Patents

Literature

116results about How to "Overcoming technical difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-pore-wall cage-shaped silica hollow sphere and preparation method thereof

InactiveCN102381715AOvercoming technical difficultiesLarge specific surface areaSilicaDispersityMicroreactor

The invention relates to a large-pore-wall cage-shaped silica hollow sphere and a preparation method thereof. A spherical wall of the silica hollow sphere is of a mesoporous structure, and the aperture of mesopores is 2.5-11nm. The preparation method comprises the steps of: firstly, synthesizing solid core / mesoporous shell SiO2 spheres with high dispersity and uniform particle sizes by using a sol-gel method and a surfactant orienting method; and then, skillfully removing solid cores in the SiO2 spheres while maintaining the completeness of the mesoporous layers of shells by performing a simple postprocessing method in an alkaline / acid solution to obtain the large-pore-wall cage-shaped SiO2 hollow spheres. The preparation method disclosed by the invention is simple and feasible, has no pollution, and is high in yield, low in cost, high in efficiency and extremely easy for industrialized production; and the prepared large-pore-wall cage-shaped SiO2 structure has wide application prospects in the fields of macromolecular medicament transportation, deoxyribonucleic acid (DNA) and small interfering ribonucleic acid (siRNA) loading and transporation, catalysis, microreactors, adsorption, separation, color spectrum and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

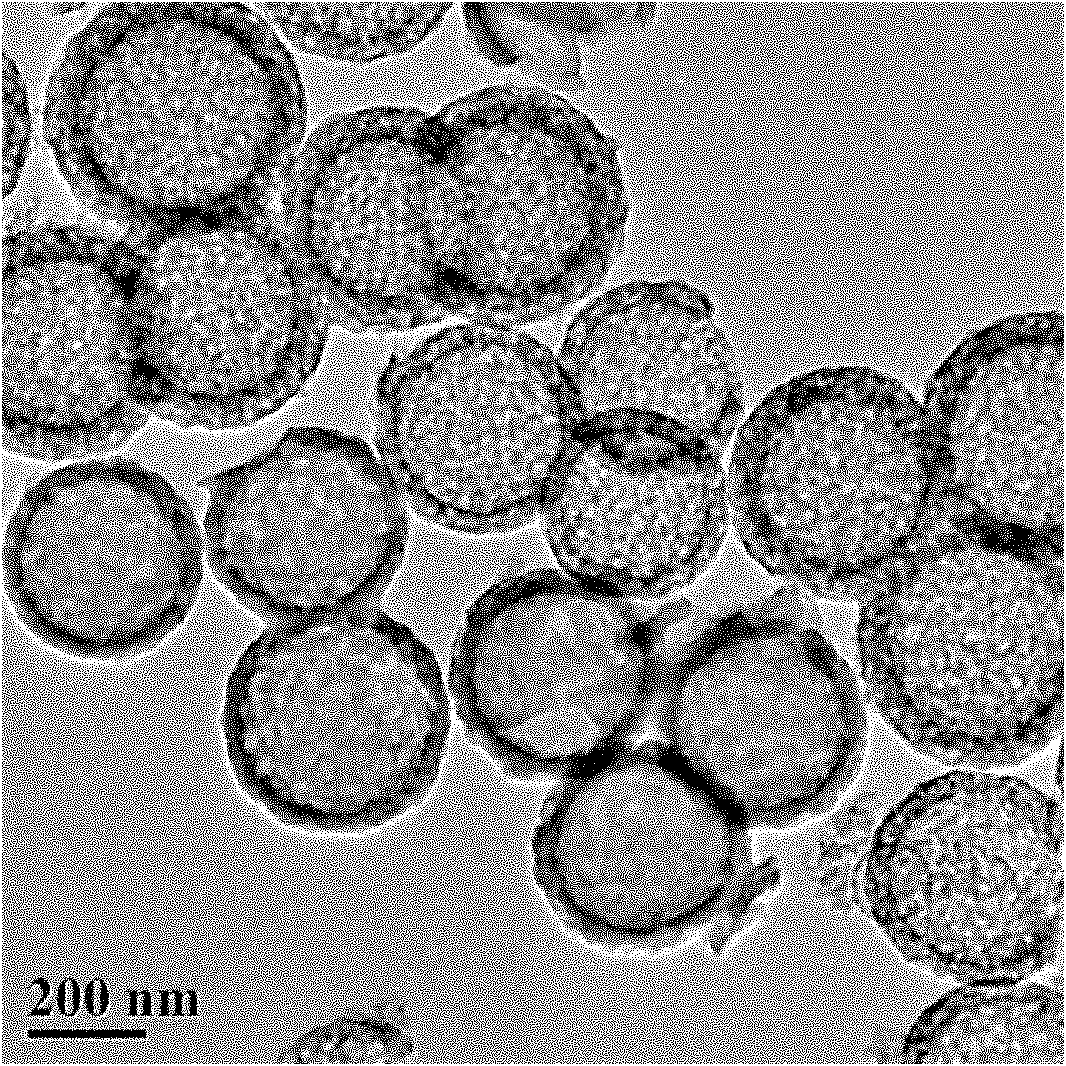

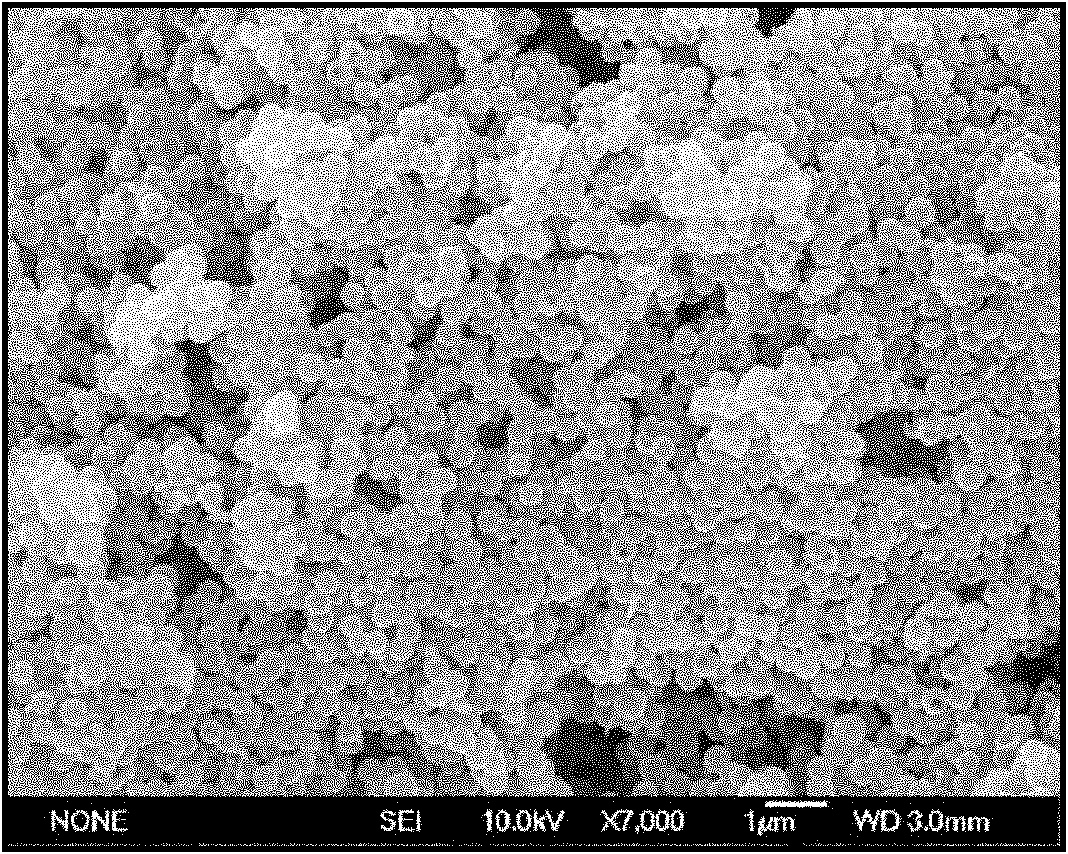

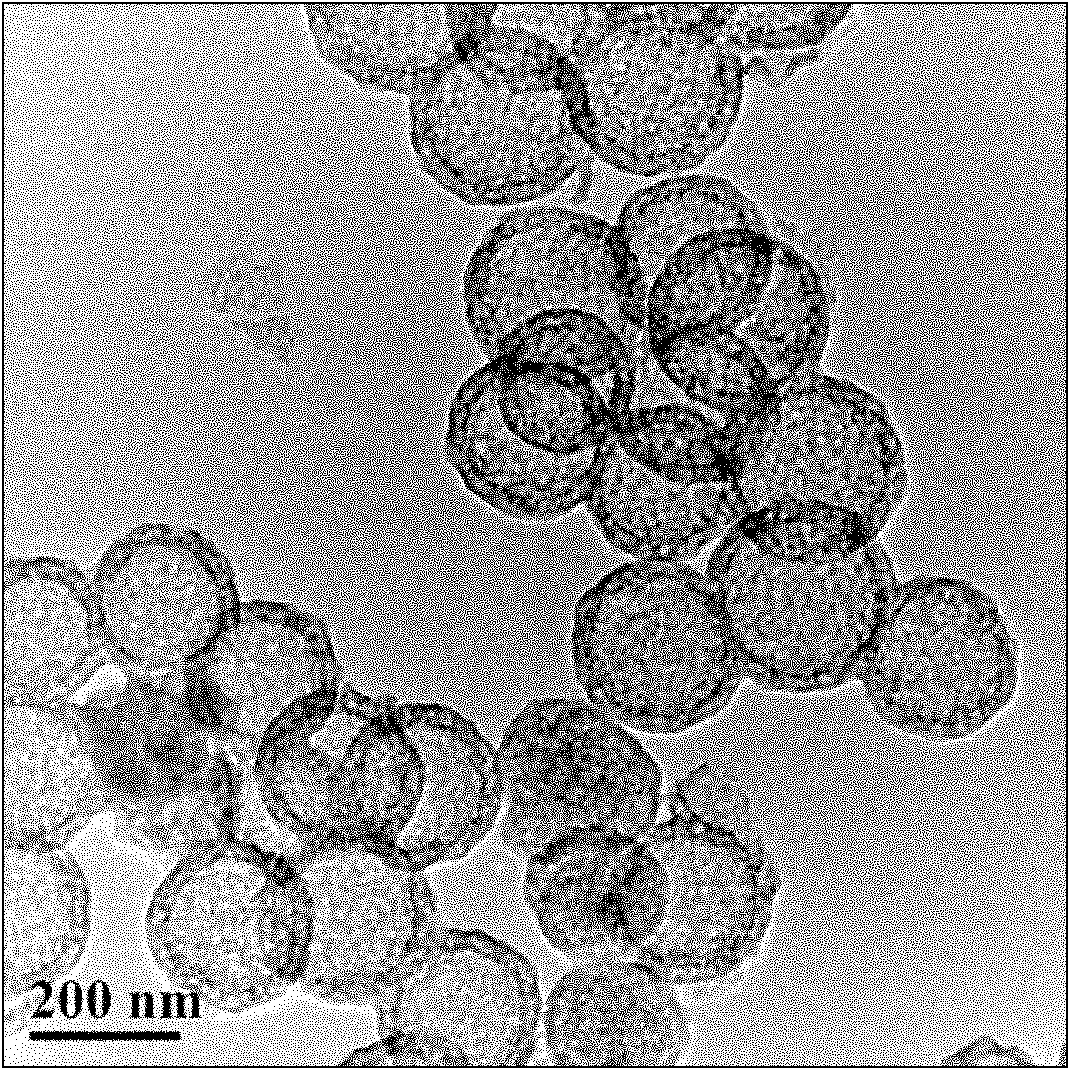

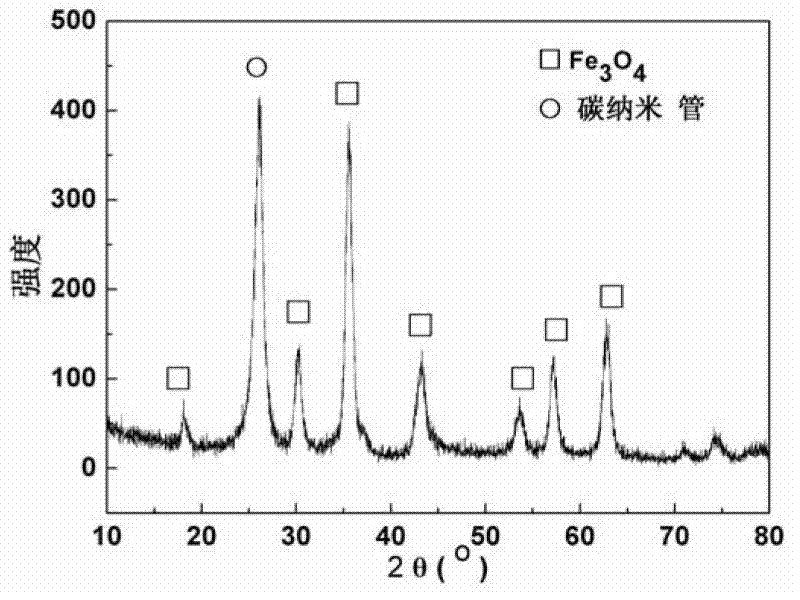

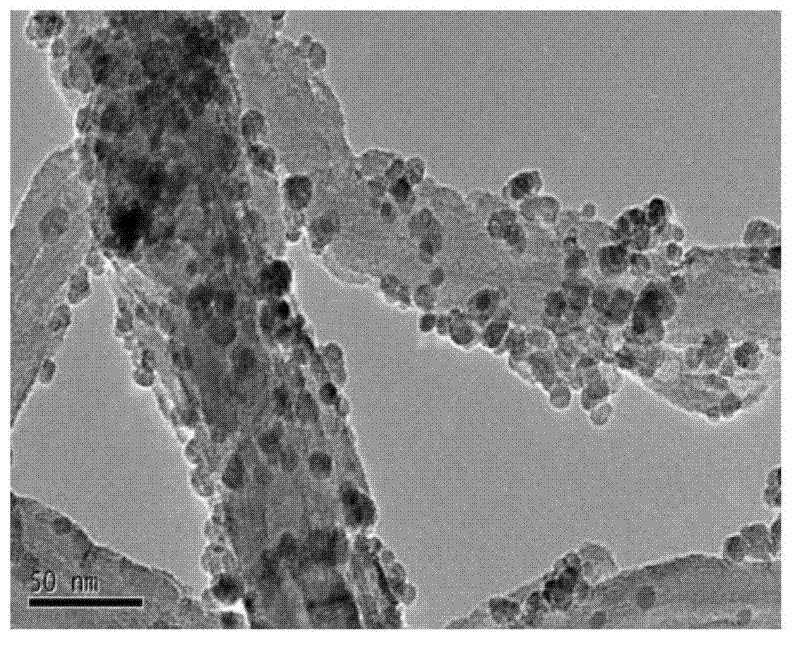

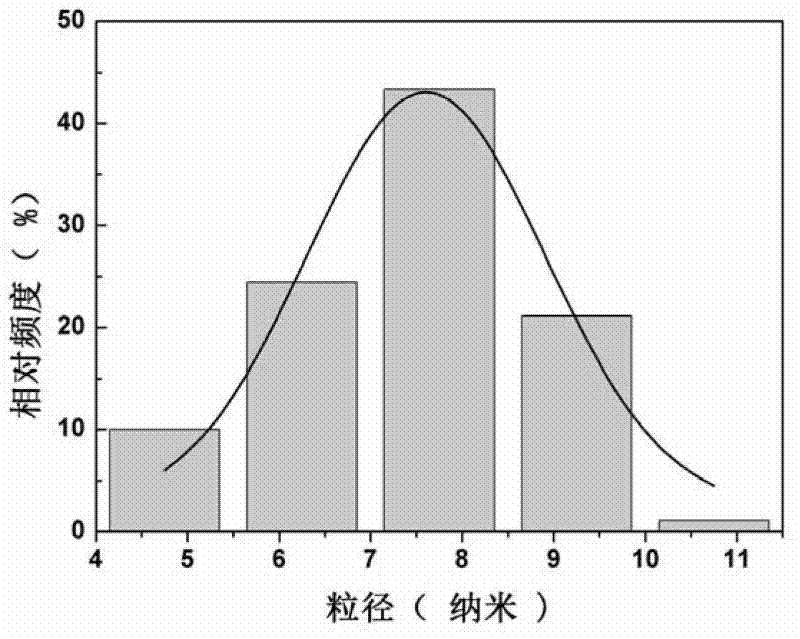

Multi-walled carbon nanotube-loaded nano ferroferric oxide catalyst and preparation method and application thereof

ActiveCN102671661AOvercoming technical difficultiesHigh activityMetal/metal-oxides/metal-hydroxide catalystsOrganic synthesisCarbon nanotube

The invention discloses a multi-walled carbon nanotube-loaded nano ferrofferic oxide (Fe3O4) catalyst and a preparation method and an application thereof. In the multi-walled carbon nanotube-loaded nano ferrofferic oxide catalyst, ferroferric oxide is distributed on the surface of the outer wall of the multi-walled carbon nanotube. The preparation process is simple, the cost is low, and easiness in industrialized popularization is realized. In the synthesized catalyst, the crystallinity of the Fe3O4 nano particles is high, the particle size is controllable, and the particles distribution is narrow. The catalytic activity of the multi-walled carbon nanotube-loaded nano ferrofferic oxide (Fe3O4) catalyst multi-walled carbon nanotube-loaded nano ferrofferic oxide (Fe3O4) catalyst (Fe3O4-MWCNTs) is high and the Fe3O4-MWCNTs is easy for being repeatedly used through magnetic separation. The Fe3O4-MWCNTs which is prepared by the method can be used as peroxide mimic enzyme and can be used as catalyst for organic pollutants which are difficult to degrade and for organic synthesis.

Owner:TSINGHUA UNIV

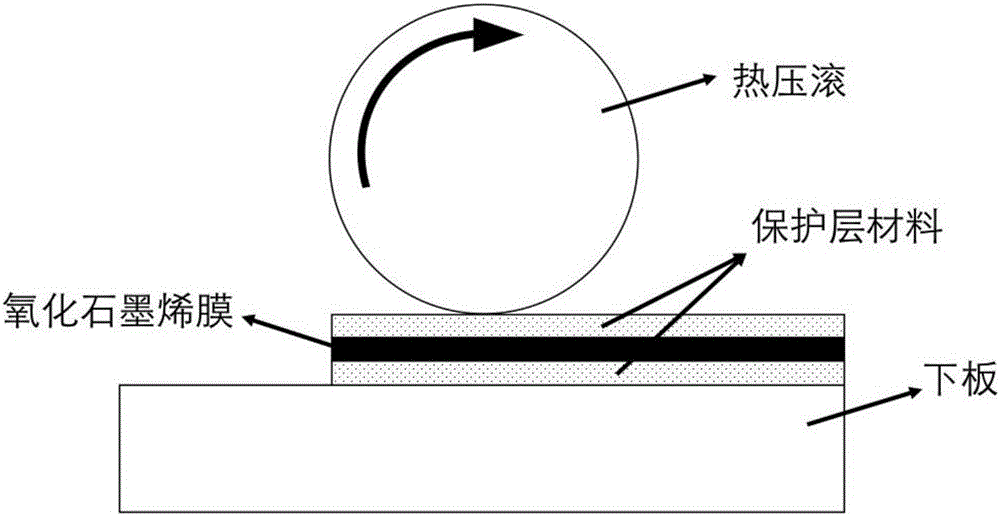

Preparation method of large-area reduced graphene oxide membrane

The invention relates to a method for preparing a large-area reduced graphene oxide membrane. The method comprises the preparation steps that graphite powder serves as the raw material to prepare a graphene oxide suspension; the graphene oxide suspension is uniformly dispersed on the surface of a substrate in a spray coating or blade coating mode, and a graphene oxide membrane is prepared; the graphene oxide membrane is subjected to reduction treatment under the hot rolling condition, and the reduced graphene oxide membrane is obtained. According to the method for preparing the large-area reduced graphene oxide membrane, rapid heat treatment is conducted under the hot rolling condition, and therefore continuous preparation of the large-area reduced graphene oxide membrane is achieved. The method is convenient to operate, the process is simple and flexible, the production cost of the reduced graphene oxide membrane is greatly reduced, the production efficiency is improved, and the method is suitable for industrial large-scale production.

Owner:王祉豫

Method for preparing multi-arc ion plating aluminium titanium chrome silicon yttrium nitride multi-component ultra-hard reaction film

InactiveCN101230448AQuality improvementGuaranteed repeatabilityVacuum evaporation coatingSputtering coatingAlloyTitanium

The invention relates to a method of preparing a multi-component super-hard reaction film for a multiple-arc ion-plated nitride of titanium, aluminum, chrome, silicon and yttrium. The method includes the following steps in sequence: the confirmation of the deposition technique and the design of the components of the target material (1); the preparation of a alloy target (2); the selection and pre-processing of a workpiece sample (3); the confirmation of the quantity of the electric arc source (4); the confirmation of the deposition technique (5); the acquirement of a transition layer (6); the processing of vacuum heating (7) and the rotation of the workpiece sample. The method confirms the variation range of the components of the Ti, Al, Cr, Si, Y elements in the complex Ti-Al-Cr-Si-Y alloy target and causes the super-hard reaction film of the (TiAlCrSiY)N to have the advantages of strong adhesive power (larger than or equal to 180 N) and high hardness (larger than or equal to HV3200).

