Patents

Literature

76results about How to "Lower pouring temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

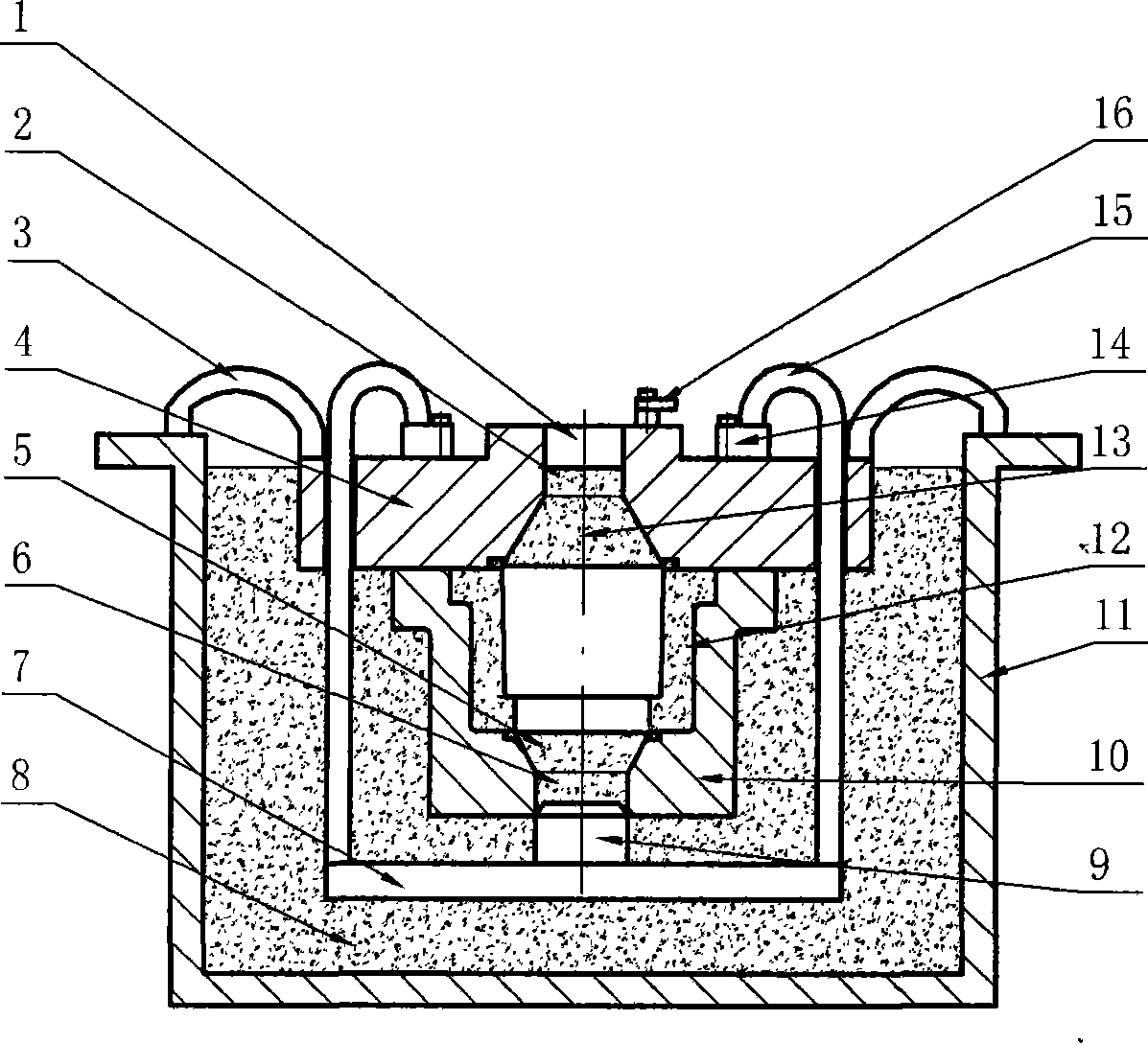

Aluminum alloy investment casting method and investment casting device adopting near liquidus pouring

InactiveCN105598372ADense structure of castingEliminate casting stressFoundry mouldsFoundry coresInvestment castingMelt temperature

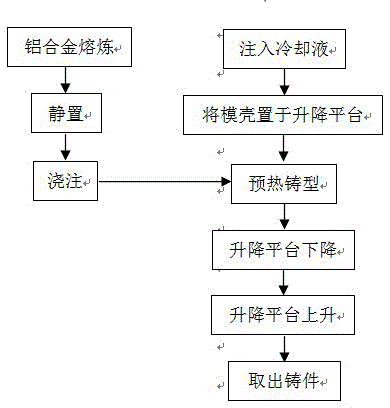

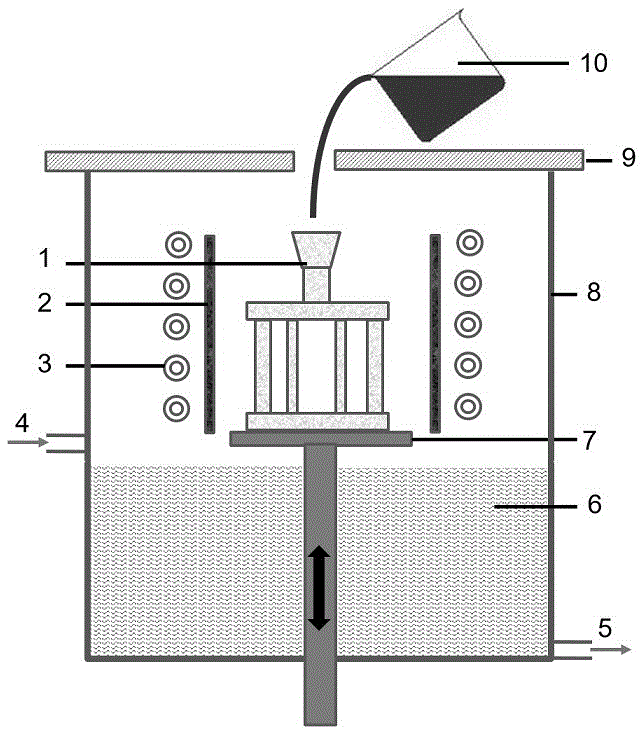

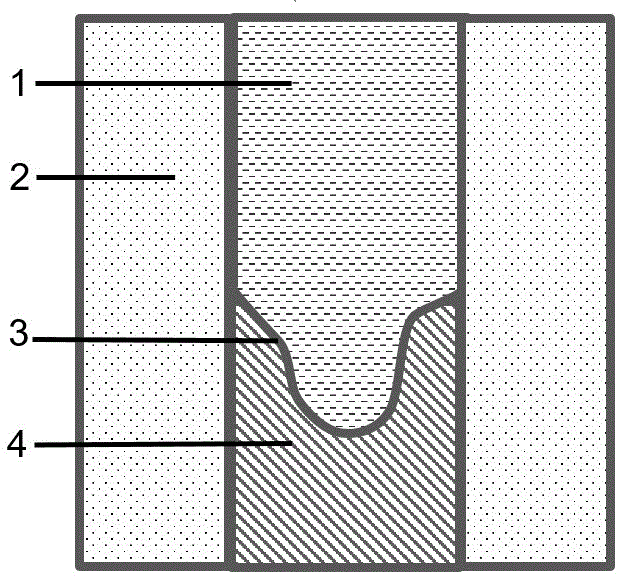

The invention discloses an aluminum alloy investment casting method adopting near liquidus pouring. The method comprises the following steps: preheating a mould shell to be close to the liquidus, performing near liquidus temperature pouring, and meanwhile, reducing the pouring temperature, and pouring after the melt temperature is higher than the temperature of the liquidus; after finishing pouring, immersing the mould shell into the cooling liquid at a certain speed, thereby effectively and accurately controlling a solidification process of the casting; quickening the cooling of the casting, thereby acquiring the high-quality aluminum alloy casting with uniform structure and small grain. In the casting solidification process, the temperature gradient can be accurately controlled, the lower part of the casting is firstly soaked into the cooling liquid and the upper part is still in the heating atmosphere and under the molten state, so that the casting can be solidified from bottom to top, the solidified part is subjected to full liquid feeding, the casting is compact in structure, and meanwhile, the casting stress in the solidification process of each part of the casting is eliminated. The method provided by the invention is fit for common aluminum alloy casting and large-size, thin-wall and complex aluminum alloy investment casting.

Owner:NANCHANG HANGKONG UNIVERSITY

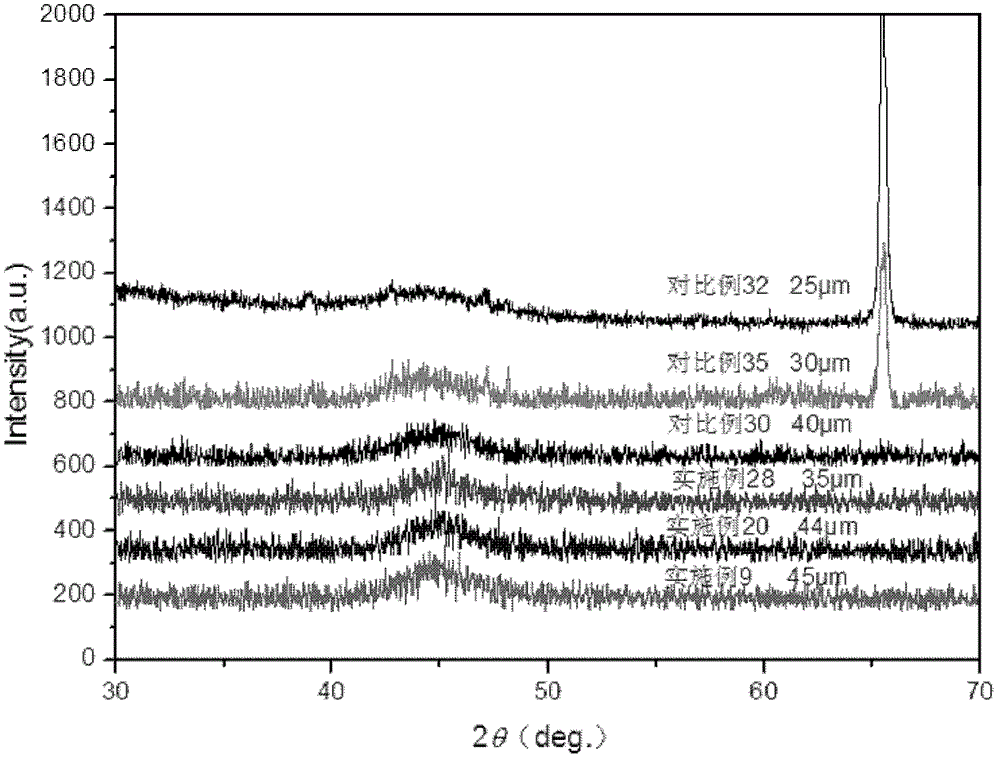

Iron base amorphous alloy and preparation method thereof

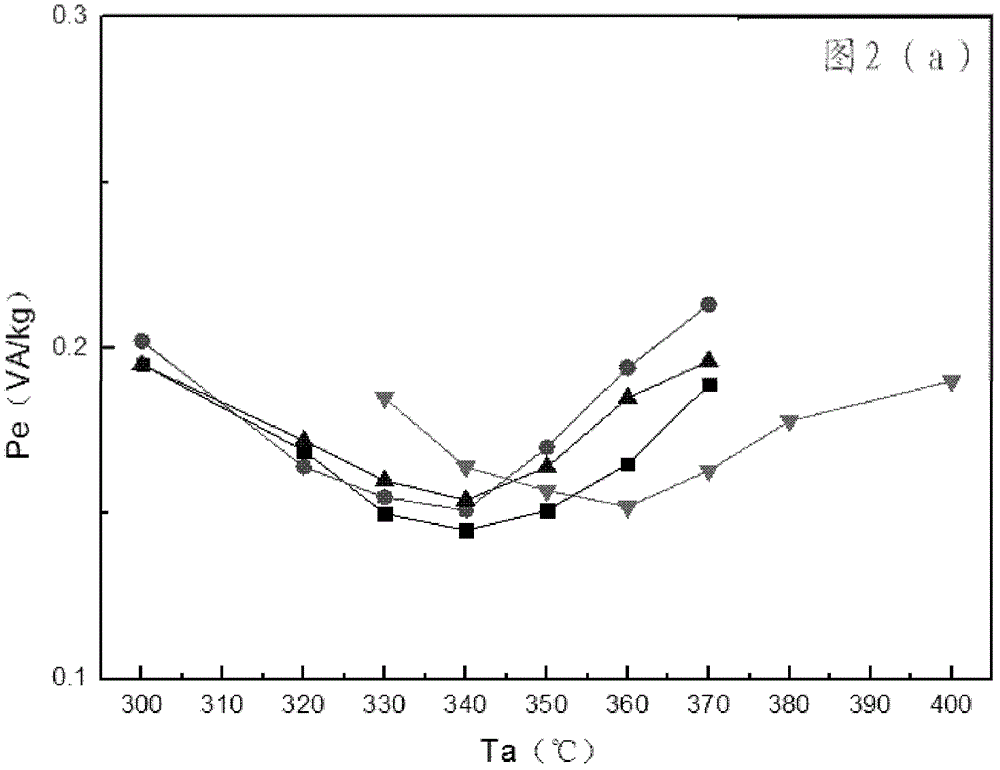

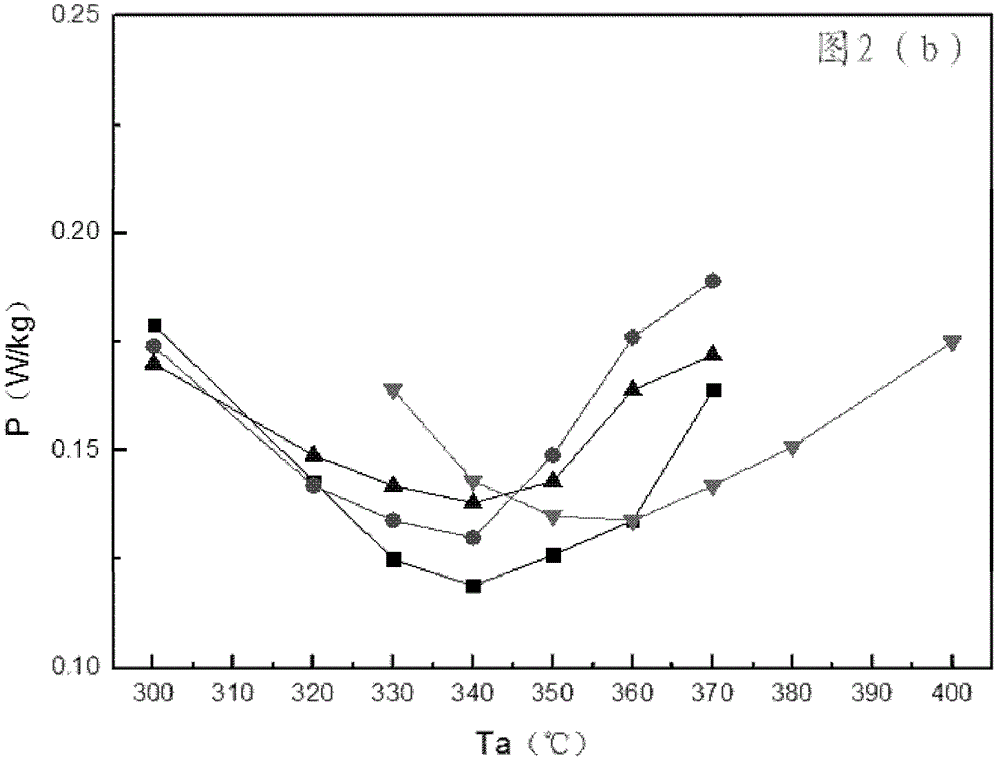

InactiveCN106702291AHigh saturation magnetic inductionGood Amorphous Formation AbilityTransformerVolumetric Mass Density

The invention provides an iron base amorphous alloy expressed in a formula (I), wherein a, b, c, d and e respectively represent the atomic percentage contents of corresponding components: a is not bigger than 84.0 and not smaller than 80.5, b is not bigger than 9.0 and not smaller than 3.0, c is not bigger than 15.0 and not smaller than 8.0, d is not bigger than 0.3 and not smaller than 0.001, e is not bigger than 0.4, and the sum of a, b, c, d and e is 100; and M is an impurity element. In the iron base amorphous alloy provided by the invention, the saturation induction density of an alloy material is not lower than 1.62 T. The invention further provides a preparation method of the iron base amorphous alloy; further, the excellent soft magnetic properties can be obtained after proper heat treatment; the alloy material can be used for manufacturing iron core materials of power transformers, generators and engines; and FeaSibBcPdMe (I).

