Organic silicon building waterproof coating and preparation method thereof

A technology of building waterproofing and silicone, which is applied in coatings and other directions, can solve the problems of poor stability of waterproofing agents, etc., and achieve the effects of enhancing waterproof performance, improving waterproof effect, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

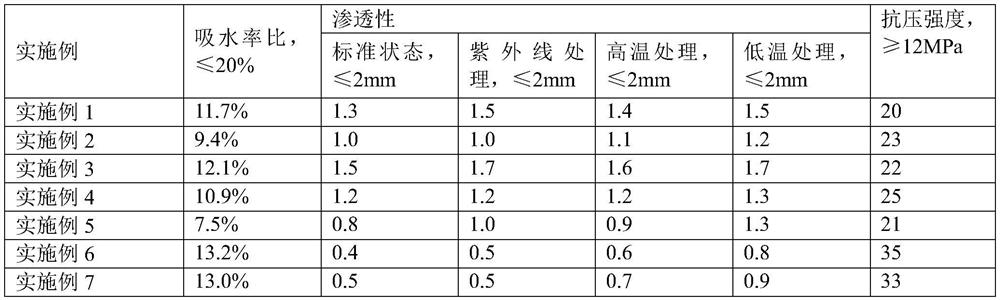

Examples

Embodiment 1

[0020] A preparation method of organosilicon-based building waterproof coating,

[0021] 1) Preparation of silicone resin powder: Add 100 parts of water into a pressure-resistant container, then discharge the high boiling matter of the slurry (the bottom of the washing tower of the methyl chlorosilane monomer synthesis device with the ultrafine waste silicon powder, and recover valuable products by distillation Finally, the liquid high boilers that enter the slurry tank, the same below) are hydrolyzed by pressurized atomization treatment technology, and the specific operation is to charge nitrogen into a pressure vessel with 50 parts of slurry high boilers under stirring conditions, Keep the pressure in the container within the range of 0-0.6 MPa, atomize the gas through the nozzle, and spray it onto the surface of the water. During the hydrolysis process, add a certain amount of water to the reactor every 10 minutes to keep the concentration of acid water in the system. Keep ...

Embodiment 2

[0024] A preparation method of organosilicon-based building waterproof coating,

[0025] 1) Preparation of silicone resin: Add 100 parts of water in a pressure vessel, then hydrolyze the high boiling matter of the slurry using pressurized atomization treatment technology, the specific operation is to add 50 parts of high boiling matter of the slurry under stirring conditions Fill the pressure vessel with air so that the pressure in the vessel is in the range of 0-0.6 MPa. The gas is atomized through the nozzle and sprayed onto the surface of the water. During the hydrolysis process, a certain amount of water is added to the reactor every 30 minutes. Keep the acid water concentration of the system below 15%, and at the same time keep the stirring speed at 1500 rpm to obtain silicone resin with uniform particle size. After washing the silicone resin with water until the pH is less than 5, react with potassium hydroxide to obtain the corresponding After filtration, react the filt...

Embodiment 3

[0028] A preparation method of organosilicon-based building waterproof coating,

[0029]1) Preparation of silicone resin: Add 100 parts of water into a pressure vessel, then hydrolyze the high boiling matter of the slurry using pressurized atomization treatment technology. The pressure container is filled with a mixed gas of oxygen and argon with a volume ratio of 1:2 so that the pressure in the container is within the range of 0-0.6 MPa. The gas is atomized through the nozzle and sprayed onto the surface of the water. Add a certain amount of water to the reactor to keep the concentration of acidic water in the system below 15%, and at the same time keep the stirring speed at 1000 rpm to obtain silicone resin with uniform particle size. After the silicone resin is washed with water until the pH is less than 5, React with potassium hydroxide and sodium hydroxide at a molar ratio of 1:1 to obtain the corresponding alkyl silicon alkoxide, and after filtration, react the filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com