Large-pore-wall cage-shaped silica hollow sphere and preparation method thereof

A technology of silica and hollow spheres, applied in the directions of silica and silica, can solve the problems of inability to deliver drugs to the target site, agglomeration of hollow spheres, harsh synthesis conditions, etc., and achieve uniform and adjustable pore size distribution. Low cost, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 71.4mL absolute ethanol, 10mL deionized water and 3.14mL ammonia water (mass concentration: 25-28%), stir at 30°C for 30min; quickly add 6mL tetraethyl orthosilicate, and magnetically stir for 1h; After 5mL tetraethyl orthosilicate and 2mL octadecyltrimethoxysilane were uniformly mixed, the above solution was quickly added, stirred magnetically for 1h, and the product was centrifuged to obtain highly dispersed solid core / mesoporous shell SiO 2 ball. The centrifuged product is dispersed with 0.6mol / L Na 2 CO 3 in solution. The dispersed sol was stirred at 80° C. for 4 h. After centrifugation, the product was washed 3 times with deionized water, dried at 100°C for 6h, and then calcined at 550°C for 6h to remove the surfactant, and the obtained cage-shaped SiO with large pore walls 2 particle.

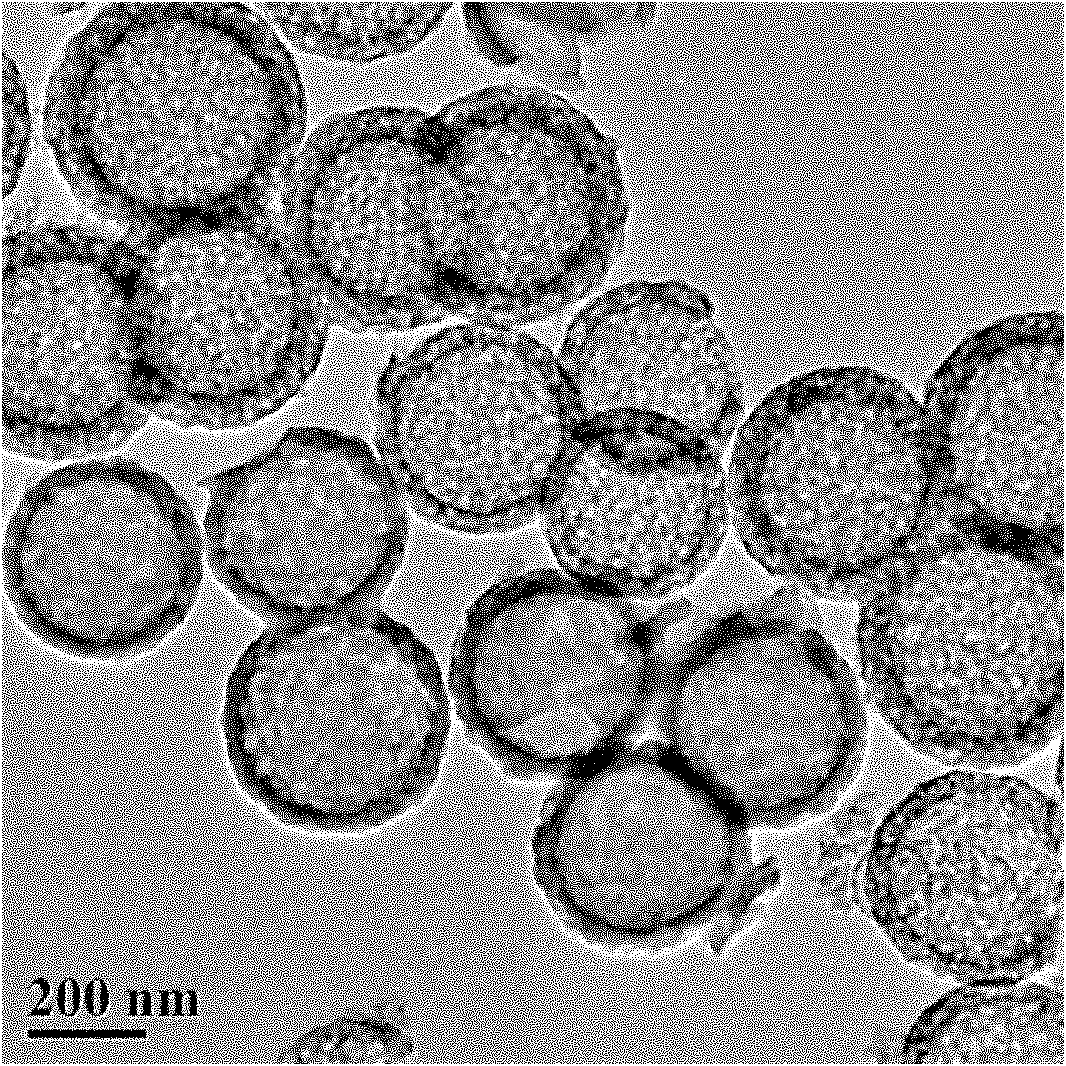

[0039] The SiO obtained in this example 2 The transmission electron microscope image of the particle is shown in figure 1 As shown, it can be seen from the figure that t...