Owner:SHENYANG UNIV

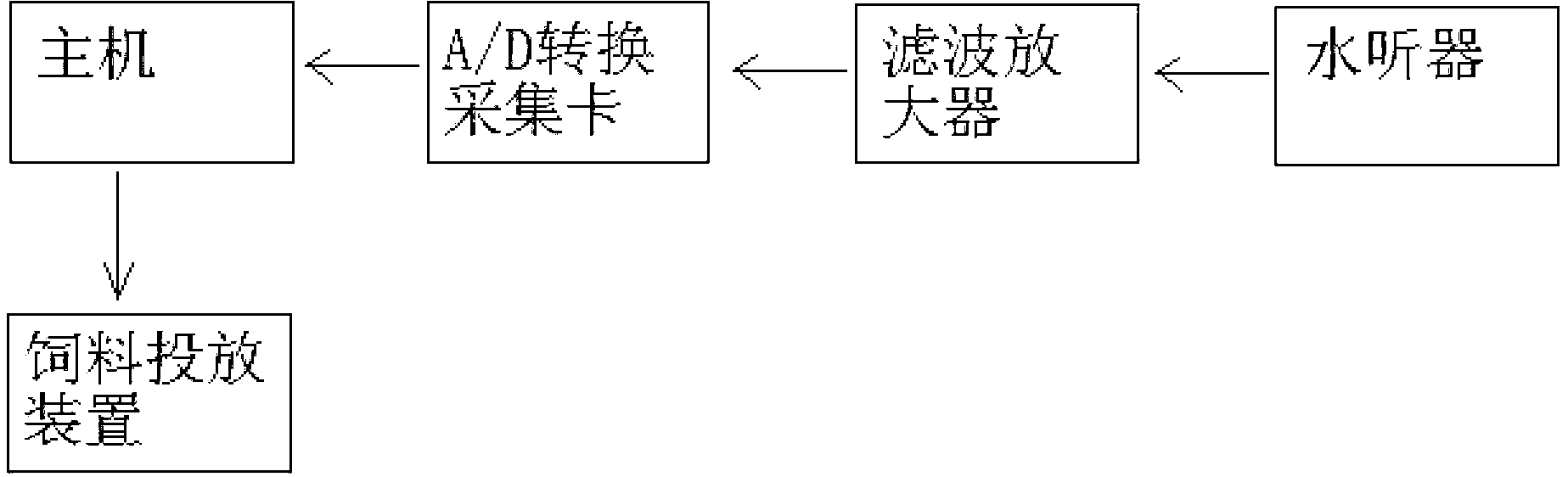

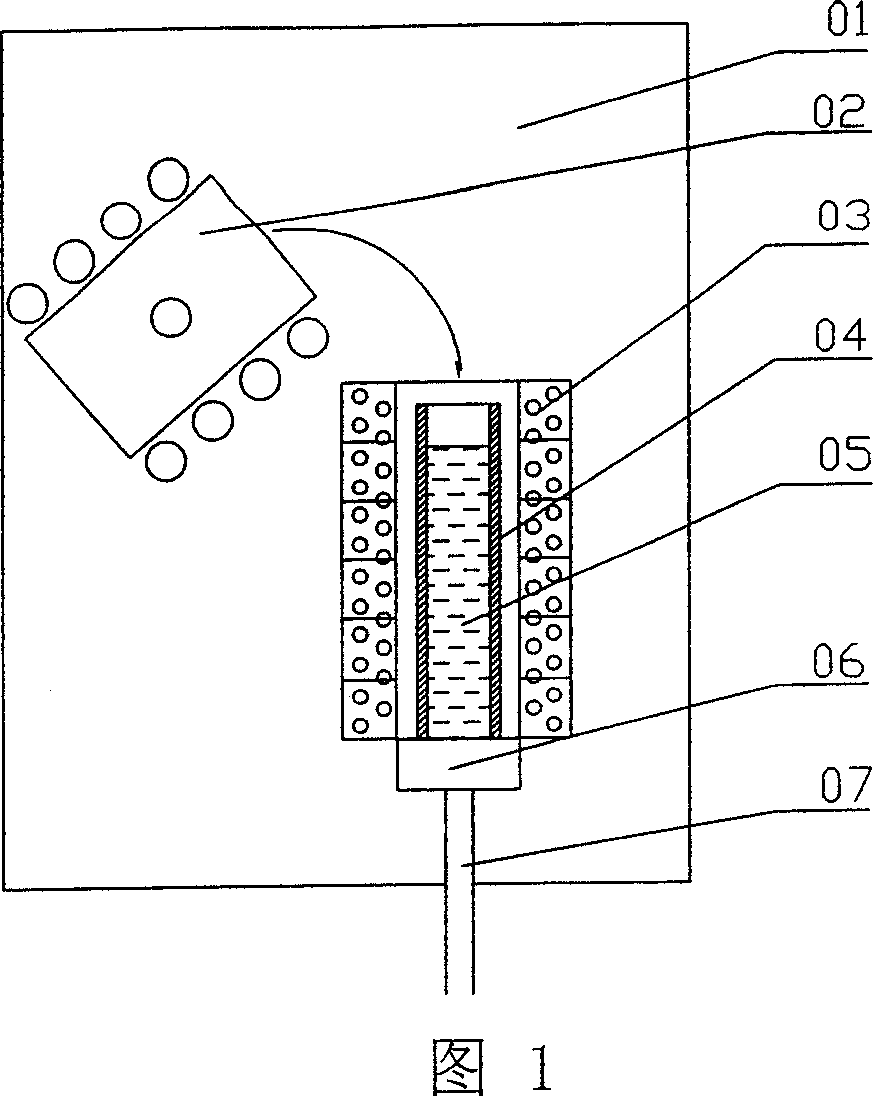

Pond culture sound control feeding method and device based on same

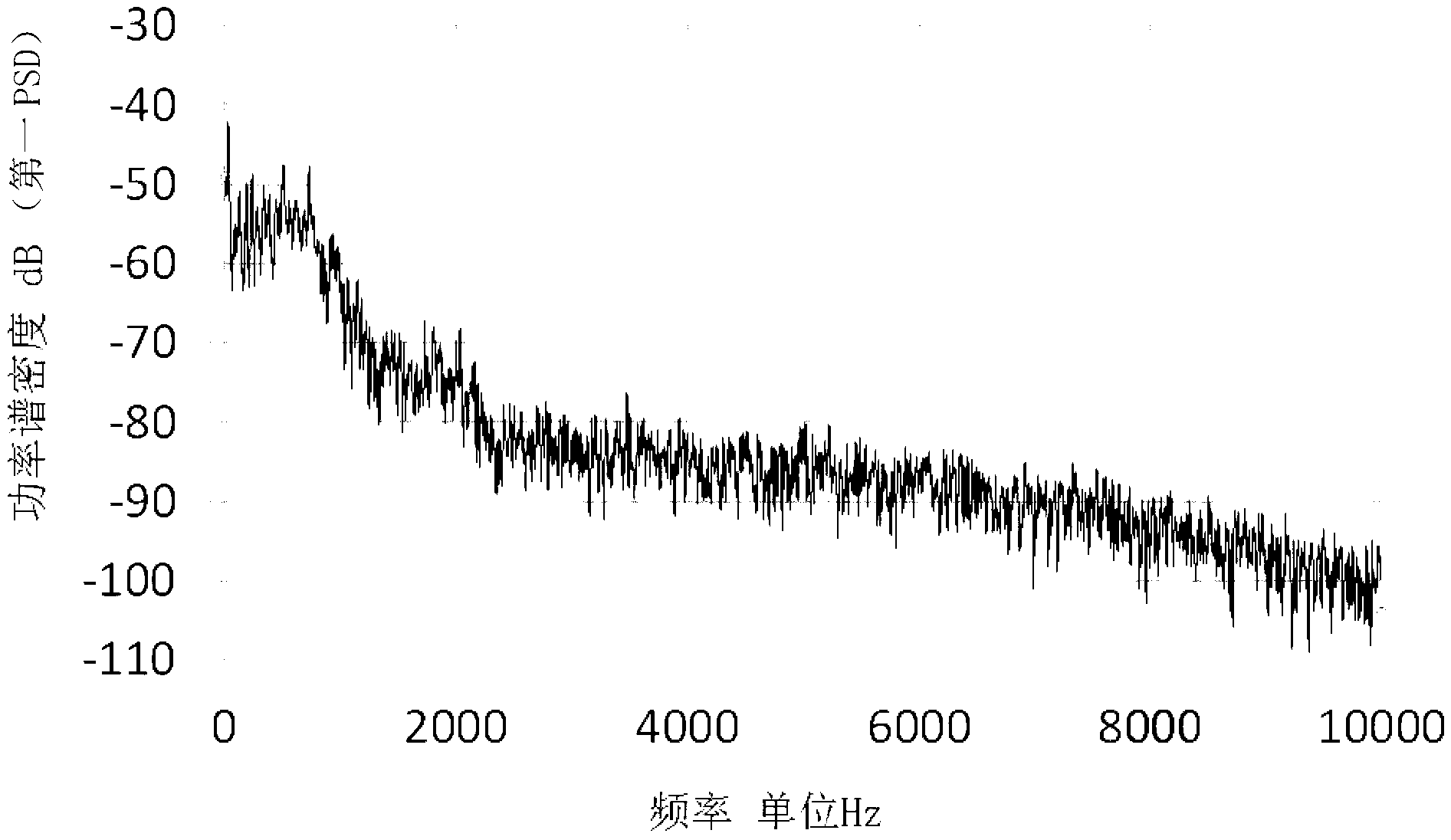

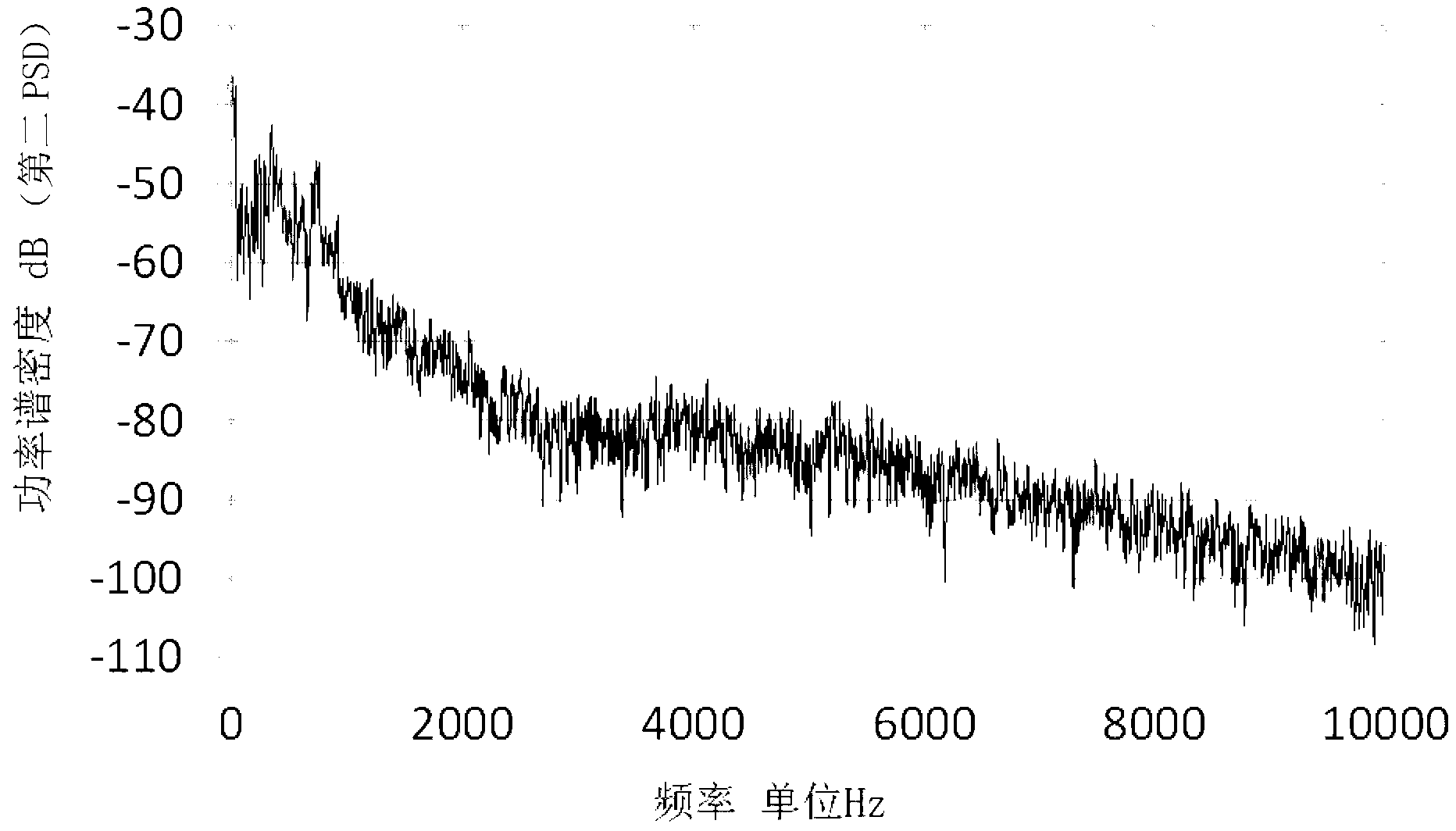

InactiveCN103070126APrecise and reliable controlImprove efficiencyPisciculture and aquariaZoologyBackground noise

The invention relates to a pond culture sound control feeding method. The pond culture sound control feeding method is characterized by comprising the following steps of 1) determining background noise of underwater environment of a feeding water area, and establishing background average PSD (Power Spectral Density) pn (m); 2) determining a sound signal of the feeding water area after feeding, and calculating sound PSD p (m) after feeding; 3) obtaining fish ingestion sound PSD after subtracting the sound PSD p (m) after feeding from the background noise average PSD pn (m) according to frequency; 4) calculating ingestion power in one moment through an integral formula as shown in the description, wherein ms refers to starting frequency, and me refers to cut-off frequency; and obtaining an ingestion power-time curve diagram; and 5) obtaining an ingestion power-time N-second average-line diagram, and respectively setting feeding ingestion quickening power, feeding ingestion power slow-down power and feeding ingestion stopping power according to ingestion power values on the ingestion power-time N-second average-line diagram.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

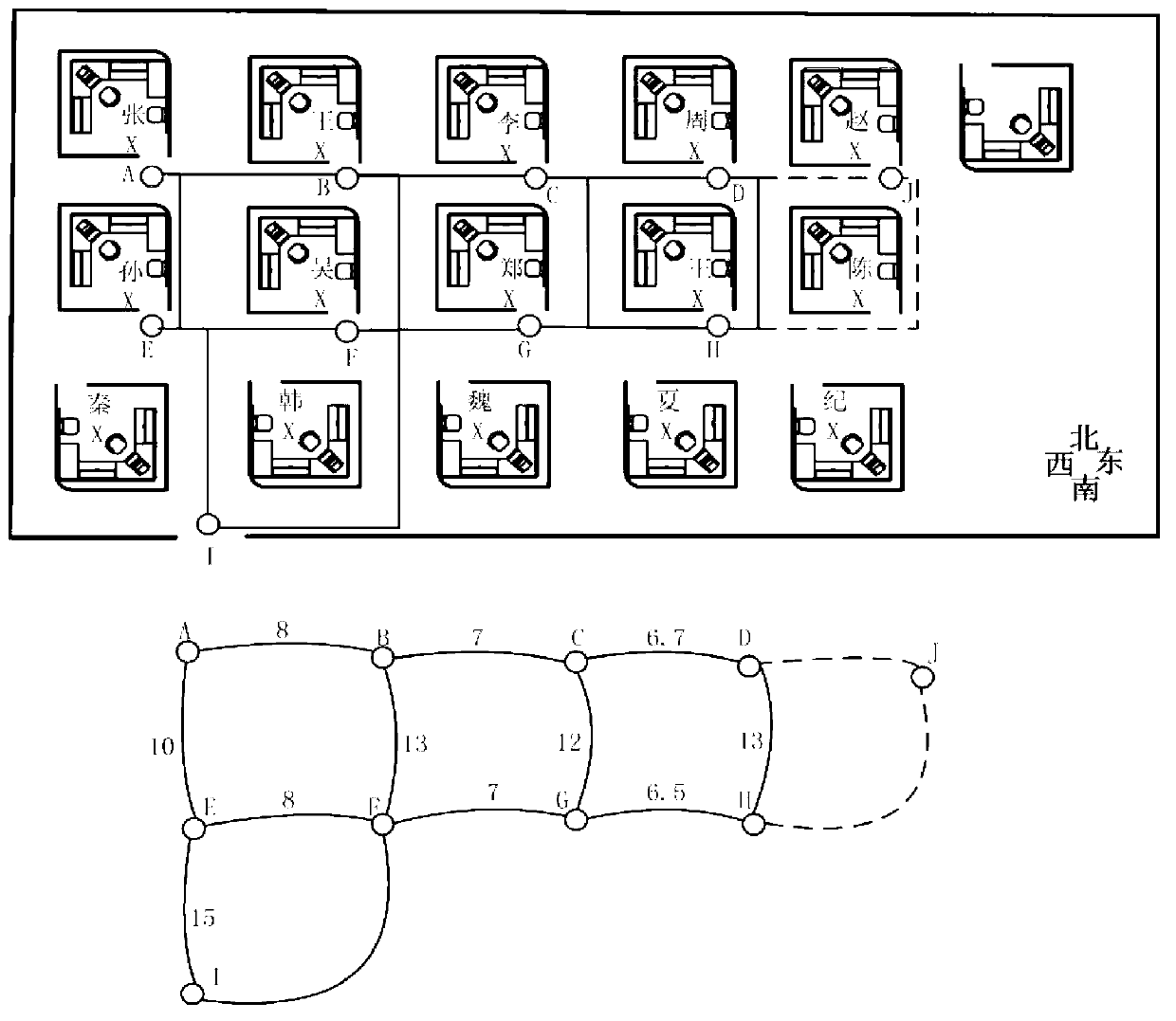

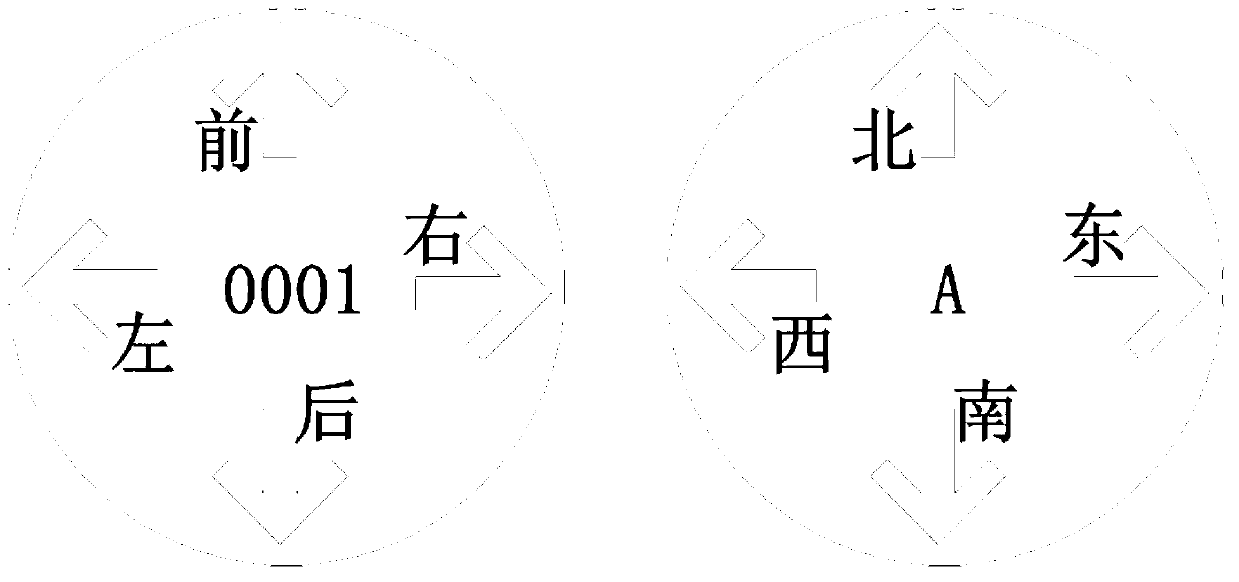

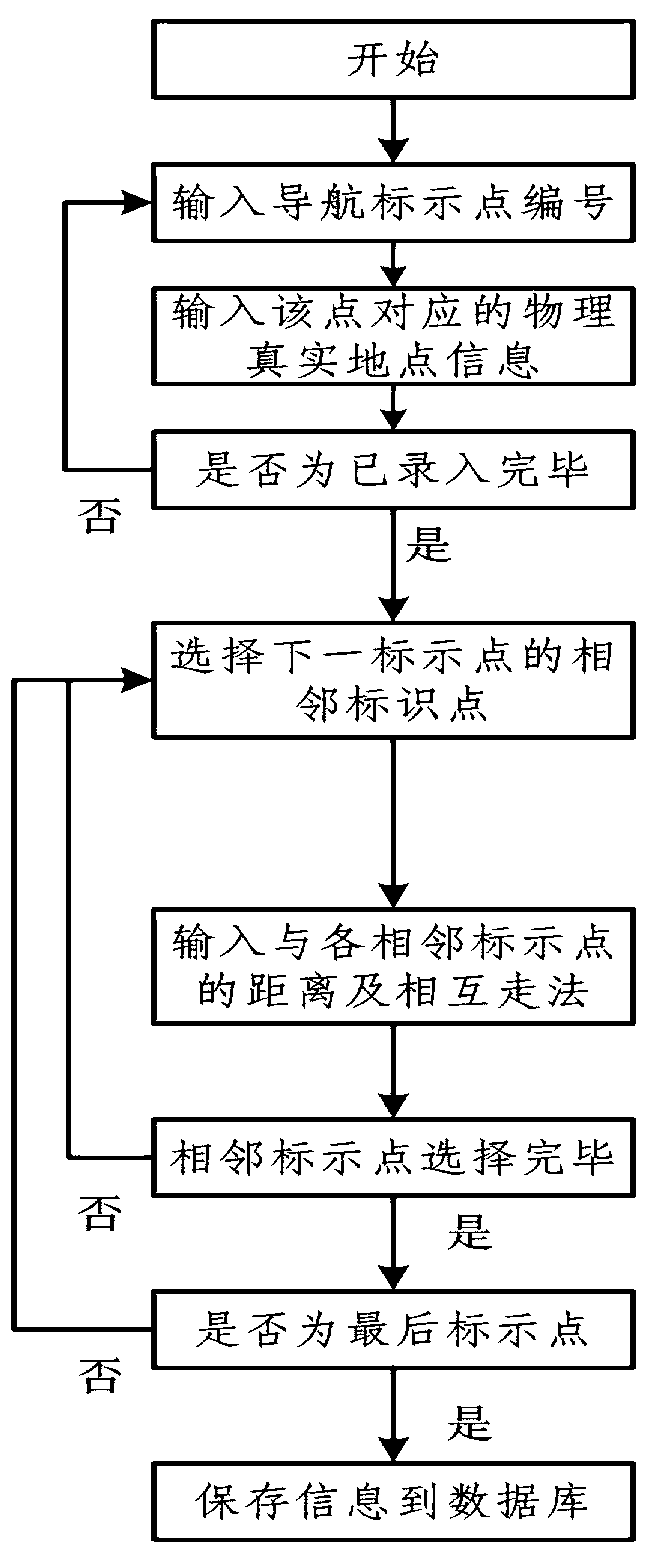

Navigation method in buildings

InactiveCN103344239AHigh precisionFinish quicklyNavigation instrumentsFire - disastersRoute planning

