Patents

Literature

32results about How to "Increase gas density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hybrid Electric Vehicle

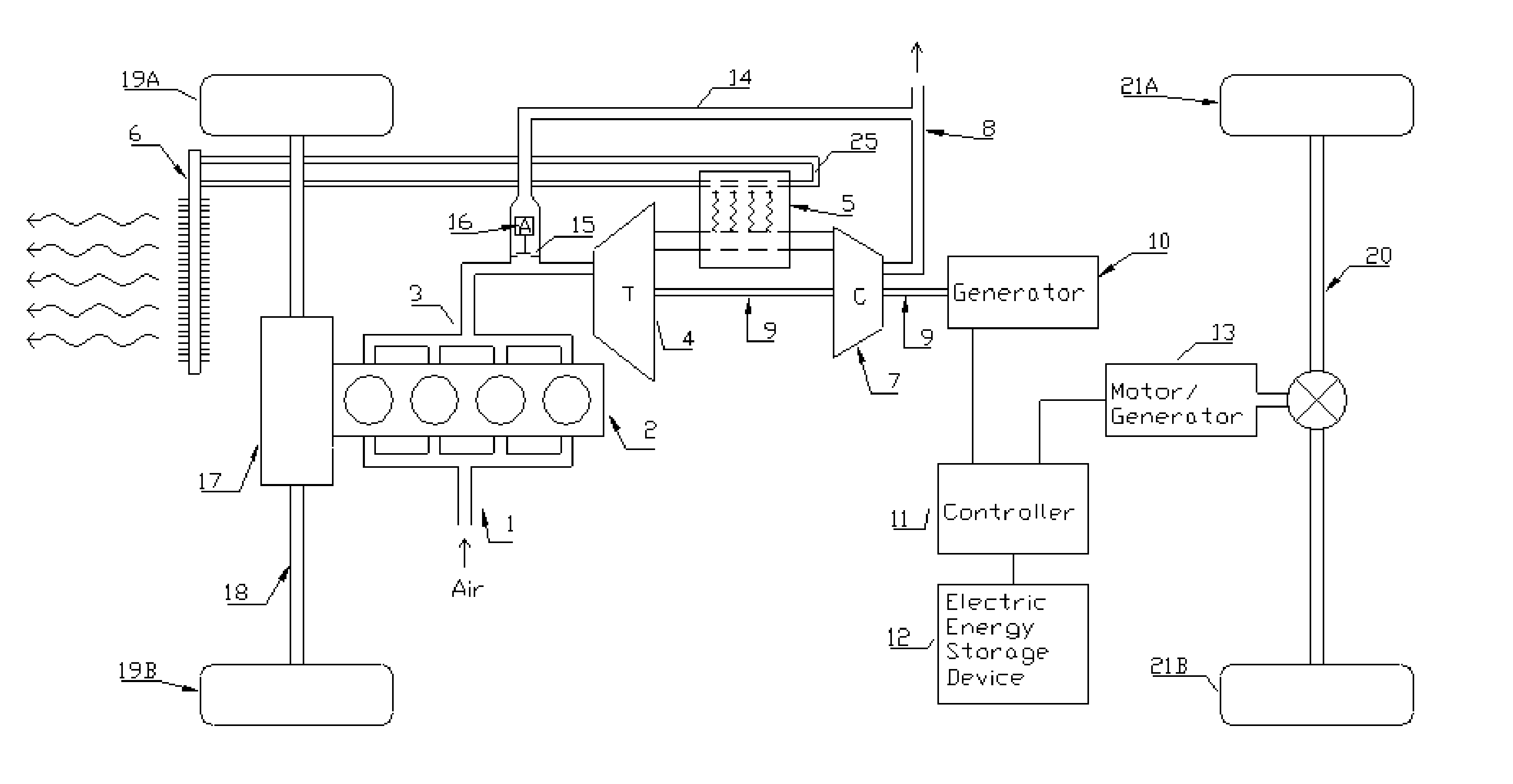

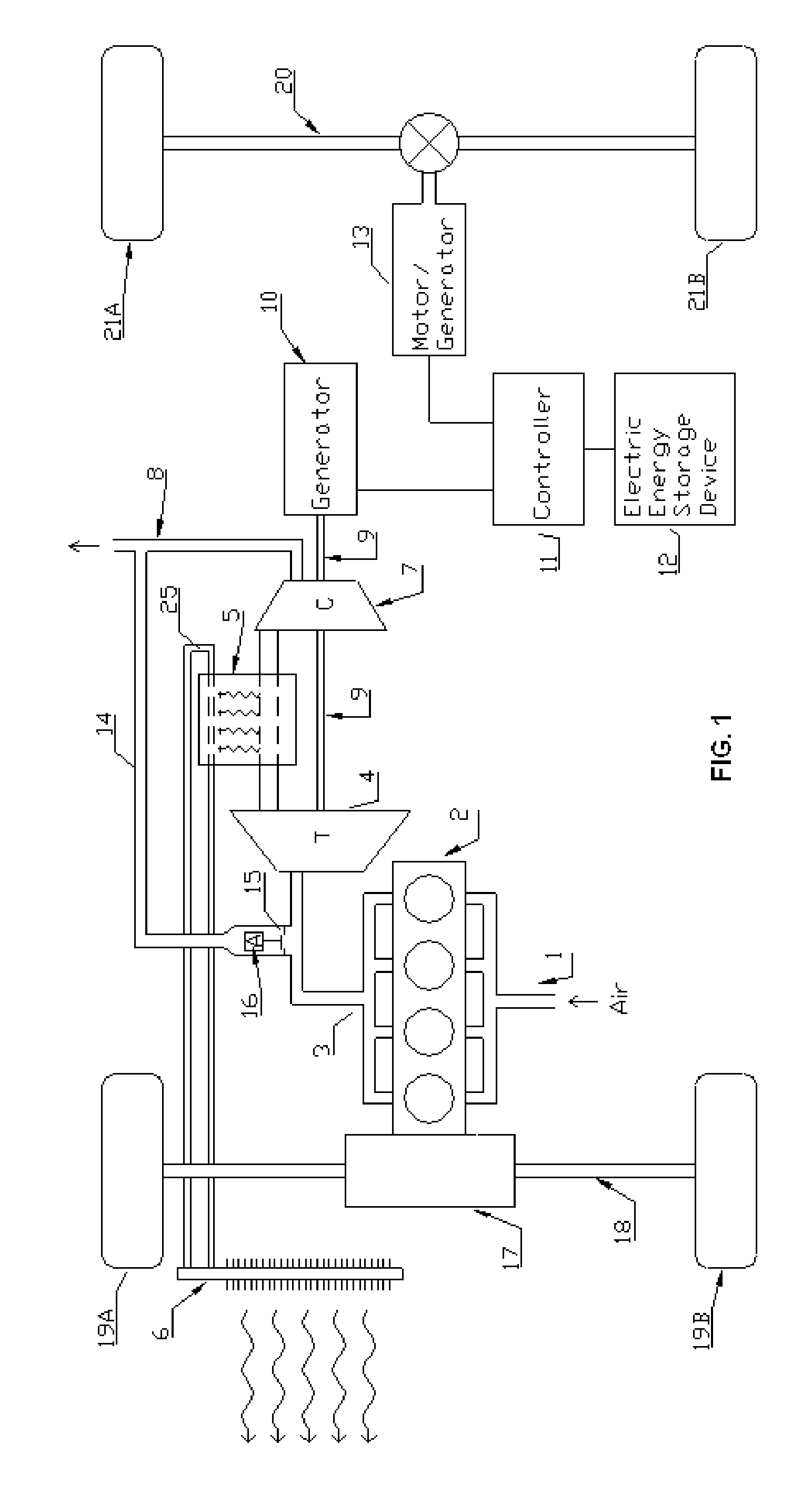

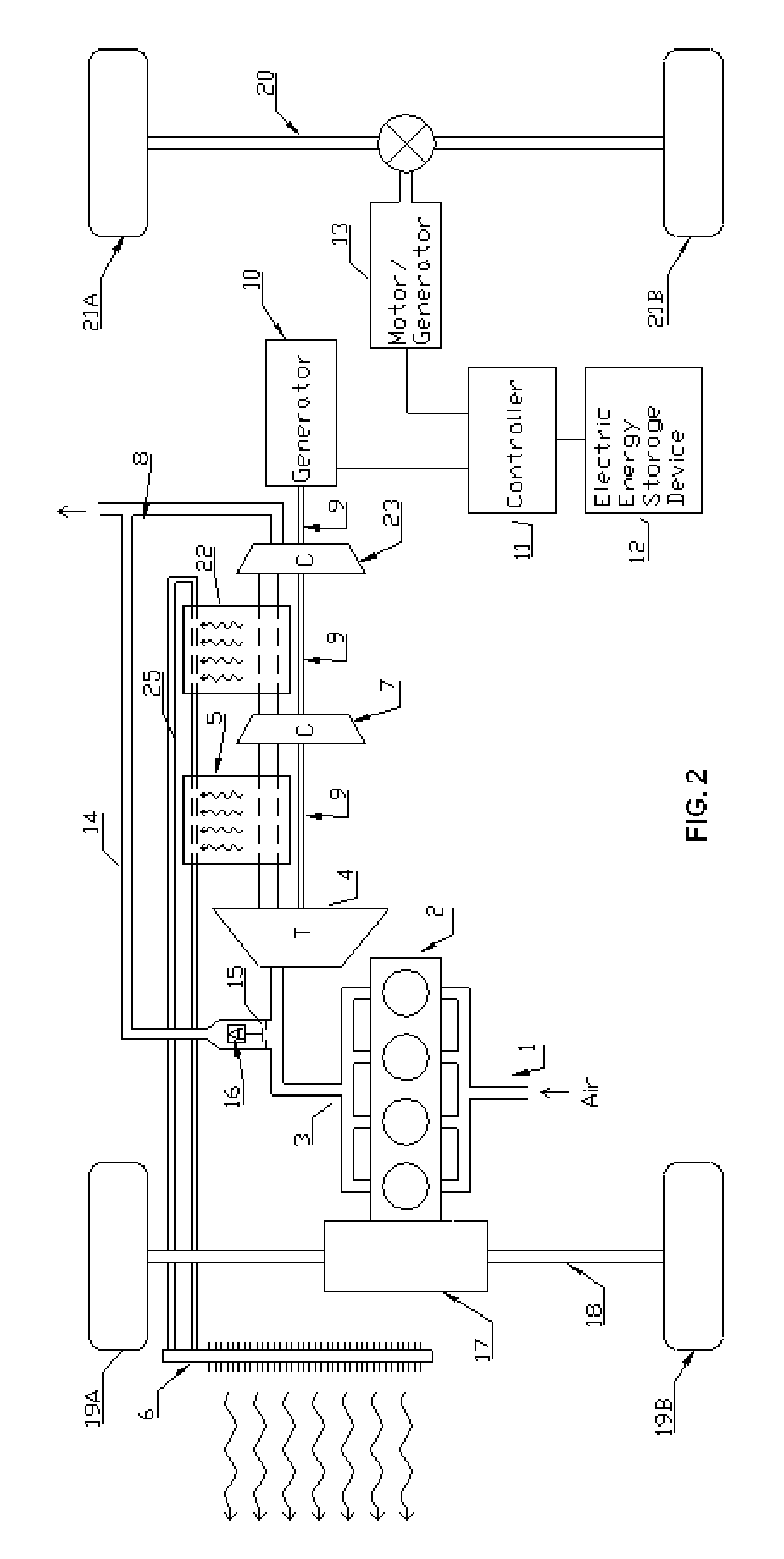

InactiveUS20070068712A1Decreased power outputIncreased power outputPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsElectric vehicleInternal combustion engine

A hybrid electric vehicle having an internal combustion engine as its primary power source and a turbine engine that is powered by waste heat from the internal combustion engine as an additional power source.

