Aluminum alloy investment casting method and investment casting device adopting near liquidus pouring

An investment casting, near-liquidus technology, applied in casting molding equipment, molds, mold components, etc., can solve problems such as poor melt flow properties, and achieve elimination of casting stress, uniform structure, and fine grains. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

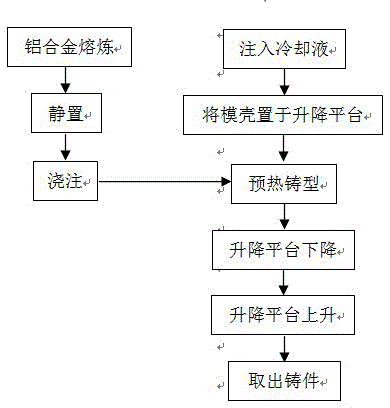

[0028] An aluminum alloy investment casting method for pouring near the liquidus line, the specific steps are as follows:

[0029] 1. Inject the water-soluble polymer PAG into the tank from the coolant inlet, and the temperature is room temperature;

[0030] 2. Place the formwork on the lifting platform, turn on the electromagnetic induction heating device, and heat up to 550°C;

[0031] 3. After smelting the ZL201A alloy, transfer it to the ladle and let it stand at 680°C (the melting temperature range is 548-650°C), then pour;

[0032] 4. According to the difference in wall thickness and size of the casting, lower the lifting platform at a speed of 0.5mm / s and immerse it in the water-soluble polymer PAG until the liquid level of the cooling liquid is flush with the bottom of the riser;

[0033] 5. Quickly raise the lifting platform, take out the casting, and clean the mold shell.

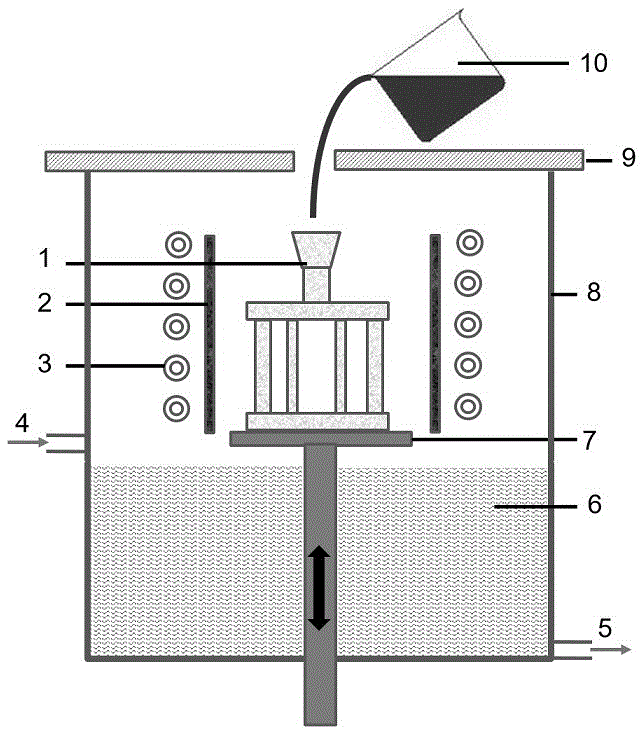

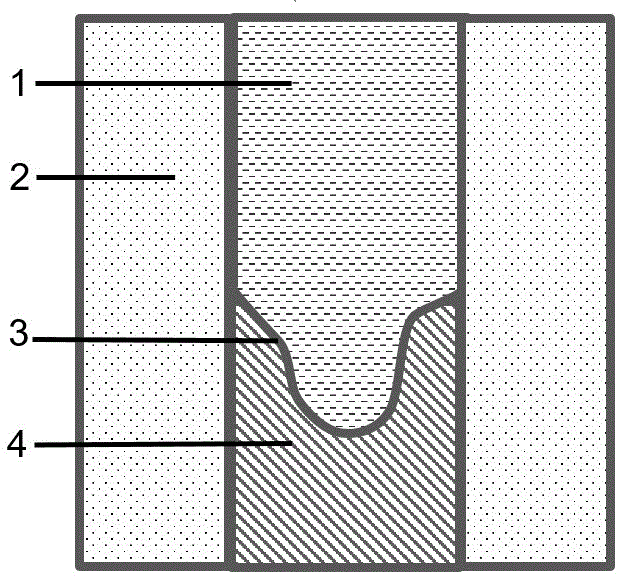

[0034] refer to figure 2 , an aluminum alloy investment casting device poure...

Embodiment 2

[0036] An aluminum alloy investment casting method for pouring near the liquidus line, the specific steps are as follows:

[0037] 1. Pour water into the tank from the coolant inlet, and the temperature is room temperature;

[0038] 2. Place the formwork on the lifting platform, turn on the electromagnetic induction heating device, and heat up to 600°C;

[0039] 3. After melting the ZL116 alloy, transfer it to the ladle and let it stand at 630°C (the melting temperature range is 557-596°C), then pour;

[0040] 4. According to the difference in wall thickness and size of the casting, lower the lifting platform at a speed of 1mm / s and immerse it in water until the liquid level of the cooling liquid is flush with the bottom of the riser;

[0041] 5. Quickly raise the lifting platform, take out the casting, and clean the mold shell.

[0042] The aluminum alloy investment casting device is the same as in Example 1.

Embodiment 3

[0044] An aluminum alloy investment casting method for pouring near the liquidus line, the specific steps are as follows:

[0045] 1. Fill the quenching oil into the tank from the coolant inlet, and the temperature is room temperature;

[0046] 2. Place the formwork on the lifting platform, turn on the electromagnetic induction heating device, and heat up to 600°C;

[0047] 3. After smelting the ZL303 alloy, transfer it to the ladle and let it stand at 680°C (the melting temperature range is 550-650°C), then pour;

[0048] 4. According to the difference in wall thickness and size of the casting, lower the lifting platform at a speed of 5mm / s and immerse it in the quenching oil until the liquid level of the cooling liquid is flush with the bottom of the riser;

[0049] 5. Quickly raise the lifting platform, take out the casting, and clean the mold shell.

[0050] The aluminum alloy investment casting device is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com