Patents

Literature

30results about How to "Solve process bottlenecks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

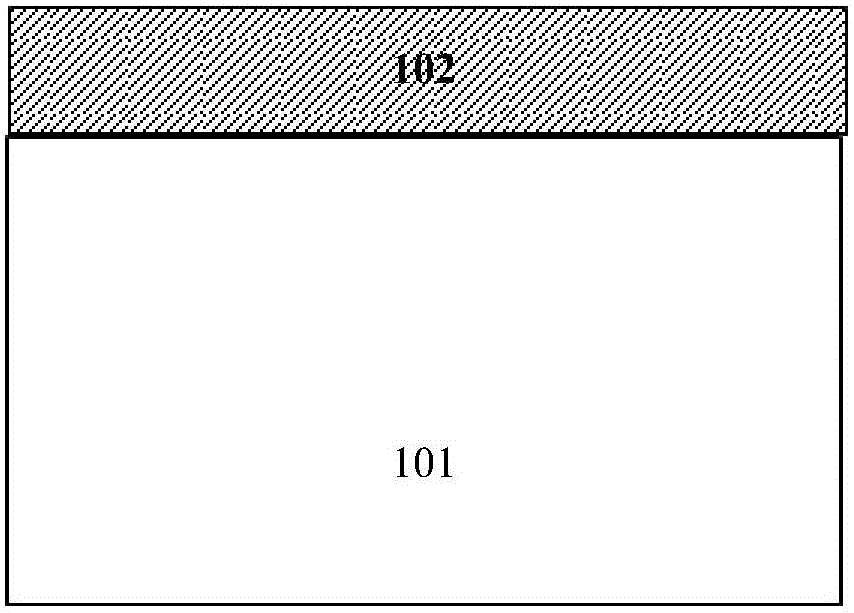

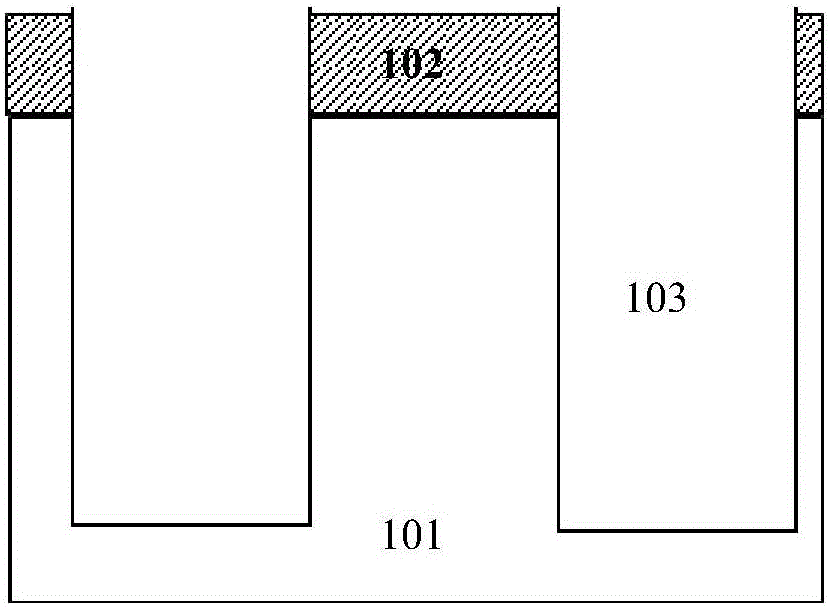

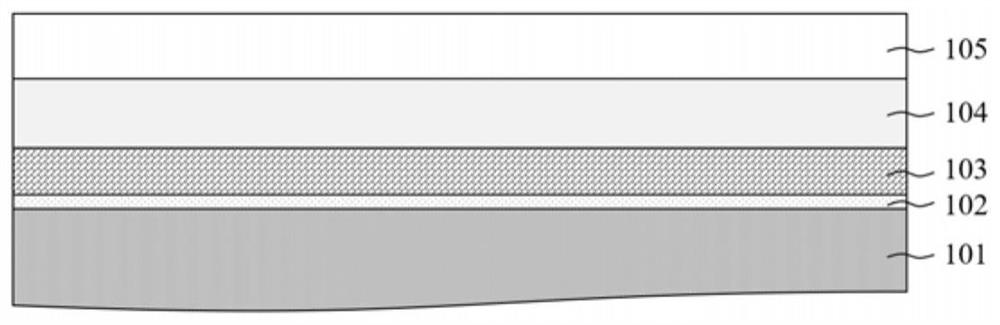

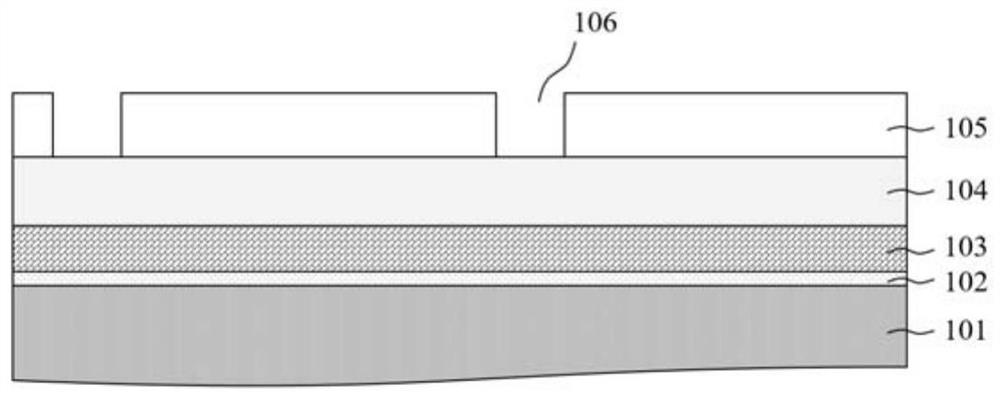

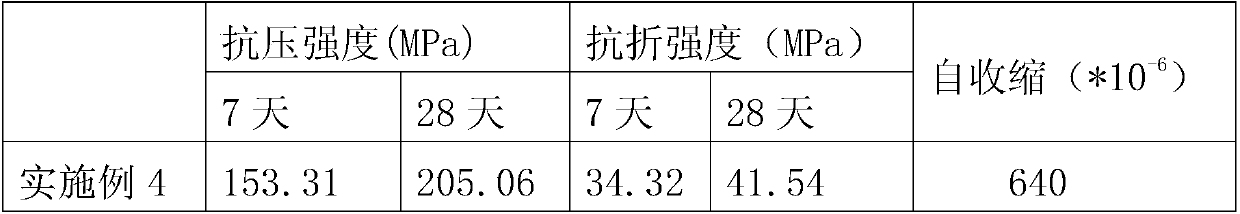

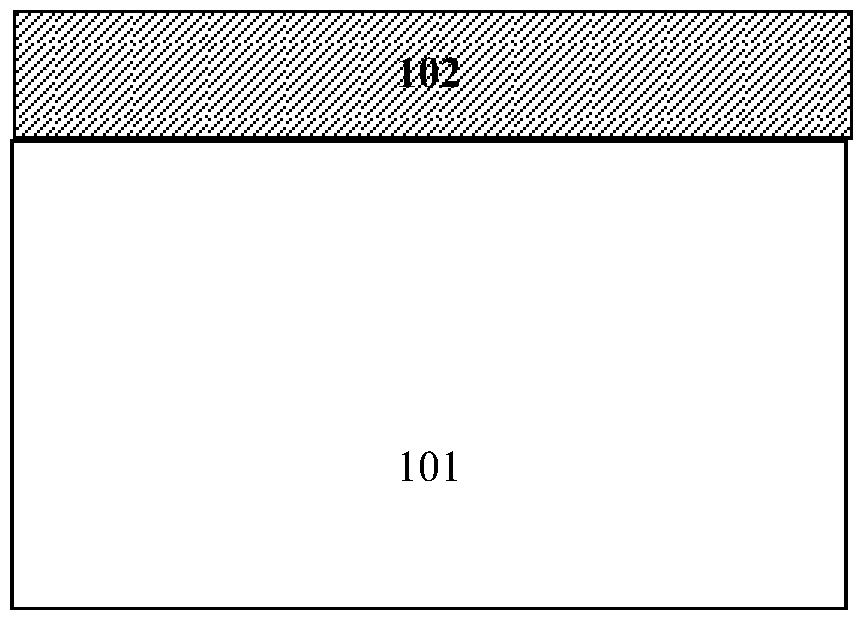

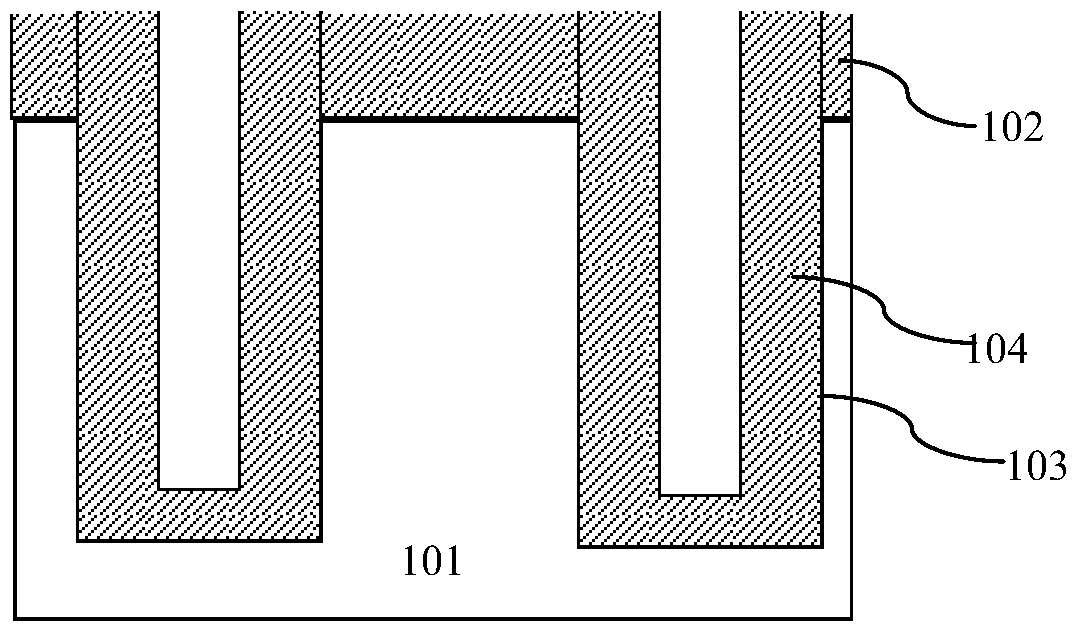

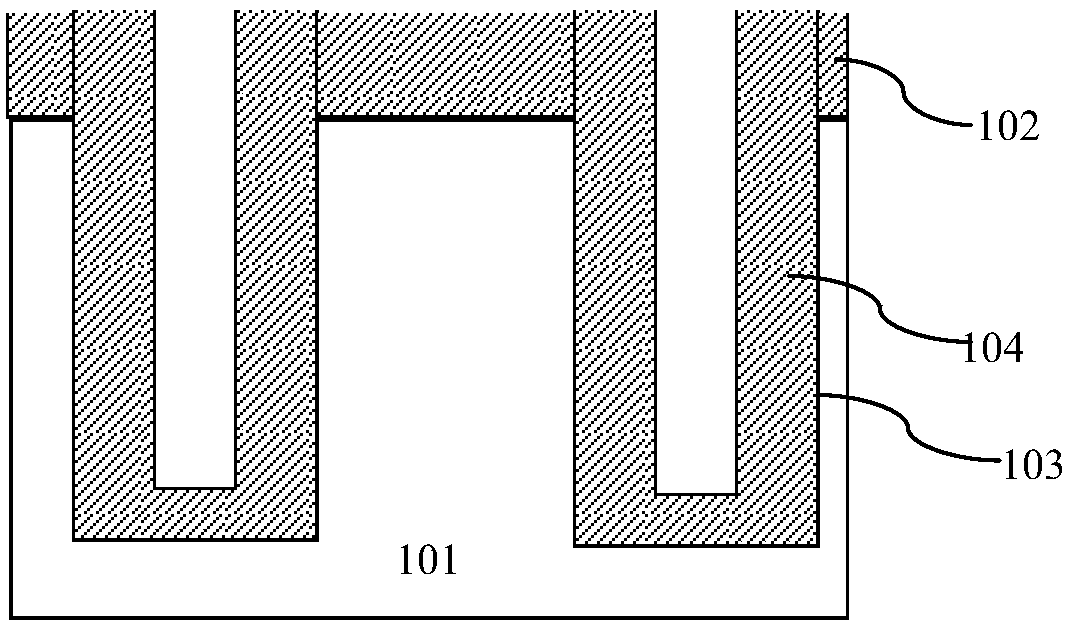

Manufacturing method of shielding gate groove MOSFET

ActiveCN105870022AReduce leakageSolve process bottlenecksSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPolysilicon gate

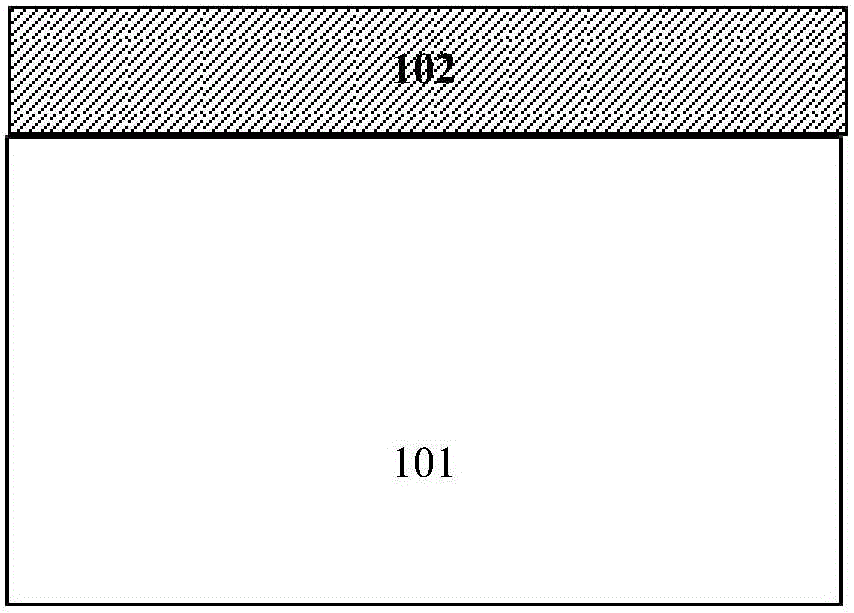

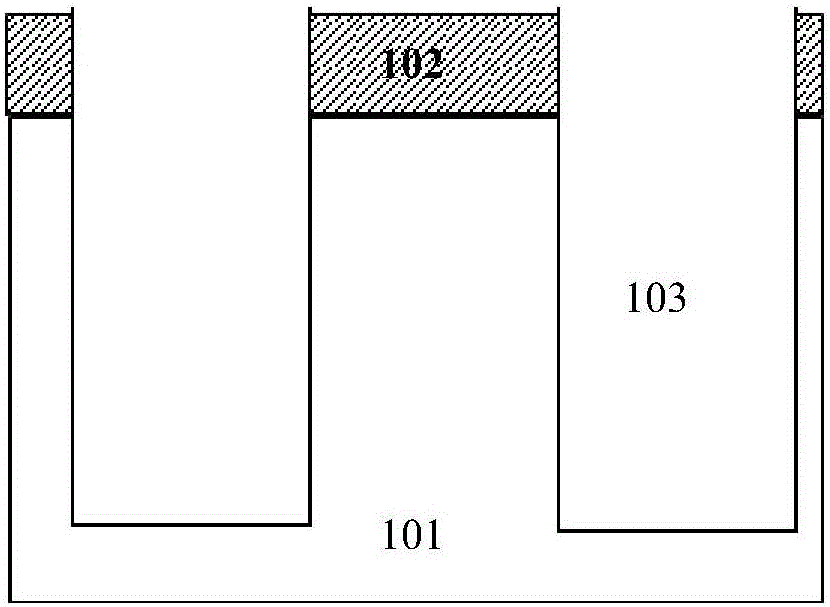

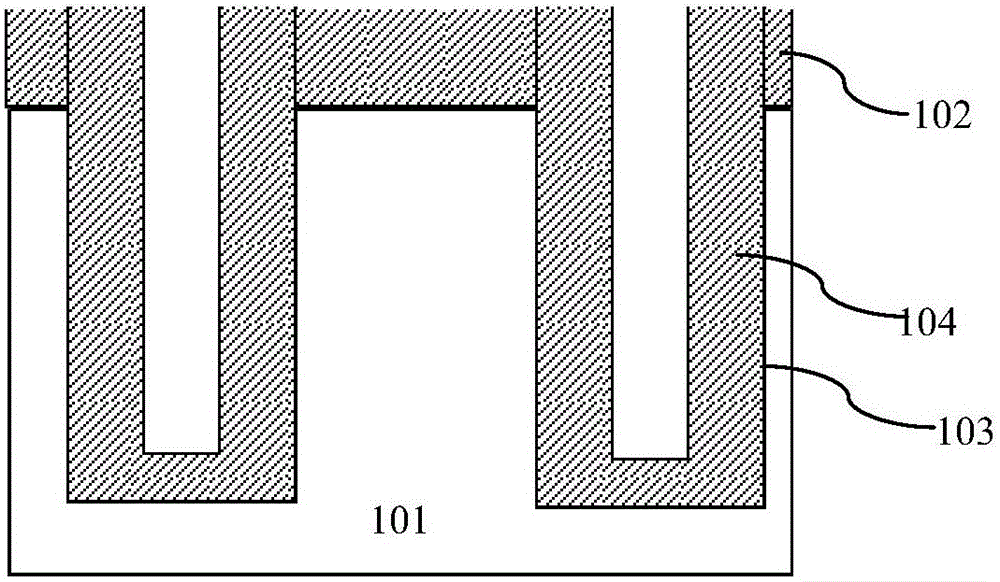

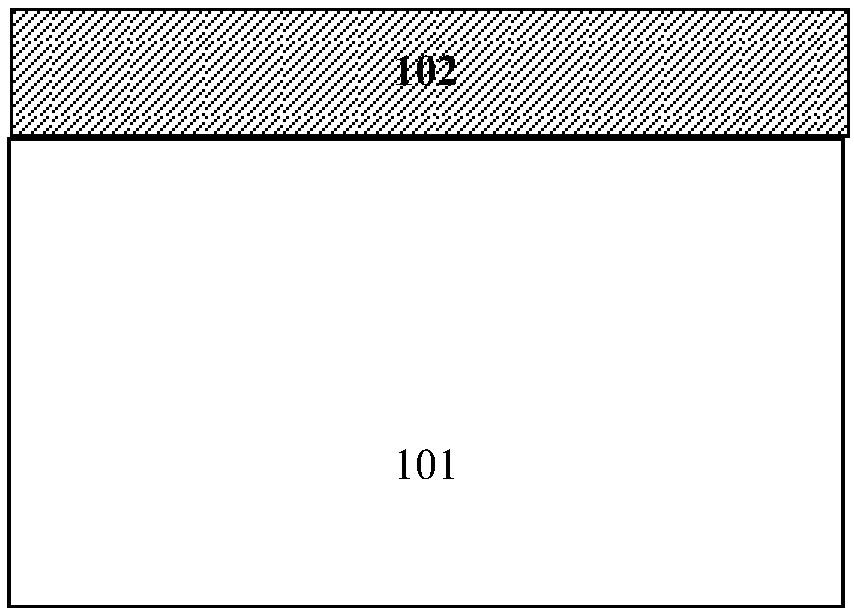

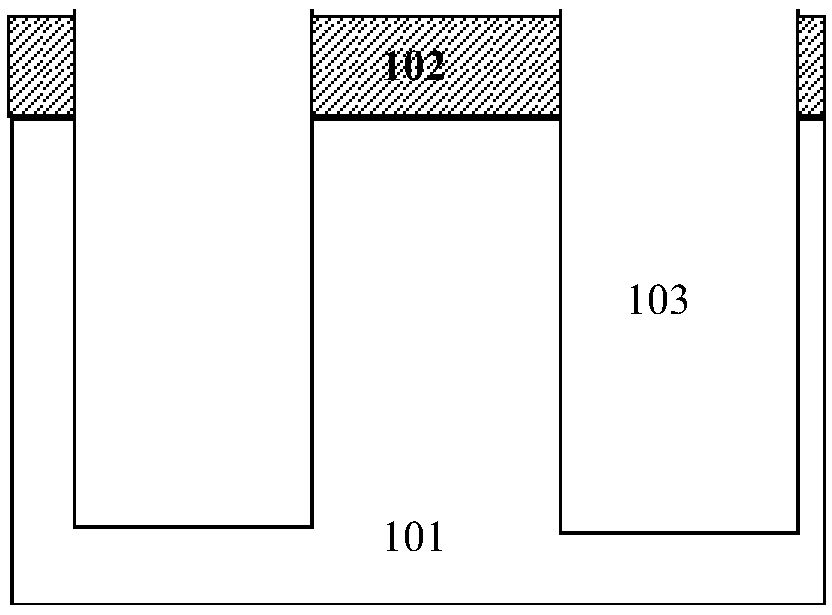

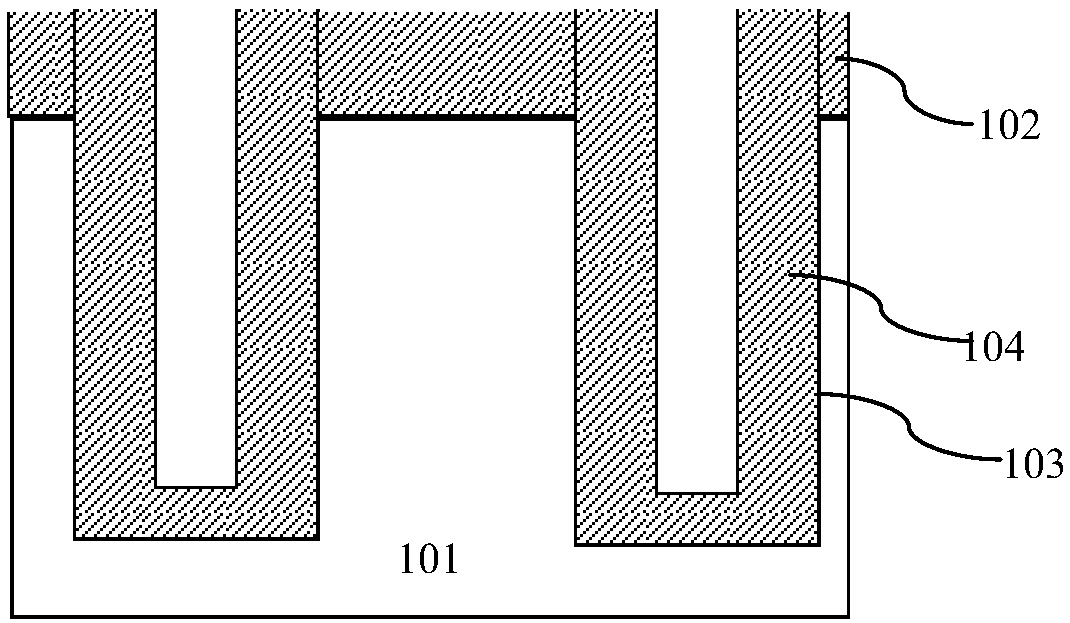

The invention discloses a manufacturing method of a shielding gate groove MOSFET. A gate electrode structure is formed through the following steps that a hard mask layer is formed, and a gate electrode forming area is defined; a semiconductor substrate is subjected to etching to form deep grooves; bottom oxidation layers are formed; pieces of source polysilicon are formed; polysilicon back etching is conducted, and the source polysilicon can be flush with the surface of the top of the hard mask layer; the hard mask layer is removed, and top protruding structures of the source polysilicon are formed; side walls composed of oxide etching and blocking layers are formed on the side faces of the protruding parts of the source polysilicon; the bottom oxidation layers are etched with the side walls as self-alignment masks, top grooves are formed, and isolation and oxidization layers among the polysilicon are formed on the two side faces of the corresponding source polysilicon; the gate medium layers are formed on the side faces of the top grooves; polysilicon gates are formed in the top grooves in a filled mode. By means of the manufacturing method, the threshold value voltage of a device is lowered, and meanwhile gate-source electric leakage of the device can be lowered.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

