A mems microvalve and its manufacturing process

A technology of micro-valve and silicon layer, which is applied in metal material coating process, process for producing decorative surface effect, decorative art, etc. It can solve the problems of exceeding the deformation range, limited flow range, and limited displacement, etc., and achieve reduction Process difficulty and complexity, expanding flow control range, and reducing the effect of wafer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

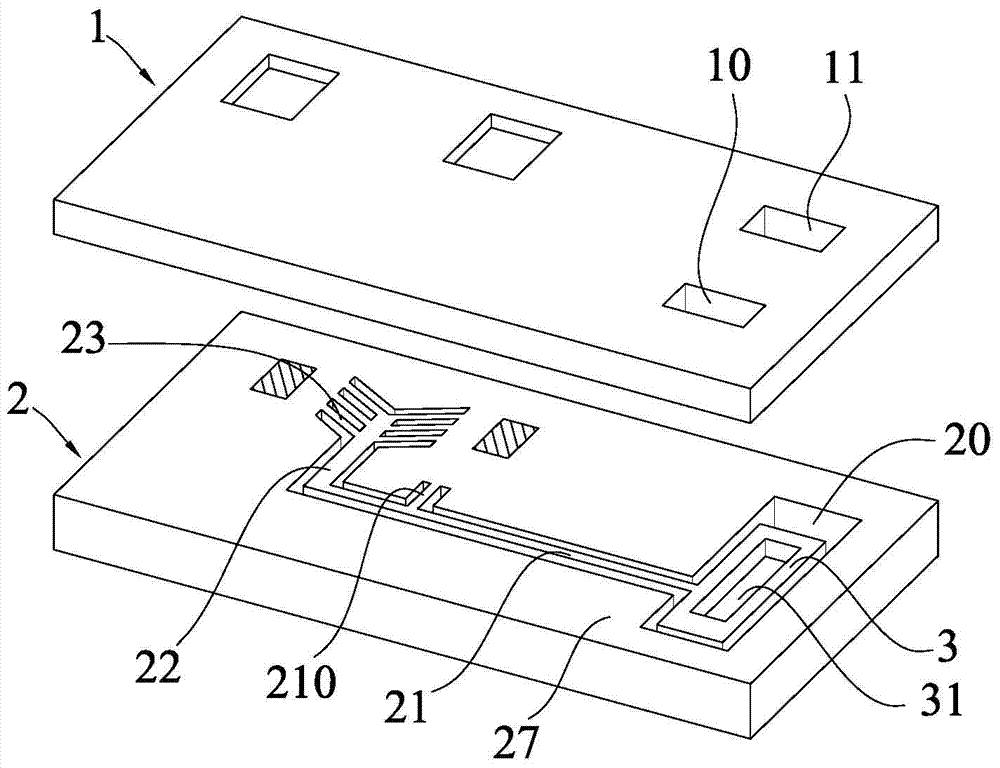

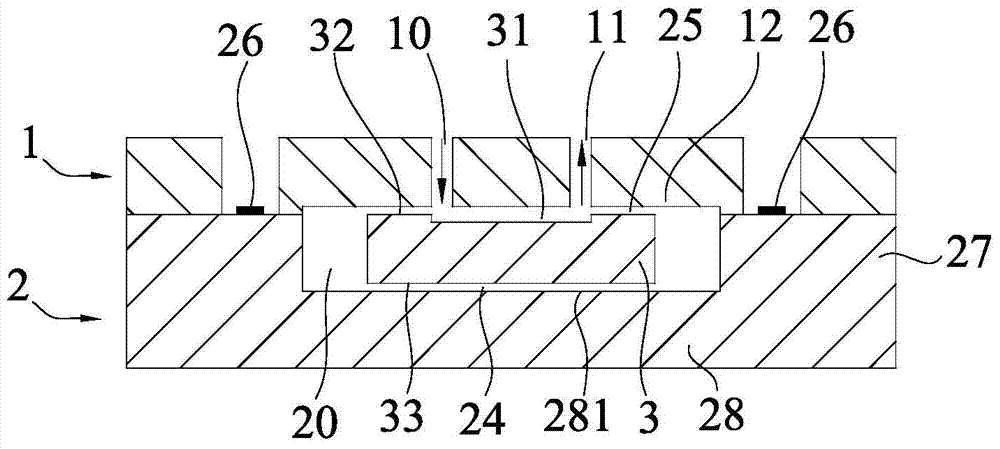

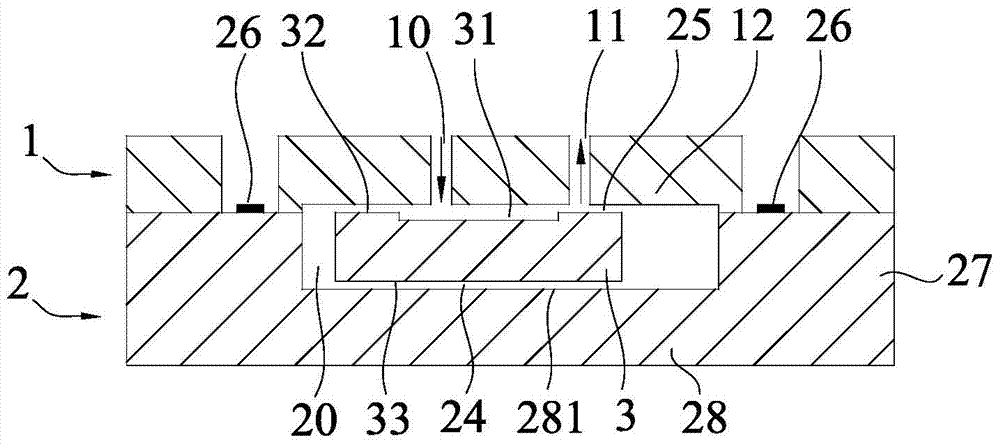

[0052] refer to Figure 1-3 , a MEMS microvalve, comprising a first silicon layer 1 and a second silicon layer 2, wherein a fluid inlet 10 and a fluid outlet 11 are opened on the first silicon layer 1, and a fluid inlet 10 and a fluid outlet 11 are formed on the second silicon layer 2 on the surface of the second silicon layer 2 The outer flow channel 20 and the rigid component 3 with the inner flow channel 31, the rigid component 3 is accommodated in the outer flow channel 20, and can move between the valve opening position and the valve closing position.

[0053] When designing the rigid component 3, this embodiment achieves a greater displacement output of the rigid component 3 through a special driving structure. Specifically: an actuating rib 23 and a transmission ridge are also provided in the outer flow channel 20 of the second silicon layer 2. 22 and the displacement amplifying beam 21, the actuating rib 23 is connected between the transmission ridge 22 and the side wa...

Embodiment 2

[0063] refer to Figure 5 , 6 , the microvalve of the present embodiment is also provided with a fluid pressure detection port 13 on its first silicon layer 1, and the fluid pressure detection port 13 is positioned between the fluid inlet 10 and the fluid outlet 11, thus, the microvalve can detect fluid inflow or Pressure at outflow.