Owner:CARNAHAN ERIC SCOTT

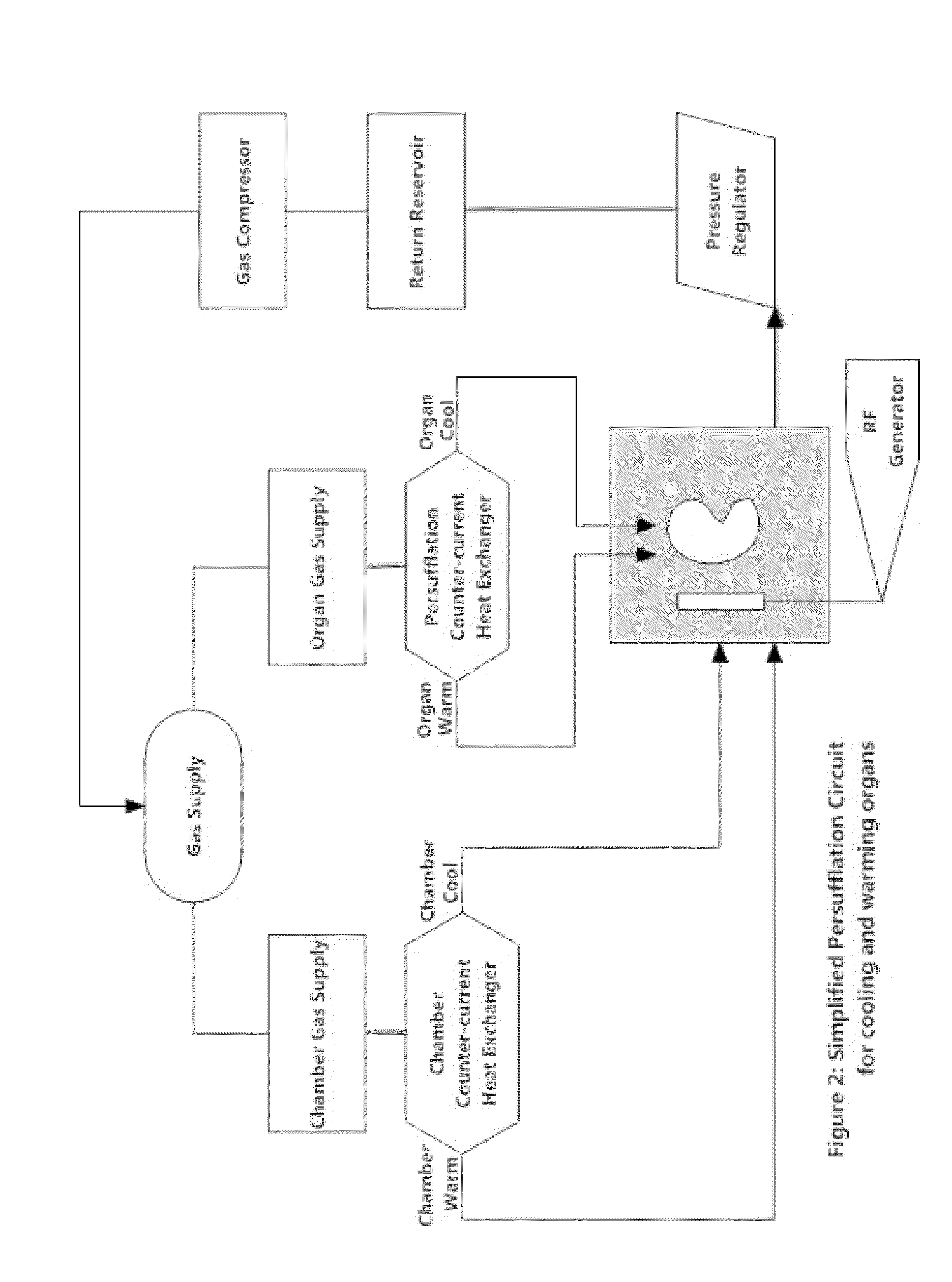

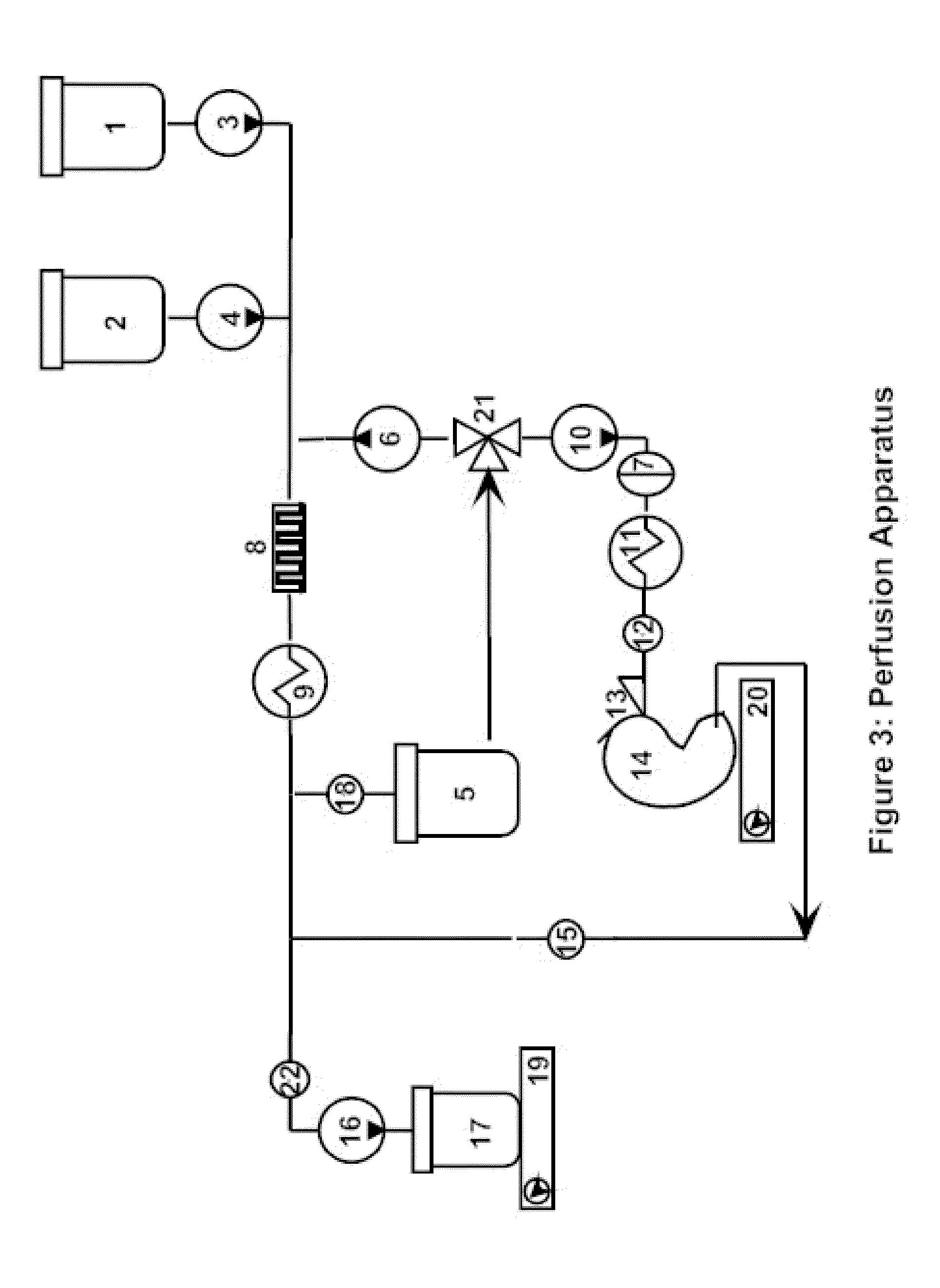

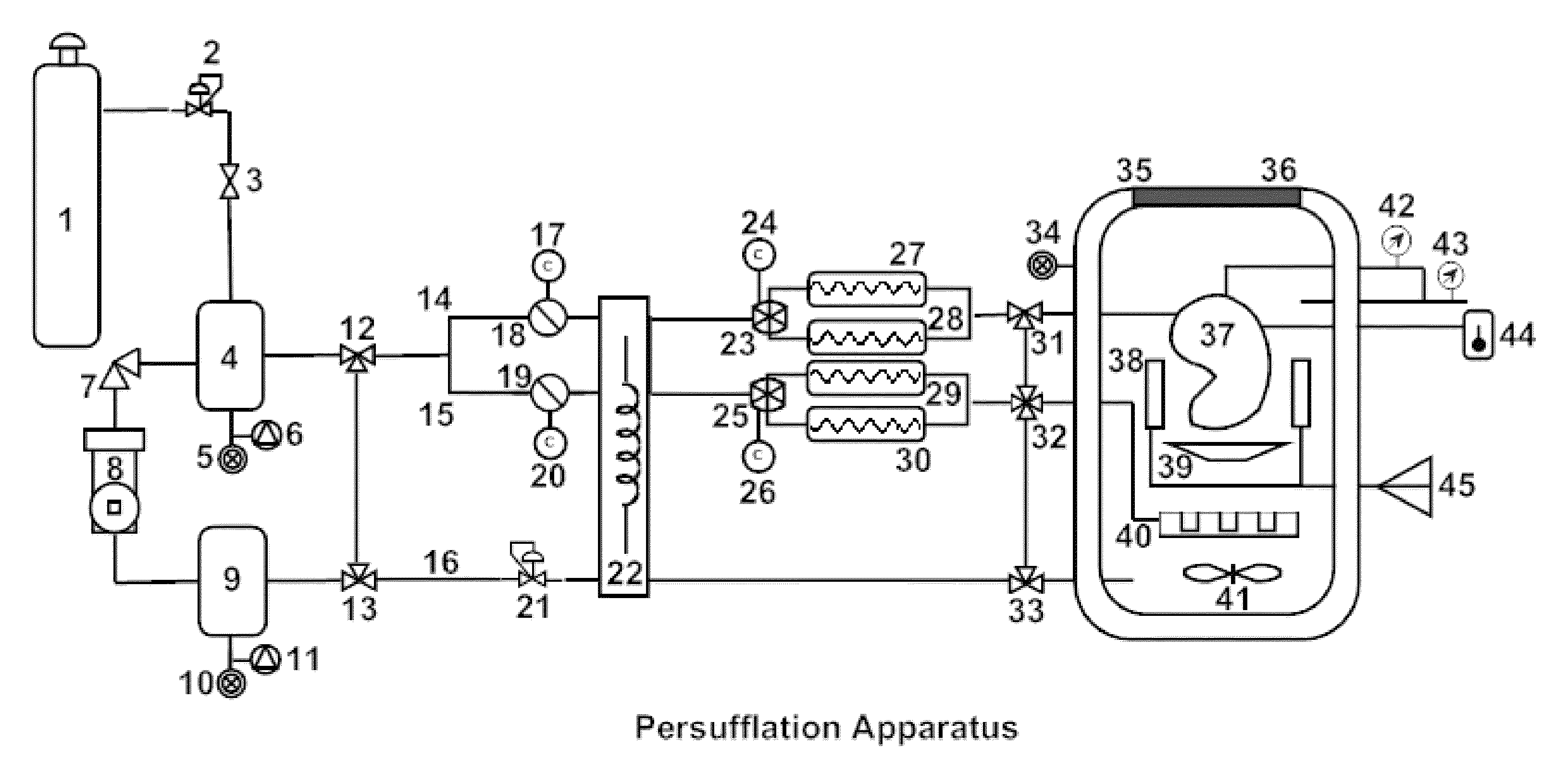

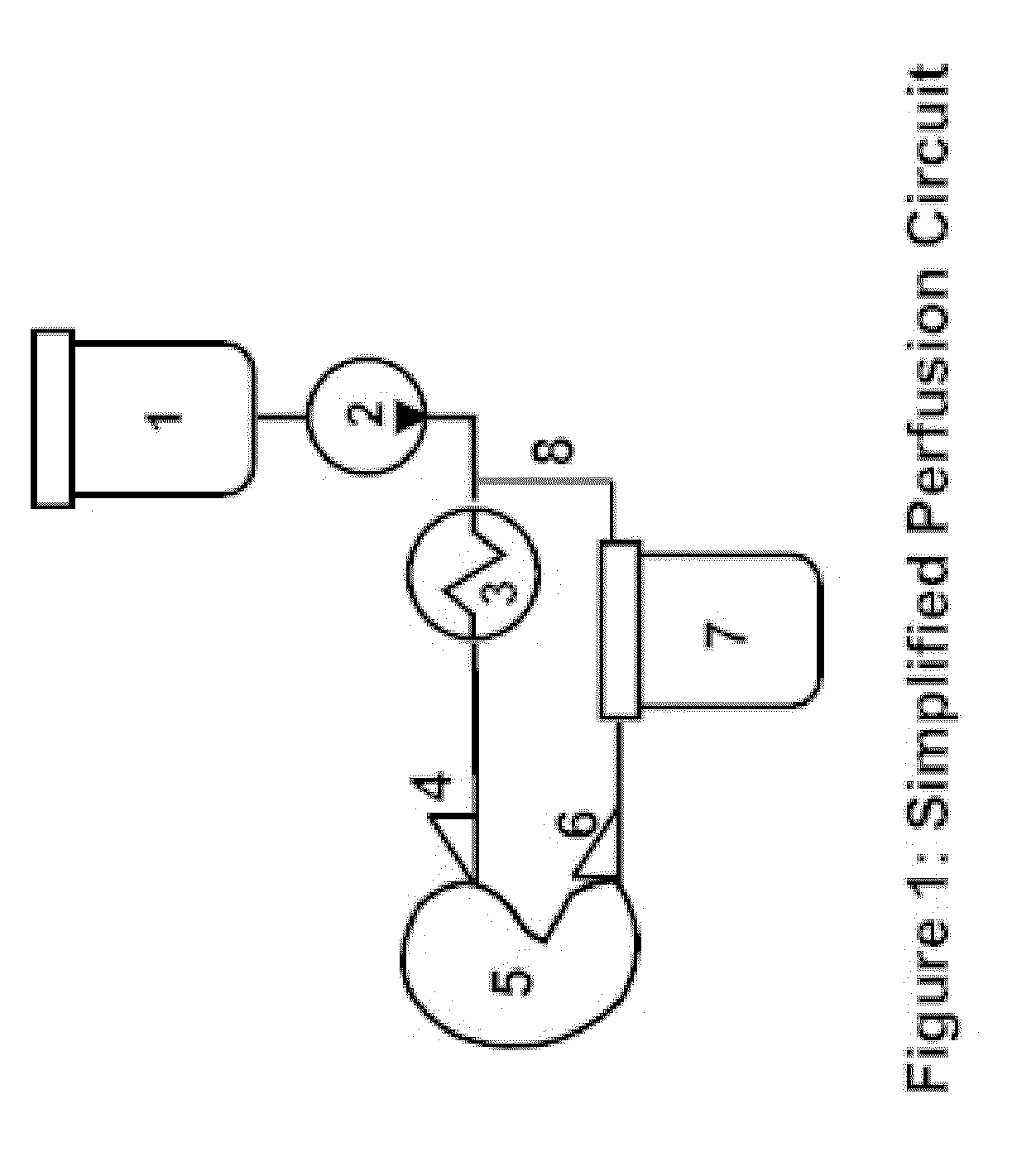

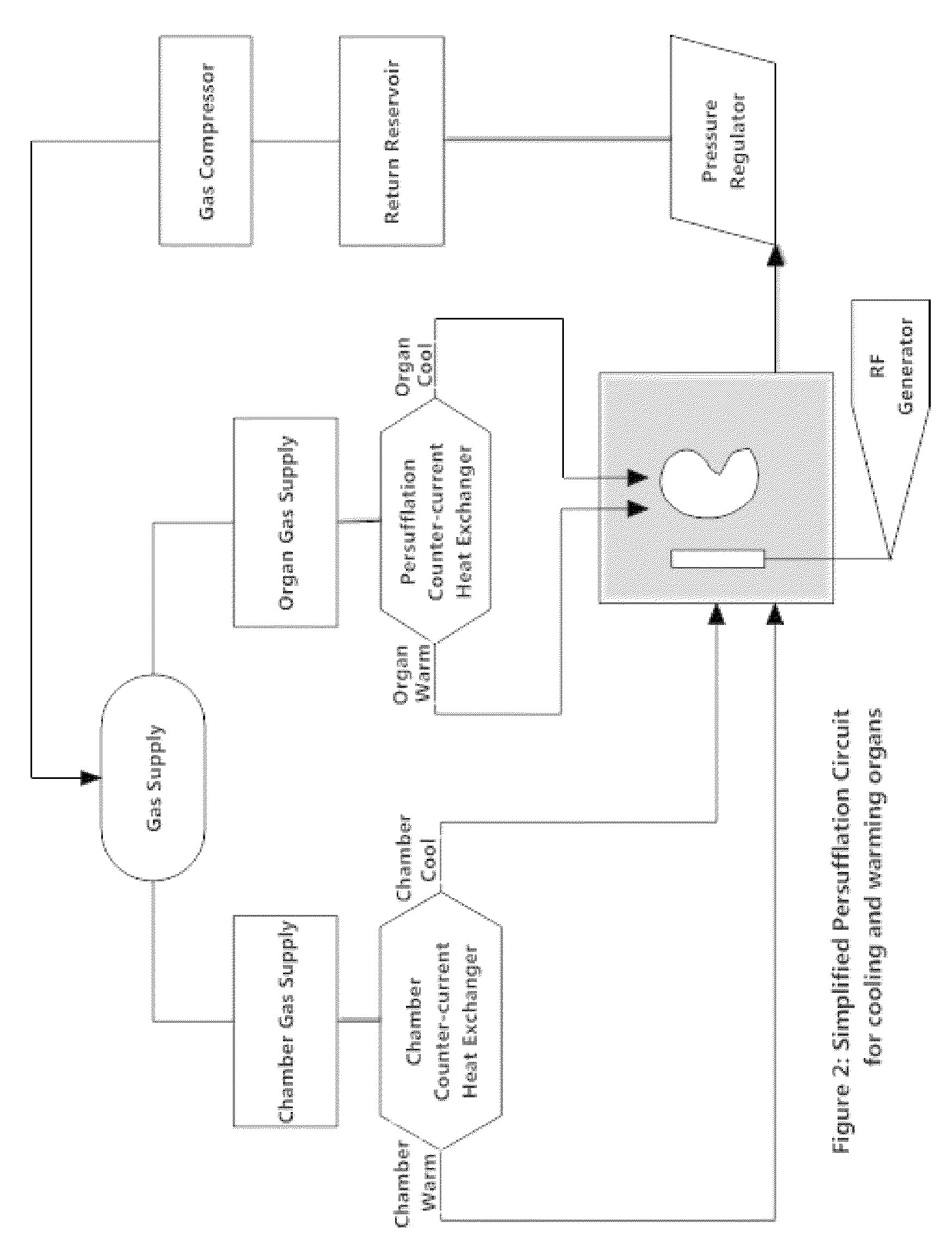

Method and apparatus for prevention of thermo-mechanical fracturing in vitrified tissue using rapid cooling and warming by persufflation

InactiveUS20140011182A1Rapid coolingLow toxicityDead animal preservationCryoprotectant toxicityHelium gas

A method and apparatus are disclosed for avoiding fracturing, e.g., thermo-mechanical fracturing, in vitrified biological systems via rapid cooling and / or warming persufflation techniques, by reducing the domain size of fracturing and by reducing thermal gradients. Also disclosed is a system adapted to rapidly cool and warm vitrifiable vascular biological tissue by persufflation, significantly reducing cryoprotectant toxicity from that of surface cooled tissue, in which the system is constructed and configured to use one or more of helium gas, hydrogen gas, neon gas, argon gas, krypton gas, xenon gas, oxygen gas, or various gaseous compounds. The system can be operated under pressure to increase the density and heat capacity of the gas relative to its density and heat capacity at atmospheric pressure and to cool the gas by one or more of mechanical action and by the phase change of a material such as a cryogenic gas or solid.