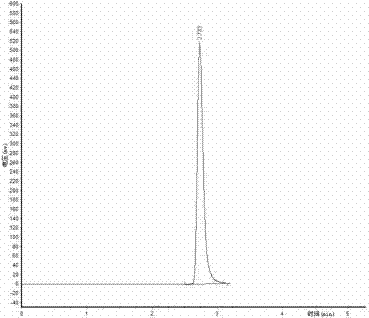

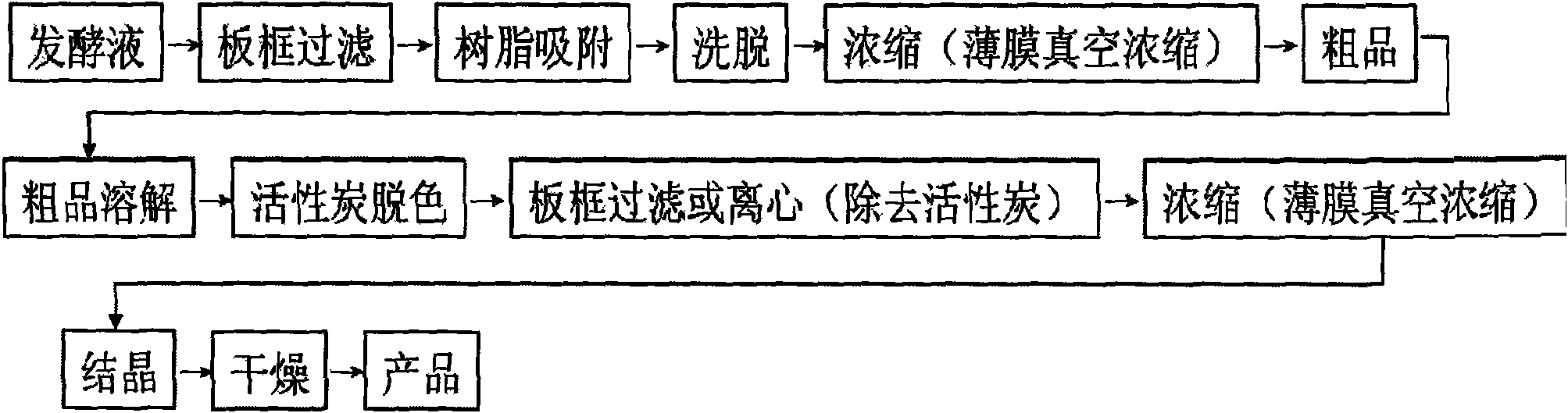

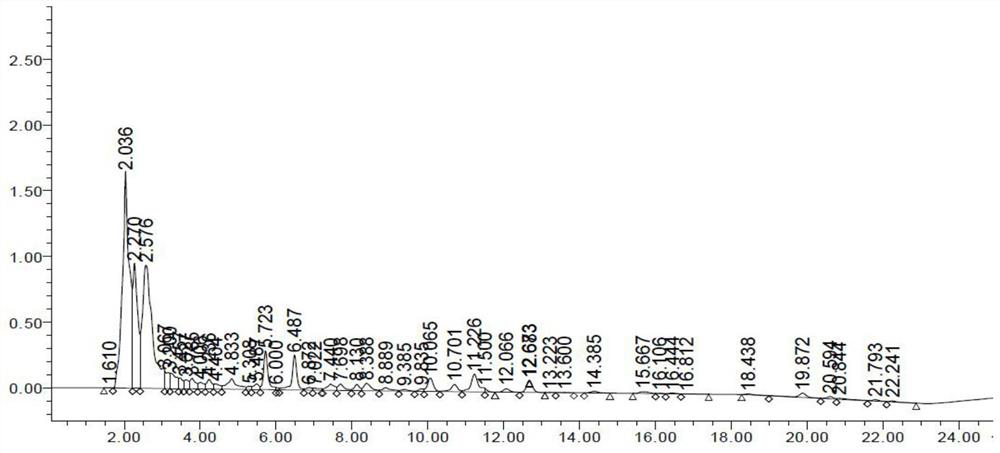

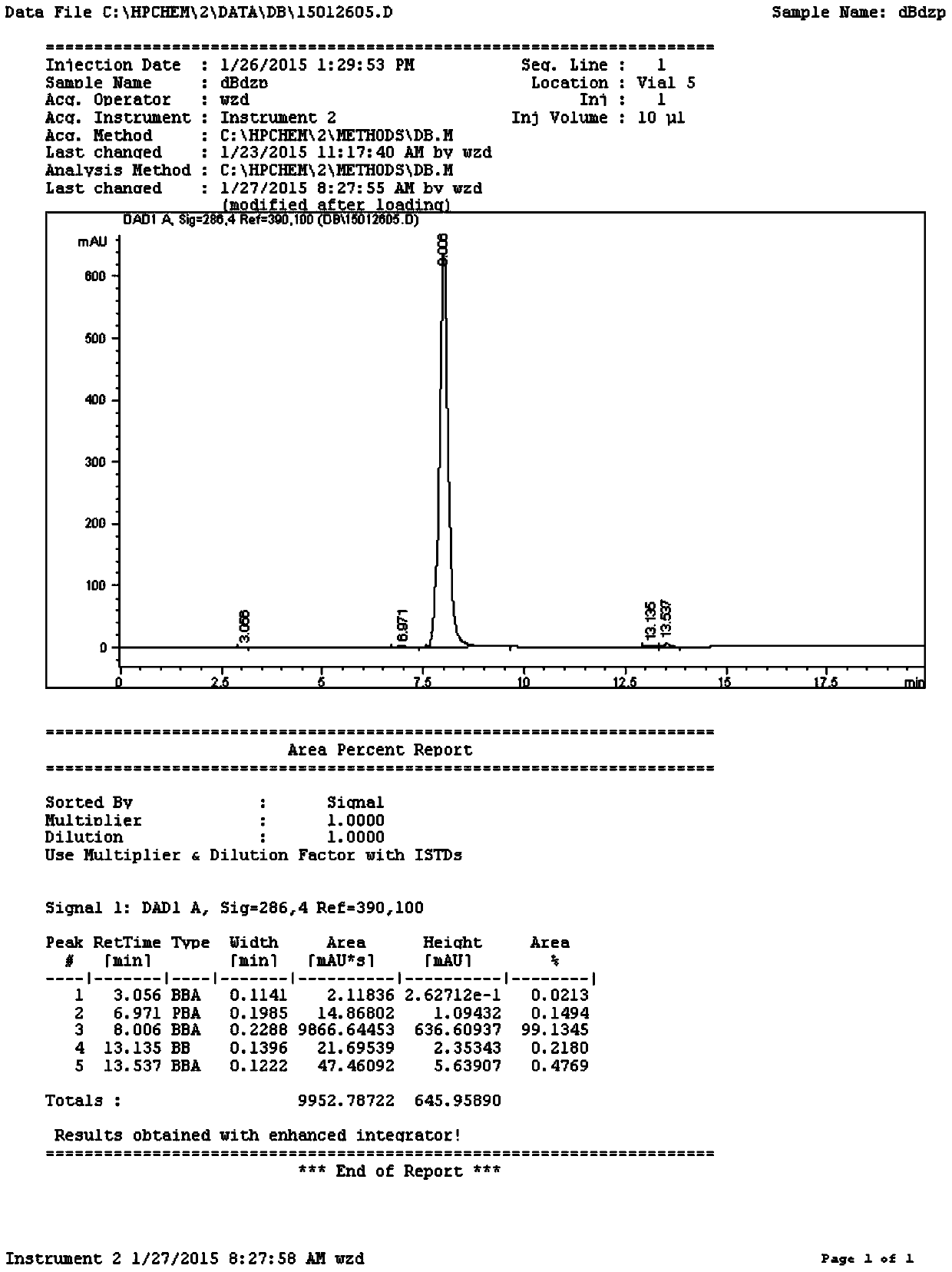

Extraction process for shikimic acid in fermentation liquor

InactiveCN102584571AFacilitate the ultrafiltration processReduce workloadCarboxylic compound separation/purificationBiochemical engineeringShikimic acid

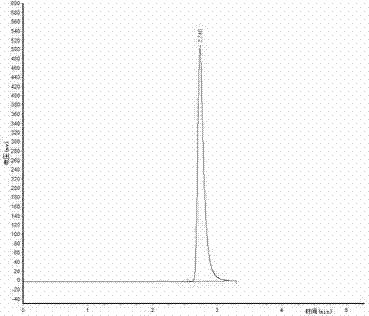

The invention relates to an extraction process for shikimic acid in fermentation liquor. The extraction process specially comprises the steps of conducting microfiltration on the fermentation liquor through a ceramic film to obtain filtrate, conducting exchange adsorption on the filtrate through anion exchange resin, then eluting the filtrate through acetic acid solution to obtain eluent, concentrating, destaining, crystallizing, crystal washing and drying the eluent to obtain finished shikimic acid. The process is simple and environment-friendly, and the finished shikimic acid extracted by the process is stable in quality, the purity of the finished shikimic acid is more than 98.5%, and the yield of the finished shikimic acid is more than 75%.

Owner:河南孟成生物药业股份有限公司

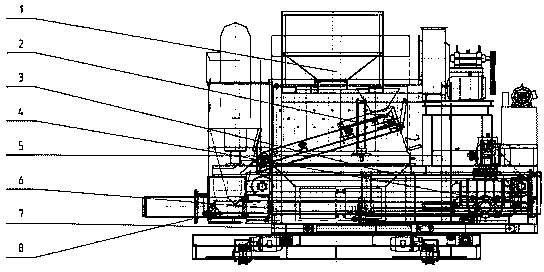

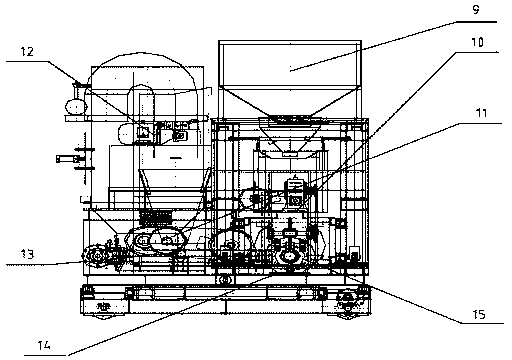

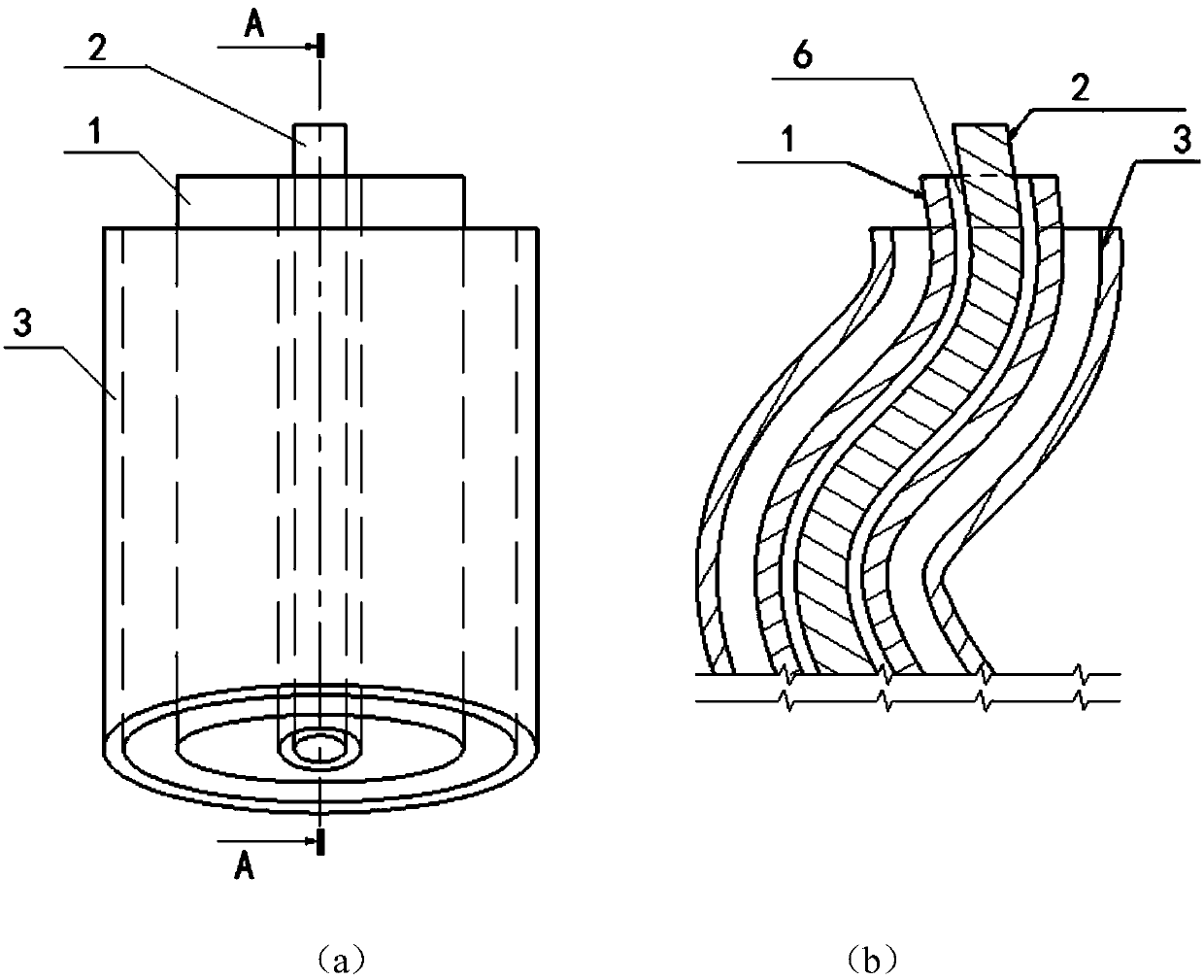

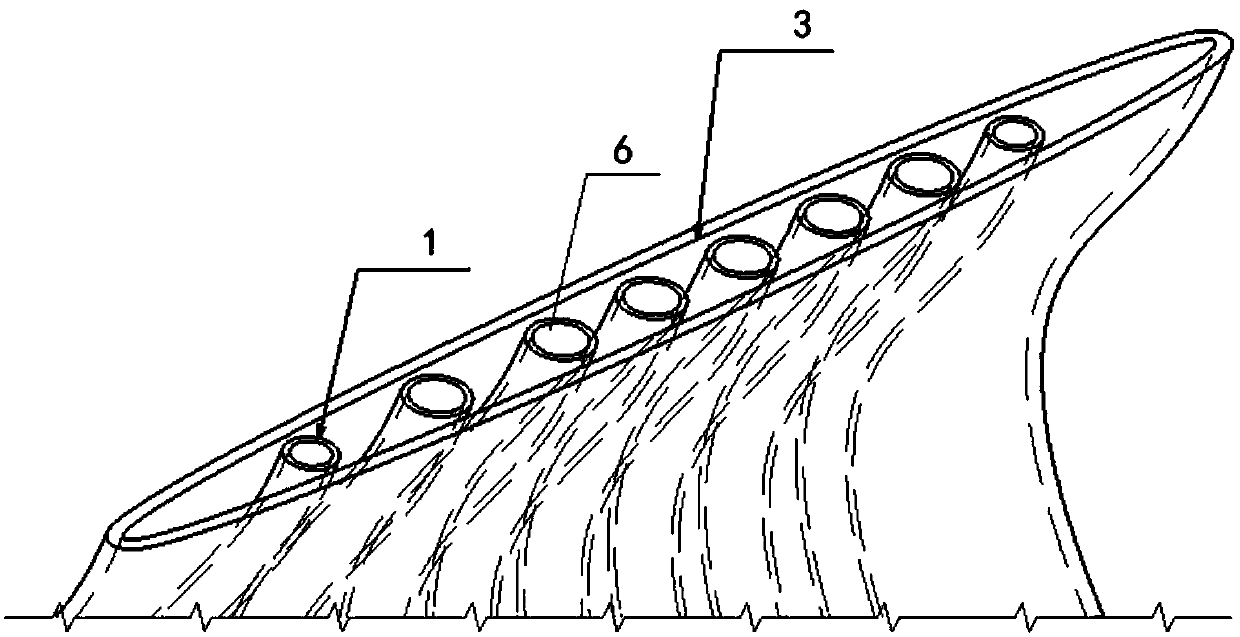

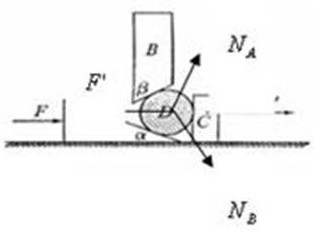

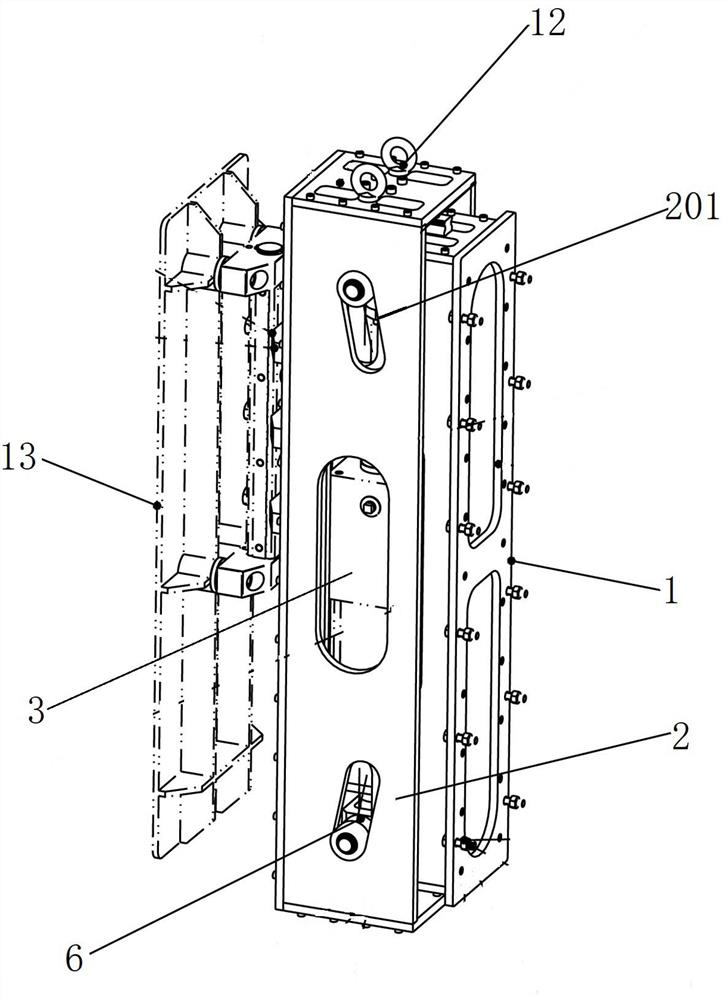

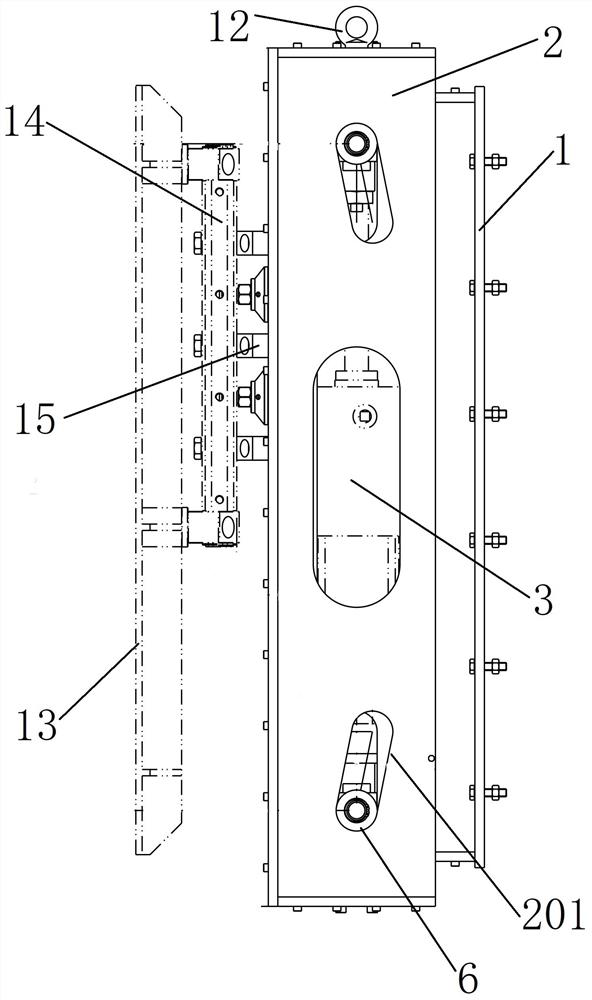

Integrated furnace charge pellet pneumatic packing and reducing slag pneumatic raking machine for magnesium metal reduction tank

InactiveCN103966461AReduce the oxidation degree of ferrosiliconLow costCharge manipulationProcess efficiency improvementFerrosiliconElectric machinery

The invention relates to smelting equipment, especially to an integrated mechanical automation machine for pneumatic packing of furnace charge pellets in a magnesium metal reduction tank and for pneumatic raking of high temperature reducing slag in the tank. The machine is applicable to pneumatic packing of furnace charge pellets and pneumatic raking of reducing slag for a ferrosilicon-process semi-continuous magnesium-smelting external heating type transverse tank. The machine is characterized in that high-flow high-pressure air flow of a Roots blower is used as material conveying power, all the units are mounted on a main running gear which walks in virtue of motor-driven rollers, and a machine body which is controlled by a hydraulic mechanism and can vertically rise and fall and a transverse running gear are arranged on a frame. An air supplying and material conveying pipeline is delivered to the reduction tank through a main drive mechanism on the machine body, reducing slag and pellet furnace charge are introduced into the air supplying and material conveying pipeline at different times and discharged from the reduction tank in virtue of the high-pressure air flow of the Roots blower, and produced dust is collected and cleaned. The machine has a high degree of automation and can both thoroughly remove reducing slag in the tank and intactly pack pellet furnace charge.