Embodiment 2

[0041] Mix 142.8mL absolute ethanol, 20mL deionized water and 3.14mL ammonia water (mass concentration: 25-28%), stir at 30°C for 30min; quickly add 6mL tetraethyl orthosilicate, and magnetically stir for 1h; After 5mL tetraethyl orthosilicate and 3mL octadecyltrimethoxysilane were evenly mixed, the above solution was quickly added, stirred magnetically for 1h, and the product was centrifuged to obtain highly dispersed solid core / mesoporous shell SiO 2 ball. The centrifuged product is dispersed in 0.6mol / L Na 2 CO 3 in solution. The dispersed sol was stirred at 80° C. for 4 h. After centrifugation, the product was washed three times with deionized water, dried at 100°C for 6h, and then calcined at 550°C for 6h to remove the surfactant.

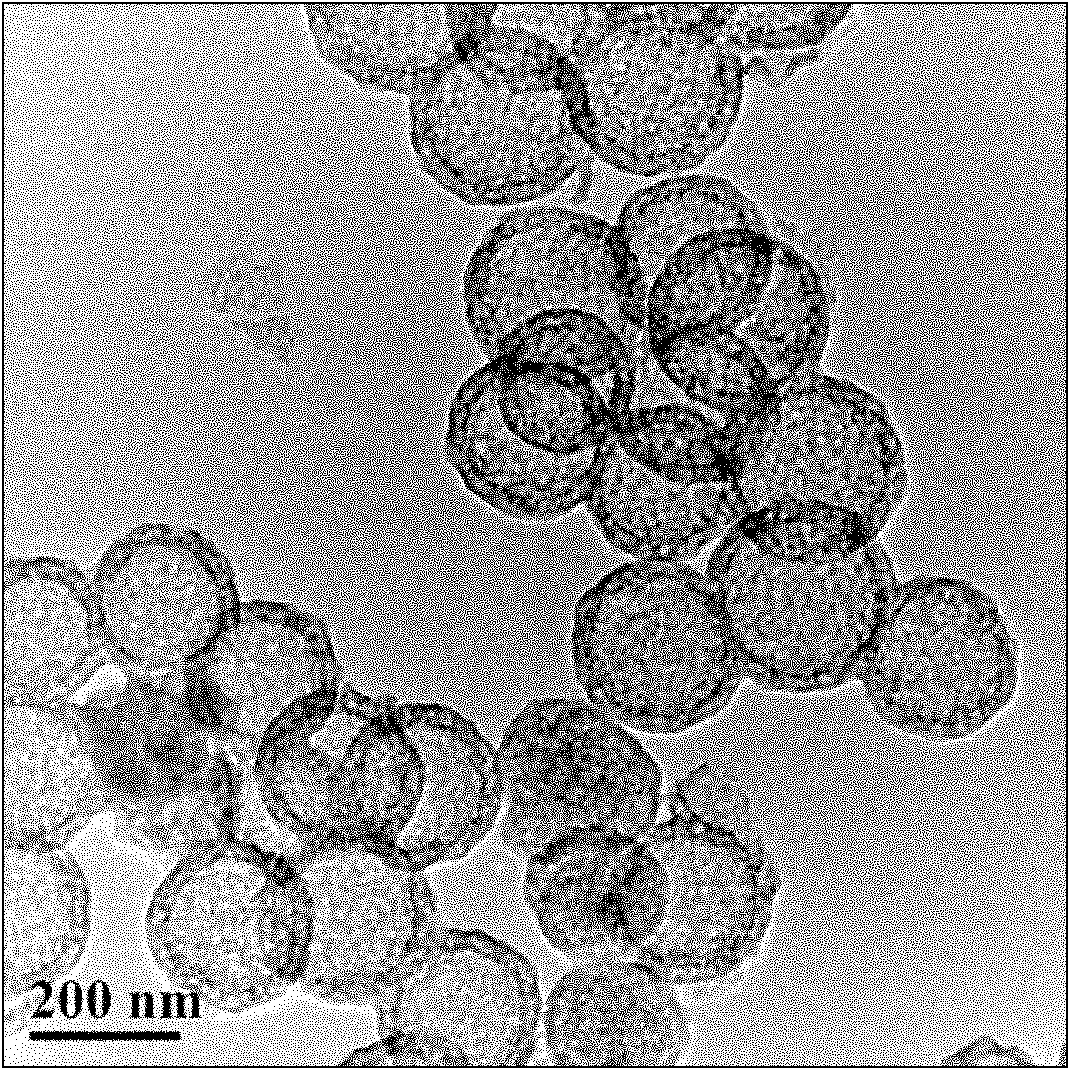

[0042] The SiO obtained in this example 2 The transmission electron microscope image of the particle is shown in image 3 As shown, it can be seen from the figure that the cage SiO 2 The particle size of the particles is 200nm, indicati...

Embodiment 3

[0046] According to the synthesis process of Example 1, the solid core / mesoporous shell SiO is first obtained 2 ball. After centrifugation, the product is dispersed in 0.6mol / L Na 2 CO 3 solution and treated at 80°C for 0.5h. Subsequent processing is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com