Vertical electroplating production equipment

A technology of vertical electroplating and production equipment, applied in electrolytic components, electrolytic processes, cells, etc., can solve the problems of complex pipeline structure, large amount of sewage, large amount of clean water, etc., achieve low water pressure, reduce sewage treatment pressure, and reduce water volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

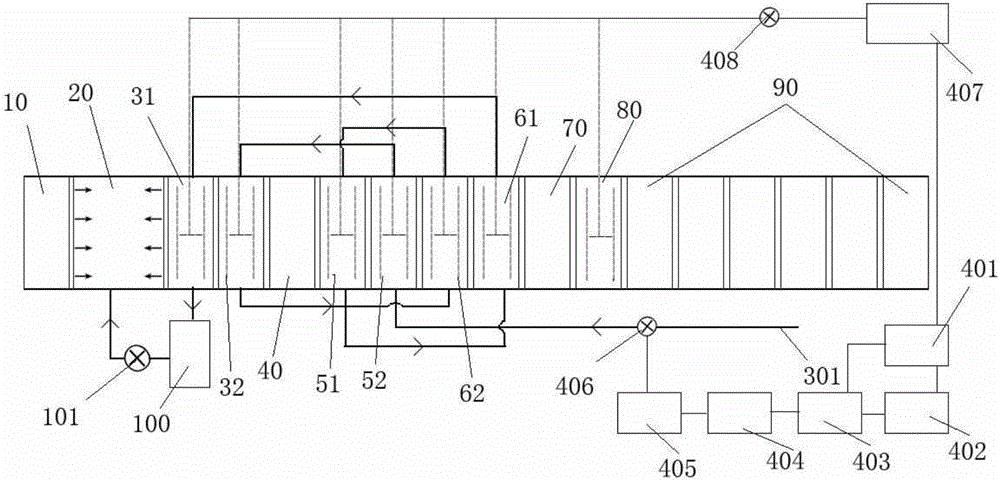

[0046] This embodiment provides a kind of vertical electroplating production equipment, such as figure 1 shown

[0047] Including, the degreasing and cleaning tank 10, the spraying and washing tank 20, the second and second-level water washing tank 31, the second-level water washing tank 32, the micro-etching tank 40, the second and second-level water washing tank 51, the second and second-level water washing tank 51, and the Second level water washing tank 52, third level water washing tank 62, third and second level water washing tank 61, electroplating tank 90;

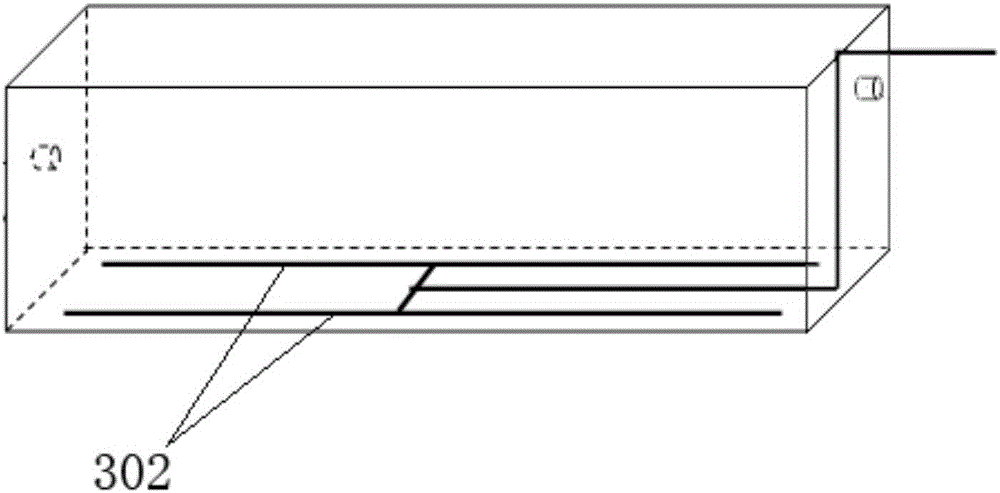

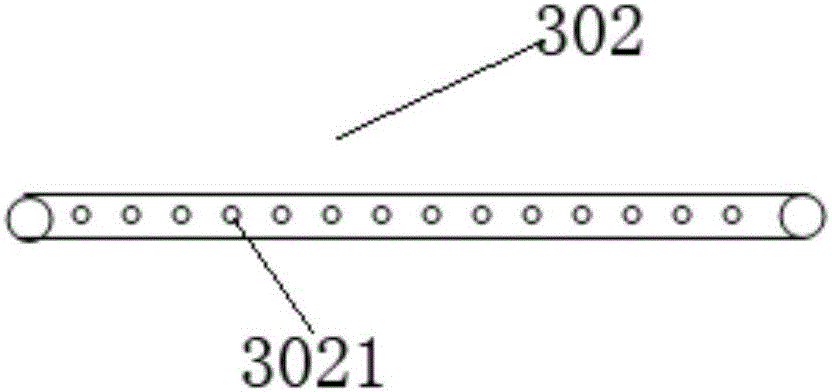

[0048] The second-level water washing cylinder 52 is connected with the clean water pipe 301 that feeds clean water, and each water washing cylinder is connected to each other through several pipelines to form a clean water pipe 301-the second-level water washing cylinder 52-the first-level water washing cylinder 32-the first level Three primary water washing tanks 62 - second and secondary water washing tanks 51 ...

Embodiment 2

[0088] The vertical electroplating production equipment of this embodiment is a deformation on the basis of Embodiment 1. The differences between this implementation and Embodiment 1 are:

[0089] There are two first water washing tanks, respectively the first and second water washing tanks 31, the first first level water washing tank 32, two second water washing tanks, respectively the second water washing tank 51, and one third water washing tank, which is The third and second level water washing tank 61 .

[0090] The second secondary water washing tank 51, the first primary water washing tank 32, the third secondary water washing tank 61, the first secondary water washing tank 31 and the spray flushing tank 20 are sequentially passed through the pipeline In communication, the second-level water washing cylinder 52 is also in communication with the clean water pipe 301 .

[0091] Therefore, the cleaning water in the clear water source passes into the second secondary washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com