Owner:ARIGOS BIOMEDICAL

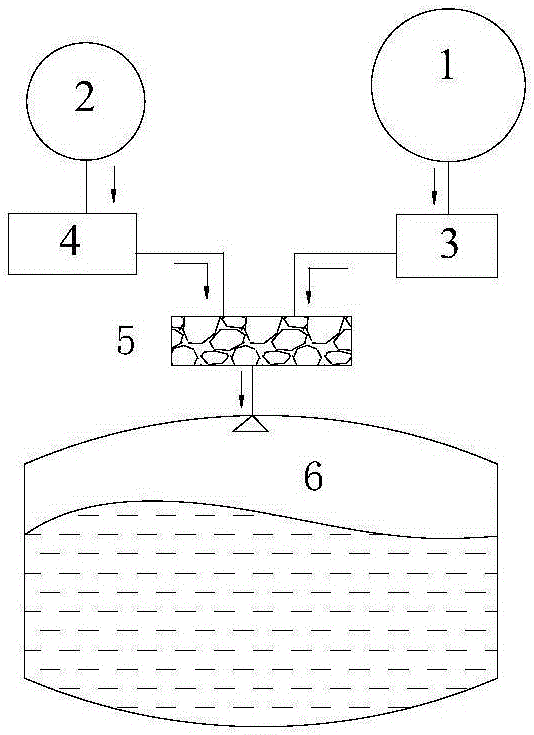

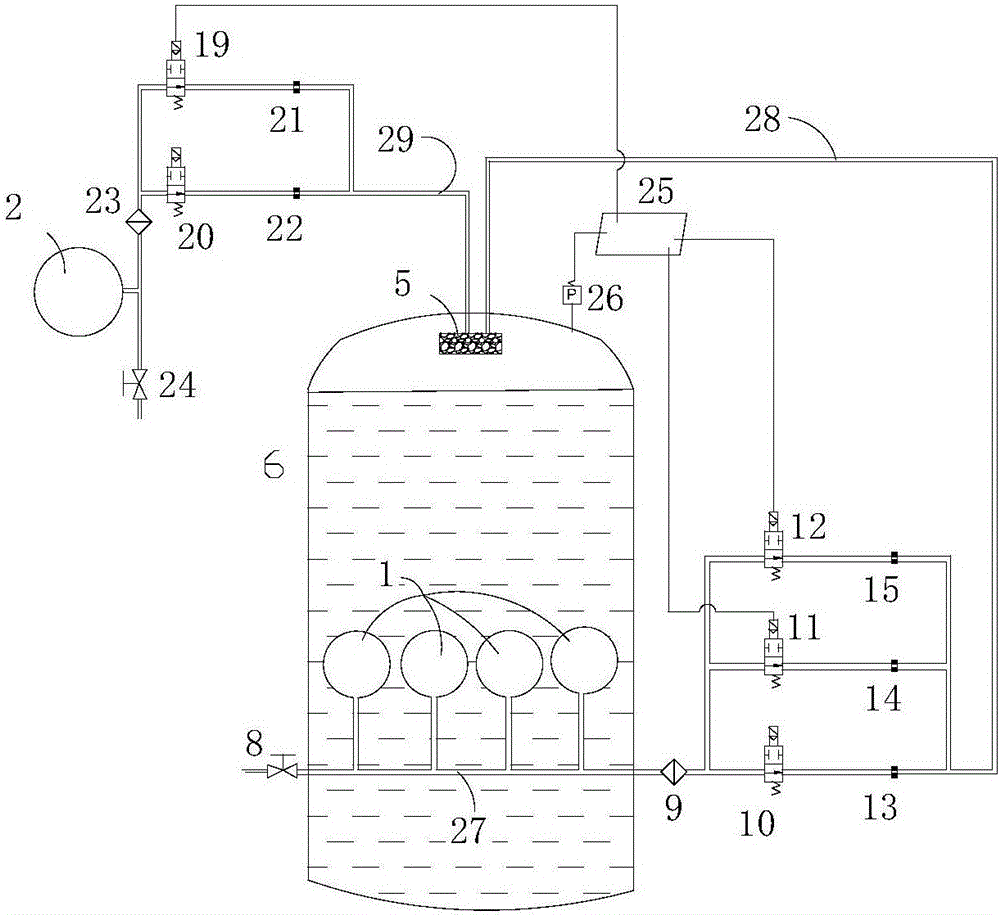

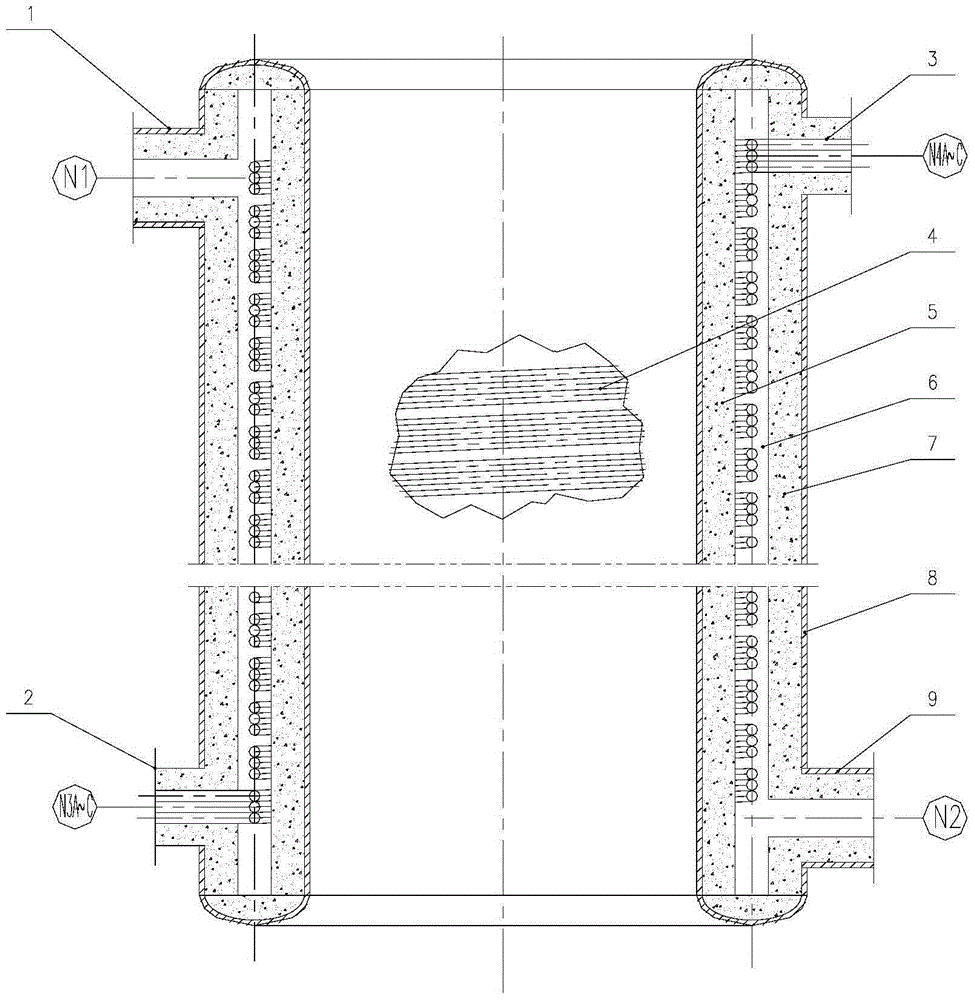

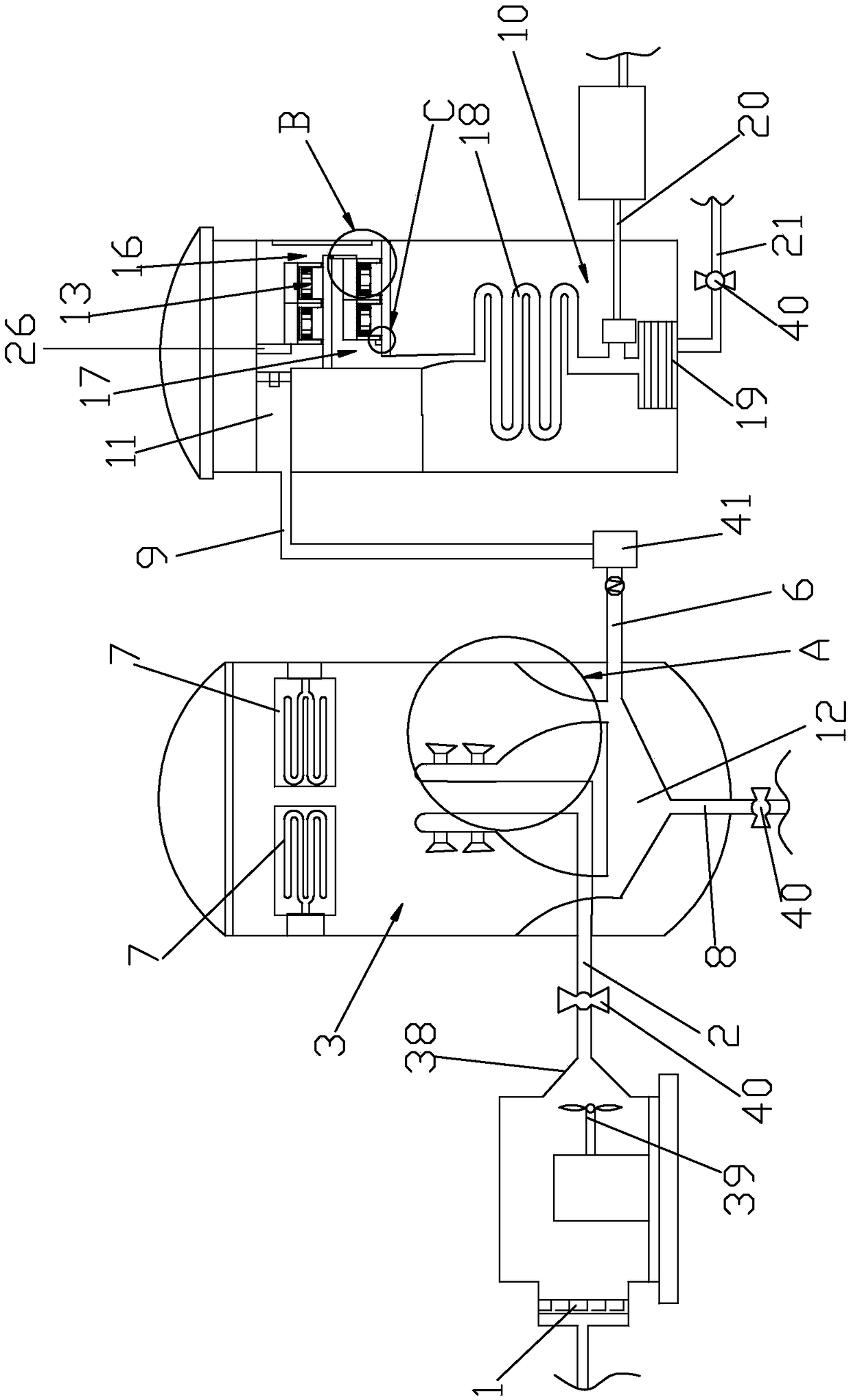

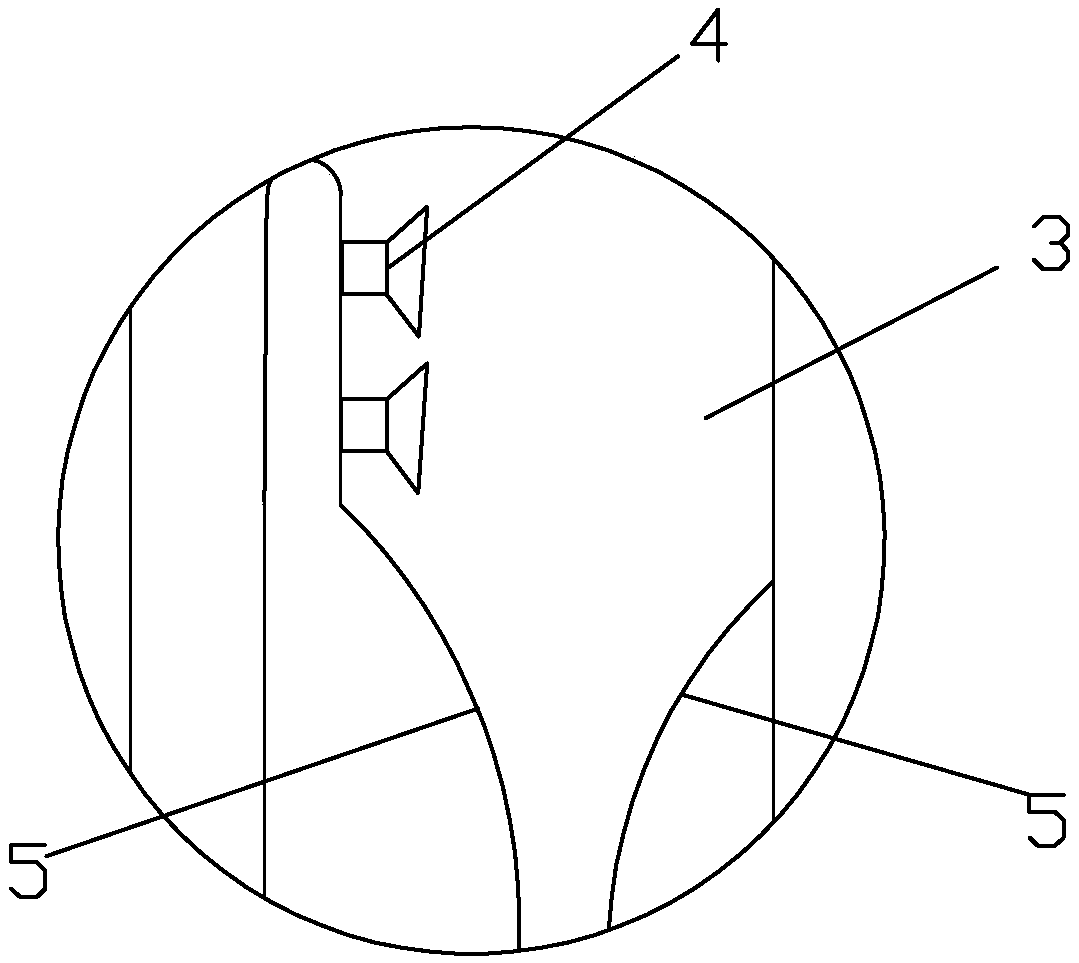

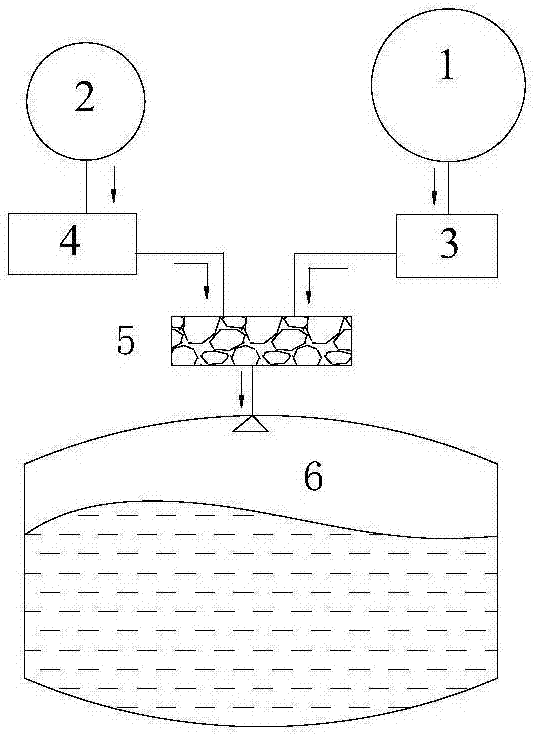

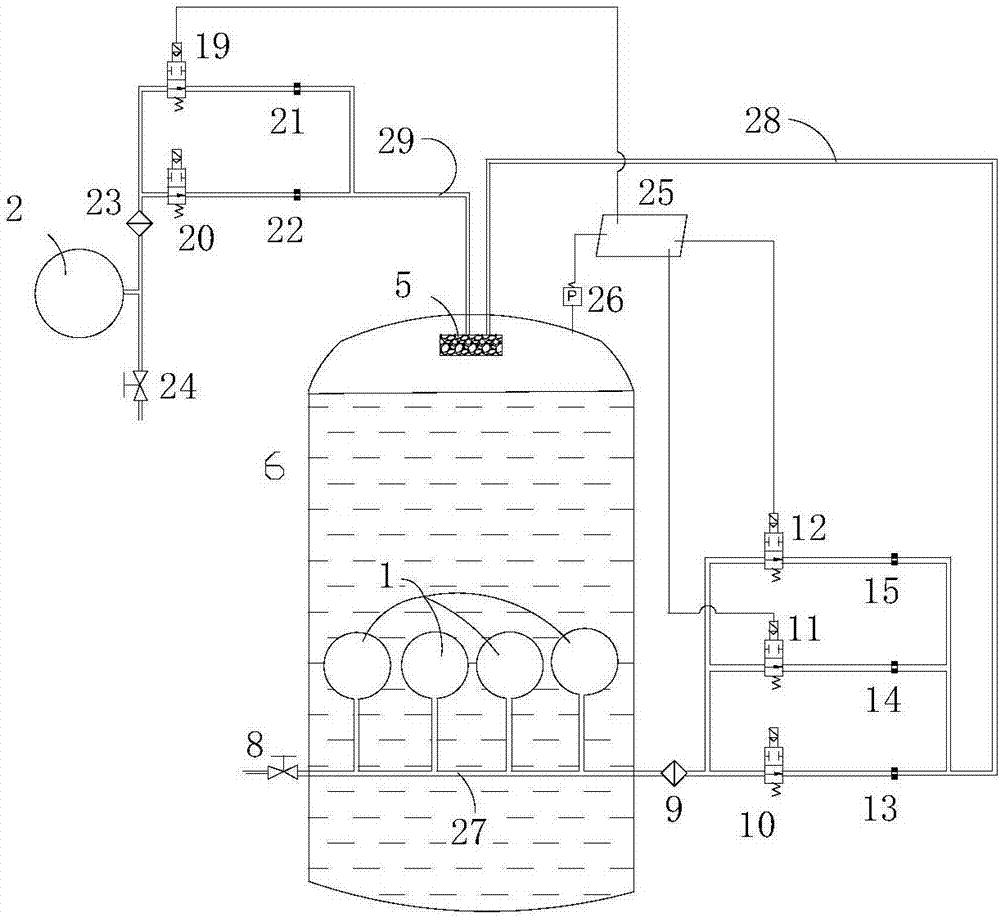

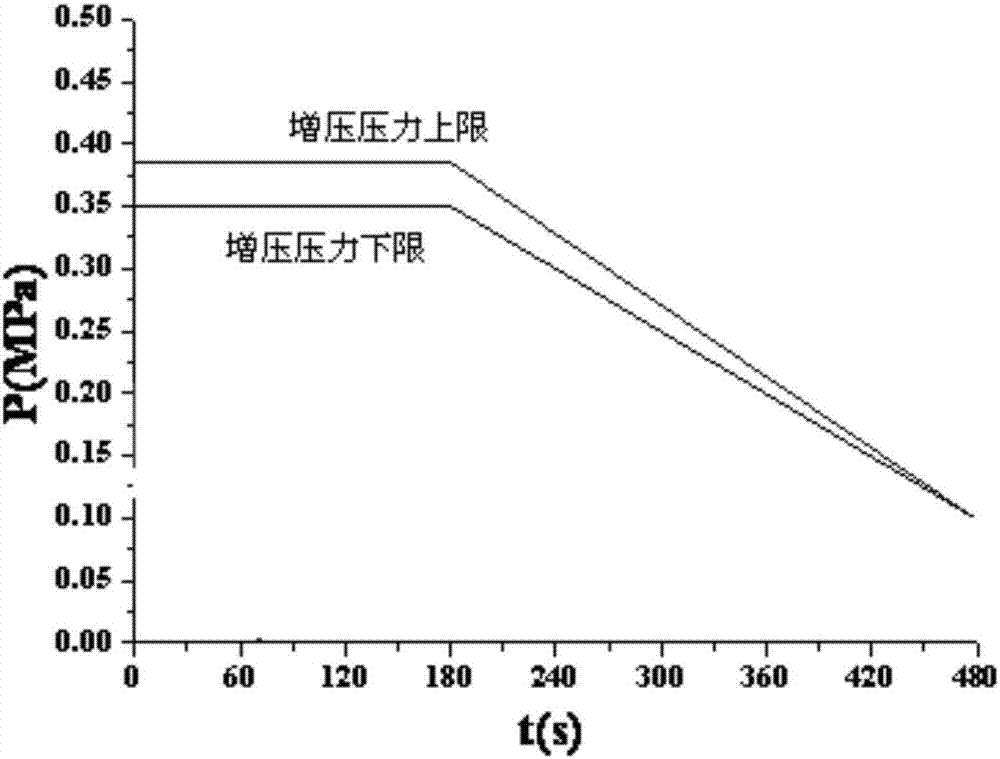

Trimix pressurization system applied to liquid rocket

ActiveCN106194500ACompact structureHigh degree of independenceRocket engine plantsHydrogenOxygen tank

The invention relates to a trimix pressurization system applied to a liquid rocket. The trimix pressurization system comprises a helium and hydrogen bottle (1), an oxygen bottle (2), a flow control unit and a catalytic bed (5), wherein mixed helium and hydrogen are stored in the helium and hydrogen bottle (1) in advance; oxygen is stored in the oxygen bottle (2); flow of gas output in the two bottles is controlled through the flow control unit; a mixed gas of output helium, hydrogen and oxygen is subjected to catalytic reaction through the catalytic bed (5); oxygen and hydrogen react to generate water vapor and release hat; and helium, water vapor and oxygen remaining after reaction are heated and enter a storage tank to pressurize the storage tank.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