[0064] Specifically: such as Figure 5 As shown, in the valve open state, the fluid inlet 10 communicates with the fluid pressure detection port 13, the fluid flows in from the fluid inlet 10, and flows out from the fluid pressure detection port 13. Within the response time, the fluid pressure detection port 13 obtains a standard fluid pressure signal, the microvalve works in boost mode.

[0065] Such as Figure 6 As shown, in the valve closed state, the fluid outlet 11 communicates with the fluid pressure detection port 13, the fluid flows out from the fluid outlet 11, the standard fluid pressure signal is released, and the microvalve works...

Embodiment 3

[0068] The present embodiment provides a kind of manufacturing technology of MEMS microvalve, comprises the following steps:

[0069] 1. Set the first silicon layer and the second silicon layer, wherein the material of the first silicon layer includes but not limited to (111), (100), (110) crystal silicon materials and other semiconductor materials, the second silicon The material of the layer is a single crystal silicon material with (111) crystal orientation;

[0070] 2. As shown in Figure 7(a), the inner flow channel 31 is etched on the upper surface of the second silicon layer 2;

[0071] 3. As shown in Figure 7(b), a mask 4 is partially deposited on the upper surface of the second silicon layer 2. In this step, the upper surface of the second silicon layer 2 is not completely covered with a mask, but the engraving of the subsequent process is reserved. Eclipse;

[0072] 4. As shown in Figure 7(c), the outer flow channel 20 is preliminarily etched on the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com