The invention discloses a navigation method applied in buildings. The method comprises the following steps of: firstly, distributing navigation indicating points at key sites according to the structure of a building, wherein the navigation indicating points are direction identifiers adhered to the ground, a handheld terminal can be used for carrying out route planning, and a walking method for walking from each navigation indicating point to another navigation indicating points by combining ground direction is stored in the handheld terminal; issuing a walking instruction for guiding a navigated person to walk to the next navigation indicating point to the navigated person by utilizing a handheld device of the navigated person and combining the walking method stored in a handheld device storing device according to a planed route when the navigated person walks to the certain navigation indicating point in a navigation process, so as to guide the navigated person to quickly find the next navigation indicating point by combining ground identifiers according to the walking instruction; and repeating the processes until finishing the navigation. The method can be used for personnel evacuating navigation in fire disasters and earthquakes as well as navigation and guiding in complex buildings at ordinary times and has the advantages of low cost, accuracy and high efficiency.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

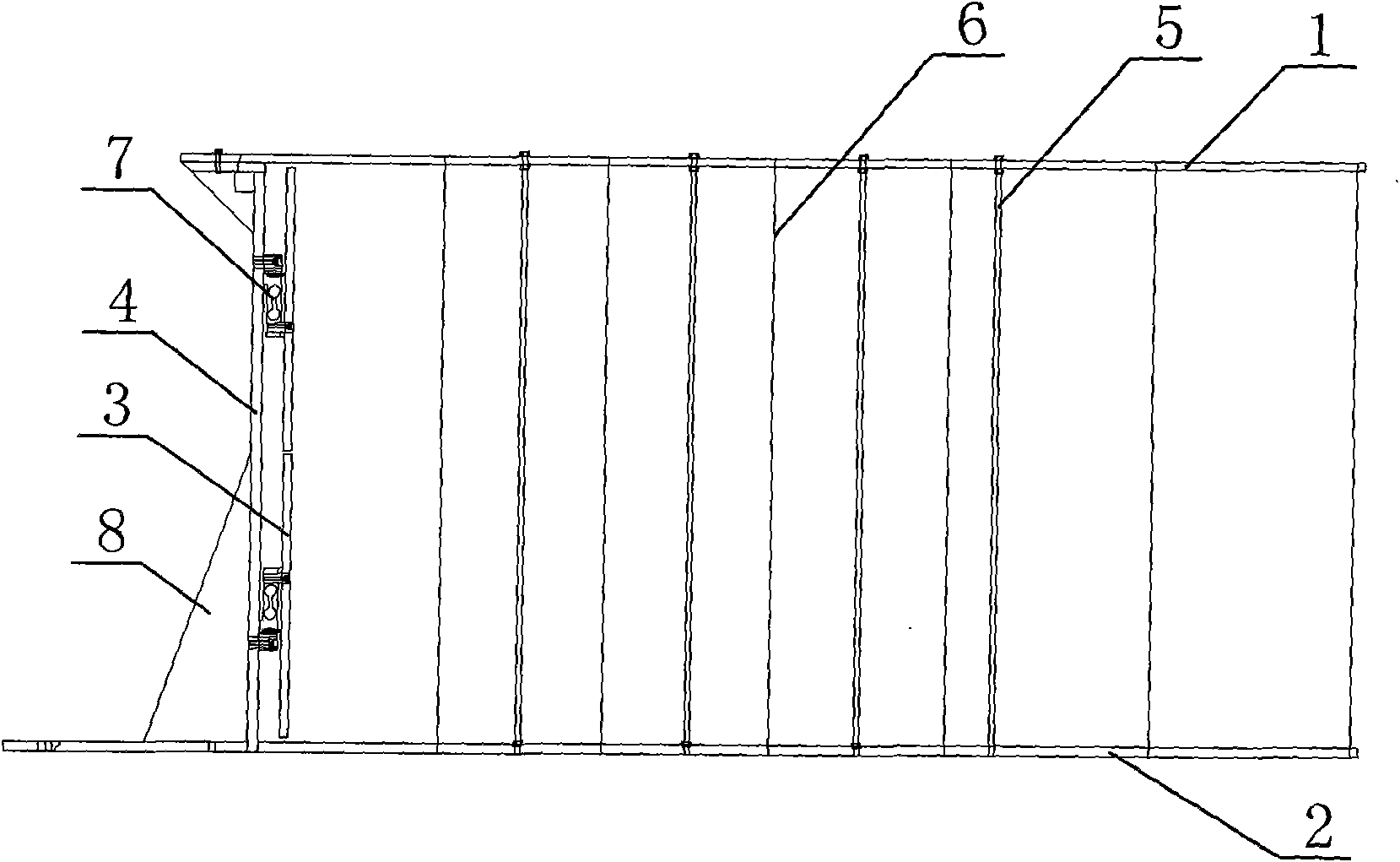

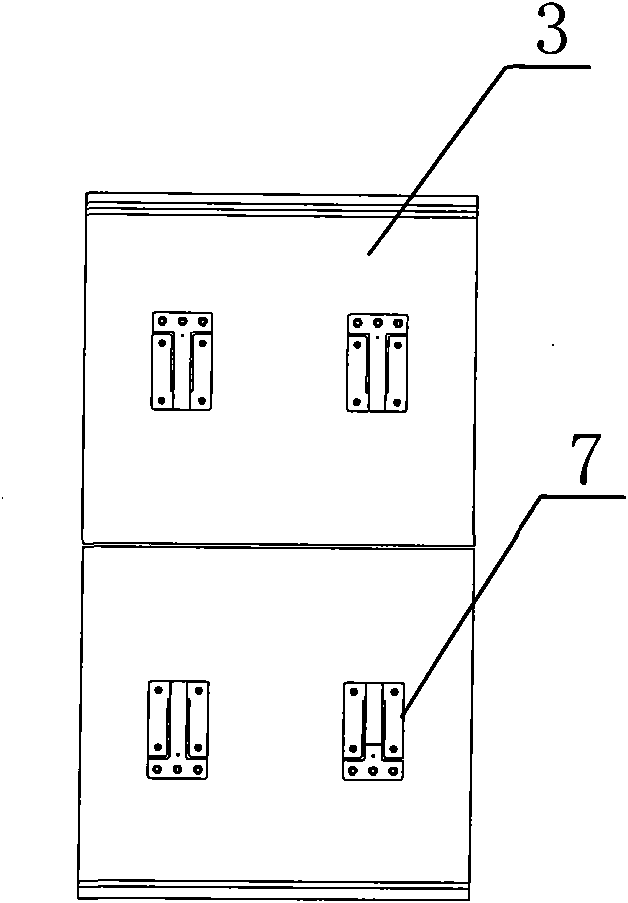

Testing device for wave surface height and impact load

InactiveCN101839743AOvercoming technical difficultiesFluid pressure measurement using ohmic-resistance variationVessel partsWire rodEngineering

The invention relates to a testing device for a wave surface height and an impact load, which is provided with an upper panel, a lower panel, a rear baffle and a front baffle. The rear baffle is vertically connected with the upper panel and the lower panel, the front baffle is connected with the rear baffle by a force-testing element, and a plurality of steel wire rods and tantalum wires are connected between the upper panel and the lower panel. The testing device for a wave surface height and an impact load is used for measuring the wave surface motion condition and the impact load quantity of green water on a bow deck and can provide a reliable measuring method for testing and researching green water in a model test.

Owner:中国船舶重工集团公司第七〇二研究所

Method for preparing (TiAlZr)N ultra-hard coating by employing multiple arc ion plating

InactiveCN101210309AGuaranteed repeatabilityStrong adhesionVacuum evaporation coatingSputtering coatingAlloySedimentation technique

A method for preparing (TiAlZr)N superhard coating by multi-arc ion plating technique sequentially comprises (1) determination of sedimentation technique; (2) determination of target component; (3) preparation of an alloy target; (4) selection and pre-treatment of a workpiece (substrate); (5) acquisition of a transition layer; (6) determination of the number of electric arc sources; (7) heating the workpiece; (8) determination of sedimentation process; (9) baking the film-coated workpiece; (10) workpiece rotation, etc. The invention can form a TiAlZr alloy target and determine the content change ranges of Ti, Al and Zr in the TiAlZr alloy target, so that the TiAlZr)N superhard coating has the advantages of strong adhesion (not less than 180 N), high hardness (not less than HV3,000), etc.

Owner:SHENYANG UNIV

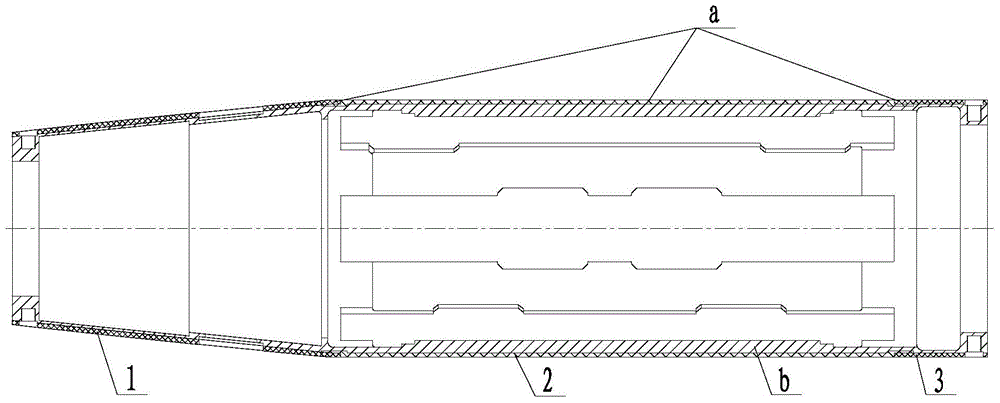

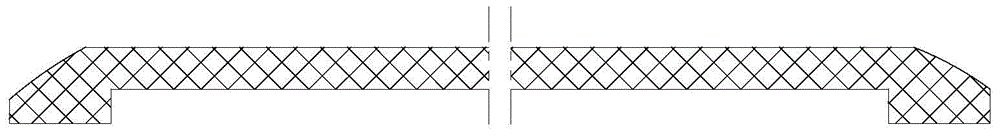

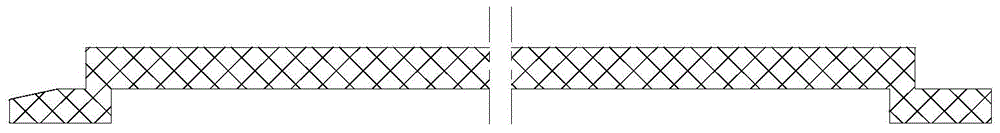

Segmented molding method of thermal protection layer of combined cabin

ActiveCN104552977AProduct quality is stable and reliableOvercoming technical difficultiesFlight testThermal protection

The invention discloses a segmented molding method of a thermal protection layer of a combined cabin and belongs to a composite material molding method which is used for solving the problem that a thermal protection layer at an opening part easily peels in an existing integral molding mode, so that the bonding and sleeving quality of the thermal protection layer can be ensured. The segmented molding method comprises the steps of segmented molding of the thermal protection layer, trial assembling of the thermal protection layer and bonding and sleeving of the thermal protection layer. According to the invention, a plurality of different modes are adopted for segmented molding of the thermal protection layer of the combined cabin, and the front segment of the thermal protection layer is molded by adopting a winding and sleeving mode; the middle segment of the thermal protection layer comprises a plurality of individual thermal protection sheets, and each thermal protection sheet is molded by adopting a mold pressing mode; the rear segment of the thermal protection layer is molded by adopting a winding and sleeving mode; meanwhile, the bonding and sleeving sequence of each segment of the thermal protection layer is optimized; according to the molded cabin provided by the invention, a product is reliable in quality, the sleeving clearance is controlled within 0.7mm, and the butt clearance is controlled within 0.2mm. By the check of the flight test, the technical difficulty of layering of the thermal protection layer is overcome, and the product sleeving and bonding quality meets the use requirement.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

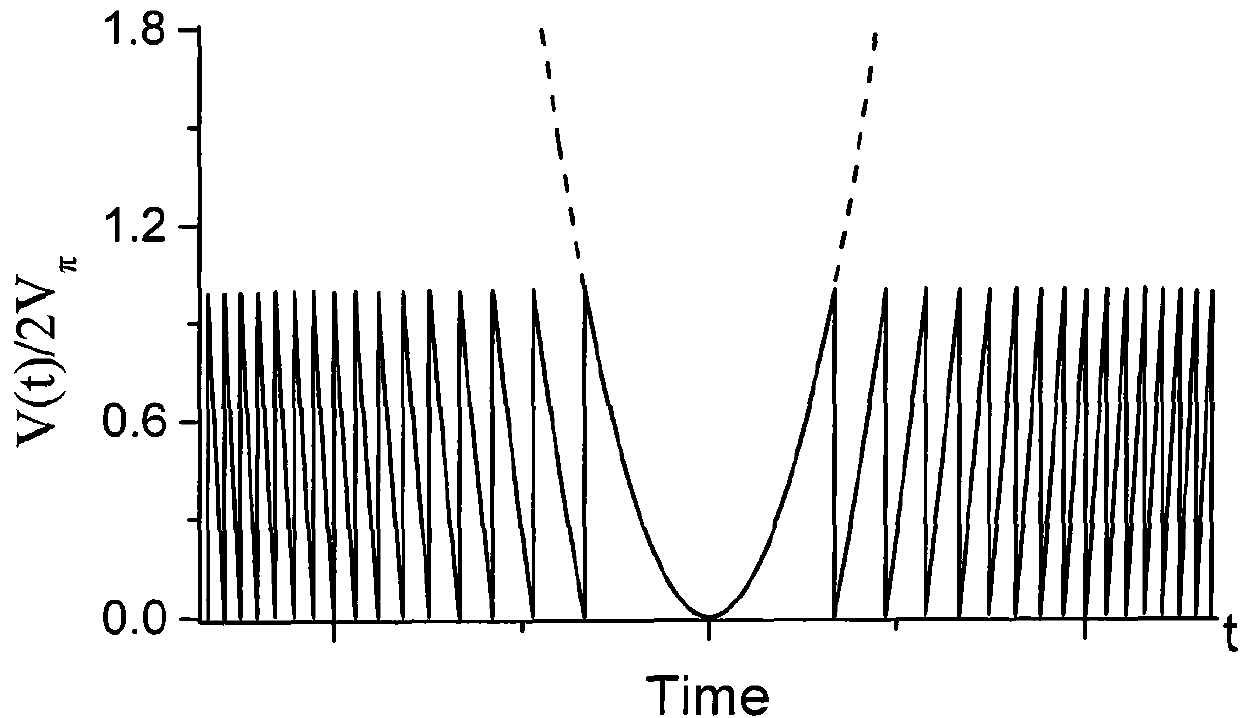

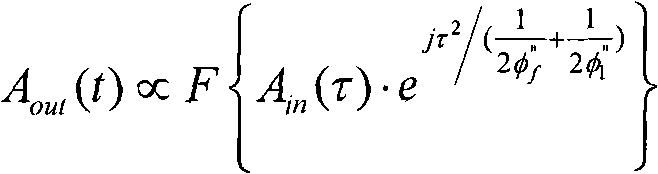

Method for generating ultra-wideband pulse of arbitrary waveform

InactiveCN101908904AOvercoming technical difficultiesEasy to integrateTransmissionNon-linear opticsBroadband pulseUltra-wideband

The invention discloses a time domain lens compression system based method for generating ultra-wideband pulse of arbitrary waveform. The method comprises the following steps: generating a wideband time domain pulse signal in a frequency domain by using an arbitrary waveform generator (AWG); respectively generating a positive amplitude part and a negative amplitude part of the wideband time domain pulse signal by using two output ports of the AWG; respectively modulating the positive amplitude part and the negative amplitude part into an optical pulse signal; compressing the two optical pulsesignals by using a time domain lens system; and detecting one compressed optical pulse signal with the other optical pulse signal by a differential photoelectric detector after one compressed opticalpulse signal is subjected to optical delay so as to acquire the ultra-wideband pulse signal. By using the time domain lens compression system, the method can flexibly and conveniently generate a narrow pulse signal with an arbitrary waveform, can effectively overcome the encountered difficulty in generating narrow pulse in the frequency domain, contributes to confusion with the optical fiber communication technology, and plays an important role in communication systems, radar systems, the sensor technology and other scientific fields as an implementation scheme of an optical AWG.

