Method and equipment for producing ethanol product by taking ethyl acetate as raw material

A technology of ethyl acetate and fuel ethanol, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of high energy consumption and material consumption, long production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

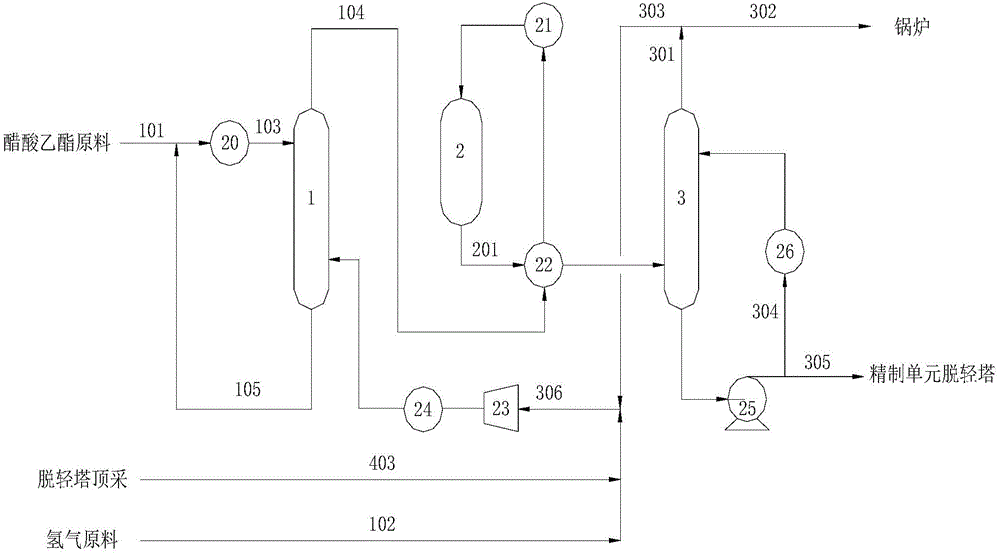

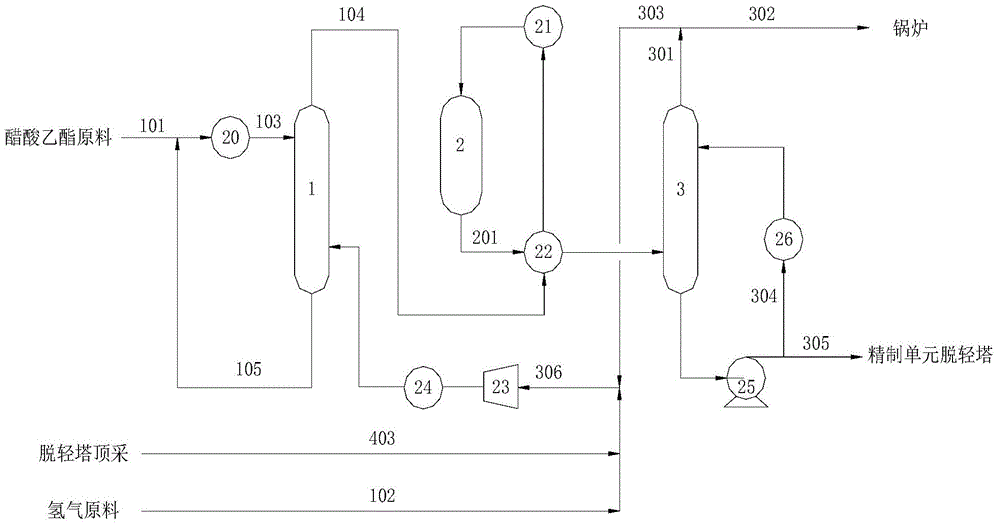

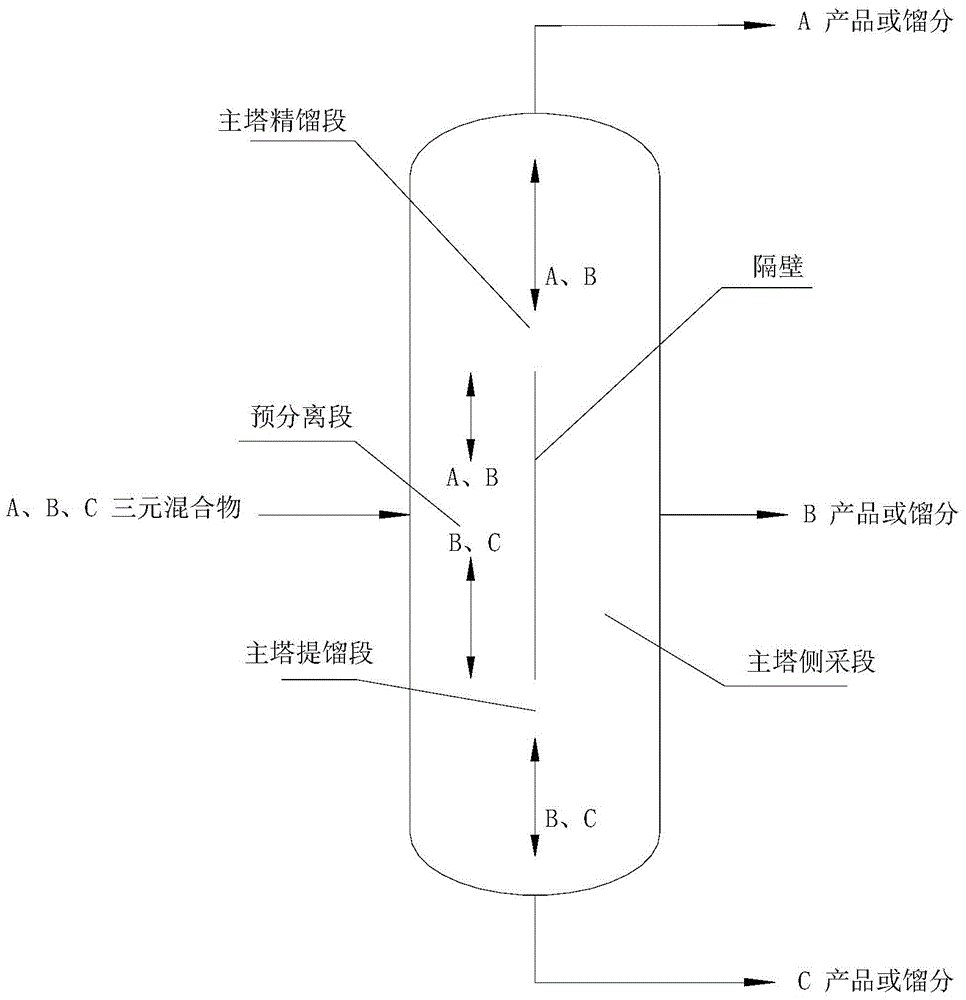

[0069] Ethyl acetate and hydrogen are used as raw materials to produce ethanol products through the catalytic hydrogenation reaction of ethyl acetate and the refining process of ethanol products. For the production process, see figure 1 —Ethyl acetate catalytic hydrogenation reaction unit flow chart, figure 2 — Flow chart of ethanol product refining unit and image 3 -Schematic diagram of the structure and operation of the next-door tower, the specific production process is as follows:

[0070] 1. Ethyl acetate catalytic hydrogenation reaction unit

[0071] Ethyl acetate catalytic hydrogenation reaction unit includes: evaporator 1, hydrogenation reactor 2, gas-liquid separation tower 3, etc. Its main function is to use ethyl acetate and hydrogen as raw materials to perform gas-phase catalytic hydrogenation in the hydrogenation reactor The hydrogenation reaction product mainly containing ethanol is obtained, and the hydrogenation reaction liquid is processed through the gas-...

Embodiment 2

[0091] Ethyl acetate and hydrogen are used as raw materials to produce ethanol products through the catalytic hydrogenation reaction of ethyl acetate and the refining process of ethanol products. For the production process, see figure 1 —Ethyl acetate catalytic hydrogenation reaction unit flow chart, figure 2 — Flow chart of ethanol product refining unit and image 3 -Schematic diagram of the structure and operation of the next-door tower, the specific production process is as follows:

[0092] 1. Ethyl acetate catalytic hydrogenation reaction unit

[0093] Ethyl acetate catalytic hydrogenation reaction unit includes: evaporator 1, hydrogenation reactor 2, gas-liquid separation tower 3, etc. Its main function is to use ethyl acetate and hydrogen as raw materials to perform gas-phase catalytic hydrogenation in the hydrogenation reactor A hydrogenation reaction product mainly containing ethanol is obtained, and the treated hydrogenation reaction liquid is sent to an ethanol p...

Embodiment 3

[0121] Ethyl acetate and hydrogen are used as raw materials to produce ethanol products through the catalytic hydrogenation reaction of ethyl acetate and the refining process of ethanol products. For the production process, see figure 1 —Ethyl acetate catalytic hydrogenation reaction unit flow chart, figure 2 — Flow chart of ethanol product refining unit, the specific production process is described as follows:

[0122] 1. Ethyl acetate catalytic hydrogenation reaction unit

[0123] Ethyl acetate catalytic hydrogenation reaction unit includes: evaporator 1, hydrogenation reactor 2, gas-liquid separation tower 3, etc. Its main function is to use ethyl acetate and hydrogen as raw materials to perform gas-phase catalytic hydrogenation in the hydrogenation reactor The hydrogenation reaction product mainly containing ethanol is obtained, and the hydrogenation reaction liquid is processed through the gas-liquid separation tower 3 and other equipment, and the excess hydrogen is rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com