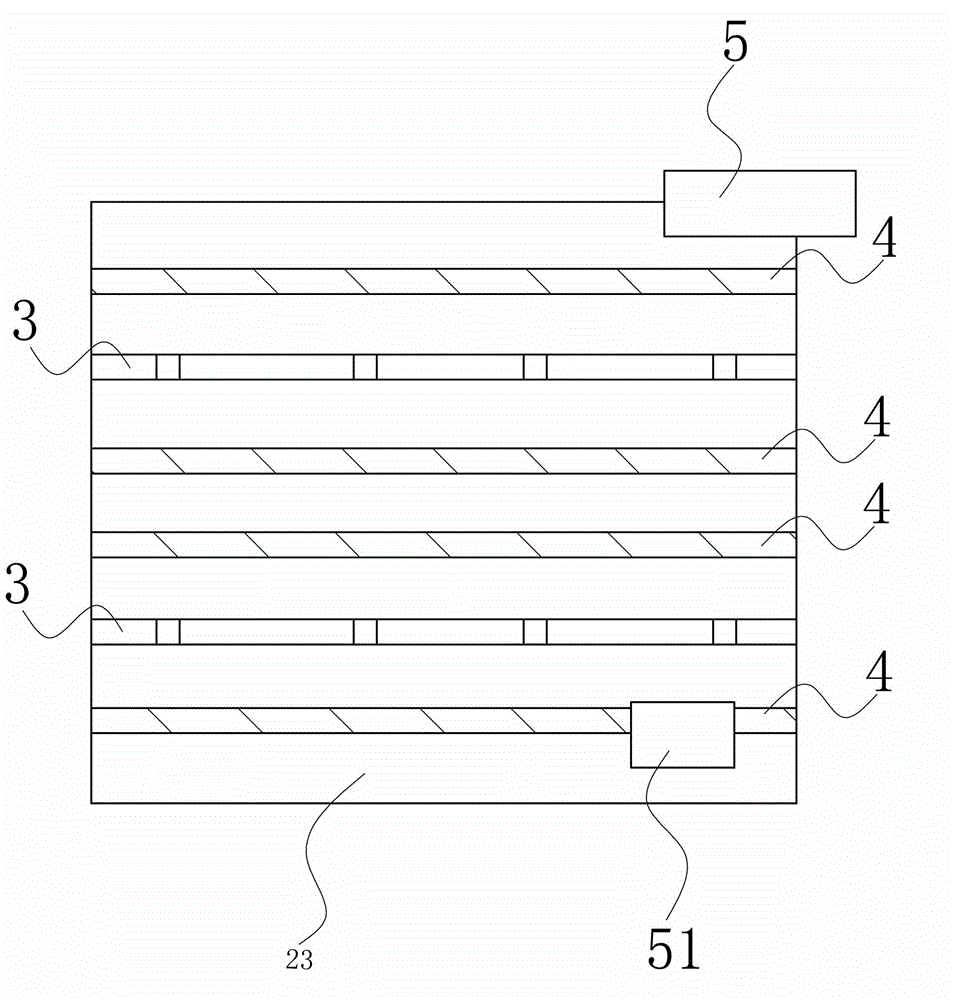

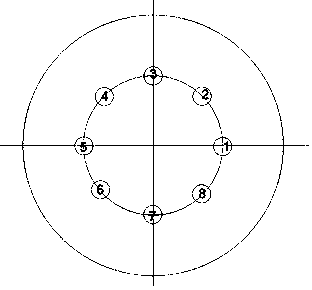

Converter bottom blowing process for grouped air blowing control of bottom blown bricks

The invention discloses a converter bottom blowing process for for grouped air blowing control of bottom blown bricks. The converter bottom blowing process includes the following two steps that firstly, bottom blown brick grouping is conducted, the bottom blown bricks located on the same circle are divided into two groups; and secondly, bottom blown brick grouped air volume control is carried out,in the converter production process, air volume control is carried out on the two groups of the bottom blown bricks, under the condition that the total air volume of bottom blowing remains unchanged,the ratio of the first group air volume to the second group air volume is 4:1-8:1 in the first furnace air volume opening mode of furnace service, the second group air volume guarantees that the bottom blowing brick process is not blocked, the second furnace air volume opening mode of furnace service is opposite to the first furnace air volume opening mode of furnace service, the ratio of the second group air volume to the first group air volume is 4:1-8:1, the first group air volume guarantees that the bottom blowing brick process is not blocked, and then heat is carried out alternately according to the first furnace air volume opening mode and the second furnace air volume opening mode. The flow of molten steel in a converter molten pool is accelerated, the reaction kinetics condition is improved, meanwhile the erosion of the bottom blown bricks is slowed down, the service life of the bottom blown bricks is prolonged, and the effect of bottom blowing is guaranteed while the furnaceage of a converter is prolonged.

Owner:HANDAN IRON & STEEL GROUP +1

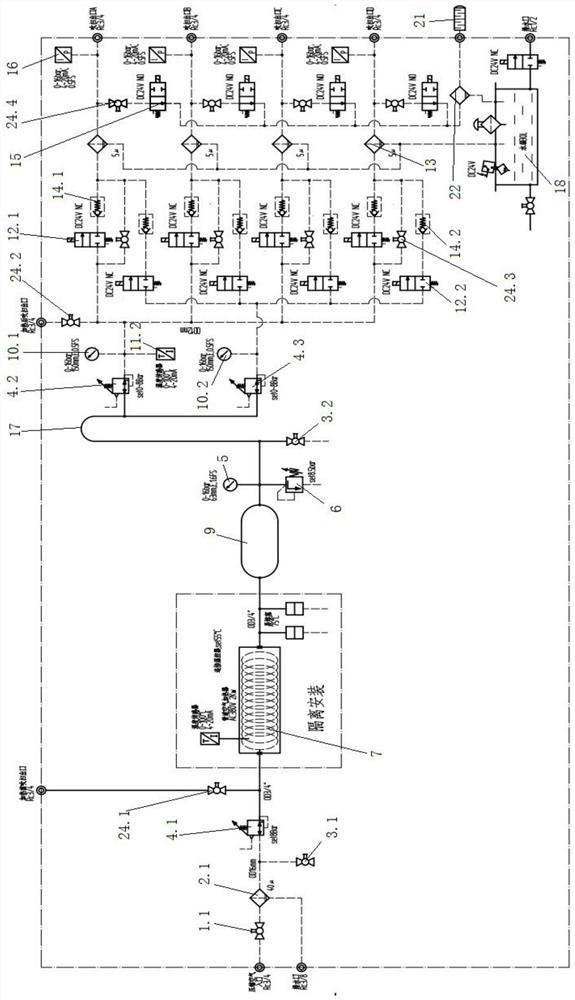

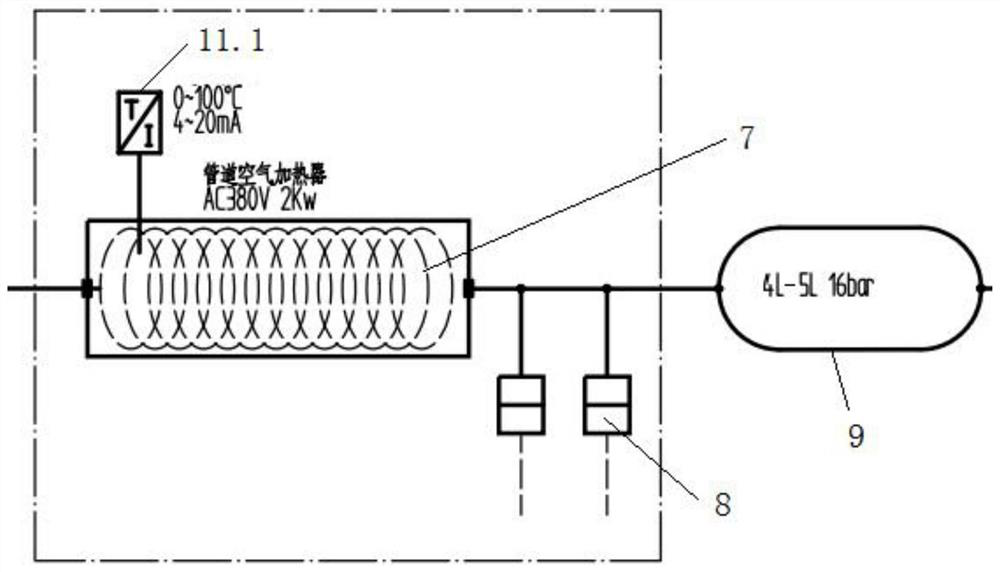

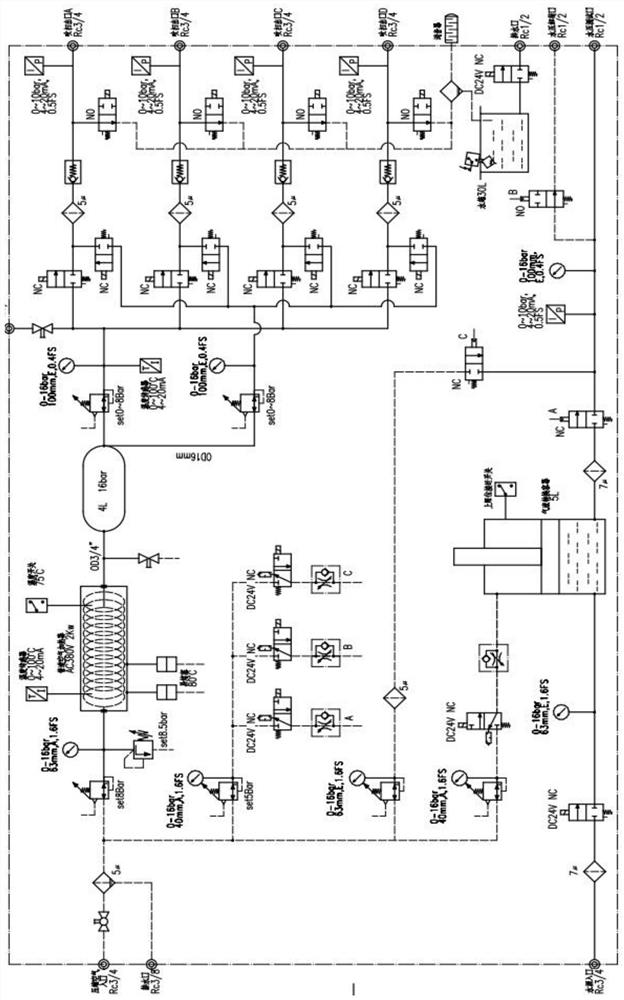

Generator stator cooling water loop drying system and method

PendingCN112332624AEasy to replaceGuaranteed uptimeDrying gas arrangementsManufacturing dynamo-electric machinesEngineeringMechanics

The invention relates to the field of generators, and concretely relates to a generator stator cooling water loop drying system and method. The generator stator cooling water loop drying system comprises a purging cabinet, and a purging loop communicated with a generator stator bar pipeline is arranged in the purging cabinet. The purging loop comprises: a first pipeline, wherein purging gas is introduced into the gas inlet end of the first pipeline, a gas inlet stop valve and a first filter are connected to the first pipeline in series, and the gas inlet stop valve is located at the front endof the first filter; a heating device, wherein the gas inlet end of the heating device is connected with the gas outlet end of the first pipeline, and the heating device heats the purge gas entering the heating device; a second pipeline, wherein the gas inlet end of the second pipeline is connected with the gas outlet end of the heating device; and a plurality of third pipelines, wherein the gas inlet end of each third pipeline is connected with the gas outlet end of the second pipeline. The full-automatic or semi-automatic pressure blowing function can be achieved, the drying time is shortened, meanwhile, the compressed air heating function is achieved, and the water blowing and drying efficiency is improved.