Owner:TSINGHUA UNIV

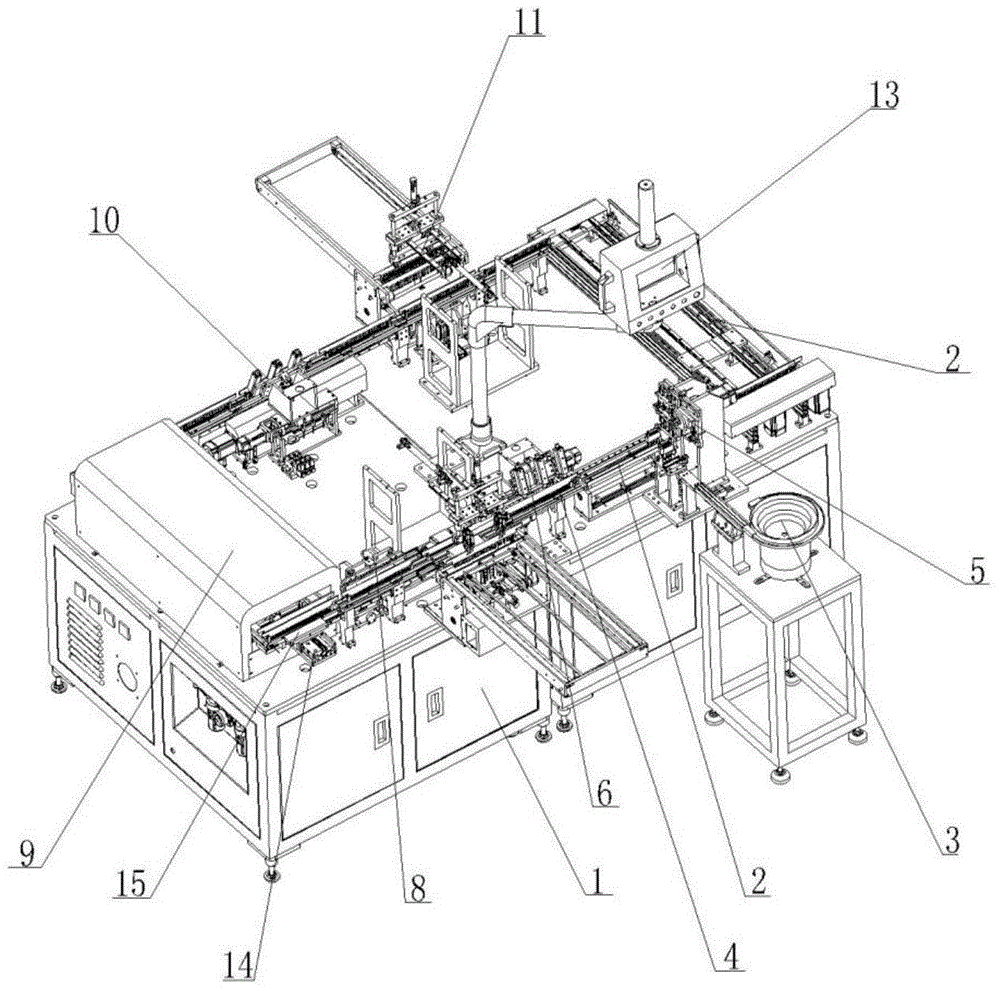

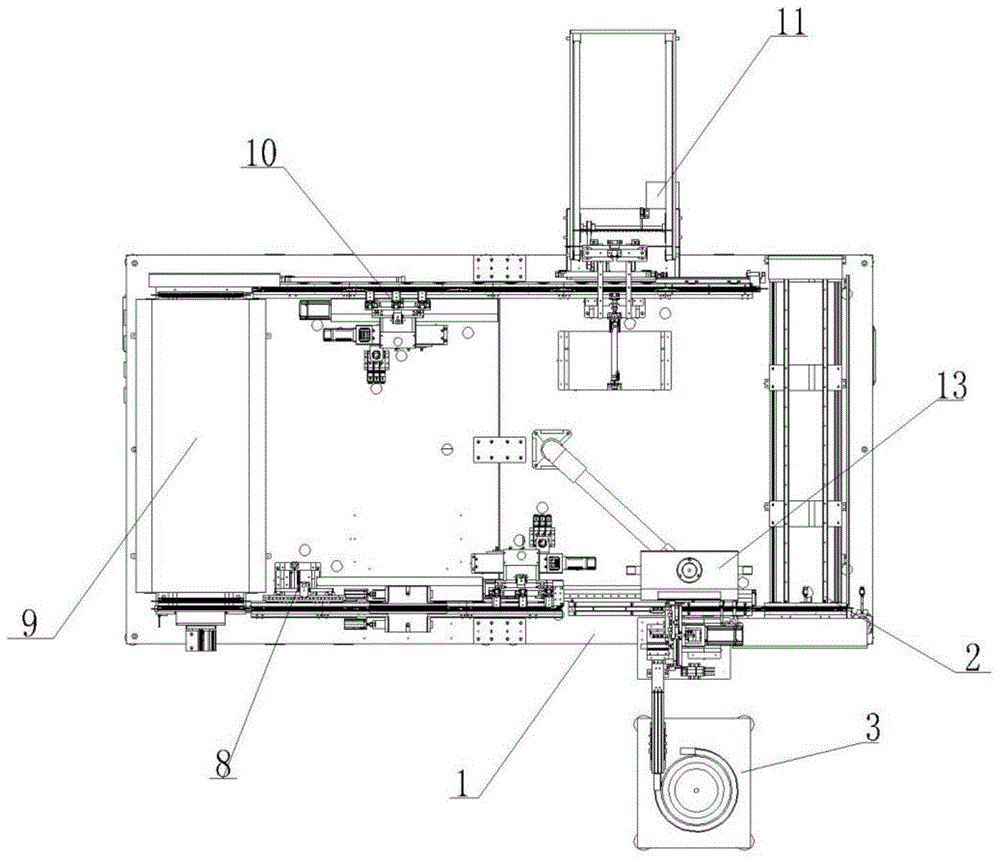

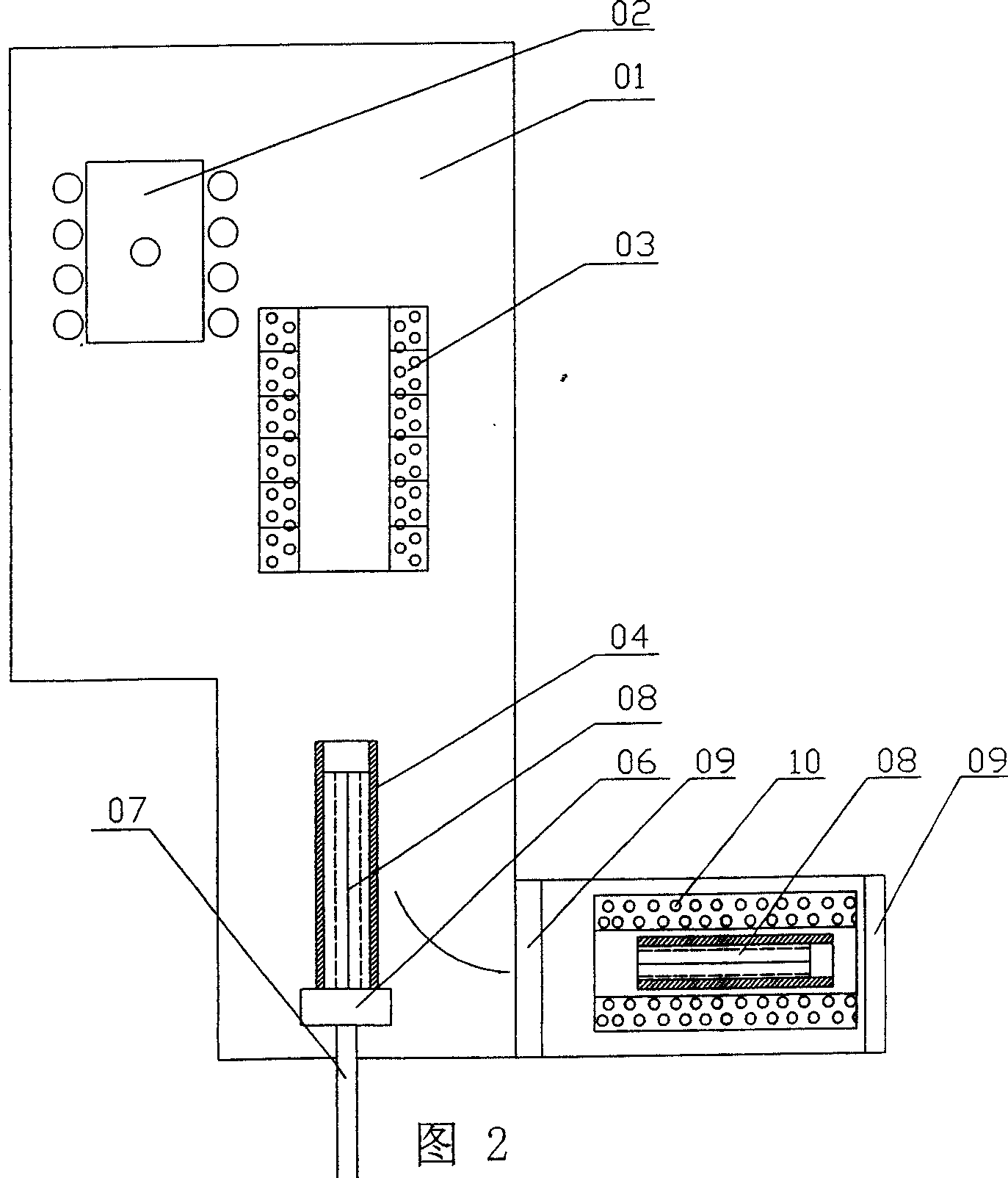

Capacitor shell-inserting machine

InactiveCN105321735AOvercoming technical difficultiesReduce the possibilityCapacitor manufactureCapacitanceMechanical engineering

The invention relates to the field of capacitor production processes, in particular to a capacitor shell-inserting machine which is capable of performing mechanical automatic shell-inserting package on a plurality of granular capacitors without the need for a manual operation and is extremely low in defective rate. The capacitor shell-inserting machine comprises a machine body, a guide rail, a vibratory feed plate, a carrier with a groove, a first conveying arm capable of conveying sleeving shells at a discharge hole of the vibratory feed plate onto the carrier, a plurality of first dispensing machines, a limiting apparatus used for limiting the spacings and positions of the granular capacitors when falling into the carrier, a pressing apparatus used for pressing the capacitors and the sleeving shells, a drying apparatus, a plurality of second dispensing machines, a second conveying arm used for removing the capacitors sleeved with the shells, and a center console, wherein the guide rail is mounted on the machine body; the carrier is positioned in the guide rail and is in sliding fit with the guide rail; and the first conveying arm, the first dispensing machines, the limiting apparatus, the pressing apparatus, the drying apparatus, the second dispensing machines and the second conveying arm are mounted on the machine body in sequence.

Owner:WUXI YUANCHUANG TECH CO LTD

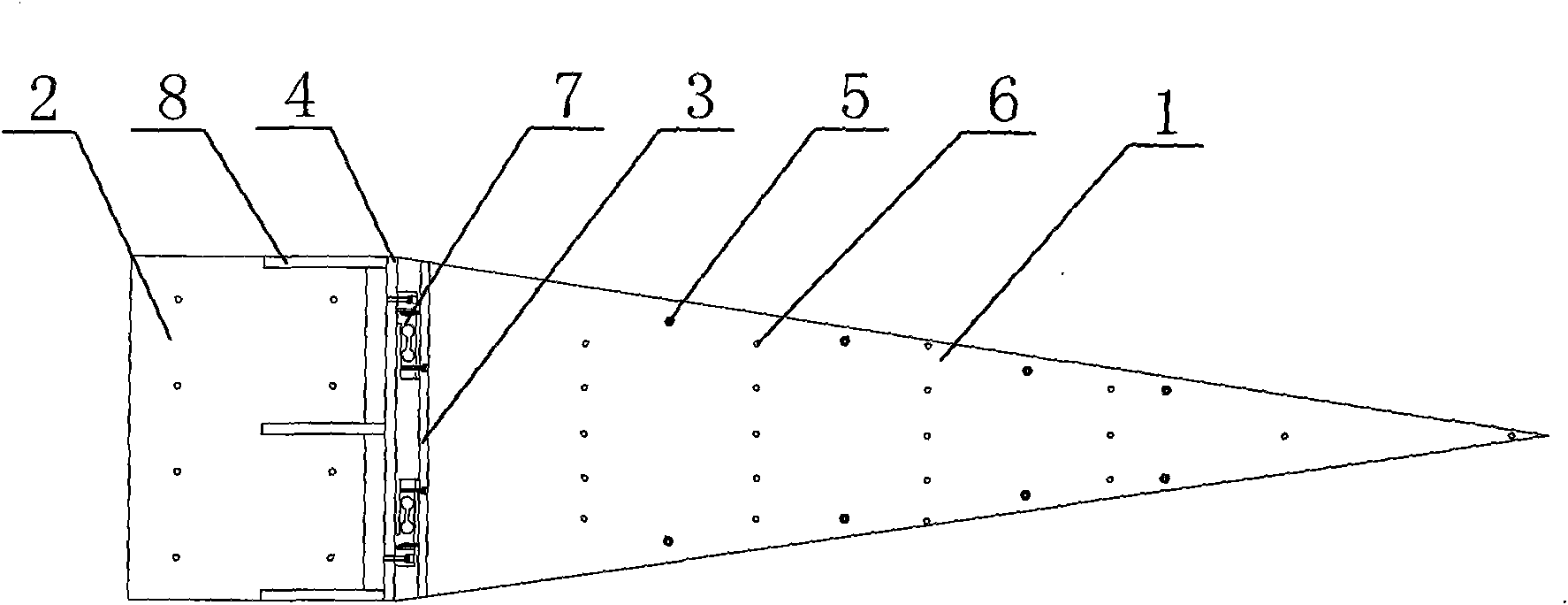

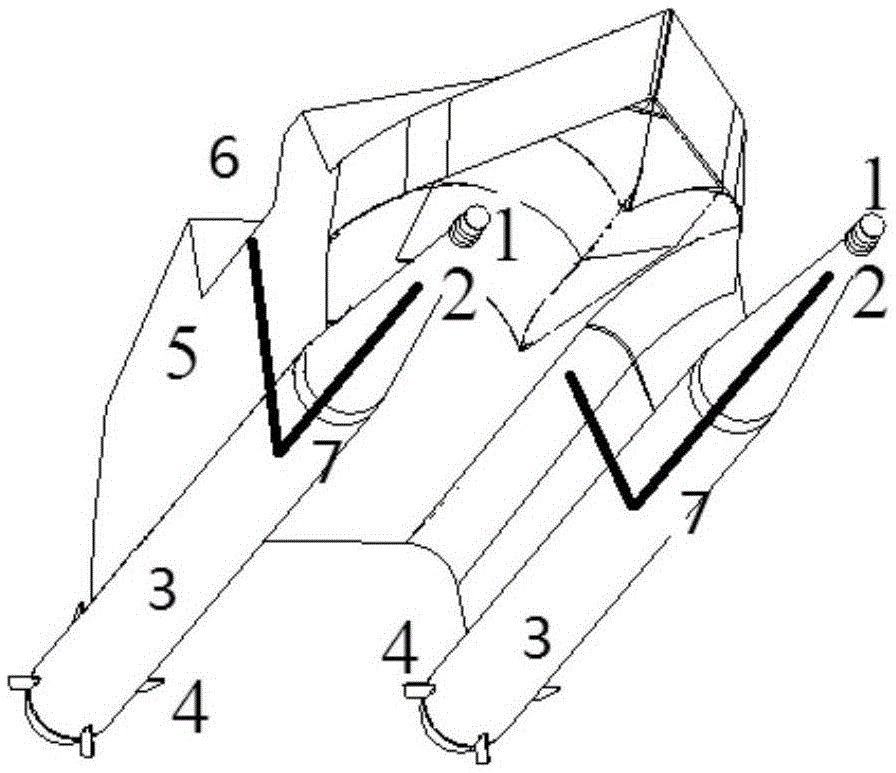

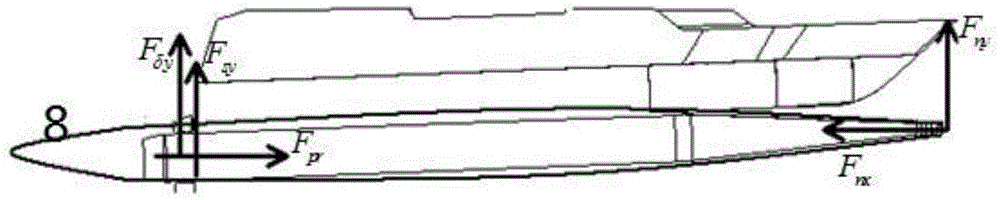

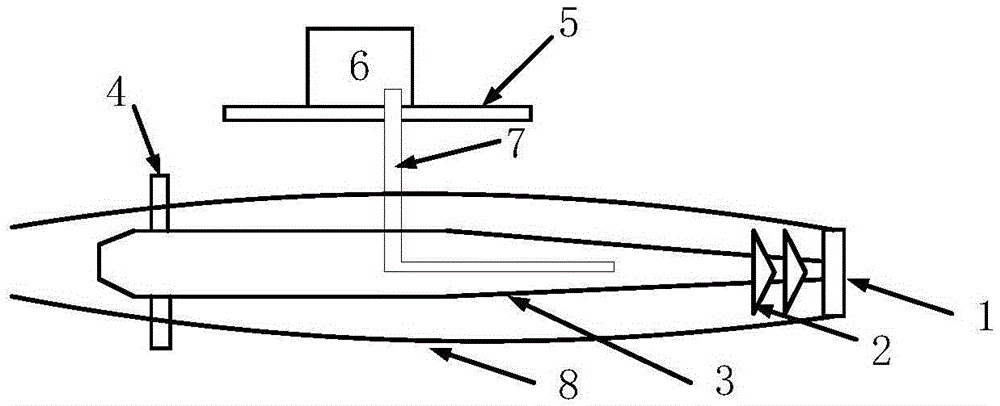

Water-surface aerating double-bubble high-speed voyage moving body structure

InactiveCN105620653AEasy to getEasy to implementWatercraft hull designHydrodynamic/hydrostatic featuresEngineeringAir compressor

The invention provides a water-surface aerating double-bubble high-speed voyage moving body structure. Two air compressors are arranged on the surface of a moving body, an aerating pipeline is connected to an output end of each air compressor, two cone-cylinder combinations are arranged at the lower end of the moving body symmetrically, a cavitator and a rectifying device are mounted on the head portion of each cone-cylinder combination, a tail control surface is mounted at the tail of each cone-cylinder combination, and the end of each aerating pipeline extends into the corresponding cone-cylinder combination. Elliptical double-cavitation-bubble multiphase flow is formed at the bottom of the moving body to enable the water-surface moving body to voyage at a high speed, so that the technical problem of applying a cavitation-bubble multiphase flow technology to the water-surface moving body currently can be solved. The water-surface aerating double-bubble high-speed voyage moving body structure is simple in structure, low in cost and easy to implement.

Owner:HARBIN ENG UNIV

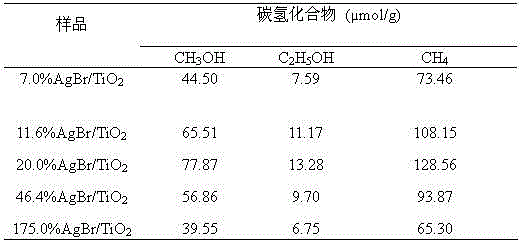

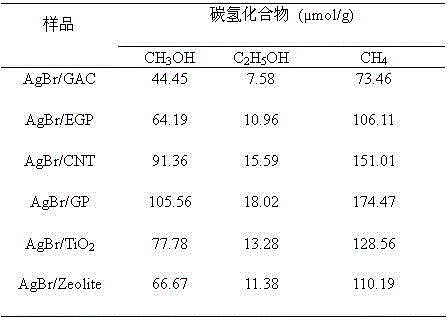

Preparation method of silver halide composite material

InactiveCN102614898AOvercoming technical difficultiesInhibition of agglomerationMolecular sieve catalystsSilver iodideSilver bromide

The invention discloses a preparation method of a silver halide composite material. The silver halide composite material is a silver halide composite which is prepared by loading silver halide on the surface of a carrier with conductive performance, wherein silver halide content occupies 1.0% to 17.5% of weight of the carrier, the silver halide is silver bromide or silver iodide, and the carrier with conductive performance is slice graphite, expansion graphite, graphene, a carbon nano tube, granular activated carbon, zeolite and titanium dioxide. The composite material prepared by the wet method and the precipitation method is capable of enabling ultrafine silver halide nanometer particles to be evenly dispersed on the surface of the carrier with the conductive performance and restrains reuniting on the surface of the silver halide.

Owner:SUN YAT SEN UNIV

Carbon fiber reinforced poly(ether-ether-ketone) composite bone fracture plate

InactiveCN1296013CPromote healingOvercoming technical difficultiesOsteosynthesis devicesPolymer scienceCarbon fibers

A bone setting-up plate is made up of the carbon fibre reinforced polyether etherone. Said carbon fibre has a mass ratio of 20-40%, tension strength greater than 300 MPa and tension modulus greater than 200 GPa. It features that its elastic modulus is matched with that of human bone.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

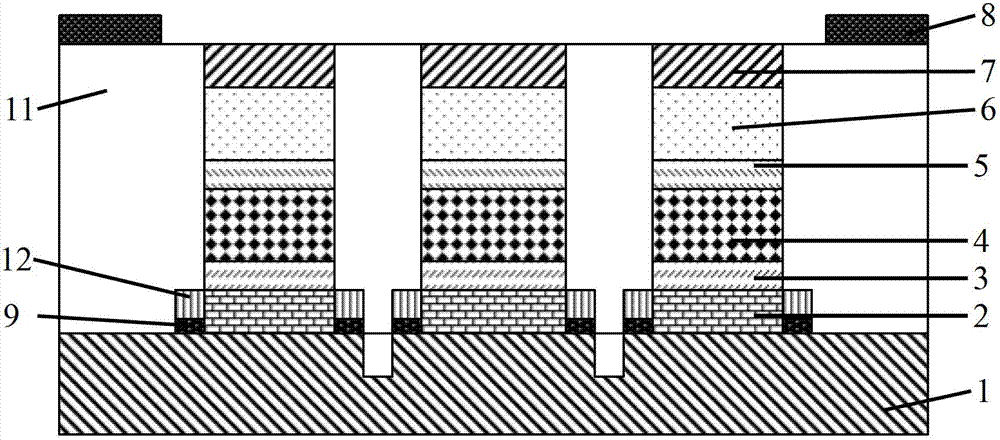

Method for manufacturing AlGaInP-LED (Light Emitting Diode) integrated micro display component with single-side electrode structure

ActiveCN102790144AAdvantages of production methodSimple structureSolid-state devicesSemiconductor devicesPlanar electrodeLed array

The invention discloses a method for manufacturing an AlGaInP-LED (Light Emitting Diode) integrated micro display component with a single-side electrode structure, wherein the steps comprises: etching multiple first grooves which are mutually intersected on a device body; growing a lower electrode metal layer on the bottom part of each groove to form the lower electrode metal layer; growing an insulating medium layer above a lower electrode; corroding an area of the lower electrode metal layer outside a lower electrode diagram downward till reaching a certain depth in an N-shaped substrate layer in order to form multiple second grooves; filling opaque diaphragms into the second grooves and the upper part of a protection medium of the lower electrode; manufacturing an upper electrode above a light emitting unit; and electroforming upper and lower electrode leads. With the adoption of the method for manufacturing the LED array micro display device with the planar electrode structure disclosed by the invention, the process difficulty resulting from the manufacturing of the electrodes on the front face and the back face respectively can be prevented; since the manufactured micro display device is provided with the double bar type upper and lower electrodes of which the different faces are perpendicular to each other, the more even current distribution can be obtained; and therefore, the micro display device available for even luminance is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