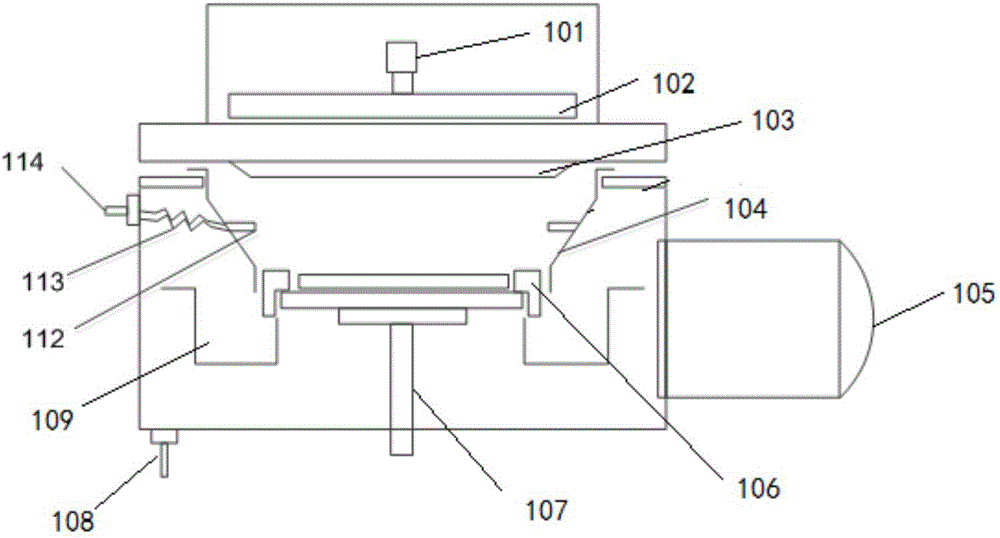

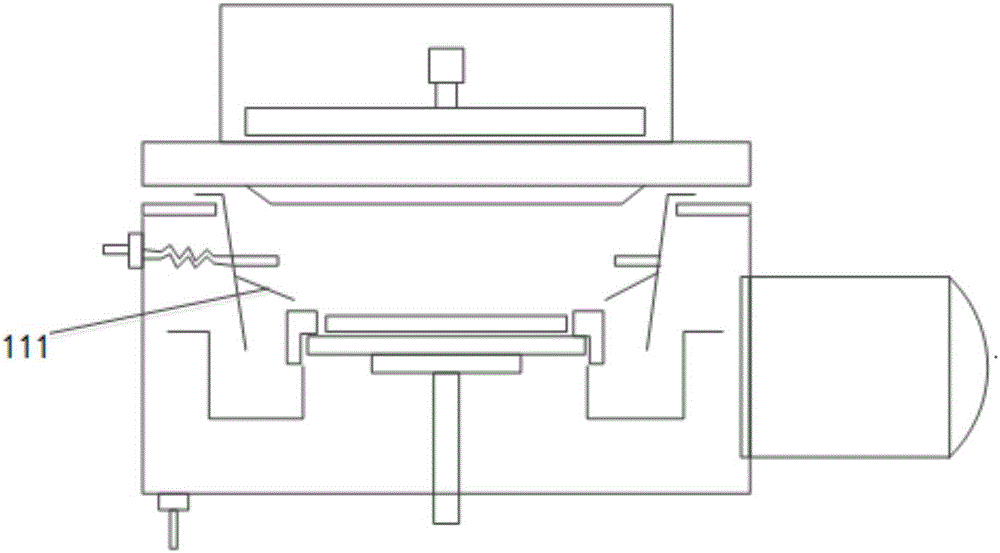

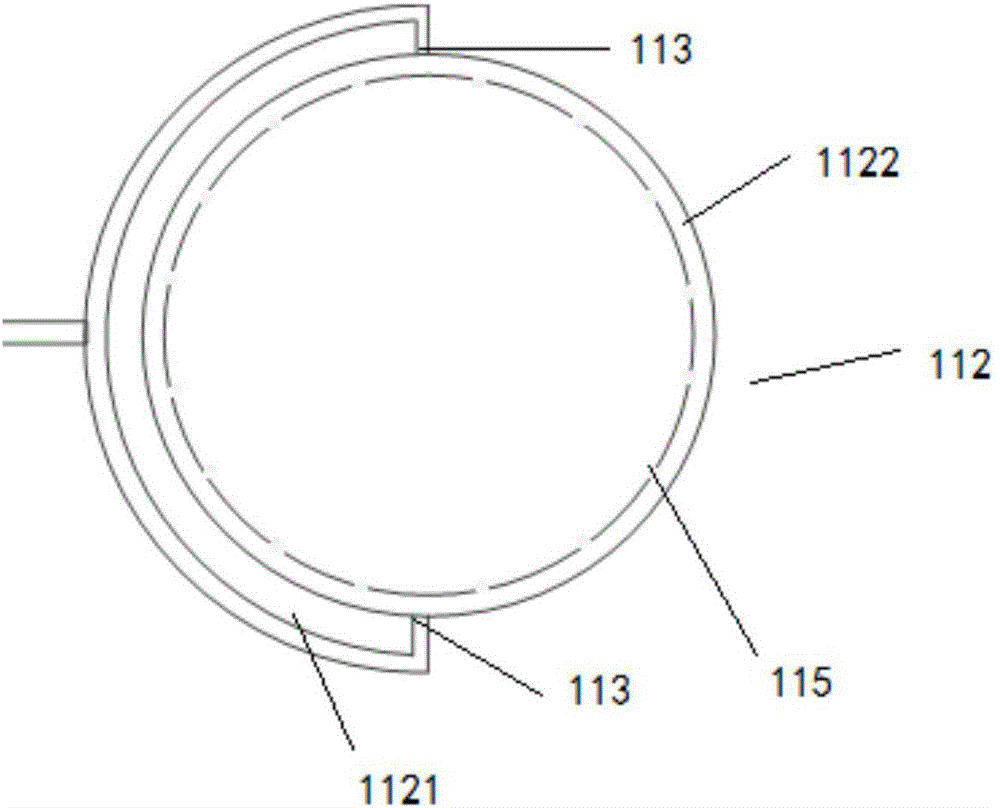

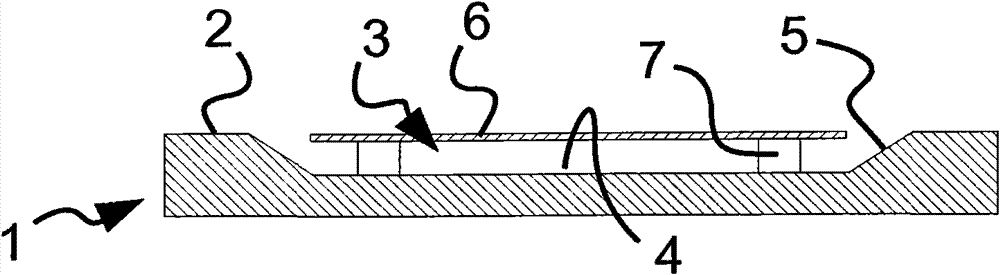

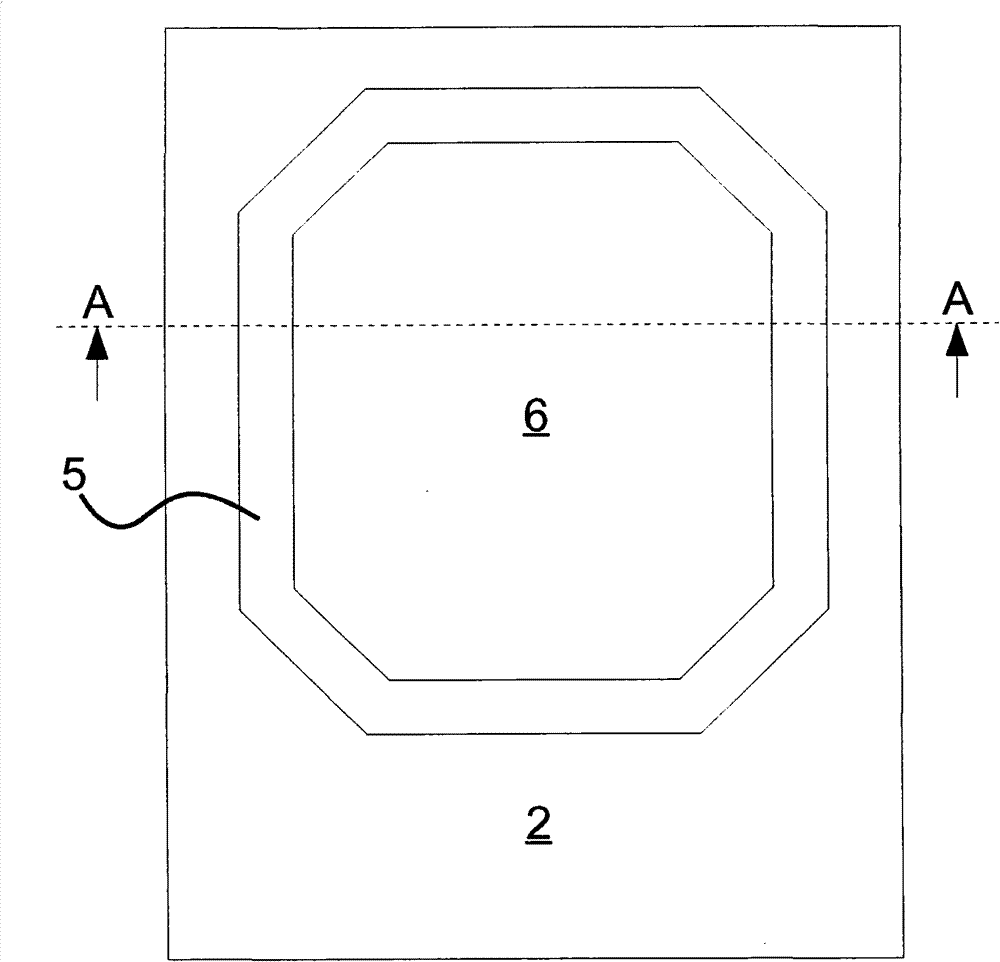

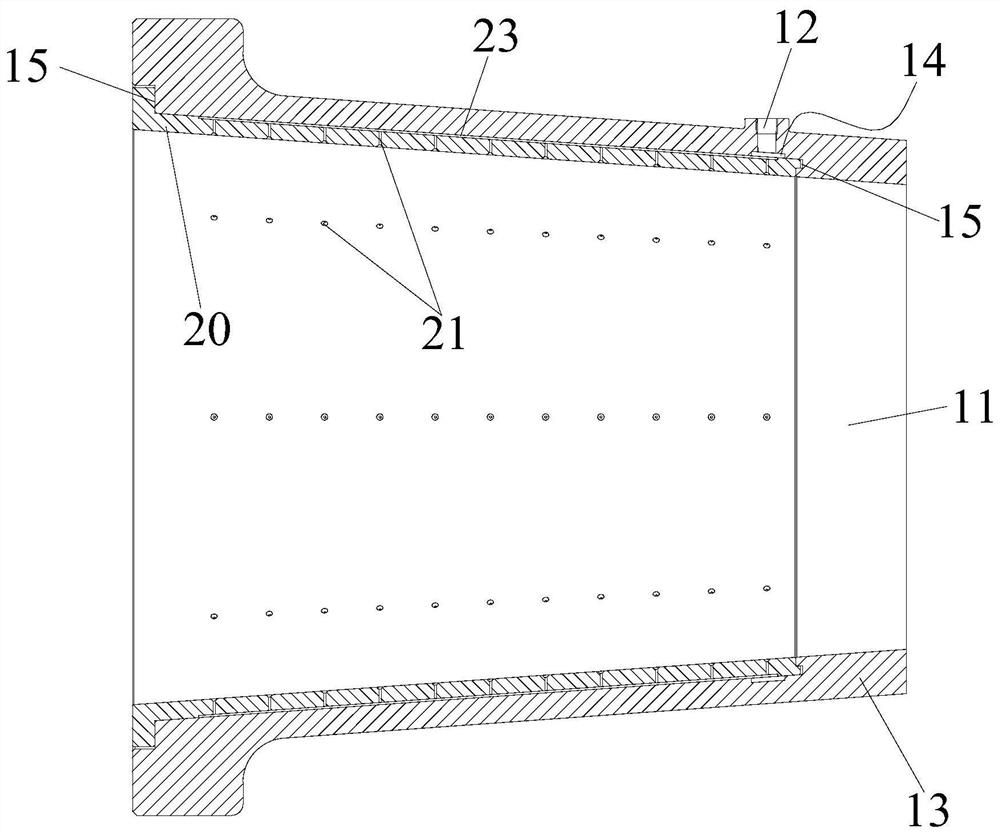

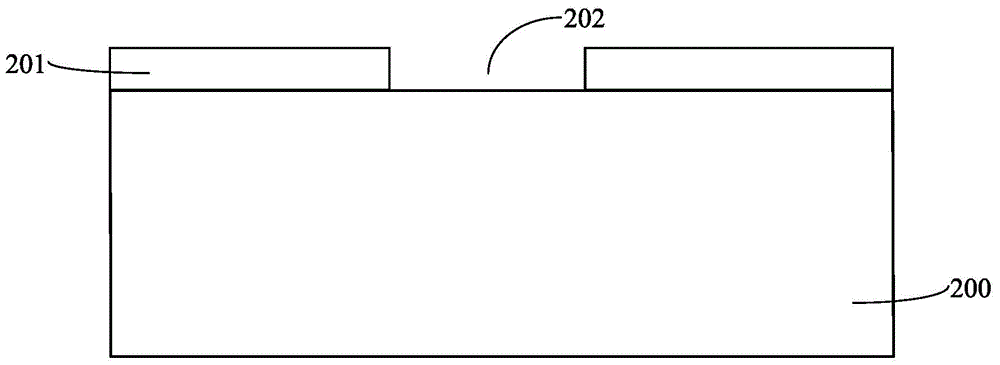

Physical vapor deposition (PVD) cavity structure for improving sheet resistance uniformity of metal oxide thin film

ActiveCN106756790AImprove square resistance uniformityIncrease gas densityVacuum evaporation coatingSputtering coatingSheet resistanceAirflow

The invention provides a physical vapor deposition (PVD) cavity structure for improving the sheet resistance uniformity of a metal oxide thin film. The PVD cavity structure comprises a cavity, a driving device, a magnetic part, a target material, an upper baffle, a lower baffle, a wafer and the like. The upper baffle is in an inverted conical barrel shape, the outer edge of the upper baffle is erected on an opening of the cavity, and the bottom end of the upper baffle is lower than the upper surface of a base pressing ring. The cavity is provided with an oxygen inlet, a gas inlet ring is installed at the oxygen inlet and is divided into an outer ring body and an inner ring body, the outer ring body is provided with a gas inlet, two gas outlets are separated, two separated branches of holes are connected with the inner ring body, and the holes of the inner ring are symmetrically distributed. According to the cavity structure, gas cannot be immediately pumped away from the gap between the upper baffle and the lower baffle after entering the cavity, gas flow generates a vector in the direction toward the center in the gas pumping process, and the reactant gas concentration at the center of the wafer is improved; and due to the fact that mixed gas feeding is changed into independent gas feeding, gas flow distribution is uniform, dispersivity is good, the oxygen inlet and the argon inlet are separated, oxygen can be better stirred by argon, and oxygen distribution is more uniform.

Owner:中科微机电技术(北京)有限公司

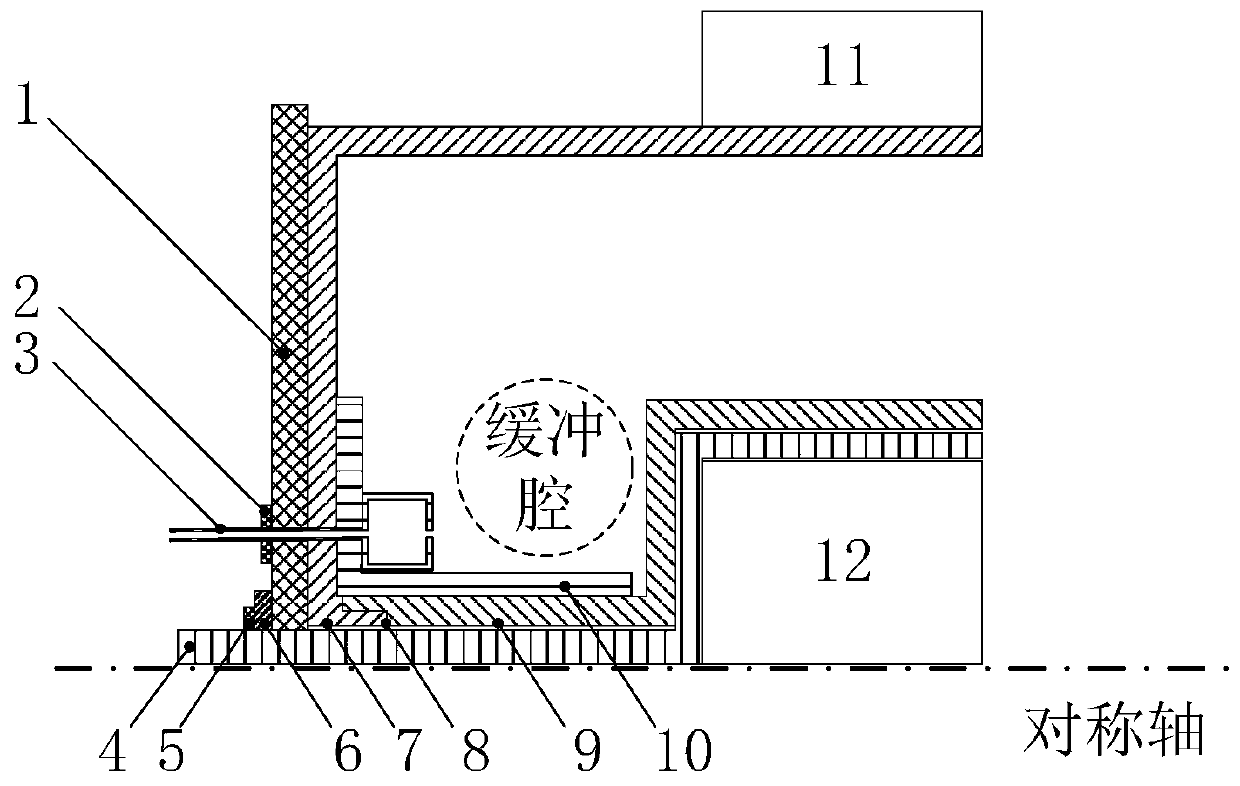

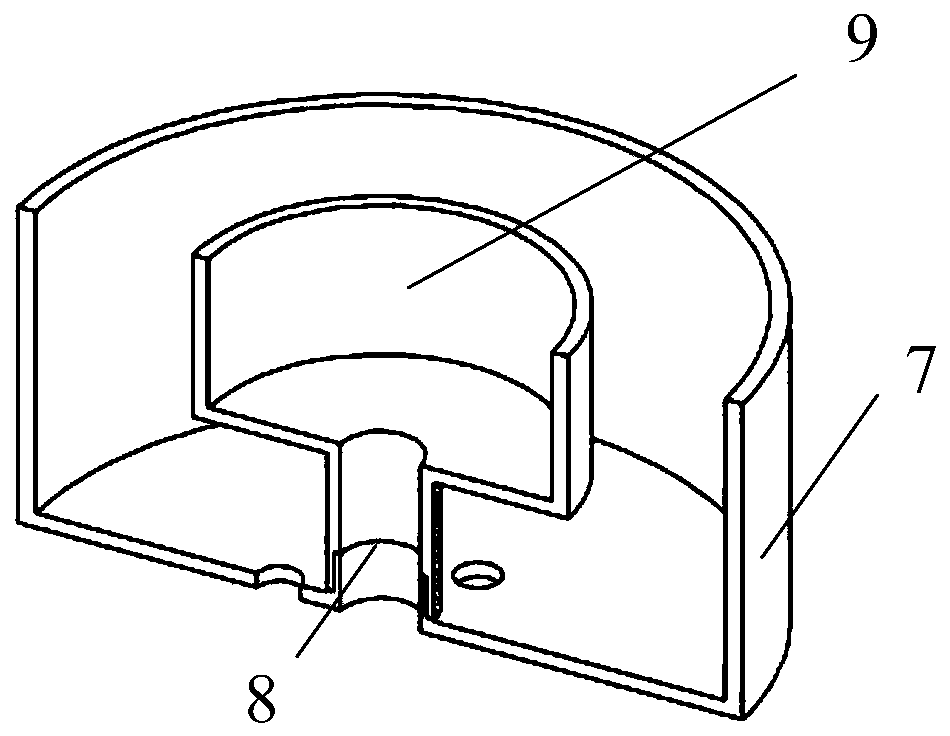

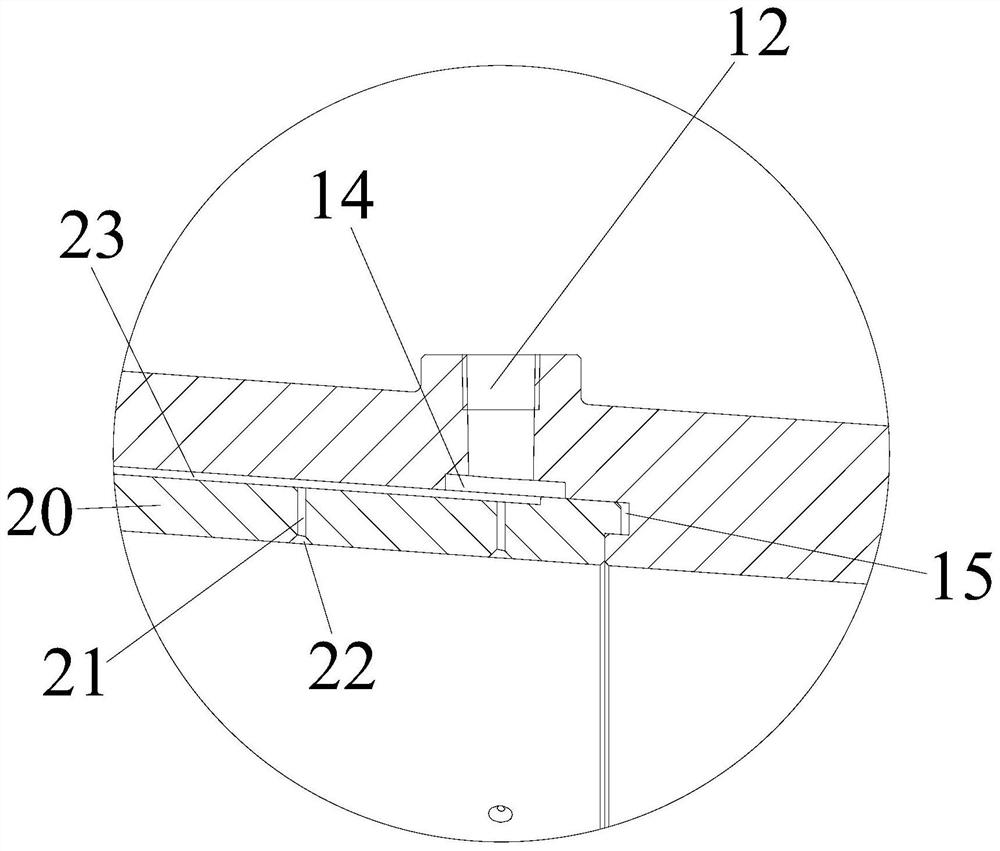

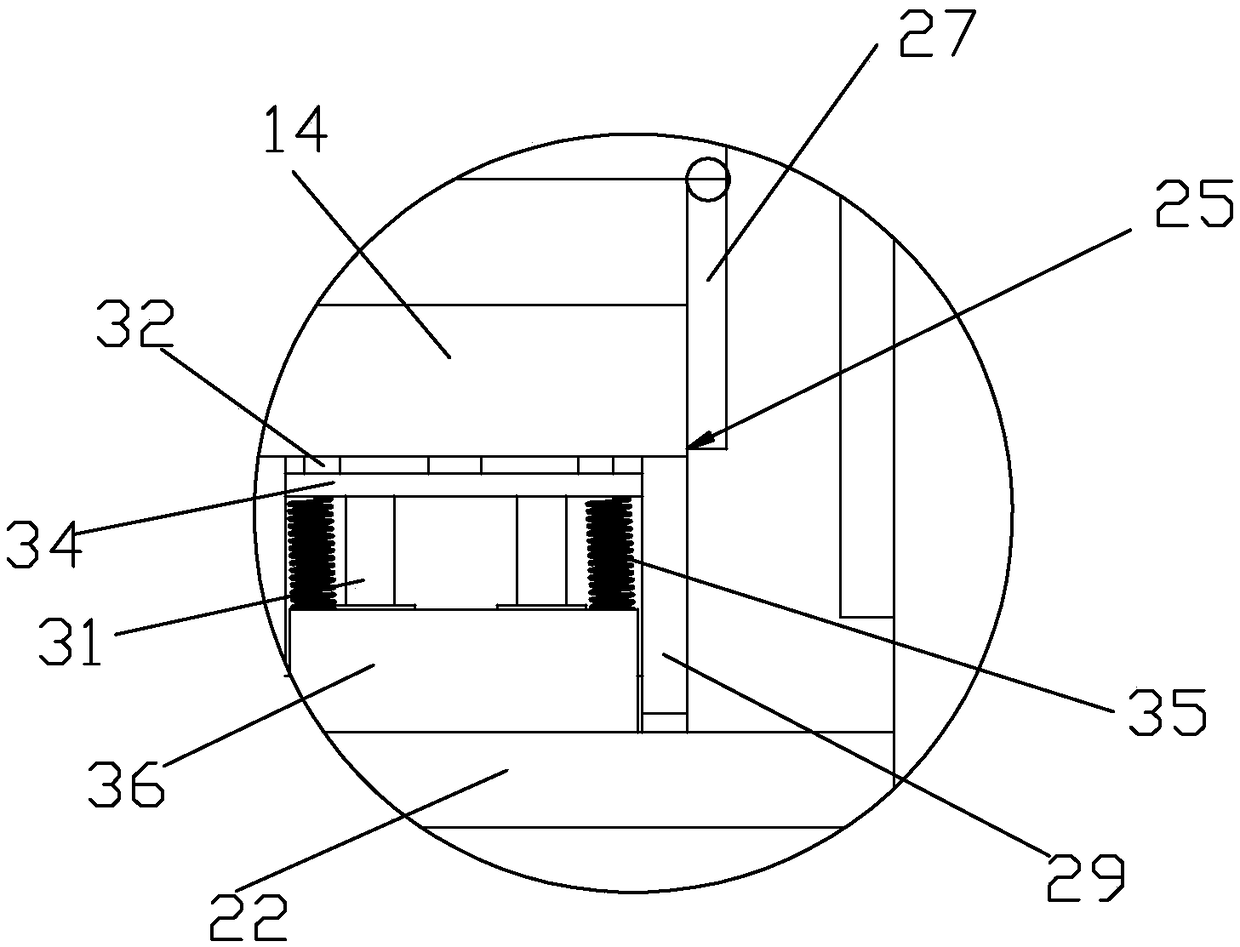

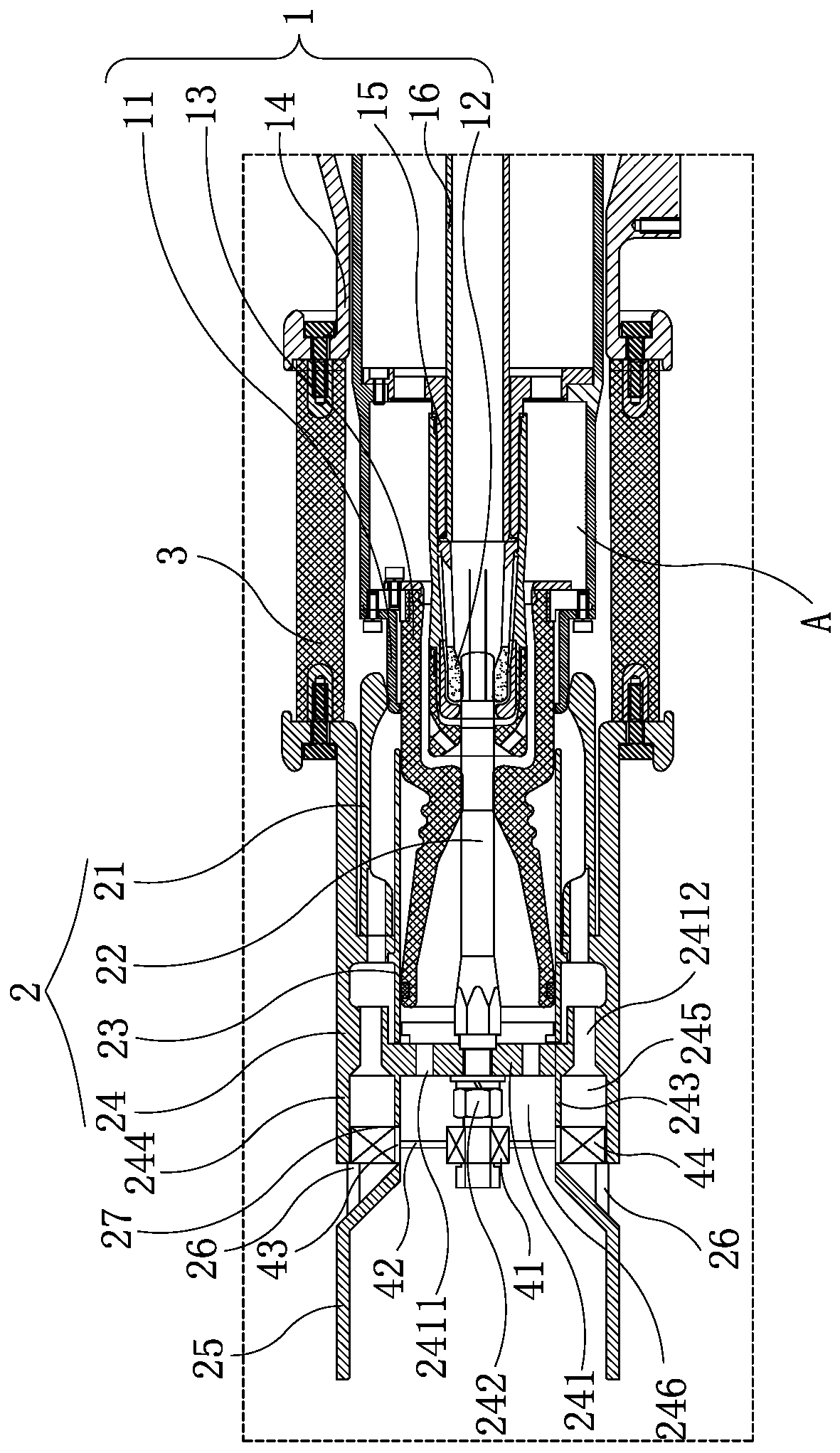

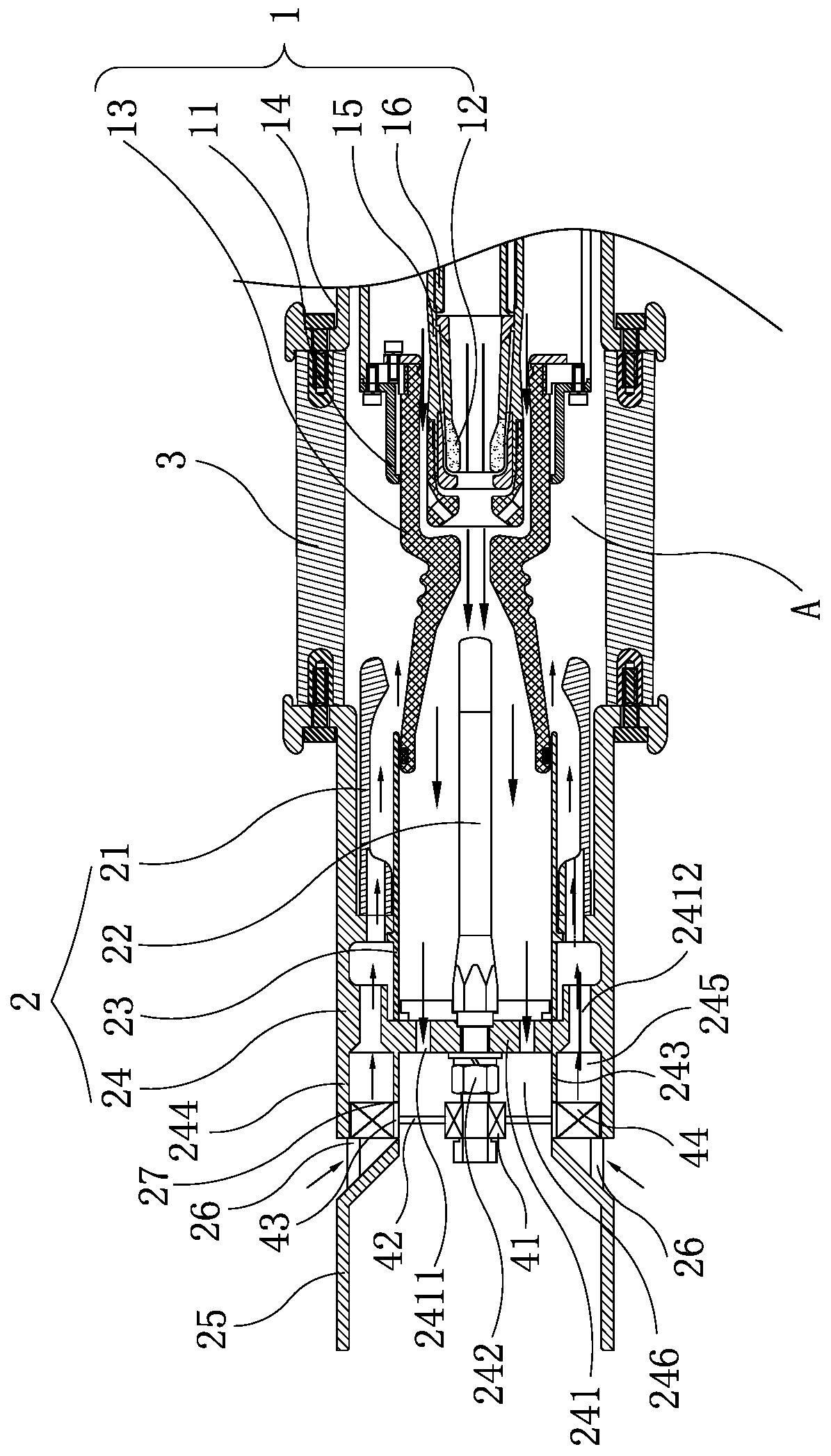

Hall thruster with novel buffer cavity

ActiveCN111219305AHigh energy productIncrease gas densityMachines/enginesUsing plasmaPhysicsEngineering