Owner:芜湖发电有限责任公司

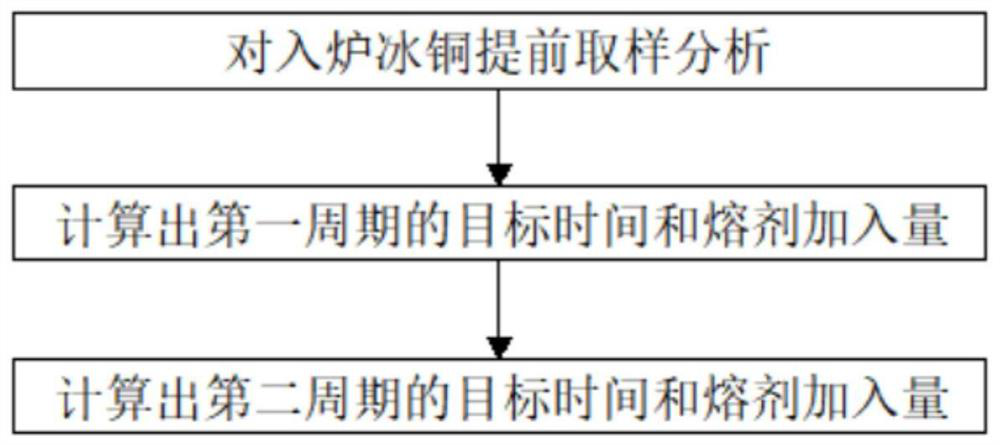

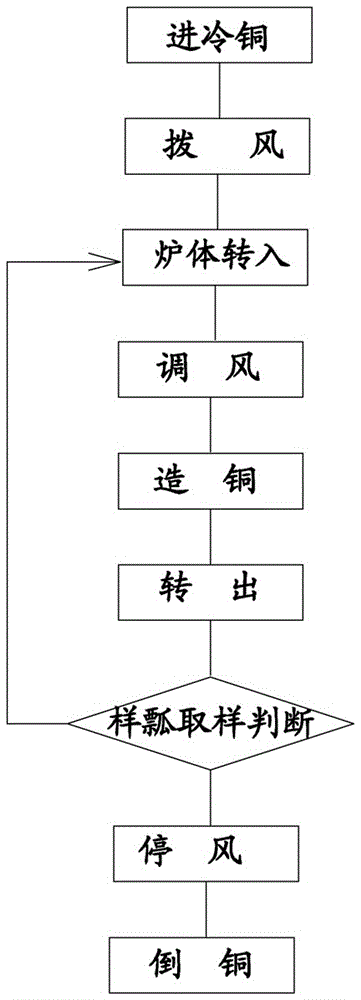

Method for judging end point time of copper smelting of converter

The invention belongs to the technical field of copper smelting of a converter, and discloses a method for judging the end point time of copper smelting of the converter. The method for judging the end point time of copper smelting of the converter comprises the following concrete steps of S1, conducting sampling analysis in advance for copper matte put into the converter: putting the copper matteinto copper matte pack after the copper matte is discharged from the previous process, and meanwhile sampling the copper matte and sending to a laboratory for analyzing copper content, iron content and sulfur content; S2, calculating the target time and the adding amounting of a fusing agent of the first cycle; and S3, calculating the target time and the adding amounting of the fusing agent of the second cycle. The method can realize continuous detection and continuous calculation of blowing end point time judgment and provide reliable data for operators, thus improving the utilization rate of the converter and reducing unnecessary operation of converter shaking. The method saves a lot of blowing time, improves the utilization rate of the air flow into the converter, reduces the air discharge amount of air and achieves the purpose of saving energy at the same time, and ensures the continuous blowing production.

Owner:李大为

Car adjustor mould core manufacturing method

ActiveCN107891125AImprove thermal stabilityImprove internal strengthFoundry mouldsFoundry coresManufacturing cost reductionHeat stability

The invention relates to the field of car adjustors, in particular to a mould for manufacturing car adjustors and particularly provides a car adjustor mould core manufacturing method. The car adjustormould core manufacturing method comprises the steps that silica sand, a curing agent and alkaline phenolic resin are sequentially mixed to obtain alkaline phenolic resin sand, the alkaline phenolic resin sand is added into a core box of a cold core box core shooting machine to be formed and hardened, and then a mould core is taken out; the mould core is immersed into mixed cohering liquid and then taken out to be dried in air; the mould core is roasted till the temperature is 1200 DEG C or over and then cooled; and the mould core is subjected to core leach to obtain a car adjustor mould core.According to the car adjustor mould core manufacturing method, the manufacturing cost can be reduced, the heat stability of the mould core is good, the hardening time can further be shortened while it is ensured that the alkaline phenolic resin sand is sufficiently formed, the surface quality and the geometric dimension accuracy of the mould core are ensured, and the service life and manufacturing accuracy of the mould core are ensured; and the labor intensity can further be reduced, the labor condition and work environment are greatly improved, environment pollution is reduced, and energy issaved.

Owner:江苏久祥汽车电器集团有限公司

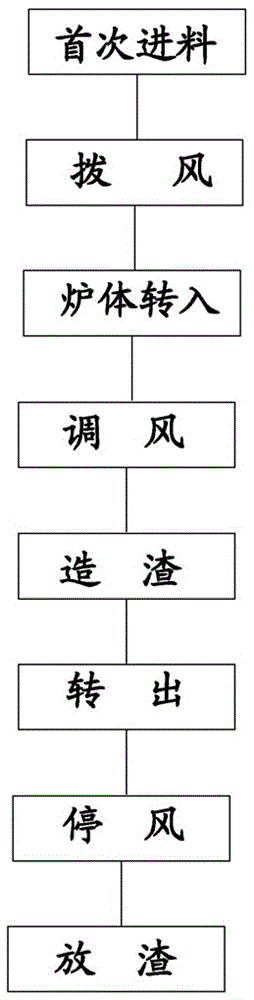

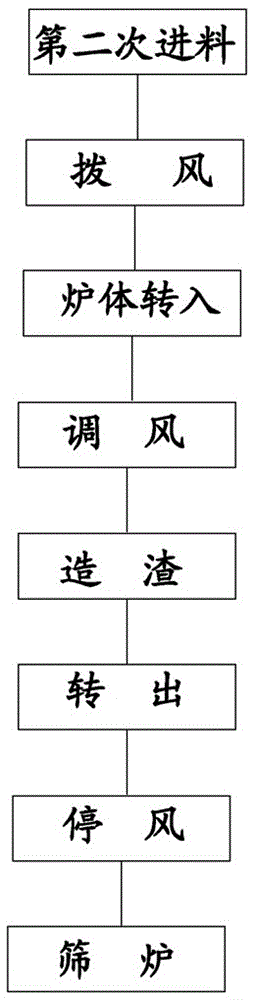

Method for blowing high-grade matte through horizontal rotary furnace

The invention relates to a method for blowing high-grade matte through a horizontal rotary furnace. The technical problem is solved that an existing matte blowing method is long in blowing cycle, lowin air supply time rate and low in single furnace output. According to the technical scheme, the method includes the following steps of firstly, selecting the matte at the grade of 70-75% as the blowing raw material; secondly, conducting thermal insulation on a hearth through natural gas when the empty rotary furnace waits for the material; thirdly, adding 50 tonnages of the raw material into therotary furnace for blowing; fourthly, conducting blowing for 30-50 minutes, and then adding 25 tonnages of the raw material into the rotary furnace to continue the blowing; fifthly, conducting blowingfor 25-35 minutes, and then adding 25 tonnages of the raw material into the rotary furnace for blowing for 5 minutes, and then adding quartz stone into the furnace to continue the blowing; sixthly, continuing the blowing for 65-75 minutes, then conducting depositing for 5 minutes, and then discharging residues. When the high-grade matte is blown in the horizontal rotary furnace, a traditional two-cycle blowing method is changed into a single-cycle blowing method, the blowing time is shortened, and the method has the advantages of high safety coefficient, large cold material throughput, low inproduction cost and the like.