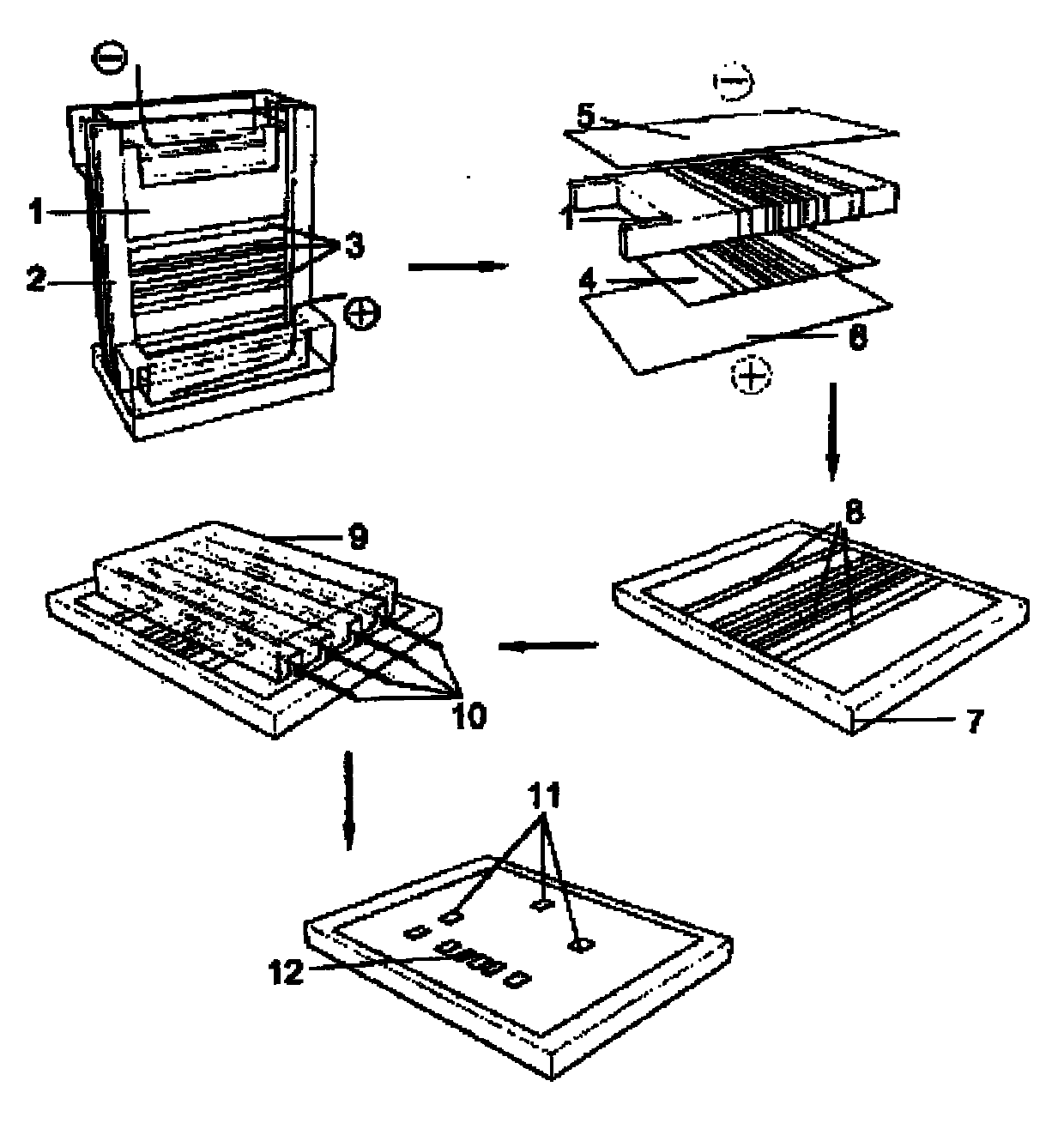

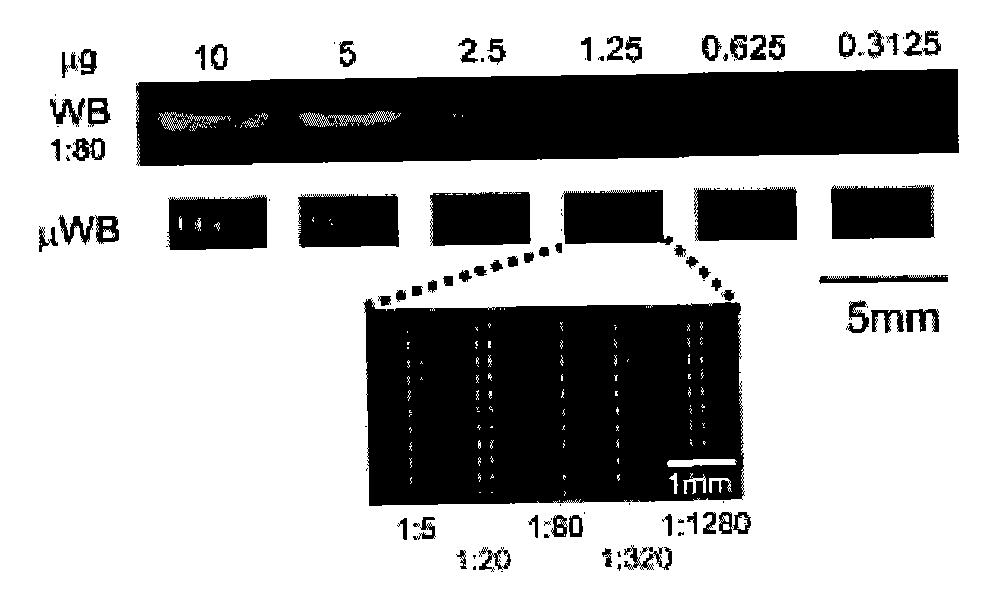

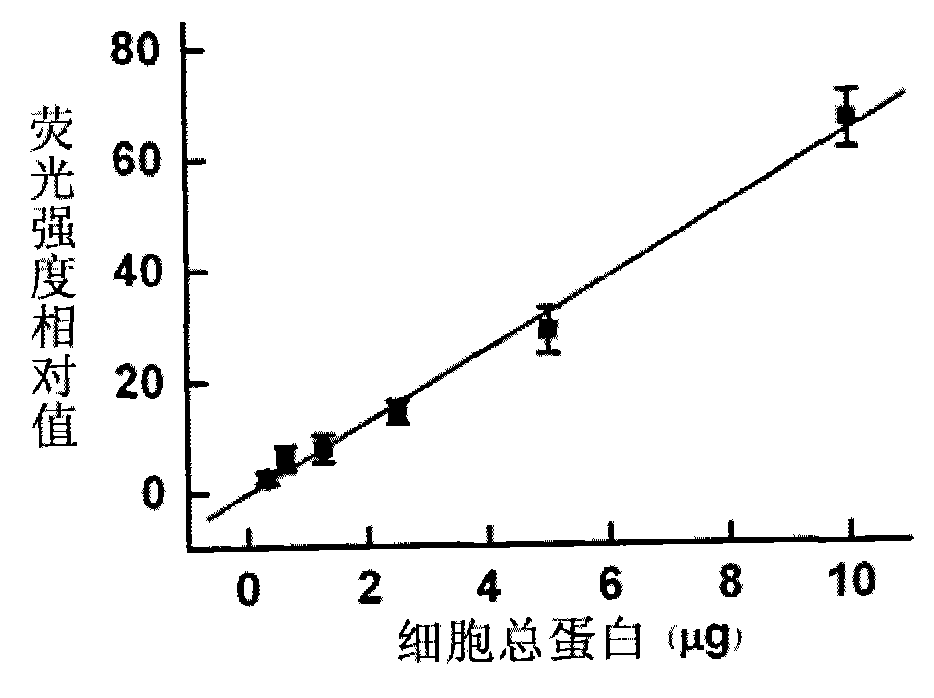

Microfluidic immune imprinting chip and preparation method and application thereof

The invention provides a microfluidic immune imprinting chip and a preparation method and application thereof. The provided microfluidic immune imprinting chip comprises: 1) a substrate fixed with protein strips separated according to molecular weight; and 2) a microfluidic pipeline. The invention also provides a method for the microfluidic immune imprinting chip, and application of the microfluidic immune imprinting chip to detecting various proteins in a sample, detecting molecular weight markers of the proteins, and optimizing antibody concentration in an immune reaction. Various proteins in a biological sample can be detected through a single immune imprinting experiment only, and the detection sensitivity is high; moreover, the molecular weights of the proteins can be detected, the operation is simple, the immune detection efficiency can be effectively improved, and the cost is reduced.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

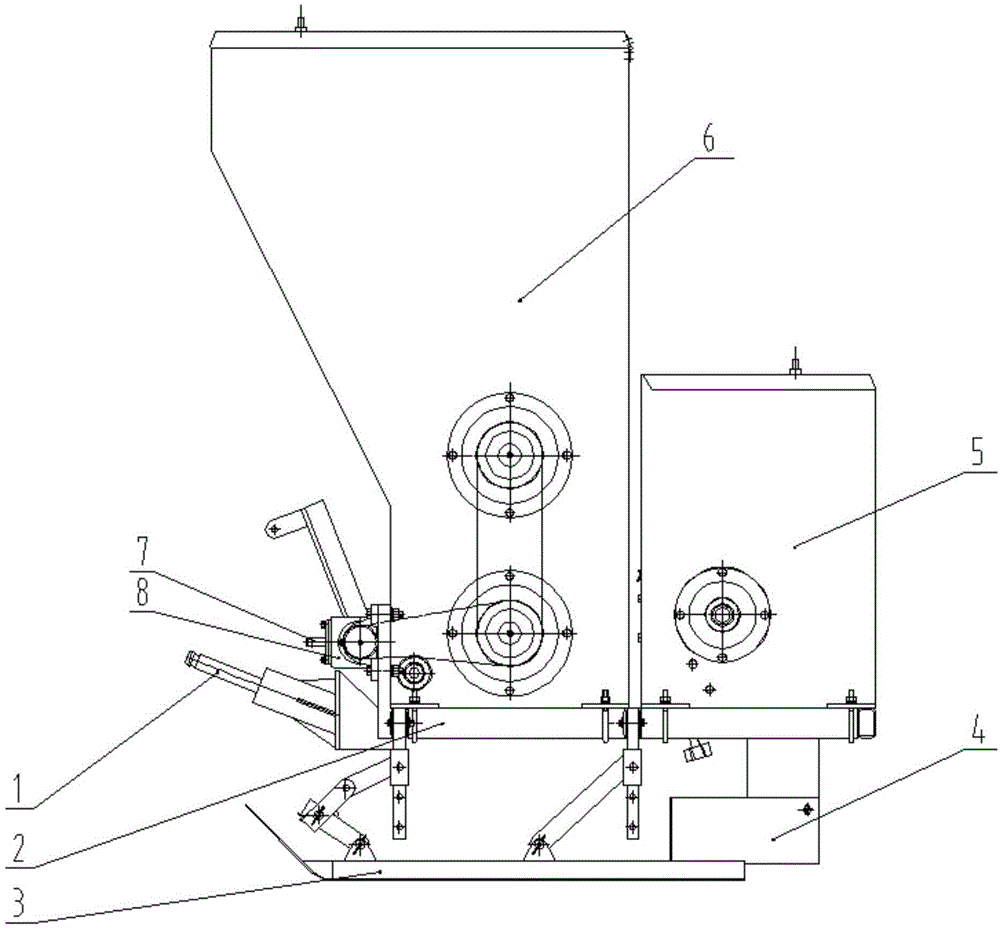

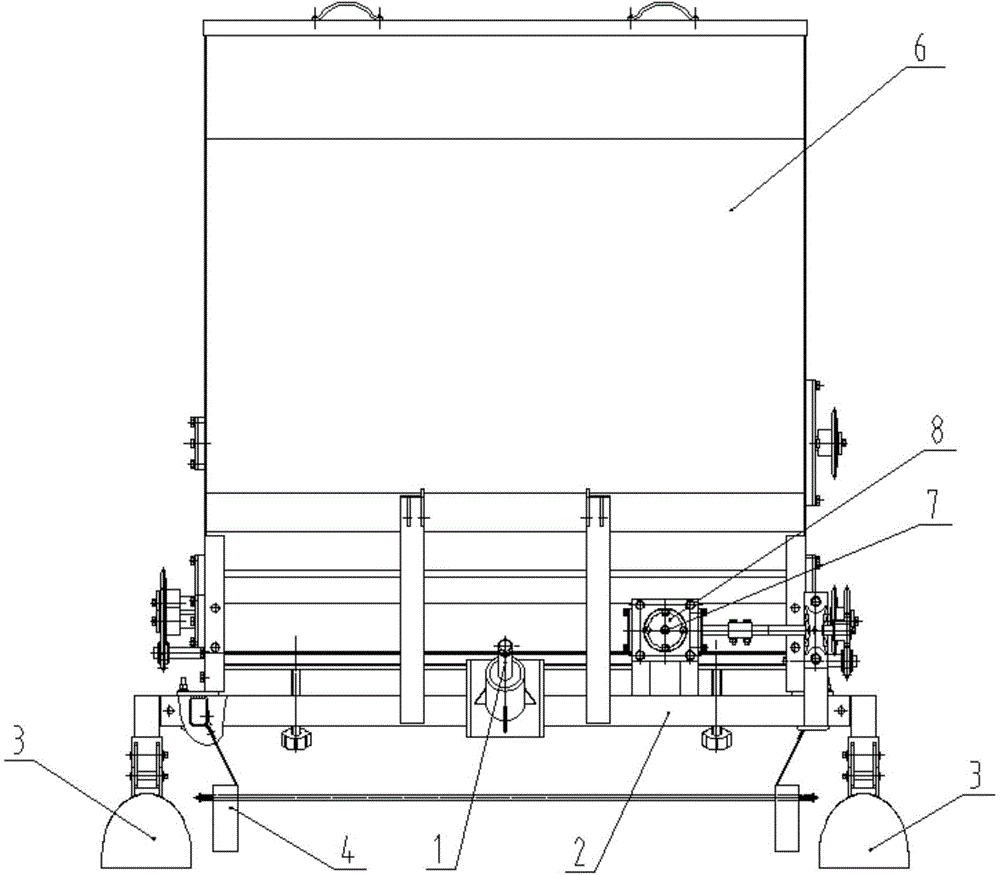

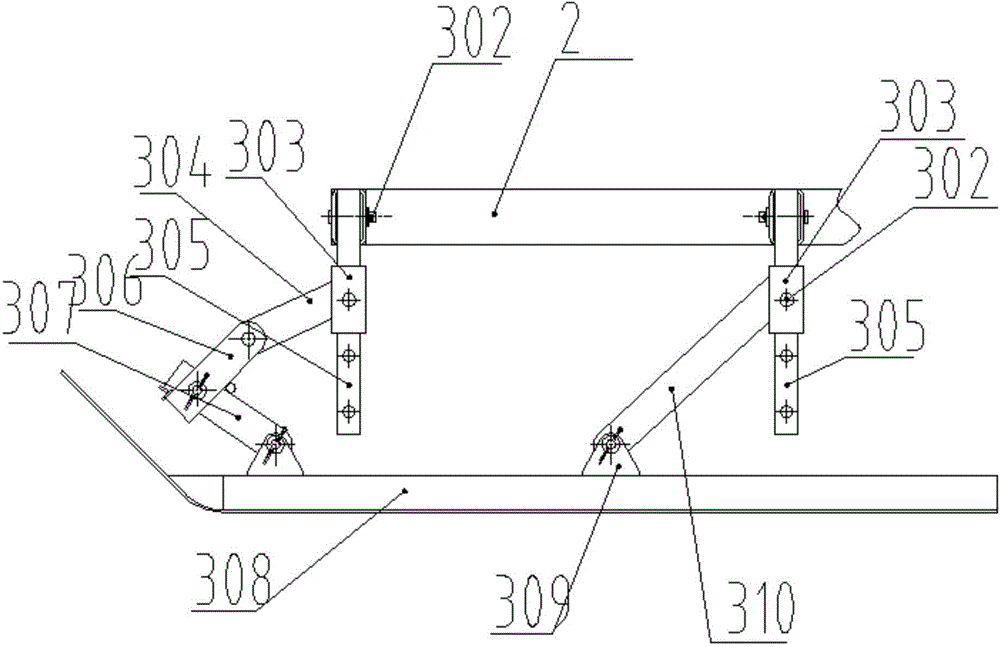

Suspension type rice field seedling-breeding and soil-spreading seeder

The invention relates to a suspension type rice field seedling-breeding and soil-spreading seeder. A hitching shaft is hitched and fixed on a chassis of a rice transplanter, wherein a power output shaft of the chassis of the rice transplanter is connected to a power input shaft of the seeder and is used for driving a soil spreading component and a seedling component to work; a support plate component comprises a pair of sliding plate mechanisms which are arranged on two sides of a seedling breeding plate; the seeding width of the seeder is larger than the total width of a seedling spreading plate; seedling row position adjusting devices are suspended and fixed on two side longitudinal beams of a frame and are in hinge connection with the two side longitudinal beams by virtue of a pair of limiting plates; the seedling row position adjusting devices are capable of freely swinging left and right in the rotation direction of the hinge; a spring is arranged between the ends of limiting rods and the limiting plates and is used for pressing the limiting plates to the middle so as to ensure that a space M between a left limiting plate and a right limiting plate is equal to the length L of the convex middle parts of the limiting rods; M is equal to or slightly larger than the width of the seedling breeding plate; a bending and guiding part with one end bending outwards is arranged at the front end of each limiting plate and is used for exerting the guiding effect.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Method for mullet artificial breeding in batches

InactiveCN108293923AExtended use timeImprove efficiencyClimate change adaptationPisciculture and aquariaBroodstockINCREASED EFFECT

A method for mullet artificial breeding in batches belongs to the field of fishery. The invention relates to a technical field of aquaculture, in particular to the method for mullet artificial breeding in multiple batches, and is characterized by comprising a whole process of the six stages of parent postpartum recovery, parent breeding, parent antenatal breeding in batches, parent fish selectionand hasten parturition, oosperm incubation and larval breeding; female fish occupying proportion is increased, the grouping is carried out at a low temperature period, and temperature and light control breeding in a back room is combined; according to the method, the use time of artificial breeding equipment is prolonged, the technical problem is solved that mullet artificial breeding for a long time in multiple batches is difficult, the egg grain cardinal number of breeding groups with same quantity is doubled or more, three batch breeding in a breeding season is achieved, the breeding time is prolonged by three times or more, and the fish fry breeding quantity is increased by three times or more. The fish yield-increasing effect in a breeding period is significant, and the method is applicable to industrialization large-scale development.

Owner:上海能淦水产专业合作社

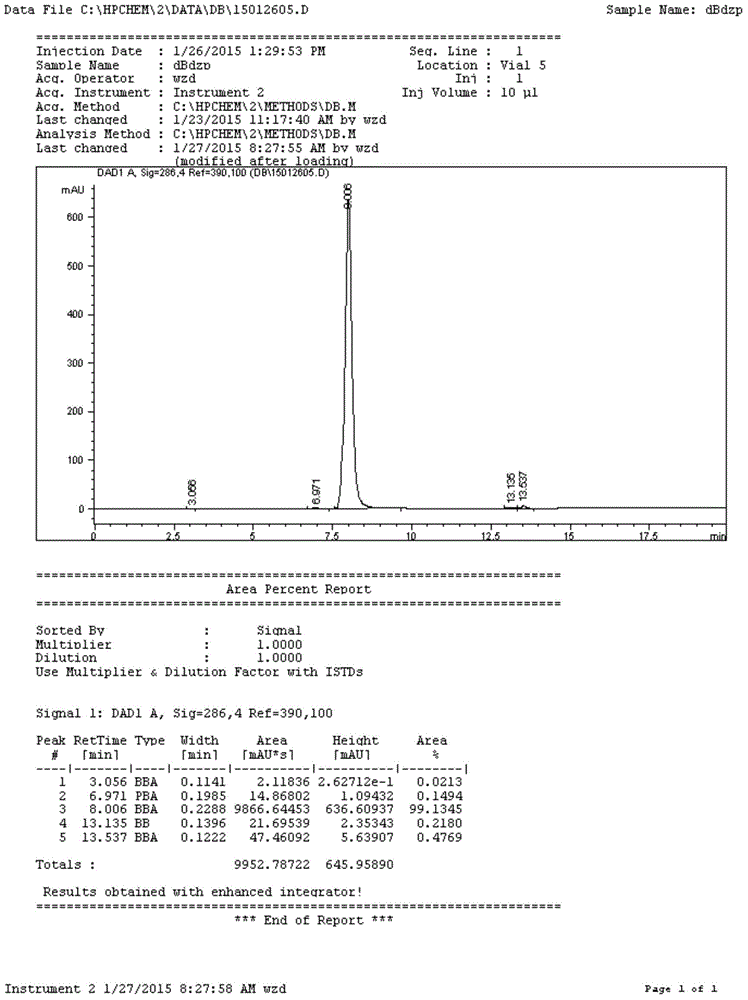

Preparation method, drug preparation and clinical application of high purity traditional Chinese medicine salvia miltiorrhiza active ingredient salvianolic acid B

ActiveCN104910112AAvoid degradationLow costOrganic active ingredientsSenses disorderSalvianolic acid BBULK ACTIVE INGREDIENT

The invention relates to a preparation method, a drug preparation and clinical application of a medicine effective component, especially relates to a preparation method of salvianolic acid B from traditional Chinese medicine salvia miltiorrhiza, and a drug preparation and clinical application, and belongs to the traditional Chinese medicine (TCM) technical field. Through use of a new method and a new idea of traditional Chinese medicine chemistry, the goal of being completely green, intelligent and circular economic can be realized, the degradation or transformation of the target compound can be effectively avoided, the preparation method has the advantages of energy conservation and emissions reduction, loss reduction, cost reduction, simple equipment and strong maneuverability, is more suitable for industrial production, and the yield is improved to 65-76% (on the basis of extract content). The present invention also discloses a variety of pharmaceutical acceptable dosage forms and new dosage forms and the clinical application in protecting of myocardial ischemia and anoxia, improvement of microcirculation, reduction of blood viscosity, inhibition of platelet aggregation and thrombosis formation and the like.

