Metallurgical ladle device with vacuum shell

A technology of vacuum shell and package device, applied in metal processing equipment, casting melt container, casting equipment and other directions, can solve the problems of large heat loss of metallurgical package, improve the quality of casting billet, reduce pouring temperature, and shorten blowing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

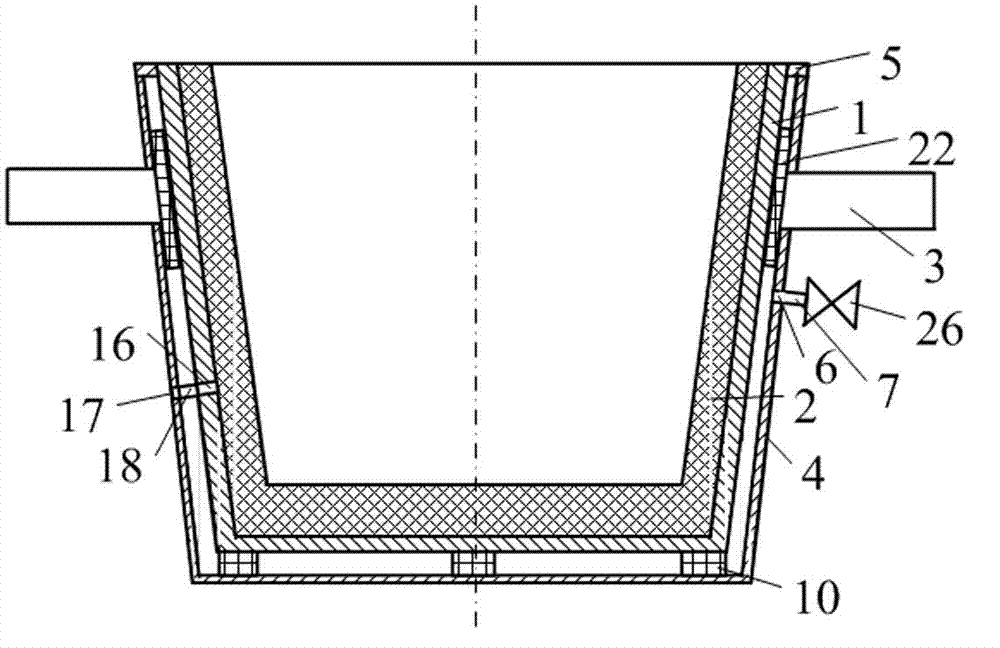

[0027] The structure of metallurgical ladle device with vacuum shell is as follows: figure 1 As shown, including a metallurgical ladle, the metallurgical ladle is mainly composed of a metallurgical cladding 1, a cladding lining 2 and two trunnions 3, each trunnion 3 is fixed on a connecting plate 22, and the connecting plate 22 is fixed on the metallurgical cladding 1 Above, the metallurgical cladding 1 is provided with a plurality of cladding vents 16, and the inner lining 2 is arranged in the metallurgical cladding 1; the outer wall of the metallurgical cladding 1 is provided with a vacuum shell, and the top of the vacuum shell is connected with the metallurgical cladding 1 The top is fixedly connected, and there is a gap between the inner wall of the vacuum shell 1 and the outer wall of the metallurgical cladding to form a vacuum chamber of the shell, and the air pressure in the vacuum chamber is 3Pa; the cladding exhaust hole 16 is connected with one end of the exhaust pipe...