Owner:山西北方铜业有限公司

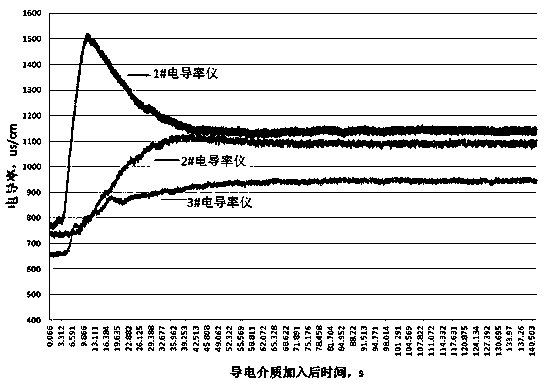

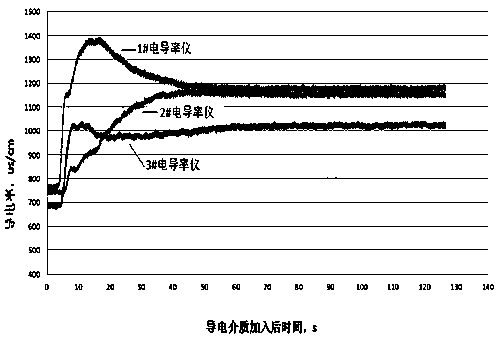

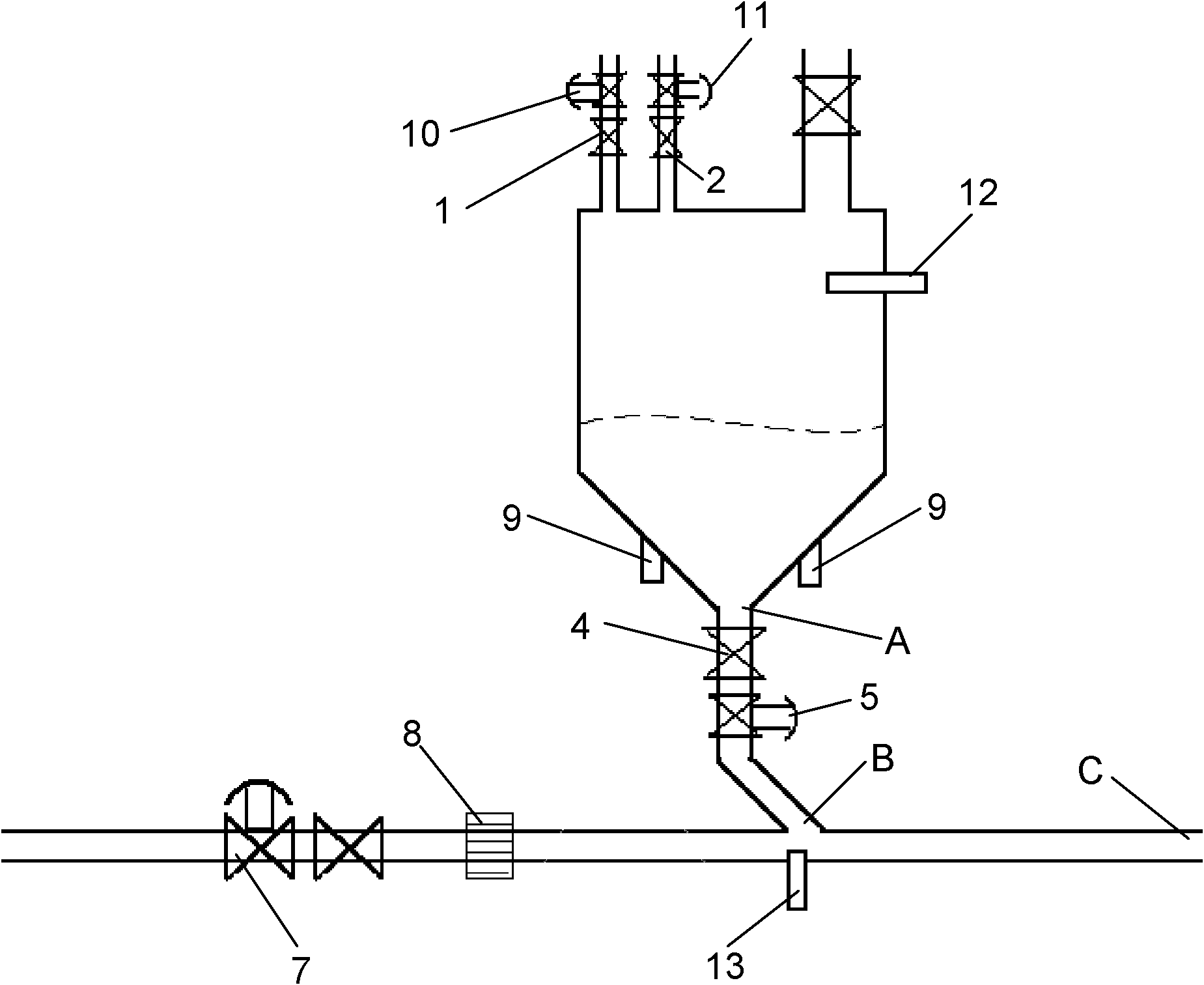

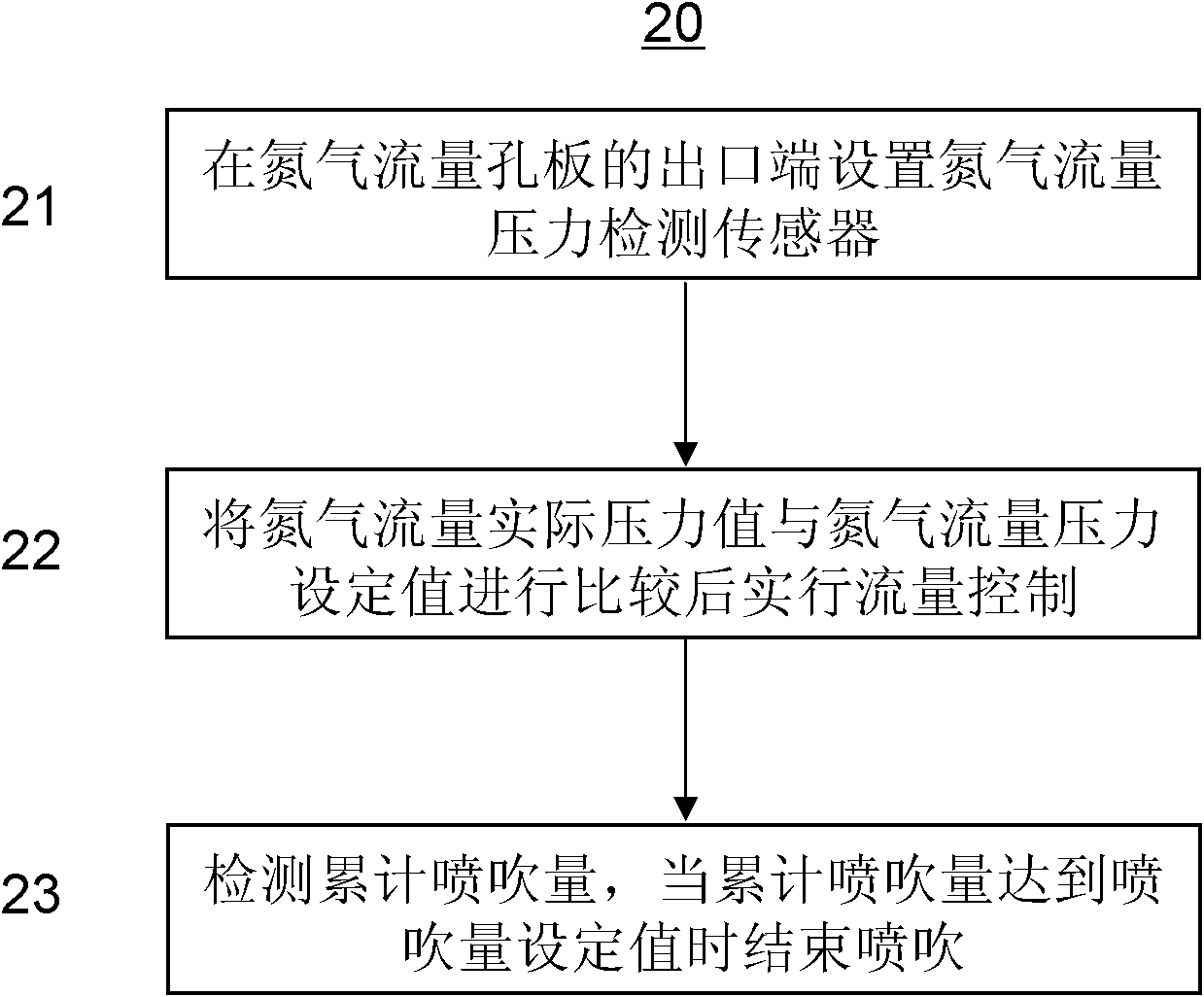

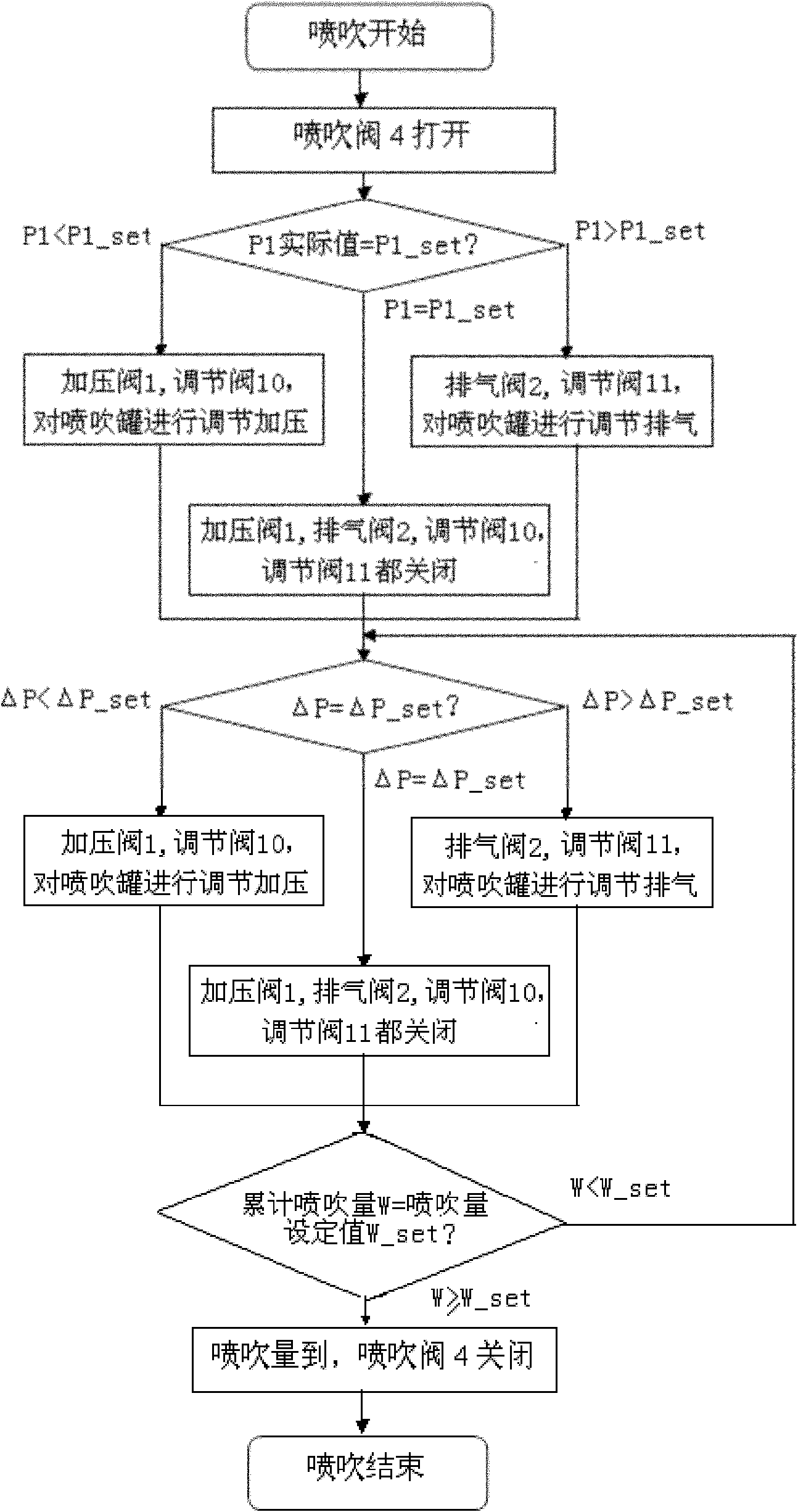

Flow control method for powder blowing in molten iron dephosphorization pretreatment process

InactiveCN102586545AImprove stabilityAvoid cloggingFlow control using electric meansEngineeringPre treatment

The invention discloses a flow control method powder blowing in a molten iron dephosphorization pretreatment process. The flow control method comprises the following specific steps of: firstly, arranging a nitrogen flow pressure detection sensor at the outlet end of a nitrogen flow pore plate to generate an actual pressure value of the nitrogen flow; next, transferring the actual pressure value of the nitrogen flow to a programmable controller to compare the actual pressure value of the nitrogen flow with a nitrogen flow pressure set value, and then carrying out flow control; and then, detecting the accumulated blowing quantity, and when the accumulated blowing quantity reaches a blowing quantity set value, ending the blowing. The flow control method can dynamically control the blowing speed through flow control according to the real-time powder blowing condition detected by the nitrogen flow pressure detection sensor, so that the stability of powder blowing is improved, pipelines are avoided being blocked by the powder, the blowing time of per ton of molten iron is shortened, the dephosphorization efficiency is improved, and the nitrogen energy consumption is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for blowing high-grade matte using a horizontal converter

The invention relates to a method for blowing high-grade matte by using a horizontal converter, the purpose of which is to solve the technical problems of long blowing cycle, low air supply rate and low output of a single furnace in the existing matte blowing method. The technical solution of the invention comprises the following steps: 1) select matte with a grade between 70%-75% as the blowing raw material; 2) when the converter is empty and waiting for materials, use natural gas to keep the furnace hearth warm; Feed 50 tons, carry out blowing; 4) After blowing 30-50min, feed 25 tons