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

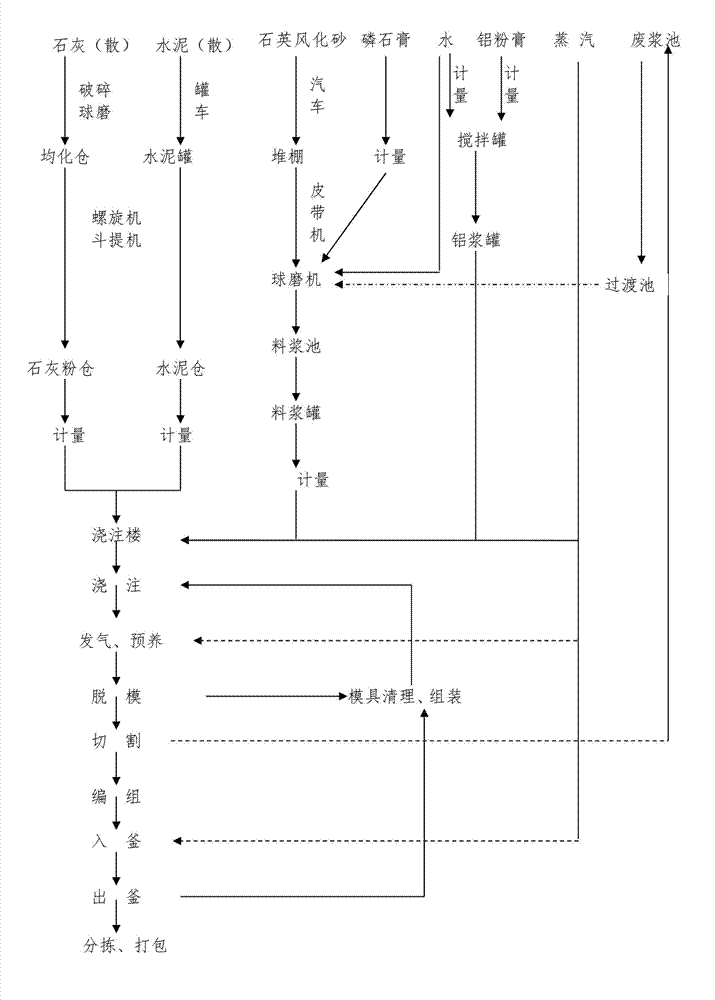

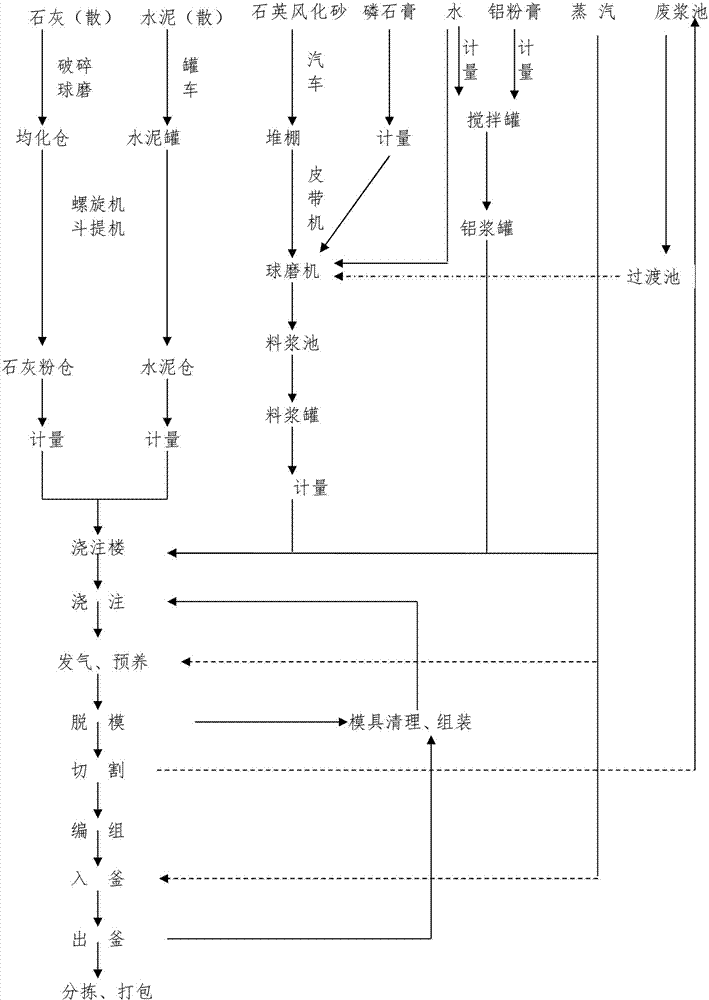

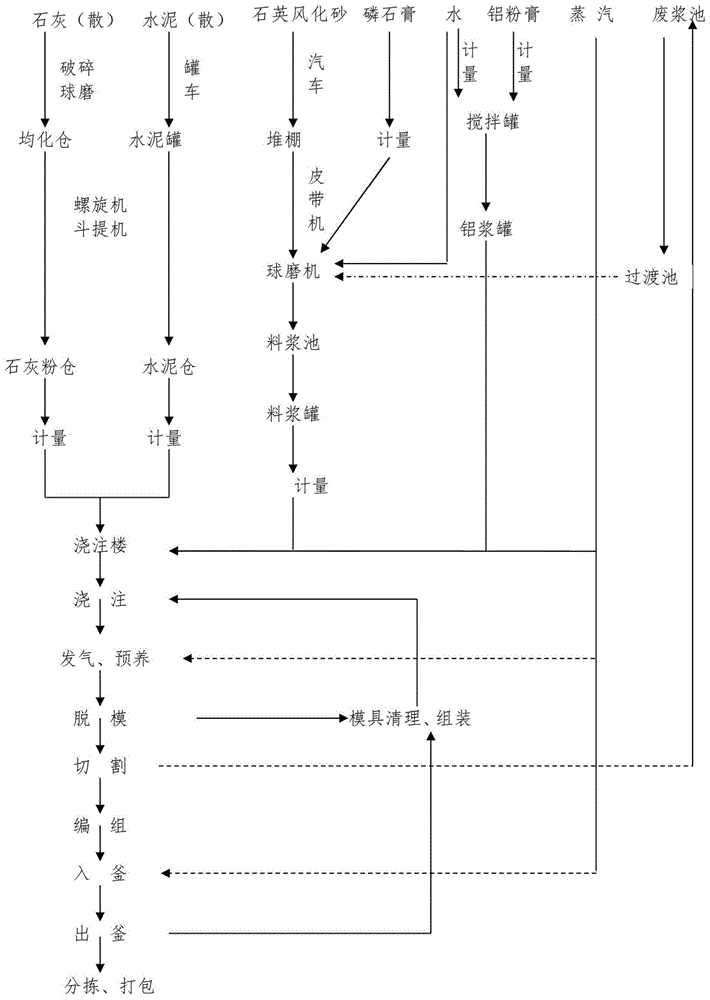

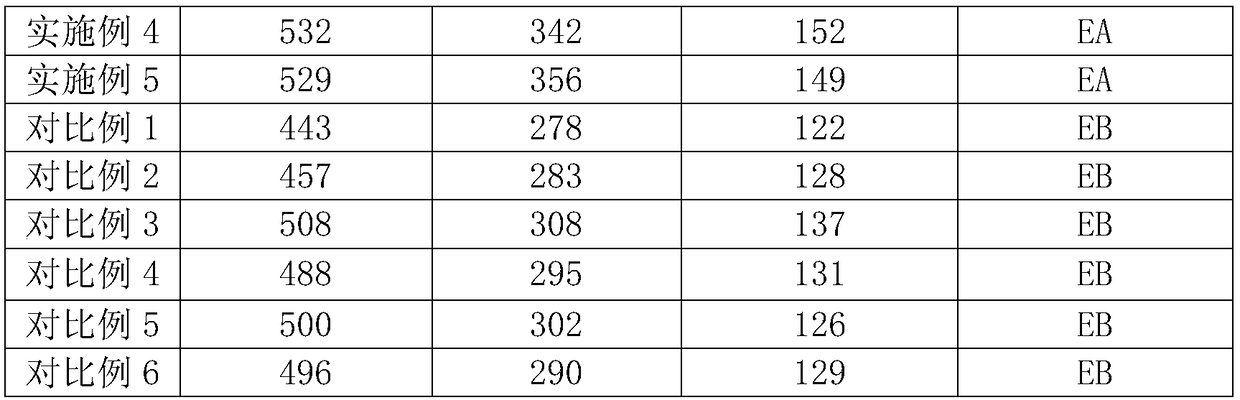

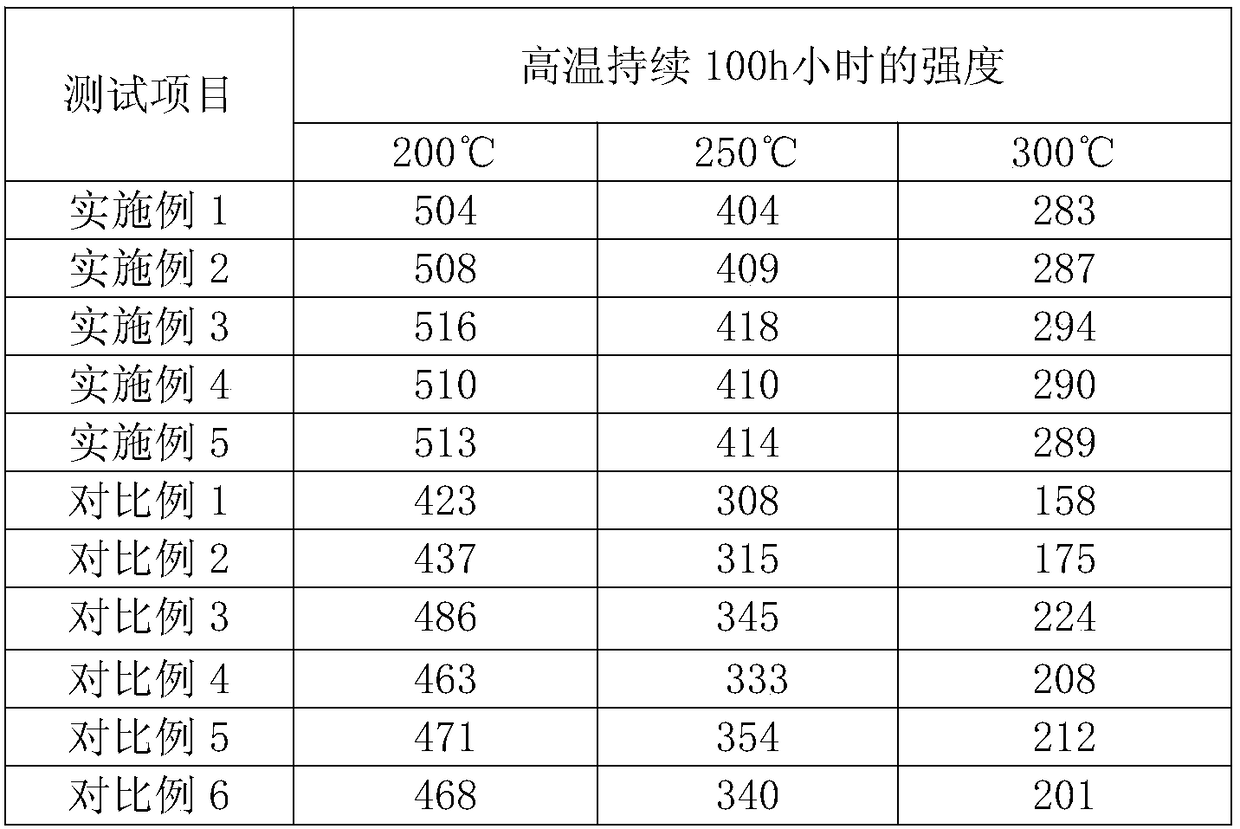

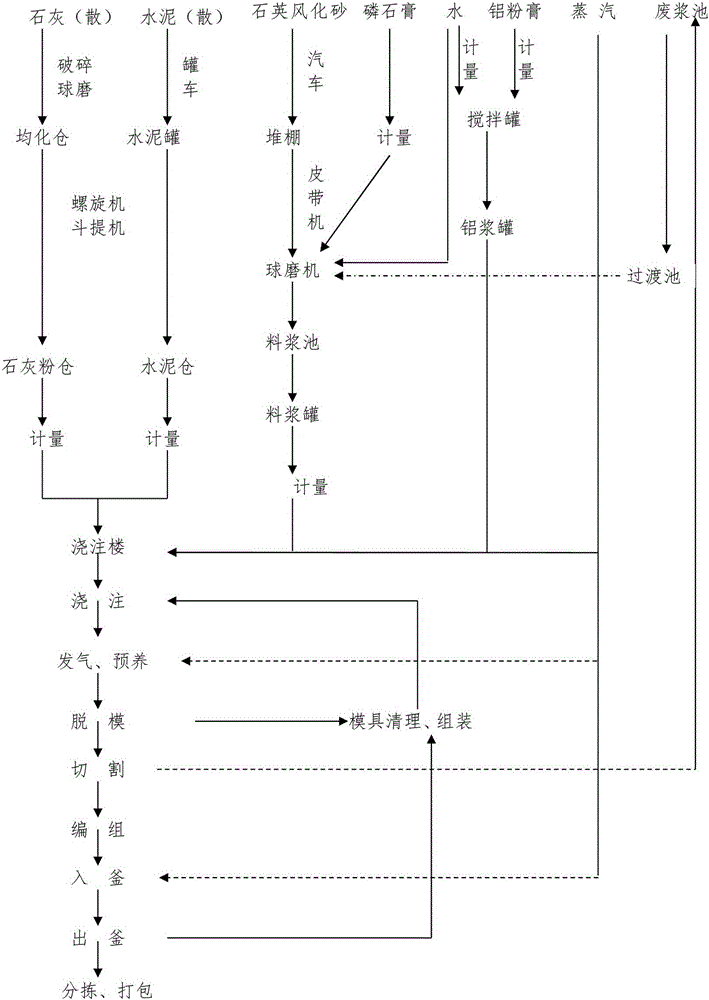

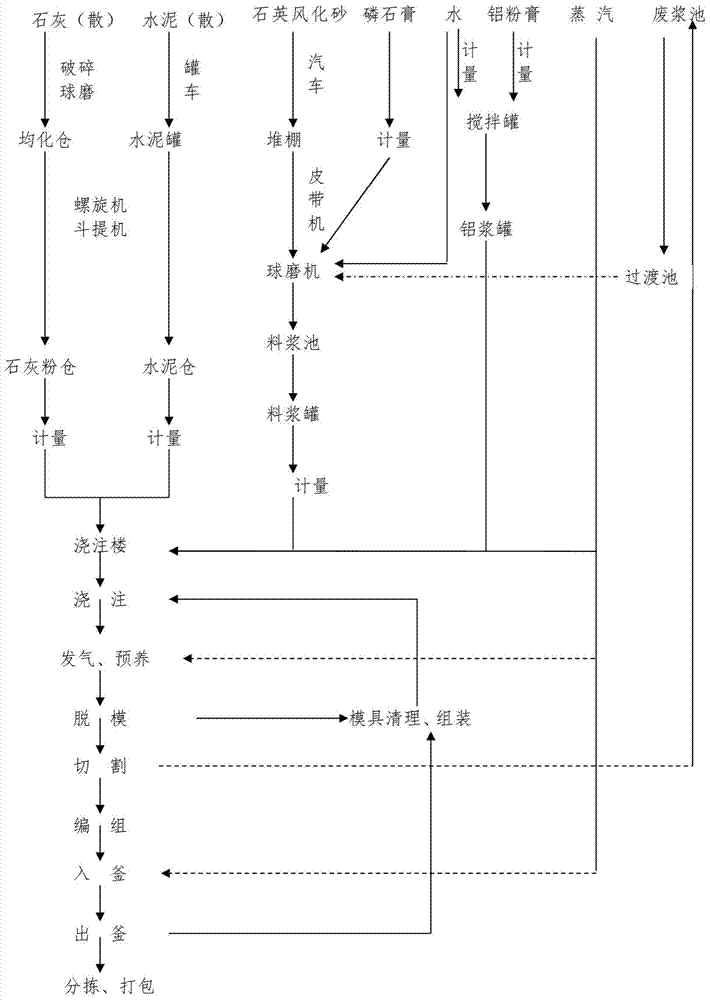

A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand and preparation method thereof

ActiveCN104774031AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention discloses an A2.0 B04 grade autoclaved aerated concrete block prepared from quartz eroded sand. The A2.0 B04 grade high-performance autoclaved aerated concrete block is prepared from quartz eroded sand, cement, quick lime, industrial waste phosphogypsum, aluminum paste and water. The dry density of the concrete block is 415kg / m<3>, the cube crushing strength average value is 2.1 MPa, the single unit minimum value is 1.9 MPa, the ratio of splitting tensile is 0.19, the frost quality loss is 3.7%, the frost strength is 1.7 MPa, the heat conductivity coefficient (dry state) is 0.116 W / (m.K), the dry shrinkage value (standard value) is 0.22 mm / m and the percent of pass is greater than 98%. The raw material processing method is reasonable, the formula calculation is scientific, the production process is simple and the production waste can be recycled. The concrete block is a novel energy-saving and environmentally-friendly wall material and is suitable for industrial process.

