Method and device for improving quality of squeezing and casting piston casting

A squeeze casting and squeeze casting machine technology, applied in the field of improving the quality of squeeze casting piston castings, can solve the problems of poor pressurization effect, high mold temperature requirements, uneven mechanical properties of pistons, etc., and achieve the improvement of slag collection ability and reduction Small handle thickness, excellent molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

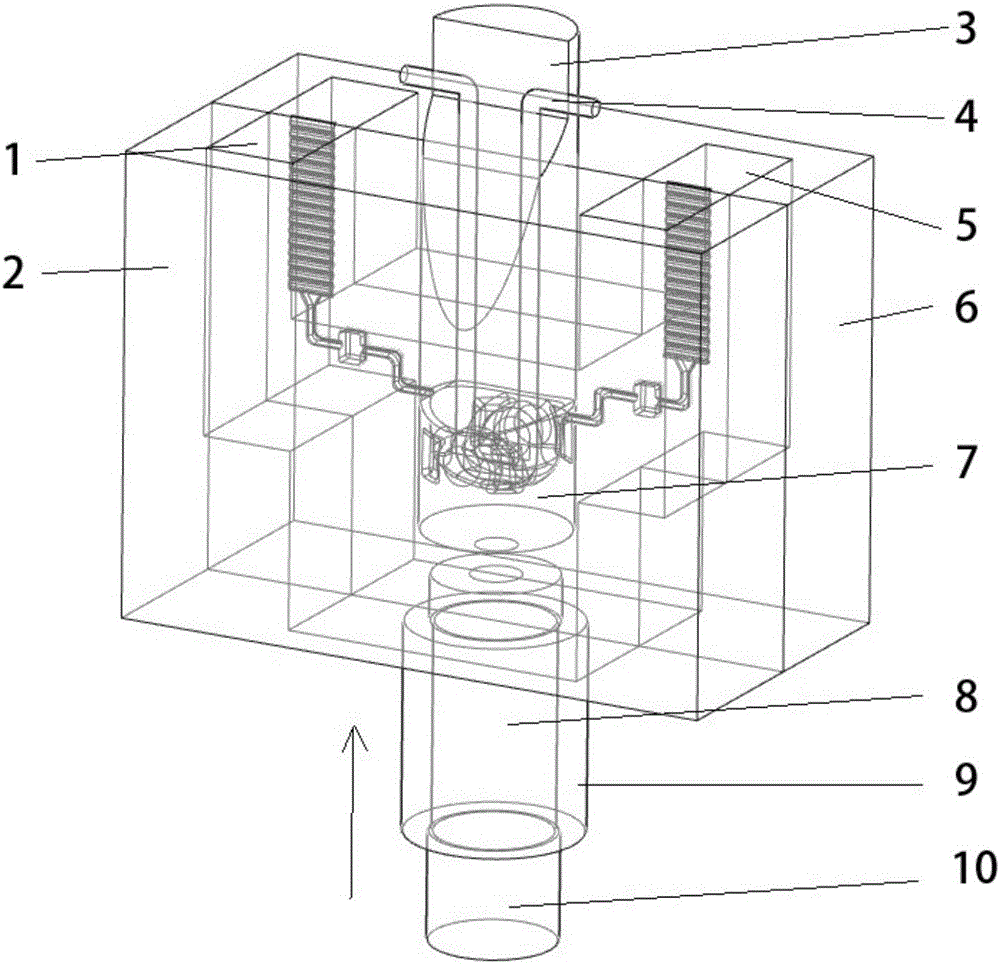

[0030] Embodiment 1: Schematic diagram of the structure of the squeeze casting piston mold is as follows figure 1 shown. Utilize three-dimensional software UG modeling to described extrusion die device, measure by numerical simulation software ProCAST, as Figure 4 shown.

[0031] At present, the conventional indirect extrusion casting piston mold does not pass cooling water and adopts expansion gate. When the mold temperature is 300°C, the extrusion barrel is 400°C, the filling temperature of Zl109 is 680°C, and the filling speed is 32.5mm / s, the piston The top of the casting is the final solidification position, and the shrinkage and shrinkage cavities are concentrated at the center of the top of the casting, which cannot be removed by machining.

[0032] This example verifies that Niyama Criterion shows that piston castings have a low tendency of shrinkage and shrinkage, and are concentrated in the expansion of the gate, which can be removed by machining. The piston is f...

Embodiment 2

[0034] Example 2: The horizontal squeeze casting machine used in this example is Suzhou Sanji SCH180 squeeze casting machine, the clamping force is 1800KN, and the conveying system uses manual weighing Zl109 to melt and rise to 700°C, and pour the extrusion material quantitatively Barrel 9.

