Soft magnetic powder core and preparation method thereof

A soft magnetic powder core, soft magnetic powder technology, applied in the direction of inductor/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

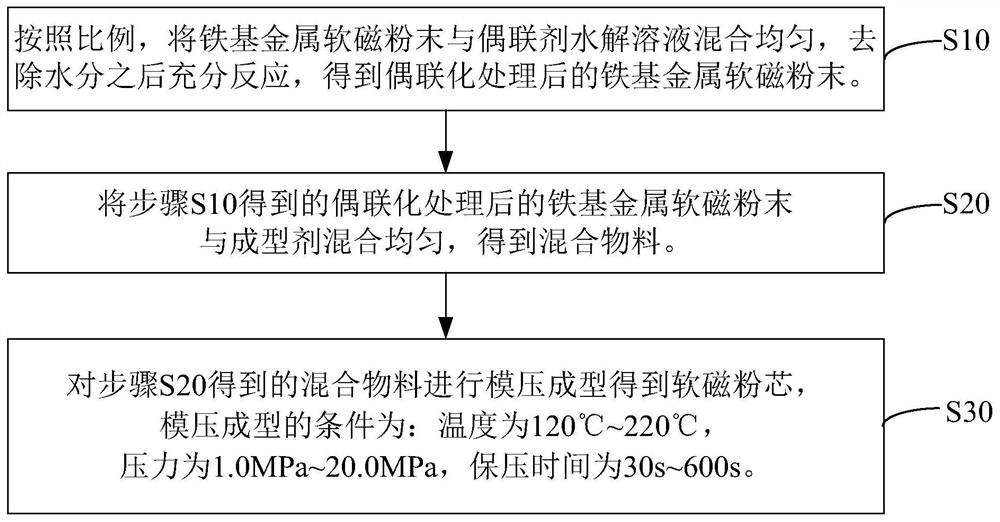

[0070] See figure 1 , the preparation method of the soft magnetic powder core of one embodiment of the present invention, comprises the following steps:

[0071] S10. According to the proportion, mix the iron-based metal soft magnetic powder with the coupling agent hydrolysis solution evenly, and fully react after removing the moisture to obtain the iron-based metal soft magnetic powder after coupling treatment.

[0072] Among them, the aspect ratio of the iron-based metal soft magnetic powder is preferably 1.00-1.50, and its preparation method may be a gas atomization method, a water-air combined atomization method, or an ultrasonic method. At this time, the iron-based metal soft magnetic powder is a sphere or an ellipsoid close to a sphere, which is more conducive to forming.

[0073] In one embodiment, the condition for sufficient reaction is: baking at a temperature of 120° C. to 150° C. for 30 minutes to 120 minutes.

[0074] In step S10, the morphology of the iron-base...

Embodiment 1

[0097] Embodiment 1 adopts iron-based amorphous soft magnetic alloy powder, and the composition is Fe 76 (SiB) 24 , the D50 particle size is 25 μm, and the aspect ratio of the powder morphology is 1.25.

[0098]Mix 1000g of iron-based amorphous soft magnetic alloy powder with 1g of epoxy silane coupling agent evenly. Then bake at 120° C. for 120 minutes to obtain the iron-based metal soft magnetic powder after coupling treatment.

[0099] Mix 1000g of coupling-treated iron-based metal soft magnetic powder with 60g of molding agent evenly, wherein, component A of the molding agent is 40g of biphenol type epoxy resin, and component B of the molding agent is 20g of phenol arane base phenolic resin, 1g of 2-methylimidazole and 3g of paraffin wax powder with a particle size of -30 mesh (its drop point temperature is 80°C), and all the above materials are preliminarily mixed in a three-dimensional mixer for 10 minutes, and then the mixed material is extruded with a screw machine,...

Embodiment 2

[0102] The preparation method of the soft magnetic powder core of embodiment 2 is the same as the preparation method of the soft magnetic powder core of embodiment 1, the difference is only: the iron-based metal soft magnetic powder of embodiment 2 is Fe 92.0 Si 3.5 Cr 4.5 powder, and Fe 92.0 Si 3.5 Cr 4.5 The morphology aspect ratio of the powder is 1.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com