Motor stator, motor, linear motor stator and linear motor

A motor stator and linear motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as motor power increase, environmental noise pollution, structural size restrictions, etc., achieve reduced production costs, simple motor structure, and reduced production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

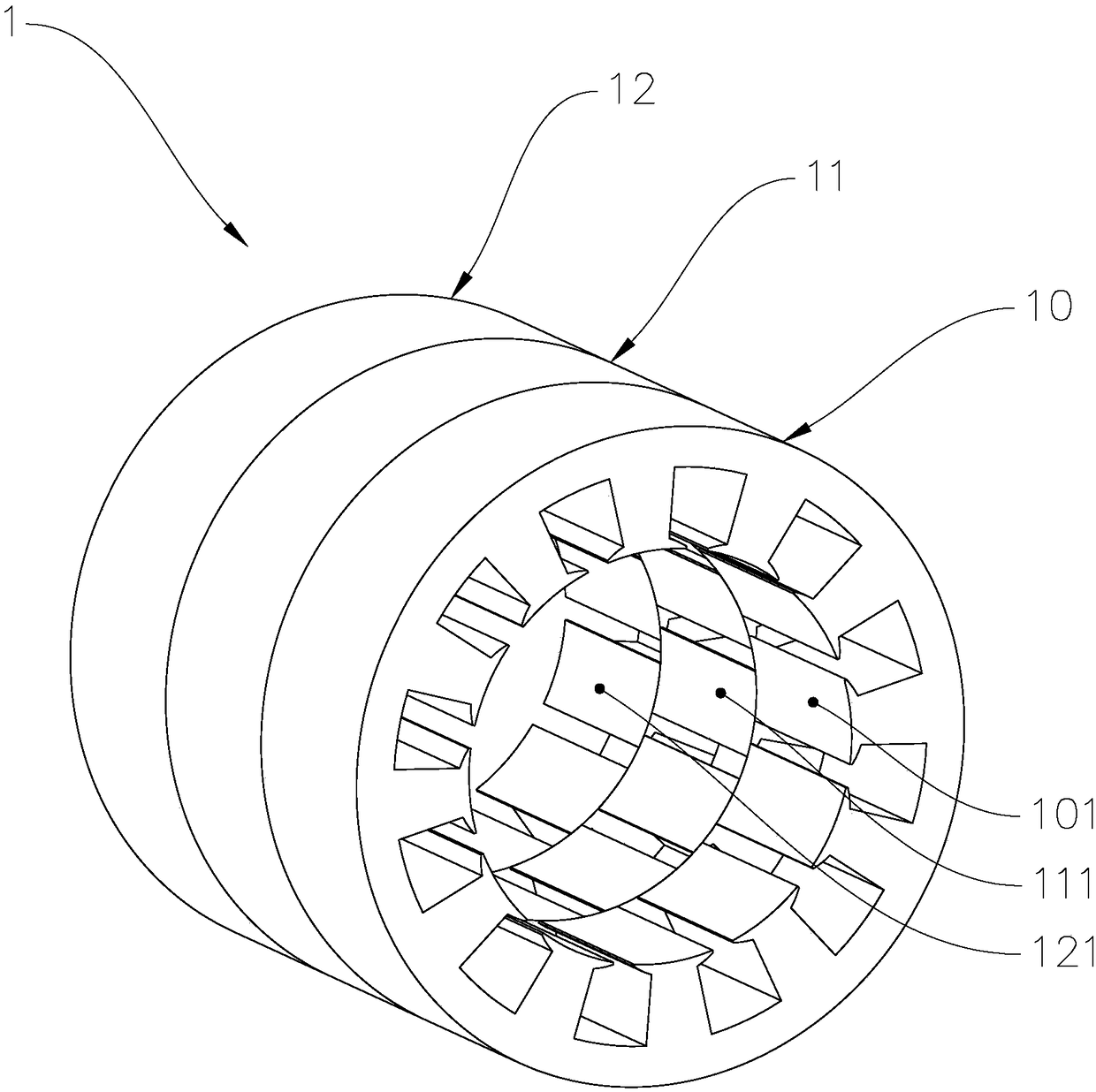

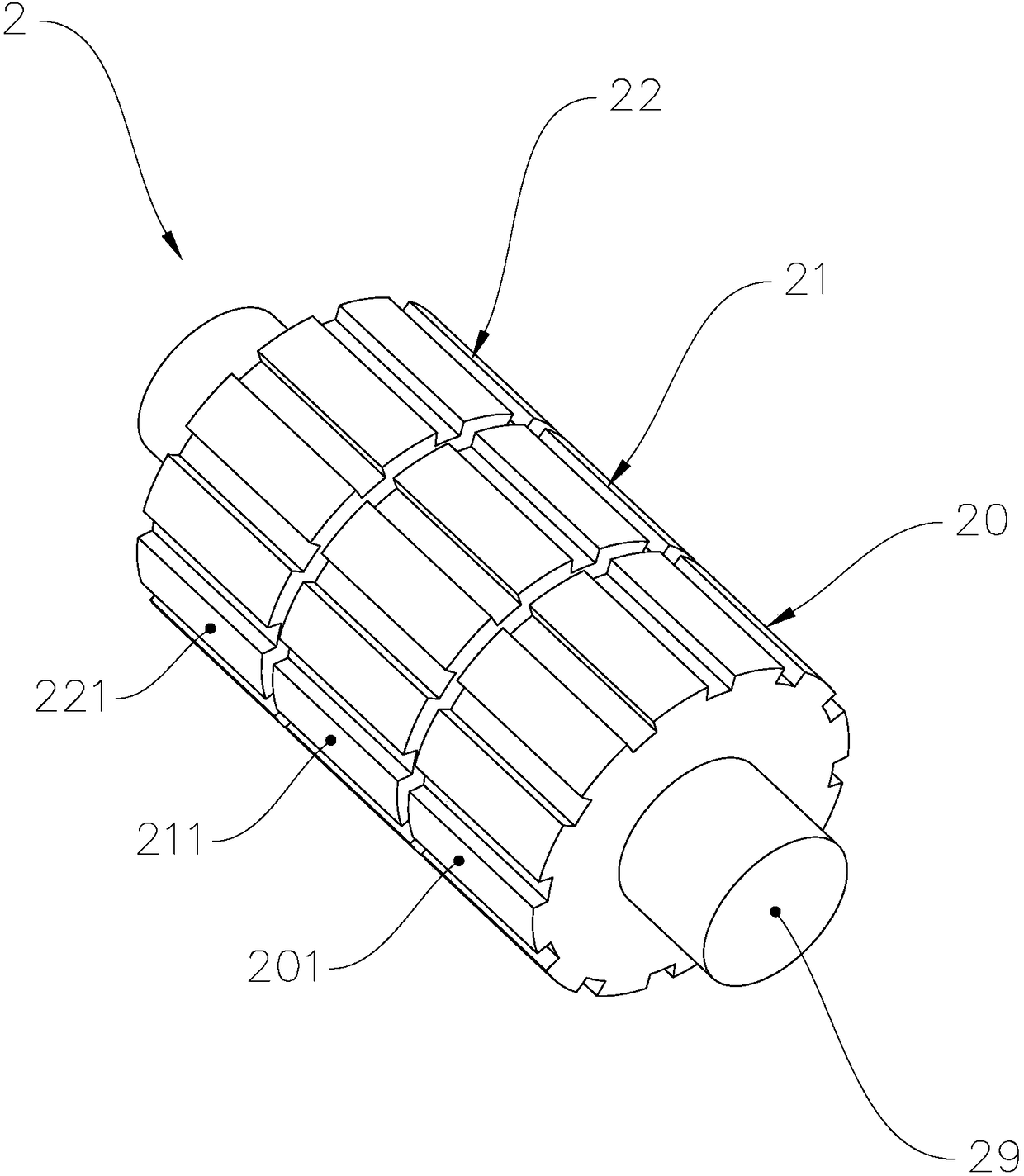

[0042] see figure 1 with figure 2 , figure 1 It is a structural schematic diagram of the hidden Hall device and winding of the motor stator in the first embodiment of the motor of the present invention, figure 2 It is a structural schematic diagram of the motor rotor in the first embodiment of the motor of the present invention. The motor of this embodiment is formed by coaxially laminating three motor units, and each motor unit includes a stator unit and a rotor unit that cooperate with each other. Correspondingly, the motor stator 1 includes three coaxially fixed stator units, and the motor rotor 2 Consists of three mover units coaxially fixed.