Owner:NANJING CHENXIANG MEDICAL RES

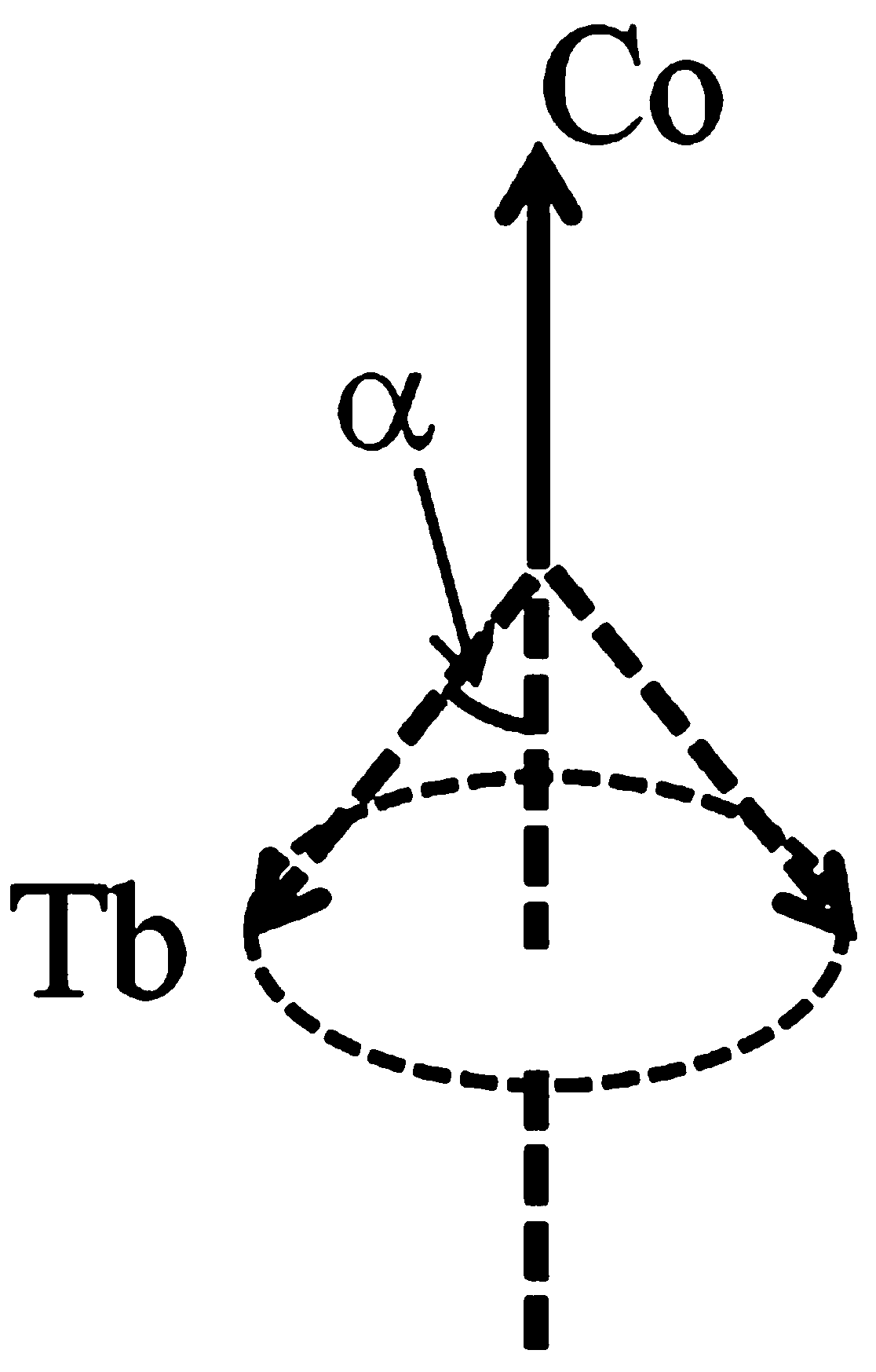

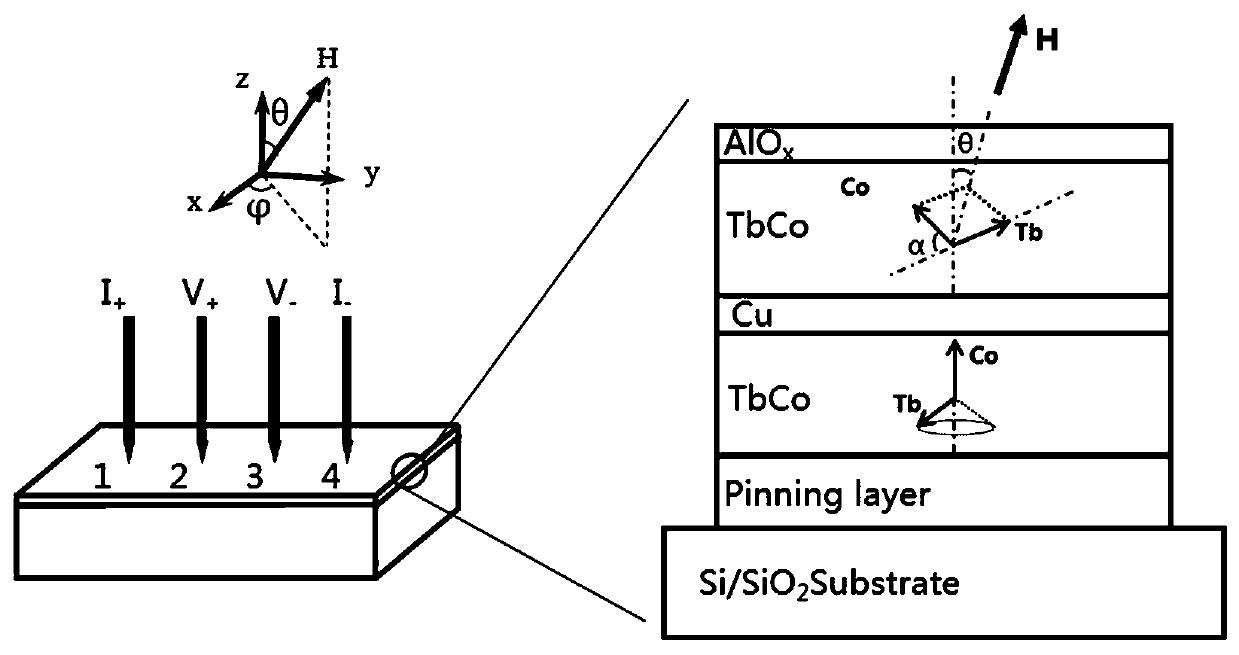

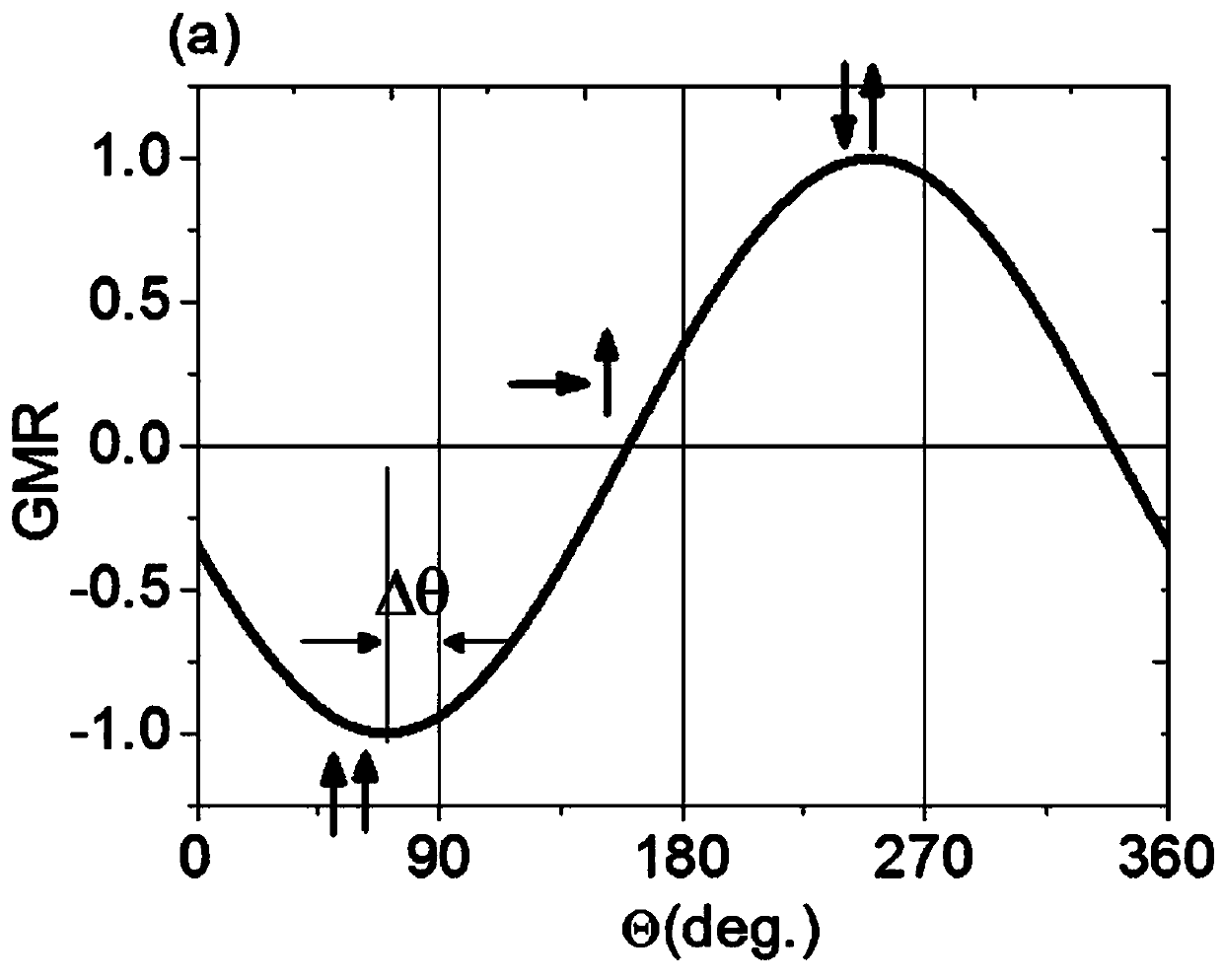

Measurement method for included angle between non-collinear anti-ferromagnetic coupling atom magnetic moments in rare earth (RE)-transition metal (TM) alloy

ActiveCN110412081ARestricted precise deconstructionOvercoming technical difficultiesMagnetic property measurementsMaterial resistanceAntiferromagnetic couplingRare earth

Provided is a measurement method for an included angle between non-collinear anti-ferromagnetic coupling atom magnetic moments in RE-TM alloy. A magnetoresistive angle resolution spectrum of a spinning valve composed of two RE-TM magnetic layers is measured to determine the included angle between the RE-TM non-collinear anti-ferromagnetic coupling atom magnetic moments; and a spinning valve composed of two RE-TM magnetic layers and an intermediate non-magnetic metal spacing layer issubjected to magnetoresistive angle resolution spectrum measurement. The angel resolution spectrum of the magnetic resistance of the pinning type spinning valve composed of the double RE-TM magnetic layers is measured to determine the included angle between the non-collinear anti-ferromagnetic coupling atom magnetic moments in the RE-TM alloy.

Owner:CHINA THREE GORGES UNIV

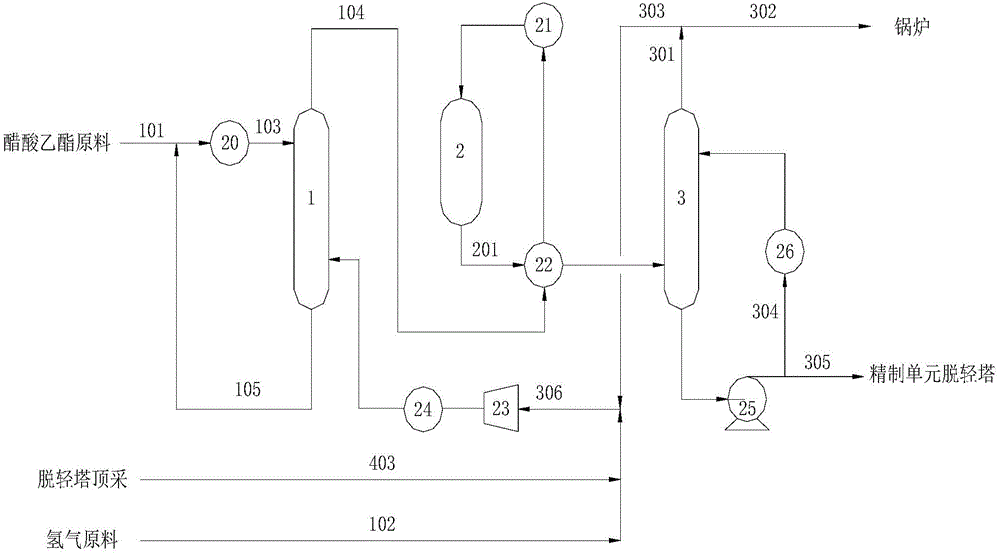

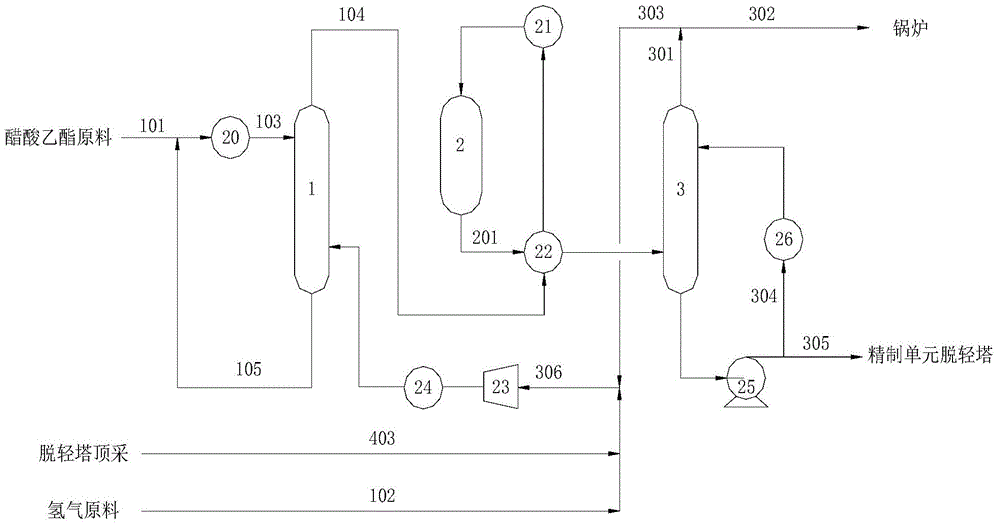

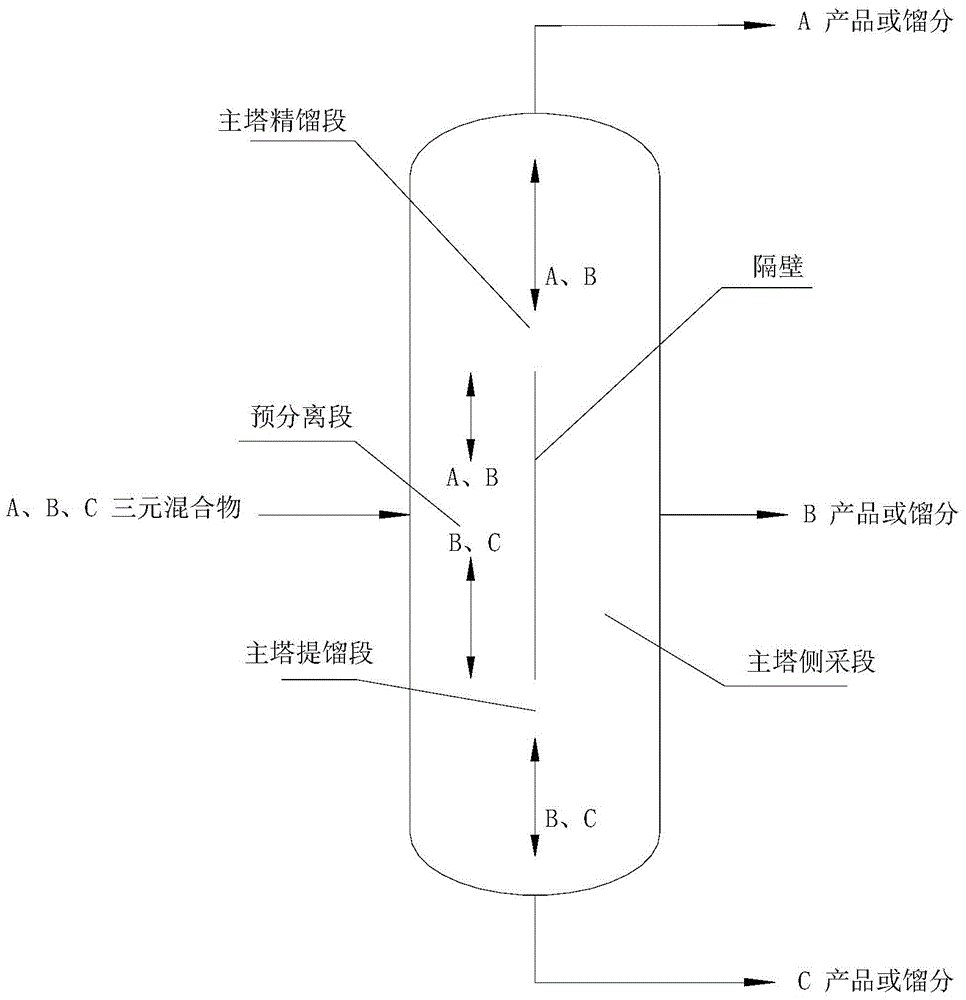

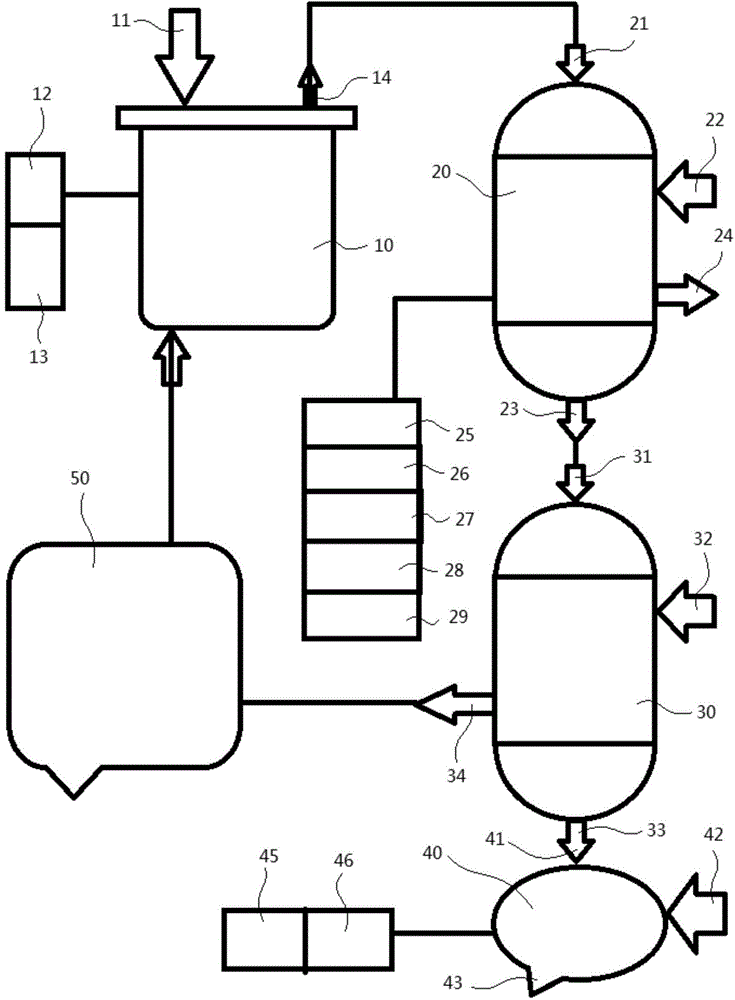

Method and equipment for producing ethanol product by taking ethyl acetate as raw material

ActiveCN104649862AGood miscibilityQuality improvementOrganic compound preparationChemical industryGas phaseNitrogen gas

The invention discloses a method and equipment for producing an ethanol product by taking ethyl acetate as a raw material. The method comprises the following step: by taking ethyl acetate and hydrogen as the raw materials, adopting technologies and equipment including a copper-based catalyst, gas phase catalytic hydrogenation, reaction heat recovery, reaction product purification, ternary azeotropic distillation, a dividing wall tower and thermally-coupled distillation. The device is mainly characterized by comprising an ethyl acetate catalytic hydrogenation reaction unit and an ethanol product refining unit, wherein ethyl acetate and hydrogen raw materials are treated by the ethyl acetate catalytic hydrogenation reaction unit to obtain hydrogenation reaction liquid containing ethanol, and the hydrogenation reaction liquid is conveyed to the ethanol product refining unit to obtain an ethanol product; and the ethanol product refining unit comprises a light component removal tower and a rectification tower, light impurity components such as hydrogen, nitrogen and ethane of the hydrogenation reaction product are firstly mainly removed by virtue of the light component removal tower, and the treated hydrogenation reaction liquid is conveyed to the rectification tower to mainly remove impurity components such as acetaldehyde, ethyl ether and ethyl acetate to obtain a fuel ethanol product or an absolute ethanol product.

Owner:TIANJIN UNIV

Method for in situ growth of metal oxide, metal nitride and metal carbide nanowires

InactiveCN102517640AAchieve in-situ electrical connectionOvercoming technical difficultiesPolycrystalline material growthAfter-treatment detailsElectrical connectionTwo step

The invention provides a method for in situ growth of metal oxide, metal nitride and metal carbide nanowires, which belongs to the technical field of chemical engineering of materials. The invention is characterized in that: a semiconductor etching process is employed for preparing parallel conductive electrodes on a polished surface of an insulation substrate; a metal salt solution soluble in an organic solvent or water is dropped between the prepared electrodes; by using a two-step dimensional electrophoresis method, an alternating current field with a frequency range of 0 to 1000 Hz and an amplitude of 1 to 20 V is applied at two ends of the electrodes for 1 to 50 s, and then frequency is increased to be in a high frequency area of 2 MHz to 20 GHz and is maintained for 1 s to 30 min; in situ growth of metal nanowires between the two electrodes is carried out, and then the metal nanowires are respectively roasted in an oxygen atmosphere, an ammonia atmosphere and a hydrocarbon atmosphere at a temperature of 400 to 1600 DEG C so as to obtain corresponding metal oxide, metal nitride and metal carbide nanowires. The beneficial effects of the invention are as follows: in situ electrical connection of a single nanowire is realized, and technical difficulties in removal of a template and transfer are avoided.