Owner:HUBEI YITONG CONSTR ENG CO LTD

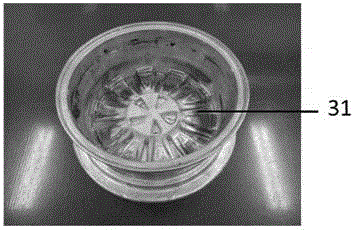

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

Method for reducing pouring temperature of iron-based surface composite material

The invention relates to an iron-based composite material and especially relates to a method for reducing pouring temperature of iron-based surface composite material through heat release of thermit reaction, wherein the principle is as follows: triggering the thermit reaction by heating molten iron, counteracting the cooling effect of a ceramic particle pre-forming block on the molten iron through the heat release part of the thermit reaction, and simultaneously forming an alloy having the ingredients the same as that of a high-chromium iron substrate through the thermit reaction; in order to generate no effect on the distribution of the ceramic reinforcement particles and improve the wearing resistance of the hexagonal prism hole or honeycomb hole part, the reactant of the thermit reaction is processed to a cylindrical shape and is added in the hexagonal prism hole or honeycomb hole of the ceramic particle pre-forming block, the reactant powder is mixed and is pressed to the cylindrical shape so as to conveniently process and apply the cylindrical reactant, and the reactant powder is wrapped by an aluminum foil to prevent the cylinder from being broken and prevent the reactant powder from dropping.

Owner:XINGHUA PRECISION CASTING & FORGING IND RES INST CO LTD

A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand, and making method thereof

ActiveCN104844106AInhibits digestive reactionsResolve fast digestionCeramicwareIndustrial wasteAluminium

The invention provides an A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand. The high-performance A3.5 B05 grade autoclaved aerated concrete block is made by using the quartz weathered sand, cement, quicklime, industrial waste phosphogypsum, aluminum powder paste and water as raw materials. The dry density of the block is 509kg / m<3>, the average cubic compressive strength of the block is 3.6MPa, the single component minimum of the block is 3.2Mpa, the split-to-compression ratio is 0.20, the mass loss after freezing is 2.8%, the strength after freezing is 3.1Mpa, the heat conduction coefficient (dry state) is 0.1251W / (m.K), the drying shrinkage value (standard process) is 0.32mm / m, and the qualified rate is greater than 98%. The method has the advantages of reasonable treatment of raw materials, scientific formula calculation, concise production flow, recycling of production wastes. The block is a novel energy saving and environmental protection wall material, and can be industrially produced.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Vacuum, gravity and precision casting method with metallic mould

A vacuum-gravitational precise casting technology with metallic mould includes such steps as preparing metallic mould, putting it in a cover, sealing the cover, vacuumizing, pouring molten metal while vacuumizing, immediately taking the cast workpiece out and cooling.

Owner:王一诚

Indirect extrusion casting process

The indirect extrusion and casting method is used in producing non-ferrous alloy casting. It is realized through low pressure filling of alloy melt via casting pipes, and extrusion with extruding head to make alloy melt solidify and crystallize under certain pressure to form extruded non-ferrous alloy casting in high yield.

Owner:龙思远

Production technology of air-conditioning compressor crankshaft

ActiveCN102397993AReduce contact areaIncrease the number of placementsFoundry mouldsFoundry coresEngineeringAir conditioning

A production technology of an air-conditioning compressor crankshaft comprises the following steps of: sand mulling; modeling; melting and interrupted front treatment; casting; casting cleaning and product quality inspection. During the modeling design process, the axial direction of a die crank is perpendicular to a parting face and parting of the die crank is carried out at the eccentric part of the crankshaft. After modeling and stripping, crankshaft cavities are formed and are respectively arranged inside two adjacent sand molds. During the casting process by a bottom casting mode, a filter screen is used to filter molten iron. On the basis of meeting technological requirements of crankshaft casting, production efficiency is raised and the purpose of energy saving and emission reduction is achieved.

Owner:上海华新合金有限公司

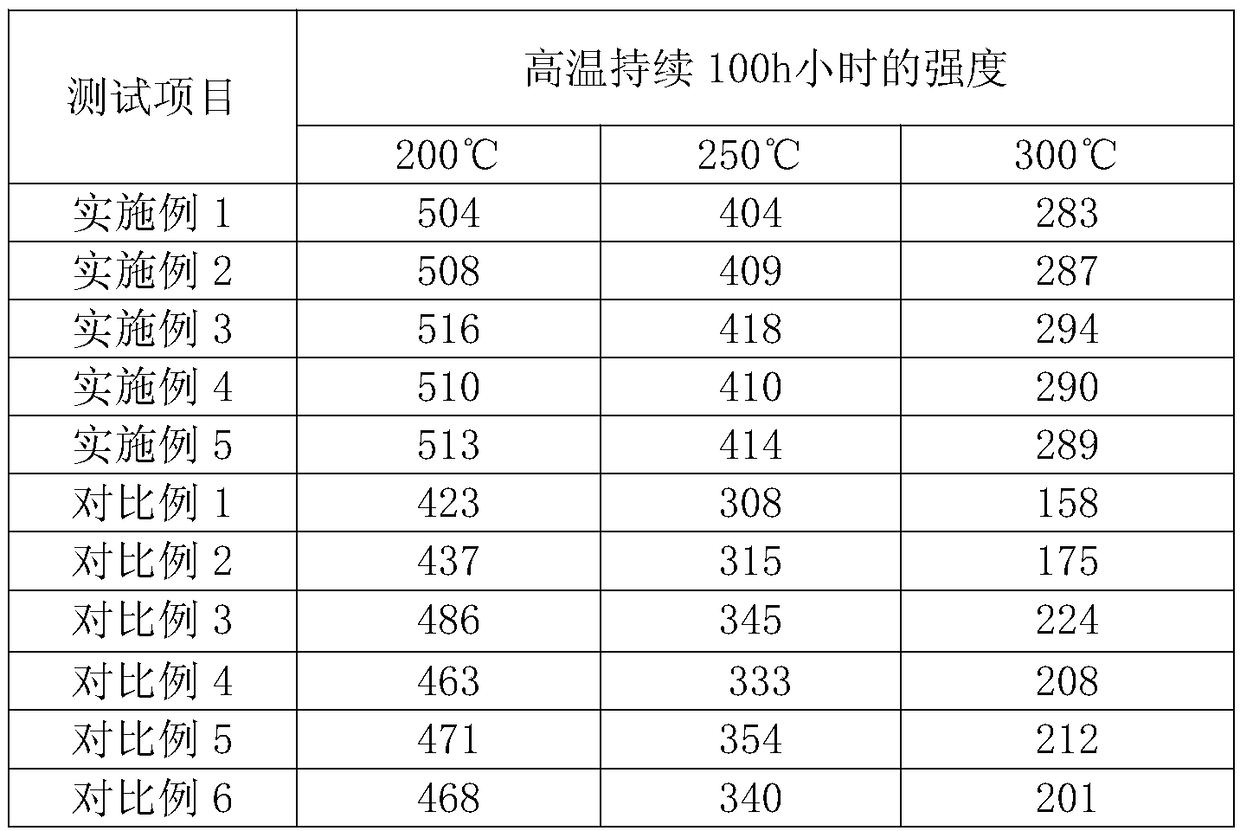

Machining method of a window and door aluminium alloy

The invention discloses a machining method of a window and door aluminium alloy. The window and door aluminium alloy comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn,0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare earth element RE and the balance of Al. The window and door aluminium alloy is prepared by using the steps of melting, slagging-off, heat preservation and standing, online refining, alloying, refining, on-line degassing, casting, homogenizing annealing, extrusion forming, heat treatment, shading, sealing treatment and the like. According to the machining method of the window and door aluminium alloy, by optimizing alloy components, a mixing ratio and a machining process, a problem that the strength and the casting performance of the aluminium alloy contradict each other can be effectively solved; and problems of large hot cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminium alloy are solved.

Owner:阜阳力佳门业有限公司

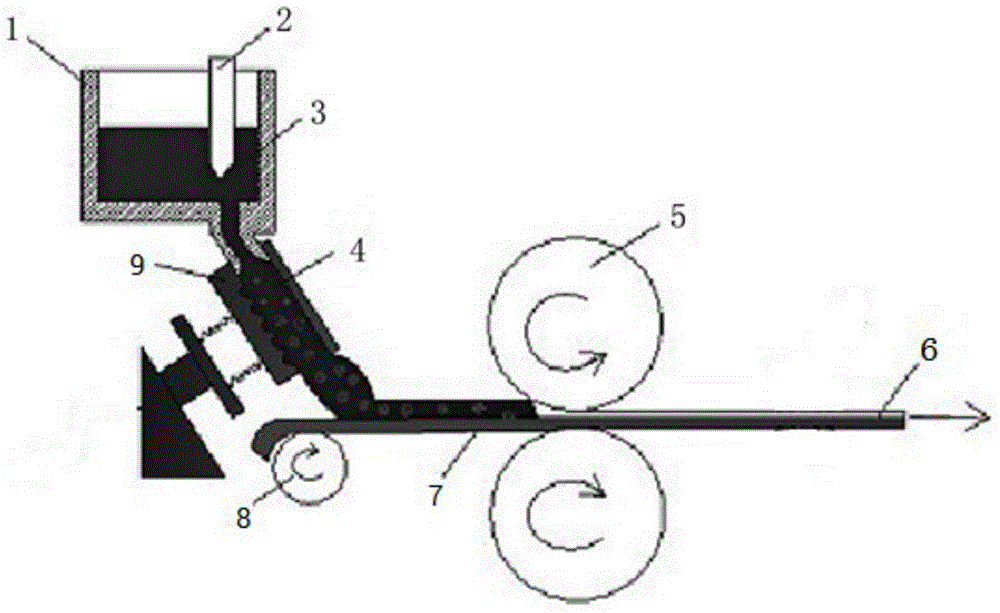

Preparation method of copper-zinc composite plates and strips

ActiveCN103551384AIncrease productivityRealize continuous productionMetal rolling arrangementsBond interfaceSemi solid

The invention discloses a preparation method of copper-zinc composite plates and strips. The method comprises the following steps of 1) removing surface impurities of zinc ingots and then smelting the zinc ingots at 420-480 DEG C to obtain liquid zinc; 2) manufacturing the liquid zinc obtained in the step 1) into semi-solid slurry; 3) pouring the slurry obtained in the step 2) onto preheated copper plates and then performing rolling to obtain the copper-zinc composite plates and strips. According to the preparation method of the copper-zinc composite plates and strips, firstly, the liquid zinc is made into the semi-solid slurry and then metallurgically composited with solid copper under pressure, the bonding interface layer is relatively thin and thinner than 10 mu m, so that the problems of low strength of composite plates and large thickness of the bonding interface layers due to the preparation process of directly compositing the liquid zinc with the copper plates can be solved, the metallurgical bonding quality of the copper-zinc composite plates and strips can be improved significantly, the strength of the copper-zinc composite plates and strips can be effectively improved and continuous production can be achieved.