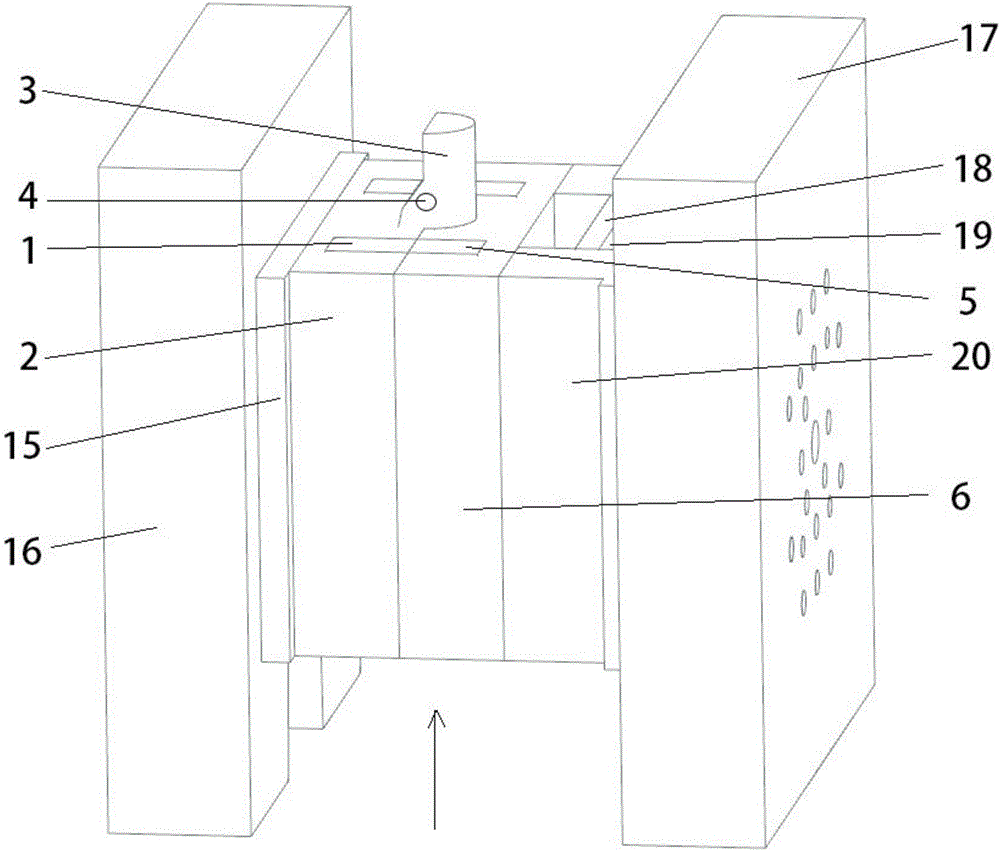

[0035] Realize the schematic diagram of the mold structure of this embodiment as image 3 shown.

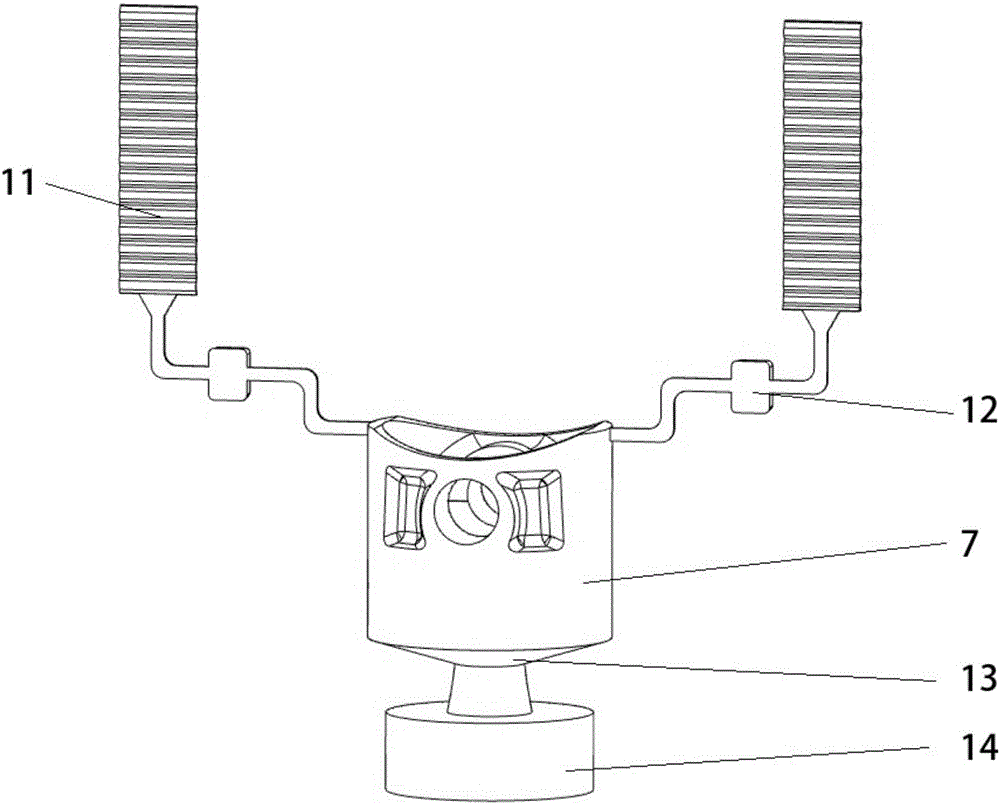

[0036] 1. After the mold is designed, the present embodiment utilizes the existing extrusion casting mold to improve; the fixed mold core 1 and the movable mold core 5 of the mold adopt H13, and the fixed mold 2 and the movable mold 6 adopt No. 45 steel;

[0037] 2. When the present embodiment utilizes the existing squeeze casting mold, the mold inner gate 13 of the mold is cut into a 120° expansion gate;

[0038] 3. Install the squeeze casting mold: Press the produced squeeze casting mold image 3 The shown is installed on the SCH180 horizontal squeeze casting machine;

[0039]4. Vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com