Flue gas desulfurization method of heating boiler and device thereof

A technology for heating boilers and desulfurization devices, applied in separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve problems such as on-site dust pollution, incomplete dehydration, and decreased desulfurization efficiency, to ensure spraying effect and desulfurization The effect of stable product and no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

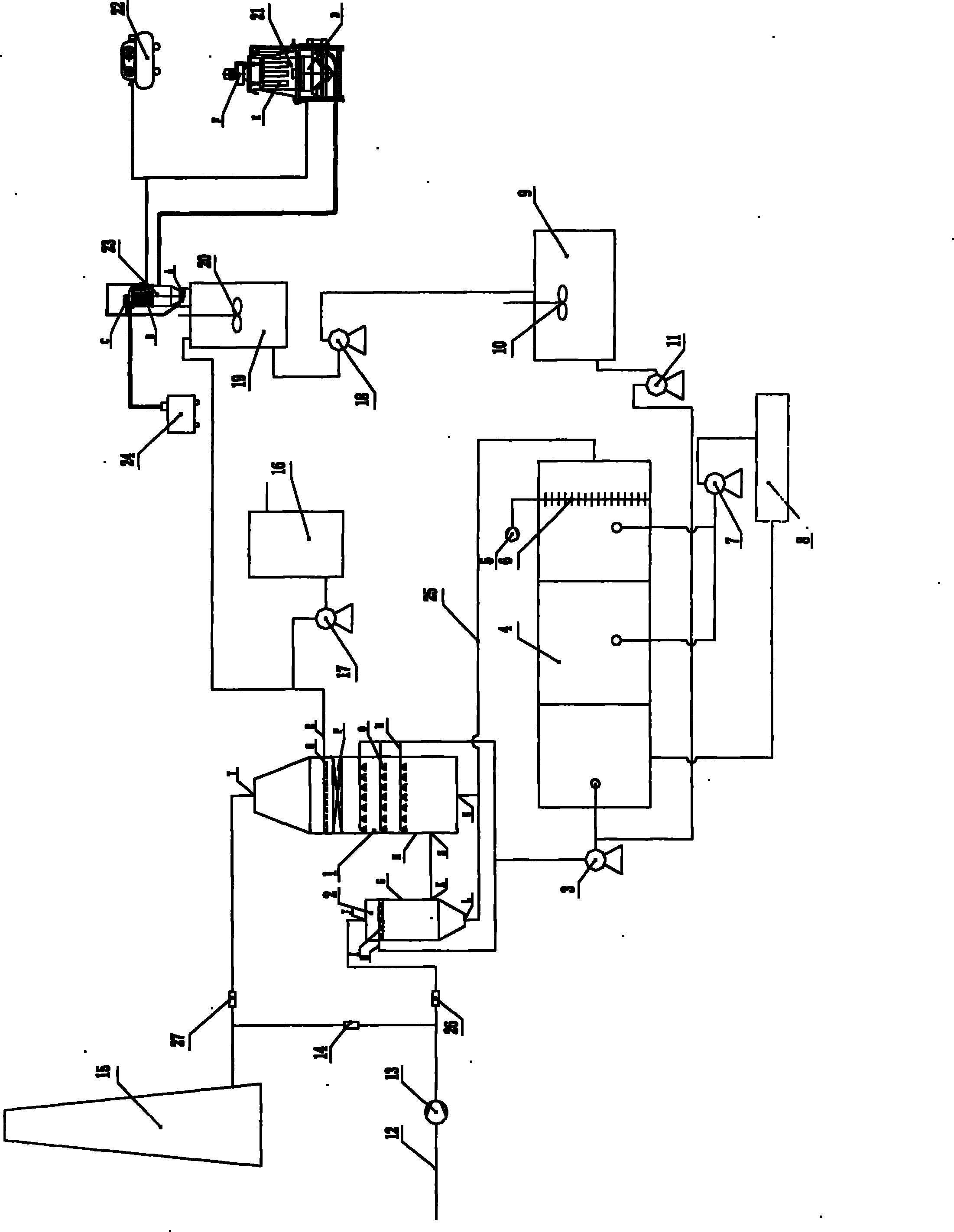

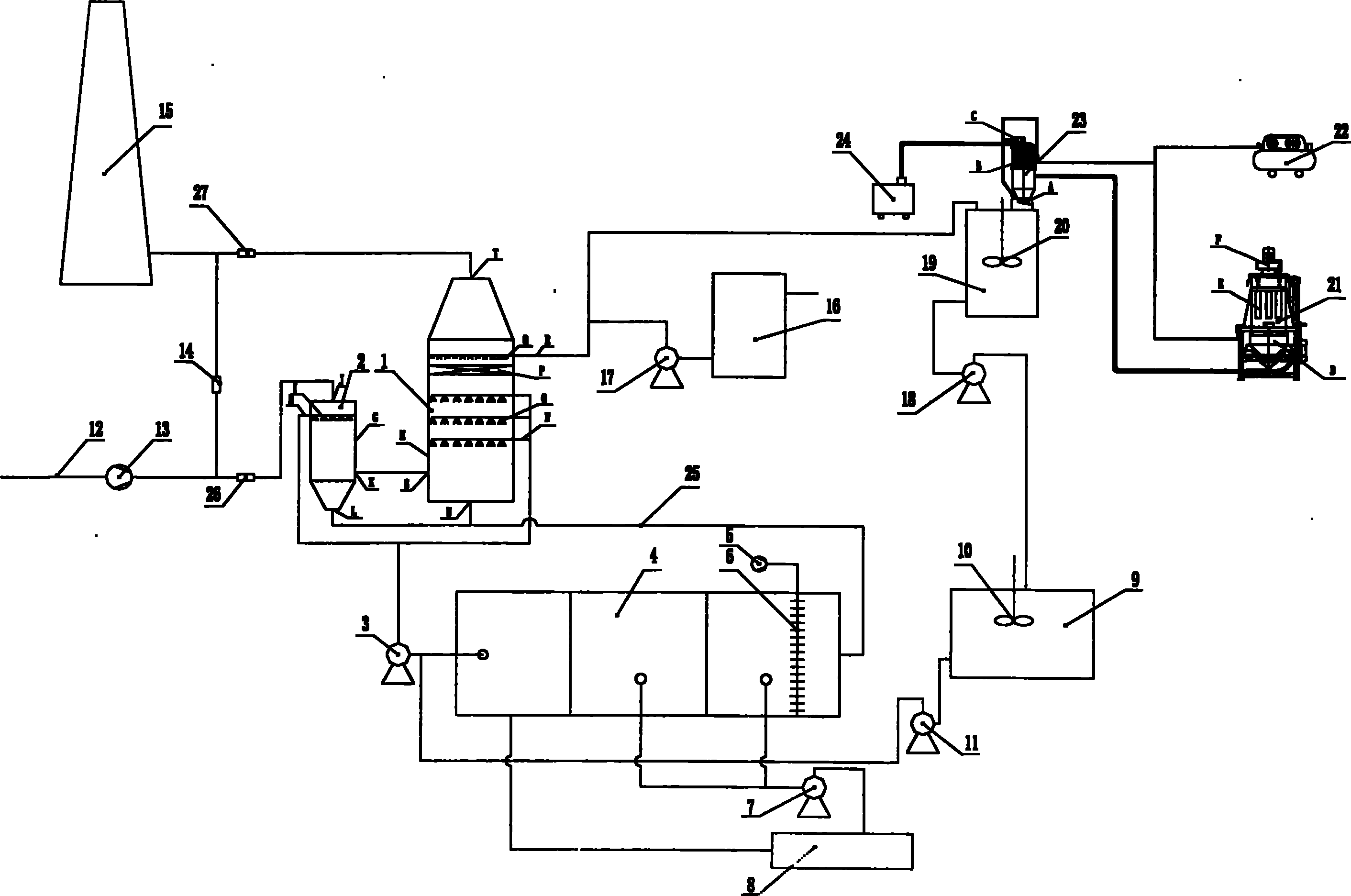

[0038] A heating boiler flue gas desulfurization method, comprising the following process:

[0039] Pre-cooling: The flue gas after dust removal is sent to the pre-cooling tower 2 by the induced draft fan 13 through the flue inlet 12 for pre-cooling; the absorption liquid is atomized and sprayed to the pre-cooling tower 2 through the circulation pump 3;

[0040] Desulfurization: the pre-cooled flue gas enters the desulfurization tower 1 for desulfurization; the absorption liquid is atomized and sprayed to the desulfurization tower 1 through the circulation pump 3; the desulfurized flue gas is discharged through the chimney 15;

[0041] Magnesium oxide pulping: Magnesium oxide powder is pulped in the digestion tank 19, and the slurry is sent to the circulation pump 3 through the slurry pump 11, and atomized and sprayed in the flue gas precooling tower 2 and the desulfurization tower 1;

[0042] Aeration of the absorption liquid: the blower 5 aerates the absorption liquid in the...

Embodiment 2

[0047] A flue gas desulfurization device for heating boilers, the flue gas after dust removal treatment enters the flue 12 through the induced draft fan 13 to connect to the precooling tower 2, the precooling tower connects to the desulfurization tower 1 through the flue, and the desulfurization tower 1 connects to the flue gas discharge The chimney 15; the precooling tower 2 and the desulfurization tower 1 have an absorption liquid atomization injection mechanism; The absorption liquid circulation pool 4 is connected to the pre-cooling tower 2 and the desulfurization tower 1, the atomization jet circulation pump 3; the blower 5 is connected to the aeration distribution pipe 6 in the circulation pool 4; the circulation pool 4 is connected to the slurry discharge pump 7 and is connected to the magnesium sulfate crystal dehydrator 8. The dehydrator 8 has a passage for the extracted water to flow into the circulating pool 4; the jet circulation pump 3 is connected to the digester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com