again in the converter, continue blowing; 5) After blowing 25-35min, feed 25 tons again in the converter, and then After blowing for 5 minutes, add quartz stones into the furnace and continue blowing; 6) After continuing blowing for 65-75 minutes, settle for 5 minutes and carry out slagging operation. The invention changes the traditional two-cycle blowing method into a single-cycle blowing method by carrying out blowing of high-grade matte in a horizontal converter, shortens the blowing time, and has the advantages of high safety factor, large cold material processing capacity, and low cost. Advantages of lower production cost.

Owner:山西北方铜业有限公司

Blow-drying device and gold exchange machine

PendingCN111981833AReduce blowing timeImprove blowing efficiencyDrying gas arrangementsPhysicsMechanical engineering

The invention belongs to the technical field of gold exchange equipment and particularly relates to a blow-drying device and a gold exchange machine. The blow-drying device comprises a clamping mechanism, an air blowing mechanism and a moving drive mechanism, wherein the clamping mechanism is used for clamping a gold cake, the air blowing mechanism comprises an air nozzle, the air nozzle is provided with a first groove, the two opposite wall faces of the first groove are both provided with air outlet holes, the moving drive mechanism is provided with one drive end, the drive end is connected with the air nozzle or the clamping mechanism, or the moving drive mechanism is provided with two drive ends, the two drive ends are connected with the air nozzle or the clamping mechanism correspondingly, and the moving drive mechanism is used for driving the clamping mechanism and the air blowing mechanism to be relatively close to or to be relatively away from to make the gold cake be stretchedinto the first groove or be moved out of the first groove to make the two air outlet holes perform back and forth air blowing on the two opposite side faces of the gold cake correspondingly. Accordingto the blow-drying device and the gold exchange machine, by means of the two-side back and forth blowing-sweeping method, water attached to the gold cake is quickly blown away and dried, the air blowing time is reduced, the blow-drying efficiency is high, and the customer use experience is improved.

