Shielded gate trench power device and manufacturing method thereof

A technology of power devices and manufacturing methods, which is applied in the manufacture of shielded gate trench power devices and in the field of shielded gate trench power devices, can solve the problems of increasing gate-source leakage, reducing gate-source leakage, and reducing threshold voltage, etc., to simplify the process flow, low source-drain capacitance or gate-drain capacitance, and improved frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

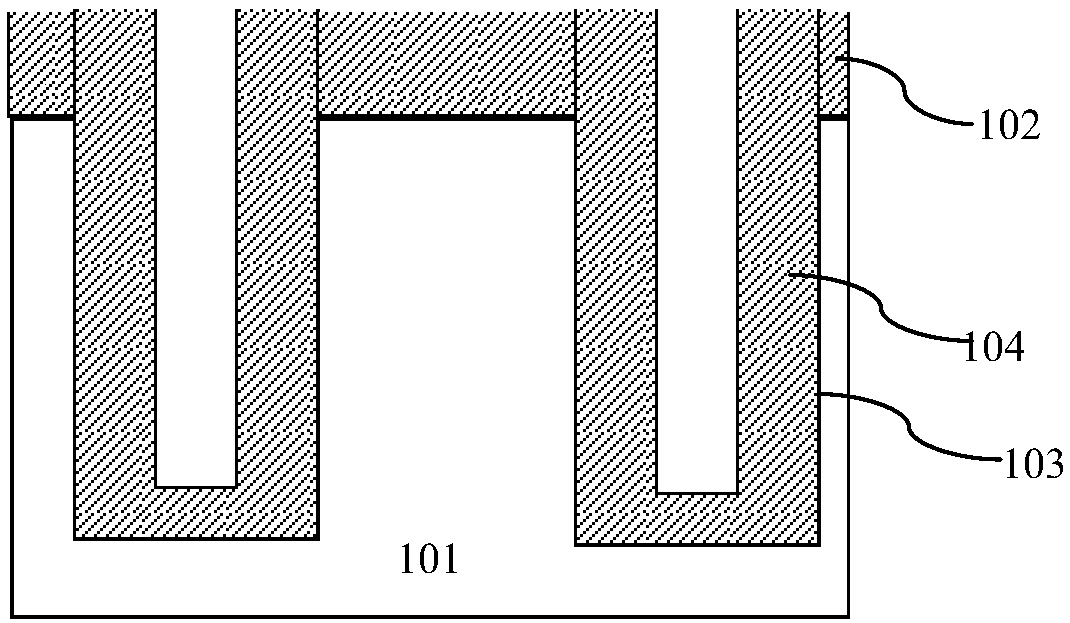

[0063] Such as figure 2 As shown, it is a schematic diagram of the structure of the shielded gate trench power device according to the embodiment of the present invention. The gate structure of the shielded gate trench power device according to the embodiment of the present invention includes:

[0064] A deep trench 201 is formed in a semiconductor substrate such as a silicon substrate 1 , and a bottom dielectric layer 2 and an isolation dielectric layer 3 between polysilicon are sequentially formed on the bottom surface and side surfaces of the deep trench 201 .

[0065] The bottom dielectric layer 2 and the inter-polysilicon isolation dielectric layer 3 do not completely fill the deep trench 201 , and the area surrounded by the inter-polysilicon isolation dielectric layer 3 forms a source trench 203 .

[0066] The bottom dielectric layer 2 at the top of the deep trench 201 is etched away by self-alignment, and a gate trench 202 is formed between the top side of the deep tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com