Owner:HENAN UNIV OF SCI & TECH

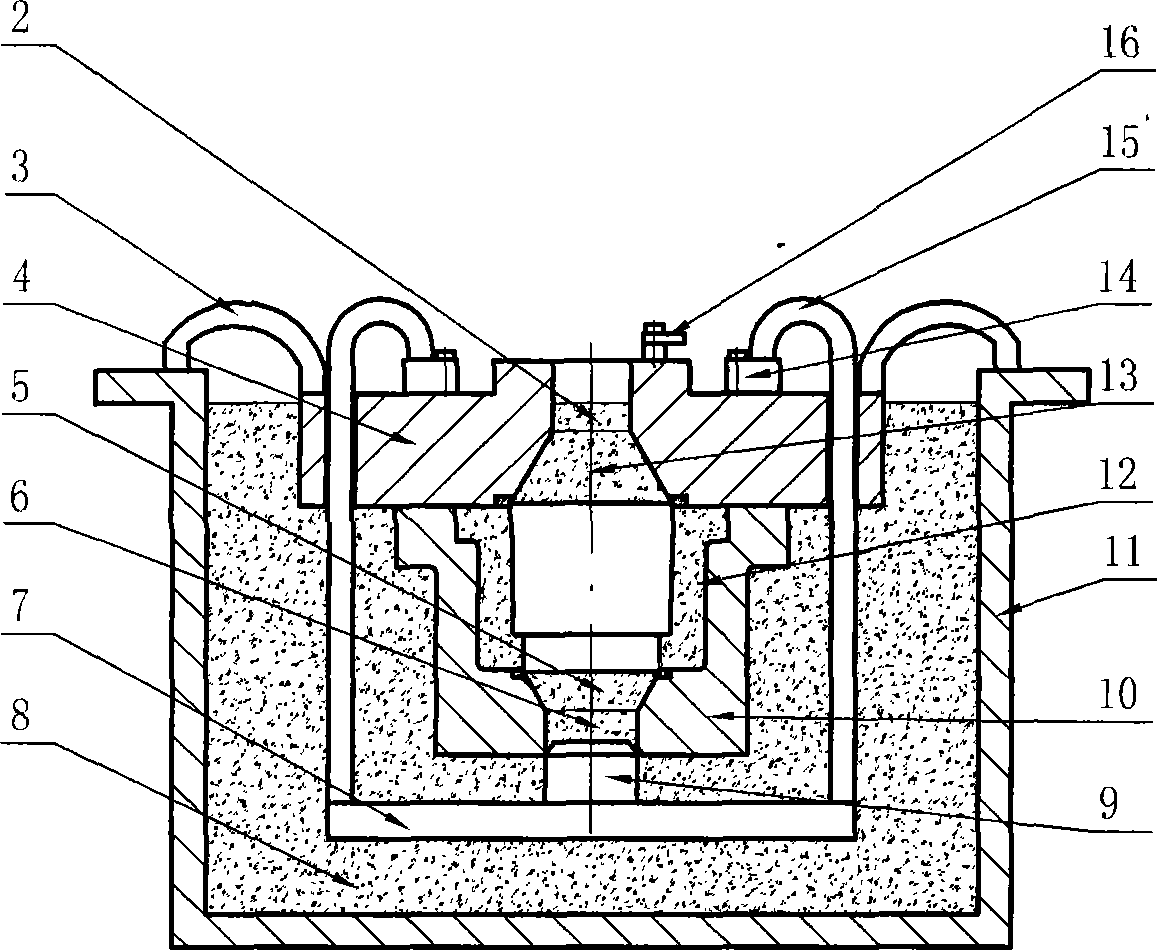

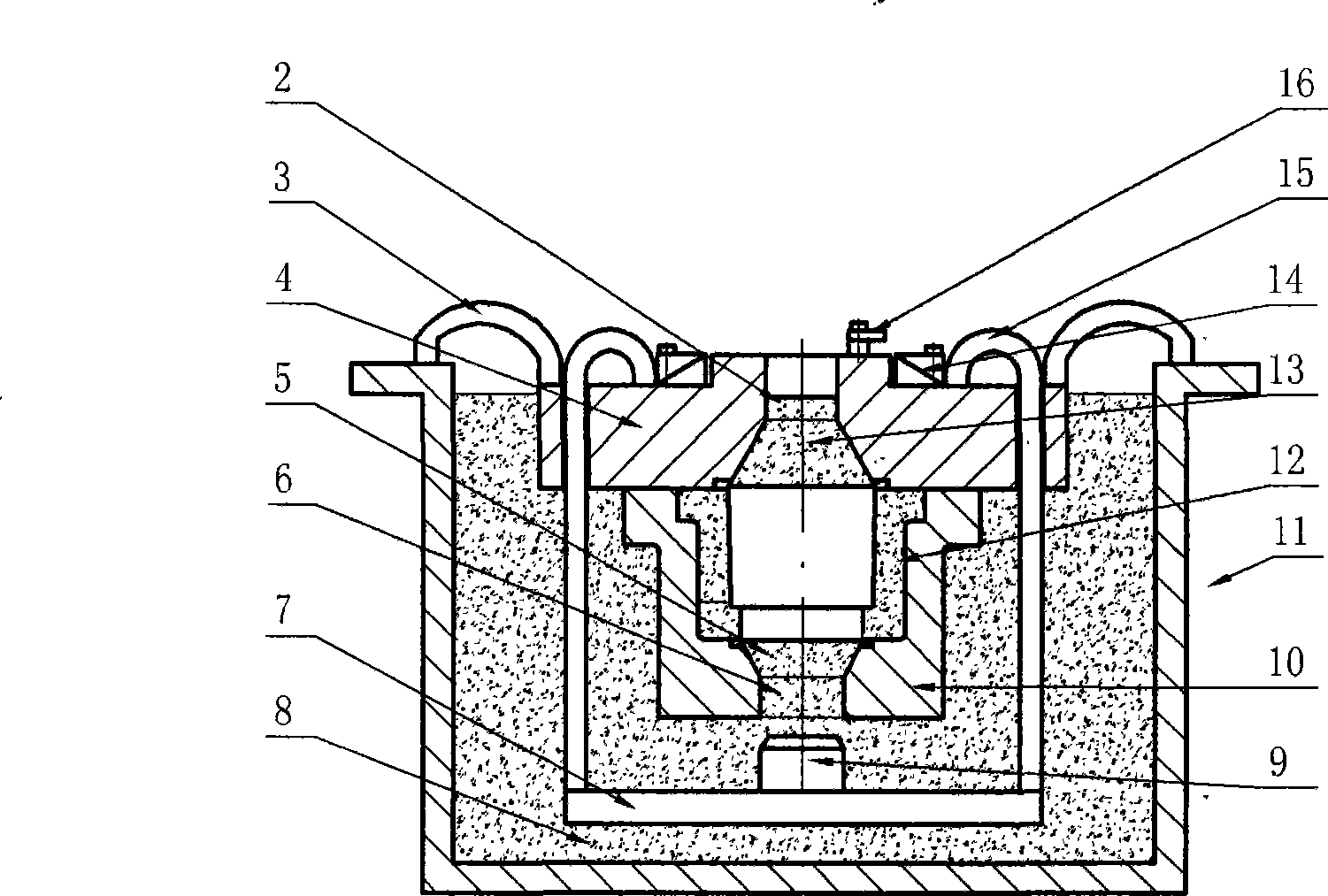

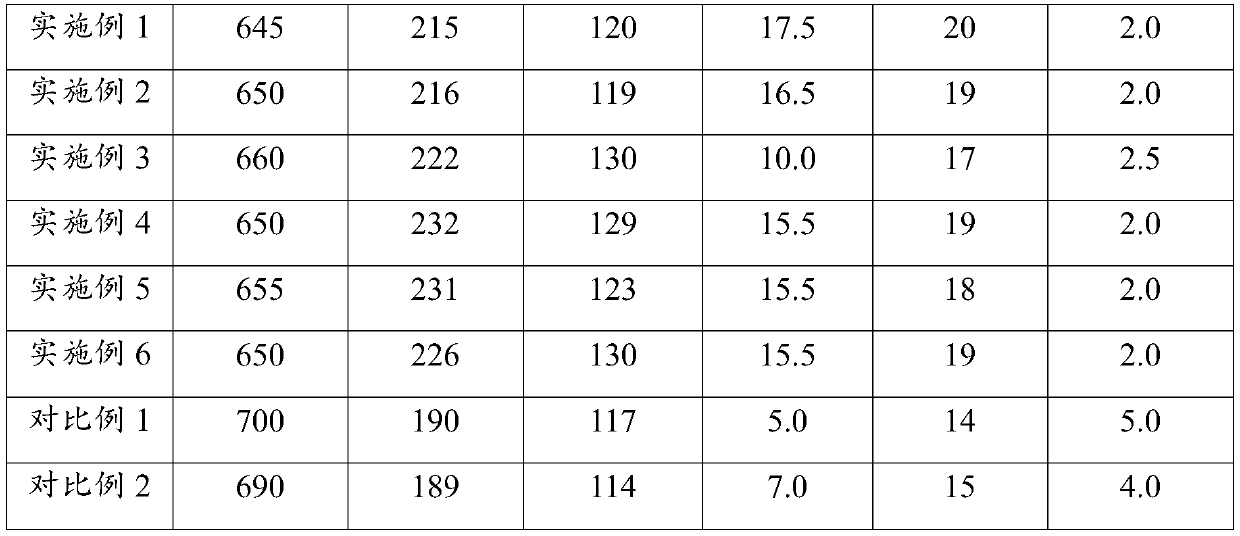

New casting method and casting die

The invention discloses a new casting method, wherein, a casting mold with a pressurizing device is immerged in the inside of molten metal (8) for casting; the pressuring device is driven to carry out pressurization by utilizing lifting force and the gravity of the casting mold or other power. The molten metal in a die cavity (12) is filled, fed and solidified under necessary pressure during the lifting process, and then the casting mold is immerged in water for chilling so as to improve the mechanical property of castings. An upper mold (4) and a lower mold (10) of the casting mold are respectively provided with a plunger hole which is communicated with the die cavity (12) by a feeding cavity; the feeding cavity is slantingly arranged at the thickness changing site of the castings, and a driving mechanism is connected on the plunger to be matched with the plunger hole. The molten metal in the die cavity (12) is pressurized under the action of the driving mechanism, thus causing the castings to be filled, fed and solidified under single directional, double directional and multi directional high-pressure pressurizing. The method is suitable for the casting of various complicated aluminum alloy castings such as the cylinder of an auto engine, wheel hub and extra large thin wall aluminum alloy castings such as cruise missile hull with 0.8m in diameter, 6m in length and 6-8mm in thickness and various common castings.

Owner:曾奇中

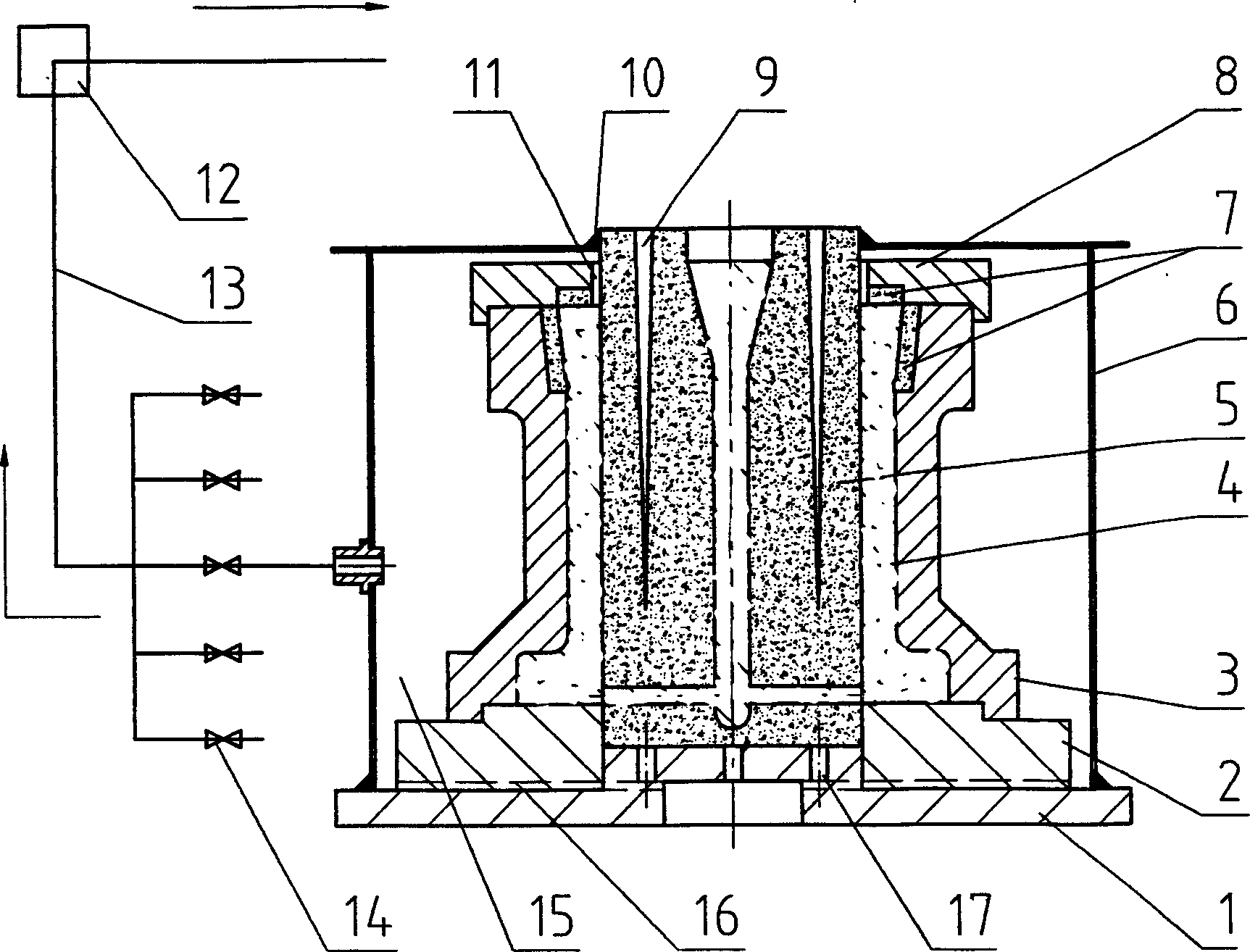

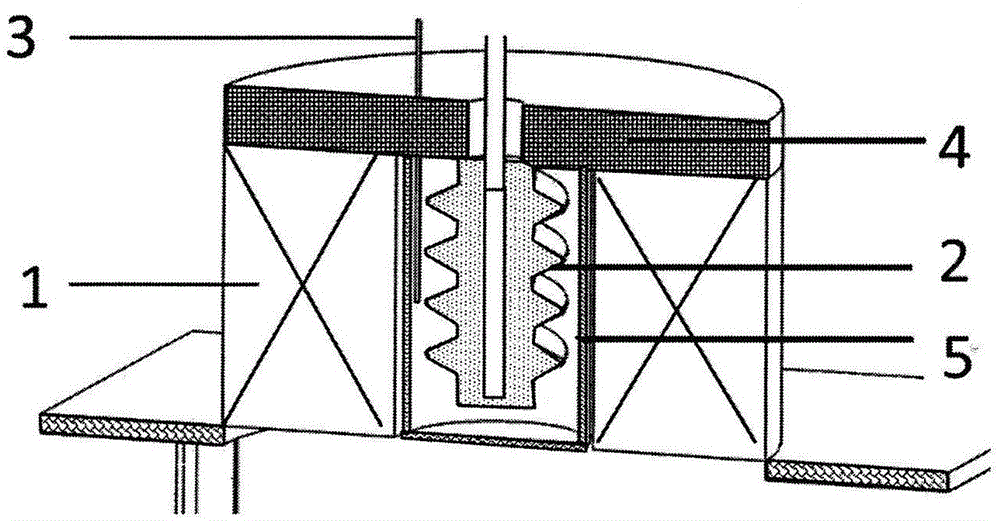

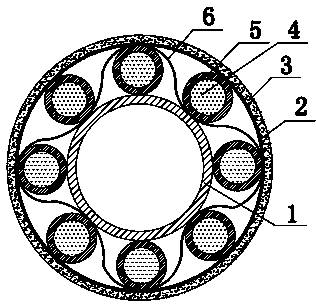

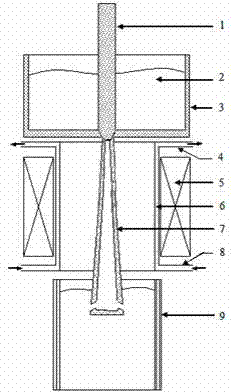

Low-pressure filling method and device using electromagnetic stirring technology

The invention discloses a low-pressure filling method and device using electromagnetic stirring technology. The device includes a crucible furnace and a riser tube. The crucible furnace is provided with a furnace cover, so that the inside of the crucible furnace forms a sealed cavity. The top of the sealed cavity is communicated to the bottom of the cavity to be filled through a riser tube. An electromagnetic stirrer is provided beside the riser tube, and the crucible furnace has a pressurized gas inlet. Pressure is applied to metal melt in the crucible furnace to make the metal melt rise through the riser. Under the filling pressure, the metal melt enters the cavity smoothly until the entire cavity is completely filled. The temperature of the metal melt passing through the riser is 30 to60% of the liquidus temperature of the metal or alloy plus the width of its solidification temperature interval; As the metal melt flows through the riser, the metal melt is electromagnetically stirred. The device disclosed in the invention uses electromagnetic stirring to break up the generated dendrites, new crystal nuclei are added, the grain structure is refined, the pouring temperature is lowered, the mechanical properties of the casting can be improved, air intake and shrinkage of the casting can be reduced, and the casting quality and metal utilization rate can be improved.

Owner:SUZHOU MINGZHI TECH

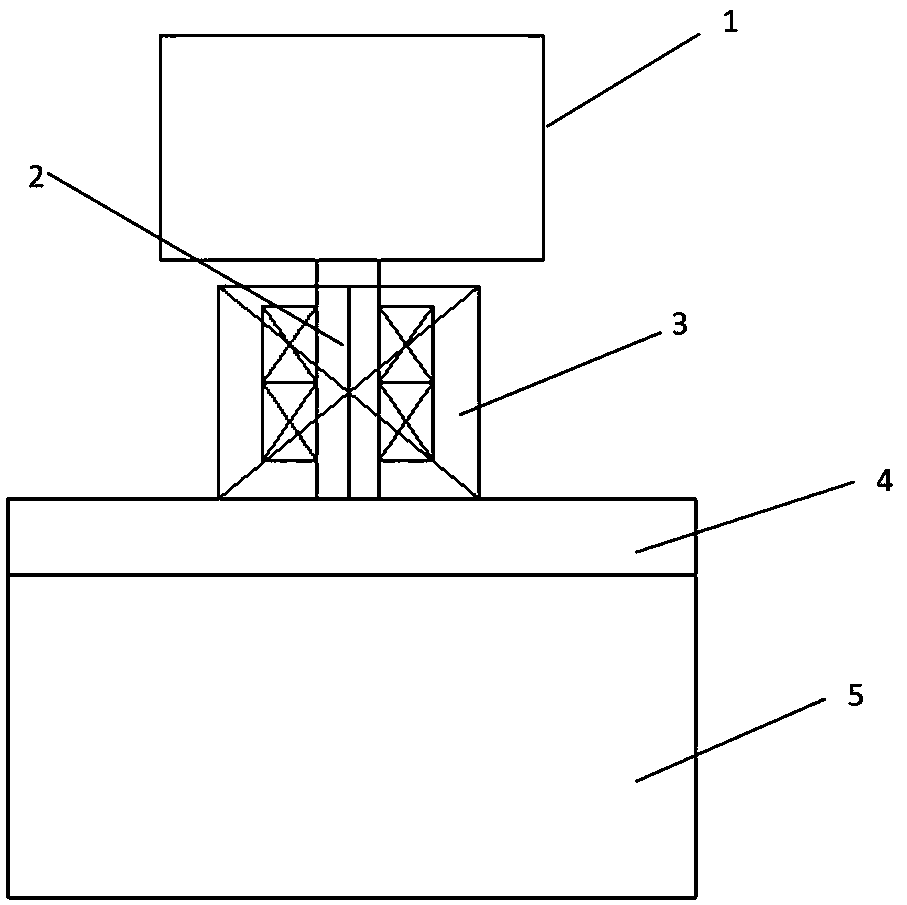

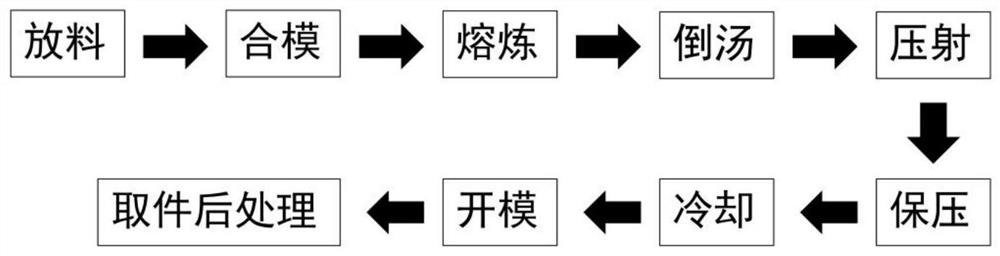

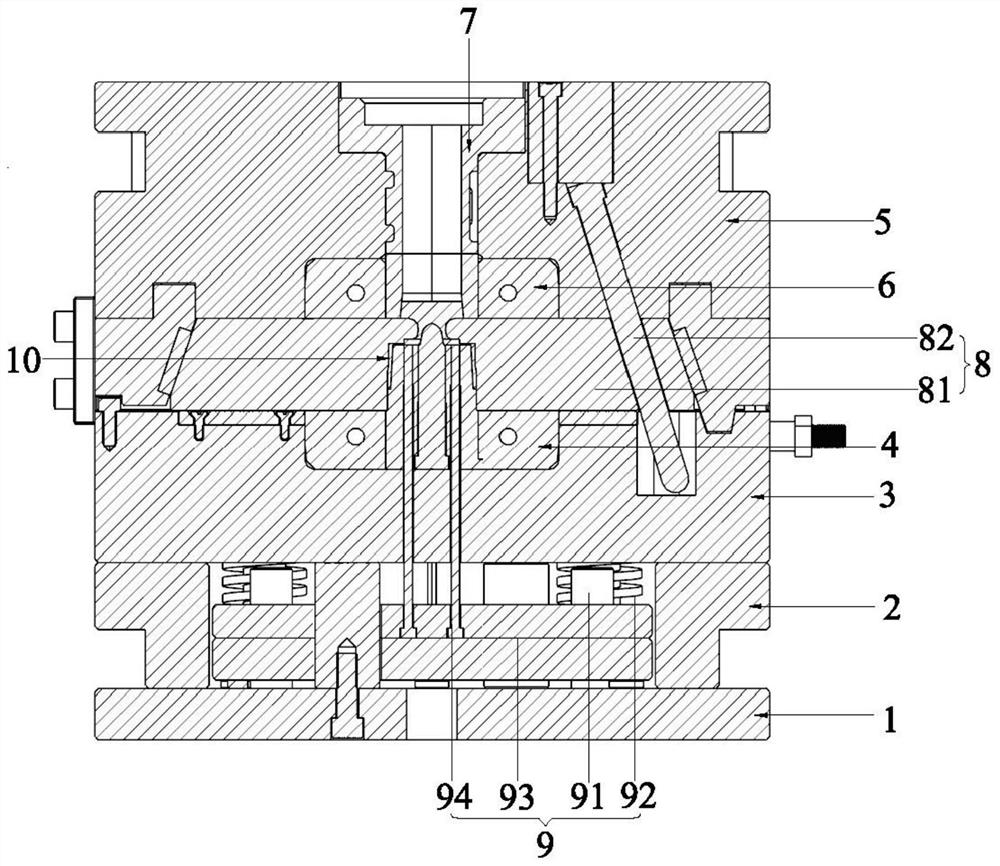

Vacuum die-casting die and method for amorphous alloy flexible gear of harmonic reducer

The invention discloses a vacuum die-casting die and method for an amorphous alloy flexible gear of a harmonic reducer. The vacuum die-casting die comprises a vacuum box, a bottom plate, square iron,a male die plate, a male die core, a female die plate, a female die core, a sprue bush, a core-pulling assembly and an ejection mechanism, wherein the bottom plate, the square iron, the male die plate, the male die core, the female die plate, the female die core, the sprue bush, the core-pulling assembly and the ejection mechanism are arranged in the vacuum box body. The vacuum die-casting methodis simple in step and easy to achieve; an amorphous alloy material of a Zr-based system is reasonably selected for die casting, fluidity is good, the pouring temperature is low, and the forming capacity is high; and the whole die is placed in a vacuum environment in a matched manner, and it is effectively guaranteed that the amorphous alloy material cannot be easily oxidized or crystallized in thedie casting process. The vacuum die-casting die is reasonable in structure, the manufactured flexible gear has better surface smoothness and dimensional precision, only a small number of post-processing procedures are needed in the subsequent process, the production period is greatly shortened, the machining cost is reduced, in addition, the yield strength and fatigue strength are higher, and theservice life is long.