Owner:DALIAN UNIV OF TECH

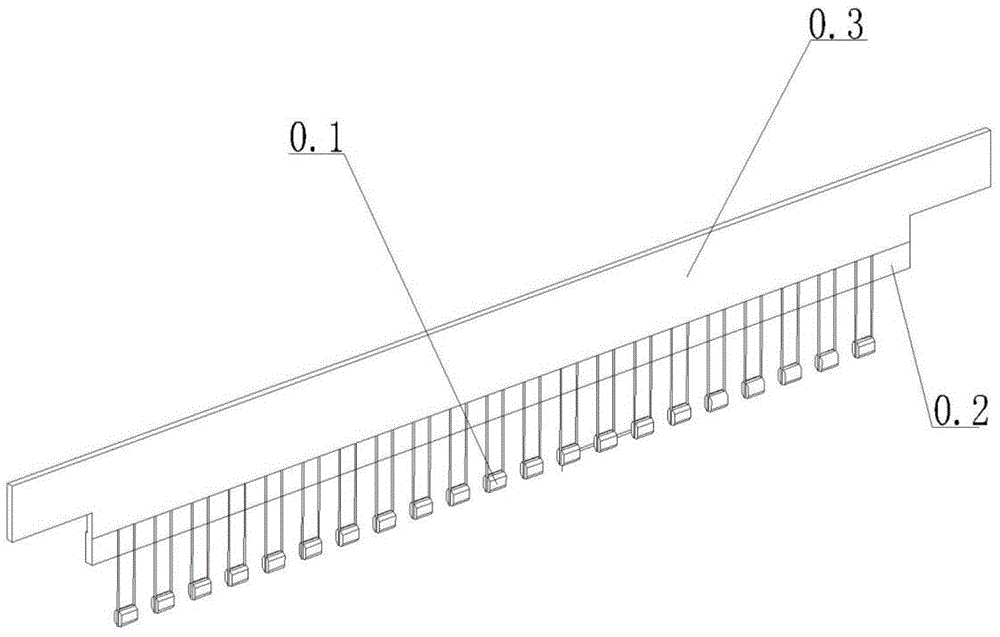

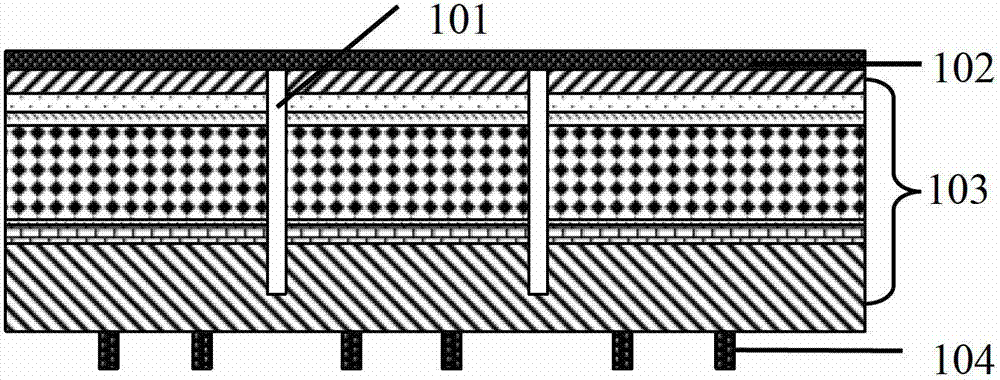

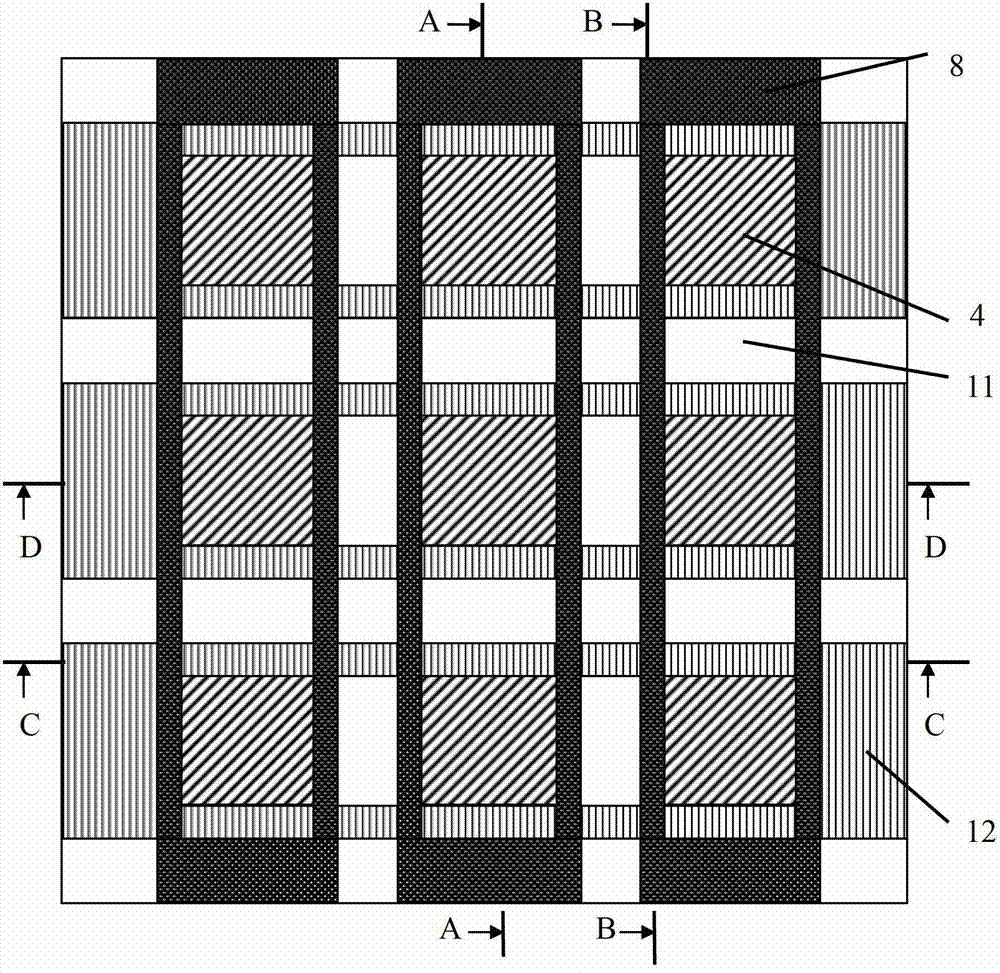

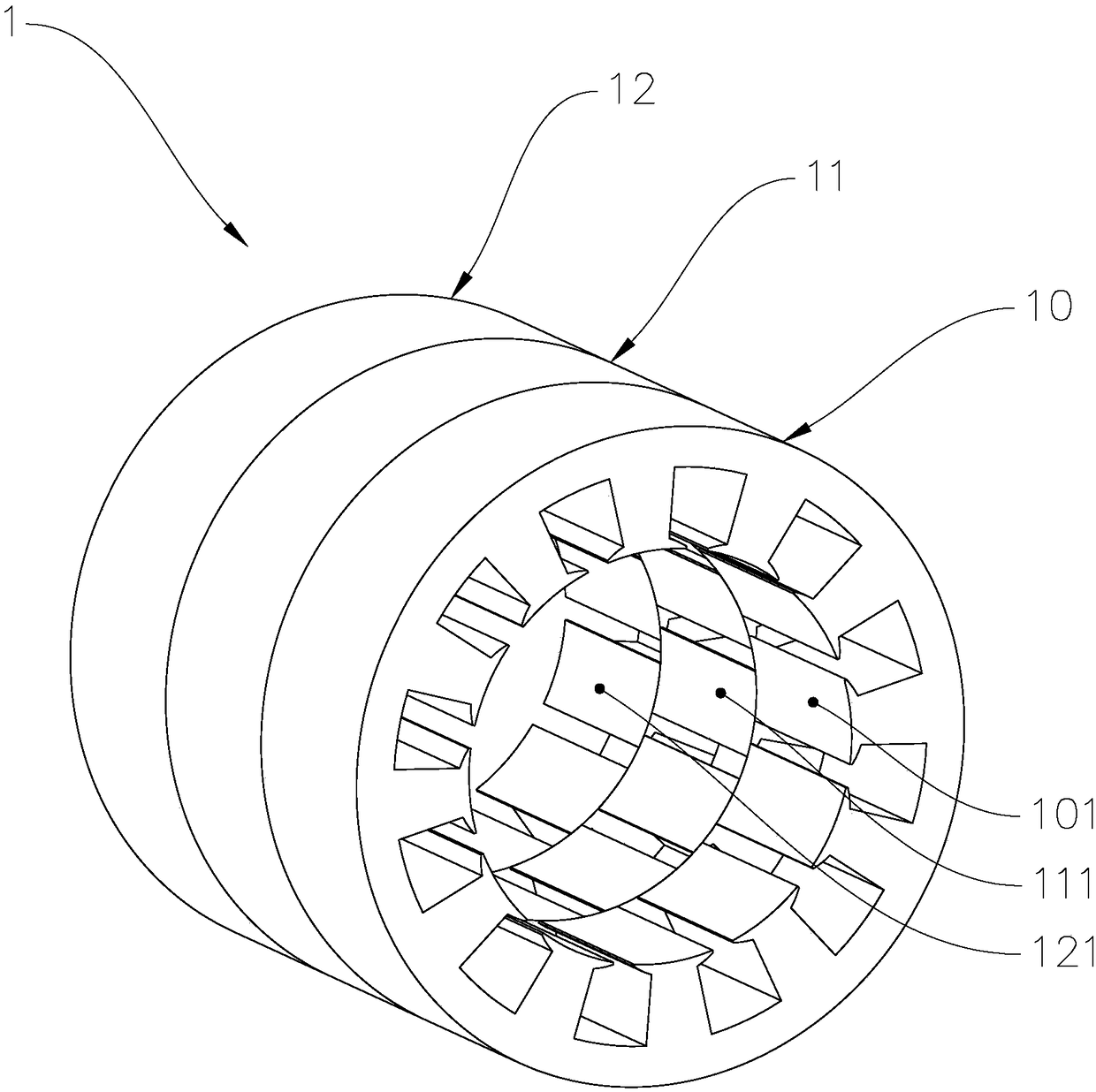

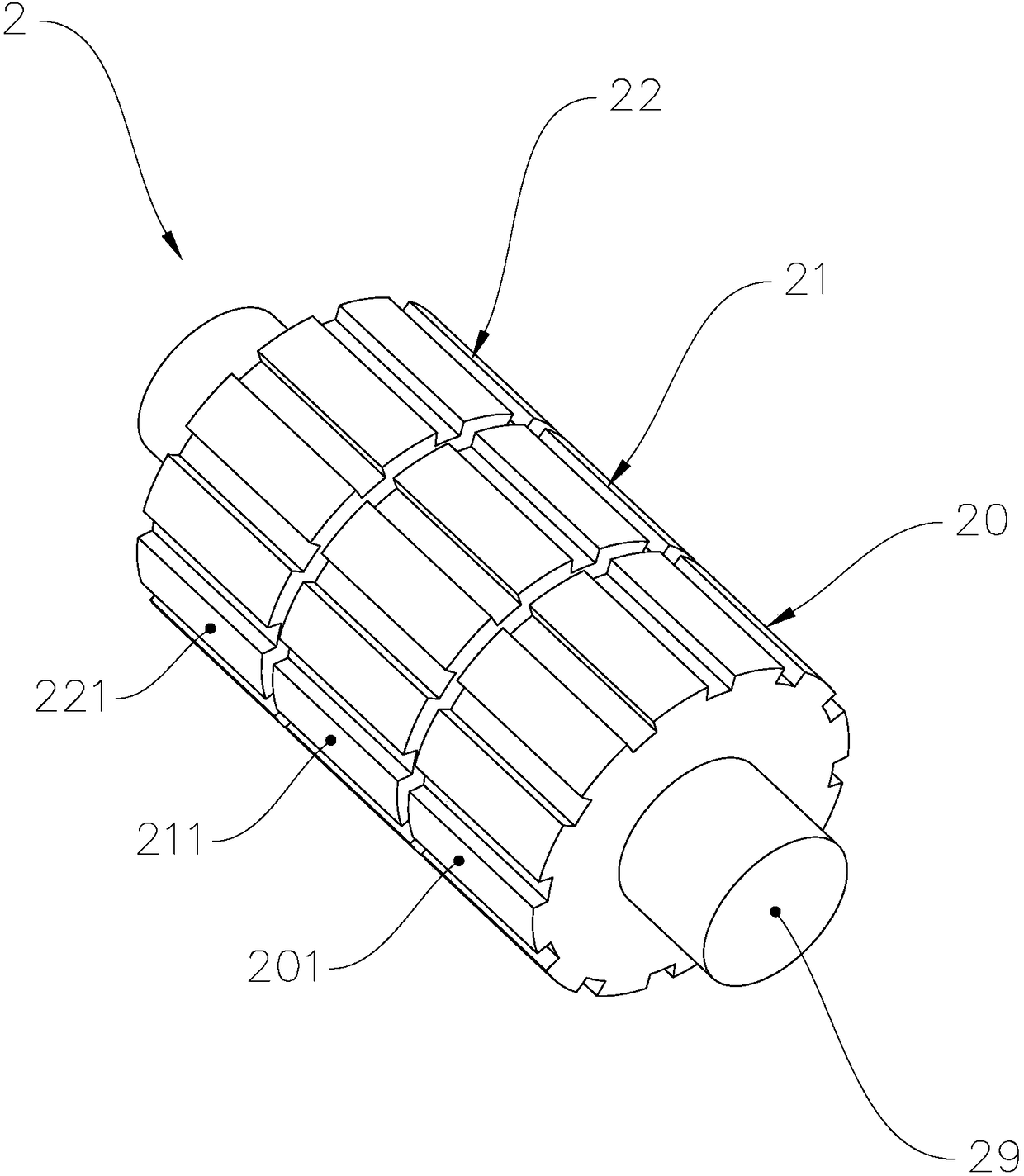

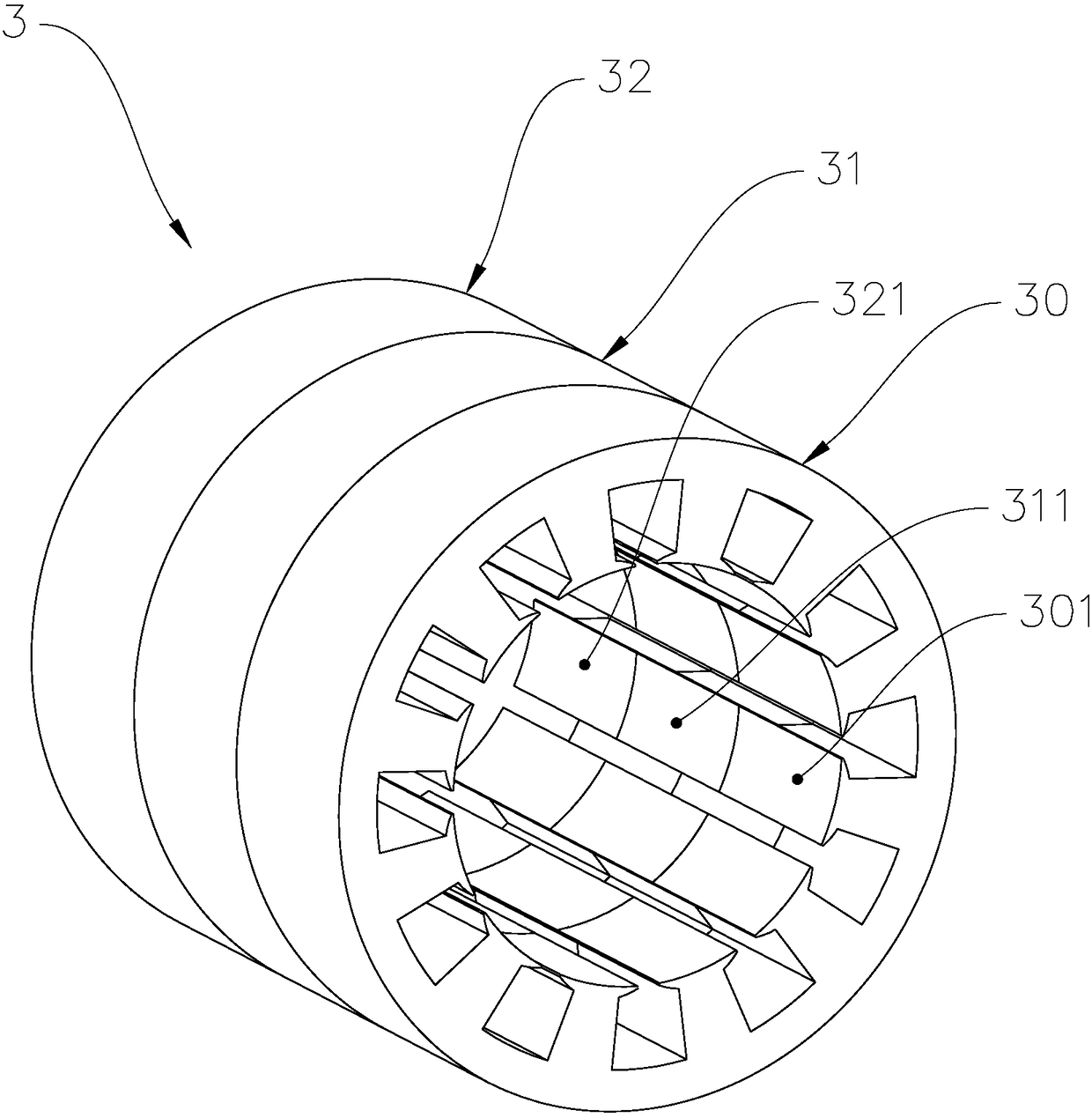

Motor stator, motor, linear motor stator and linear motor

PendingCN108429418ARealize subdivision rotationRealize subdivision rotation, advanceMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedHall element

The invention provides a motor stator, a motor, a linear motor stator and a linear motor. The motor includes n coaxial motor units. The motor unit includes a rotor unit and a stator unit. The numbersof rotor magnetic poles and stator poles are both n. A mechanical deflection angle is arranged between adjacent motor units. The mechanical deflection angle a=360 / (n*m) degrees. The polarities of theadjacent rotor magnetic poles are opposite; a Hall element is arranged between adjacent stator magnetic poles. The linear motor comprises n motor units arranged side by side along the Y-axis direction, wherein the motor unit comprises a rotor unit and a stator unit. The number of the stator magnetic poles is m. The number of the rotor magnetic poles is z. A Hall element is arranged on the stator unit every z-1 stator magnetic poles; the stator magnetic pole has a distance d. The rotor magnetic pole has a distance d. An offset h is arranged between adjacent motor units and the offset h=d / n. Both the motor and the linear motor have the characteristics of direct drive, low speed and large load output.

Owner:ZHUHAI ENPOWER ELECTRIC

Method of producing major diameter TbDyFe-base alloy directionally solidified crystal

InactiveCN1920117ANo coupling mismatch issuesGuaranteed continuityFrom frozen solutionsCrucibleAlloy

The invention relates the technology for producing directional freeze TbDyFe magnetostriction alloy, comprising the following steps: smelting master alloy with copper cold-crucible in vacuum induction suspending smelting furnace; installing ring heater out of die, every heater being a ring heating layer, the temperature being controlled and measured separately, opening heaters, making the temperature above the fusing point of alloy; putting the molten liquid into tubular die, bottom-up reducing the temperature of heater, making the alloy liquid freeze, and then carrying out heat treatment at the cooling course. The invention has the advantages of high productivity, low cost and mass production.

Owner:李碚

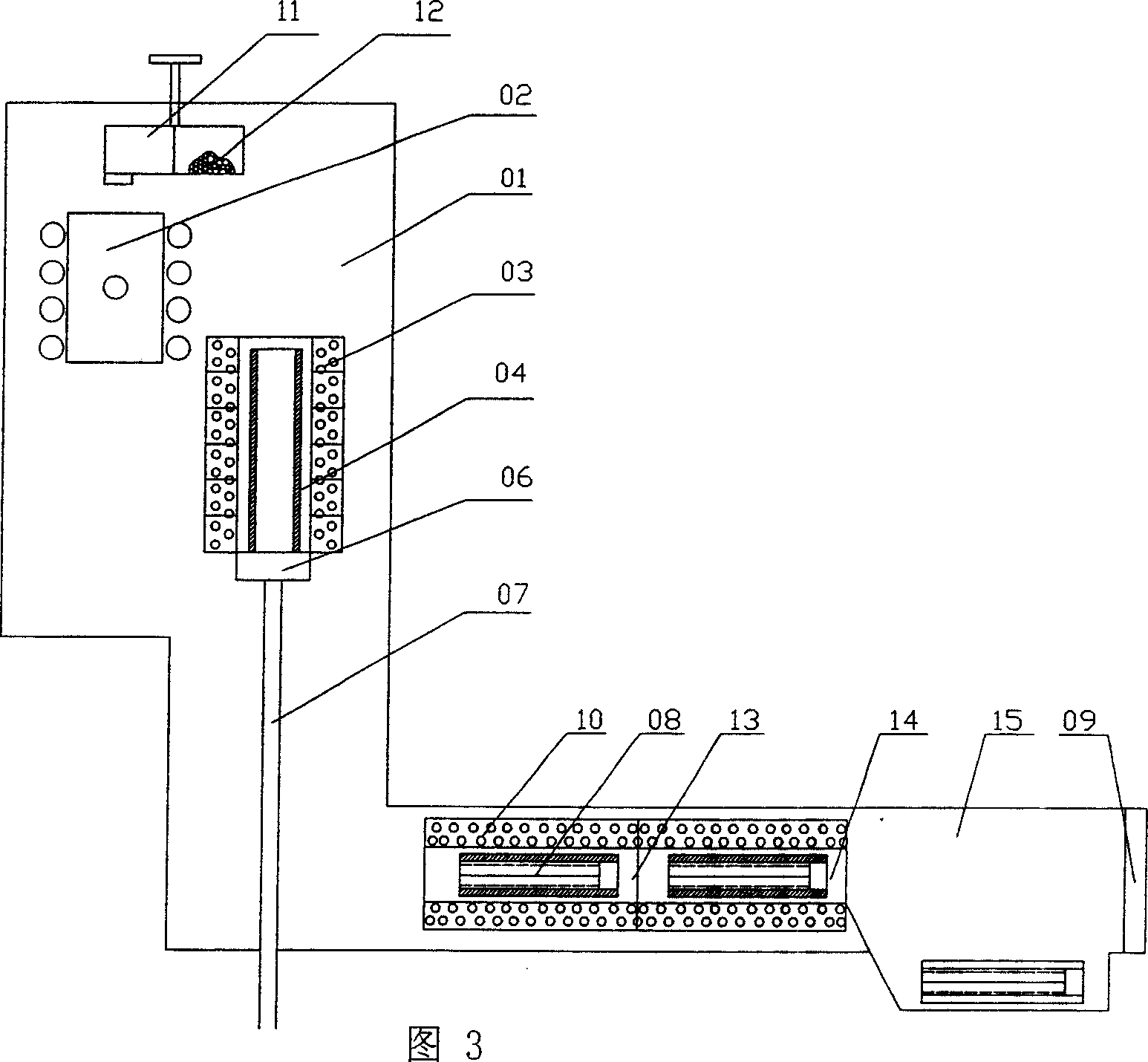

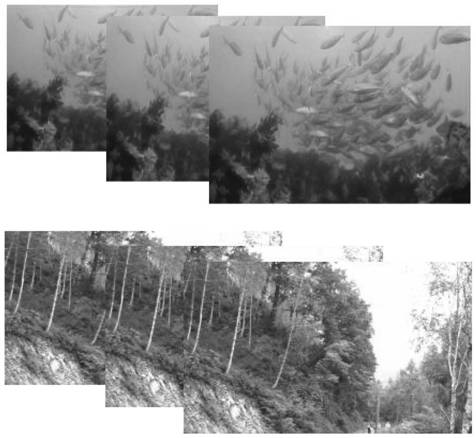

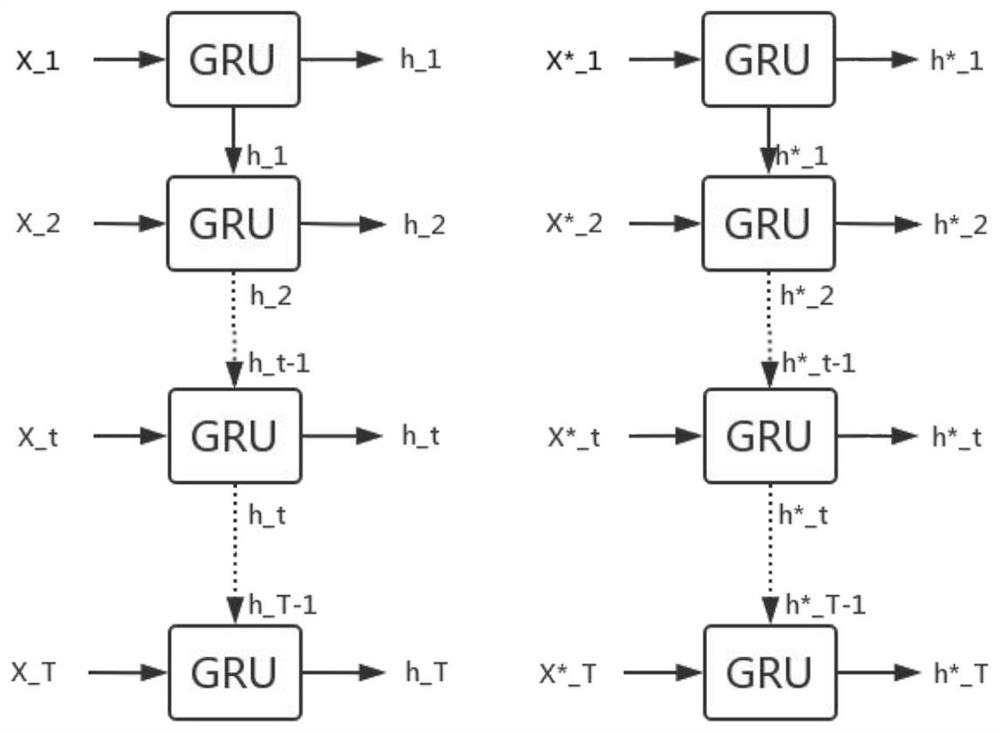

No-reference video quality evaluation method based on deep learning

PendingCN113411566AOvercoming technical difficultiesFeatures that meet content dependenciesCharacter and pattern recognitionTelevision systemsNetwork ConvergenceTime domain