The invention discloses a Hall thruster with a novel buffer cavity, and belongs to the technical field of Hall thrusters. The Hall thruster with the novel buffer cavity solves the problems that in thecase of an existing low-power Hall thruster, due to the fact that the size is too small, gas density and homogenization degree are not high. An inner ceramic screen and an outer ceramic screen of theHall thruster with the novel buffer cavity are of an inside-and-outside nested cylindrical structure, a radial gap and an axial gap are formed between the inner ceramic screen and the outer ceramic screen, so that a buffer cavity structure between the inner ceramic screen and the outer ceramic screen is formed, an anode and the outer ceramic screen are fixedly mounted on a bottom plate through agas distributor and a nut, an inner permanent magnet is fixedly mounted in the inner ceramic screen through a permanent magnet support, and is fixedly mounted on the bottom plate through a fixing nut,and an outer permanent magnet is mounted on the outer side of the outer ceramic screen in a sleeving mode. A discharge channel of the Hall thruster with the novel buffer cavity is formed by insertingthe outer ceramic screen and the inner ceramic screen, the buffer cavity is formed at the area between the outer ceramic screen and the inner ceramic screen, a gas motion path is enlarged through thenovel buffer cavity structure, and gas is more sufficiently homogenized.

Owner:HARBIN INST OF TECH

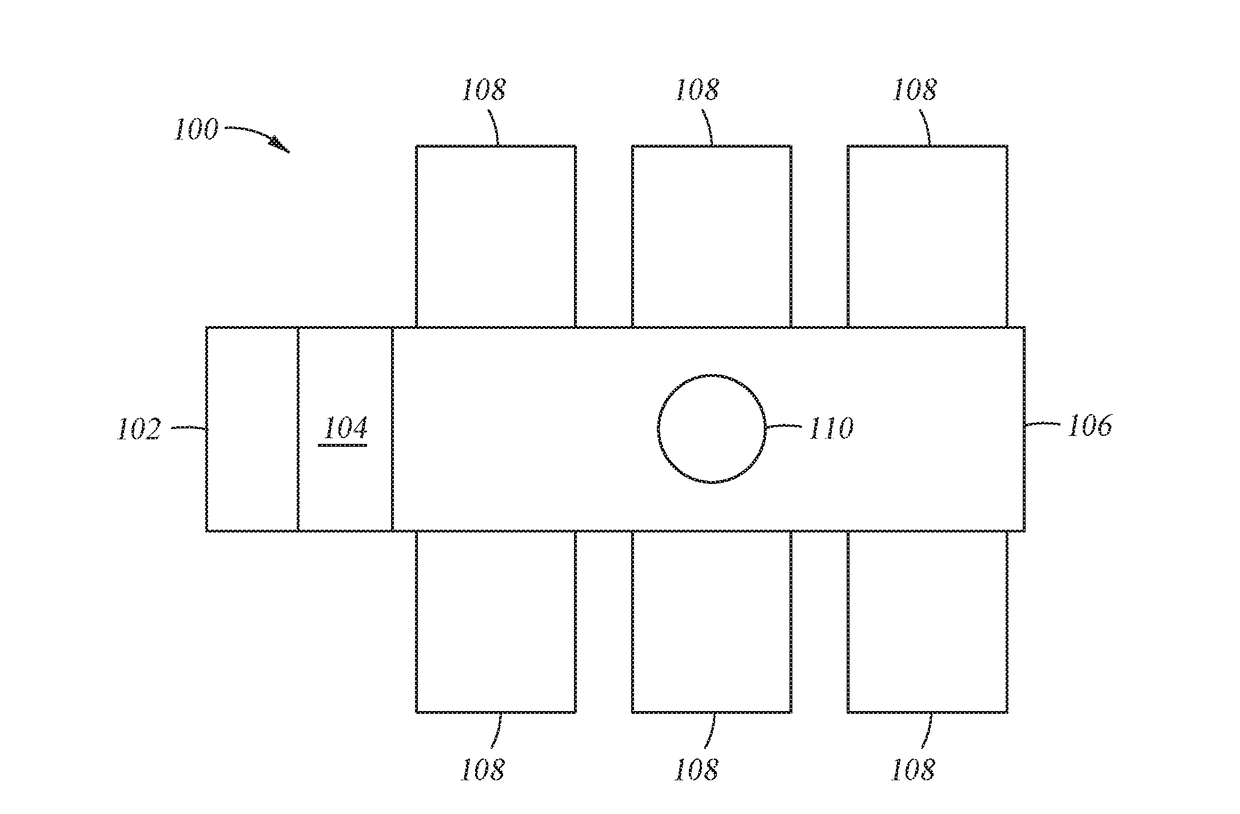

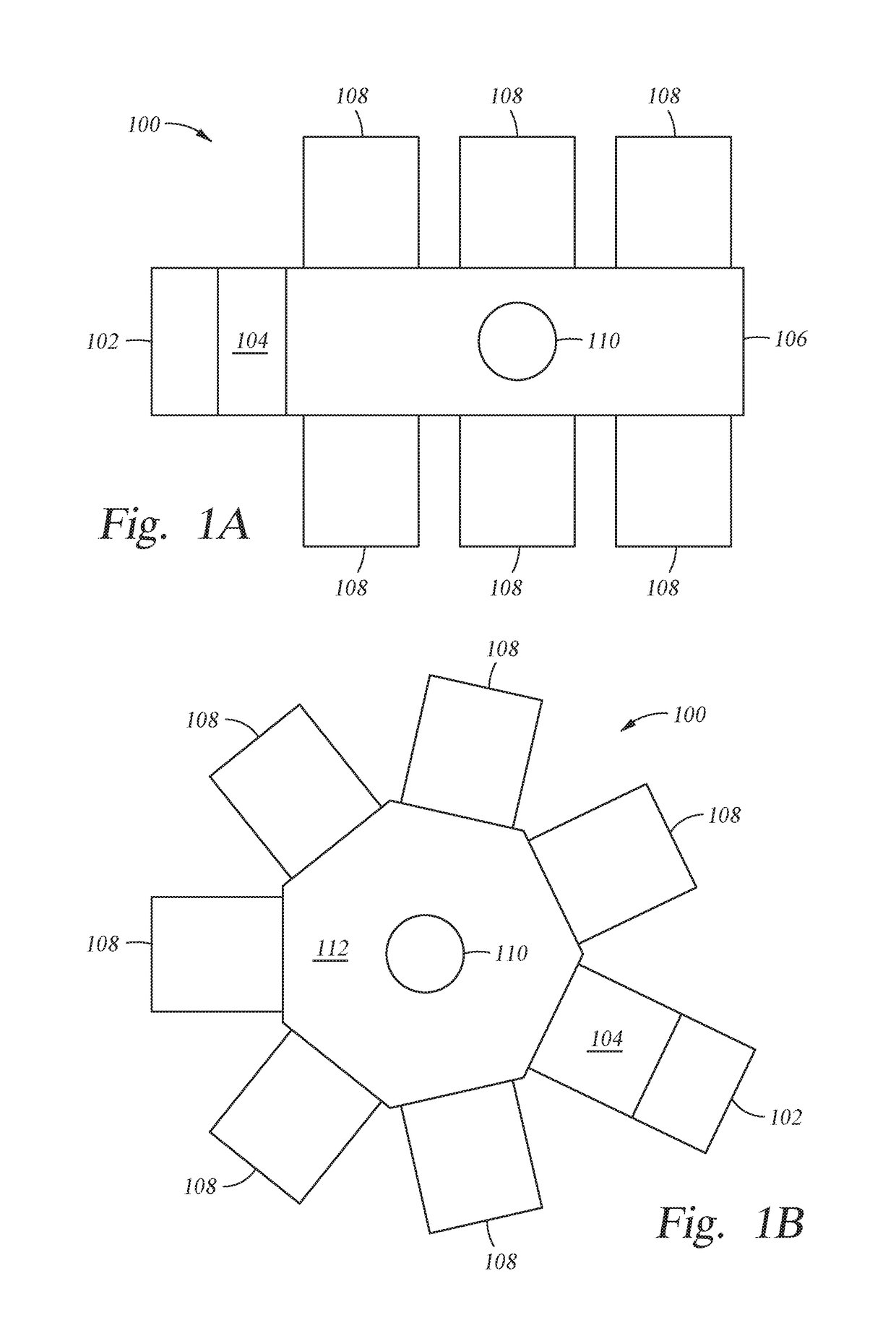

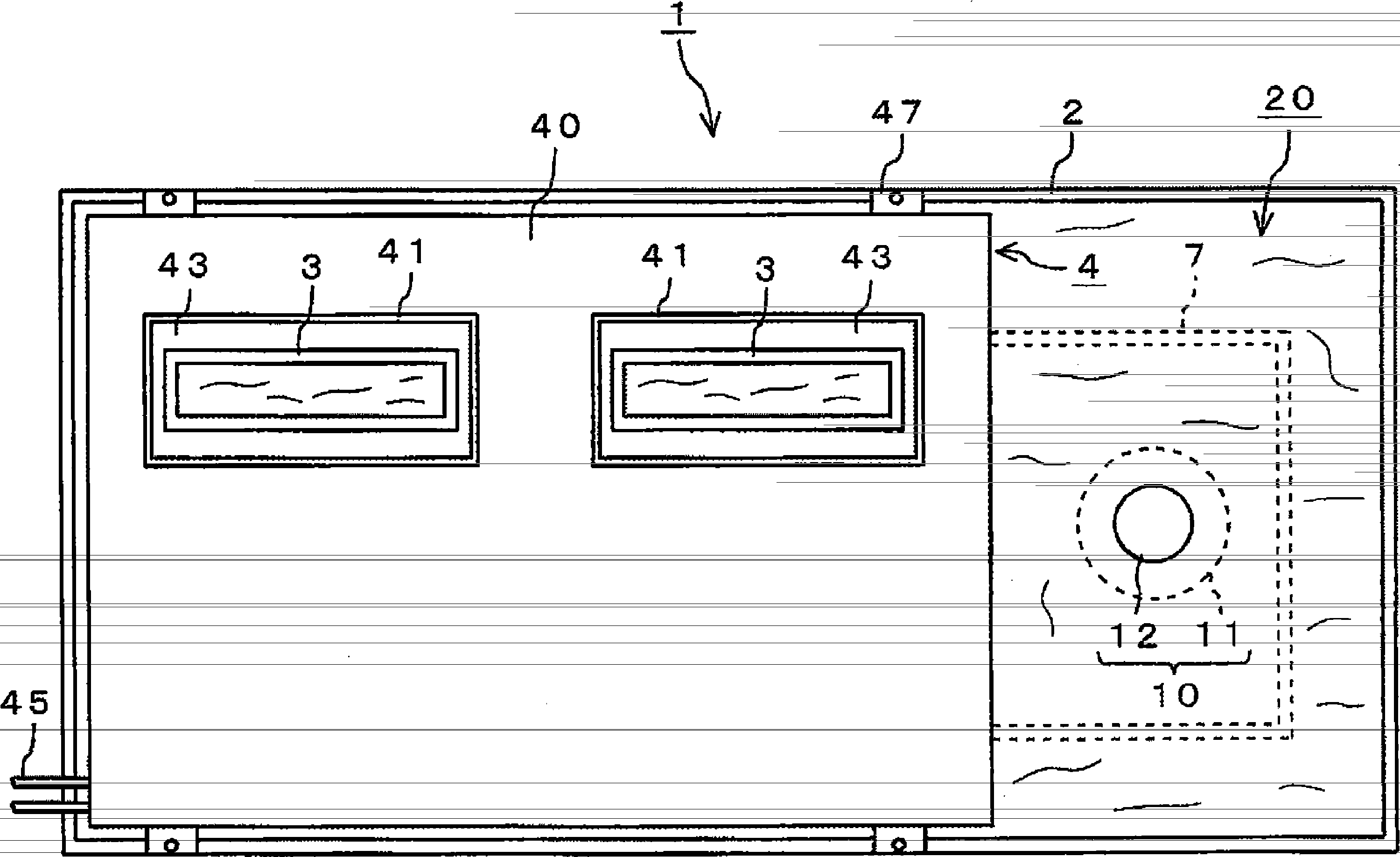

High productivity pecvd tool for wafer processing of semiconductor manufacturing

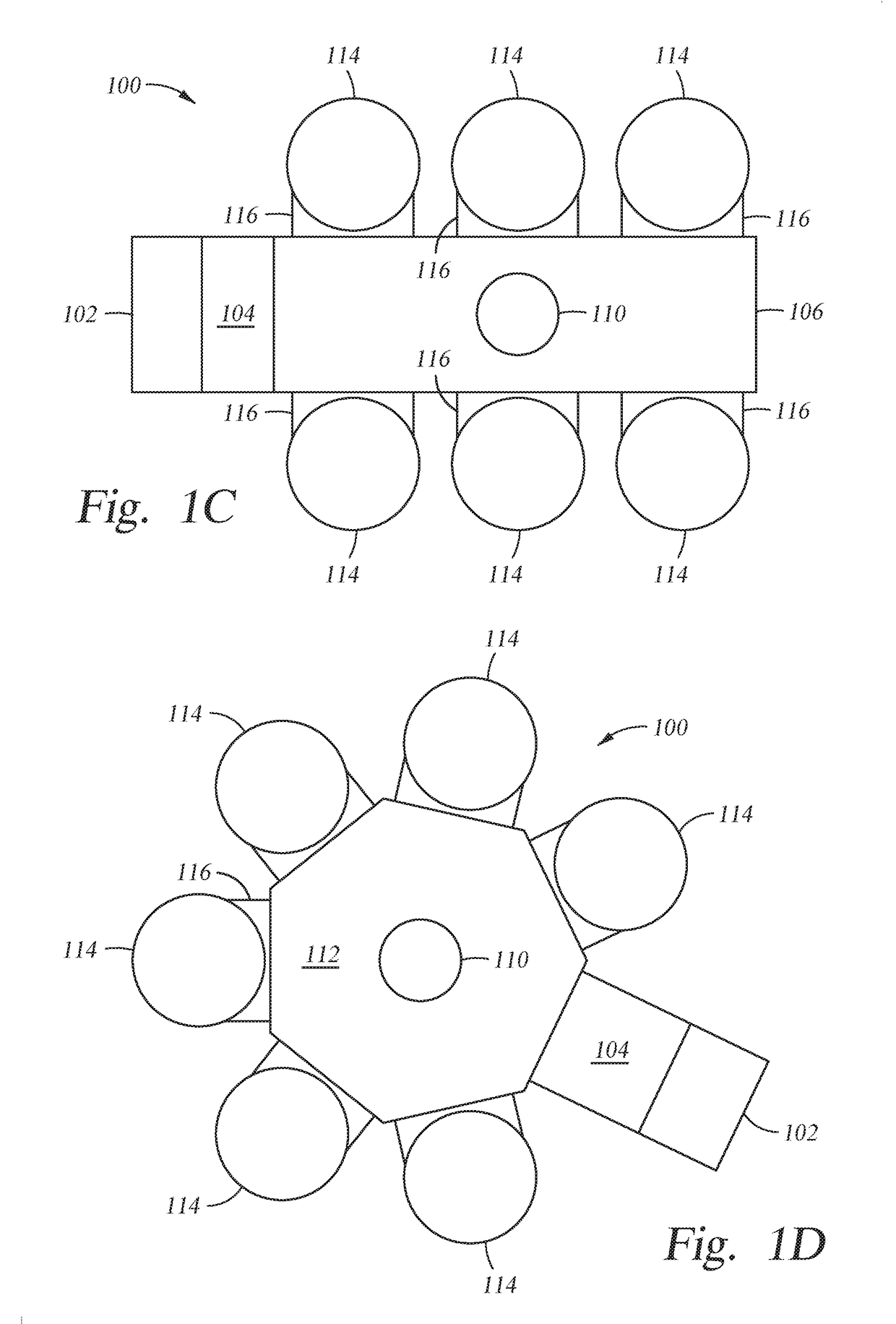

InactiveUS20170114462A1Cost reductionImproved process uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyProduction rate

Embodiments of the present disclosure generally relate to a cluster tool for processing semiconductor substrates. In one embodiment, a cluster tool includes a plurality of process chambers connected to a transfer chamber and each process chamber may simultaneously process four or more substrates. In order to reduce cost, each process chamber includes a substrate support for supporting four or more substrates, single showerhead disposed over the substrate support, and a single radio frequency power source electrically coupled to the showerhead. The showerhead may include a first surface facing the substrate support and a second surface opposite the first surface. A plurality of gas passages may be formed in the showerhead extending from the first surface to the second surface. Process uniformity is improved by increasing the density of the gas passages from the center of the showerhead to the edge of the showerhead.