Owner:SHENZHEN LINK GOLD TECH CO LTD

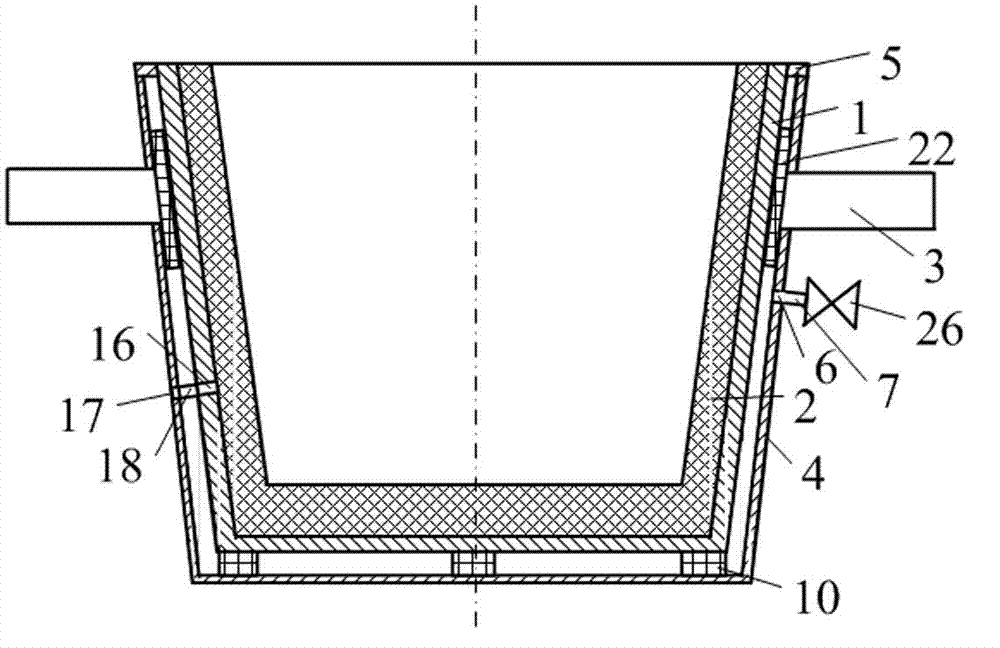

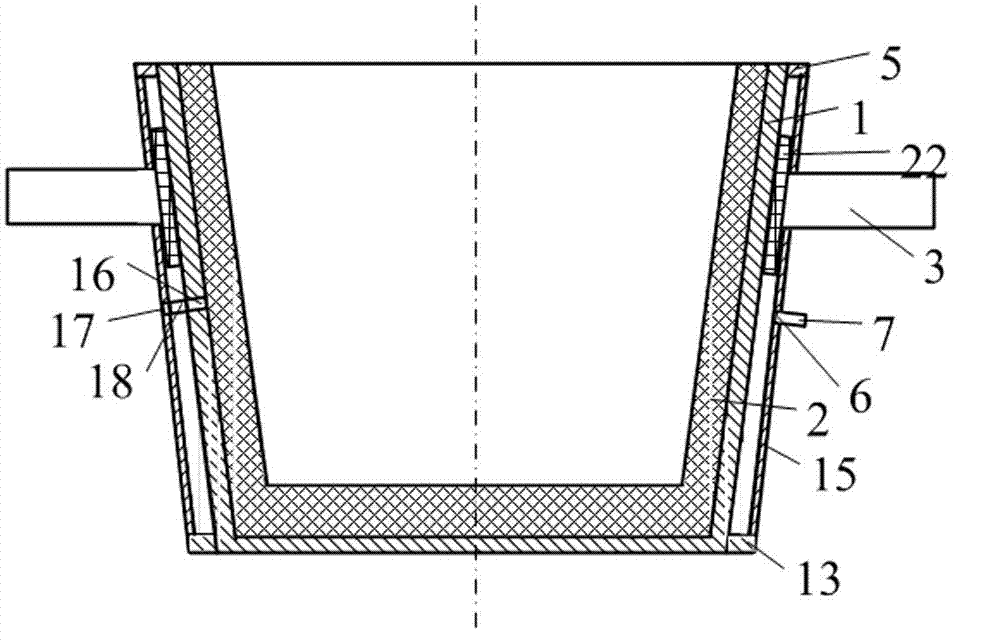

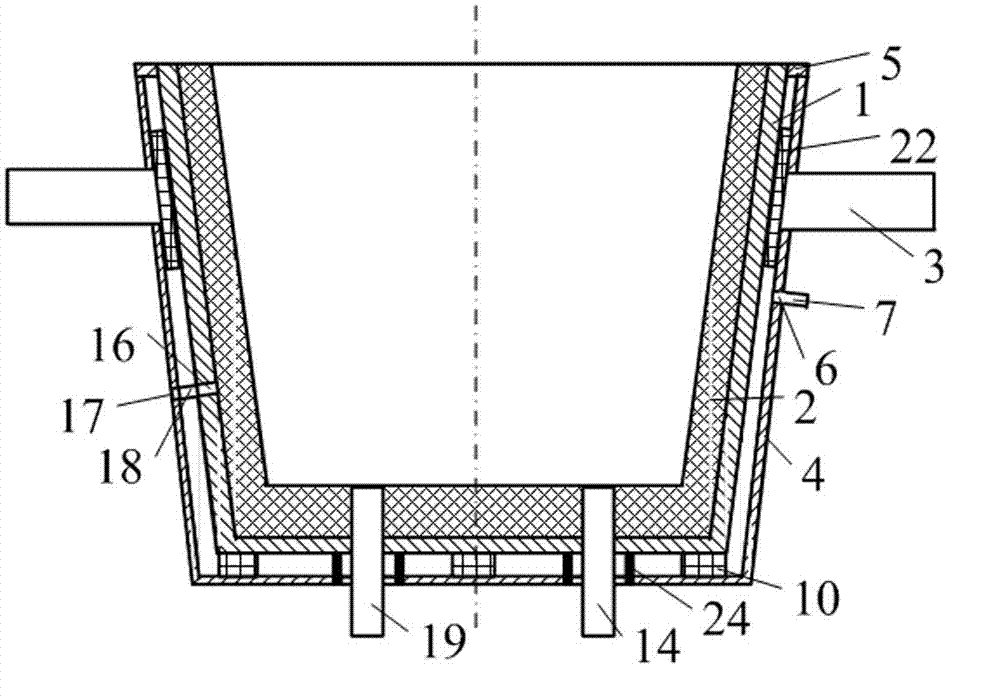

Metallurgical ladle device with vacuum shell

ActiveCN102151820BReduce heat lossReduce crustMelt-holding vesselsAtmospheric pressureVacuum chamber

The invention discloses a metallurgical ladle device with a vacuum shell and belongs to the technical field of metallurgical equipment. The vacuum shell is arranged on the outer wall of a metallurgical ladle shell; the top of the vacuum shell is fixedly connected with the top of the metallurgical ladle shell; a gap between the inner wall of the vacuum shell and the outer wall of the metallurgicalladle shell forms a shell vacuum chamber; and the air pressure in the vacuum chamber is 1 to 5Pa. The device has the advantages of low manufacturing cost, long service life, high heat insulation performance, working stability and the like, is suitable for metallurgical ladle, such as foundry ladle, steel ladle or tundish, and can also be suitable for metal liquid ladle or a metal liquid tank in the non-ferrous metallurgical industry.

Owner:武汉市赟巨科技有限公司

Manufacturing method of automobile regulator mold core

ActiveCN107891125BImprove thermal stabilityImprove internal strengthFoundry mouldsFoundry coresManufacturing cost reductionHeat stability

The invention relates to the field of car adjustors, in particular to a mould for manufacturing car adjustors and particularly provides a car adjustor mould core manufacturing method. The car adjustormould core manufacturing method comprises the steps that silica sand, a curing agent and alkaline phenolic resin are sequentially mixed to obtain alkaline phenolic resin sand, the alkaline phenolic resin sand is added into a core box of a cold core box core shooting machine to be formed and hardened, and then a mould core is taken out; the mould core is immersed into mixed cohering liquid and then taken out to be dried in air; the mould core is roasted till the temperature is 1200 DEG C or over and then cooled; and the mould core is subjected to core leach to obtain a car adjustor mould core.According to the car adjustor mould core manufacturing method, the manufacturing cost can be reduced, the heat stability of the mould core is good, the hardening time can further be shortened while it is ensured that the alkaline phenolic resin sand is sufficiently formed, the surface quality and the geometric dimension accuracy of the mould core are ensured, and the service life and manufacturing accuracy of the mould core are ensured; and the labor intensity can further be reduced, the labor condition and work environment are greatly improved, environment pollution is reduced, and energy issaved.

Owner:江苏久祥汽车电器集团有限公司

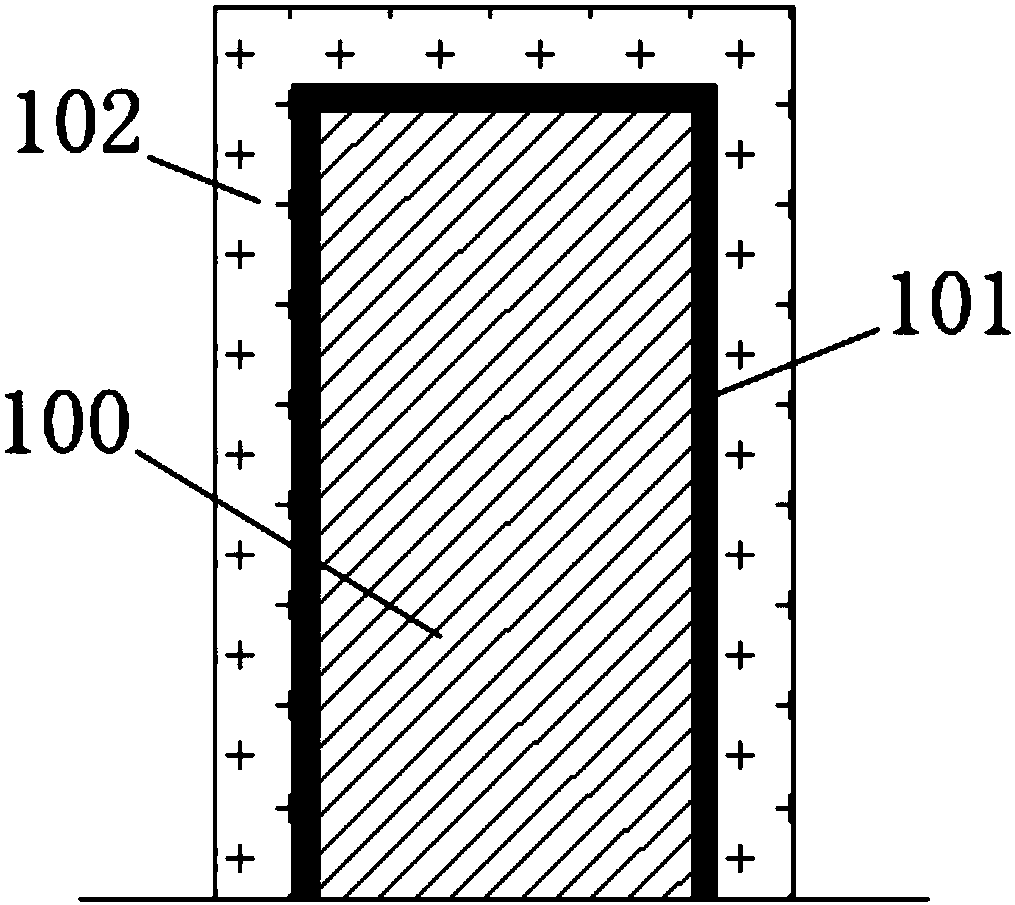

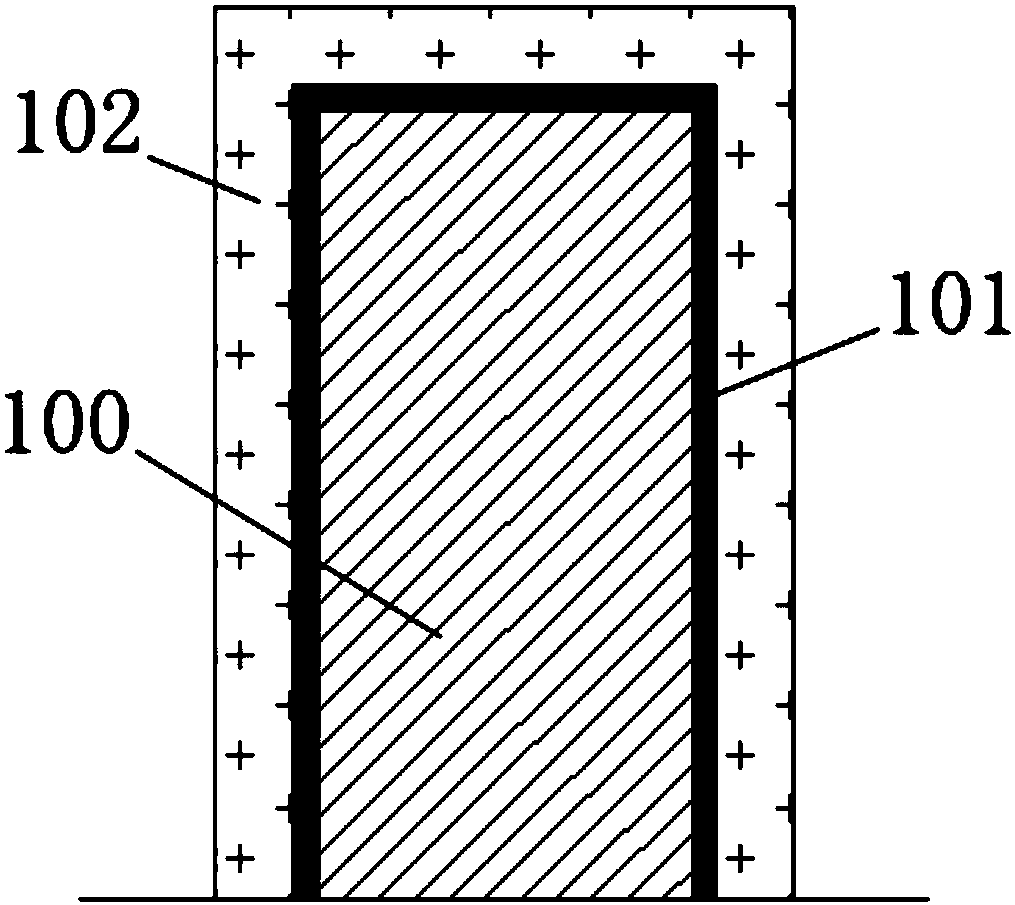

Method for preparing ladle liner permanent layer by adopting perlite composite insulation board

The invention relates to a method for preparing a ladle liner permanent layer by adopting a perlite composite insulation board, which comprises the preparation of a perlite composite insulation board and the arrangement of the perlite composite insulation board on a ladle shell inner wall. The method for preparing the perlite composite insulation board comprises the following steps of: (1) evenlymixing 1 percent by weight of expanded perlite, 0.3-1.2 percent by weight of adhesive and 0.02-0.06 percent by weight of fiber materials under the stirring condition to obtain a mixture; and (2) putting the mixture in a die; pressuring and smoothening the surface; and then, hardening at 15-110 DEG C for 0.2-24h to obtain a perlite composite insulation board. The perlite composite material of the invention adopts environment-friendly natural materials which are nontoxic, tasteless and taintless and have low production cost, low price and good insulation performance; and the insulation board has the advantages of light capacity weight, small conductive coefficient, good stability, strong strength, convenient construction, and the like.

