Method for degrading vomitoxin in deep processing process of corn

A technology of vomitoxin and deep processing, which is applied in the field of deep processing of corn, can solve the problems of excessive vomitoxin content in corn by-products, excessive vomitoxin content, and vomitoxin pollution, etc., and achieves the effect of significant detoxification effect, alleviation of utilization problems and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

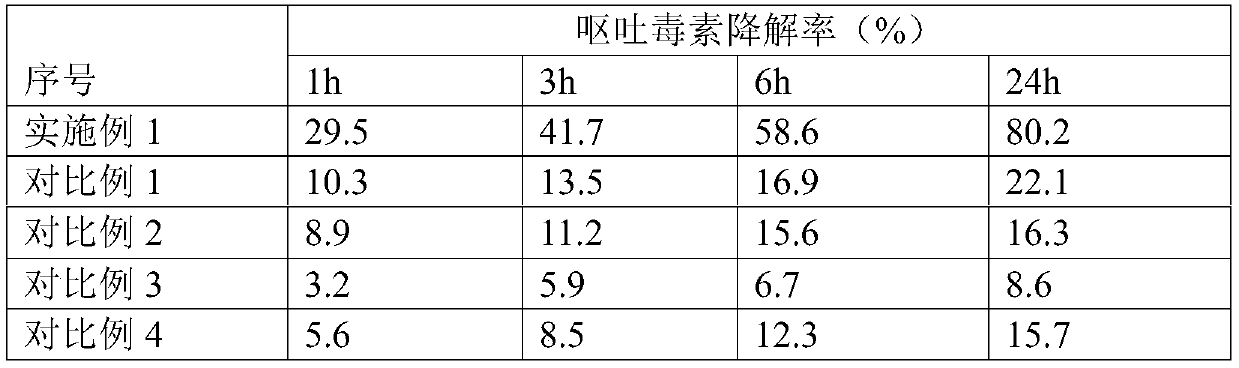

Embodiment 1

[0075] The live thallus of Bacillus subtilis whose preservation number is CGMCC NO.14597 is in 30mL LB liquid culture medium (10g peptone, 5g yeast powder, 10g sodium chloride, deionized water is settled to 1L, adjusts pH to 7, through 121 ℃ sterilization for 15 min), shake culture overnight at 180 rpm and 37 ℃ for activation. Then, inoculate in 60mL LB liquid culture medium with the inoculation amount of 1v / v%, shake culture under the condition of 180rpm, 37 ℃ until the bacterium concentration in the bacterial liquid is (1±0.1)×10 5 CFU / mL, the fermentation broth was centrifuged at 8000rpm for 10min, and the bacteria were removed to obtain the supernatant, which was to prepare the crude enzyme solution. The crude enzyme solution prepared above was mixed with 200mL factory corn steep liquor (30wt% dry solids content, pH 5.0) at a volume ratio of 1:100, adjusted to pH 7 with sodium hydroxide, and fully mixed and reacted at 37°C. Samples were taken before the reaction (0h) and ...

Embodiment 2

[0091] The crude enzyme solution prepared in Example 1 was added into 200 mL factory corn steep liquor (dry solid content 50 wt%, pH 3.0) at a volume ratio of 1:100, and mixed and reacted at 50° C. for 24 hours. Samples were taken before and after the reaction to detect the content of vomitoxin. It is calculated that the degradation rate of vomitoxin can reach 43.8%.

[0092] The results of Example 1-Example 2 illustrate that the method of the present invention not only has a significant degradation effect under neutral mild conditions (37°C, pH7.0), but also at higher temperatures (50°C) and lower Under pH (pH 3), it can also obviously degrade the vomitoxin in corn steep liquor, which proves that the method of the present invention can overcome most of the existing biological method detoxification and be applied to the higher temperature or harsh acid-base conditions in the grain processing process The problem that the detoxification efficiency is significantly reduced under...

Embodiment 3

[0094]The fermentation broth was obtained in the same manner as in Example 1, the fermentation broth was centrifuged at 8000 rpm for 10 min, and the bacteria were collected and freeze-dried to prepare a freeze-dried microbial agent. Mix 200g of mildewed corn with 200mL of 50°C tap water, soak at a constant temperature of 50°C for 2 hours, filter and recover the corn to obtain a corn soaking solution (pH 5.0), use sodium hydroxide to adjust the pH of the corn soaking solution to 7.0 and cool to 37°C, and then add the above-mentioned freeze-dried bacterial agent into it at a ratio of 2w / v%, mix well, and react at 37°C and pH 7.0 for 24h. Samples were taken before and after the reaction to detect the content of vomitoxin. The calculated degradation rate of DON can reach 85.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com