Owner:APPLIED MATERIALS INC

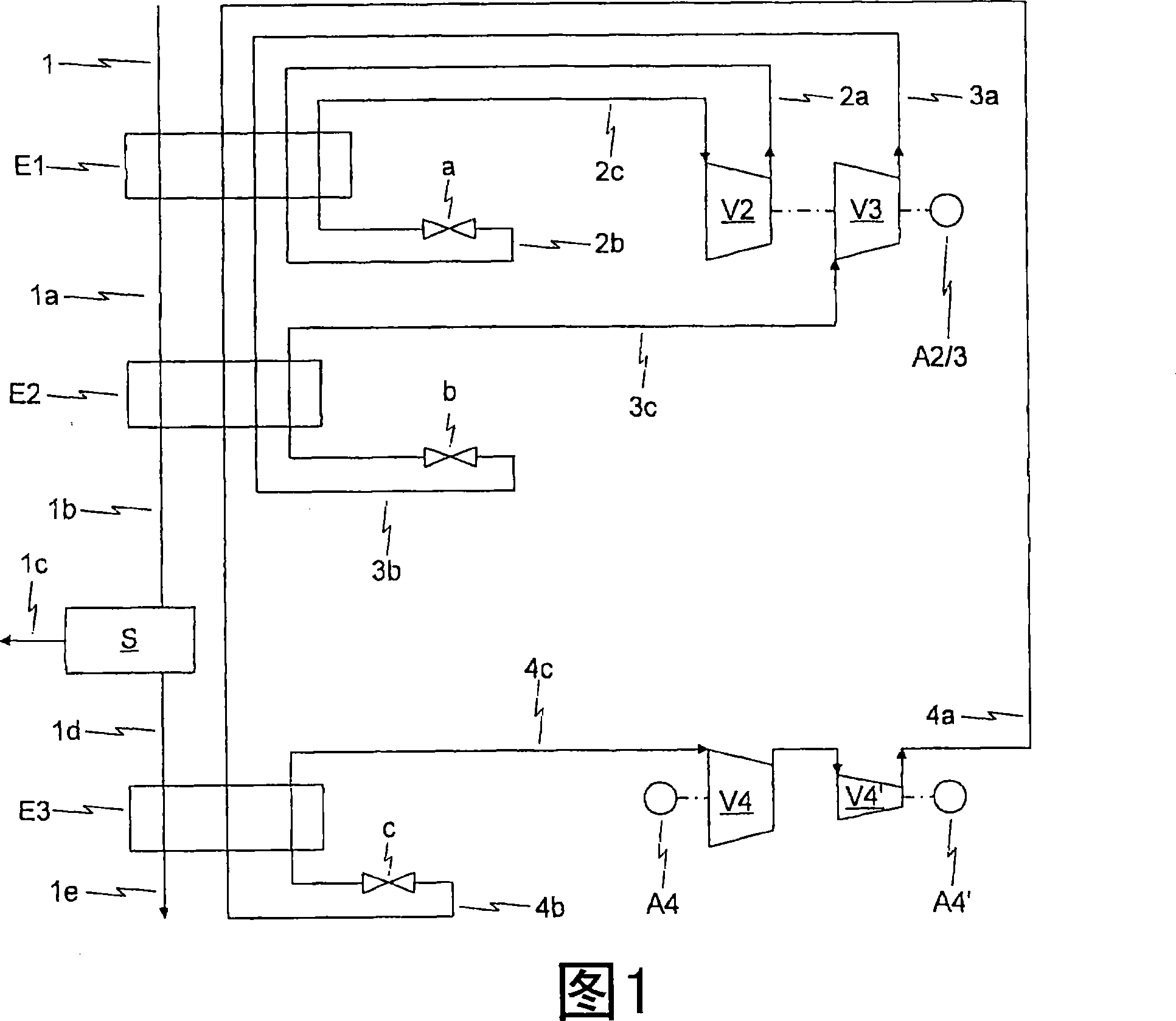

Method for liquefying a hydrocarbon-rich flow

InactiveCN101223410AIncrease gas densityCompact equipmentSolidificationLiquefactionSubcoolingNatural gas

The invention relates to a method for liquefying a hydrocarbon-rich stream, in particular a natural gas stream, wherein the liquefaction of the hydrocarbon-rich stream is carried out against a mixed refrigerant cycle cascade consisting of three mixed refrigerant cycles. According to the invention, the first and second mixed refrigerant cycles (2a-2b, 3a-3b) are used for precooling, and the third mixed refrigerant cycle (4a-4b) is used for liquefaction and subcooling of the hydrocarbon-rich stream. Here, the first and / or second mixed refrigerant cycle (2a-2b, 3a-3b) is preferably designed as a single-stage mixed refrigerant cycle, while the third mixed refrigerant cycle (4a-4b) is preferably designed as It is a two-stage mixed refrigerant cycle.

