Group-III/nitride epitaxial structure, an active element thereof and a manufacturing method thereof

A gallium nitride epitaxy and gallium nitride technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of difficult control of etching depth and uneven epitaxy layer thickness of epitaxial chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

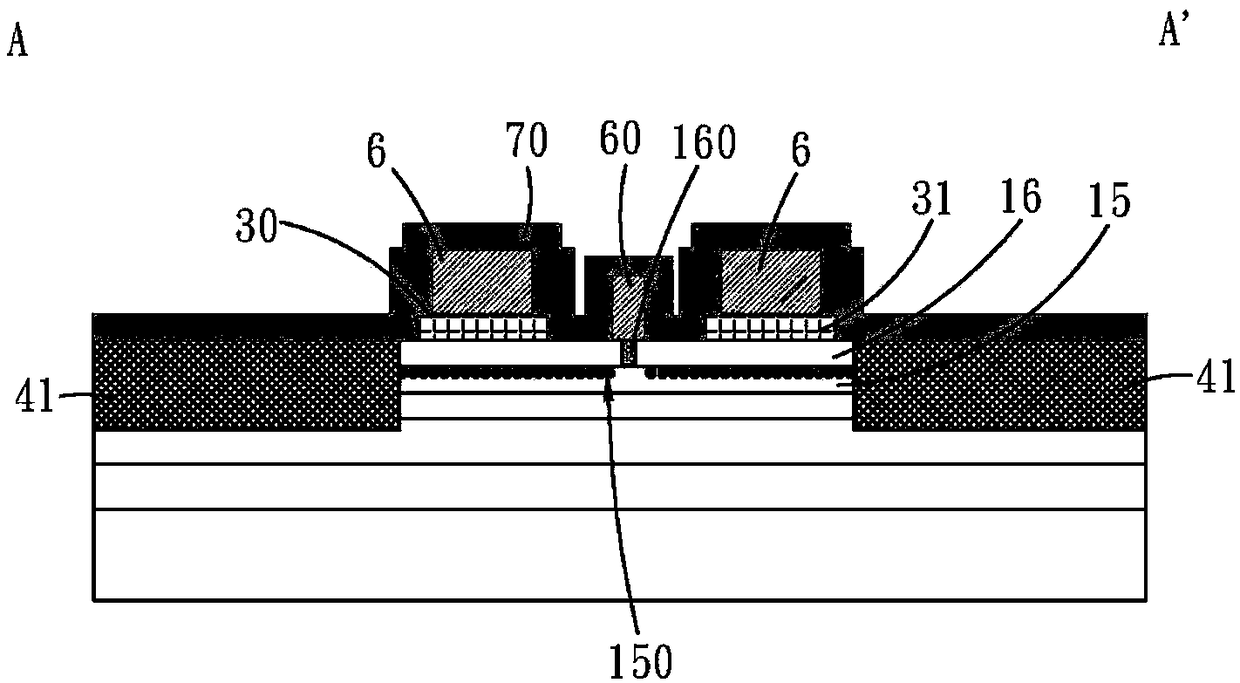

[0131] Embodiment two: such as Figure 5A , 5B , The fluorine ion implantation enhanced aluminum gallium nitride / gallium nitride (AlGaN / GaN) high-speed electron mobility transistor of the present invention is connected in series with a depletion type aluminum gallium nitride / gallium nitride (AlGaN / GaN) without a gate insulating dielectric layer / GaN) The first structure diagram and the second structure diagram of the fluorine ion implantation hybrid enhanced aluminum gallium nitride / gallium nitride (AlGaN / GaN) high-speed electron mobility transistor formed by the high-speed electron mobility transistor. Such as Figure 5A , 5B As shown, fluorine ions (F-) are implanted in the i-AlGaN barrier layer 16 under the first gate electrode metal 60 to form a reinforced aluminum gallium nitride / gallium nitride (AlGaN / GaN) high-speed electron mobility transistor is connected in series with a depletion type aluminum nitride / gallium nitride (AlGaN / GaN) high-speed electron mobility transisto...

Embodiment 4

[0155] The manufacturing process of the fourth embodiment is the same as that of the previous embodiment. After the fluorine ion implantation process is performed on the aluminum gallium nitride / gallium nitride (AlGaN / GaN) epitaxial structure designed in the present invention, the second region L1 is formed. A source ohmic contact electrode 30 and a first drain ohmic contact electrode 31 form a cathode ohmic contact electrode (cathode electrode metal) 34 of a Schottky barrier diode (SBD) synchronously with the right region R1. An anode field plate insulating dielectric layer 92 is formed on the right region R1, and a first gate insulating dielectric layer 50 is also formed on the left region L1.

[0156] Next, as previously described, the first gate electrode metal 60 and each connecting metal are formed, such as the first gate of the fluorine ion implantation hybrid aluminum gallium nitride / gallium nitride (AlGaN / GaN) Schottky barrier diode The electrode electrode connection met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com