Owner:湖北兴冶特钢实业发展有限公司

Method for automatic bottom blowing control of converter

InactiveCN102041346BQuality improvementShorten blowing timeManufacturing convertersHuman–machine interfaceEngineering

Owner:BEIJING JIANLONG HEAVY IND GROUP

Highly effective metallurgical complexing agent for convertor (electric oven) and its preparation method and uses

The invention relates to an admixture removing foreign matter of converting process in the field of fusion alloy treatment. It is formed by (by weight ratio) manganese oxide powdered ore 40-50%, iron powdered ore20-25%, dolomitic limestone powder 10-20%, silicon powder 4-6%, carbon powder 3-5%, catalyst 4-6% and some water; the complex agent is made by preparing for the material, stirring, adding catalyst and water to mix them, extrusion molding drying and sieving and so on.

Owner:黄志勇

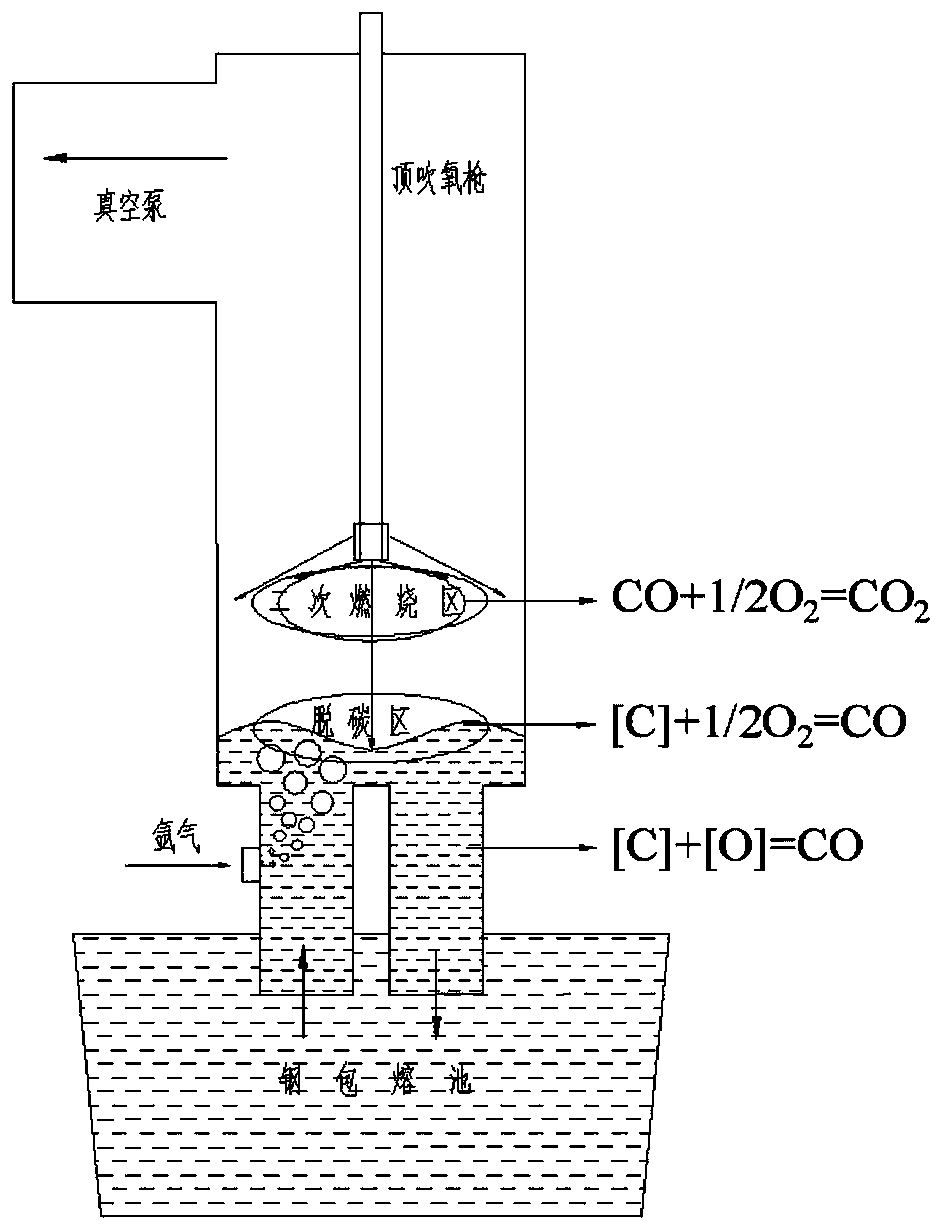

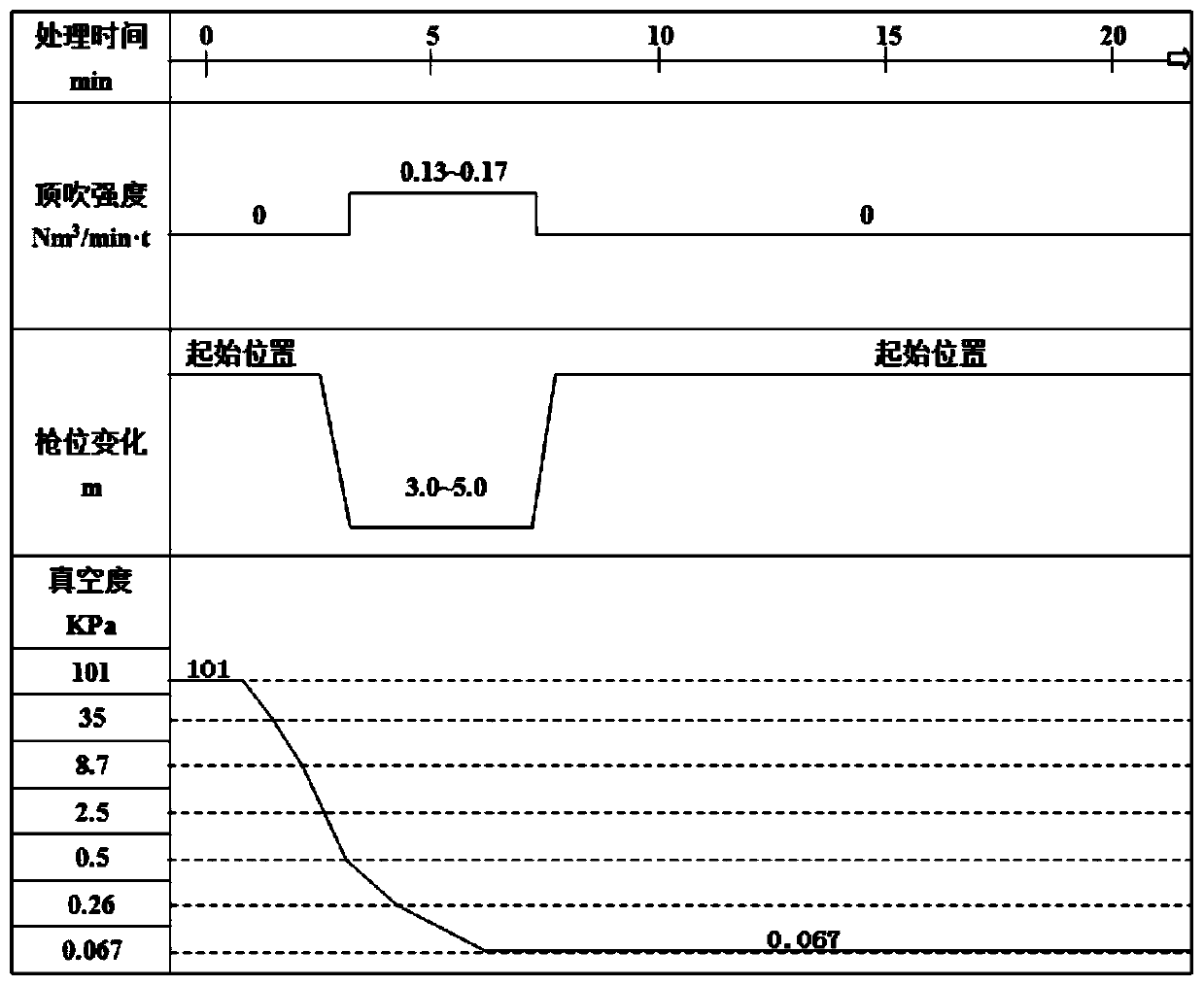

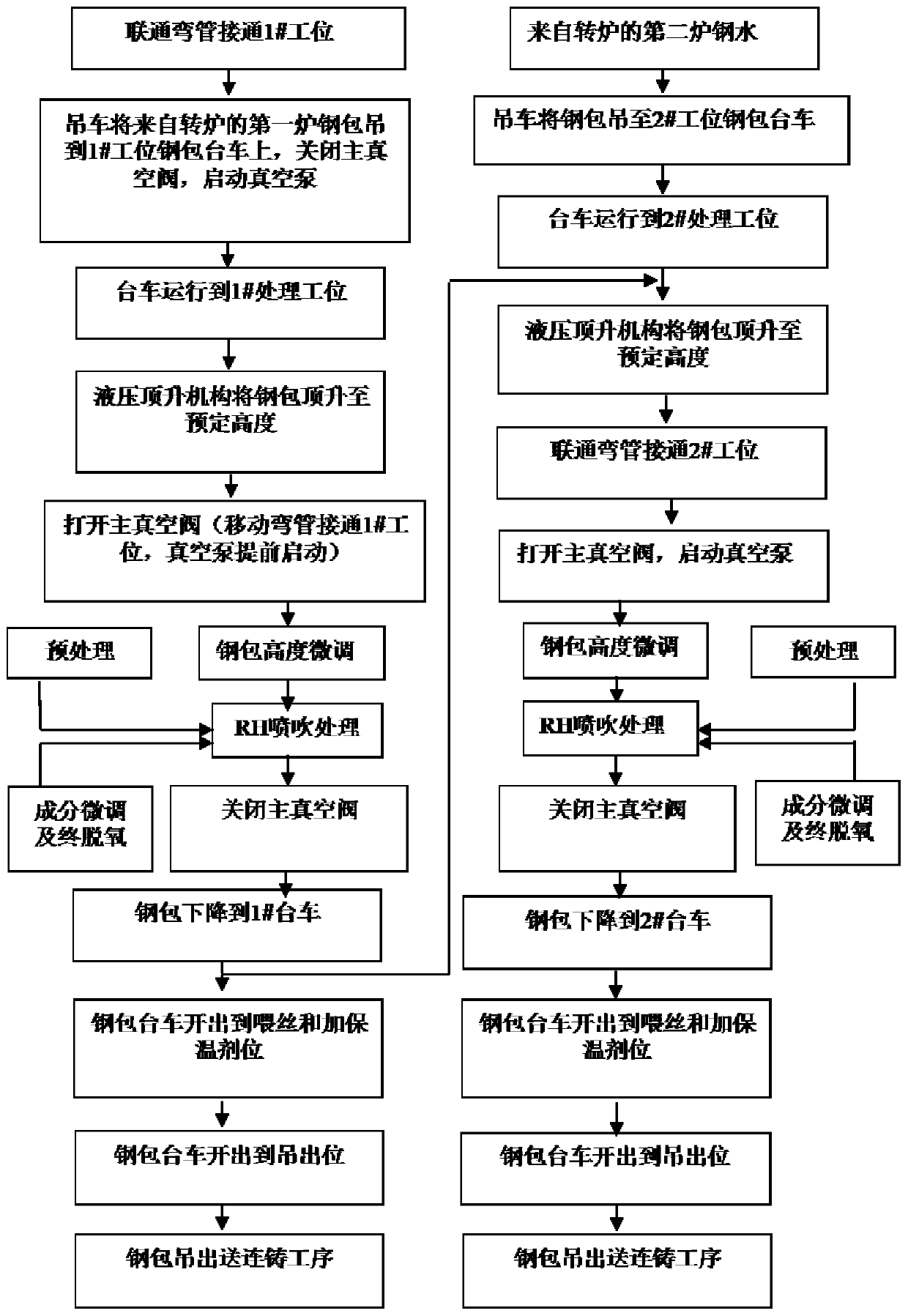

A kind of injection process that can improve the secondary combustion efficiency of rh refining furnace

The invention relates to a blowing process capable of improving the secondary combustion efficiency of an RH refining furnace, and belongs to the technical field of steelmaking. According to the blowing process, a top-blowing secondary combustion oxygen lance blowing process is adopted in the RH refining furnace, so that CO gas generated by a carbon oxygen reaction is in more contact with oxygen,the secondary combustion area is expanded, and therefore the secondary combustion rate can be further improved. The blowing process is mainly characterized in that for steel types needing RH deep decarbonization treatment, when tapping [ C ] of a converter blowing end point is larger than or equal to 0.05%, top-blowing oxygen forced decarbonization operation is carried out, the top-blowing intensity is 0.13-0.17 Nm<3> / min.t, and the oxygen blowing and decarbonization time is 4-6 minutes, the pressure of a vacuum chamber is gradually reduced from 101 kPa to 0.067kPa, treatment is carried out for 18minutes, and then the content of [ C ] can be controlled to be below 0.0012%. By adopting the blowing process, the secondary combustion rate can be improved by 20-30%., and the temperature of molten steel is further compensated by about 4-6 DEG C compared with a traditional top lance oxygen blowing decarbonization process.

Owner:CENT IRON & STEEL RES INST

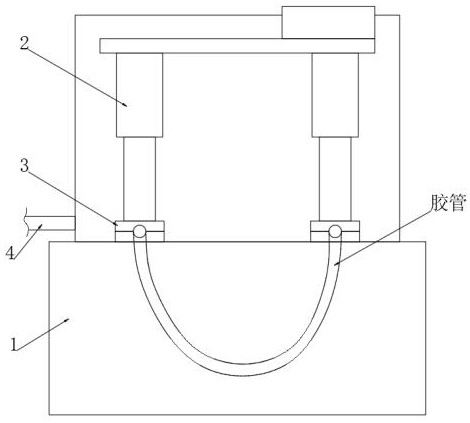

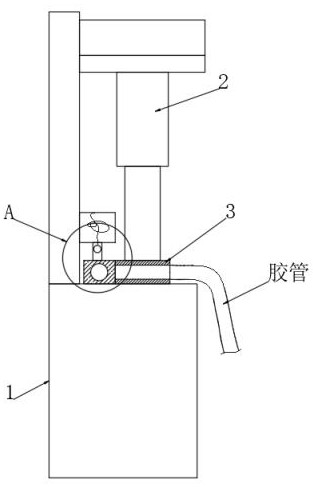

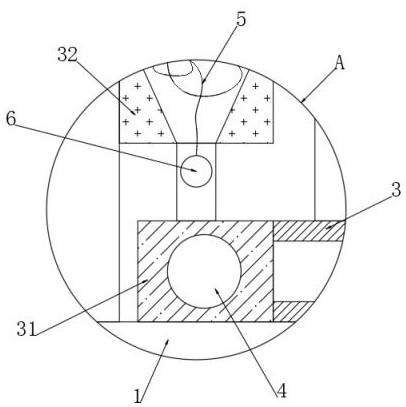

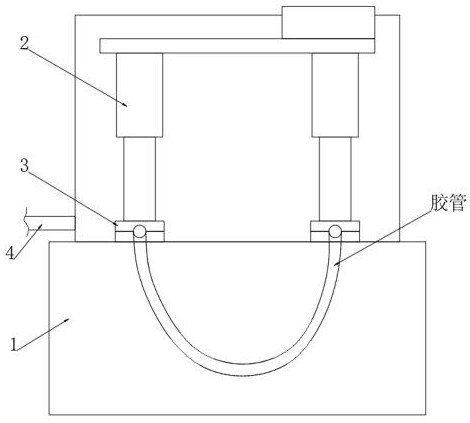

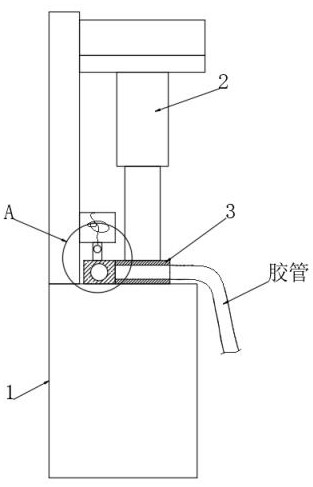

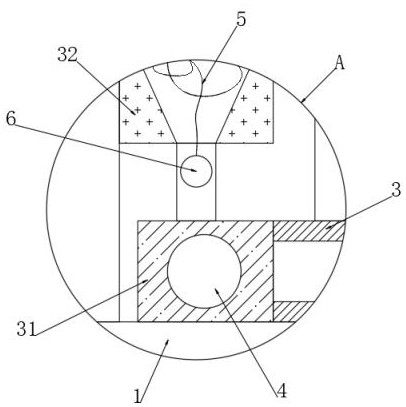

A hose blowing and drying device after static pressure detection

ActiveCN113587565BImprove drying efficiencyAvoid blindly prolonging the blowing timeDrying gas arrangementsDrying solid materialsColor testThermodynamics