Owner:LINDE AG

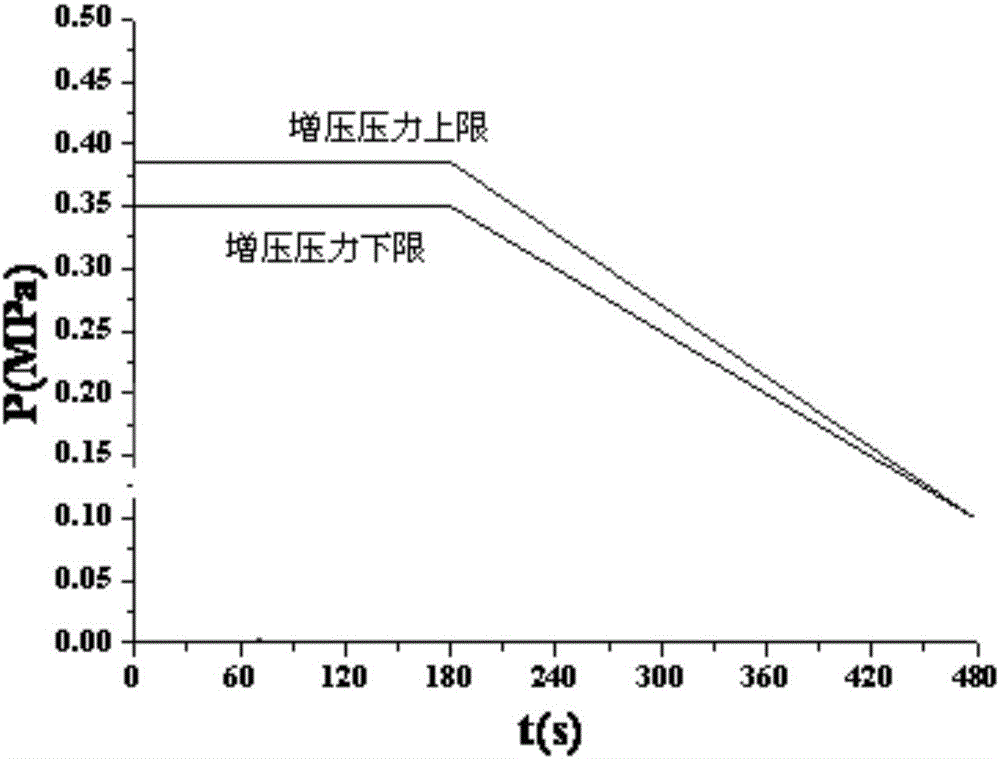

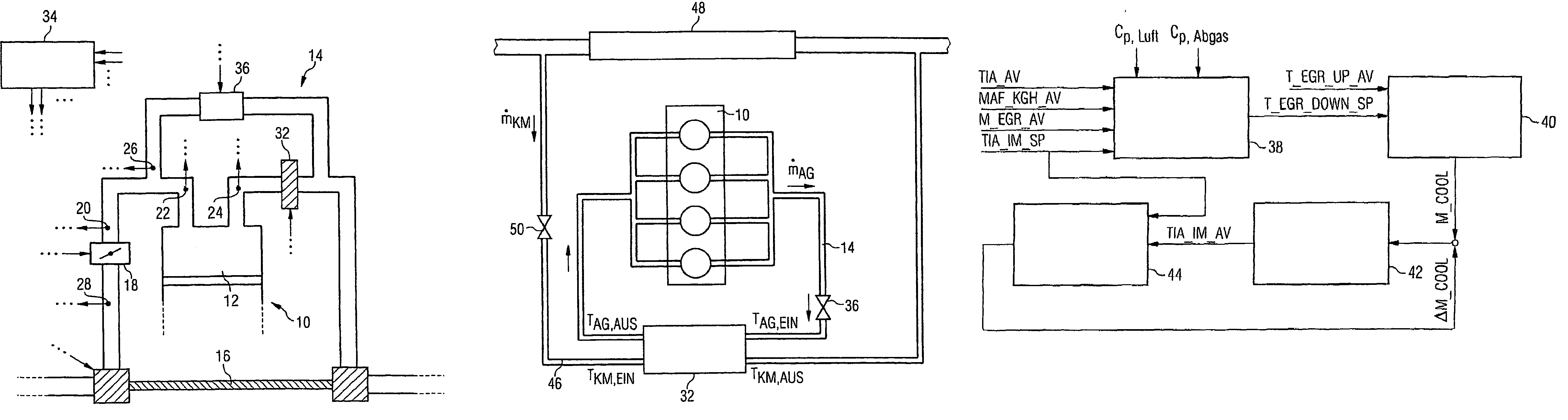

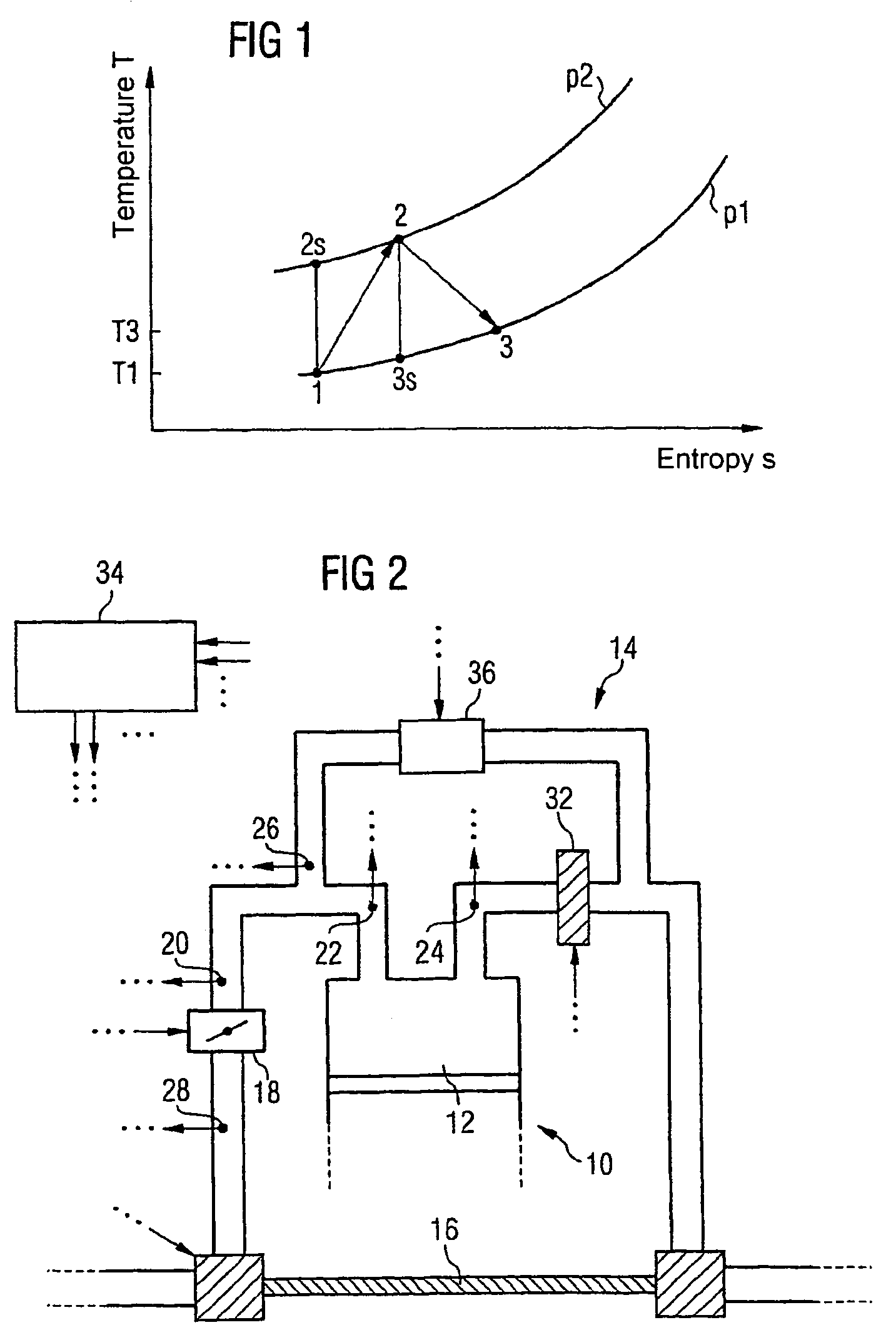

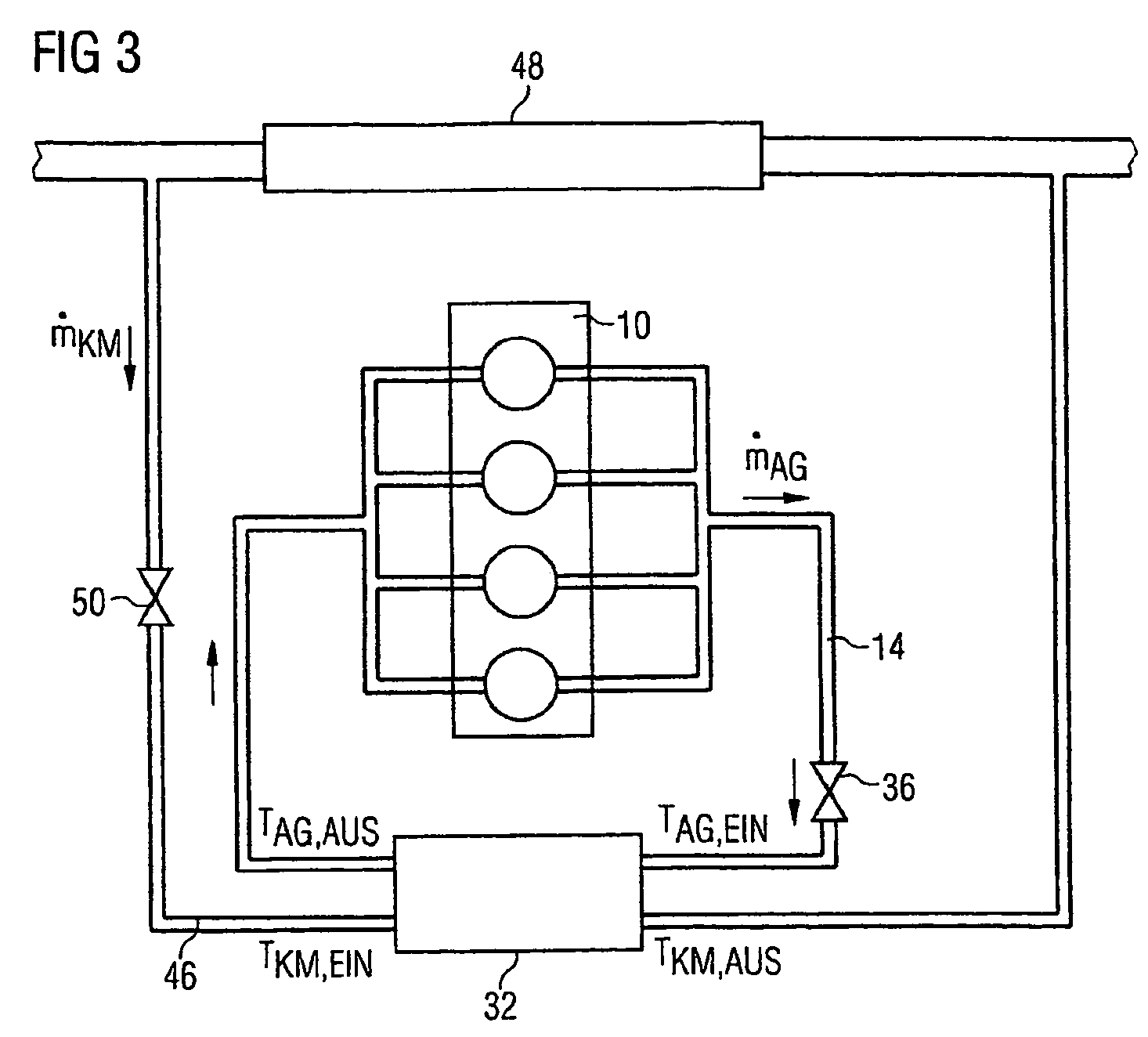

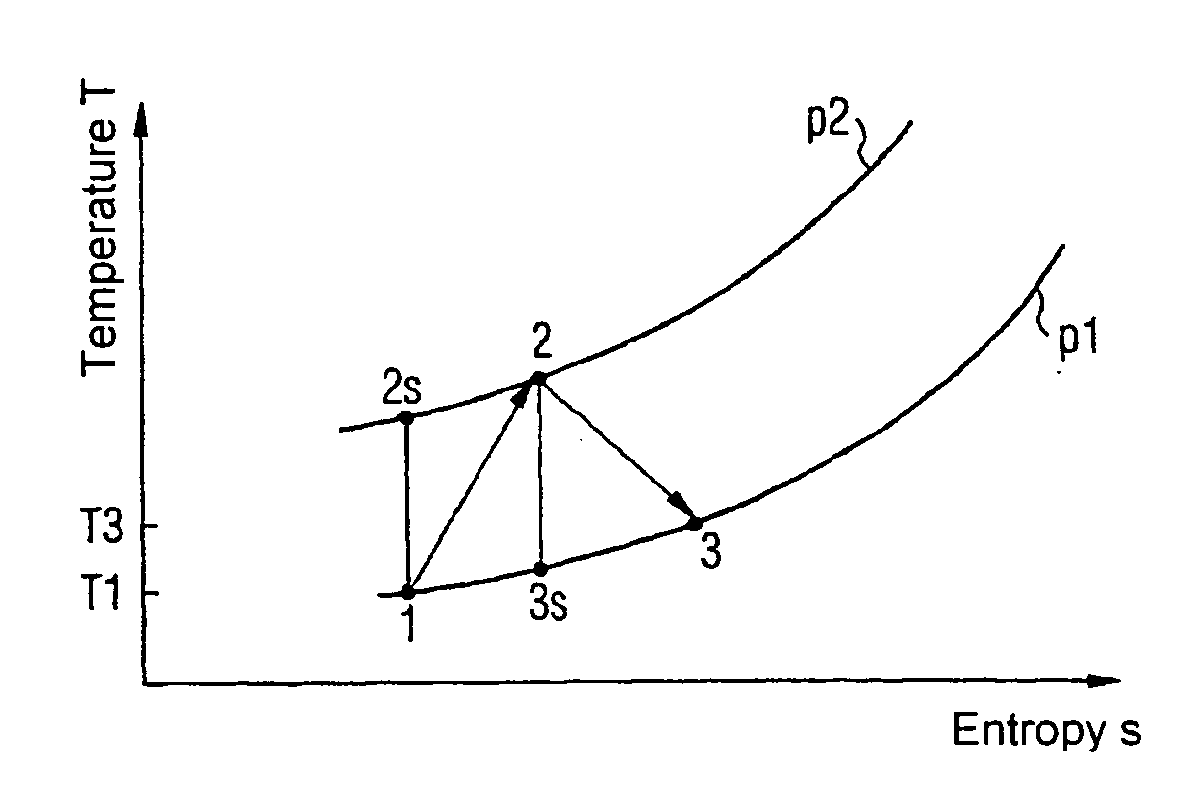

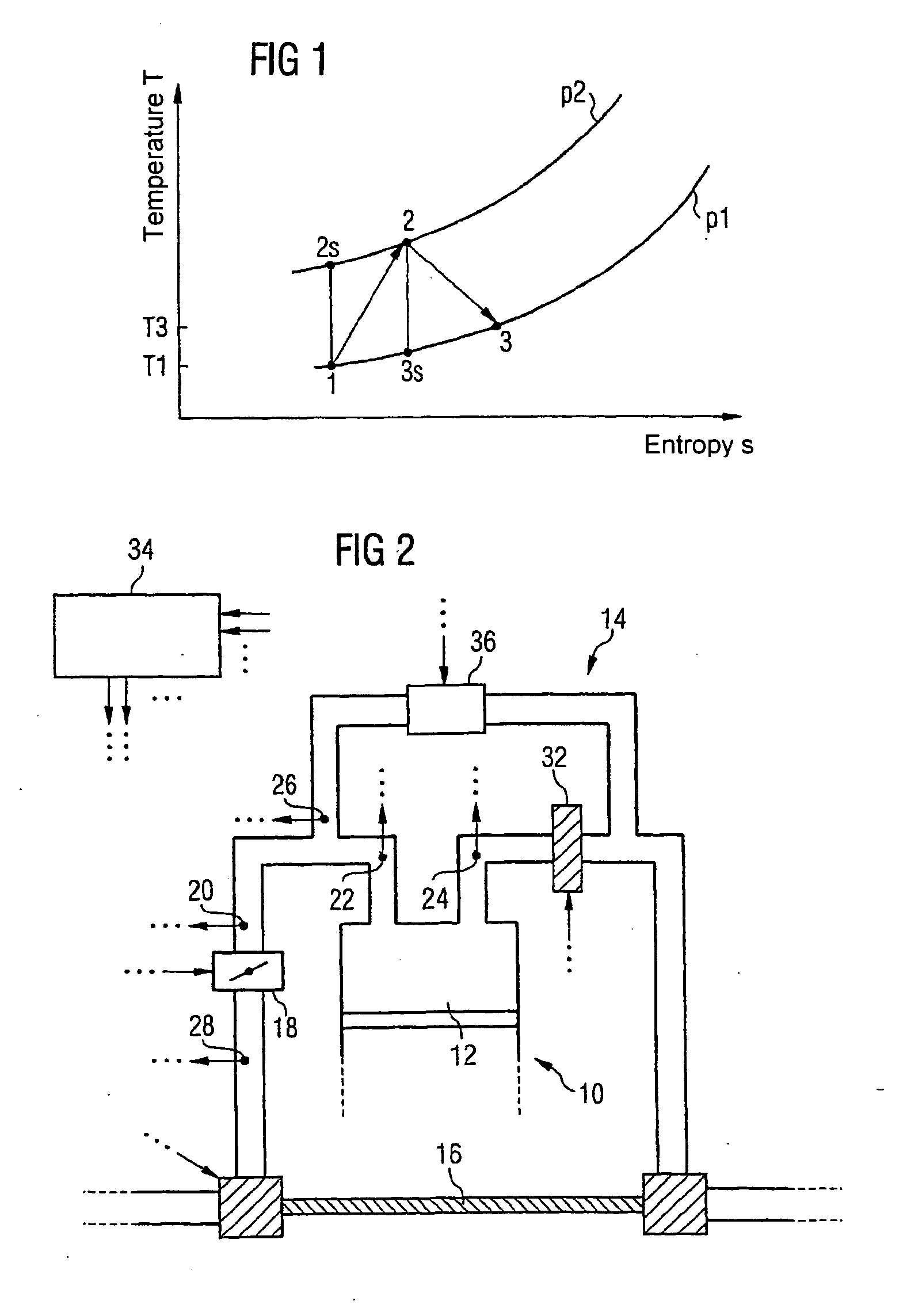

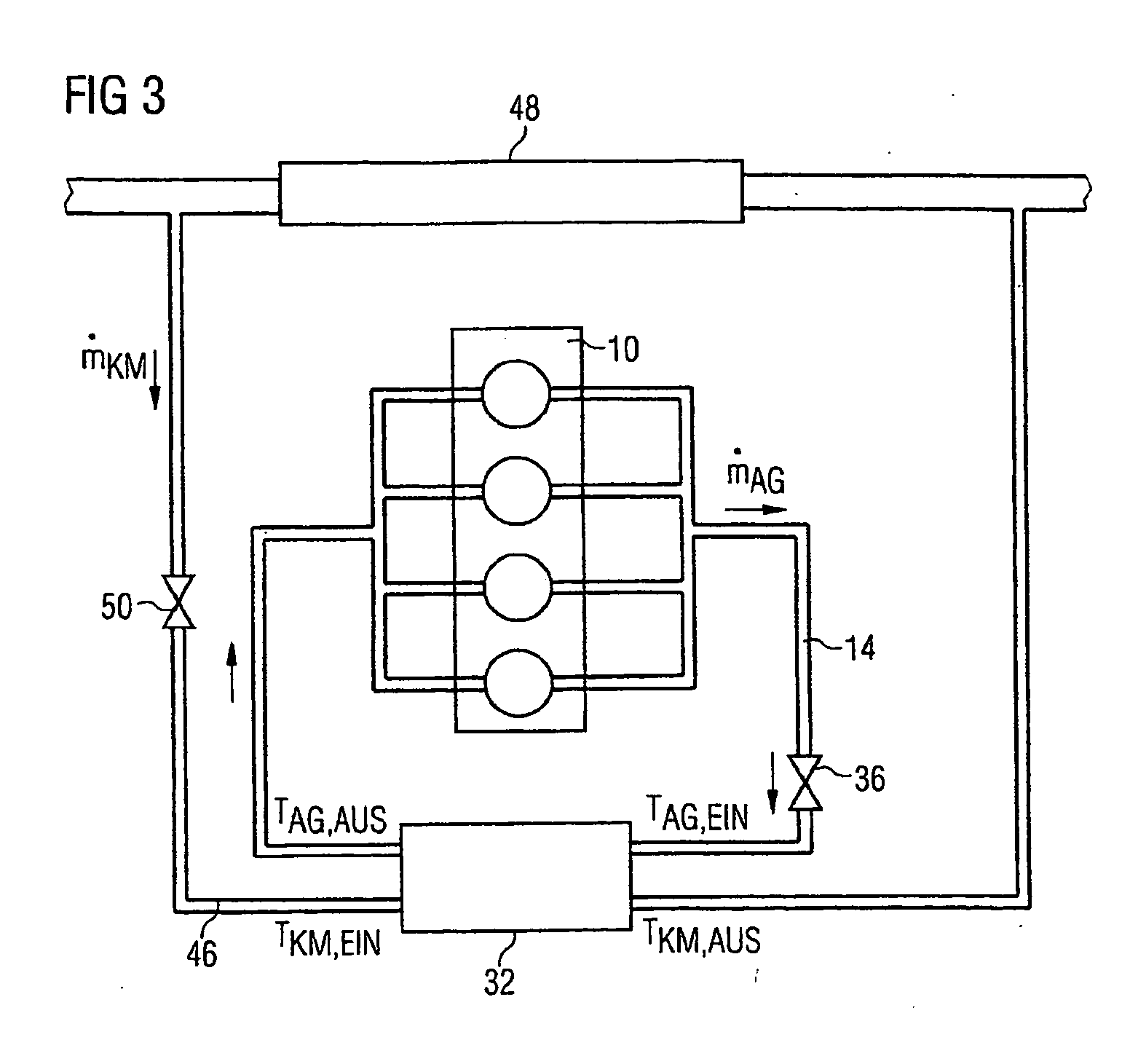

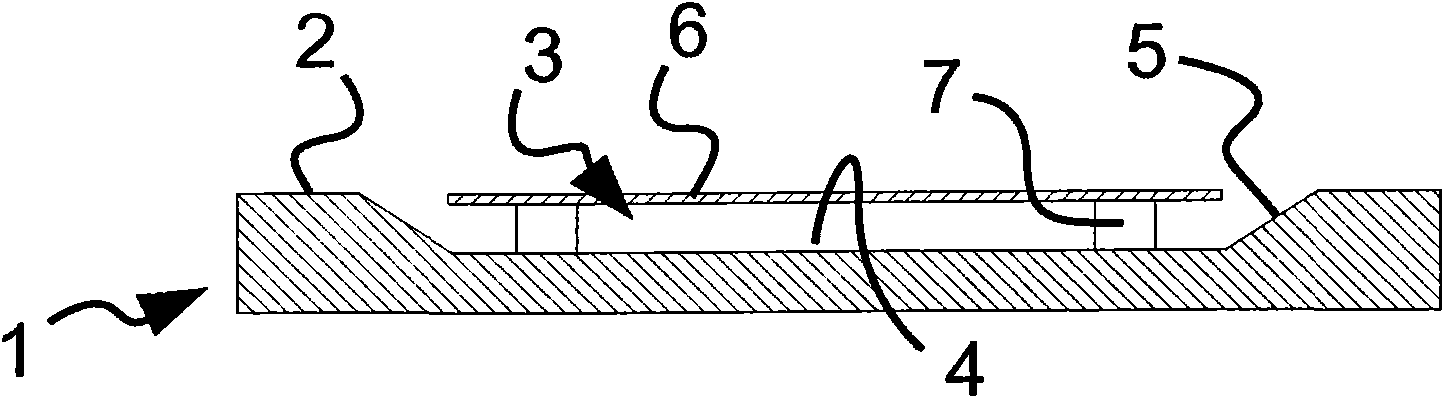

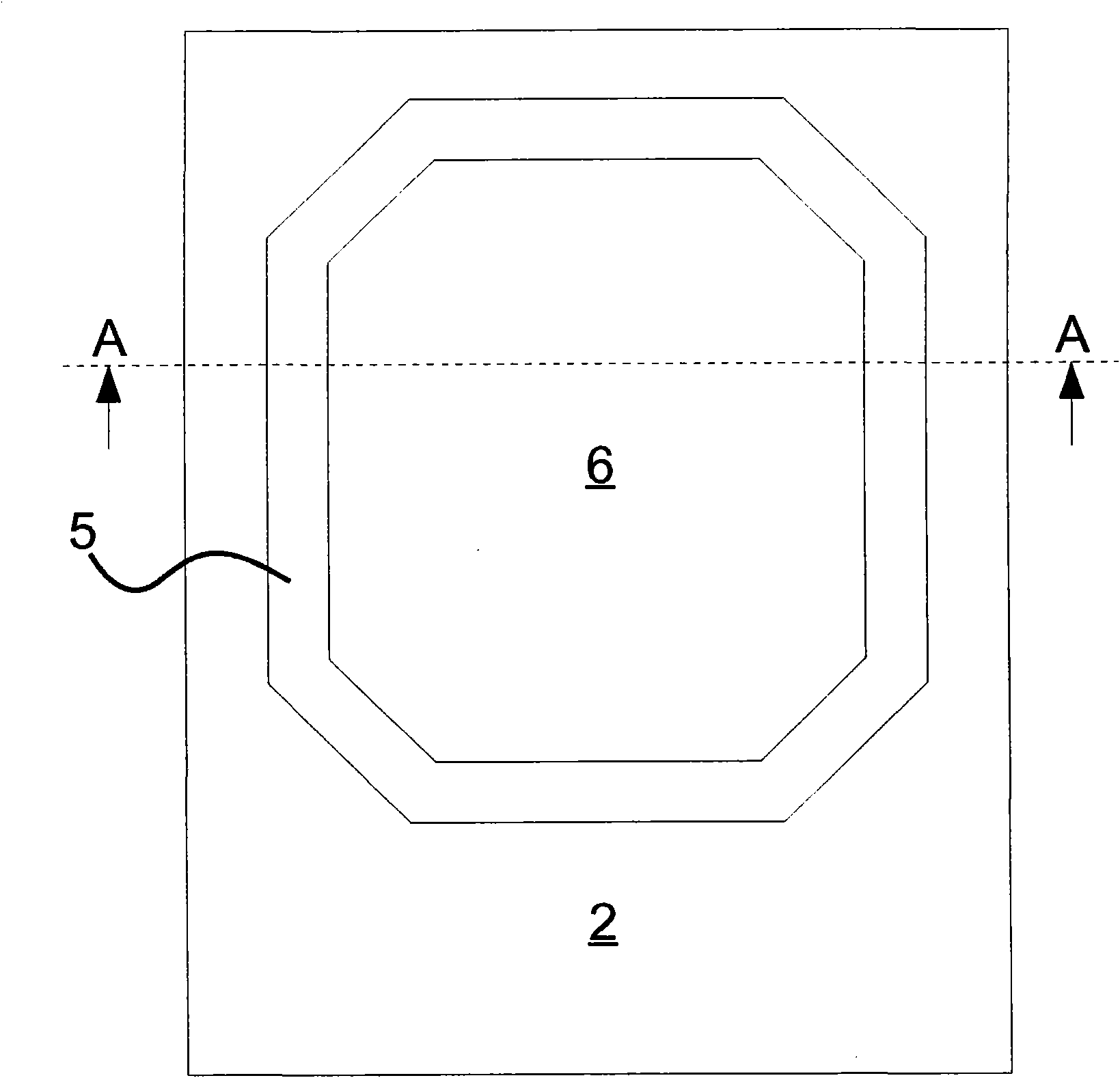

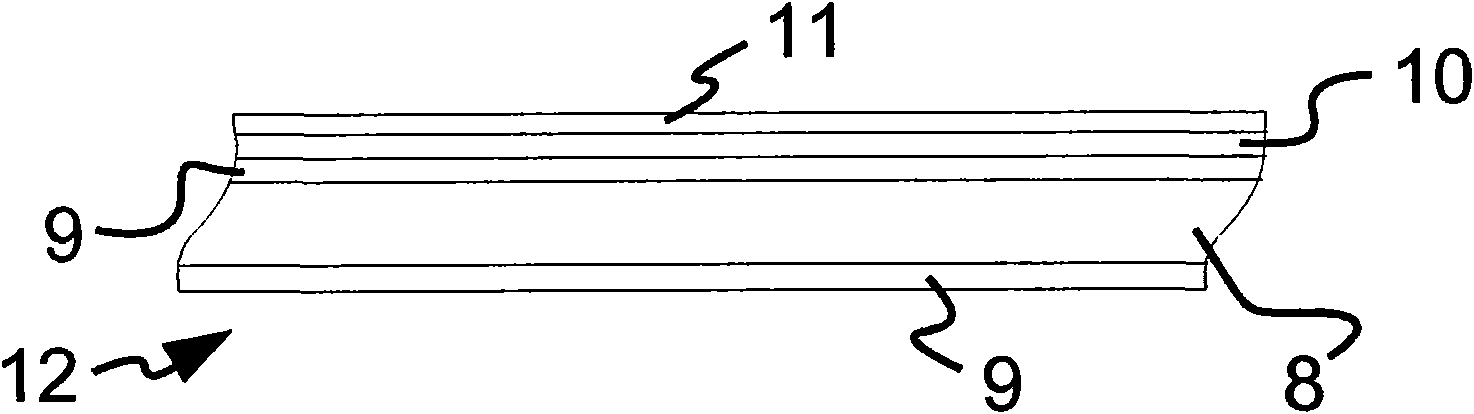

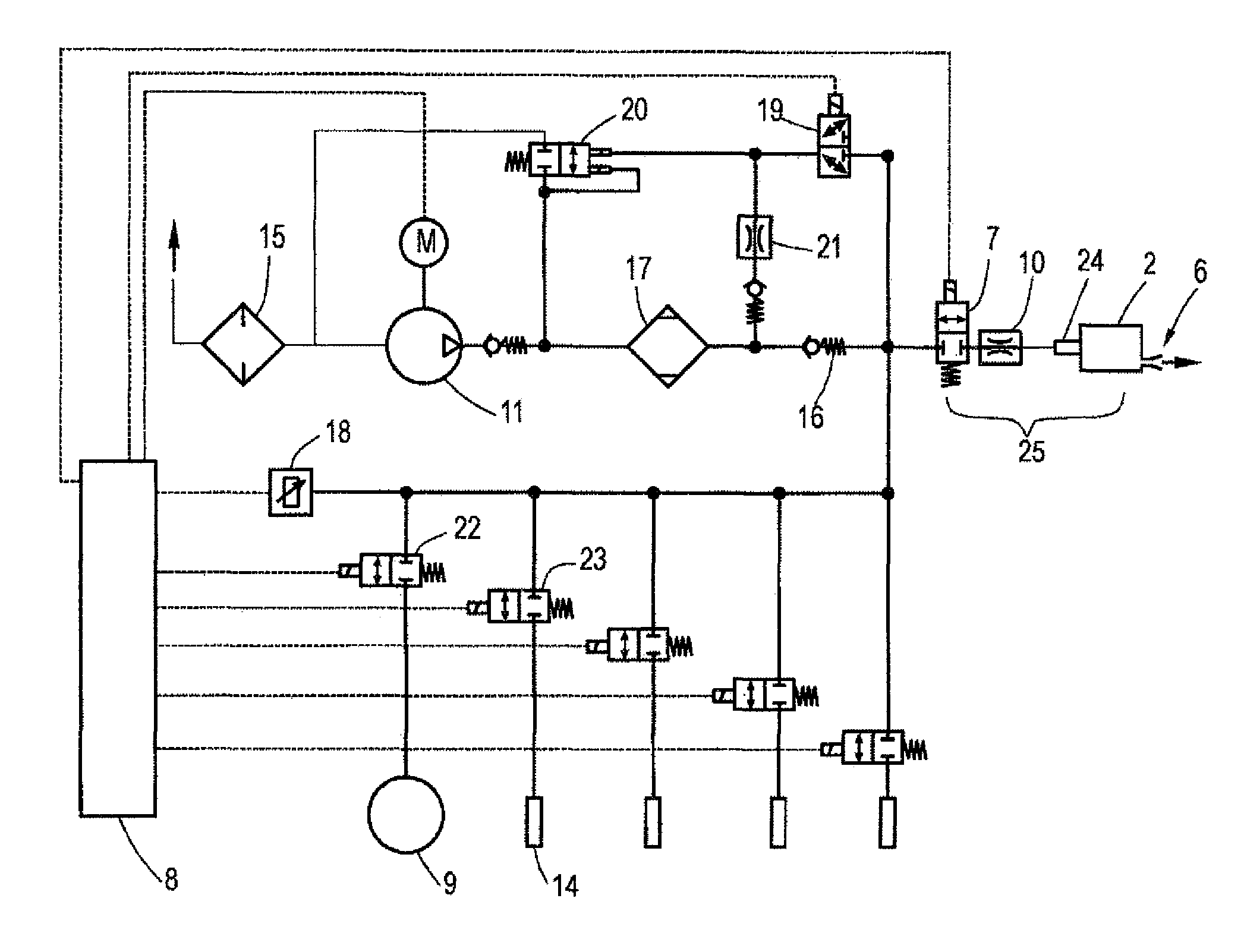

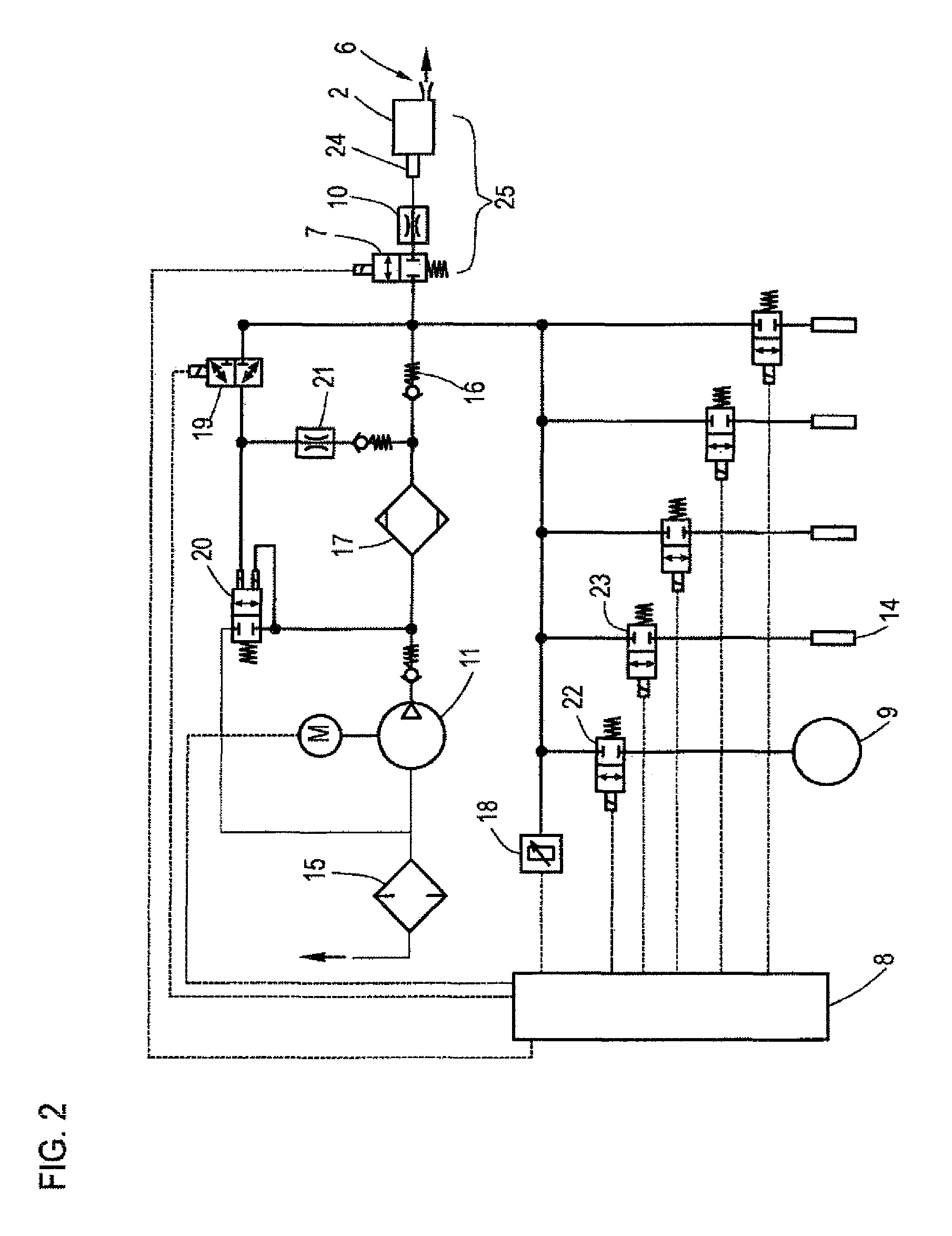

System and method for influencing the induction gas temperature in the combustion chamber of an internal combustion engine

InactiveUS7398649B2Improve variationEasy to set upElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionRegulation temperature

The invention relates to a system and method for use in a homogeneous charge compression ignition (HCCI) combustion engine that is preferably equipped with an exhaust gas recirculation device. This system and method enable an improved adjustment of the temperature level inside the combustion chamber. In addition to adjusting the temperature by using the exhaust gas recirculation device, an influencing of the temperature, which is independent thereof, ensues based on the compression of the induced fresh air by the exhaust gas turbocharger. An increase in temperature is maintained even after the compressed air is expanded on a throttle valve, and this increase in temperature can, in the end, be used for influencing the energy content inside the combustion chamber.

Owner:SIEMENS AG

System and method for influencing the induction gas temperature in the combustion chamber of an internal combustion engine

InactiveUS20060218922A1Efficient systemImprove variationElectrical controlInternal combustion piston enginesThrottleRegulation temperature

The invention relates to a system and method for use in a homogeneous charge compression ignition (HCCI) combustion engine that is preferably equipped with an exhaust gas recirculation device. This system and method enable an improved adjustment of the temperature level inside the combustion chamber. In addition to adjusting the temperature by using the exhaust gas recirculation device, an influencing of the temperature, which is independent thereof, ensues based on the compression of the induced fresh air by the exhaust gas turbocharger. An increase in temperature is maintained even after the compressed air is expanded on a throttle valve, and this increase in temperature can, in the end, be used for influencing the energy content inside the combustion chamber.