Owner:宁夏鹏程致远自动化技术有限公司

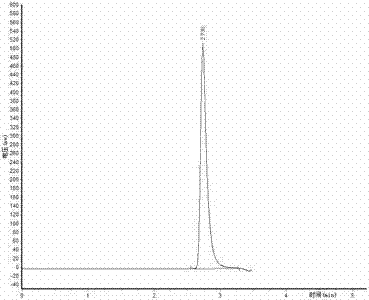

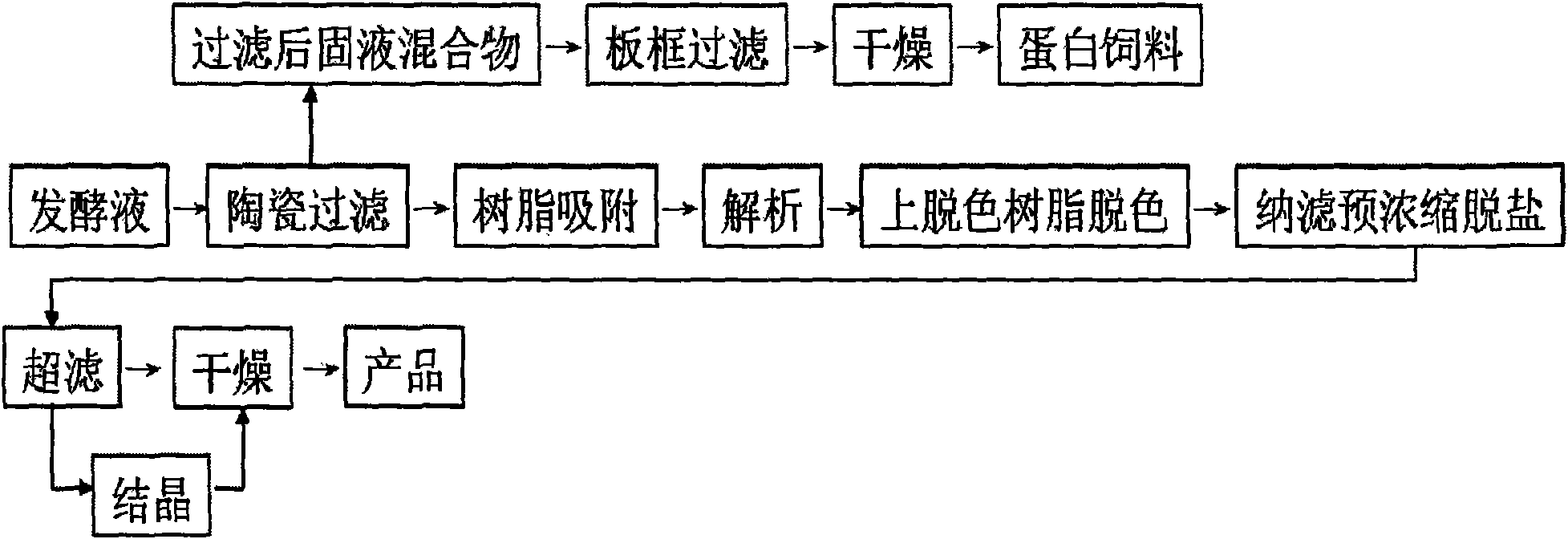

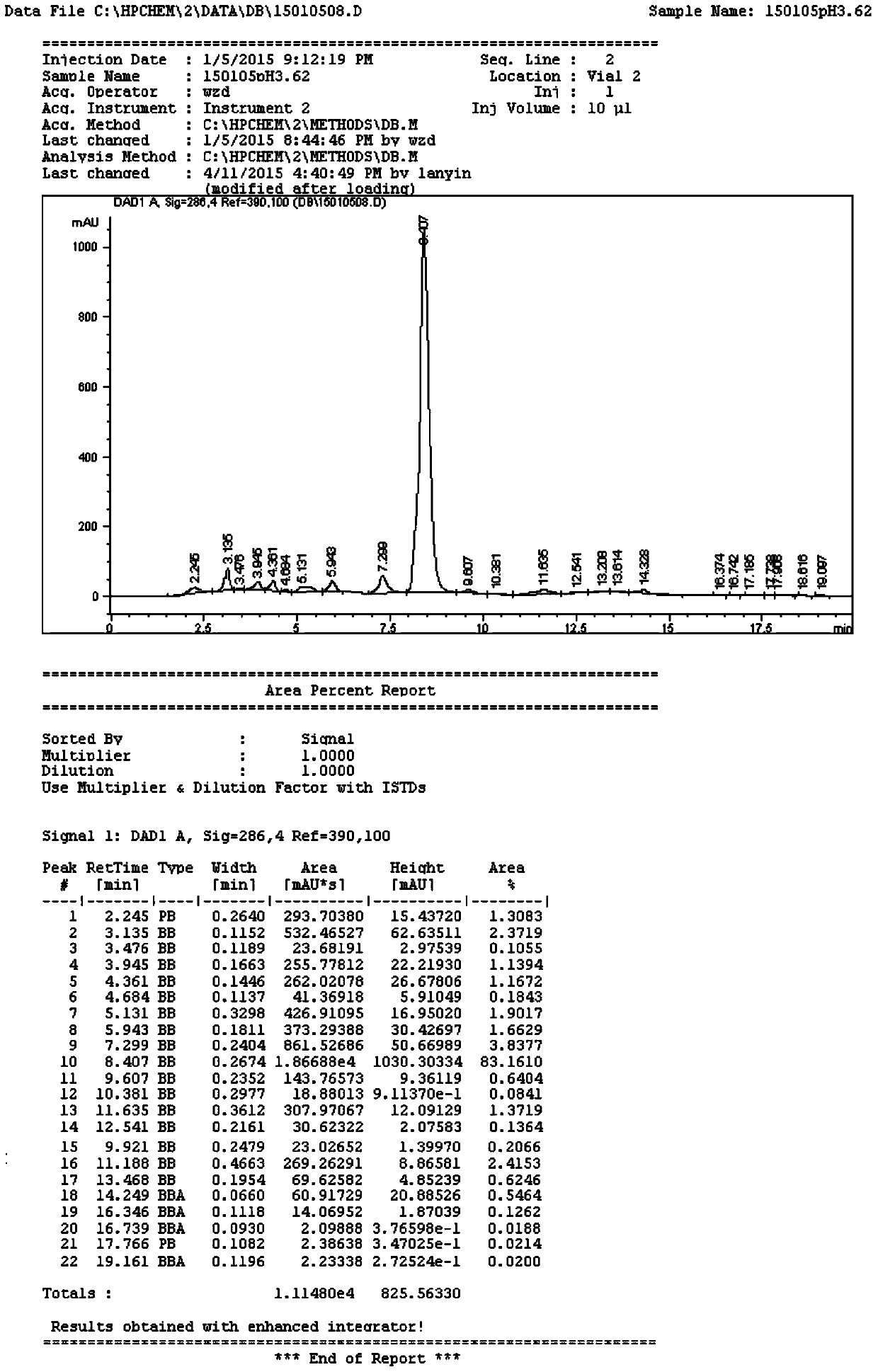

Technique for extracting L-tryptophan in fermentation liquor

InactiveCN101565395AHigh yieldIncrease the adsorption equivalentOrganic chemistryUltrafiltrationSal ammoniacChemistry

The invention pertains to the technical field of biological engineering and particularly discloses a technique for extracting L-tryptophan in fermentation liquor. The fermentation liquor is filtered by a ceramic film, filtered liquid is adsorbed by polymeric adsorbent and resolved by ammonia, and L-tryptophan product is obtained through decolorizing, filtering and drying resolved liquid sequentially. The technique is simple and environment-friendly. The L-tryptophan extracted by the technique has both high yield and stable quality.

Owner:河南孟成生物药业股份有限公司

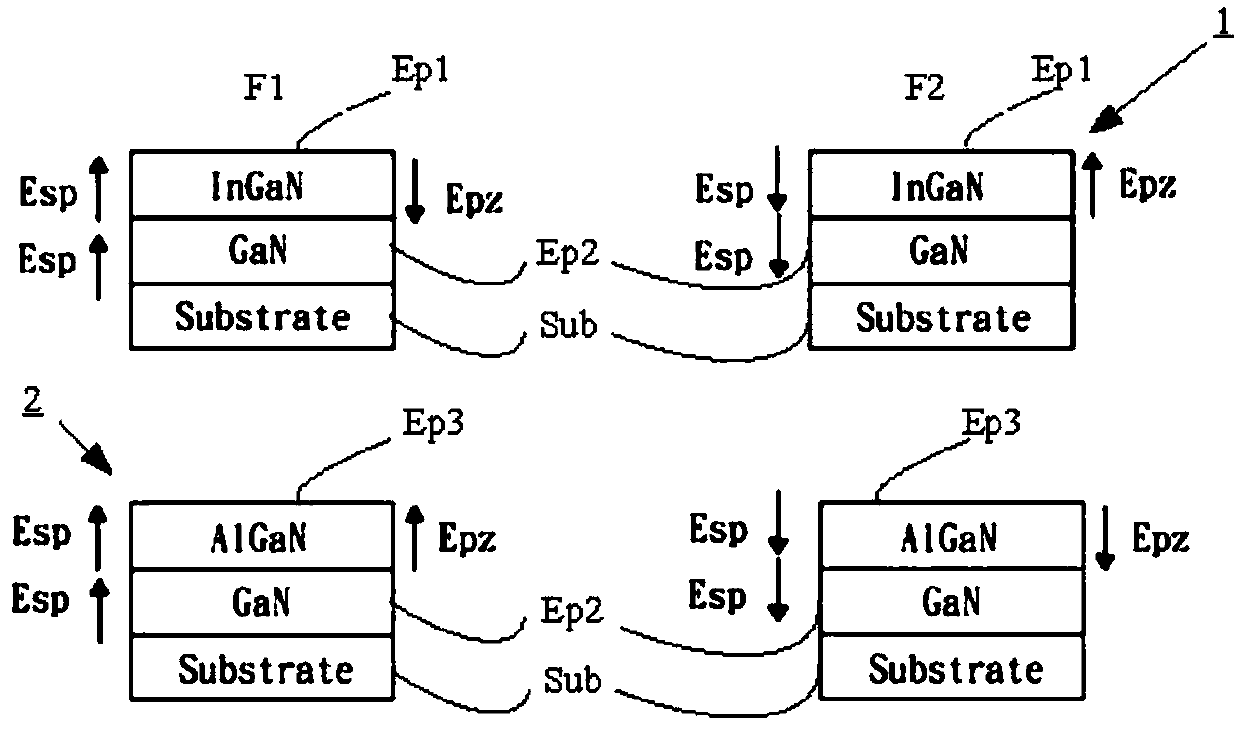

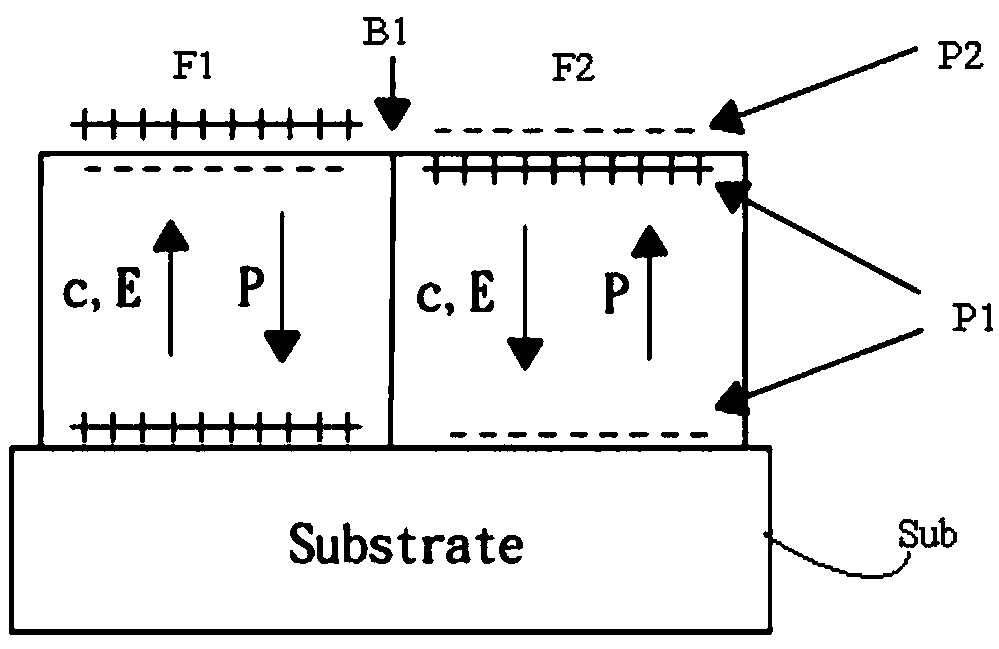

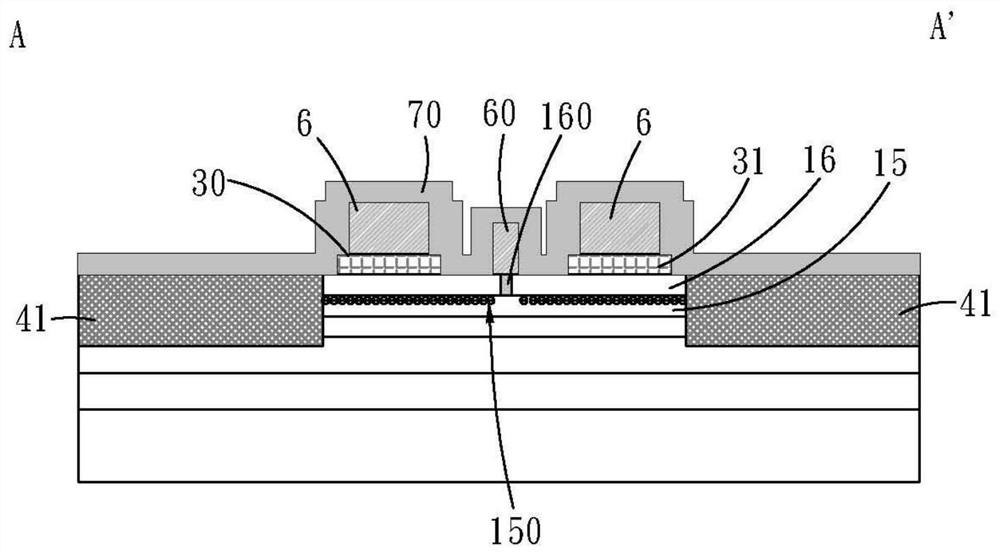

Epitaxial structure of ga-face group III nitride, active device, and method for fabricating the same

ActiveCN107507856ASolve process bottlenecksTransistorSolid-state devicesSchottky barrierHigh electron

The present invention provides an epitaxial structure of Ga-face group III nitride, its active device, and the method for fabricating the same. The epitaxial structure of Ga-face AlGaN / GaN comprises a substrate, an i-GaN (C-doped) layer on the substrate, an i-Al(y)GaN buffer layer on the i-GaN (C-doped) layer, an i-GaN channel layer on the i-Al(y)GaN buffer layer, and an i-Al(x)GaN layer on the i-GaN channel layer, where x=0.1-0.3 and y=0.05-0.75. By using the p-GaN inverted trapezoidal gate or anode structure in device design, the 2DEG in the epitaxial structure of Ga-face group III nitride below the p-GaN inverted trapezoidal structure will be depleted, and thus fabricating p-GaN gate enhancement-mode (E-mode) AlGaN / GaN high electron mobility transistors (HEMTs), p-GaN anode AlGaN / GaN Schottky barrier diodes (SBDs), or hybrid devices.

