A three-gas supercharging system applied to liquid rockets

A technology for liquid rockets and supercharging systems, applied in rocket engine devices, jet propulsion devices, machines/engines, etc., can solve problems such as inability to meet high efficiency and low quality, and achieve reduced development risks, high reliability, and low system quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

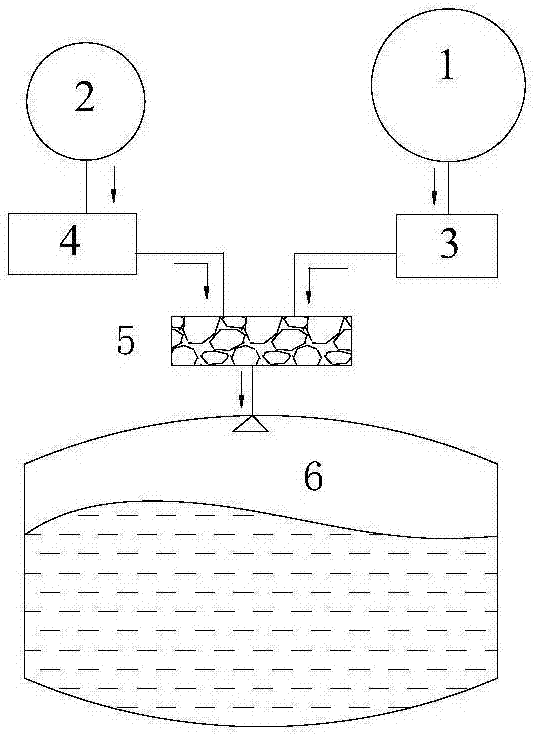

Method used

Image

Examples

Embodiment

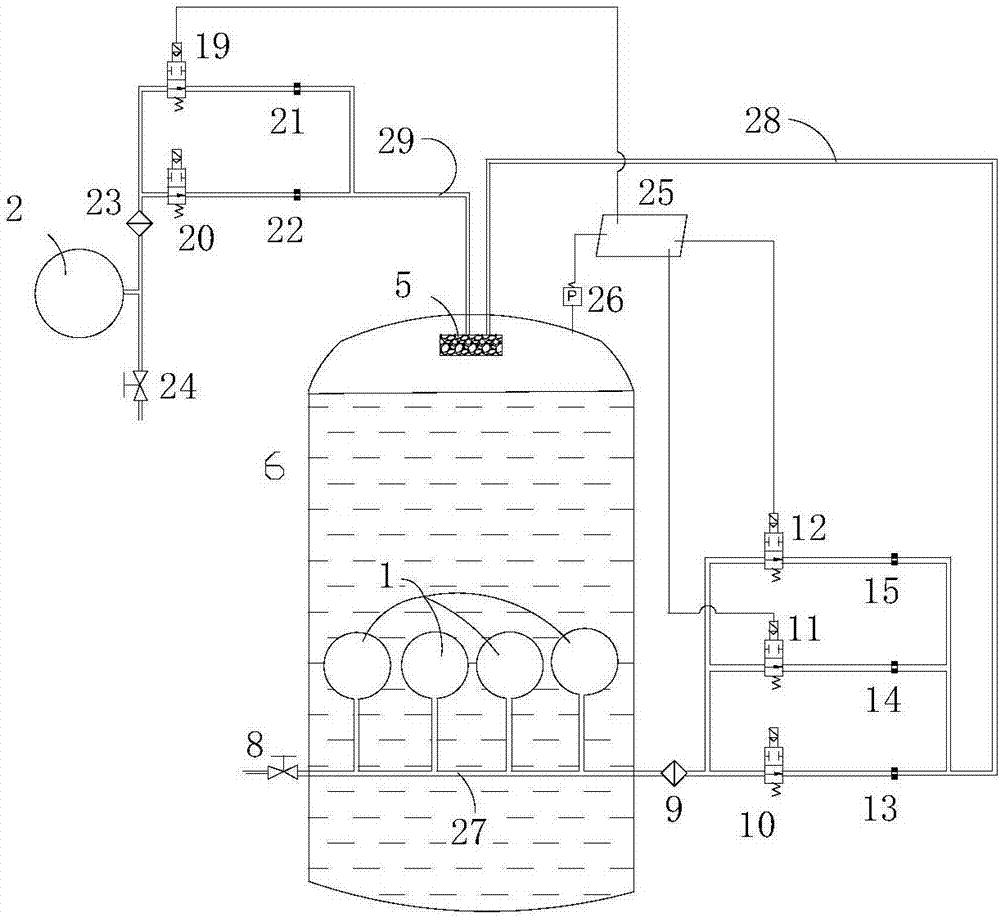

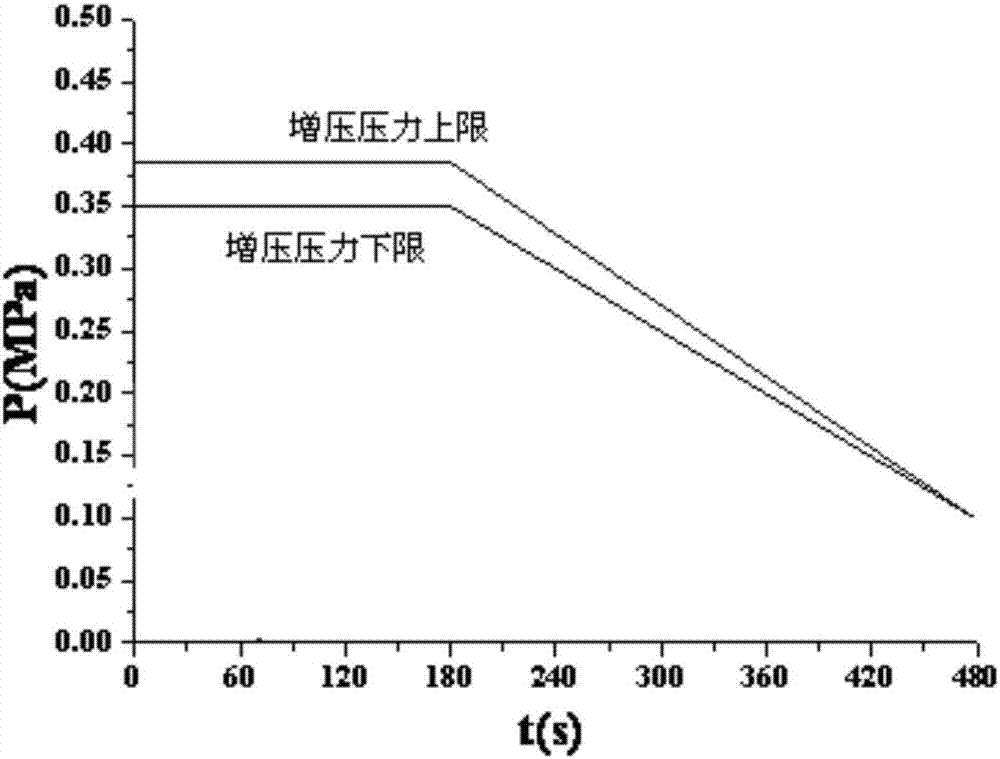

[0041] According to the supercharging pressure requirements of the storage tank during rocket flight, the scheme design and supercharging calculation of the triple gas supercharging system are carried out to meet the supercharging demand and complete the system design. The specific implementation is as follows:

[0042] a) According to the boost pressure requirement of a certain type of rocket, the temperature of the air pillow and the volume of the storage tank, the total amount of helium in the pressurized gas is preliminarily calculated by using the gas state equation. According to the temperature required for pressurized helium, the mixing ratio and dosage of hydrogen and oxygen are obtained through preliminary calculation from the specific heat of helium and the heat of reaction of hydrogen and oxygen. On this basis, select the cylinder pressure and design the cylinder volume. Since the stage flow control unit with solenoid valve and orifice plate is used, in order to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com