Preparation method of large-area reduced graphene oxide membrane

A graphene film, a large-area technology, applied in the field of large-area reduced graphene oxide film preparation, can solve the problems of layered structure density reduction, large-area integrity damage, affecting mechanical properties and applications, etc., to achieve size and The effect of controllable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of large-area reduced graphene oxide film of the present invention comprises the following steps:

[0027] (1) Using graphite powder as a raw material to prepare a suspension of graphene oxide;

[0028] (2) Evenly disperse the suspension of graphene oxide on the surface of the substrate by spraying or scraping to form a graphene oxide film;

[0029] (3) Reducing the graphene oxide film under hot rolling conditions to obtain a reduced graphene oxide film.

[0030] In the step (1), the graphene oxide suspension is a deionized water phase suspension, or an organic phase suspension, and the concentrations of the deionized water phase suspension and the organic phase suspension are controlled at 1-30mg / mL, the organic solvents include ethanol (ethanol), dimethylformamide (DMF), N-methylpyrrolidone (NMP), tetrahydrofuran (THF), dimethyl sulfoxide (DMSO), acetone (Acetone) or Isopropyl alcohol (IPA).

[0031] In the step (1), the graphene oxide...

Embodiment 1

[0047] A kind of preparation method of large-area reduced graphene oxide film of embodiment 1, preparation steps are:

[0048] (1) Graphene oxide was prepared by the improved Hummers method, the specific steps were: mix 6g graphite powder with 5g K 2 S 2 o 8 and 5g P 2 o 5 were added to 25mL of concentrated sulfuric acid at 80°C for pretreatment, and then the pretreated graphite was mixed with 30g KMnO 4 Add together to 230mL of concentrated sulfuric acid for further oxidation, then add 25mL of 30% hydrogen peroxide to the solution and wash with 2L of 10% dilute hydrochloric acid to obtain graphite oxide; dialyze the graphite oxide with deionized water to remove the remaining acid and salt until the pH value of the dialysate is 6-7; the graphite oxide is mechanically peeled off with a probe ultrasonic at a power of 150W for 1 hour, and the graphene oxide solution is centrifuged at 3000rpm with a rotary centrifuge, and Separating the upper layer solution to obtain a suspen...

Embodiment 2

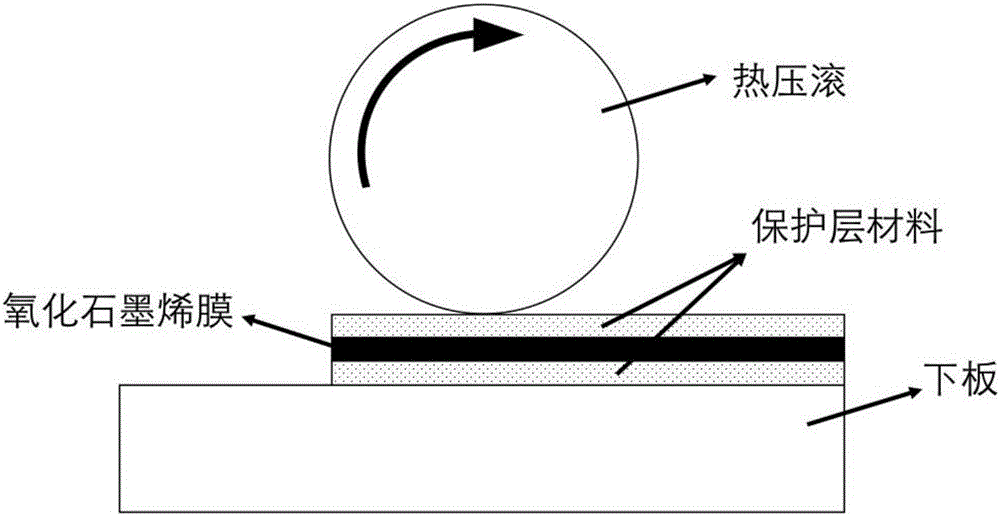

[0051] A method for preparing a large-area reduced graphene oxide film in Example 2, the preparation steps (1) and (2) are the same as the steps (1) and (2) of Example 1; the preparation step (3) is: the oxidation The graphene film is sandwiched between two 60cm×20cm copper foils; adjust the pressure of the hot roll and the lower plate to 10MPa, and raise the temperature of the hot roll to 600°C, and then place the graphene oxide film protected by the copper foil at 20cm / The speed of min is to carry out hot rolling reduction treatment by hot rolling, and the reduced graphene oxide film is exported and separated from the copper foil, such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com