Owner:黄知澍

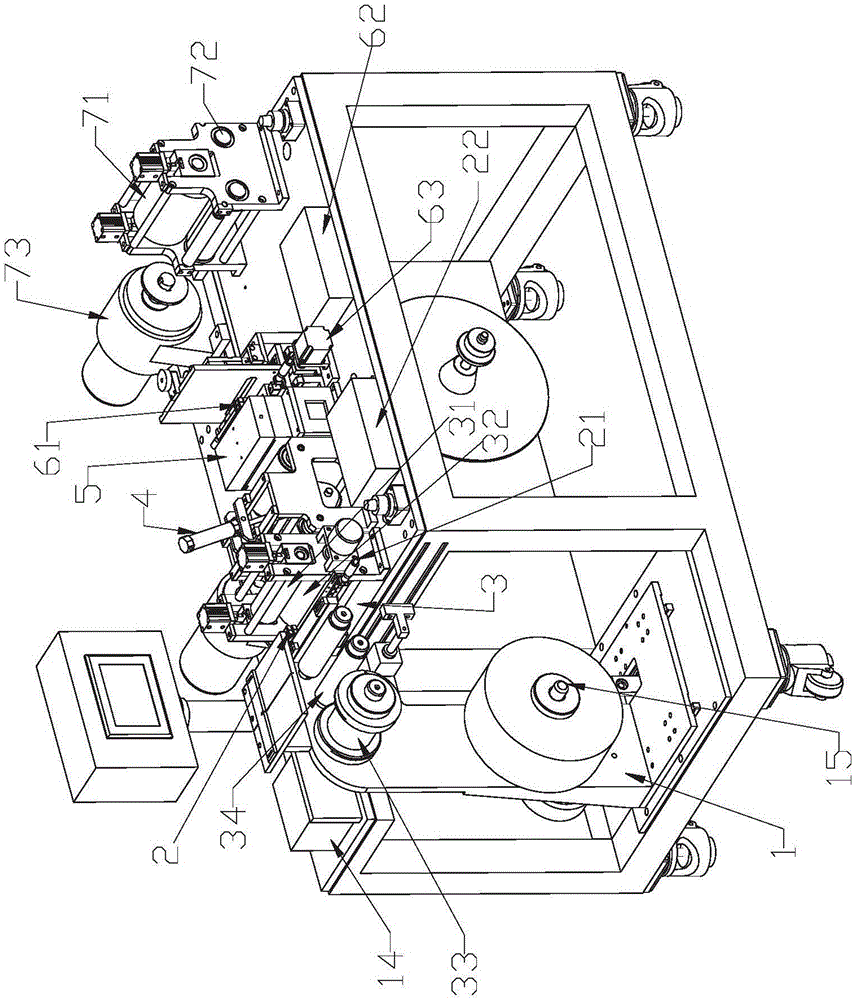

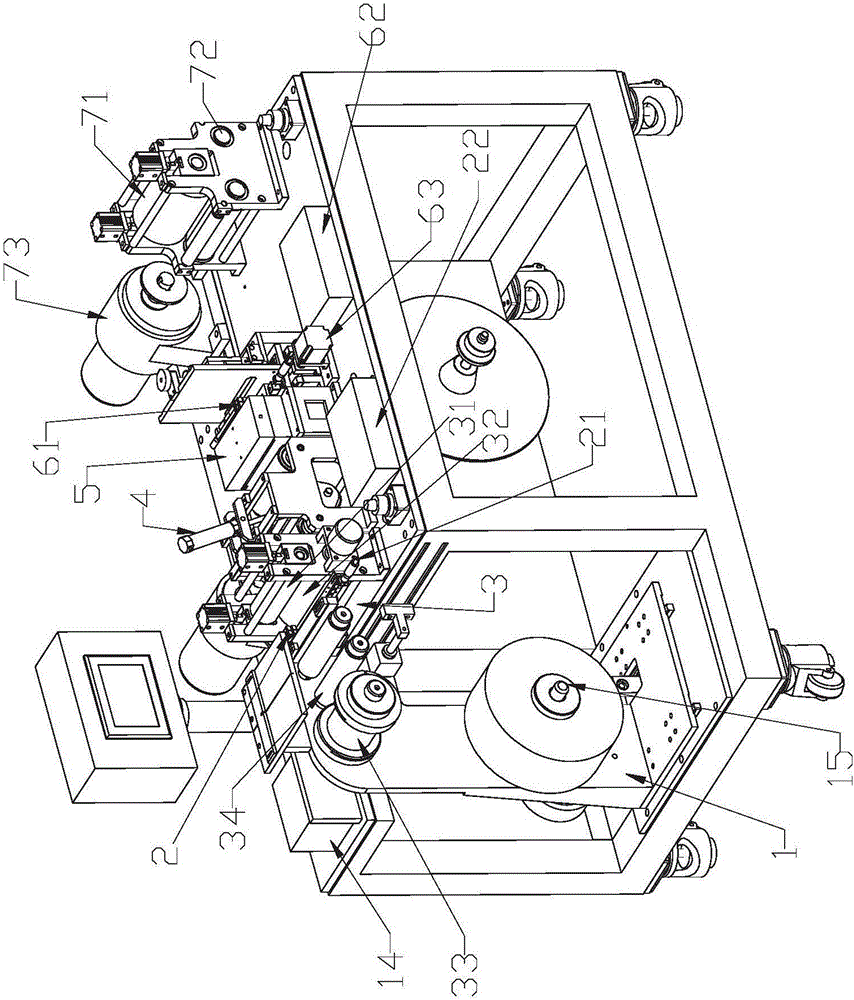

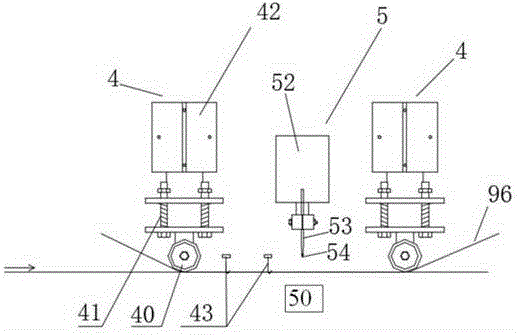

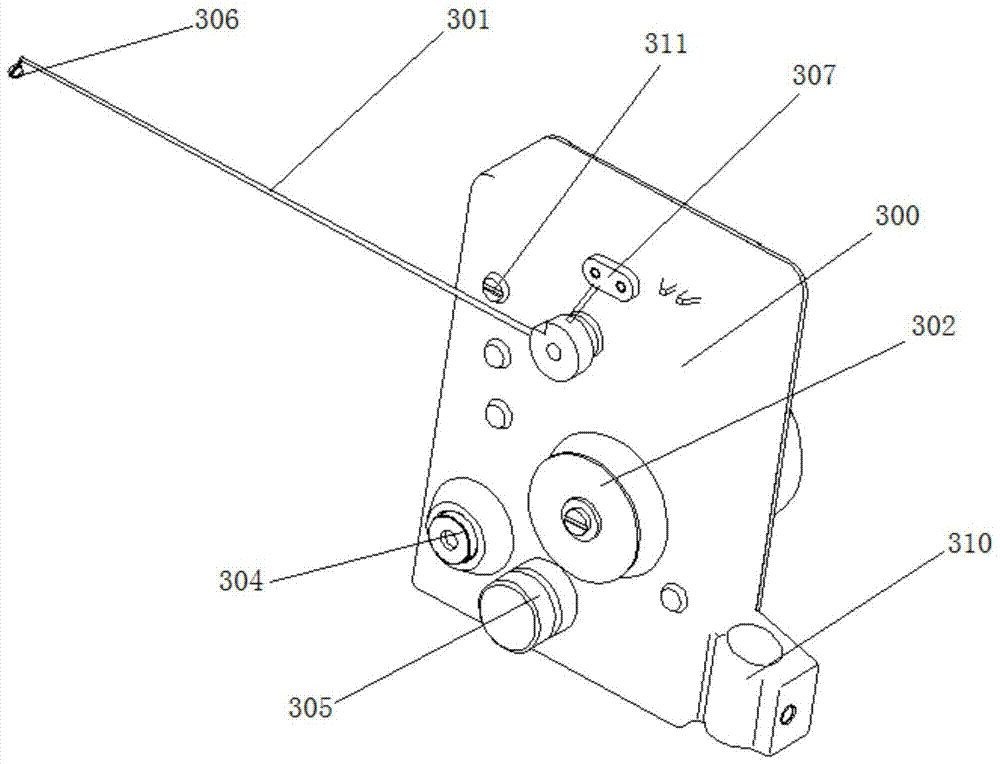

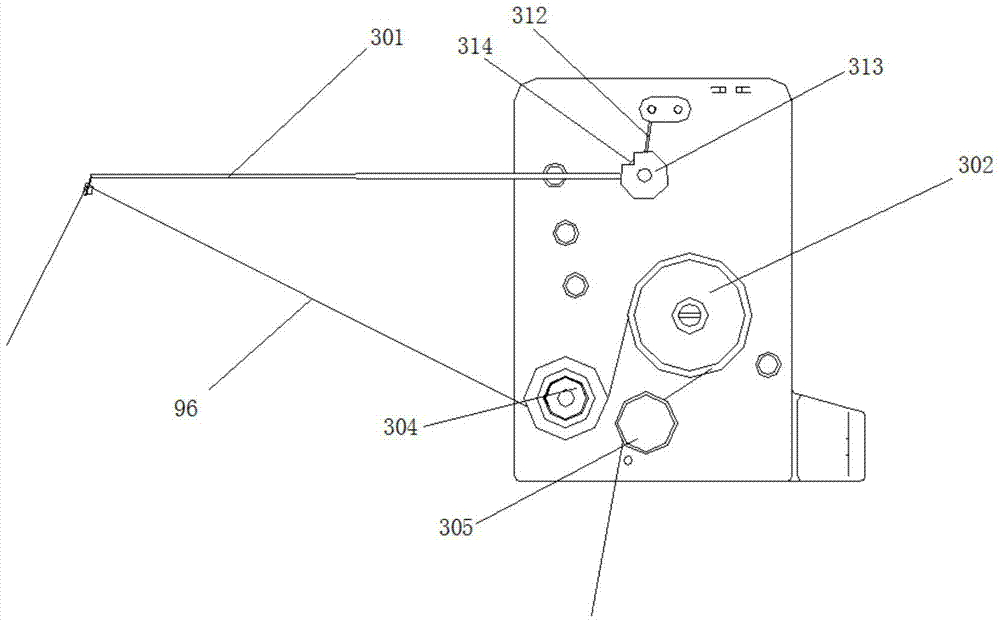

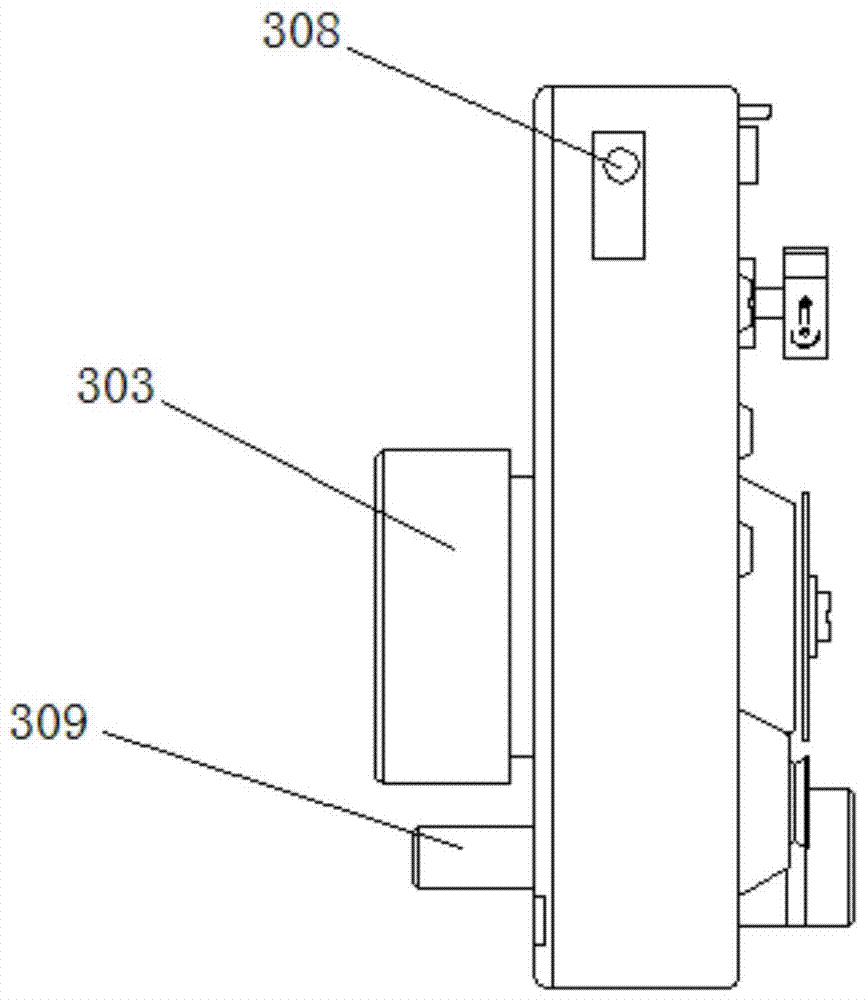

Electrode plug manufacturing system and use method thereof

ActiveCN105014222ASolve process bottlenecksReasonable production efficiencyWelding/cutting auxillary devicesHigh frequency current welding apparatusWire cuttingEngineering

The invention relates to an electrode plug manufacturing system and a use method thereof. The electrode plug manufacturing system comprises a supporting device, a tool circulation device, a bridge wire positioning device, a bridge wire welding device, a wire cutting device, a micro tension wire feeding device and a feeding device used for feeding an electrode plug basic body into the tool circulation device, wherein the tool circulation device comprises a circulation track and pushing devices; tool moving guide grooves are formed in the circulation track; the pushing devices push a tool to move in the circulation track; the bridge wire positioning device is arranged on the circulation track; and the bridge wire welding device and the wire cutting device are arranged on the supporting device or the circulation track. The electrode plug manufacturing system has the beneficial effects that full-automatic bridge wire welding can be realized; and the welding efficiency is high.

Owner:SHANGHAI REAL INDAL

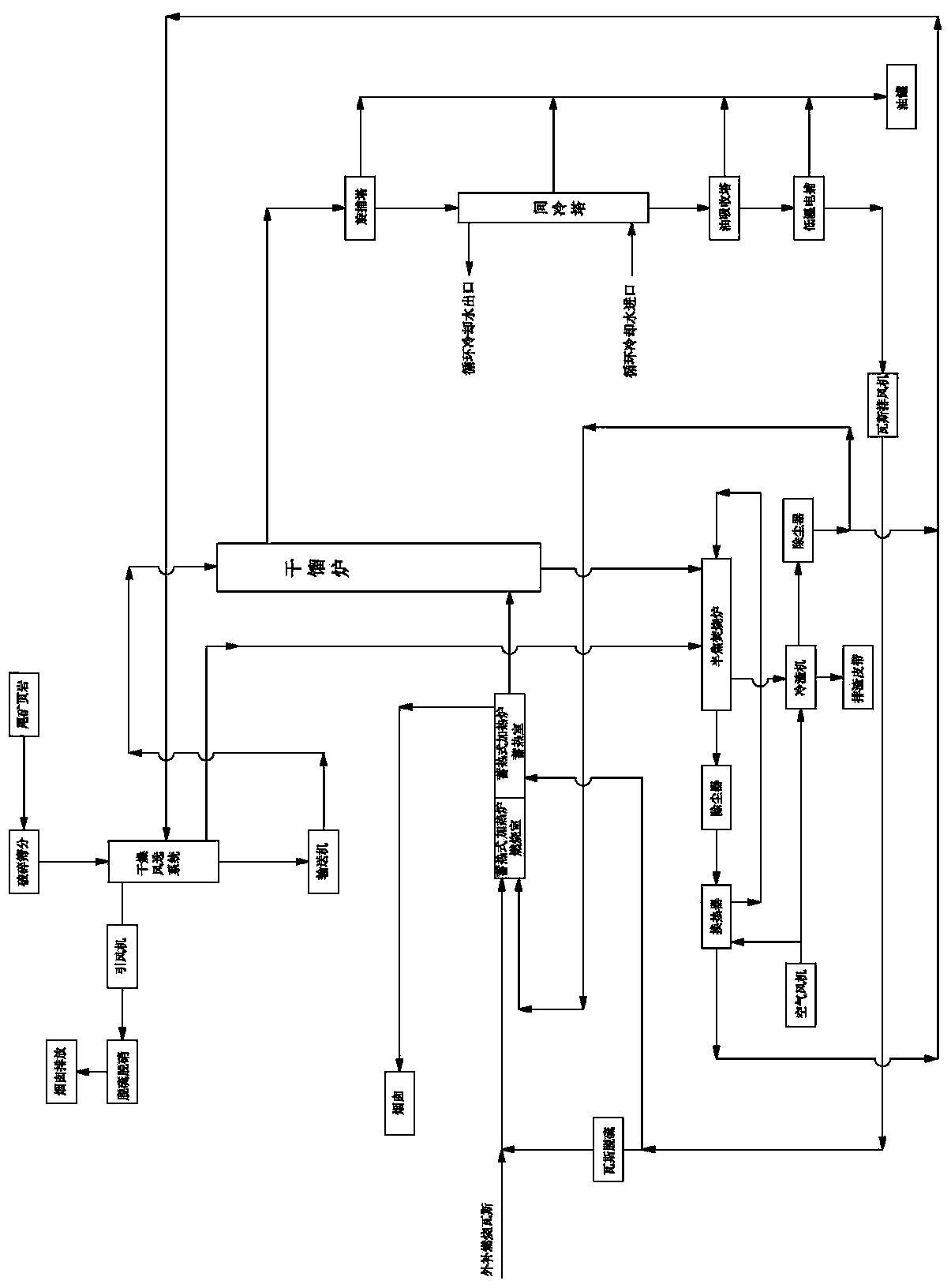

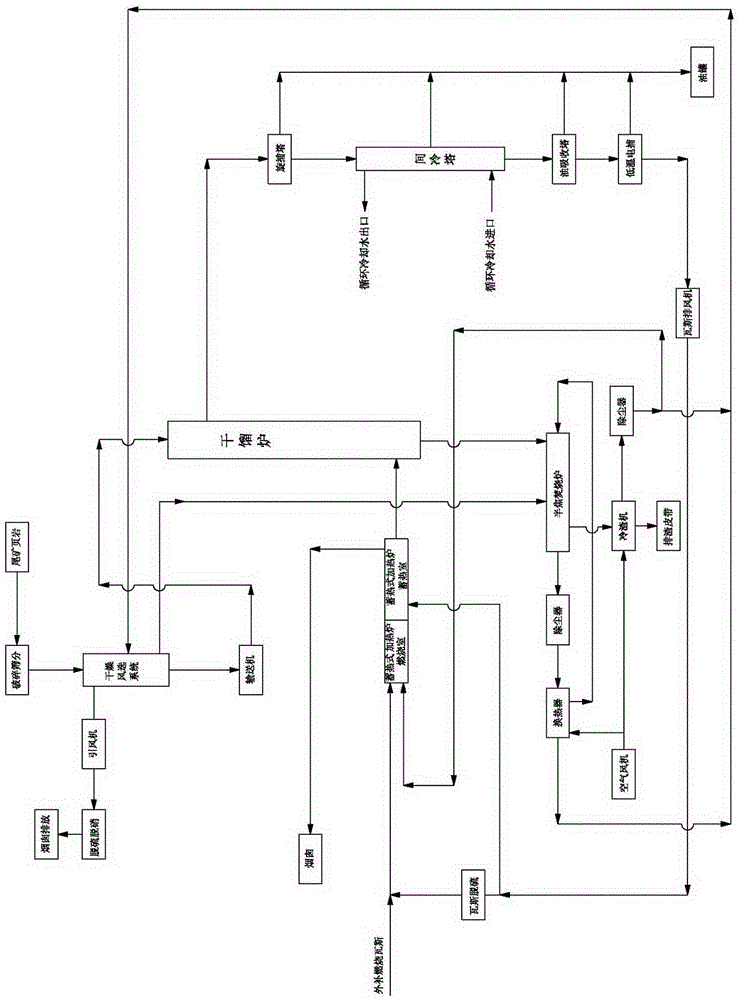

Granule shale gas heat carrier destructive distillation technology

ActiveCN104004533AEnsure heating stabilityReduce heat loadDirect heating destructive distillationSpecial form destructive distillationHeat carrierEngineering

The invention discloses a granule shale gas heat carrier destructive distillation technology. The technology comprises the steps of raw ore treatment, dry air classification, destructive distillation oil refining, product recovery and incineration heat obtaining. The heat recovery technological measures such as dry air classification and incineration heat obtaining are added, heat generated by burning oil shale semicoke is thoroughly recovered and applied to the whole process of destructive distillation heat consumption, heat efficiency is greatly improved, production cost is reduced, and the granule shale gas heat carrier destructive distillation technology is made to mature. The technological shortage of low heat efficiency is effectively overcome, output is larger than cost, benefits can be obtained through industrialization, the novel destructive distillation technology is developed, and the use ratio of resources is greatly increased.