Owner:SONGSHAN LAKE MATERIALS LAB +1

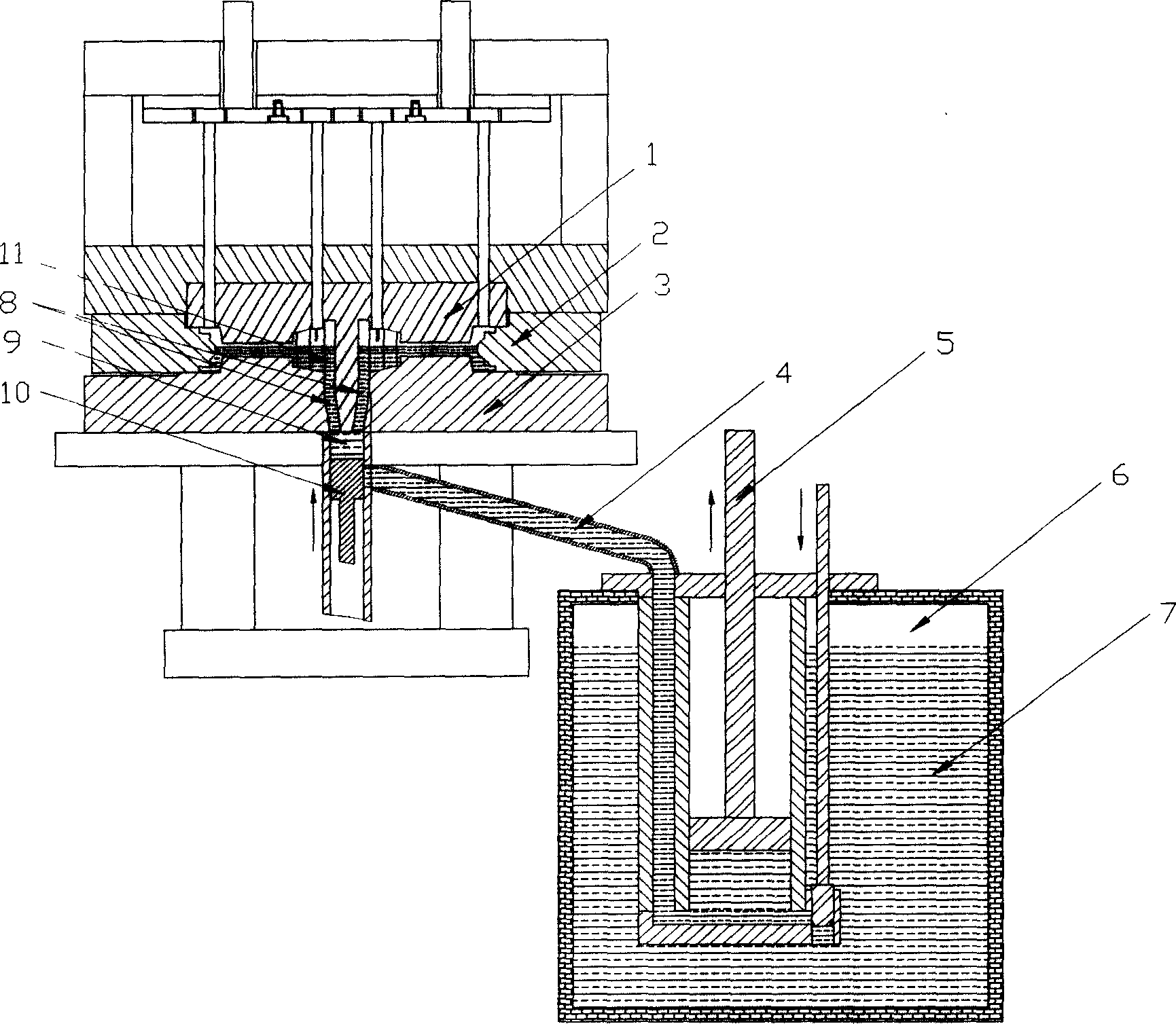

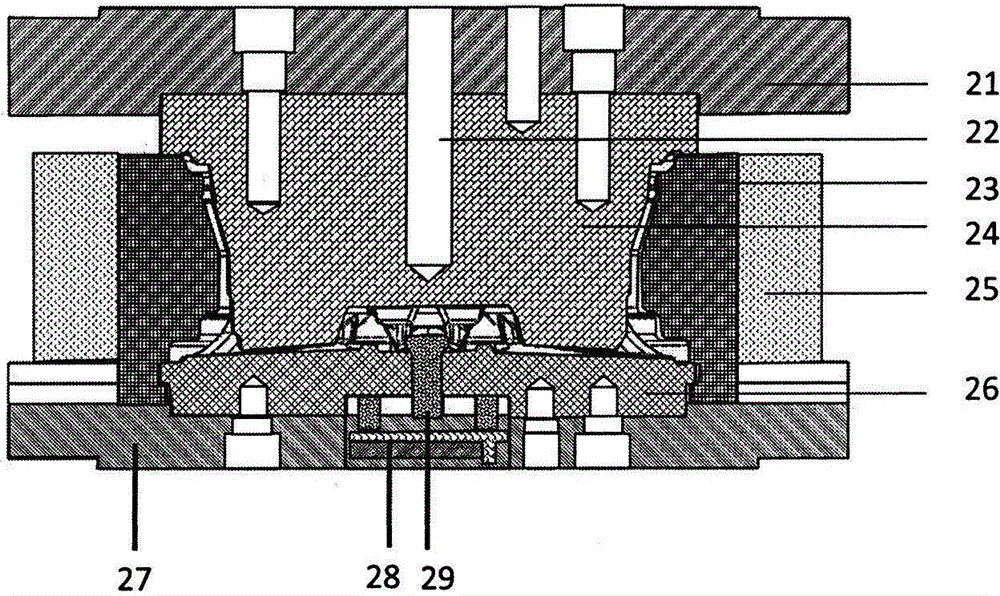

Method and device for improving quality of squeezing and casting piston casting

The invention relates to a method and device for improving quality of a squeezing and casting piston casting and belongs to the technical field of castings. Based on the situation that when the connection position between a material handle and the casting and the outer surface of the casting forms an divergence angle, the state of molten metal can be steadier in the mold filling process, and turbulent flow is prevented; a material handle neck is shortened, cutting of a shrinkage supplement channel in a piston in the solidification process is delayed, the molten metal in an expansion opening can be used for shrinkage supplement, and the shrinkage porosity and shrinkage cavity rate is lowered; and a piston mold is preheated, the requirement for the mold filling temperature is lowered, and a molten pool in the top of the piston is downwards moved ad convenient to cut, machine and remove.

Owner:JIANGSU UNIV

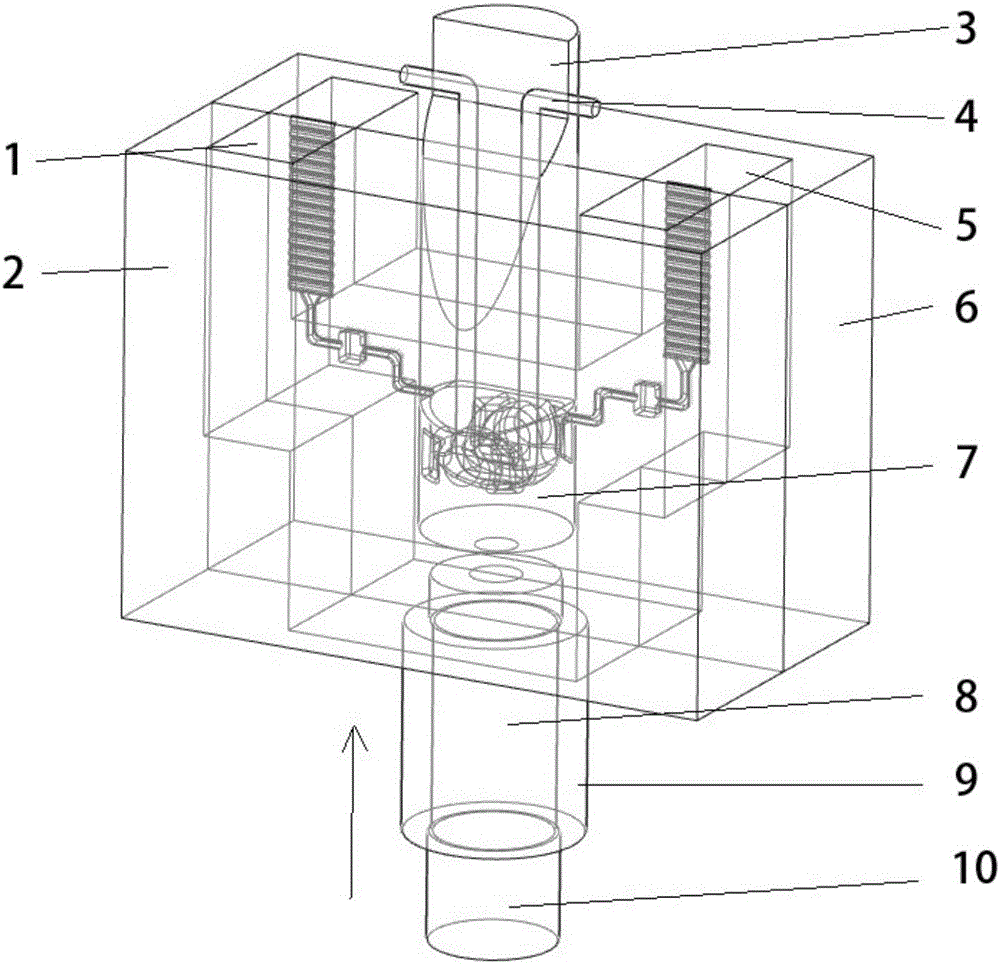

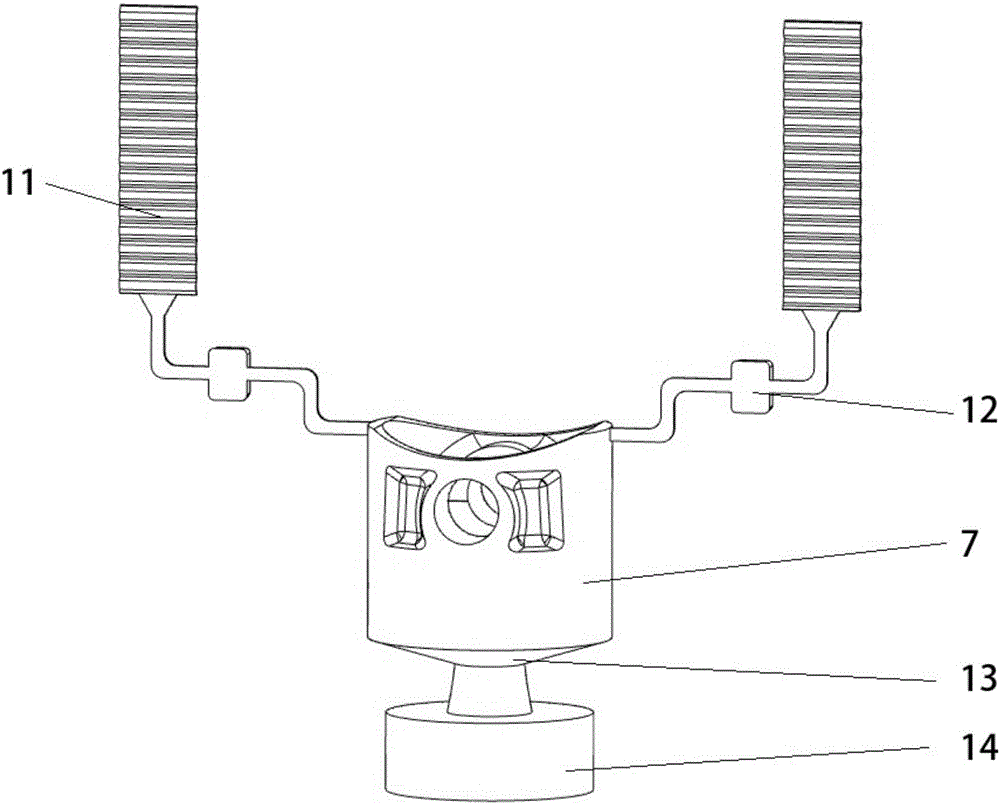

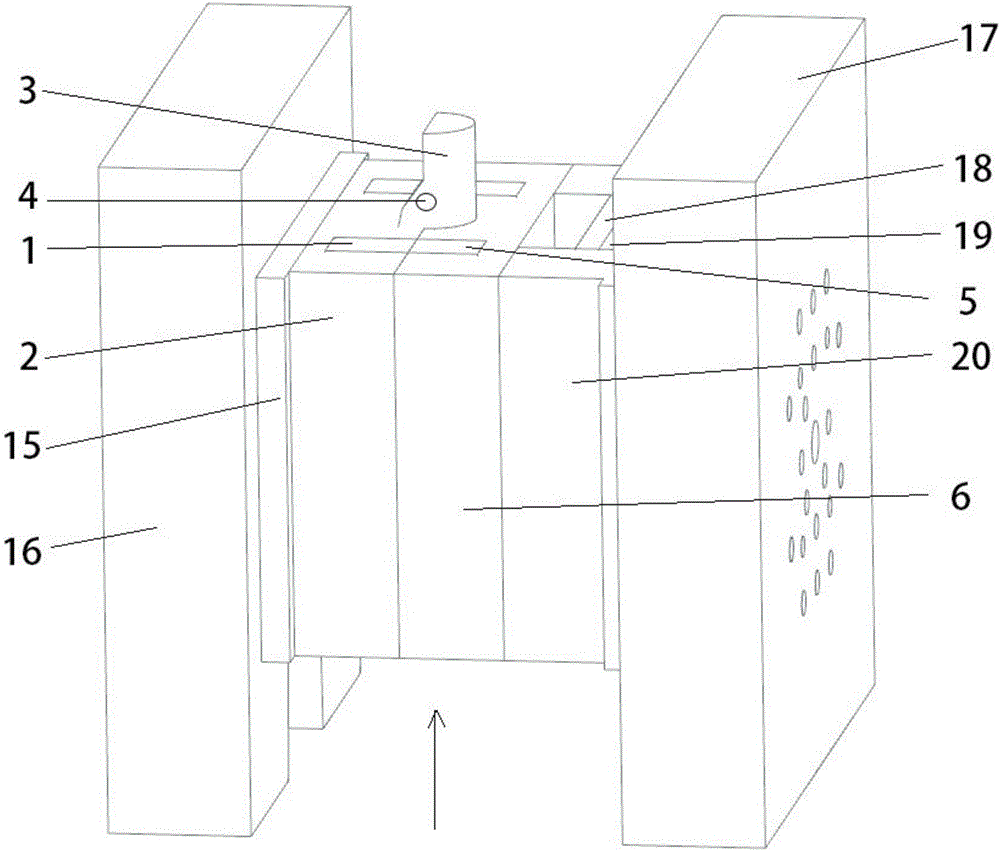

Forming device and method for preparing high-structural strength aluminum alloy hub

ActiveCN105798261ASmall and uniform tissueImprove structural strengthTemperature controlUltimate tensile strength

The invention discloses a forming device and a method for preparing a high-structural strength aluminum alloy hub. The forming device consists of an alloy smelting device, a quantitative pouring cup, a graphite crucible, an electromagnetic stirring melt treatment device, a rheologic extrusion casting forming mold and an extrusion casting machine, wherein the quantitative pouring cup, the graphite crucible, the alloy smelting device, the electromagnetic stirring melt treatment device and the extrusion casting machine are known equipment; the rheologic extrusion casting forming mold includes an upper template and a lower template for connecting with the extrusion casting machine to form an upper mold core, a lower mold core and a side mold of a casting cavity of a hub to be cast; a temperature control device is arranged in the center position of the upper mold core; a side mold locking device is arranged on the outer side of the side mold; and an ejector rod and an ejector rod support plate are arranged on the lower mold core. The aluminum alloy hub prepared by the device and the method is uniform and fine in structure and high in structural strength; the structural strength is near the strength of forged hub; and meanwhile, the nearly final formation of the aluminum alloy hub can be realized, and the utilization rate and the complex shape of low-pressure casting materials are realized.