Embodiment 2

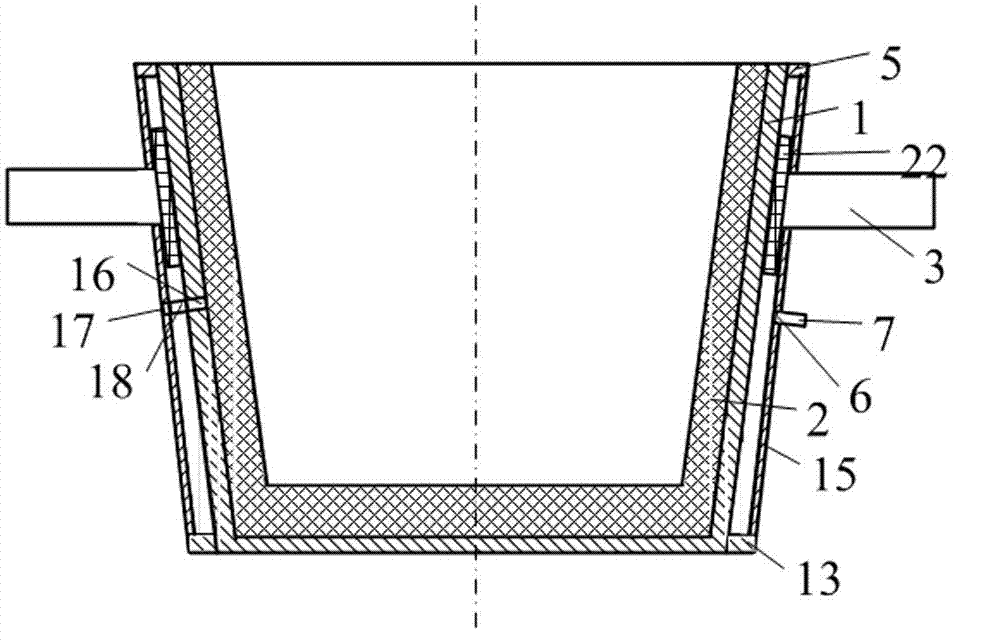

[0037] The structure of metallurgical ladle device with vacuum shell is as follows: figure 2 as shown,

[0038] Including a metallurgical ladle, the metallurgical ladle is mainly composed of a metallurgical cladding 1, a cladding lining 2 and two trunnions 3, each trunnion 3 is fixed on a connecting plate 22, and the connecting plate 22 is fixed on the metallurgical cladding 1, and the metallurgical A plurality of cladding vents 16 are provided on the cladding 1, and the inner lining 2 is arranged in the metallurgical cladding 1; a vacuum shell is provided on the outer wall of the metallurgical cladding 1, and the top of the vacuum shell is fixedly connected to the top of the metallurgical cladding 1 , there is a gap between the inner wall of the vacuum shell 1 and the outer wall of the metallurgical cladding to form a vacuum chamber of the shell, and the air pressure in the vacuum chamber is 4Pa; The vacuum shell exhaust hole 18 on the shell communicates;

[0039] The vacu...

Embodiment 3

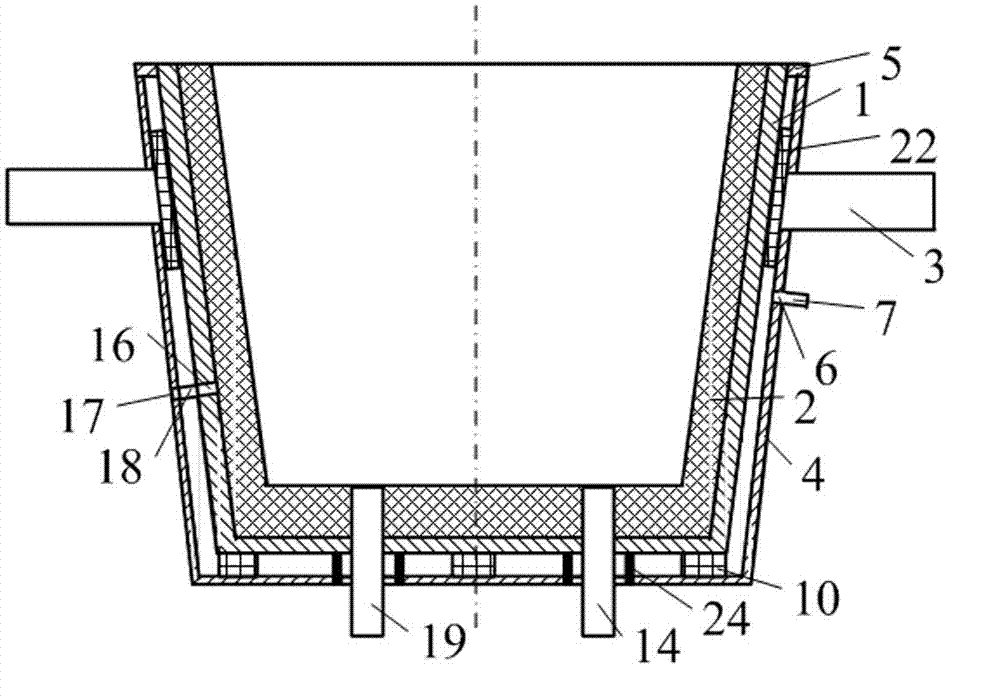

[0047] The structure of metallurgical ladle device with vacuum shell is as follows: image 3 As shown, the structure of the metallurgical ladle is the same as in Embodiment 1, the difference is that: the bottom of the metallurgical ladle is provided with a bottom blowing device hole 14 and a metal liquid flow hole 19, and the structure of the vacuum shell is the same as in Embodiment 1, the difference is that:

[0048] (1) An isolation tube 24 is arranged around the hole 14 of the bottom blowing device and the metal liquid flow hole 16, and two through holes are arranged at the bottom of the barrel wall. The bottom of each isolation tube 24 communicates with a through hole respectively, and the isolation tube 24 The top is connected to the bottom surface of the metallurgical cladding 1, so that the bottom blowing device hole 14 and the metal liquid flow hole 16 are isolated from the vacuum chamber;

[0049] (2) The distance between the inner surface of the cylindrical side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com