A micro-tension wire feeding device and a bridge wire automatic welding system containing the device

A wire feeding device and micro tension technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve problems such as enlargement, large damage, harm to the environment, etc., and achieve a reasonable process route, solve process bottlenecks, and improve competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

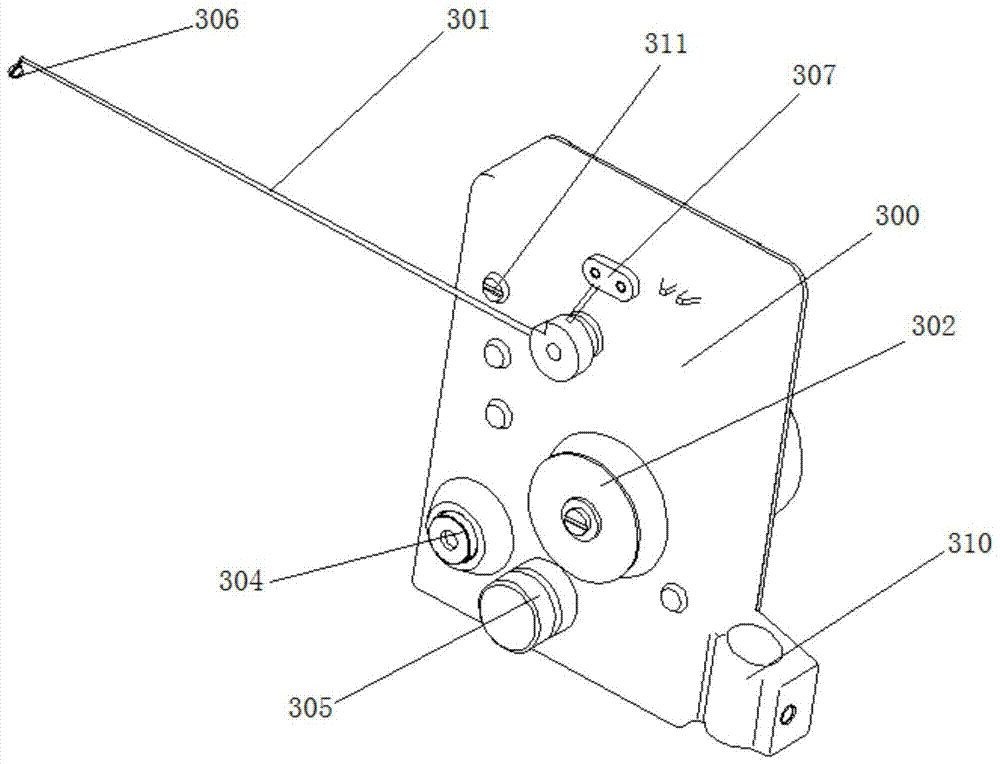

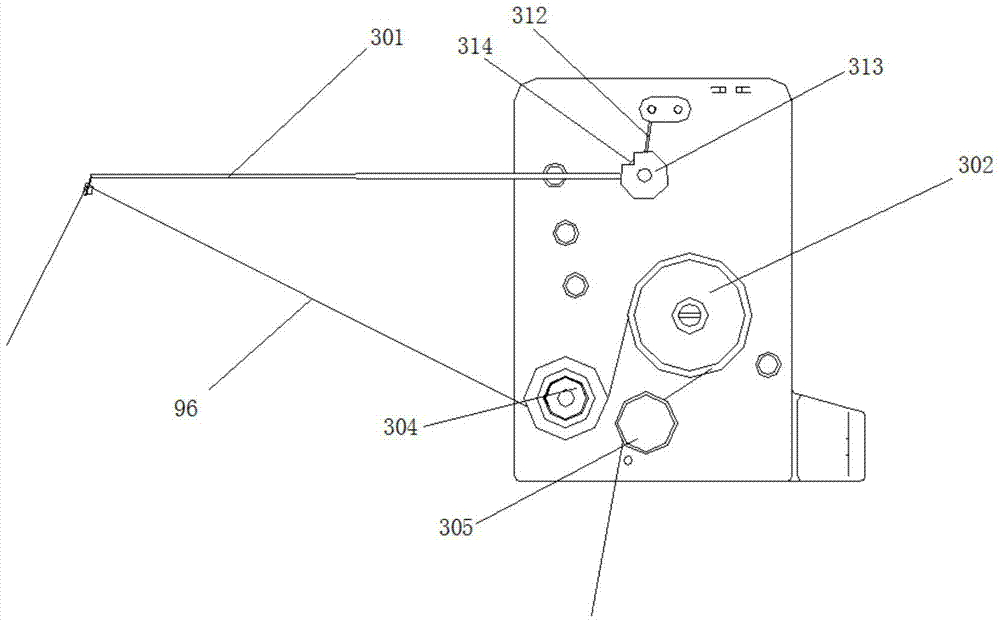

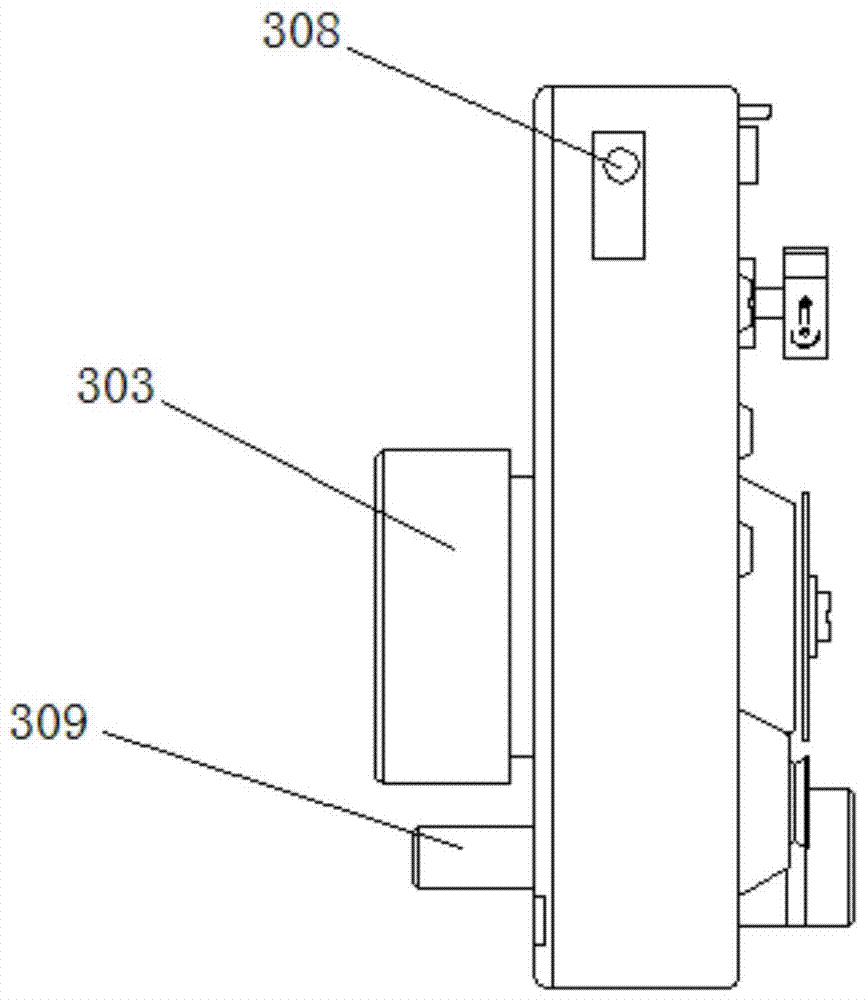

[0038] see Figure 1 to Figure 5, a micro-tension wire feeding device provided in this embodiment includes a housing 300, and a tension rod 301, a wire passing wheel 304, a clamping member and a tension wheel 302 arranged on the housing 300, and a transmission with the tension wheel 302 The connected damper; the damper can be a hysteresis brake or a magnetic damper 315 , in this embodiment, the damper is a magnetic damper 315 , and the clamping member is a wool felt 305 . One end of the tension rod 301 is connected to the housing 300, and the other end is provided with a pulley 306; in this embodiment, the direction of the bridge wire 96 is as follows: the bridge wire 96 passes through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com