Owner:有研金属复材技术有限公司

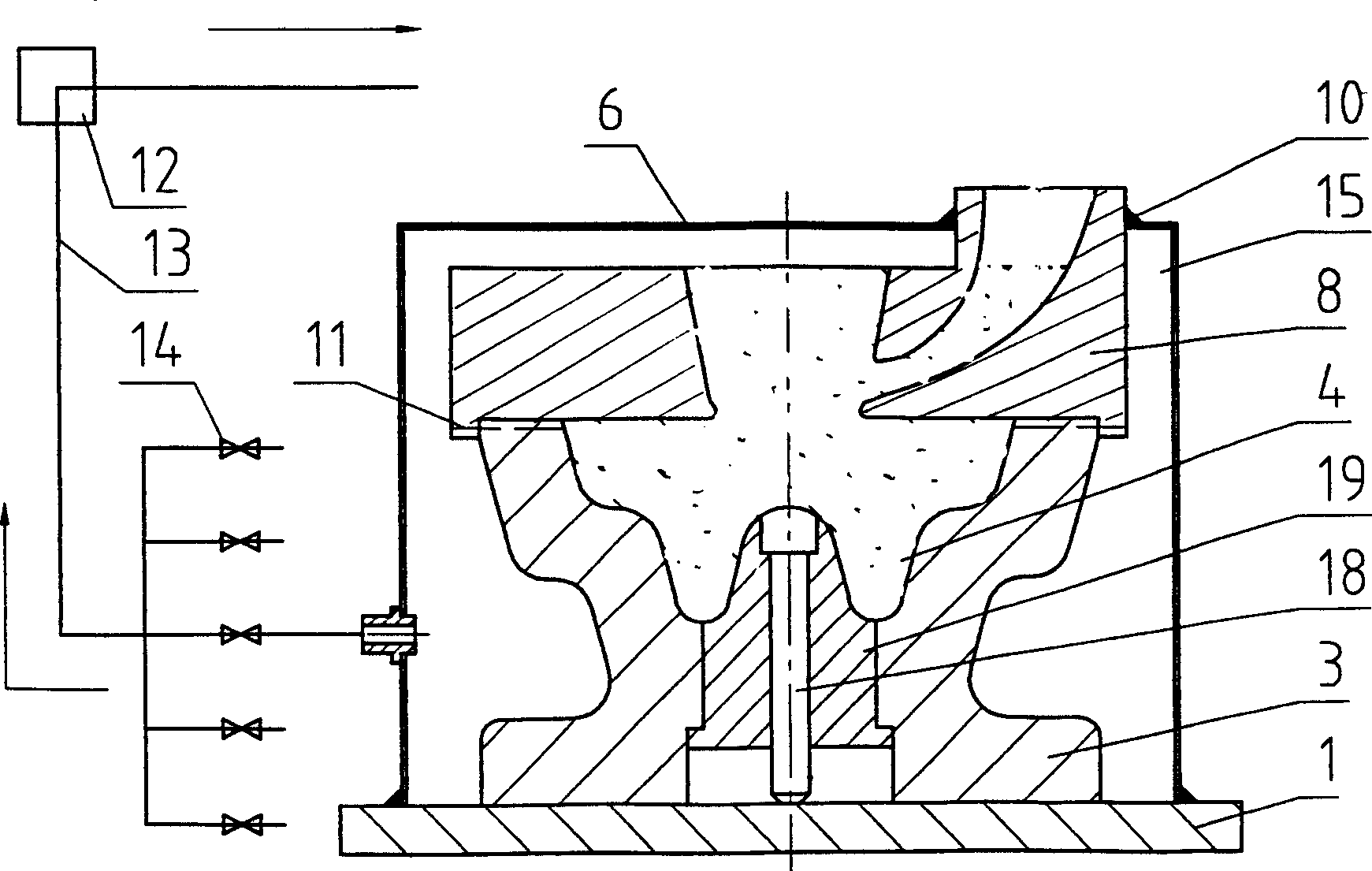

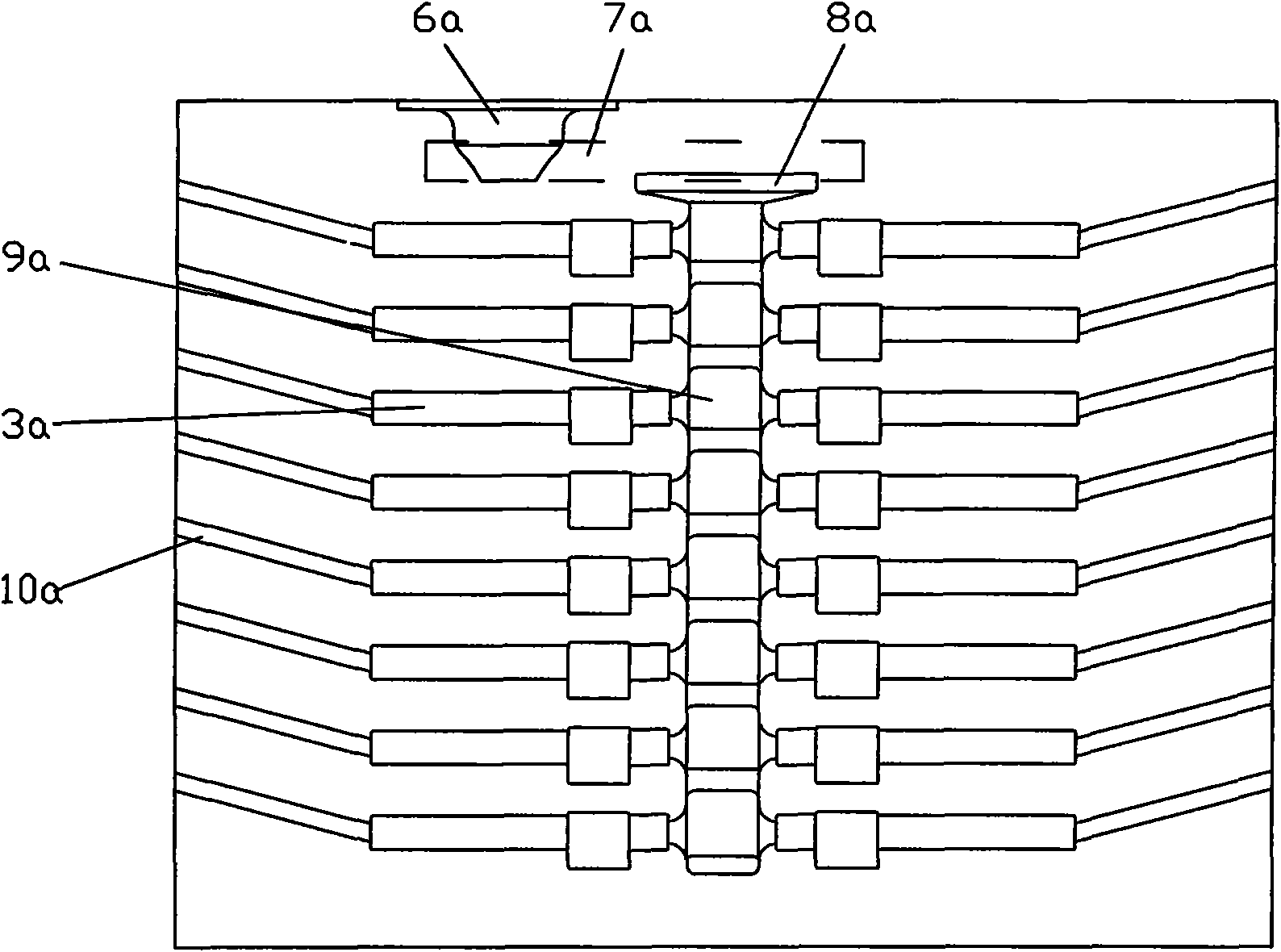

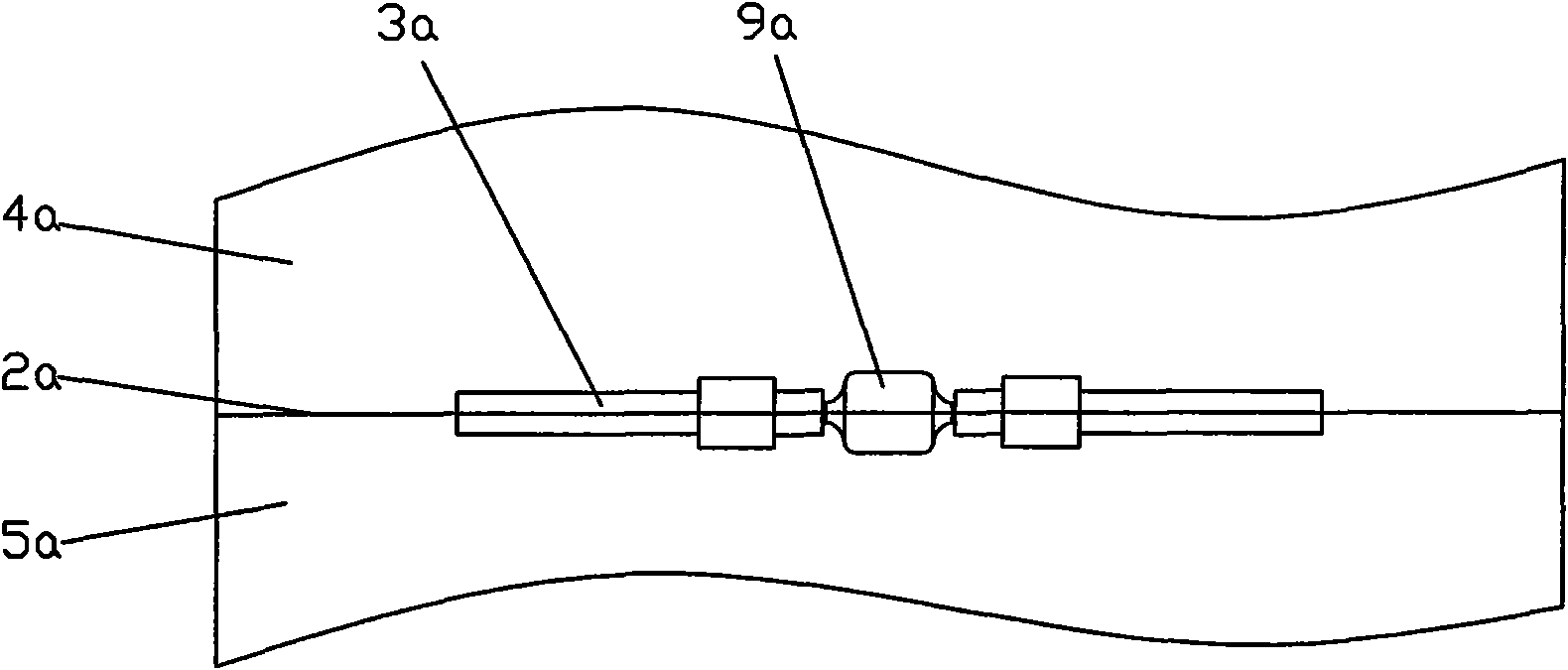

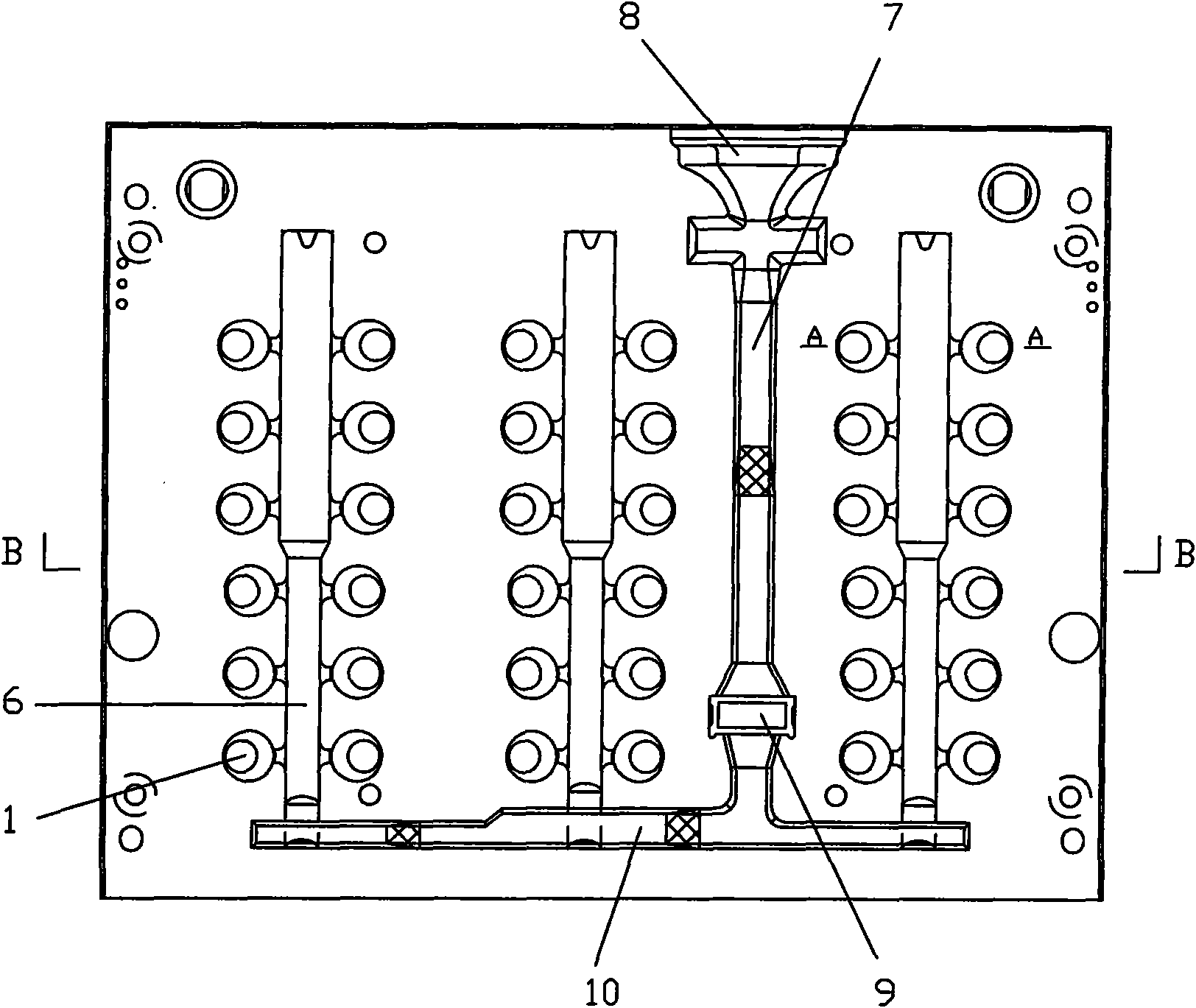

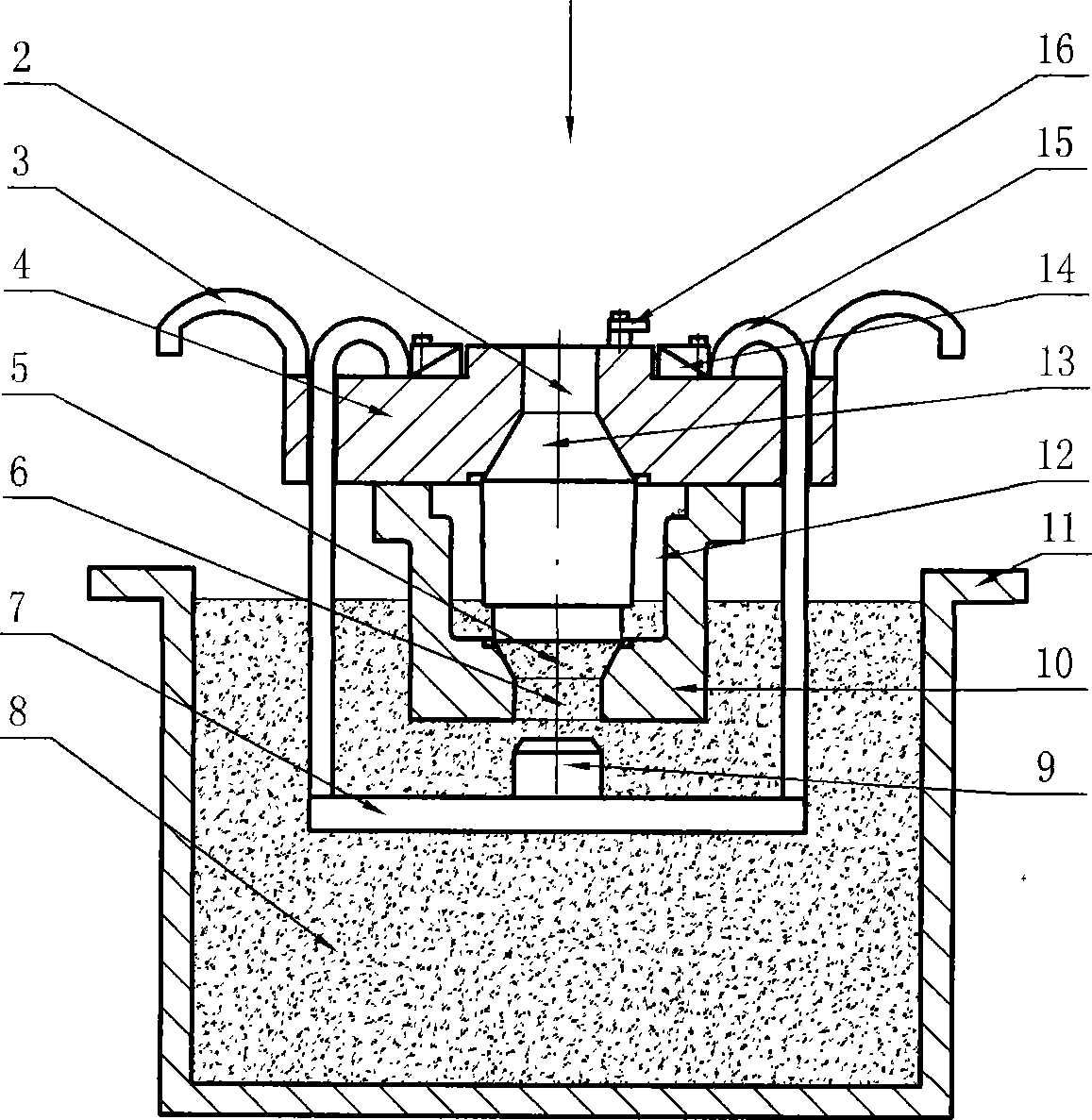

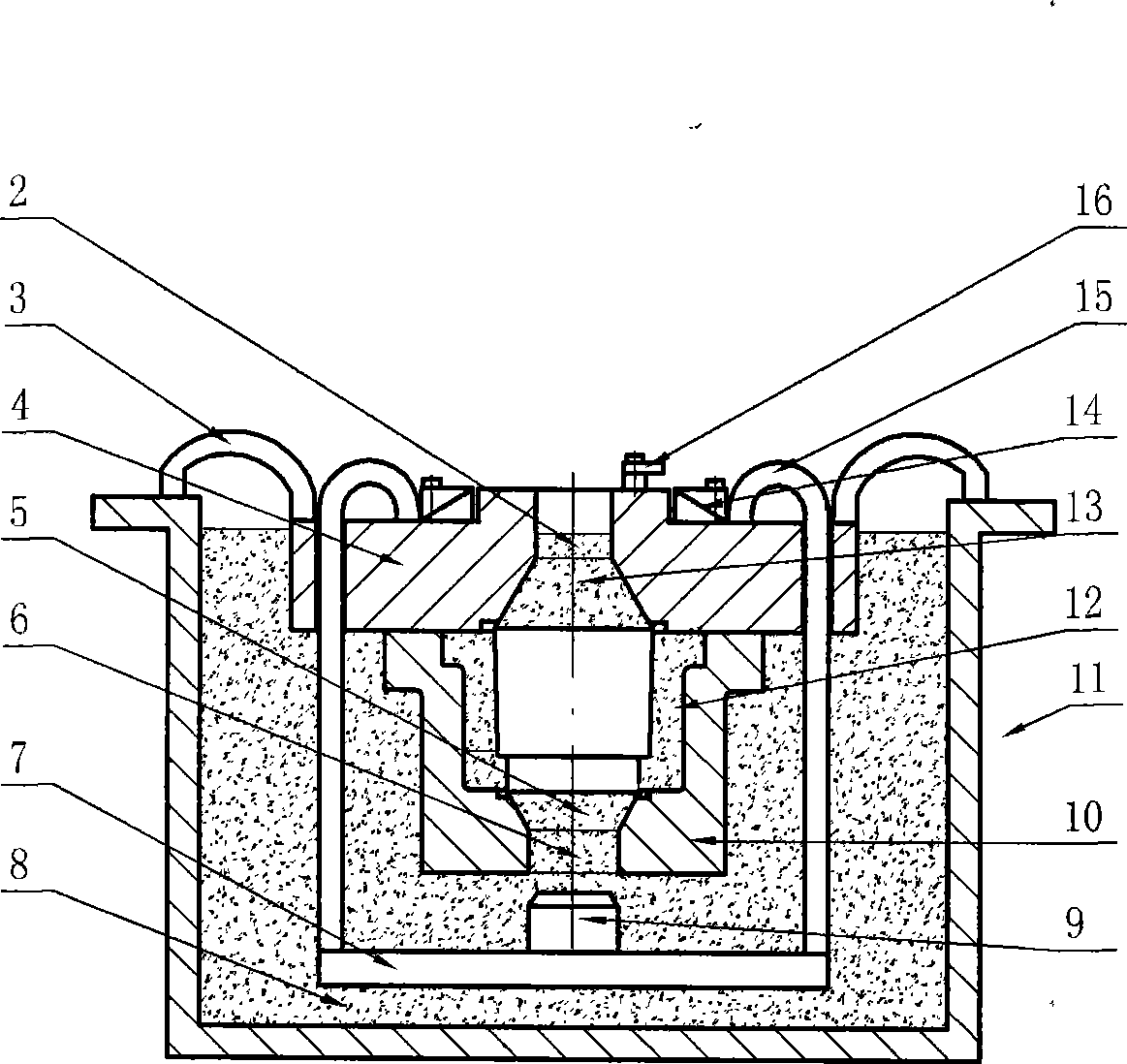

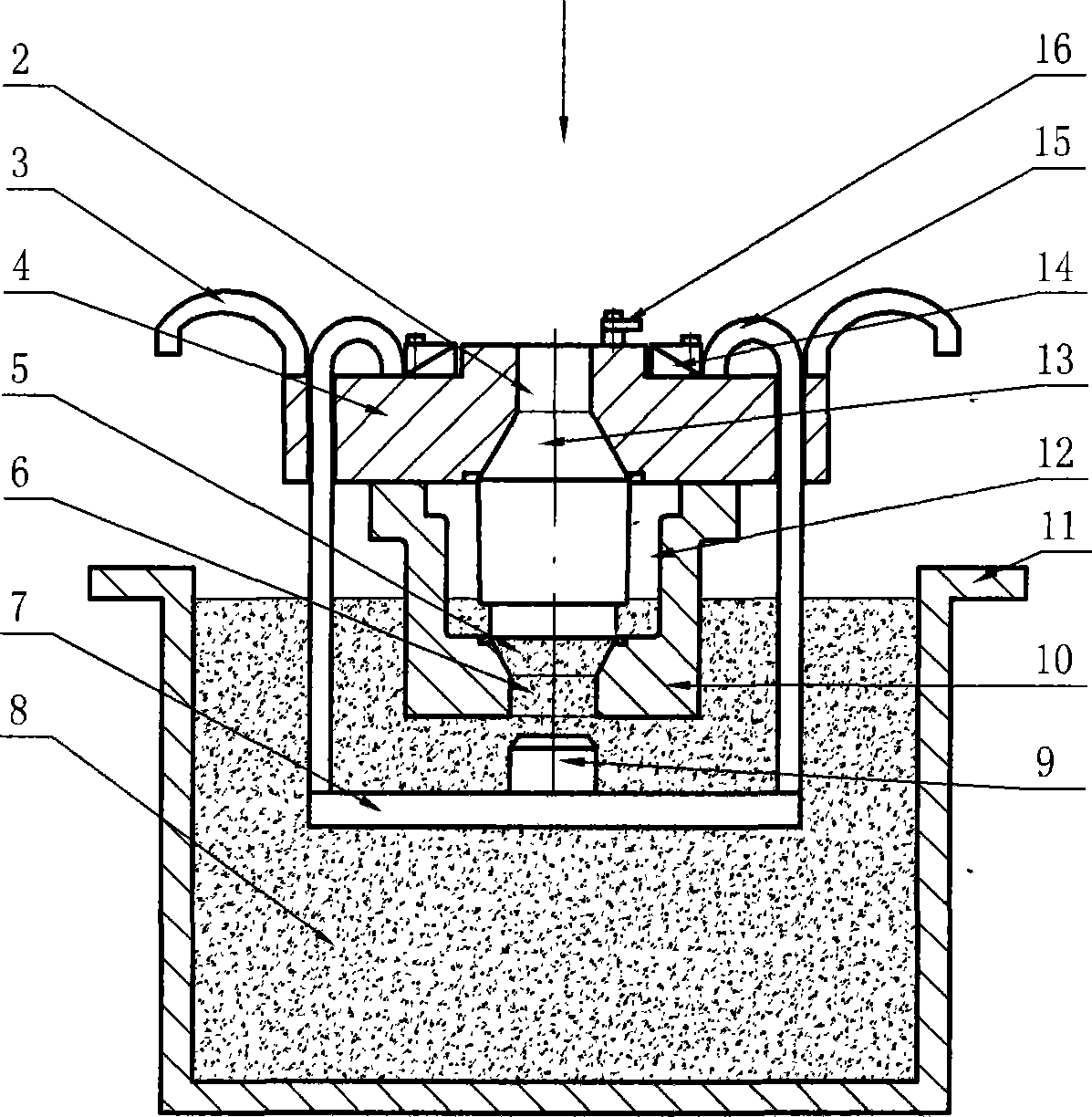

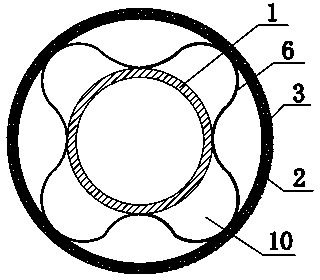

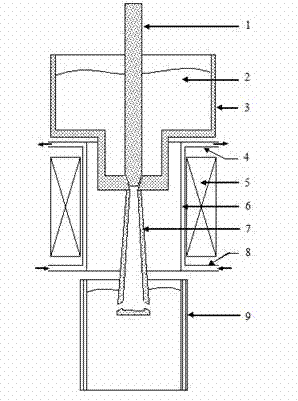

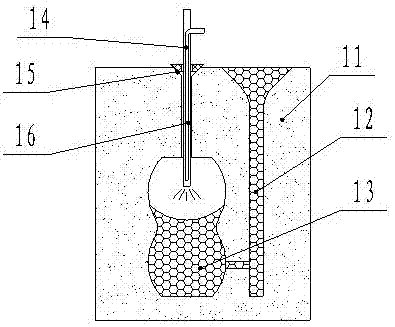

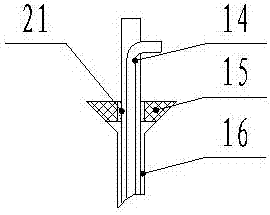

Novel casting method and mould

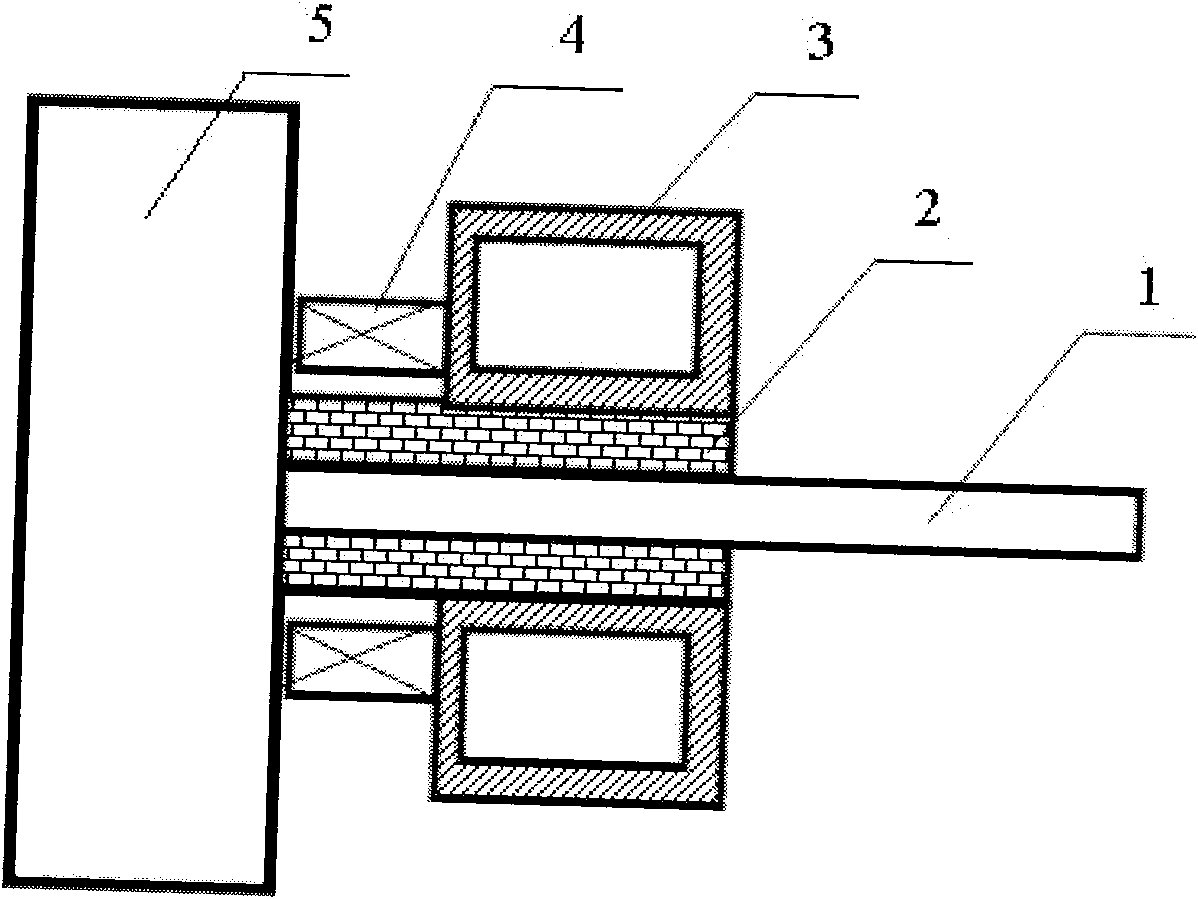

InactiveCN101367126AMaster the pouring situationLower pouring temperatureMechanical propertyMolten metal

The invention discloses a novel casting method and a casting mould thereof. The method comprises the following steps: the casting mould is immersed in molten metal(8) for casting, an upper pressure device and a lower pressure device are driven to be pressurized by utilizing the lifting force and the gravity of the casting mould, the molten metal is subjected to cavity fill, compensation shrinkage, solidification and crystallization in a mould cavity(12) at the needed pressure, and the casting mould is immersed in water for chilling, thereby improving the mechanical property of a cast. The mould is characterized in that an upper mould(4) is provided with the upper pressure device, a lower mould(10) is provided with the lower pressure device, an upper and a lower pressure plugs(1 and 9) pressurize the molten metal in the mould cavity(12) from the upper part and the lower part of the casting mould respectively, and an upper and a lower compensation shrinkage cavities(5 and 13) replenish the molten metal to the cast for eliminating shrinkage cavity and dispersed shrinkage phenomena. The novel casting method and the casting mould thereof can be used to cast various complicated thin wall aluminum alloy casts such as a cylinder cover of an engine and wheel hub of a vehicle and large-sized thin wall aluminum alloy casts such as a cabin body of a large-sized cruise missile, quickly cast a cast aluminum rotor of a motor with high quality and replace the prior casting method in large scale.