[0043] combine Figure 5 , Figure 5 It is a structural schematic diagram of the motor unit in the first embodiment of the motor of the present invention. In order to facilitate the description of the structure of the motor stator 1, the Hall device and the winding on the electronic core are in figure 1 hidden in . The mot...

no. 2 example

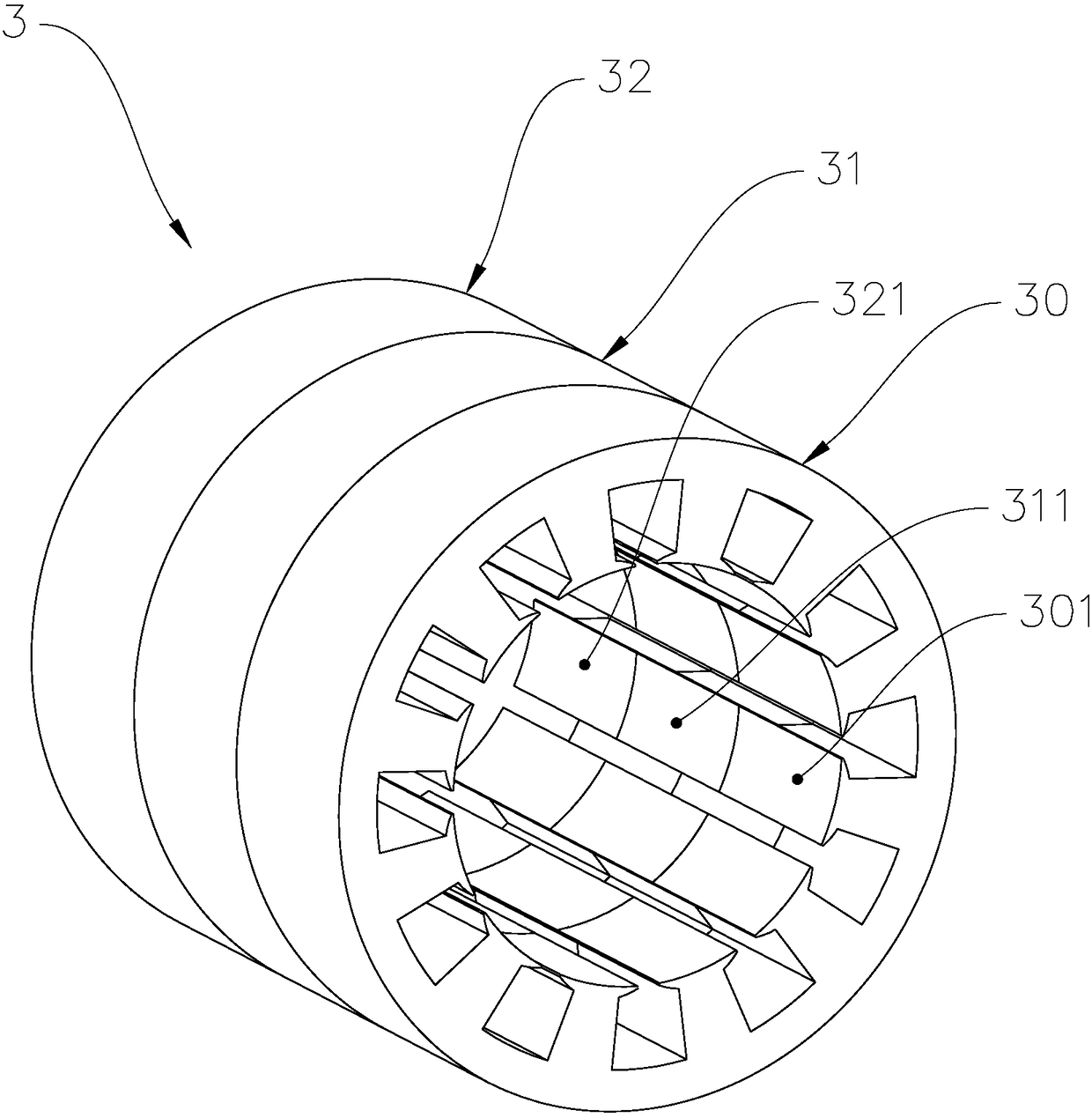

[0055] see image 3 with Figure 4 , image 3 It is a structural schematic diagram of some components hidden in the stator of the motor in the second embodiment of the motor of the present invention. Figure 4 It is a structural schematic diagram of the motor rotor in the second embodiment of the motor of the present invention. Optionally, the mechanical deflection angle a between the motor units can be realized only by the deflection angles between a plurality of rotor units in the motor rotor. On the axial projection of the motor stator 3 , the teeth 301 of the stator unit 30 , the teeth 311 of the stator unit 31 and the teeth 321 of the stator unit 32 overlap and align with each other without an off-angle. On the axial projection of the motor rotor 4, there is a mechanical deflection angle a between the permanent magnet 401 of the rotor unit 40 and the permanent magnet 411 on the rotor unit 41, and the permanent magnet 421 on the rotor unit 42 and the permanent magnet 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com