Owner:FUSHUN MINING IND GROUP

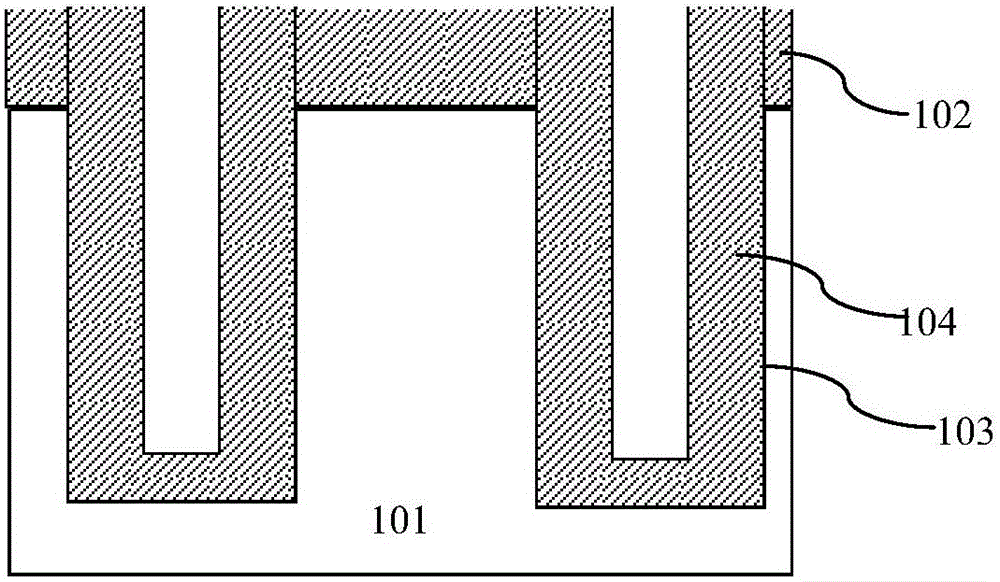

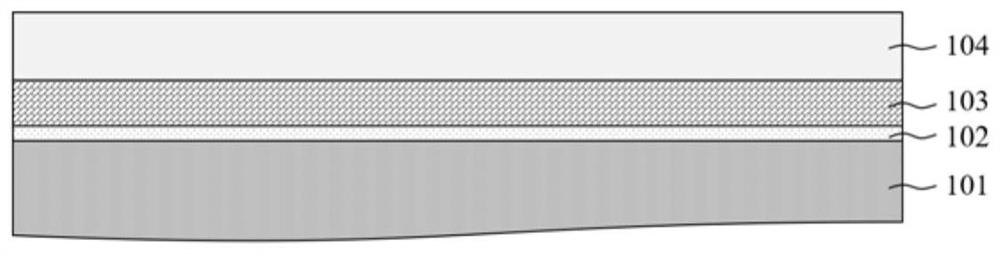

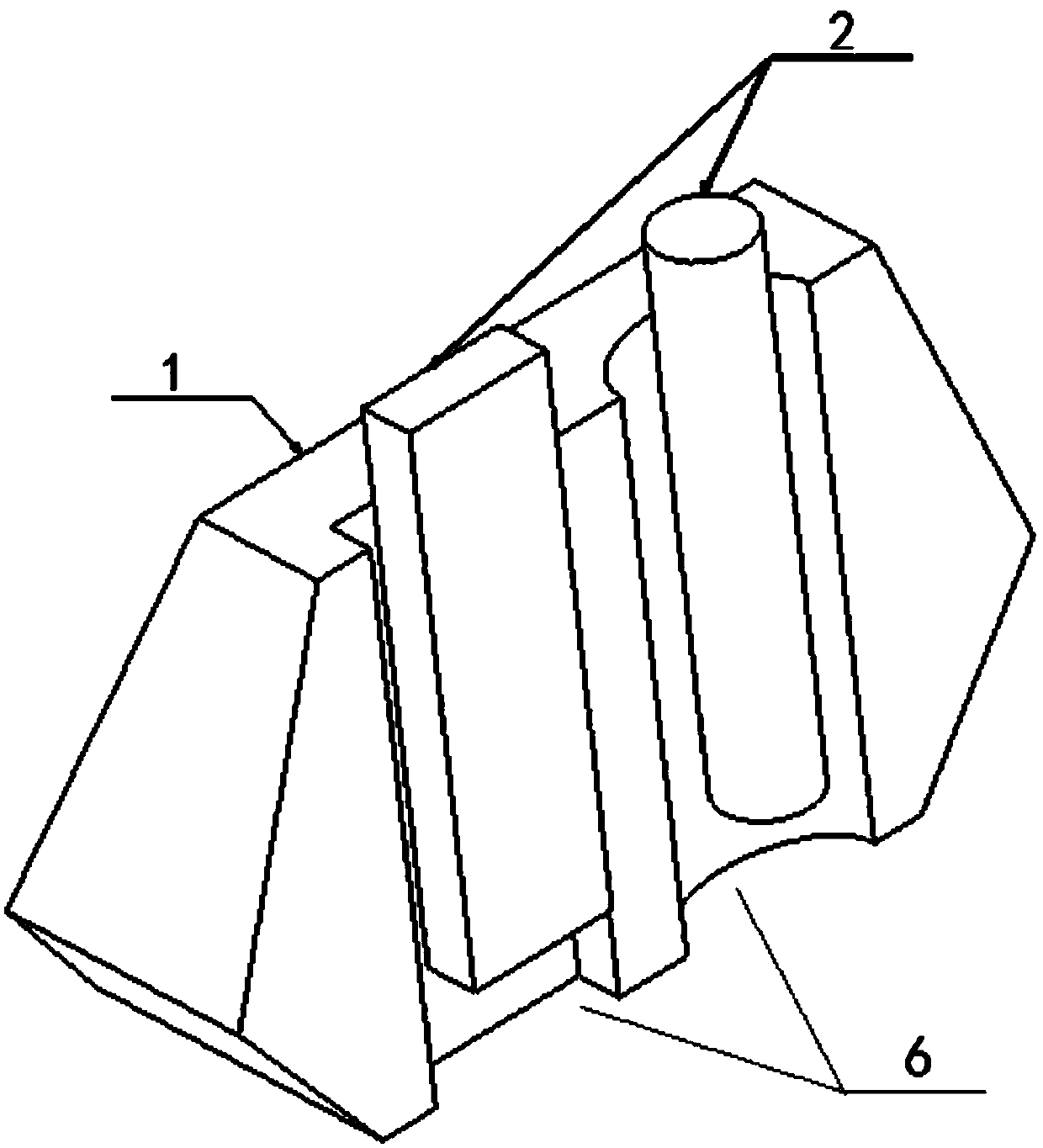

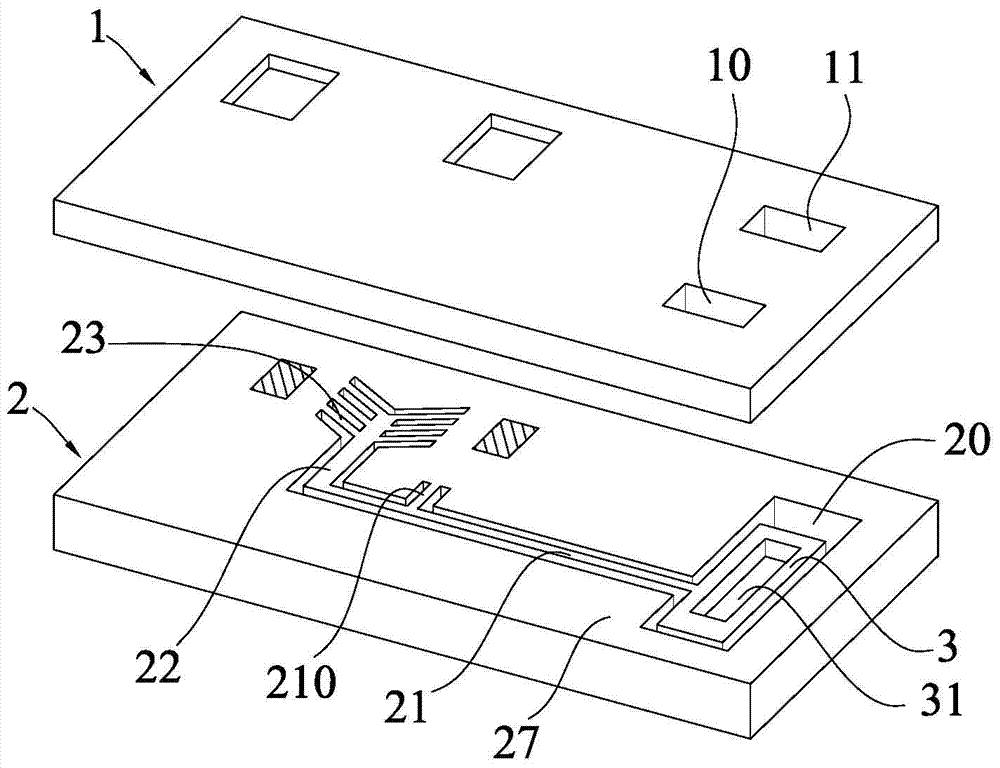

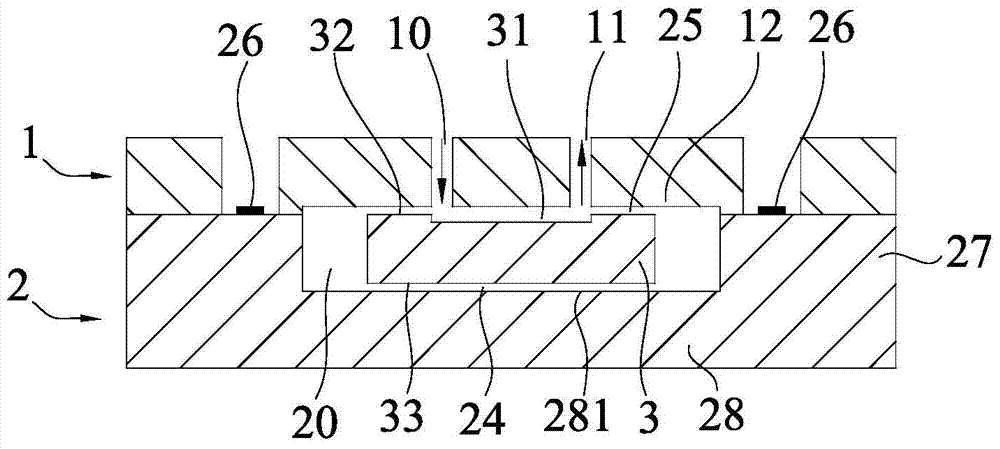

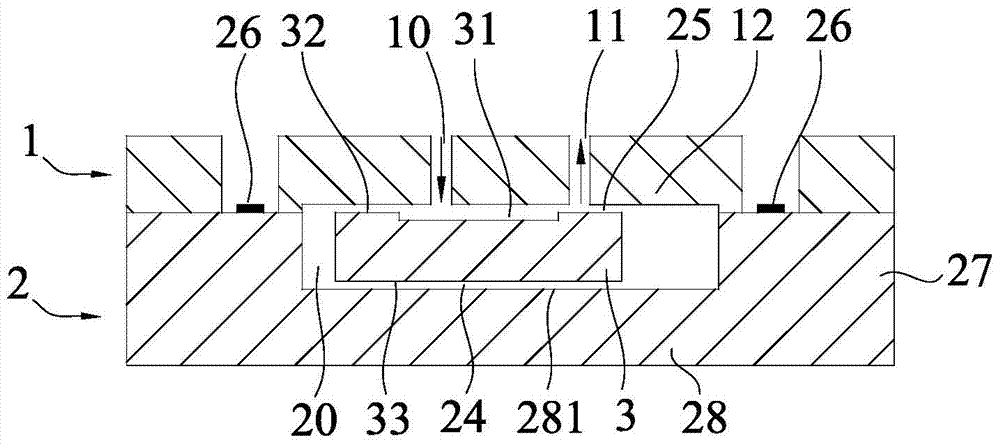

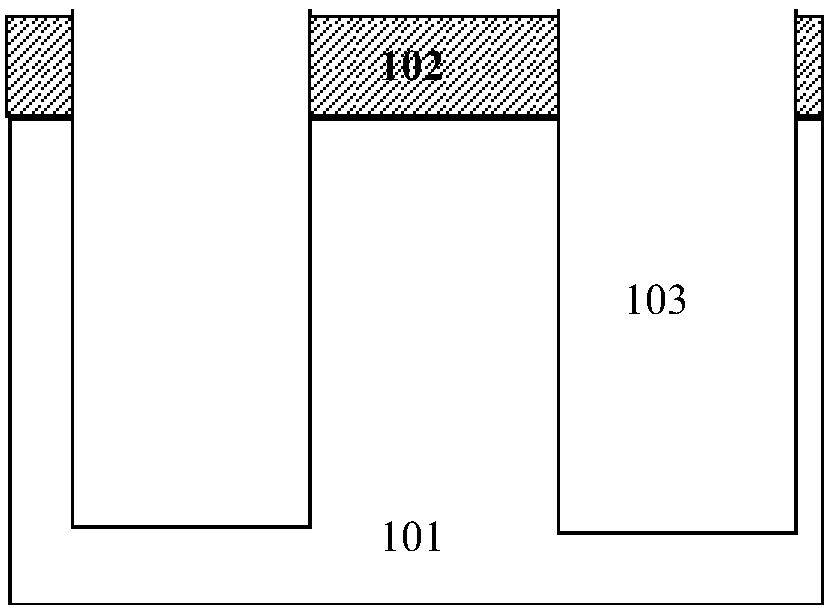

Shield gate trench MOSFET manufacturing method

ActiveCN106057675AReduce leakageSolve process bottlenecksSemiconductor/solid-state device manufacturingSemiconductor devicesConvex structureEtching

The invention discloses a shield gate trench MOSFET manufacturing method. Gate structure forming comprises steps: a hard mask layer is formed, and a gate forming area is defined; a semiconductor substrate is etched to form a deep trench; thermal oxidation is carried out to form a bottom oxidation layer; source polysilicon is formed; back etching of the polysilicon is carried out, and thus, the source polysilicon is flush with the top surface of the hard mask layer, a source polysilicon lateral extension part is formed outside the opening of the bottom oxidation layer and the top part of the bottom oxidation layer inside the opening of the hard mask layer; the hard mask layer is removed to form a top convex structure of the source polysilicon; the source polysilicon lateral extension part serves as a self-alignment mask to etch the bottom oxidation layer to form top trenches and inter-polysilicon isolation oxidation layers at two side surfaces of the source polysilicon; a gate dielectric layer is formed on the side surface of the top trench; and the top trench is filled to form a polysilicon gate, and chemical mechanical polishing is carried out. Thus, while the threshold voltage of the device is reduced, the gate source electric leakage of the device is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

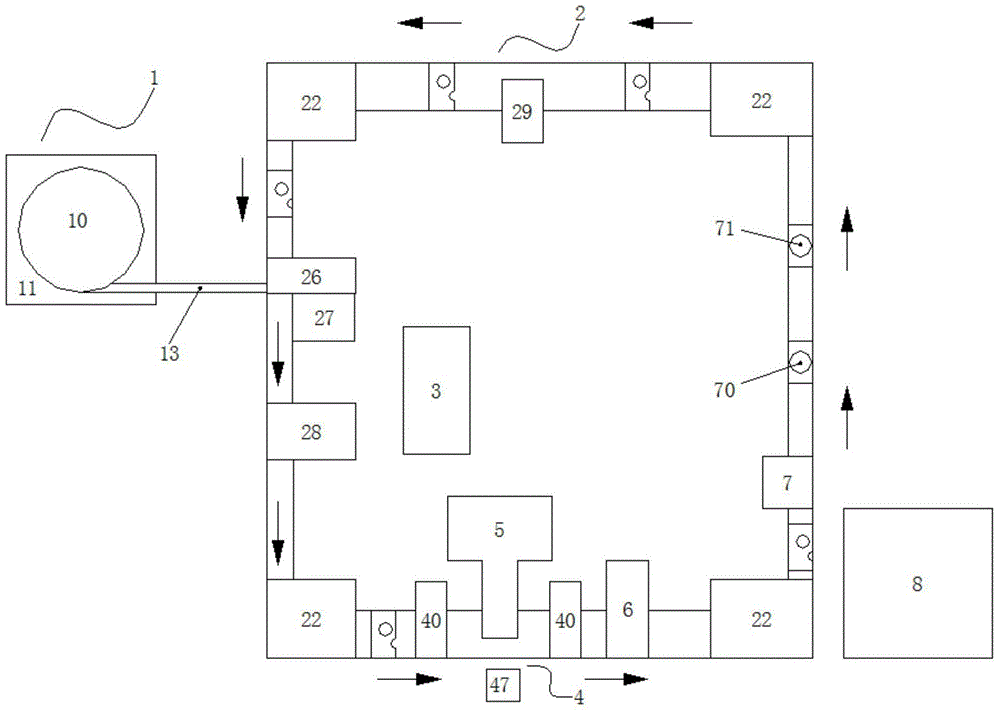

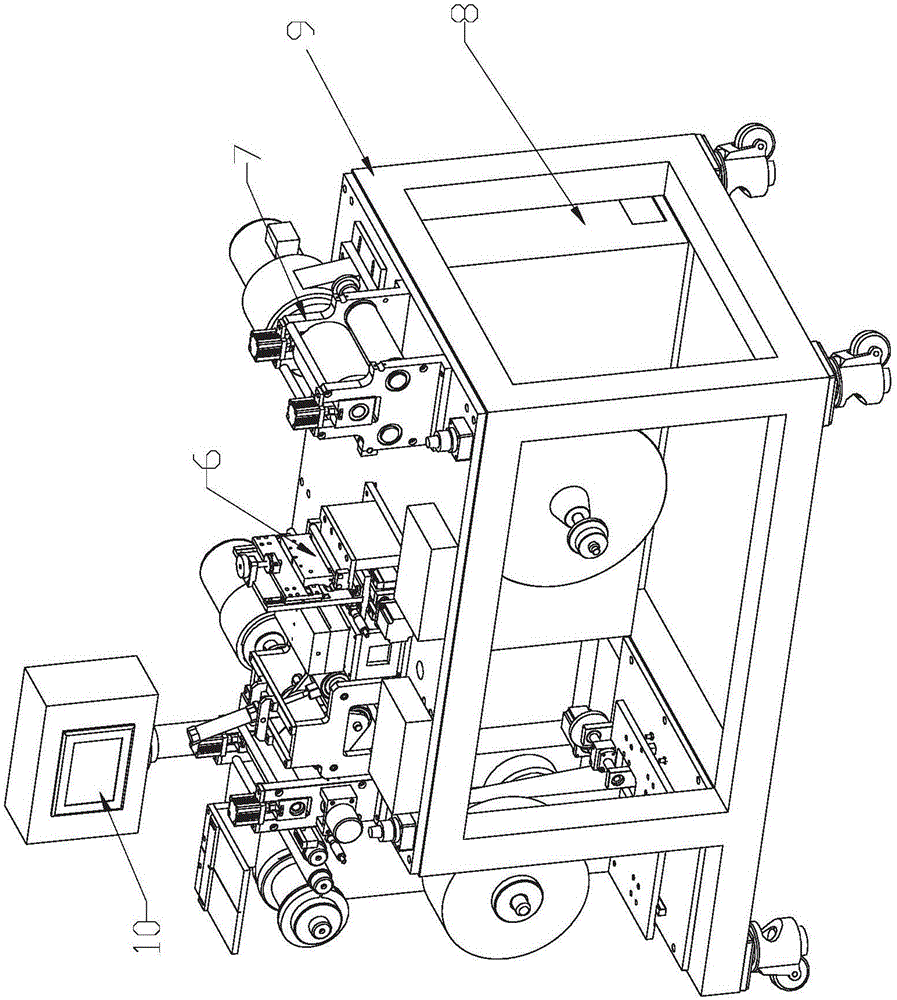

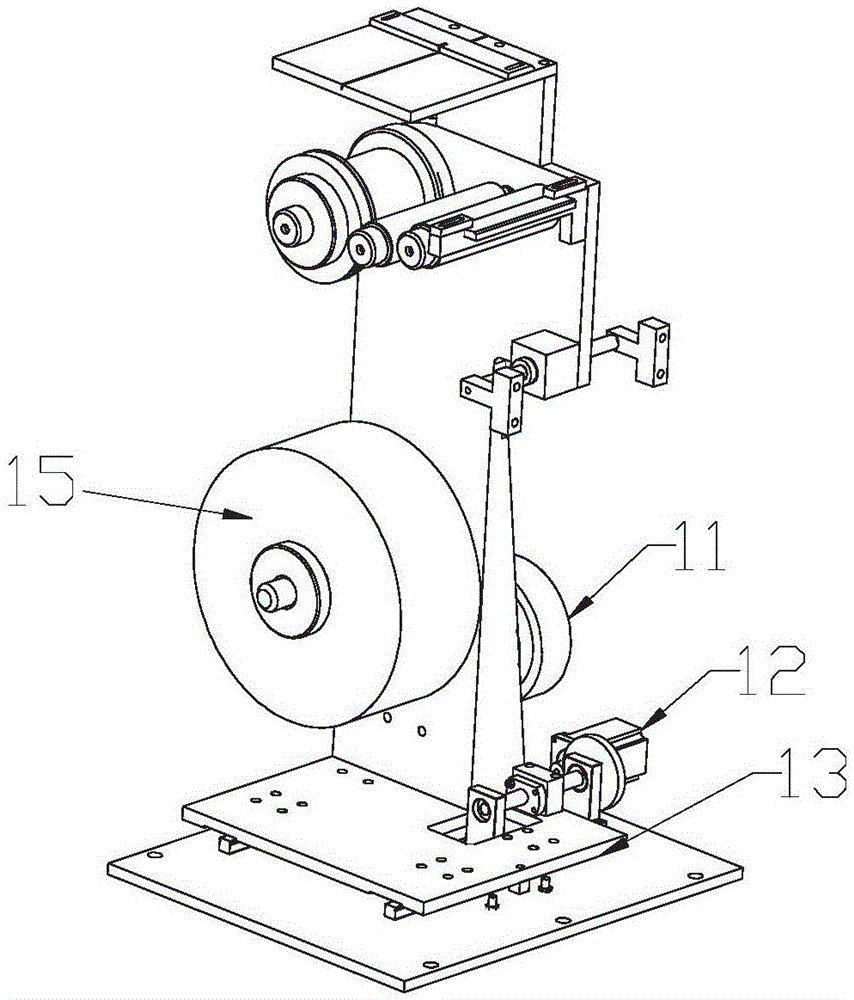

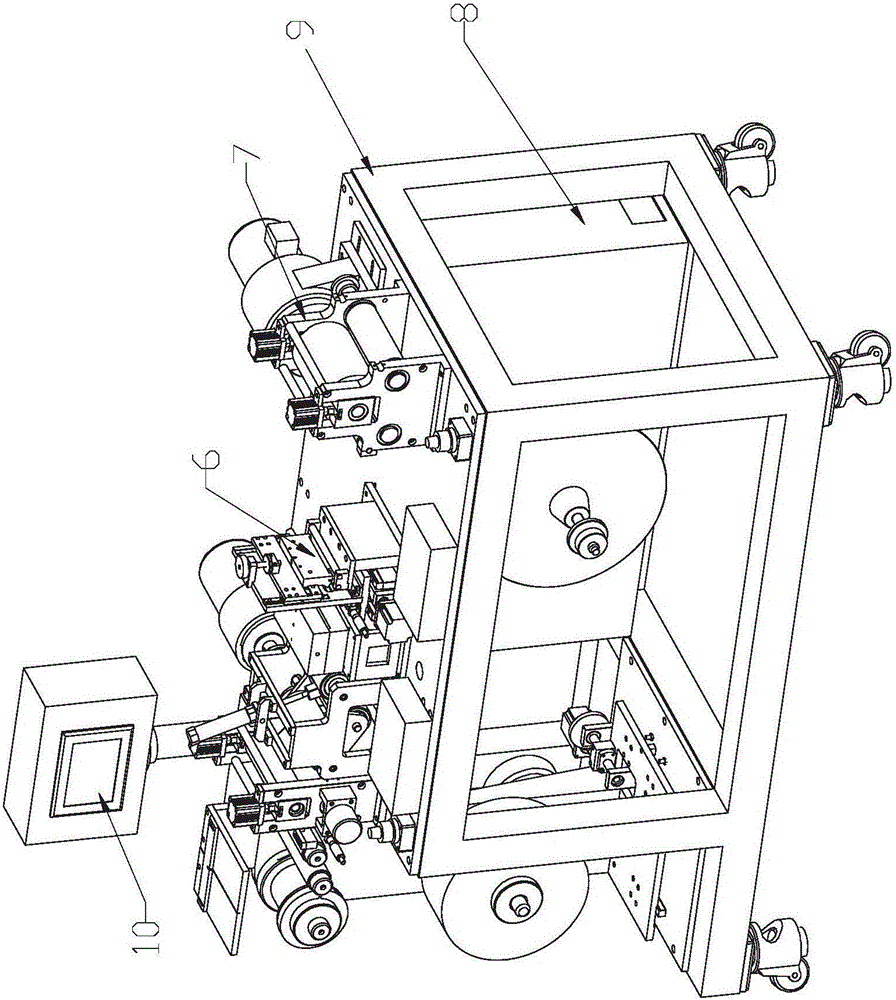

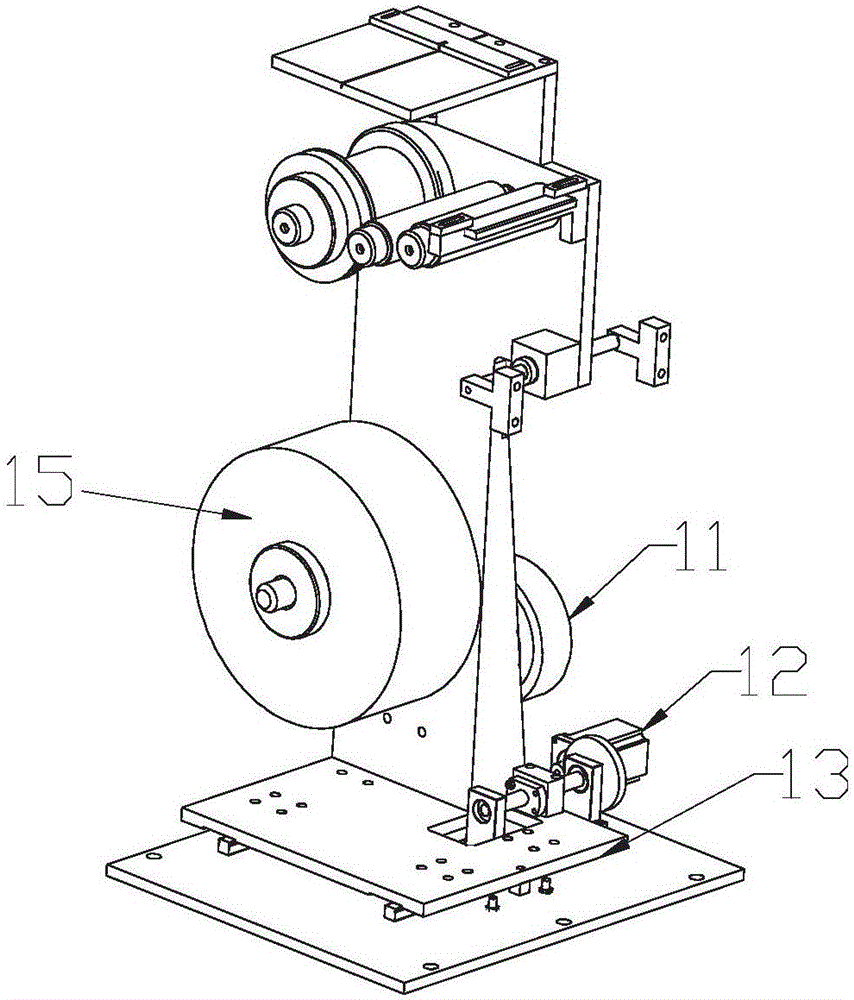

Automatic stripping device of flexible flat cable

ActiveCN105097137AIncrease productivityLess bad processCable/conductor manufactureTectorial membraneEngineering

The invention relates to an automatic stripping device of a flexible flat cable. The automatic stripping device sequentially comprises a discharging mechanism, a strip deviation correction sensor, a feeding mechanism, a flexible flat cable tension mechanism, a heating blowing mechanism, a stripping mechanism, a leading-out mechanism and a scrap edge receiving mechanism from left to right. The automatic stripping device of the flexible flat cable substitutes a post-engineering processing operation mode such as traditional double-sided adhesive tape and protective film pasted one by one; a particular process flow comprises the following steps of: firstly, fabricating the flexible flat cable by using a flexible flat cable processing device; secondly, carrying out the post-engineering processing operation such as double-sided adhesive tape and protective film pasted in a roll; thirdly, stripping by using the automatic stripping device of the flexible flat cable; and finally, cutting the flexible flat cable by using an automatic cutting machine. Compared with the traditional operation mode, the operation mode has the advantages that production efficiency is high, manufacturing procedure deficiency is few, and a large amount of labor is not needed.

Owner:东莞市诚业机械科技有限公司

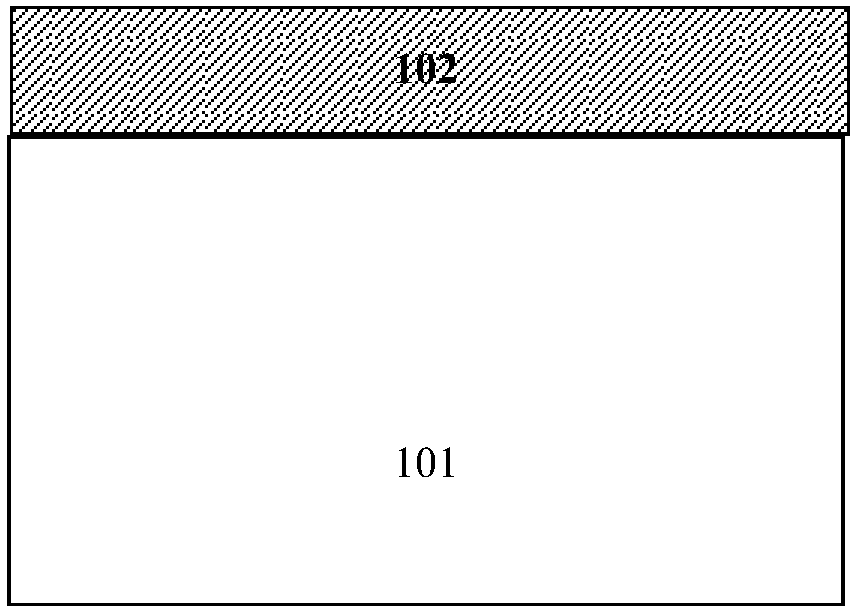

Panchromatic Micro/Nano LED array direct epitaxy method and structure

InactiveCN112331747ASolve process bottlenecksHigh LED DensitySolid-state devicesSemiconductor devicesLed arrayPhysical chemistry

The invention discloses a panchromatic Micro / Nano LED array direct epitaxy method and structure. The panchromatic Micro / Nano LED array direct epitaxy method comprises the following steps: 1) epitaxially growing a buffer layer, an unintentional doping layer and an n-type layer on a substrate; 2) depositing a first dielectric layer on the n-type layer, manufacturing a first group of micro or nano-pore arrays on the first dielectric layer, and epitaxially growing a first light-emitting unit in the manufactured first group of micron or nano-pore arrays; 3) manufacturing a second dielectric layer,manufacturing a second group of micro or nano-pore arrays on the second dielectric layer, and epitaxially growing a second light-emitting unit in the manufactured second group of micro or nano-pore arrays; 4) manufacturing a third dielectric layer, manufacturing a third group of micro or nano-pore arrays on the third dielectric layer, and epitaxially growing a third light-emitting unit in the manufactured third group of micro or nano-pore arrays; and 5) removing the corrosion of the dielectric layer by using a chemical solution to expose the light-emitting unit. The problem of huge transfer issolved, the panchromatic Micro / Nano LED array can be directly grown in an epitaxial mode, and the method and the structure have huge application potential.