Owner:曾奇中

Casting, pouring method, application of casting method, casting method of automobile wheel, and automobile wheel

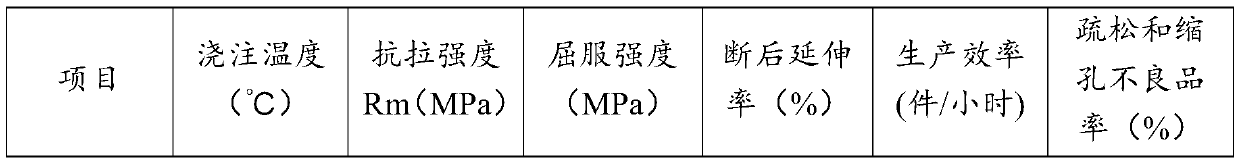

The invention belongs to the technical field of casting, and relates to a casting, a pouring method, application of the casting method, a casting method of an automobile wheel and the automobile wheel. The pouring method is characterized in that the pouring temperature is 645-660 DEG C, the lift pressure is 0.018-0.022 MPa, the lift time is 4-8 seconds, the mold-filling pressure is 0.023-0.027 MPa, the mold-filling time is 10-20 seconds, the boost pressure is 0.08-0.12 MPa, and the pressurization time is 3-8 seconds; after pressurization is completed, the pressure is kept under 0.08-0.12 MPa for 70-130 seconds; and a die is opened after pressure relief cooling. According to the casting, the casting method, the application, the casting method of the automobile wheel and the automobile wheel, the mechanical performance of the casting is improved, the defect of many pinholes on the casting is overcome, the production efficiency is greatly improved, and the casting period is shortened.

Owner:重庆市超群工业股份有限公司

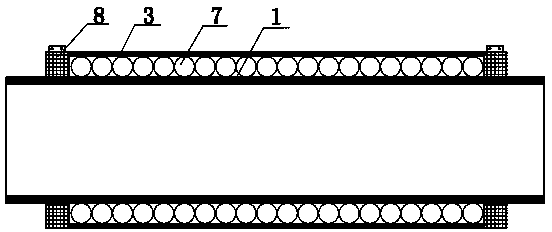

High-temperature concrete pumping pipeline cooling device and cooling method thereof

ActiveCN104179353AIncrease temperatureGuaranteed mold entry temperatureBuilding material handlingMetallurgyConcrete pump

The invention relates to a high-temperature concrete pumping pipeline cooling device and a cooling method thereof. The cooling device is characterized in that the cooling device comprises steel ice, a sleeve and a thermal insulating layer, the steel ice integrally comprises refrigerating fluid and a stainless steel shell, the refrigerating fluid comprises edible alcohol and purified water, the stainless steel shell is set into a ball or cylinder, a hollow structure is arranged inside the stainless steel shell and filled with the refrigerating fluid, the sleeve comprises an inner pipe, an outer pipe and an arc slab, the arc slab is welded between the inner pipe and the outer pipe to form spaced arc grooves for placing the steel ice, the steel ice is slidably arranged in the arc grooves, and the thermal insulating layer wraps the outside of the sleeve. The cooling device is connected with a pumping pipeline, heat generated by friction between concrete and the pipeline and heat generated by hydration of the concrete are evenly absorbed, and the temperature of the pumping pipeline and the temperature of the concrete are reduced by the aid of the steel ice, so that the temperature of casting concrete is kept within a specified range.

Owner:MINGYE CONSTR GRP

Method for preparing A3.5B05-grade autoclaved aerated concrete block by quartz weathered sand and application thereof to wall

ActiveCN105693178AAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareToxic industrial wasteWaste material

The invention provides a method for preparing an A3.5B05-grade autoclaved aerated concrete block by quartz weathered sand and application thereof to a wall. The A3.5B05-grade high-performance autoclaved aerated concrete block is prepared by using the quartz weathered sand, cement, quick lime, industrial waste ardealite, aluminum powder paste and water as raw materials. The block has a dry density of 509kg / m<3>, a cube crushing strength average value of 3.6MPa, a single group minimum value of 3.2Mpa, a splitting pressure ratio of 0.20, post freezing mass loss of 2.8%, post freezing strength of 3.1Mpa, a heat conductivity coefficient (dry state) of 0.1251W / (m K), a drying shrinkage value (standardized method) of 0.32mm / m, and a qualified rate of over 98%. According to the method provided by the invention, a raw material treatment method is reasonable, a formula is scientific in calculation, the production flow is simple, and production waste can be recycled. According to the invention, the block is applied to a thermal-insulating wall.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Production method for copper-aluminum high-temperature compounding

PendingCN113026070ASolving difficult-to-prepare problemsSolve the strength problemMetal rolling arrangementsSemi solidSlurry

The invention discloses a production method for copper-aluminum high-temperature compounding. The production method comprises the following steps of (1) surface treatment of a copper strip; (2), electroplating and texturing treatment; (3) preparation of aluminum semi-solid slurry; (4) heat treatment and annealing; and (5) cold rolling. The method solves the problem that the copper-aluminum composite material is difficult to prepare due to the fact that the proportion of the copper layer obtained through an existing preparation method for copper-aluminum compounding is low, and also solves the problem that the peeling strength between the copper layer and aluminum layer of existing copper-aluminum compounding is low.

Owner:刘飞

Method for realizing low superheat pouring of continuous casting process by using high-intensity magnetic field, and device for method

The invention discloses a method for realizing low superheat pouring of a continuous casting process by using a high-intensity magnetic field, and a device for the method. According to the method, a strong magnet produces the steady high-intensity magnetic field in metal melt, so the metal melt can still keep liquid state at the temperature of less than liquidus temperature when flowing through a water gap; the metal melt is in a supercooled state or a superheated state and is not solidified when flowing through the water gap, and the metal melt flowing out of an outlet at the bottom of the water gap is poured into a crystallizer in a supercooled or superheated mode. The invention also discloses a magnetic field intervention device for the low superheat pouring of metal liquid. The device comprises a superheat control system and a supercooling degree intervention system. According to the method and the device, the nucleation of the metal melt can be obviously inhibited by the steady high-intensity magnetic field, the supercooling degree of the melt can be improved, a large amount of isometric crystal textures can be obtained, the problem that the water gap is blocked easily in the low superheat pouring process can be avoided, the quality of casting blank can be improved obviously, equipment and the process are simple, and large-scale industrial production and application can be realized conveniently.

Owner:SHANGHAI UNIV

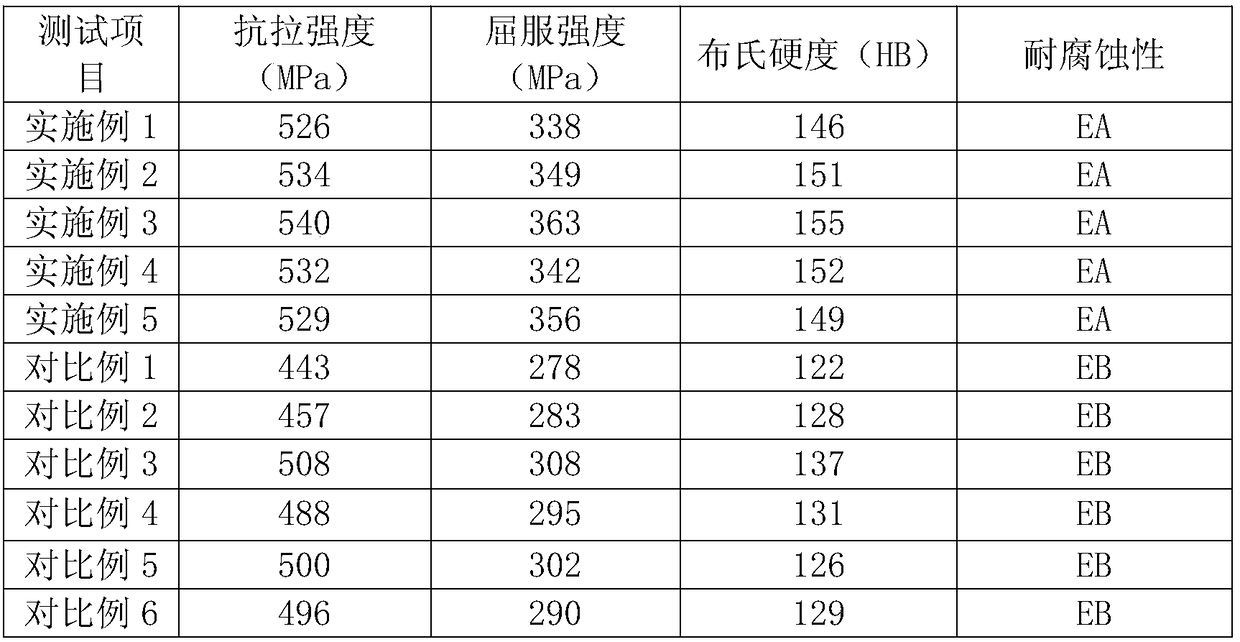

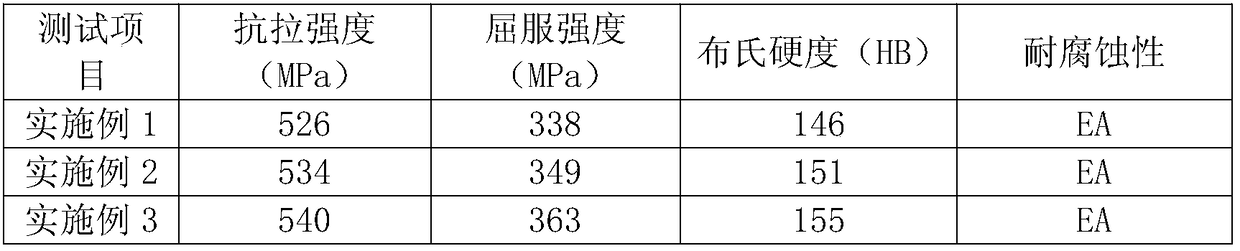

Aluminum alloy for high-strength corrosion-resistant doors and windows and preparation method thereof

InactiveCN109161746AImprove toughnessAccelerated corrosionSurface reaction electrolytic coatingRare-earth elementUltimate tensile strength

The invention discloses an aluminum alloy for high-strength corrosion-resistant doors and windows, which comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn, 0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare-earth element Re, and the balance of Al. The aluminum alloy is prepared by the steps of melting, slag-off, heat preservation, standing, on-line refining, proportioning, refining, on-line degassing, casting, uniform annealing, extrusion molding, heat treatment, coloring and pore sealing. By optimizing the composition, proportion and processing technology of the alloy, the contradiction between the strength and the casting performance of the aluminum alloy can be effectively solved, and the problems of large thermal cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminum alloy are solved.

Owner:阜阳力佳门业有限公司

A3.5 B05 grade autoclaved aerated concrete block prepared from quartz weathered sand and method thereof

ActiveCN104844106BAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareEngineeringPhosphogypsum

The invention provides A3.5 prepared from quartz weathered sand? B05 grade autoclaved aerated concrete block is A3.5 made of quartz weathered sand, cement, quicklime, industrial waste phosphogypsum, aluminum powder paste and water. B05 grade high performance autoclaved aerated concrete block. The dry density of the block is 509kg / m3, the average cubic compressive strength is 3.6MPa, the minimum value of a single group is 3.2Mpa, the splitting pressure ratio is 0.20, the mass loss after freezing is 2.8%, the strength after freezing is 3.1MPa, and the thermal conductivity (dry state) is 0.1251 W / (m·K), drying shrinkage value (standard method) 0.32mm / m, pass rate> 98%. The invention has reasonable raw material processing method, scientific formula calculation, simple production process and recyclable production waste. The block is a new type of energy-saving and environment-friendly wall material, which can be produced industrially.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Horizontal electromagnetic continuous casting equipment for copper alloy sheet

An apparatus for the horizontal electromagnetic conticasting of Cu-alloy plate (or band) features that the traveling-wave linear magnetic field generator is fixed in the front end of water cooling copper jacket of horizontally conticast plate (or band) and outside graphite crystallizer and said magnetic field generator is internally cooled by water. Its method features that an AC at 1-100 H2 is applied to the said magnetic field generator and the phase and direction of said AC is changing to stir the molten metal, resulting in uniform temp, less generation of tree crystals, and high quality of product.

Owner:DALIAN UNIV OF TECH +1

Iron sand lined steel casting horizontal type shaping, vertical pouring casing method

InactiveCN101380668ANo shrinkage cavityNo shrinkageFoundry mouldsFoundry coresSheet steelSteel casting

The invention relates to a method for the horizontal molding and vertical casting of a sand-coated steel cast of an iron-mold, the method includes the following steps: a, an upper mold plate and a lower mold plate are horizontally molded; a pouring head is arranged at one side of the mold plate; the pouring head is plugged by a steel plate for sand shooting; after that the sand shooting, the steel plate is taken away; b, after mold assembling, the iron mold is vertically arranged; the pouring head is led to face upwards and is arranged in a prepared frame; then casting is carried out. The technique is simplified in design and fully complements shrinking; the cast doses not generate a shrinkage cavity and a shrinkage porosity; besides, the yield is high and the casting temperature is relatively low, thus being beneficial for energy saving.

Owner:SHANXI MOFAN MACHINERY MFG

Method for eliminating contraction stomata around iron crankshaft core of iron sand lined steel casting ball

The invention relates to a method for the shrinkage cavities surrounding a crankshaft core of a sand-coated casting ductile iron of an iron mold; the method includes the following steps: a, the chemical components of an iron liquid are adjusted for leading the content of CE to be equal to or more than 4.25 percent and leading the content of SC to be equal to or more than 1 percent, the optimal content of CE is between 4.6 and 4.7; b, the smallest wall thickness of the manufactured iron mold is not less than 30mm and the back surface is not hollowed; c, a maximized iron core is adopted, thus maintaining the thinnest location of a sand-coated layer to be not less than 2.5mm under the situation of being capable of taking out the iron core; d, the casting temperature is controlled between 1400 and 1450 DEG C. By adopting the method, the generated shrinkage cavities surrounding the crankshaft core of the sand-coated casting ductile iron of the iron mold are eliminated, the qualified rate of a product is increased by 5 to 30 percent, the casting temperature is lowered, the service life of an electric furnace is prolonged, energy is saved and the energy consumption is reduced.

Owner:SHANXI MOFAN MACHINERY MFG

Ceramic mould casting process for magnesium alloy

The invention provides a ceramic mould casting process for a magnesium alloy. The flow of the ceramic mould casting process for the magnesium alloy is as follows: carrying out female die treatment, brushing silicon rubber, vacuumizing, filling with gypsum, drawing a silicon rubber / gypsum die, preparing a hydrolysate, preparing a ceramic slurry, grouting, drawing the die, carrying out spray combustion, roasting, producing a sand mould, smelting the alloy, pouring, unboxing, inspecting, and setting die drawing time for spraying a refractory material according to the sizes of workpieces, wherein the die drawing time of the small workpieces is about 5 minutes, and the die drawing time of the large workpieces is about 20 minutes; the roasting temperature is 850 DEG C, the temperature rise speed is 3 DEG C / min, the insulation time is 1 hour, and organic matters are eliminated to prevent the reaction between the sand mould and the magnesium alloy. The ceramic mould casting process for the magnesium alloy enables the casting effect to be good, and the cast product is good in quality.

Owner:吴光英

A3.5 B05 grade autoclaved aerated concrete block made of quartz weathered sand and its application on the wall

ActiveCN105753420BAlleviate the problem of comprehensive utilizationInhibits digestive reactionsCeramicwareWaste materialToxic industrial waste

The invention provides an A3.5B05 level autoclaved aerated concrete building block prepared from quartz weathered sand and application of the building block to a wall body. The A3.5B05 level high-performance autoclaved aerated concrete building block is prepared by using quartz weathered sand, cement, quicklime, industrial waste ardealite, aluminum powder paste and water as raw materials. The dry density of the building block is 509kg / m<3>; the average value of the cubic compressive strength is 3.6MPa; the single-unit minimum value is 3.2Mpa; the split pressure ratio is 0.20; the frozen mass loss is 2.8 percent; the frozen strength is 3.1Mpa; the heat conductivity coefficient (the dry state) is 0.1251 W / (m K); the drying shrinkage value (a standard method) is 0.32mm / m; the qualified rate is greater than 98 percent. The raw material treatment method is reasonable; the formula calculation is scientific; the production flow process is simple and compact; production waste materials can be cyclically utilized. The building block can be applied to heat insulation wall body materials.

Owner:HUBEI YITONG CONSTR ENG CO LTD

Combustion method for garage kit mold block of vacuum evanescent mold

InactiveCN107470561AEliminate carbon increaseEliminate casting defectsFoundry mouldsFoundry coresVacuum pumpingExcess oxygen

The invention discloses a method for burning a white mold module before vacuum lost foam casting. After the modeling is completed, cover the plastic film, vacuumize, and gradually burn the white mold module with a burning gun from the outlet of the module. The burning gun is fed with combustible gas and oxygen. In addition to ensuring the complete combustion of the combustible gas, the combustion-supporting oxygen must have excess gas. The oxygen guarantees the combustion of the module, and the outlet remains sealed during the entire combustion process and the subsequent pouring process. The invention eliminates casting defects caused by the vaporization residue of the lost foam model, reduces the pouring temperature, improves the product qualification rate, and simplifies the process parameters of the vacuum lost foam casting.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com