Water-surface aerating double-bubble high-speed voyage moving body structure

A moving body and double-bubble technology, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, hull, hull design, etc., can solve the problems of gas leakage, achieve the effect of less gas leakage, solve technical difficulties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

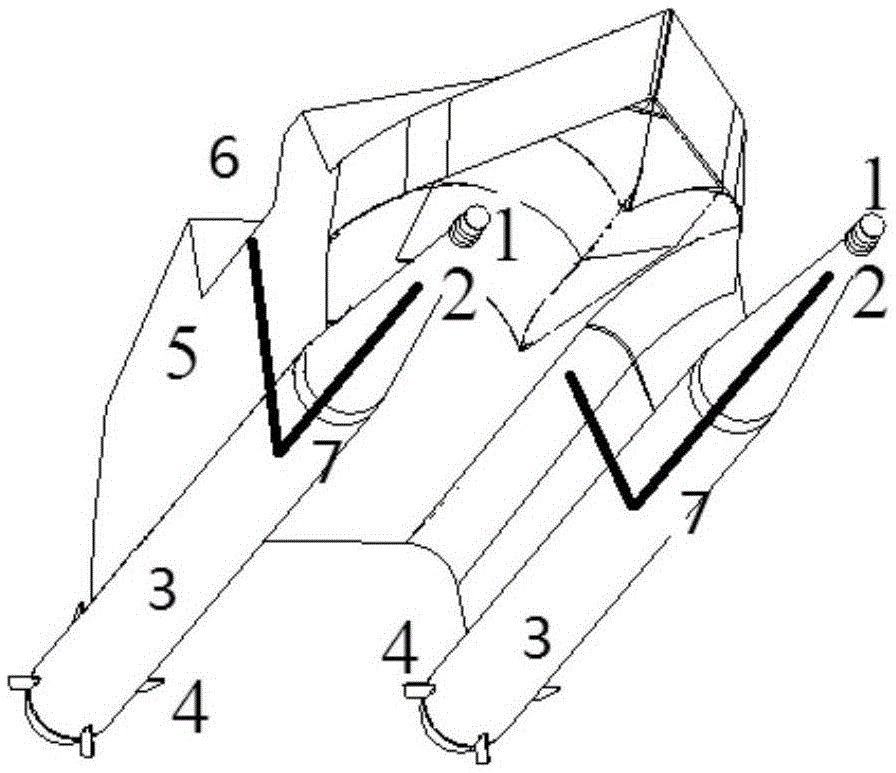

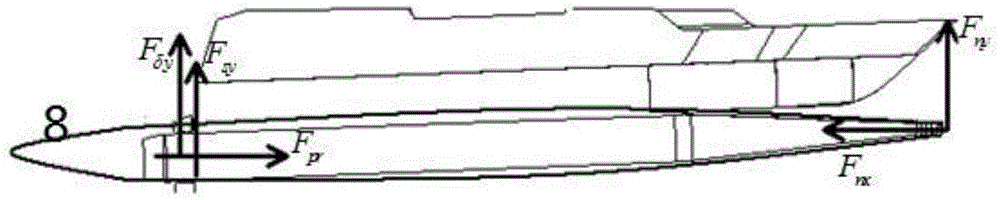

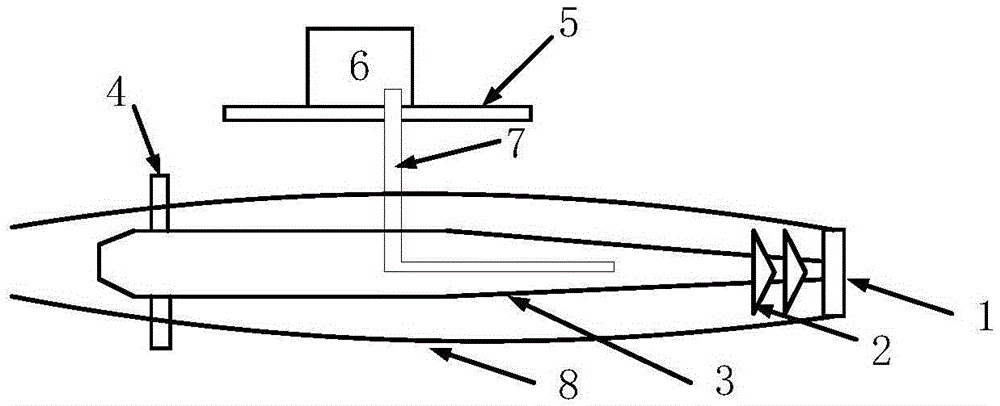

[0014] The present invention proposes a water surface ventilated double-bubble high-speed navigation moving body structure, the scheme diagram is shown in the appendix Figure 1-3 . The specific names of each number in the figure are as follows: 1—cavitation device; 2—rectification device; 3—cone-column assembly; 4—tail control rudder surface; 5—upper surface of moving body; 6—compressed gas device; 7—ventilator Road; 8—bubble multiphase flow interface.

[0015] Concrete connection form of the present invention sees image 3 , supported by two cone-column assemblies 3 at the bottom of the moving body, usually only these two cone-column assemblies are in contact with water. A rotatable cavitator 1 and a ventilation rectifier 2 are installed on the head of the cone-column assembly (the end of the cone). The main function of the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com