Owner:XIAMEN UNIV

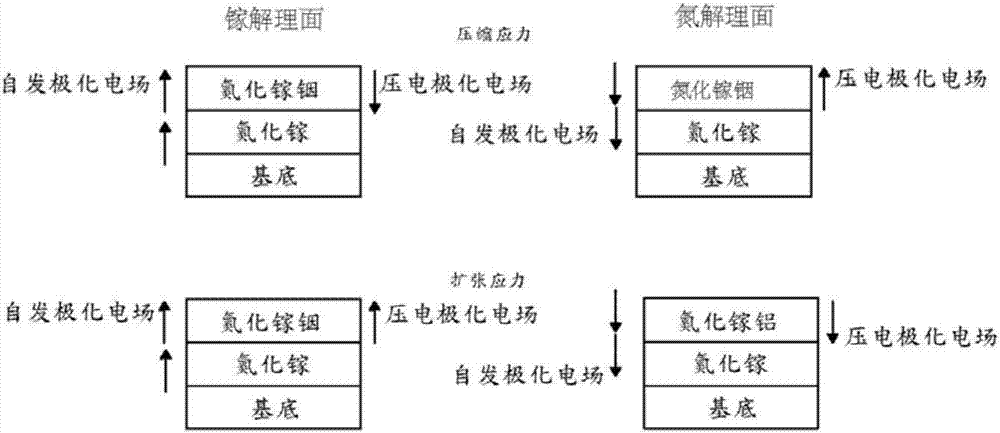

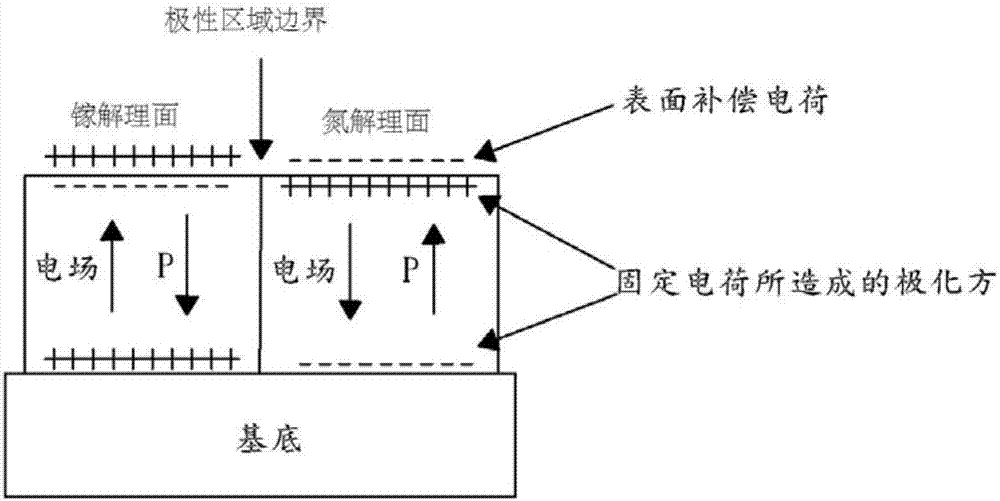

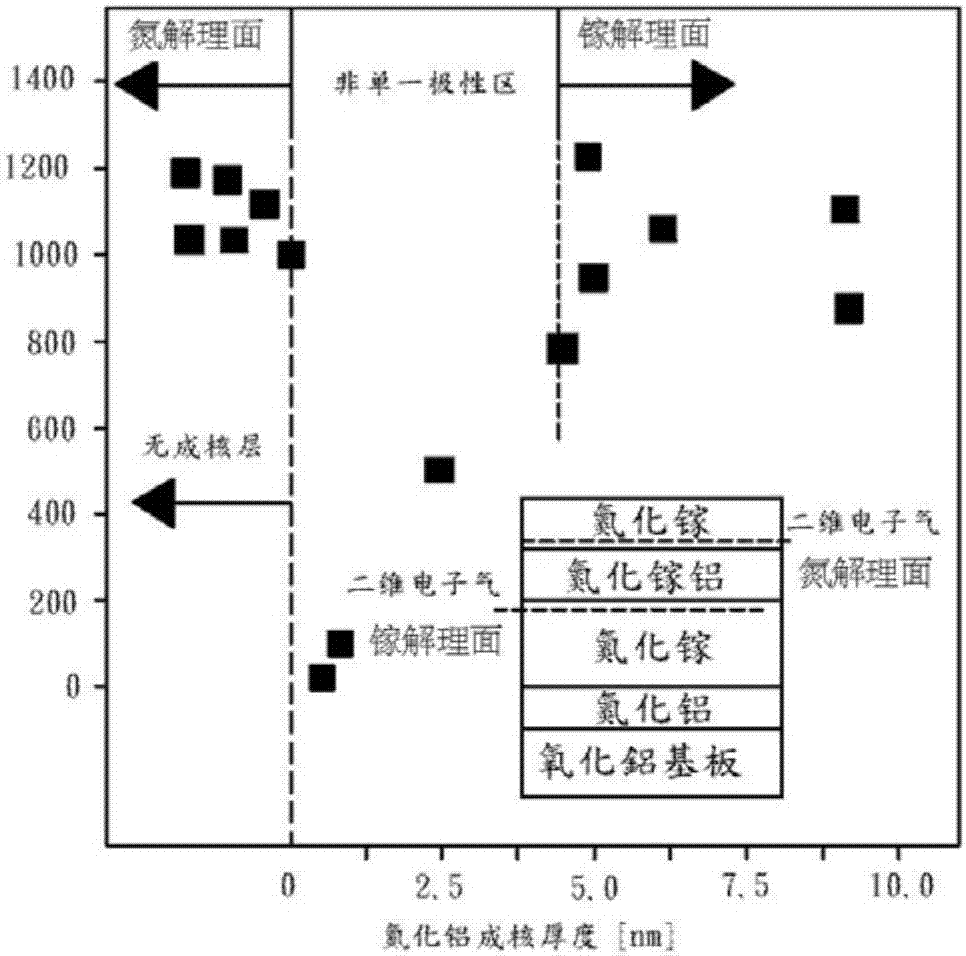

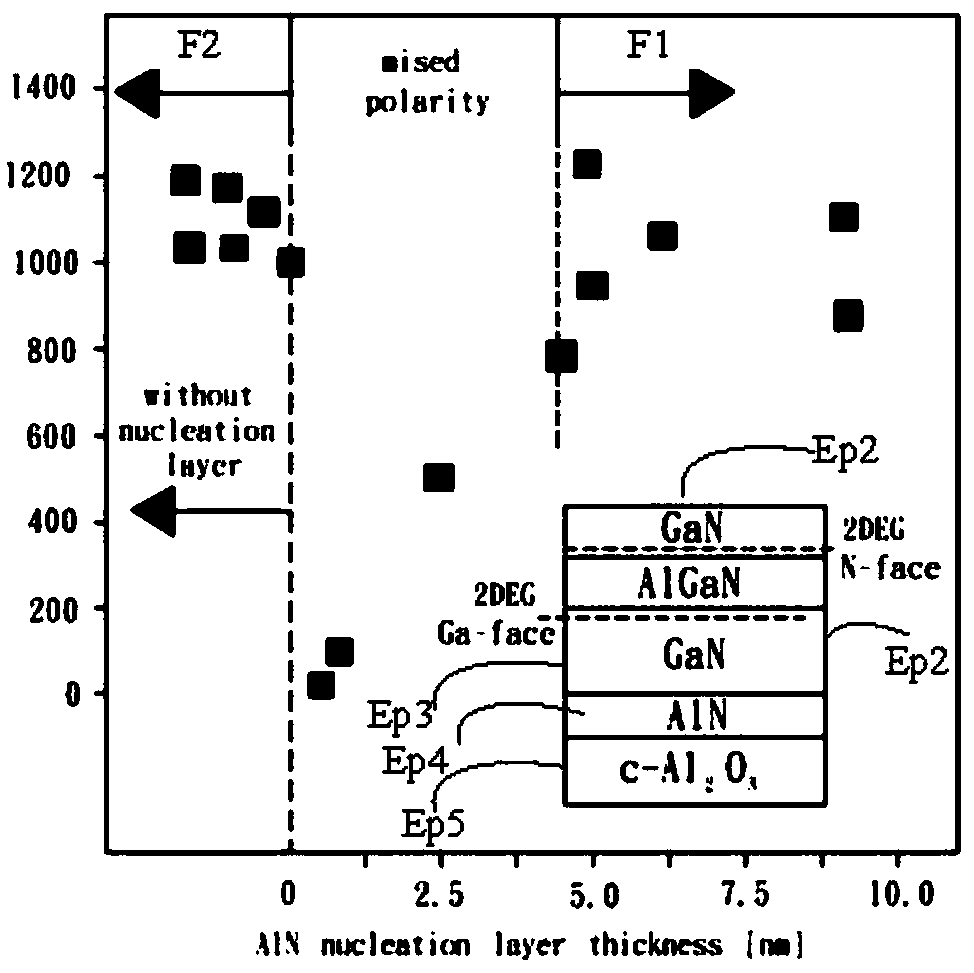

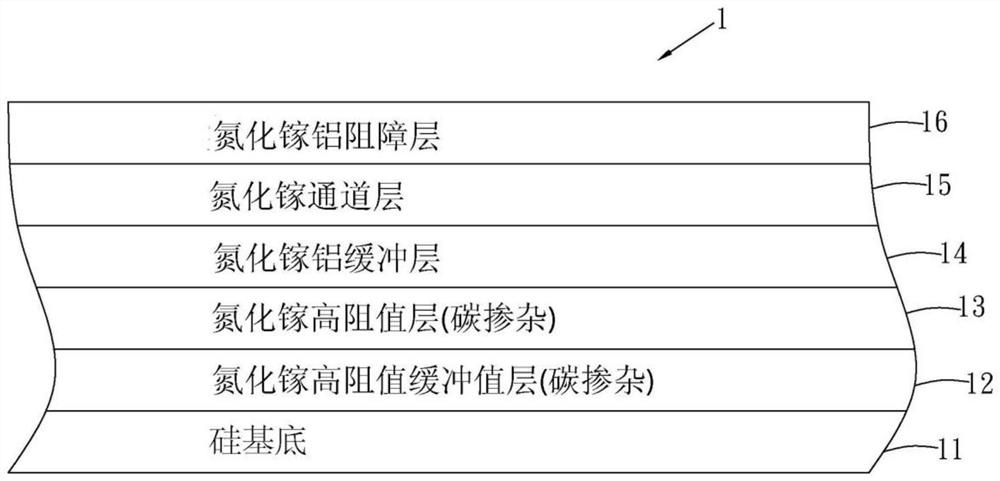

N-face AlGaN/GaN epitaxial structure, active component of N-face AlGaN/GaN epitaxial structure and integrated polarity inversion manufacturing method of N-face AlGaN/GaN epitaxial structure

PendingCN110931550ASolve process bottlenecksSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographyActive component

The invention relates to an N-face AlGaN / GaN epitaxial structure, an active component thereof and a manufacturing method of the N-face AlGaN / GaN epitaxial structure. The structure comprises a substrate; a buffer layer which is positioned on the silicon substrate and is doped with carbon; a GaN layer with carbon doping which is positioned on the buffer layer with carbon doping; an intrinsic Al (y)GaN buffer layer which is positioned on the intrinsic GaN carbon doped layer; an intrinsic GaN channel layer which is positioned on the intrinsic Al (y) GaN buffer layer; and an intrinsic Al (x) GaN layer which is positioned on the intrinsic GaN channel layer, X is equal to 0.1 to 0.3, and y is equal to 0.05 to 0.75. According to the assembly, a two-dimensional electron gas in an N-face AlGaN / GaNepitaxial structure can be in a depletion state below a P-GaN inverted trapezoidal structure by virtue of a P-GaN inverted trapezoidal gate or an anode structure; wherein the two-dimensional electrongas is located at the junction of the intrinsic GaN channel layer and the intrinsic Al (y) GaN layer; thereafter, active components such as a P-type gallium nitride gate enhanced AlGaN / GaN high-speedelectron mobility transistor and the like are manufactured by the structure.

Owner:黄知澍

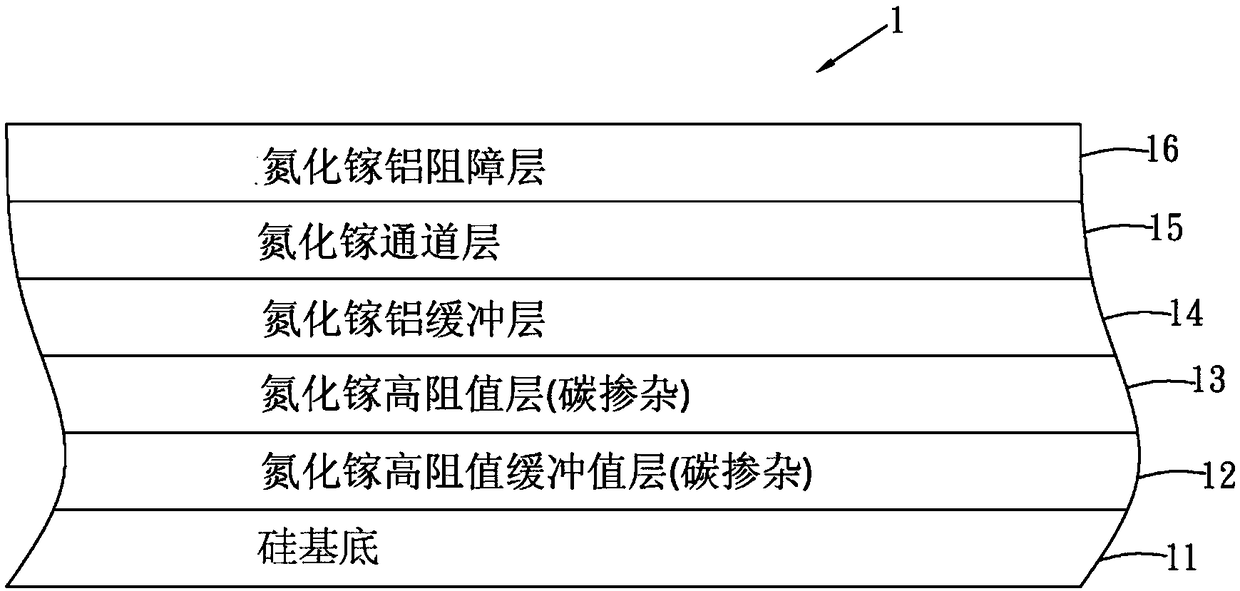

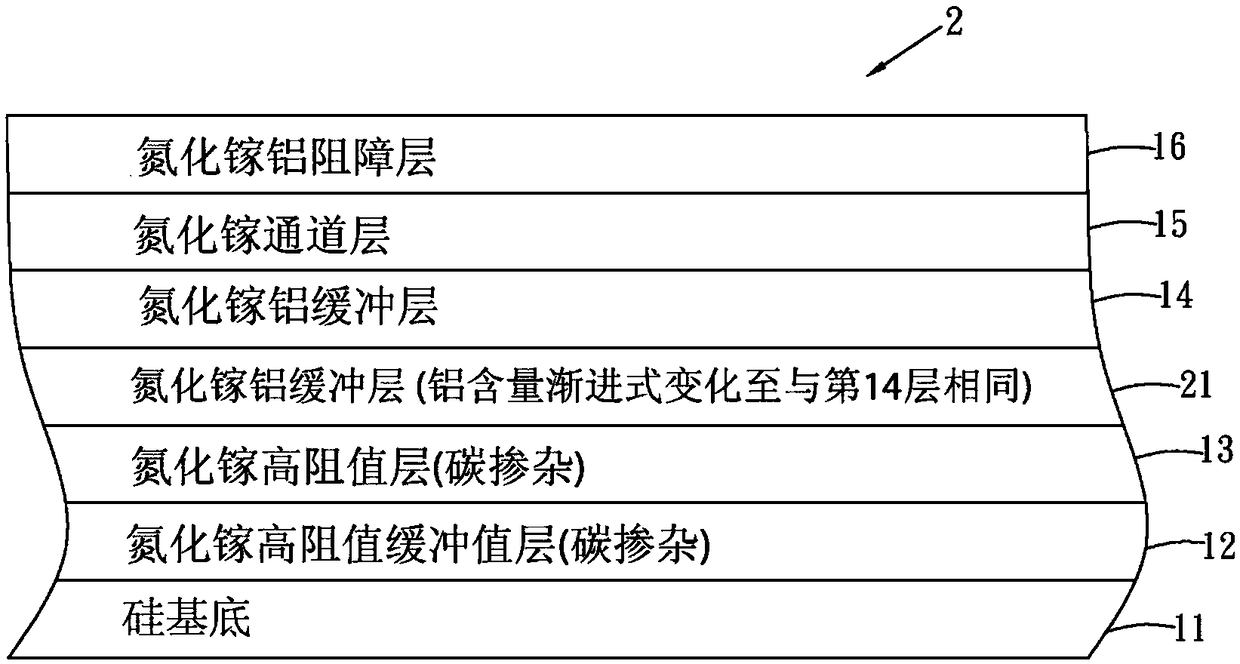

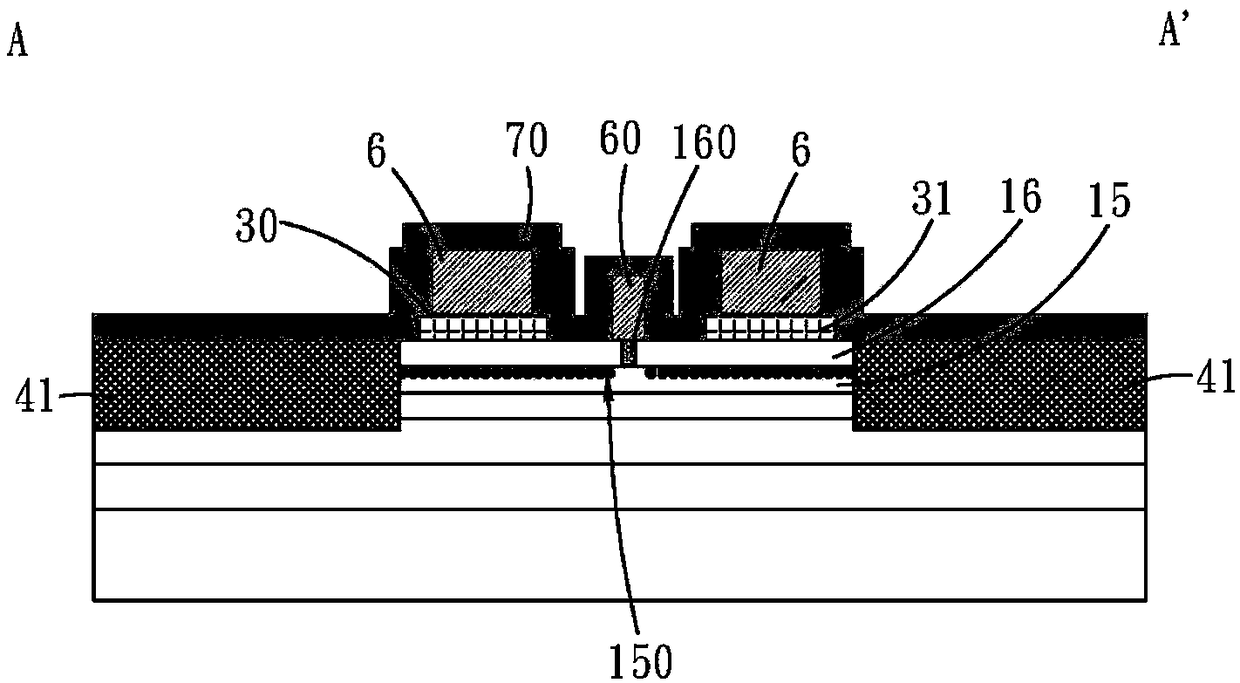

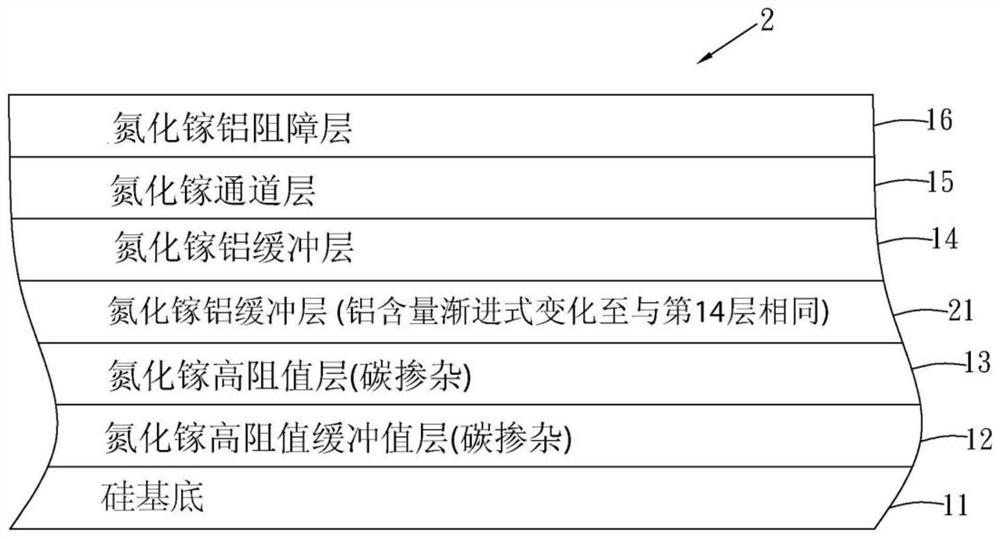

Group-III/nitride epitaxial structure, an active element thereof and a manufacturing method thereof

ActiveCN109004026ASolve process bottlenecksSolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceSchottky barrier

The invention relates to a group III / nitride epitaxial structure, an active element thereof and a manufacturing method thereof. The structure includes a substrate; A gallium nitride high resistance layer on the substrate; A gallium aluminum nitride buffer layer located on the gallium nitride high resistance layer; A gallium nitride channel layer located on the gallium aluminum nitride buffer layer; A gallium aluminum nitride barrier layer located on the gallium nitride channel layer; A fluorine ion structure located within the gallium aluminum nitride barrier layer; And a first gate insulatingdielectric layer located on the fluorine ion structure. GaN buffer layer is the problem of blocking electrons from entering the channel layer and reducing the current collapse effect. A GaN reinforcealuminum gallium nitride / GaN high-speed electron mobility transistor, a hybrid Schottky barrier diode or a hybrid device reinforce aluminum gallium nitride / GaN high-speed electron mobility transistorare fabricated by that structure.