The invention discloses a water blowing and drying device for rubber hose after static pressure detection, which belongs to the field of rubber hose drying. Blow the trailing water test polo into the middle of the hose bend to test the water, so that the trailing water test polo can absorb the water that may exist in the middle of the hose. When the trailing water test polo is directly blown out of the hose, it means that there is more water inside. When the trailing test water polo is not blown out, pull it out of the hose through the pull rope, and the distribution range of the toner particles on the color test suction ring expands, indicating that there is accumulated water inside. There is very little water, and the drying of the hose can be completed by continuing to blow water for 1-2 minutes. Compared with the existing technology, it can effectively avoid the situation of blindly prolonging the time of blowing water, thereby greatly improving the drying efficiency of the hose.

Owner:NANTONG CITY WEISHI VACUUM EQUIP

Semi-steel steelmaking slag former

ActiveCN114686639AShorten blowing timeLow viscosityManufacturing convertersProcess efficiency improvementSteelmakingCompression molding

The invention discloses a semi-steel steelmaking slag former, which belongs to the technical field of metallurgical engineering, and comprises the following raw materials by weight: 75-85 parts of lime, 15-20 parts of magnesium oxide, 0.8-1 part of a binder, 2-3 parts of hydrocarbon particles, and 6-8 parts of an auxiliary agent. And the hydrocarbon particles, magnesium oxide, lime, an auxiliary agent and a binding agent are evenly mixed and then ground and subjected to compression molding, and the slag former is obtained. The hydrocarbon particles and the auxiliaries are added and have a synergistic effect, generation of FeO is promoted, dissolution of CaO is promoted, slagging and dephosphorization reactions can be accelerated, the converter blowing time is effectively shortened, and the overall converter steelmaking efficiency is improved; in addition, no other impurities are introduced into the molten steel, and the quality of steel finished products is improved.

Owner:芜湖县天海耐火炉料有限公司

Method of folding items of laundry

ActiveUS9347172B2Good folding effectShorten blowing timeFolding thin materialsPackagingTelecommunicationsLaundry

In apparatuses for automatically folding items of laundry, items of laundry of different lengths usually are folded in an irregular sequence, resulting in idling and / or delays in particular in the longitudinal-folding station (13). The invention provides for determining the length of each item of laundry (10) upstream of the longitudinal-folding station (13) and for accelerating short items of laundry as they are transported through the longitudinal-folding station (13), whereas larger items of laundry are slowed down in the longitudinal-folding station (13). Following completion of the longitudinal-folding operation, the respectively folded item of laundry is located at the end of the longitudinal-folding station (13) and, immediately following completion of the longitudinal folding, is transported away out of the longitudinal-folding station (13). This avoids unnecessary idling times, and for relatively long items of laundry to be folded longitudinally during continuous, relatively slow onward transportation through the longitudinal-folding station (13).