The invention discloses a non-reference video quality evaluation method based on deep learning. The method adopts a pre-trained convolutional neural network, a bidirectional GRU network fusing time domain features and a video quality prediction network. The method comprises the steps that: firstly, the pre-trained convolutional neural network extracts content sensing features of each frame, global pooling is used for processing the features, redundant information is discarded, and change information is stored. secondly, dimensionality reduction is carried out on the features by adopting a full connection layer, and the time domain features before and after are fused by using a bidirectional GRU network; and finally, a frame quality score is calculated by using a full connection layer, and then the overall video quality is aggregated to generate a prediction score. The network model provided by the invention fully and effectively considers the content dependence and the time lag effect of the video to realize the evaluation of the video quality score.

Owner:HANGZHOU DIANZI UNIV

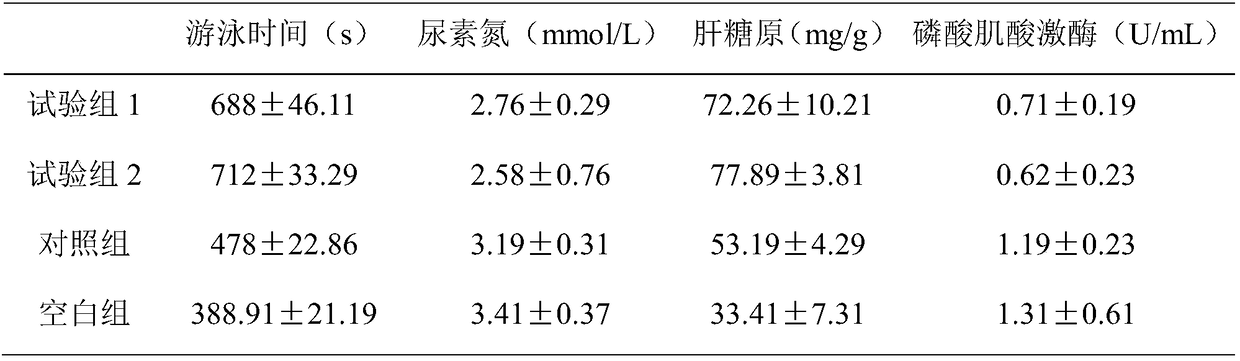

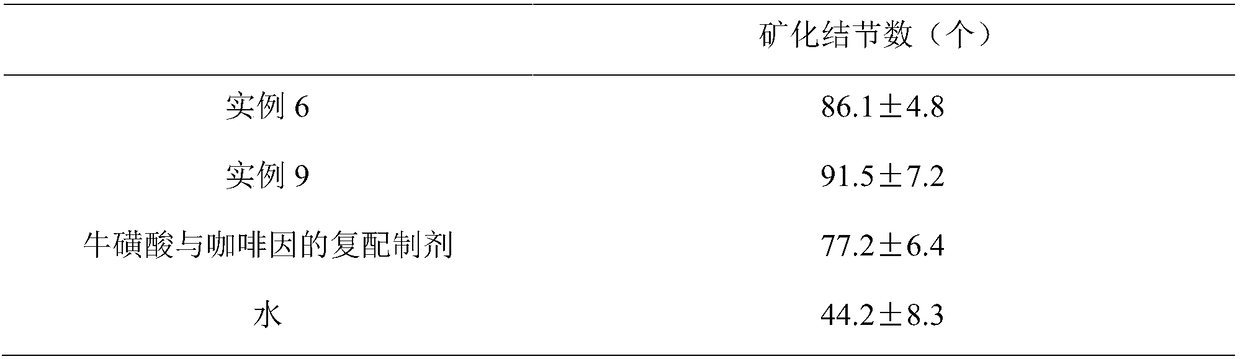

Tablet for relieving physical fatigue and preparation technology thereof

PendingCN108851089AImprove solubilityPromote absorptionHydroxy compound active ingredientsAntinoxious agentsMedicineNatural substance

The invention discloses a tablet for relieving physical fatigue. The tablet is prepared from the following raw materials in parts by weight: 400 to 500 parts of taurine, 90 to 110 parts of caffeine, 140 to 160 parts of L-lysine hydrochloride, 45 to 55 parts of inositol, 30 to 40 parts of nicotinamide and 4 to 6 parts of vitamin B6. The invention also discloses a preparation technology of the tablet for relieving the physical fatigue. The preparation technology disclosed by the invention creatively prepares health-care products into tablets and extracts the taurine and the caffeine from naturalsubstances; the safety of the tablet is higher than the safety of artificially synthesized products; the prepared product can significantly relieve the physical fatigue.

Owner:沈方雄

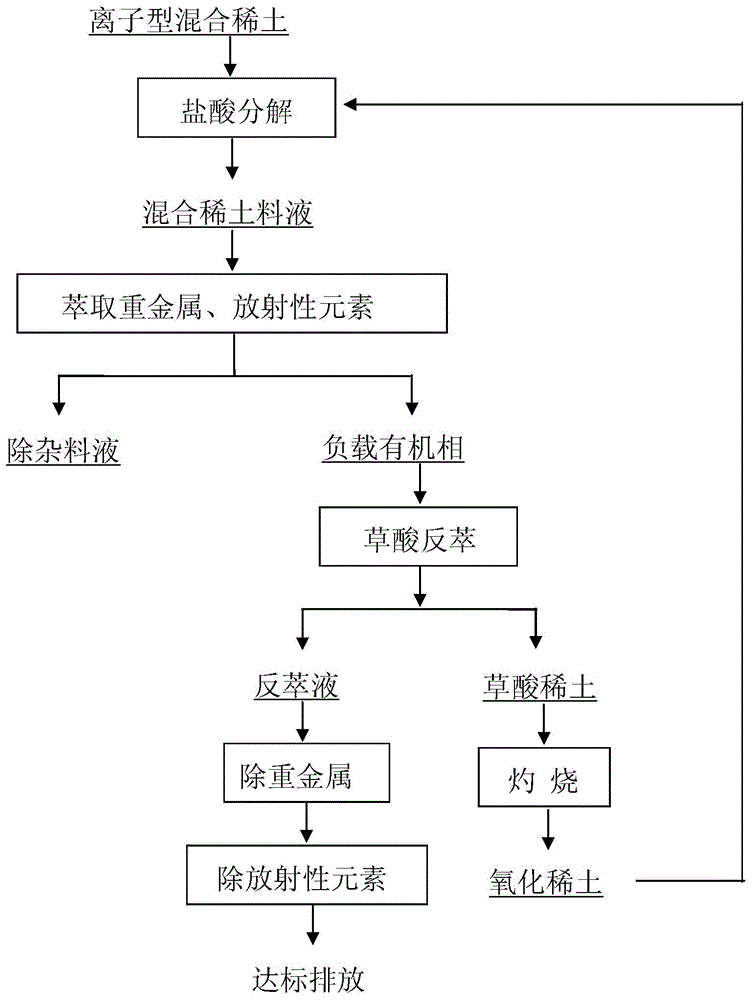

Method for removing heavy metals and radioactive elements in ionic type mixed rare earth material liquid

The invention relates to a method for removing heavy metals and radioactive elements in ionic type mixed rare earth material liquid. The method is characterized by comprising the following steps: performing acid decomposition on ionic mixed rare earth to form the ionic mixed rare earth material liquid; performing extraction and separation by using an ammonia-free saponified organic extracting agent and the ionic mixed rare earth material liquid, wherein the heavy metals and the radioactive elements are extracted into an organic phase, and the rare earth material liquid after impurity removal is in a water phase; performing back extraction on a loaded organic phase, so that the heavy metals, the radioactive element and other impurities in the loaded organic phase and a small quantity of extracted rare earth are all subjected to back extraction; removing the heavy metals and the radioactive elements in back extraction liquid by adding a heavy metal, uranium and thorium removing agent, so that wastewater after impurity removal reaches the standard to be discharged. According to the method provided by the invention, the contents of the heavy metals and the radioactive elements are reduced from a source, so that the follow-up sewage heavy metal and radioactive element treatment procedures are omitted, the sewage treatment cost is reduced, and meanwhile, sewage is discharged after reaching the standard.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

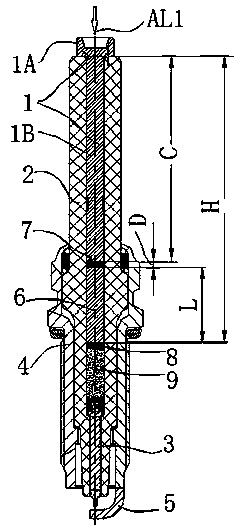

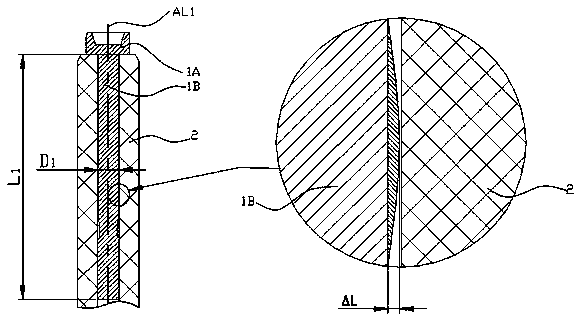

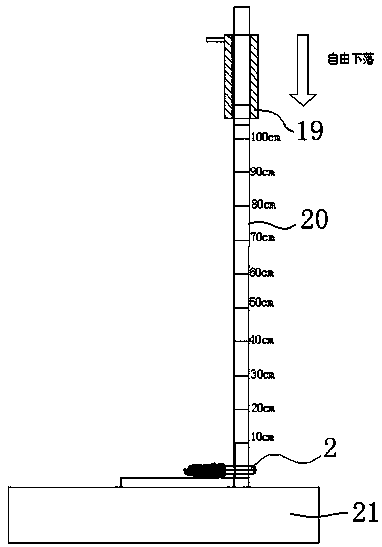

Spark plug and manufacturing method thereof

ActiveCN111446627AShorten the rod lengthAddressing Forced GrowthSparking plugs manufactureEngineeringSpark plug

The invention discloses a spark plug and a manufacturing method thereof. The spark plug comprises an insulator, a wiring screw, a central electrode, side electrodes and a shell. The insulator is provided with a stepped hole along the axis direction; at least one part of the central electrode is inserted into the front end side of the stepped hole; the wiring screw is provided with a terminal partand a rod-shaped part, and the rod-shaped part is inserted into the stepped hole of the insulator; the length of the rod-shaped part of the wiring screw extending into the insulator along the axis direction is less than 35mm, and a rod-shaped connecting piece is arranged between the front end of the rod-shaped part and the central electrode; the length of the rod-shaped part of the wiring screw isreduced by increasing the rod-shaped connecting piece, and the connection between the wiring screw and the central electrode is ensured. According to the invention, the rod-shaped part of the screw is limited below 35mm, and the rod-shaped connecting piece extends the length of the rod-shaped part of the wiring screw, so that the length of the rod-shaped part of the wiring screw is effectively shortened; and the process difficulty of the wiring screw in production caused by forced growth of the rod-shaped part due to the fact that the distance between the terminal part and the shell is prolonged can be solved.

Owner:ZHUZHOU TORCH SPARK PLUG CO LTD

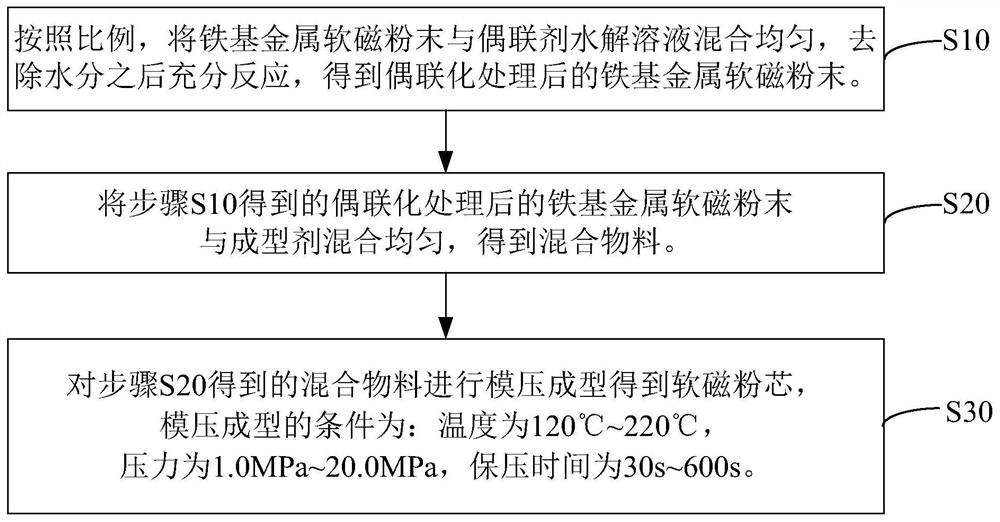

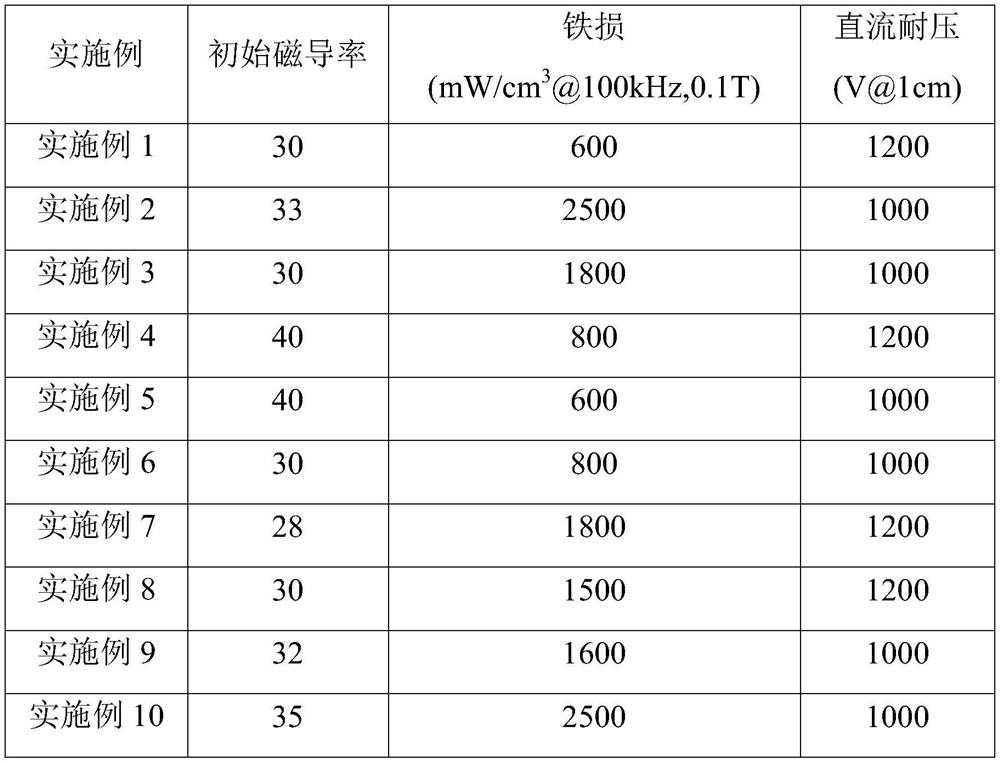

Soft magnetic powder core and preparation method thereof

PendingCN113192714AWell mixedOvercoming technical difficultiesInorganic material magnetismInductances/transformers/magnets manufactureImidePolymer science

The invention relates to a soft magnetic powder core and a preparation method thereof. The soft magnetic powder core is prepared from the following raw materials in parts by mass: 100 parts of iron-based metal soft magnetic powder; 0.01 to 0.3 part of a coupling agent; and 3-6 parts of a forming agent. The forming agent comprises the following components in parts by mass: 2-4 parts of first resin; 1-2 parts of phenolic resin; and 0.03 to 0.3 part of a curing accelerator. The first resin is selected from at least one of functional epoxy resin, cyanate ester and bismaleimide resin. In the raw materials of the soft magnetic powder core, the coupling agent is used for carrying out coupling treatment on the surface of the iron-based metal soft magnetic powder, the forming agent can be uniformly and firmly adsorbed on the surface of the iron-based metal soft magnetic powder subjected to coupling treatment, and the forming agent also plays a mechanical transmission role in the preparation process of the soft magnetic powder core. By means of the whole technical schemes, the soft magnetic powder core can be formed under the low forming pressure, the process difficulty that a traditional soft magnetic powder core needs high-pressure forming is solved, and the production efficiency can be improved.

Owner:苏州锦鳞电子科技有限公司

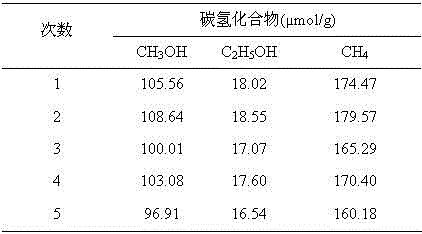

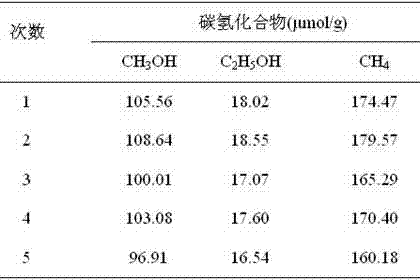

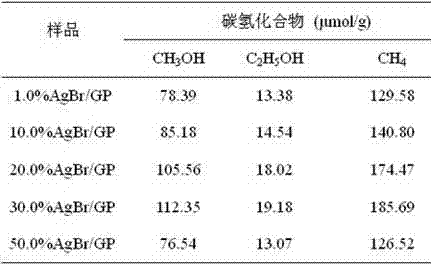

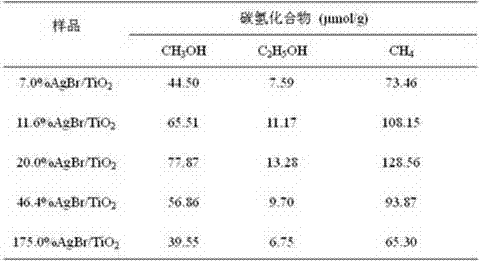

Application of silver halide composite materials in preparing carbon dioxide into hydrocarbon under visible-light catalysis

InactiveCN102068999BOvercoming technical difficultiesInhibition of agglomerationCatalyst carriersHydrocarbon from carbon oxidesHydrocotyle bowlesioidesCarbon nanotube

The invention discloses an application of silver halide composite materials in preparing carbon dioxide into hydrocarbon under visible-light catalysis. The silver halide composite materials are composed of AgX and conductive carriers, such as graphite (GP), expanded graphite (EGP), graphene oxide (GO), carbon nanotube (CNT), granular activated carbon (GAC), zeolite, TiO2 and the like, thus forming AgX / flake graphite, AgX / EGP, AgX / graphene, AgX / CNT, AgX / GAC, AgX / zeolite and AgX / TiO2 and the like. The invention also discloses a method for preparing the silver halide composite materials, in which the AgX is evenly dispersed on the carrier surfaces with the aid of cationic surfactant by wet co-precipitation. The silver halide composite materials provided by the invention can efficiently utilize the sunlight, wherein the AgX is excitated under the visible light, and electrons generated are transferred from an AgX conduction band to the conductive-carrier surfaces, thus improving catalytic activity and stability of the silver halide composite materials under visible light.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com