Owner:黄知澍

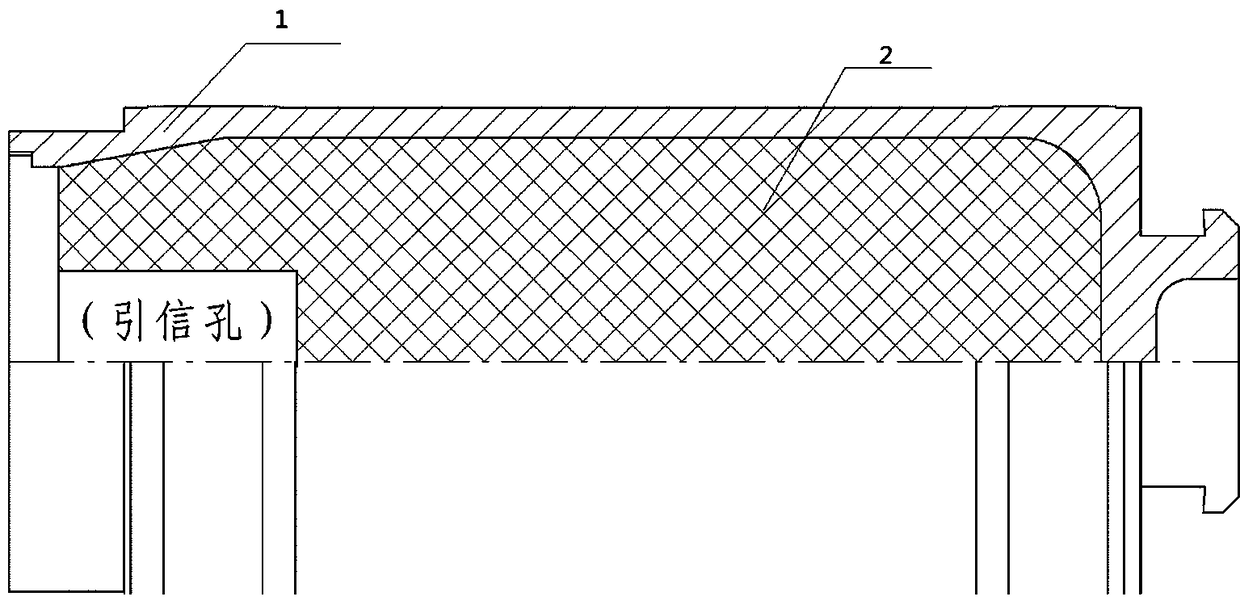

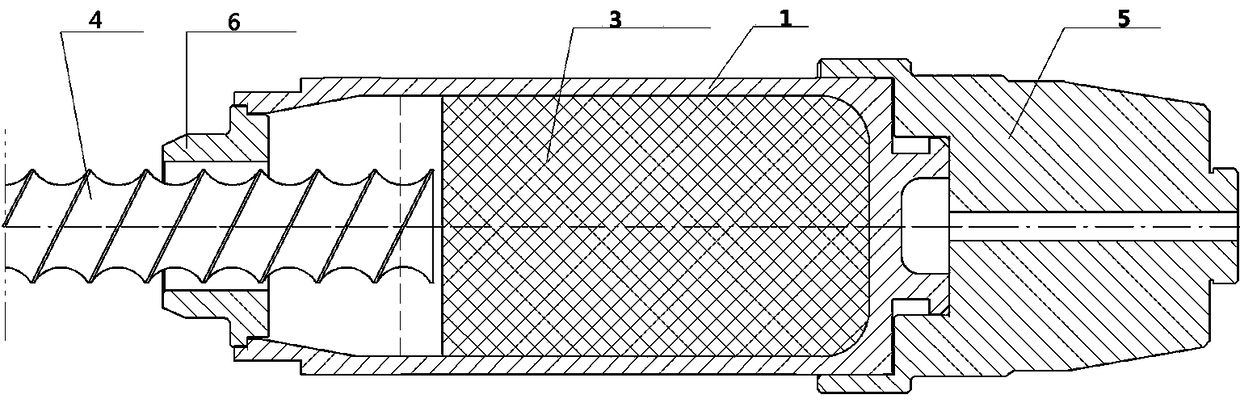

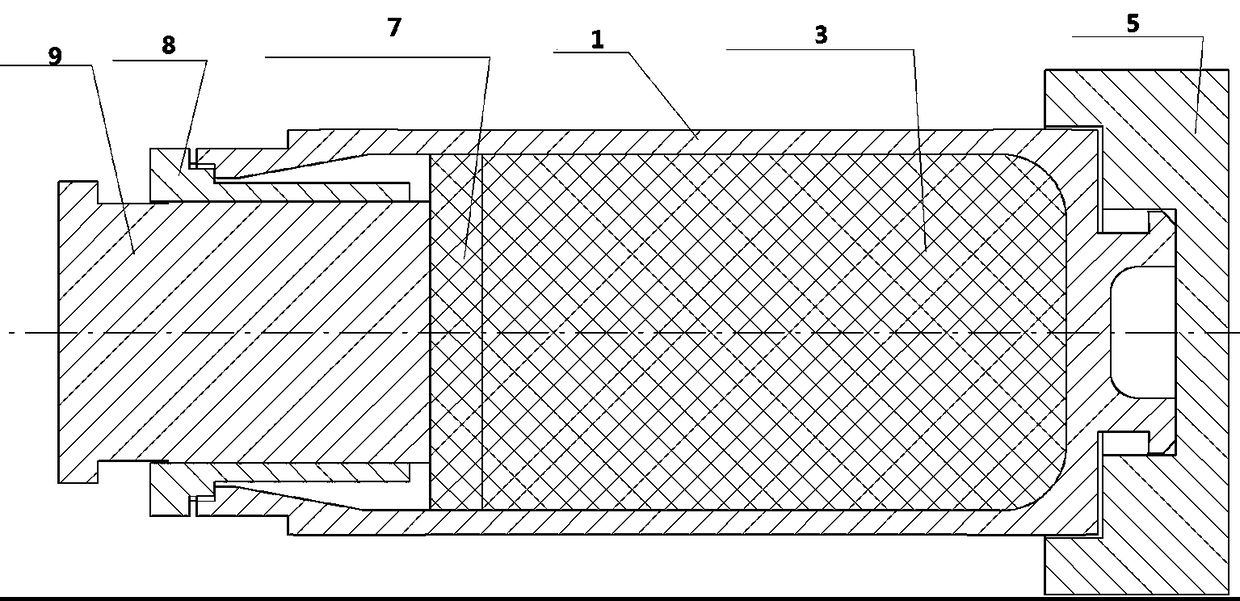

Deep-fuze-hole-provided thin-wall shell warhead composite powder charging method

The invention discloses a deep-fuze-hole-provided thin-wall shell warhead composite powder charging method. According to the technical scheme, a step-by-step powder press charging technological manneris adopted for shell powder charging (a screw rod with the outer diameter being 60 mm is used), then a direct powder press charging method is used at an opening part for three times of powder chargesupplementing (a specially-designed powder pressing die is used), and fuze hole bottom powder face molding (one time of powder pressing molding is carried out) and fuze hole molding (two times of power pressing molding are carried out) are sequentially carried out. According to the powder charging method, the problem that a thin-wall shell is prone to deformation in the powder pressing charging process in the powder charging process is solved, the powder charging density of a large-size inner cavity shell is guaranteed, the powder charging quality is improved, the technological safety and theemission safety of the powder charging process are improved, meanwhile, the production efficiency is improved, the production cost is reduced, the technical problem about how to press and mold a deepfuze hole and the like is solved, and the method has the reference and popularization effects on various deep-fuze-hole-provided thin-wall shell warhead composite powder charging.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

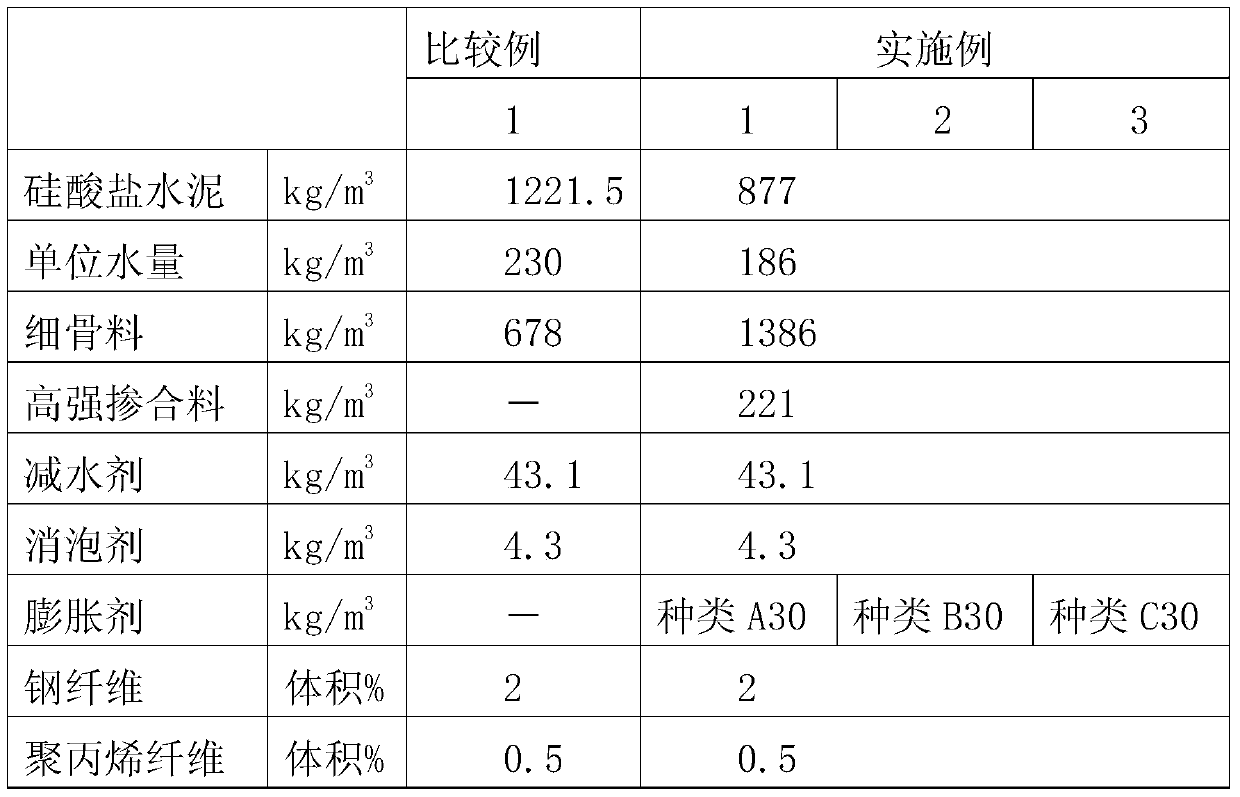

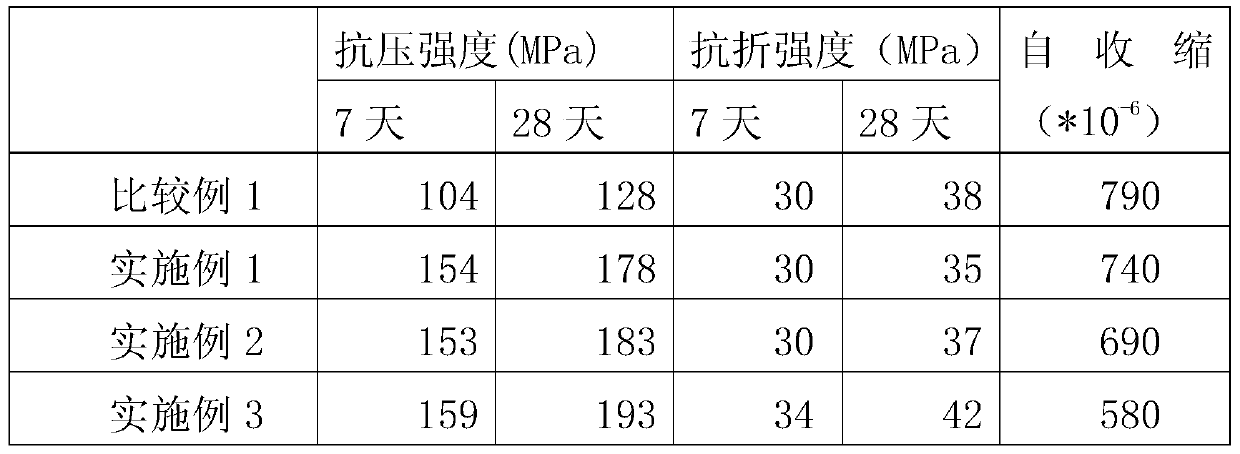

Normal temperature curing reactive powder concrete and preparation method thereof

The invention discloses normal-temperature maintenance-type active powder concrete and a preparation method thereof. Each cubic meter of the normal-temperature maintenance-type active powder concrete is prepared from 600-1600kg of cement, 400-2800kg of fine aggregate, 30-560kg of a high-strength admixture, 3-500kg of high tensile strength fibers, 0.4-45kg of organic fibers, 0.6-43.2kg of a water reducer (based on solid content), 0.06-43kg of an antifoaming agent, 6-129kg of an expanding agent and 100-430kg of water. The normal-temperature maintenance-type active powder concrete has superhigh strength and high toughness performances under the conditions of normal-temperature maintenance.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Manufacturing method of shielded gate trench mosfet

ActiveCN106057675BReduce leakageSolve process bottlenecksSemiconductor/solid-state device manufacturingSemiconductor devicesConvex structureGate dielectric

The invention discloses a shield gate trench MOSFET manufacturing method. Gate structure forming comprises steps: a hard mask layer is formed, and a gate forming area is defined; a semiconductor substrate is etched to form a deep trench; thermal oxidation is carried out to form a bottom oxidation layer; source polysilicon is formed; back etching of the polysilicon is carried out, and thus, the source polysilicon is flush with the top surface of the hard mask layer, a source polysilicon lateral extension part is formed outside the opening of the bottom oxidation layer and the top part of the bottom oxidation layer inside the opening of the hard mask layer; the hard mask layer is removed to form a top convex structure of the source polysilicon; the source polysilicon lateral extension part serves as a self-alignment mask to etch the bottom oxidation layer to form top trenches and inter-polysilicon isolation oxidation layers at two side surfaces of the source polysilicon; a gate dielectric layer is formed on the side surface of the top trench; and the top trench is filled to form a polysilicon gate, and chemical mechanical polishing is carried out. Thus, while the threshold voltage of the device is reduced, the gate source electric leakage of the device is reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

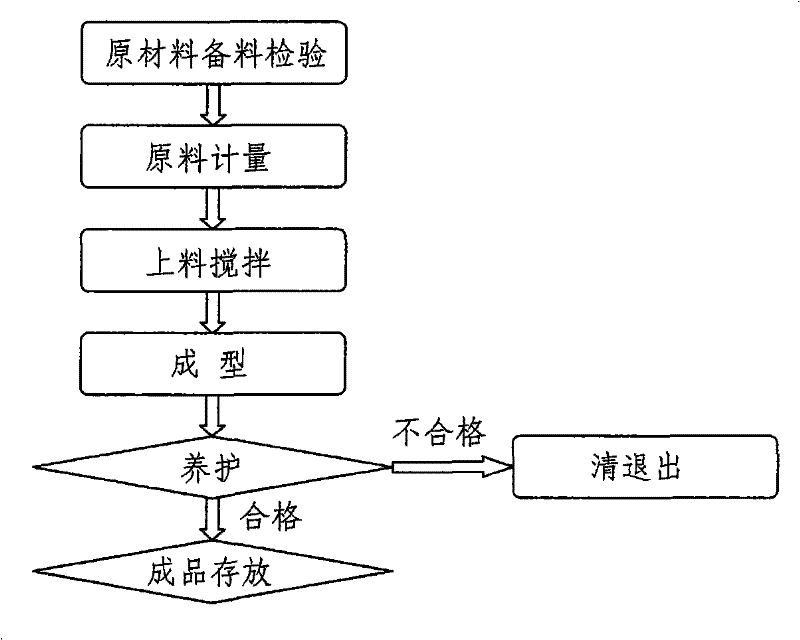

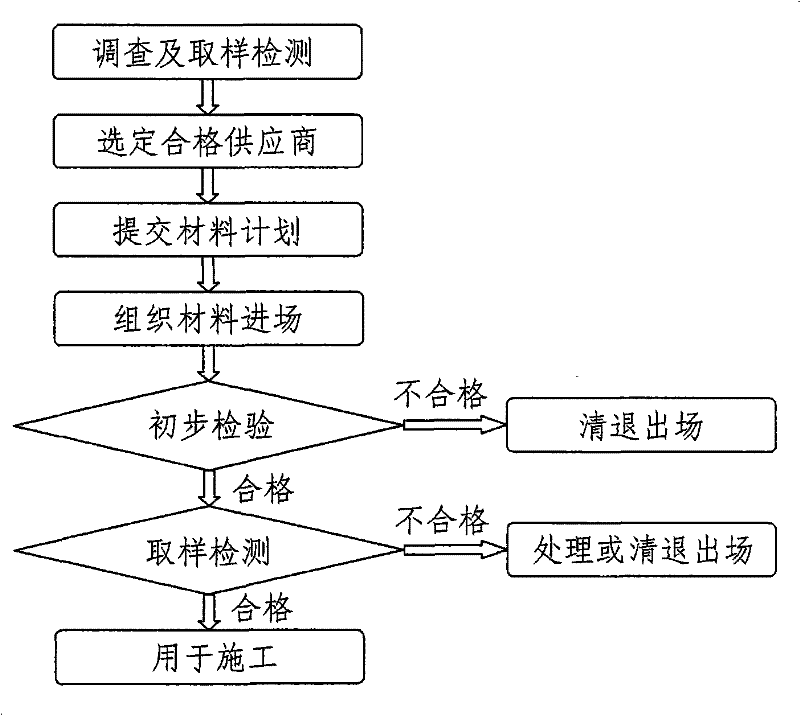

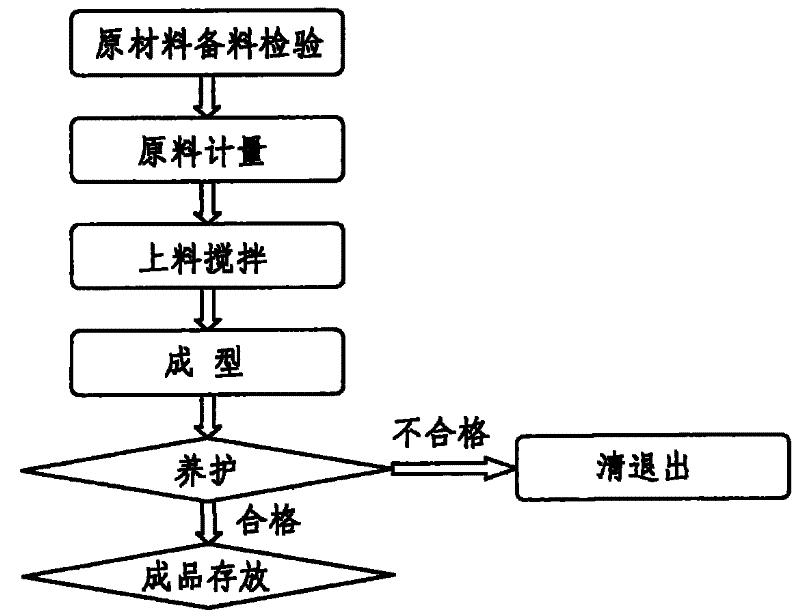

Manufacturing technique of reactive power concrete products

The invention discloses a manufacturing technique of reactive power concrete (RPC) products, belonging to the methodological technical field of the manufacturing technical process of the reactive power concrete (RPC) products in new building materials. The method comprises the following steps: according to the approaching process of raw material preparation, the raw material preparation is checked; according to the composition measured by the raw material mass mixture ratio, the raw material is measured; the checked raw material preparation is charged to a mixing plant for being mixed by utilizing charging equipment; the mixed reactive power concrete (RPC) is injected into a product mould to be formed; the formed product is maintained with the steam and hot water according to the curing temperature control requirement; the maintained product is stored according to the storing requirement. The manufacture technique is easy to be realized, has simple and convenient operation and high production efficiency, solves the technique bottleneck preparing the large scale commercial process of the reactive power concrete (RPC) products, and is suitable for manufacturing various reactive power concrete (RPC) products.

Owner:北京惠诚基业工程技术有限责任公司

Shielded gate trench power device and manufacturing method thereof

ActiveCN106298941BHigh dielectric constantLower threshold voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowGate dielectric

The invention discloses a shield gate trench power device. A bottom dielectric layer and an inter-polysilicon isolation dielectric layer are formed in a deep trench of a gate structure, a region encircled by the inter-polysilicon isolation dielectric layer forms a source trench, a gate trench is formed in a region, on which self-alignment etching is performed, of the bottom dielectric layer arranged at a top of the deep trench, a gate dielectric layer is formed on a side surface of a top, corresponding to the deep trench, of the gate trench, a polysilicon gate is formed in the gate trench, source polysilicon is formed in the source trench, and the polysilicon gate and polysilicon of the source polysilicon are simultaneously formed. The invention also discloses a fabrication method of the shield gate trench power device. By the fabrication method of the shield gate trench power device, the threshold voltage of the device can be reduced, and meanwhile, the gate-source electric leakage of the device can be reduced; the process flow can be substantially simplified, so that the process cost is reduced; and the frequency characteristic can be improved, and the shield gate trench power device has relatively large working current density.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

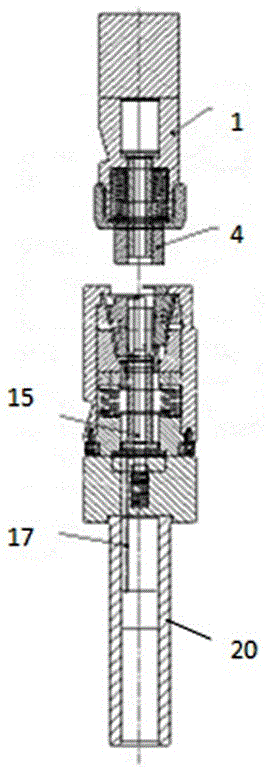

Electroslag casting manufacturing method and device for special-shaped castings with three-dimensional changes

ActiveCN107649664BSolve the process bottleneck of melting and castingSolve process bottlenecksElectrode materialCasting

The invention relates to the field of manufacturing three-dimensionally changed special-shaped castings through electroslag smelting casting, in particular to a method and device for manufacturing a three-dimensionally changed special-shaped casting through electroslag smelting casting. Electroslag smelting casting is used for completing secondary refining purification and casting near-net formingof consumable electrode materials. The method for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting comprises the specific processes that (1) acasting blank crystallizer adopts a combined structural form or a split type structural form; and (2) consumable electrodes in the smelting casting process are composed of two parts, namely the guiding electrode and the supplementary electrodes; the guiding electrode is followed and fixed relative to the crystallizer and internally provided with guiding channels; the supplementary electrodes aremovable and are arranged in the guiding channels; and the working form of the electrodes in the smelting casting process is as follows: the supplementary electrodes are continuously supplemented to the molten electroslag position through the guiding channels, and thus the smelting casting process is completed. Therefore, the method and device for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting is mainly suitable for casting of the three-dimensionally changed special-shaped casting.

