A3.5 B05 grade autoclaved aerated concrete block prepared from quartz weathered sand and method thereof

A technology of quartz weathered sand and concrete blocks, which is applied in the field of A3.5B05 autoclaved aerated concrete blocks and its preparation, which can solve the problems of few building materials enterprises, achieve high SiO2 content, fast digestion speed, and inhibit digestion The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

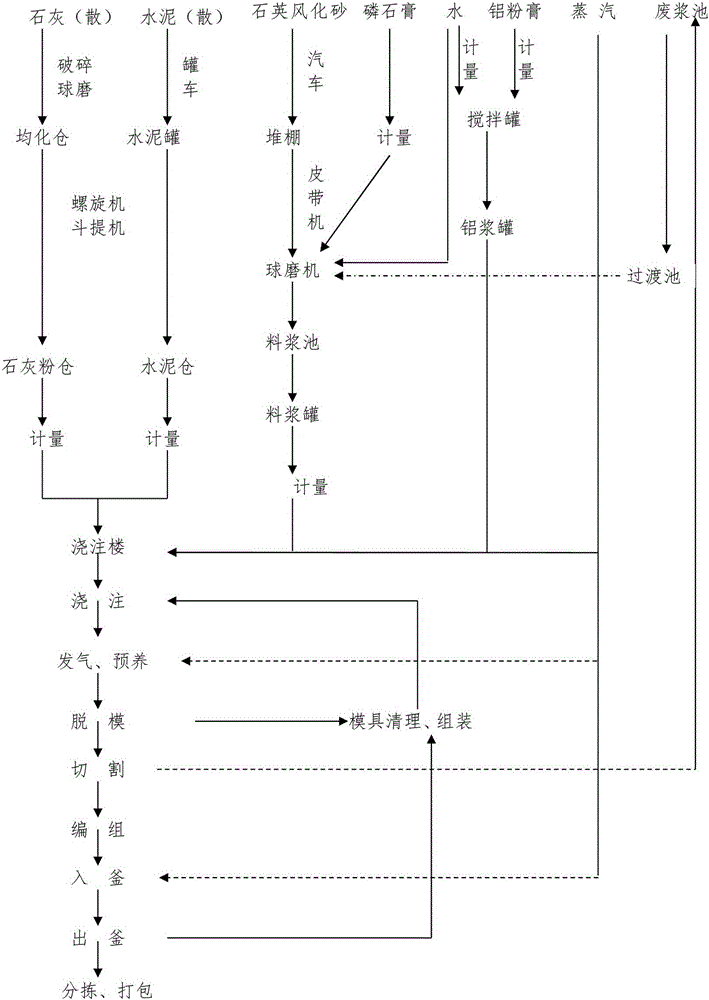

Method used

Image

Examples

Embodiment 1

[0039] Quartz weathered sand and phosphogypsum are measured with a belt scale at a mass ratio of 100:6.2, and transported to the feed port of the ball mill, and mixed with water and waste slurry (the flow ratio of water and waste slurry is 7:1) to obtain a fineness of 26% slurry with a concentration of 62.0% by mass; crush quicklime and ball mill to prepare quicklime powder with a fineness of 12%, a digestion time of 9min, a digestion temperature of 81°C, and a mass fraction of A(CaO+MgO) of 78%; water and The aluminum powder paste is stirred evenly at a mass ratio of 9:1 to form an aluminum paste. The fineness is the mass percentage of the sieve residue of the dry material passing through the 180-mesh standard inspection sieve. The waste slurry described below is that after the leftover waste in the following enters the circulating water, the density formed by stirring is 1.28g / cm 3 The main components of the mixture include water, quartz weathered sand and silica provided b...

Embodiment 2

[0048] Quartz weathered sand and phosphogypsum were measured with a belt scale at a mass ratio of 100:6.5, and mixed with water and waste slurry (the flow ratio of water and waste slurry was 7.2:1) to obtain a fineness of 25% and a mass percentage concentration of 62.3% slurry; crush quicklime and ball mill to prepare quicklime powder, the fineness is 12%, the digestion time is 12min, the digestion temperature is 82°C, the mass fraction of A(CaO+MgO) is 76%; the water and aluminum powder paste are mixed in a mass ratio of 9 : 1 Stir evenly to form aluminum paste. The fineness is the mass percentage of the sieve residue of the dry material passing through the 180-mesh standard inspection sieve. The waste slurry is the density of 1.25g / cm formed by stirring after the leftovers in the following enter into the circulating water 3 The main components of the mixture include water, quartz weathered sand and silica provided by cement, lime and calcium hydroxide formed by hydration re...

Embodiment 3

[0053]Quartz weathered sand and phosphogypsum were measured with a belt scale at a mass ratio of 100:7, and transported to the feed port of the ball mill, and mixed with water and waste slurry (the flow ratio of water and waste slurry was 7.5:1) to obtain a fineness of 27%, mass percent concentration of 62.2% slurry; crushed quicklime, ball milled to prepare quicklime powder, fineness 11%, digestion time 12min, digestion temperature 81 ℃, A(CaO+MgO) mass fraction 80%; water and The aluminum powder paste is stirred evenly at a mass ratio of 9:1 to form an aluminum paste. The fineness is the mass percentage of the sieve residue of the dry material passing through the 180-mesh standard inspection sieve. The waste slurry is the density of 1.26g / cm formed by stirring after the leftovers in the following enter into the circulating water 3 The main components of the mixture include water, quartz weathered sand and silica provided by cement, lime and calcium hydroxide formed by hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com