Nozzle for atomizing water with air suitable for round billet continuous casting secondary cooling

A technology of secondary cooling and gas-water atomization, applied in spraying device, spraying device, liquid spraying device, etc., can solve the problem of unification of atomization particle size and coverage uniformity, to ensure spraying effect and good solid effect , the effect of a large flow control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the air-water atomizing nozzle suitable for the secondary cooling of round billet continuous casting according to the present invention will be described in conjunction with the accompanying drawings and embodiments.

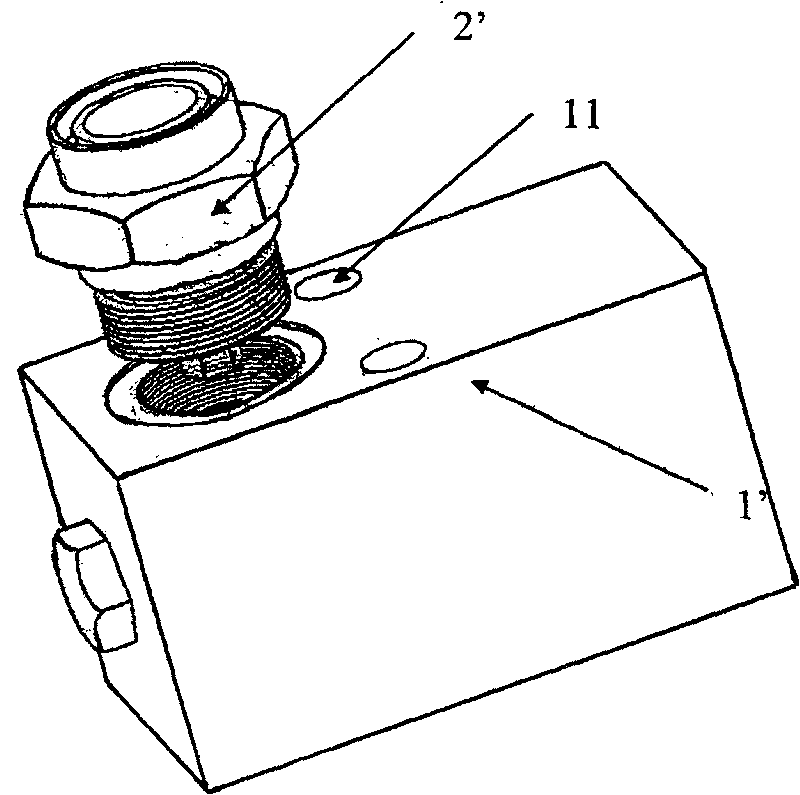

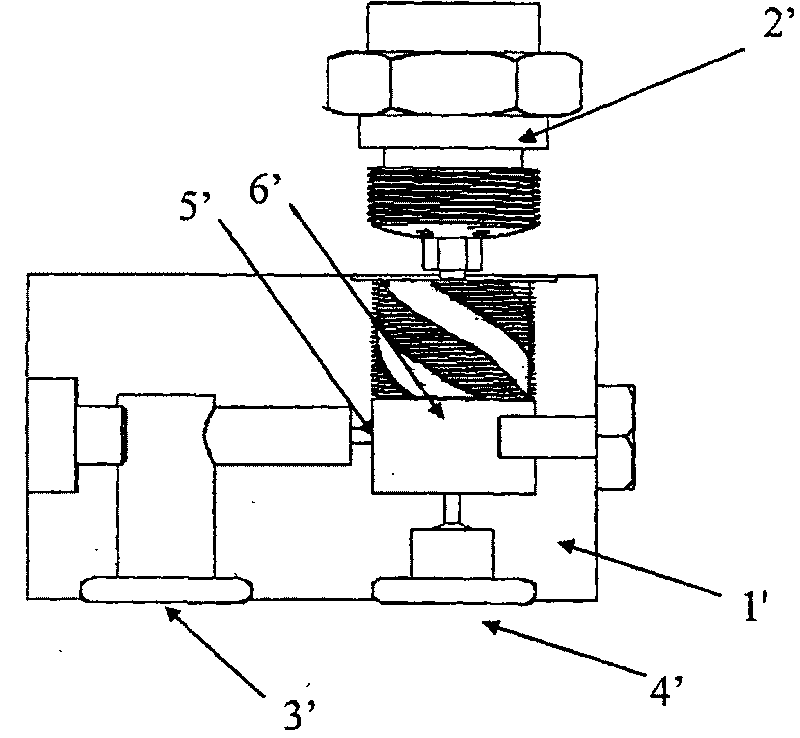

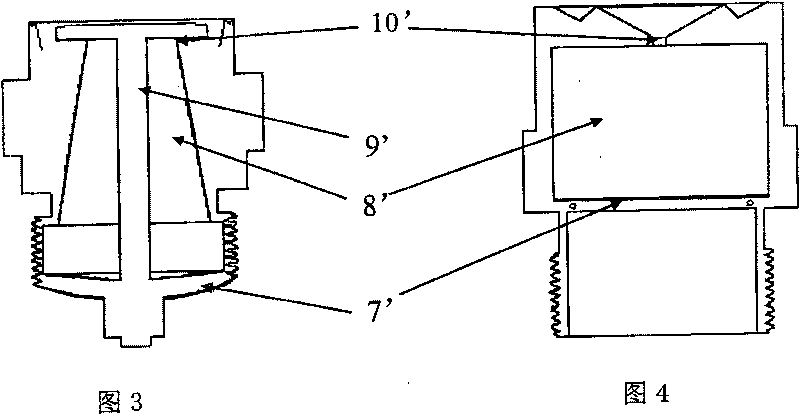

[0021] The air-water atomizing nozzle suitable for round billet continuous casting secondary cooling of the present invention, such as Figure 5 , 6 As shown, it includes a base 1 and a spray head 2 screwed to the base. The base 1 is provided with a water inlet 3 connected with a water pipe and an air inlet 4 connected with an air pipe. The nozzle 2, such as Figure 7 As shown, the back cover of the shower head is provided with a water-saving outlet 5, the front cover is provided with a nozzle 10, the middle part between the front and rear covers of the shower head is provided with a guide plate 7, and the outer circumference of the guide plate 7 is evenly arranged. There are sloped rectangular pouring troughs. The first air-water mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com