Owner:沈阳市盛华特种铸造有限公司

A flexible flat cable automatic slitting equipment

ActiveCN105097137BIncrease productivityLess bad processCable/conductor manufactureTectorial membraneOperation mode

The invention relates to an automatic stripping device of a flexible flat cable. The automatic stripping device sequentially comprises a discharging mechanism, a strip deviation correction sensor, a feeding mechanism, a flexible flat cable tension mechanism, a heating blowing mechanism, a stripping mechanism, a leading-out mechanism and a scrap edge receiving mechanism from left to right. The automatic stripping device of the flexible flat cable substitutes a post-engineering processing operation mode such as traditional double-sided adhesive tape and protective film pasted one by one; a particular process flow comprises the following steps of: firstly, fabricating the flexible flat cable by using a flexible flat cable processing device; secondly, carrying out the post-engineering processing operation such as double-sided adhesive tape and protective film pasted in a roll; thirdly, stripping by using the automatic stripping device of the flexible flat cable; and finally, cutting the flexible flat cable by using an automatic cutting machine. Compared with the traditional operation mode, the operation mode has the advantages that production efficiency is high, manufacturing procedure deficiency is few, and a large amount of labor is not needed.

Owner:东莞市诚业机械科技有限公司

A mems microvalve and its manufacturing process

ActiveCN104445043BLarge flow control rangeImprove structural strengthDecorative surface effectsChemical vapor deposition coatingCrystal orientationMaterials science

The invention discloses a MEMS microvalve and its manufacturing process, relates to the MEMS technical field, and solves the technical problems of high requirements for the existing microvalve manufacturing process and poor pressure bearing capacity. The MEMS microvalve of the present invention includes a first silicon layer, composed of (111) crystal silicon material, and has a fluid inlet and a fluid outlet; the second silicon layer is made of (111) crystal silicon material, and has a fluid formed on the surface of the second silicon layer The outer flow channel and the rigid component with the inner flow channel, the rigid component is accommodated in the outer flow channel and can move between the valve opening position and the valve closing position, the second silicon layer includes a bonding part and a sealing part, and the second silicon layer The layer is bonded to the first silicon layer through the bonding part, the fluid inlet and the fluid outlet are located in the non-bonding area of the first silicon layer, the outer flow channel is located between the non-bonding area of the first silicon layer and the sealing part, and the upper part of the rigid part A buffer liquid gap is formed between the surface and the lower surface of the non-bonded region of the first silicon layer, and a suspension liquid gap is formed between the lower surface of the rigid component and the inner wall surface of the sealing part.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

Group III/nitride epitaxial structure and its active device and its integrated method

ActiveCN109004026BSolve process bottlenecksSolid-state devicesSemiconductor/solid-state device manufacturingSchottky barrierGallium nitride

The invention relates to a group III / nitride epitaxial structure, an active element and a manufacturing method thereof. It includes a substrate; a gallium nitride high resistance layer on the substrate; a gallium aluminum nitride buffer layer on the gallium nitride high resistance layer; a gallium nitride channel layer on the gallium aluminum nitride buffer layer an aluminum gallium nitride barrier layer on the gallium nitride channel layer; a fluorine ion structure in the aluminum gallium nitride barrier layer; and a first gate insulating dielectric layer on the fluorine ion structure. The gallium aluminum nitride buffer layer is to block the defect electrons of the buffer layer from entering the channel layer and thus reduce the current collapse effect; the gallium nitride enhanced aluminum gallium nitride / gallium nitride high-speed electron mobility transistor, hybrid Schottky barrier diodes or hybrid device-enhanced AlGaN / GaN high-speed electron mobility transistors.

Owner:黄知澍

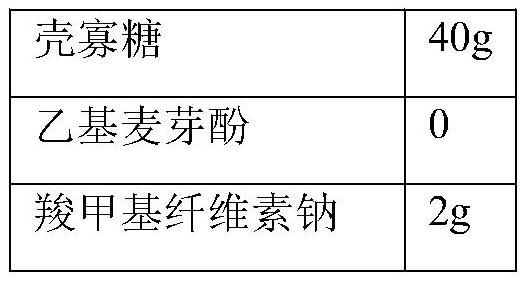

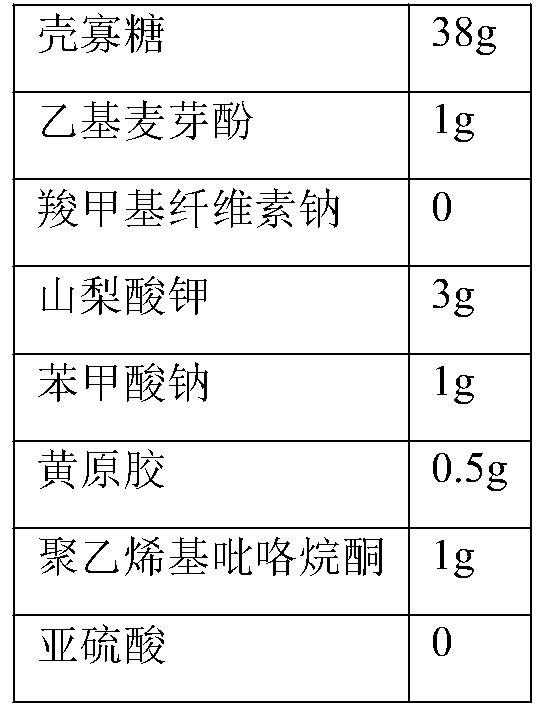

A kind of chitosan oligosaccharide oral solution and preparation method thereof

ActiveCN108653317BSolve hygroscopicityDeliciousOrganic active ingredientsMetabolism disorderPolymer sciencePreservative

Owner:GUANGDONG PHARMA UNIV

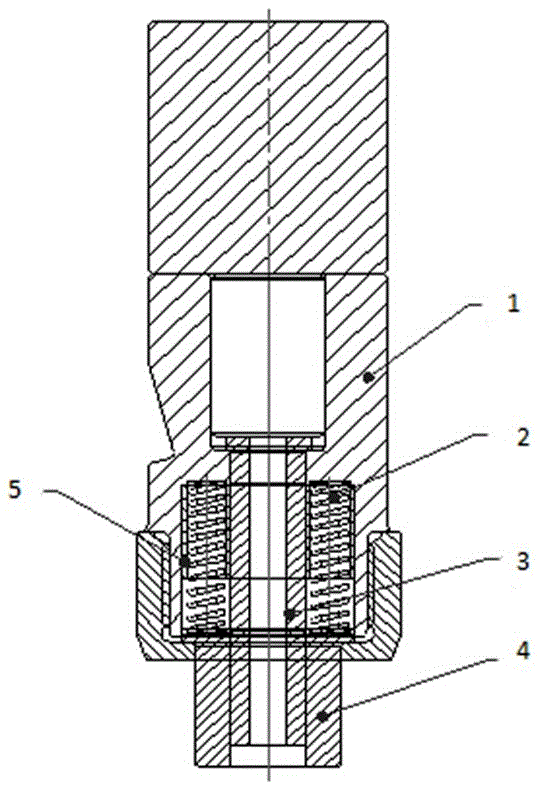

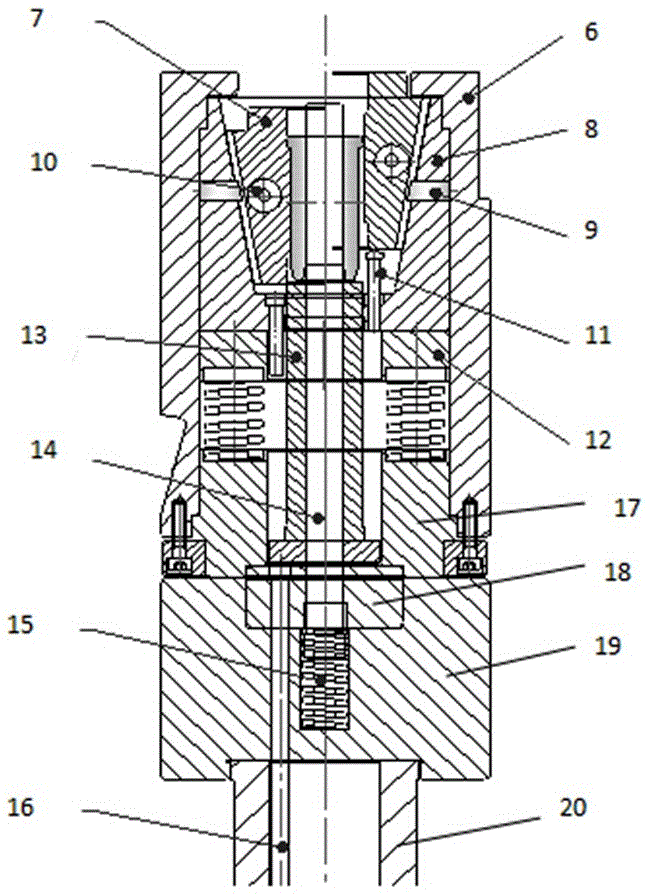

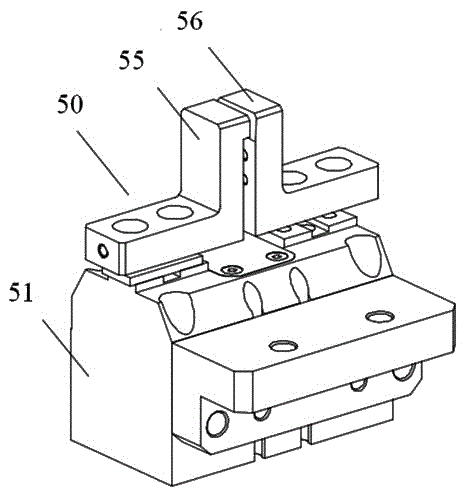

A cold heading opening and closing mold for special-shaped parts with double flanges for automobiles

ActiveCN104139148BReasonable designImprove work efficiencyForging/hammering/pressing machinesEngineeringRetaining Pin

Owner:GUANGZHOU KOIDE KOKAN

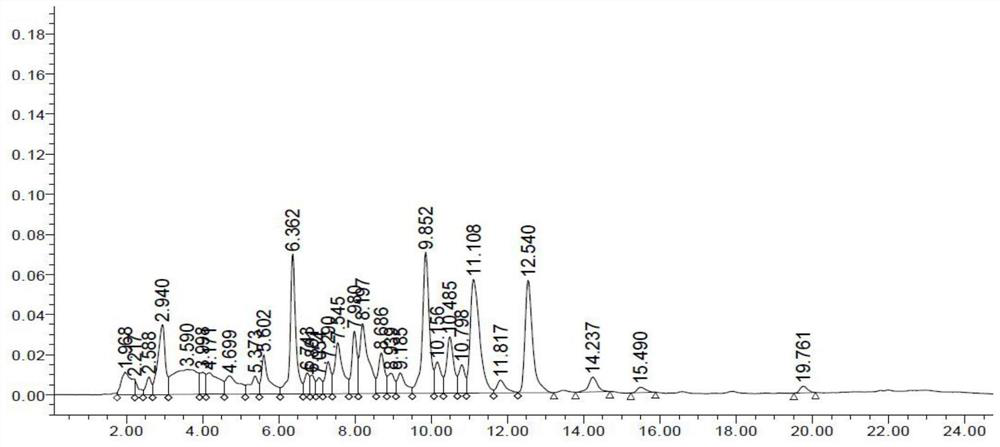

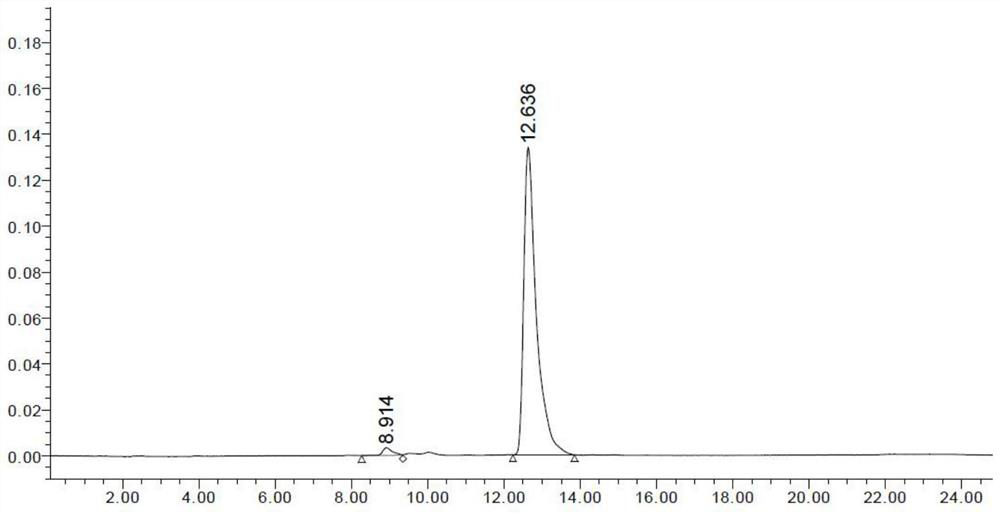

Preparation method of digital green intelligent high-purity marsdenia tenacissima component group and marsdenia tenacissima glycoside H and pharmaceutical composition thereof

PendingCN111690034AReduce demandShorten the production cycleOrganic active ingredientsAntipyreticAlcohol contentCross-flow filtration

The invention provides a preparation method of a digital green intelligent high-purity marsdenia tenacissima component group and marsdenia tenacissima glycoside H and a pharmaceutical composition thereof, and belongs to the technical field of traditional Chinese medicine preparation. The preparation method comprises the following steps: taking, stirring and extracting marsdenia tenacissima middlepowder with a 30% alcohol solution; carrying out throwing filtration and intelligent cross-flow filtration; passing through a macroporous adsorption resin column; performing gradient washing with an 8-16BV 0-50% alcohol solution; eluting with a 3BV 50%-60% alcohol solution; collecting target marsdenia tenacissima component group eluent, recovering alcohol until the alcohol content is 15%, passingthrough a macroporous resin column for enrichment or spray drying to obtain marsdenia tenacissima component groups, or passing through a C18 alkyl bonded silica gel column, washing and eluting with 46% acetonitrile solution, collecting target interval eluent, recovering acetonitrile until the target interval eluent is exhausted, and spray drying to obtain marsdenia tenacissima glucoside H. The method has the advantages of simple operation, energy saving, emission reduction, intelligent on-line control of the whole process, stable and controllable product quality, realization of digitization, greenization and intelligentization, and suitableness for industrial production of traditional Chinese medicines.

Owner:NANJING CHENXIANG MEDICAL RES +1

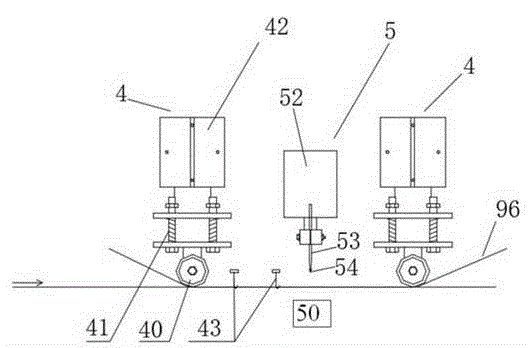

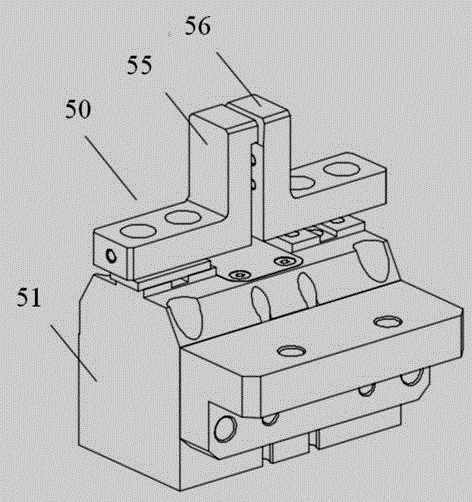

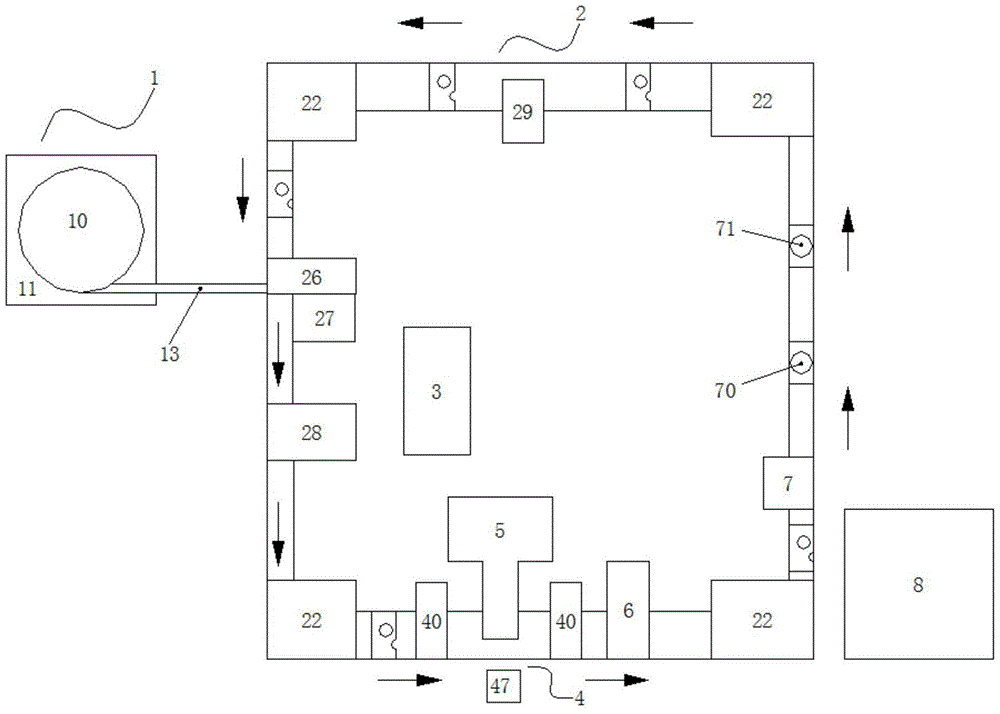

A kind of manufacturing system of electrode plug and using method thereof

ActiveCN105014222BSolve process bottlenecksReasonable production efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsWire cuttingManufacturing systems

Disclosed are an electrode plug manufacturing system and a use method therefor. The electrode plug manufacturing system comprises a supporting device (80), a tool circulation device (2), a bridge wire positioning device (4), a bridge wire welding device (5), a wire cutting device (6), a micro-tension wire feeding device (3), and a feeding device used for feeding an electrode plug base body into the tool circulation device. The tool circulation device comprises a circulation track (20) and a pushing device (22). A moving guide groove for a tool (23) is formed in the circulation track, and the pushing device pushes the tool to move in the circulation track. The bridge wire positioning device is disposed on the circulation track. The bridge wire welding device and the wire cutting device are disposed on the supporting device or the circulation track. The system can fully-automatically welds a bridge wire, and the welding efficiency is high.

Owner:SHANGHAI REAL INDAL

Manufacturing method of shielded gate trench mosfet

ActiveCN105870022BReduce leakageSolve process bottlenecksSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetGate dielectric

The invention discloses a method for manufacturing a shielded gate trench MOSFET. The gate structure is formed by the following steps: forming a hard mask layer and defining a gate forming region; etching a semiconductor substrate to form a deep trench; forming Bottom oxide layer; forming source polysilicon; performing polysilicon etching back to make the source polysilicon and the top surface of the hard mask layer level; removing the hard mask layer to form the top protruding structure of the source polysilicon; on the side of the protruding part of the source polysilicon Forming sidewalls composed of an oxide etch barrier layer; using the sidewalls as a self-aligned mask to etch the bottom oxide layer to form a top trench and an isolation oxide layer between polysilicon on both sides of the source polysilicon; in the top trench Form the gate dielectric layer on the sides; fill the top trench to form a polysilicon gate. The invention can reduce the gate-source leakage of the device while reducing the threshold voltage of the device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method, pharmaceutical preparation and clinical application of salvianolic acid b, an effective component of traditional Chinese medicine Salvia miltiorrhiza

ActiveCN104910112BAvoid treatmentOvercoming technical difficultiesOrganic active ingredientsSenses disorderSalvianolic acid BPharmaceutical medicine

The invention relates to a preparation method, a drug preparation and clinical application of a medicine effective component, especially relates to a preparation method of salvianolic acid B from traditional Chinese medicine salvia miltiorrhiza, and a drug preparation and clinical application, and belongs to the traditional Chinese medicine (TCM) technical field. Through use of a new method and a new idea of traditional Chinese medicine chemistry, the goal of being completely green, intelligent and circular economic can be realized, the degradation or transformation of the target compound can be effectively avoided, the preparation method has the advantages of energy conservation and emissions reduction, loss reduction, cost reduction, simple equipment and strong maneuverability, is more suitable for industrial production, and the yield is improved to 65-76% (on the basis of extract content). The present invention also discloses a variety of pharmaceutical acceptable dosage forms and new dosage forms and the clinical application in protecting of myocardial ischemia and anoxia, improvement of microcirculation, reduction of blood viscosity, inhibition of platelet aggregation and thrombosis formation and the like.

Owner:NANJING CHENXIANG MEDICAL RES

A small particle shale gas heat carrier dry distillation process

ActiveCN104004533BEnsure heating stabilityReduce heat loadDirect heating destructive distillationSpecial form destructive distillationHeat carrierMature technology

The invention discloses a dry distillation process of small particle shale gas heat carrier. The process comprises the process steps of raw ore treatment, dry winnowing, dry distillation and oil refining, product recovery and incineration for heat extraction. Added heat recovery technologies such as drying winnowing and incineration to obtain heat, fully recover the heat generated by the combustion of oil shale semi-coke, and apply it to the entire heat consumption process of oil shale carbonization, greatly improving thermal efficiency and reducing The production cost makes the dry distillation technology of small particle oil shale gas heat carrier mature. It effectively overcomes the process bottleneck of low thermal efficiency, makes the output greater than the cost, makes industrialization profitable, develops a brand-new dry distillation process, and greatly improves the utilization rate of resources.

Owner:FUSHUN MINING IND GROUP

A micro-tension wire feeding device and a bridge wire automatic welding system containing the device

ActiveCN105171257BStable tensionGuaranteed accuracyBlasting cartridgesFilament handlingEngineeringBridgewire

Owner:SHANGHAI REAL INDAL

A kind of expansion device and expansion method

An expansion device and an expansion method, the device comprises a base and a moving frame, a telescopic mechanism is arranged in the base, a telescopic end of the telescopic mechanism and an end away from the telescopic end are provided with rotating components, and a side wall of the base is provided with a rotating assembly A sliding hole through which the component passes, a sliding slot matched with the rotating component is arranged on the moving frame, and a push plate component is arranged on the side of the moving frame away from the base. The device can amplify the thrust to meet the requirements of technical indicators.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com