Granule shale gas heat carrier destructive distillation technology

A gas heat carrier and small particle technology, applied in the field of dry distillation process, can solve the problems of low thermal efficiency, no small particle gas heat carrier dry distillation technology, high production cost, and achieve the effect of improving thermal efficiency, increasing energy utilization effect, and reducing heat load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

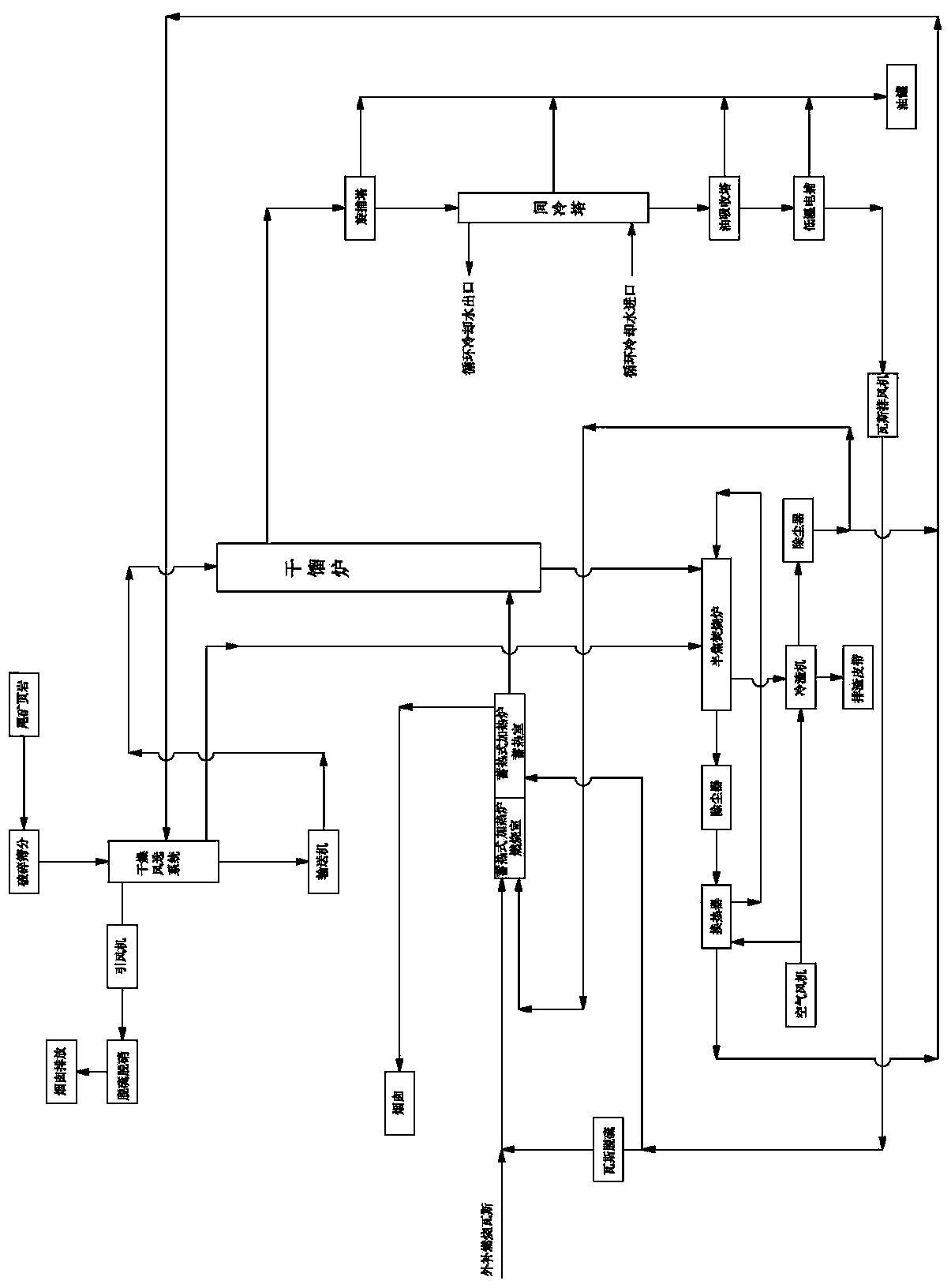

[0016] As shown in the figure, the tailings oil shale has a particle size of 0mm to 20mm, and after crushing and screening, it becomes small-grain oil shale in the particle size range of 0mm to 12mm. It is transported to the inlet of the drying winnowing system, enters the drying winnowing system and passes into the hot flue gas. The drying air separation system uses multi-layer mechanical vibration to process incoming shale materials. The whole system is fully enclosed. While shale is being screened, hot flue gas is introduced from the bottom to contact the shale in reverse to dry it. , At the same time, it can take away the dust particles. The whole system has three functions of screening, drying and winnowing. The shale is heated by the hot flue gas at 300°C, the temperature is raised, and part of the external water is removed, so that the water content of the shale is reduced from 9% to 1%, and the temperature of the shale is raised from the ambient temperature to 80°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com