Owner:KANNEGIESSER GMBH CO HERBERT

Oxygen-enriched blowing device and method thereof

ActiveCN103882244BShorten blowing timeImprove productivityRotary drum furnacesCrucible furnacesEngineeringCopper

The invention relates to an oxygen-enriched blowing device which comprises a blowing lance and a lance supporting device, wherein the blowing lance comprises a blowing gas pipe, a lance outer pipe and an intermediate partition pipe located between the lance outer pipe and the blowing gas pipe; the lance-supporting device is a semi-circular concave groove and is located below the blowing lance, at least three pairs of rollers are arranged in the concave groove and the blowing lance is supported on the rollers. The blowing method suitable for the oxygen-enriched blowing device comprises the steps of 1) after deslagging, putting the front end surface of the blowing lance at a position 10-30cm above the copper liquid level, introducing a mixed gas of oxygen and air under the conditions that the air flow rate is 4000-11000Nm<3> / h, the air pressure is 0.3-0.4MPa and the oxygen flow rate is 200-300Nm<3> / h and blowing for 10-20 minutes; 2) carrying out oxygen-enriched blowing for 10-20 minutes under the condition that the oxygen flow rate is 100-150Nm<3> / h; and 3) turning off the oxygen switch and carrying out air blowing until the blowing is completed. By the blowing technology disclosed by the invention, the productivity can be improved, labor intensity is reduced and the service life of the blowing lance can be prolonged.

Owner:铜陵四通环境科技有限公司

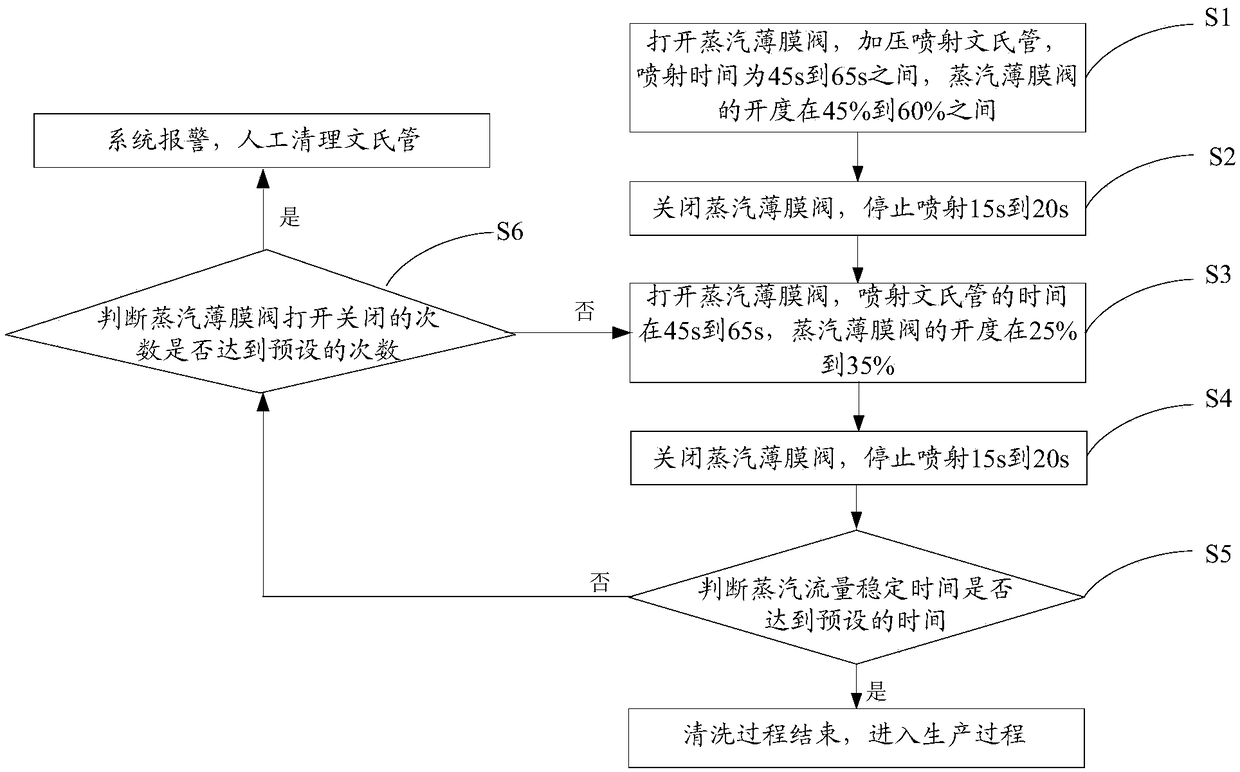

A kind of flash steam cleaning method

ActiveCN107116071BReduce noiseReduce consumptionHollow article cleaningEngineeringUltimate tensile strength

The invention discloses a flash steam cleaning method. A subsection cleaning method is adopted, firstly, pressurized injection is performed, opening of a steam film valve is in a range from 45% to 60% during pressurized injection, a part of a material in a venturi tube is rapidly blown out, the material in the venturi tube is reduced, then injection is performed again, the opening of the steam film valve is in a range from 25% to 35% during injection, and the injection intensity is divided into two sections, so that unnecessary steam consumption is reduced; besides, the opening of the steam film valve is reduced, and accordingly, noise in the venturi tube is also reduced. Additionally, injection is stopped once the condition that all the material is blown out or the venturi tube is blocked severely is detected, so that the injection time is shortened, and the injection flow is reduced.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Argon-oxygen furnace and operation method thereof

ActiveCN102899455AImprove corrosion resistance of refractory materialsImprove flushing effectGas emission reductionBrickSmelting process

The invention relates to an argon-oxygen furnace and an operation method thereof. The argon-oxygen furnace is characterized in that: I, the physical and chemical indexes of a magnesium-calcium brick for the working layer of a furnace lining meet requirements; II, a total included angle of blower guns is 108 to 120 DEG, the distance between the blower guns is no less than 380 mm, and the blower guns, blower gun bricks and adjacent bricks are bonded by using resin mortar; and III, the furnace lining undergoes maintenance and baking. The operation method is characterized in that: I, the content of Si in pre-melting liquid of smelting is no more than 0.30%; II, during blowing, the integral argon-oxygen furnace is backwardly revolved and tilted by 3 to 7 DEG; III, air feeding intensity of a top gun during decarburization in stage 1 to 3 is 0.85 to 1.40 Nm<3> / min.t; IV, the basicity of slag is 1.8 to 2.2; V, no-load time is less than 90 min, a furnace mouth is swayed down to 120 to 240 DEG, and if no-load time is greater than 90 min, on-line baking is carried out; and VI, temperature monitoring is carried out on steel plate surface temperature corresponding to easy-leaking points of the blower guns and slag lines in the whole process of furnace smelting. With the argon-oxygen furnace and the operation method thereof in the invention, the furnace life of the argon-oxygen furnace is prolonged to no less than 160 heats.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A ps-converter incomplete exchange matte blowing method

The invention relates to a blowing method of interchanging copper matte in an imperfect stage of PS-converters. The method is characterized by comprising the following steps: (1) preparing four PS-converters and two pressure blowers; (2) randomly dividing the four converters into two groups, wherein the converters in each group are matched with one pressure blower; (3) starting the PS-converters and the pressure blowers, wherein each converter is in a hot state to-be-smelted state; and (4) adjusting the blowing step of the converters in each group, wherein the stage B of one of the converters is just between the stage S1 and the stage S2 of the other converter; and during blowing, inserting one of the converters in one of the groups between the stages S1 and S2 of any one of the converters in the other group according to actual demand to realize the blowing operation. Compared with the conventional switching blowing method, the blowing method provided by the invention is low in cost, high in capacity and high in blowing efficiency, and in the blowing process, the blowing time ratio of the pressure blowers is high and the electric energy is greatly saved.

Owner:DAYE NONFERROUS METALS

Water blowing and drying device for rubber tube after static pressure detection

ActiveCN113587565AImprove drying efficiencyAvoid blindly prolonging the blowing timeDrying gas arrangementsDrying solid materialsEngineeringHydrology

The invention discloses a water blowing and drying device for a rubber tube after static pressure detection, and belongs to the field of rubber tube drying. The water blowing and drying device for the rubber tube after static pressure detection is characterized in that a trailing water testing ball is arranged and can be blown into the bent middle part of the rubber tube for water testing after water blowing and drying are carried out for a certain time, the tailing water testing ball absorbs water that may exist in the middle of the rubber tube, when the trailing water testing ball is directly blown out of the rubber tube, it shows that the interior of the rubber tube is more accumulated water, when the trailing water testing ball is not blown out, the trailing water testing ball is pulled out of the rubber tube through a pull rope, the distribution range of toner particles on a color inspection suction ring is enlarged, it shows that the interior of the rubber tube contains accumulated water, when the color inspection suction ring does not change obviously, it means that the interior of the rubber tube contains very little water accumulation, and the rubber tube can be dried by continuing to blow water for 1-2 minutes. Compared with the prior art, the water blowing and drying device for the rubber tube after static pressure detection has the advantages that the situation that the water blowing time is prolonged blindly is effectively avoided, and the drying efficiency of the rubber tube is greatly improved.

Owner:NANTONG CITY WEISHI VACUUM EQUIP

Argon-oxygen furnace and operation method thereof

The invention relates to an argon-oxygen furnace and an operation method thereof. The argon-oxygen furnace is characterized in that: I, the physical and chemical indexes of a magnesium-calcium brick for the working layer of a furnace lining meet requirements; II, a total included angle of blower guns is 108 to 120 DEG, the distance between the blower guns is no less than 380 mm, and the blower guns, blower gun bricks and adjacent bricks are bonded by using resin mortar; and III, the furnace lining undergoes maintenance and baking. The operation method is characterized in that: I, the content of Si in pre-melting liquid of smelting is no more than 0.30%; II, during blowing, the integral argon-oxygen furnace is backwardly revolved and tilted by 3 to 7 DEG; III, air feeding intensity of a top gun during decarburization in stage 1 to 3 is 0.85 to 1.40 Nm<3> / min.t; IV, the basicity of slag is 1.8 to 2.2; V, no-load time is less than 90 min, a furnace mouth is swayed down to 120 to 240 DEG, and if no-load time is greater than 90 min, on-line baking is carried out; and VI, temperature monitoring is carried out on steel plate surface temperature corresponding to easy-leaking points of the blower guns and slag lines in the whole process of furnace smelting. With the argon-oxygen furnace and the operation method thereof in the invention, the furnace life of the argon-oxygen furnace is prolonged to no less than 160 heats.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com