Owner:SIEMENS AG

Mold and method for foaming a cooling device

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

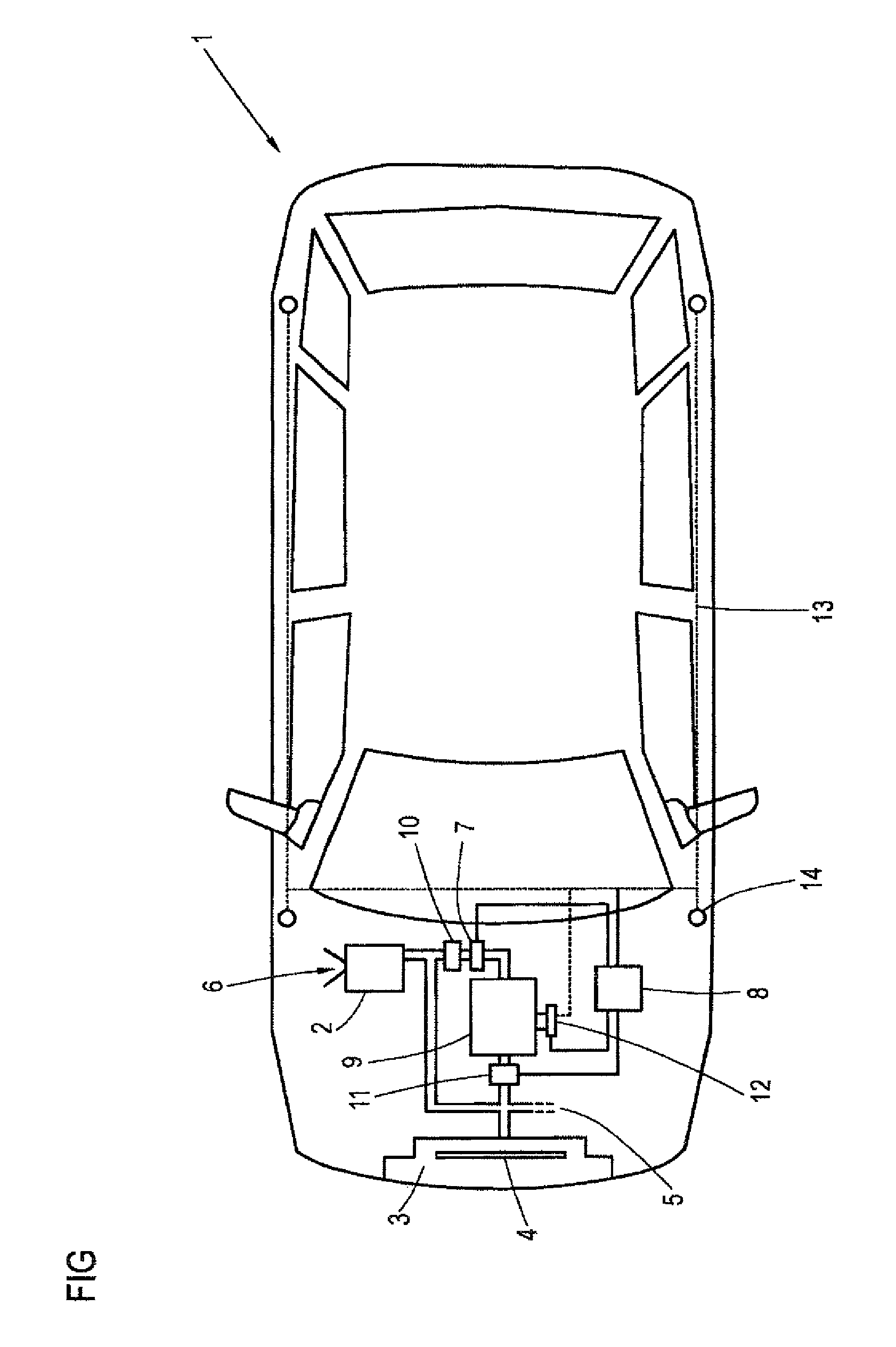

Motor vehicle with battery cooling system

ActiveUS9490509B2Easy maintenanceEasy to integrateHybrid vehiclesElectric devicesElectrical batteryMotorized vehicle

A motor vehicle includes at least one battery module configured to be cooled by compressed gas. The battery module has a cooling system which has an accumulator for compressed gas that can be fed to the battery module for cooling. A control device controls supply of gas from the accumulator to the battery module in dependency of at least one output value from at least one sensor configured to measure a current output from the battery module.

Owner:AUDI AG

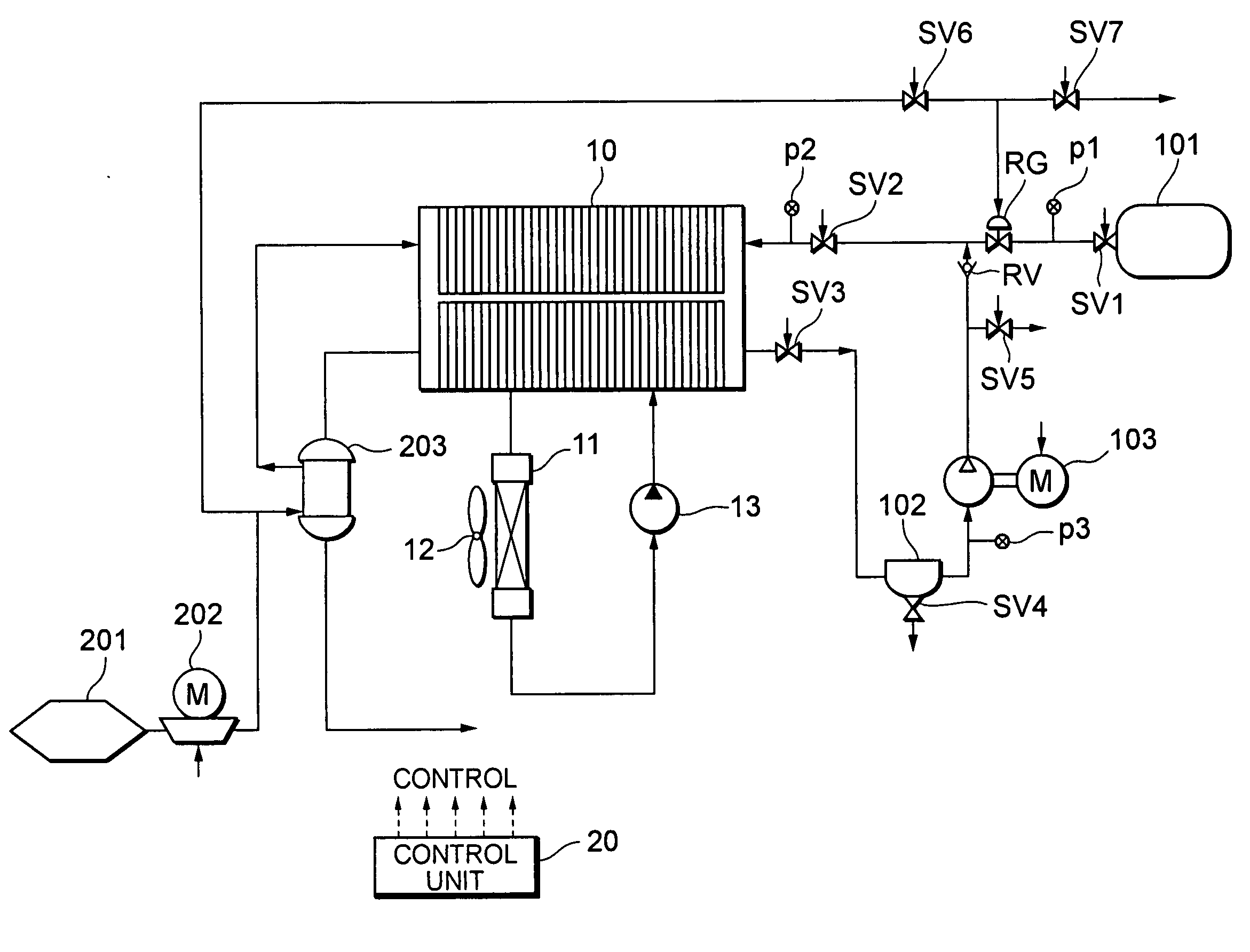

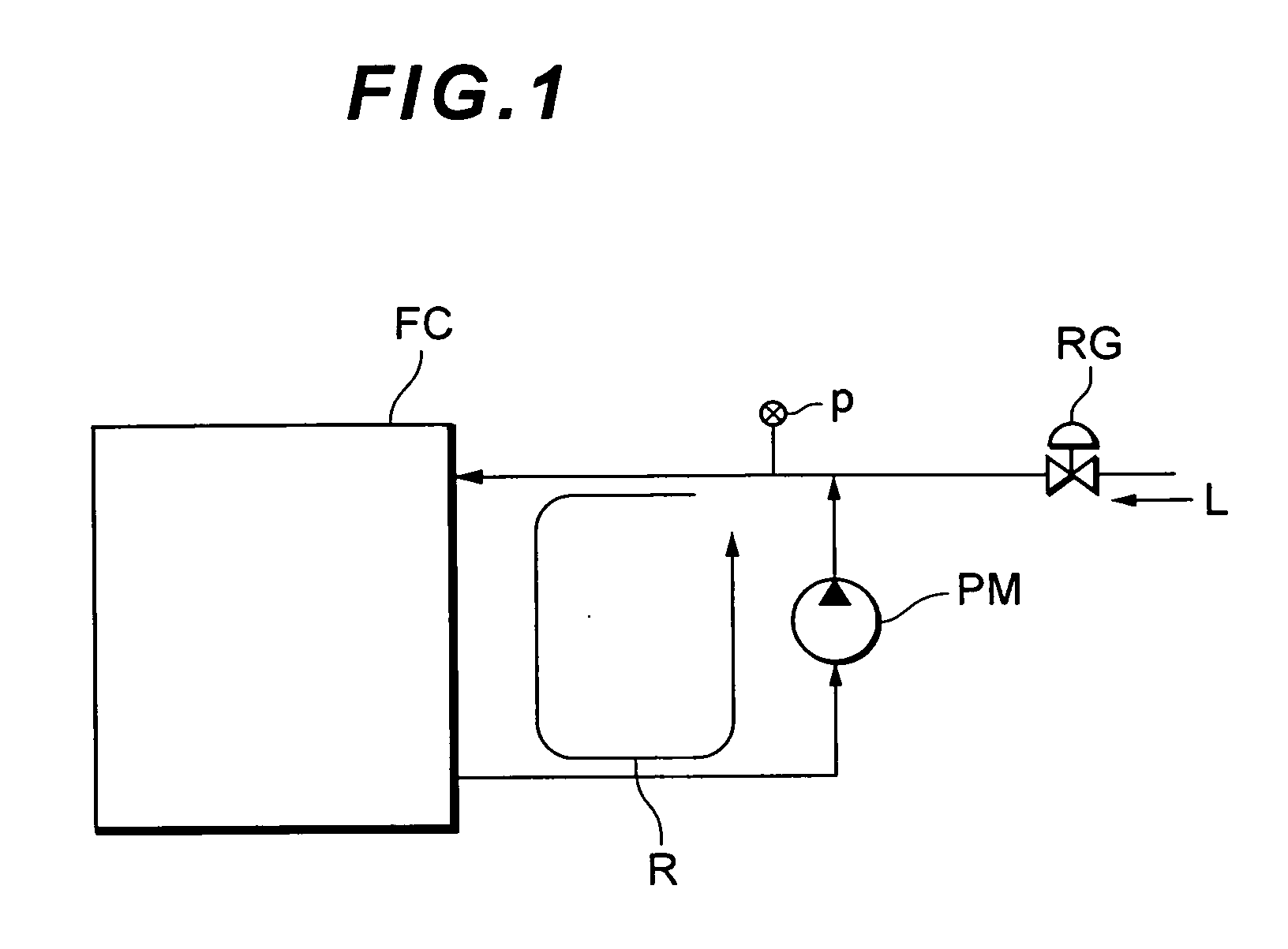

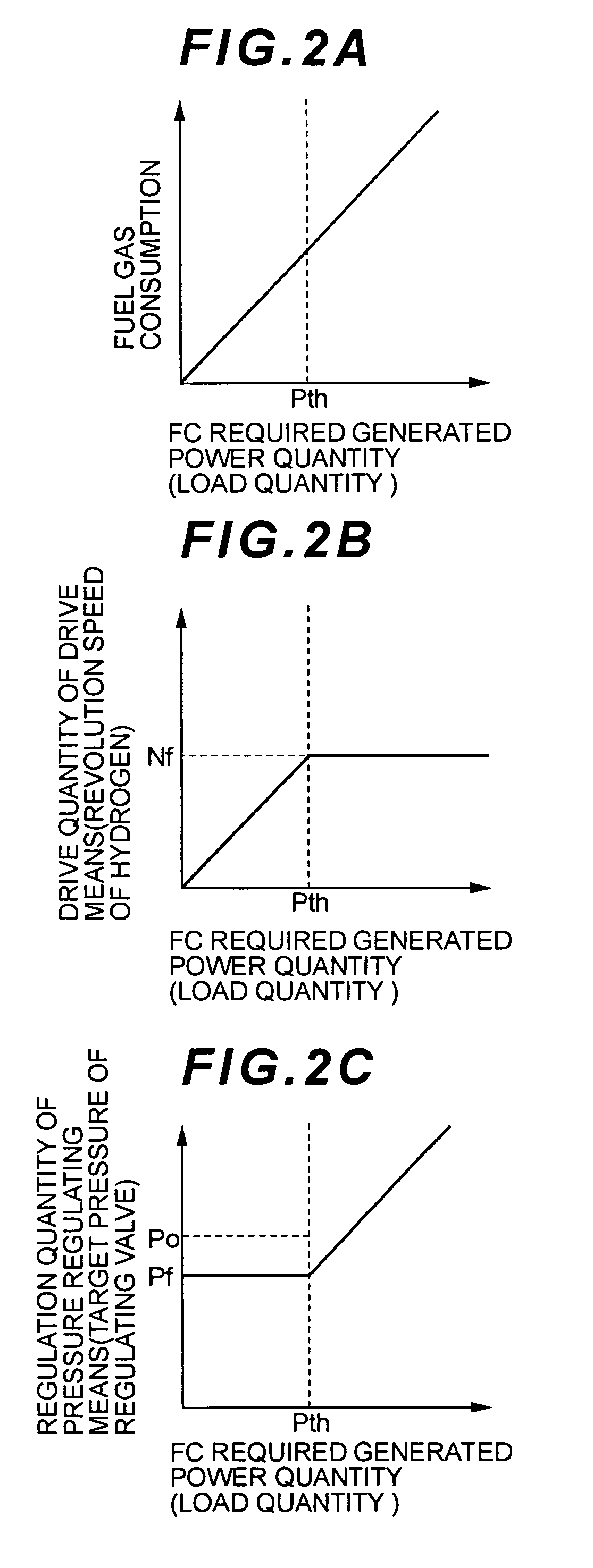

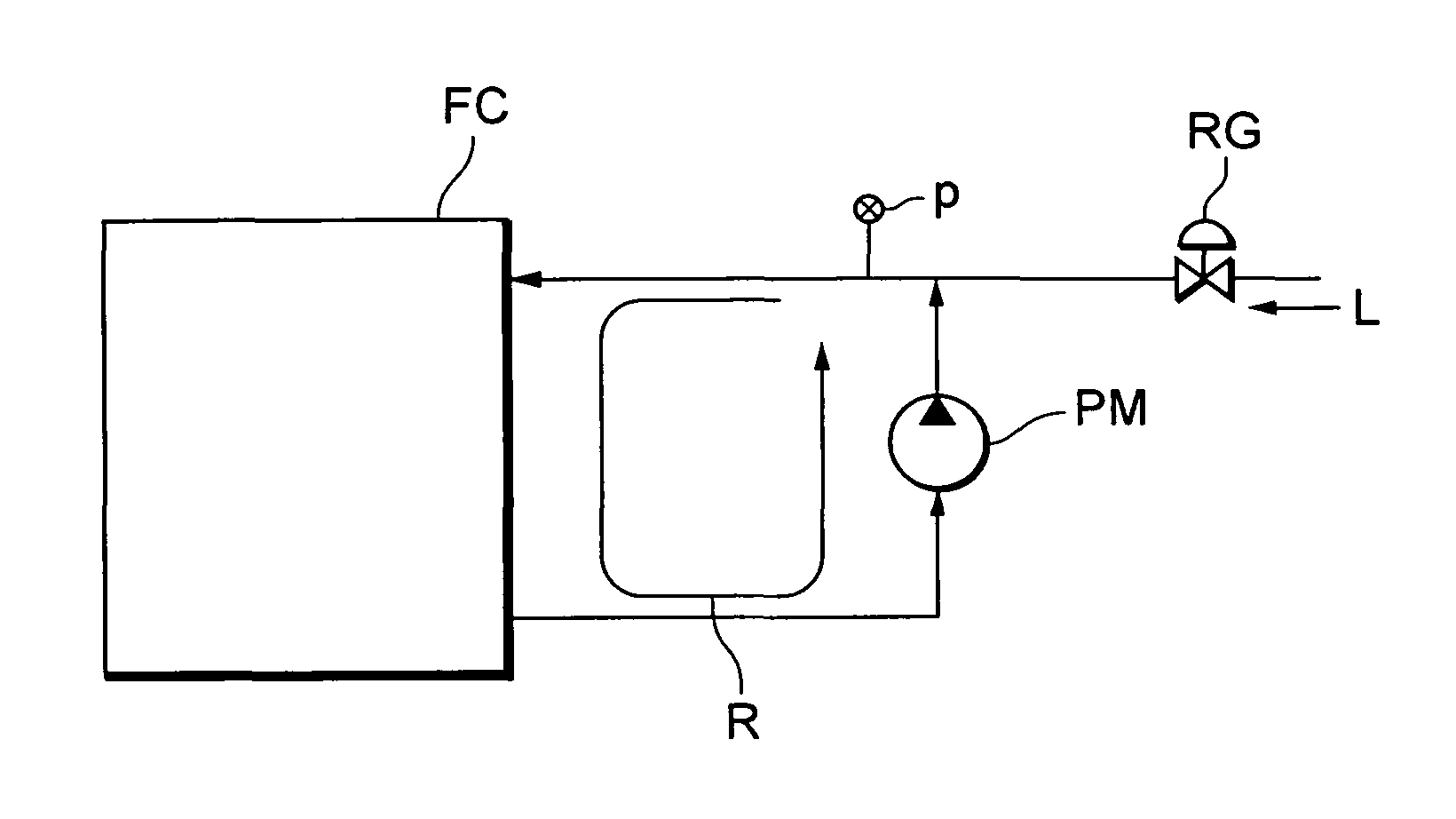

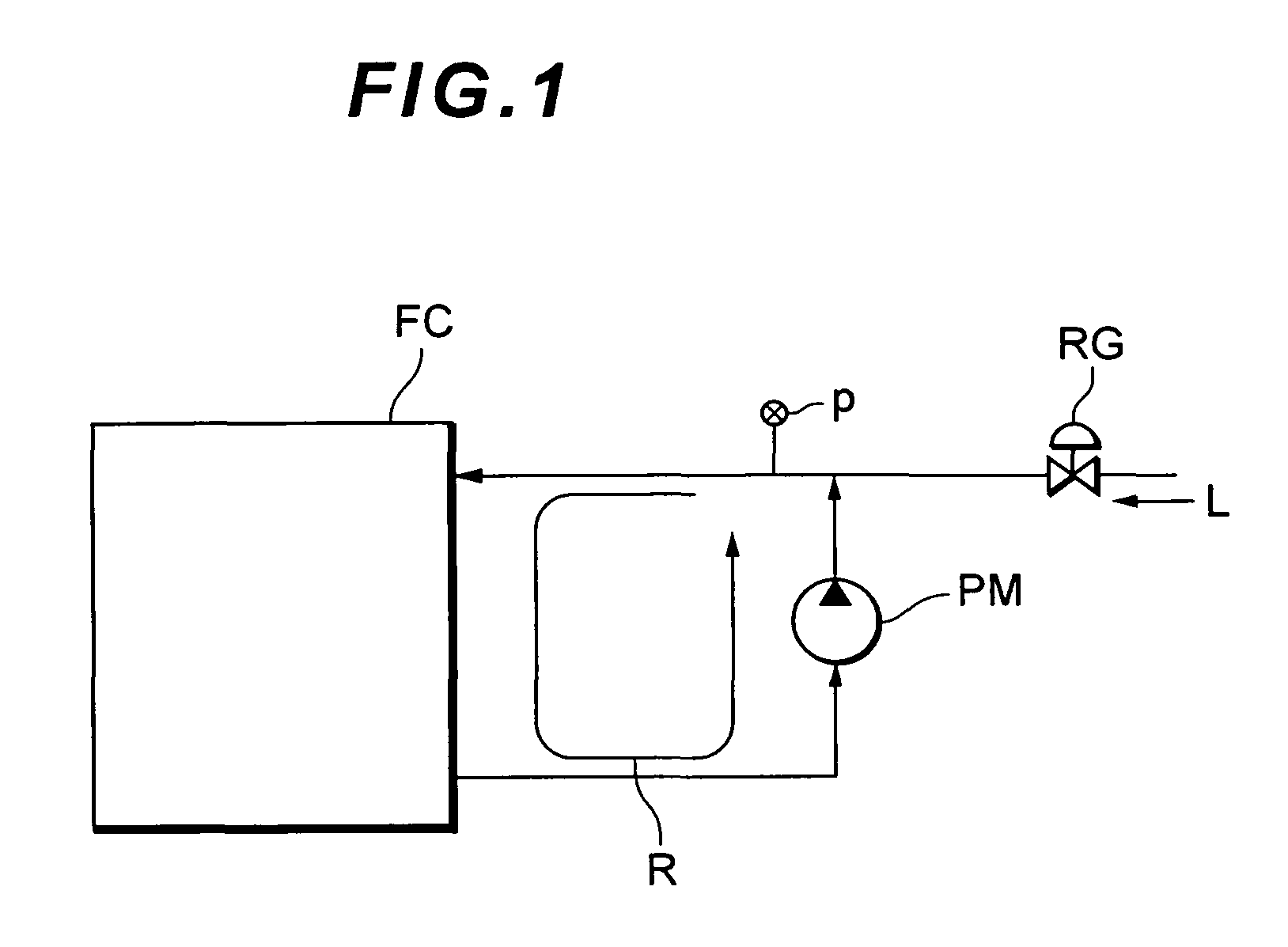

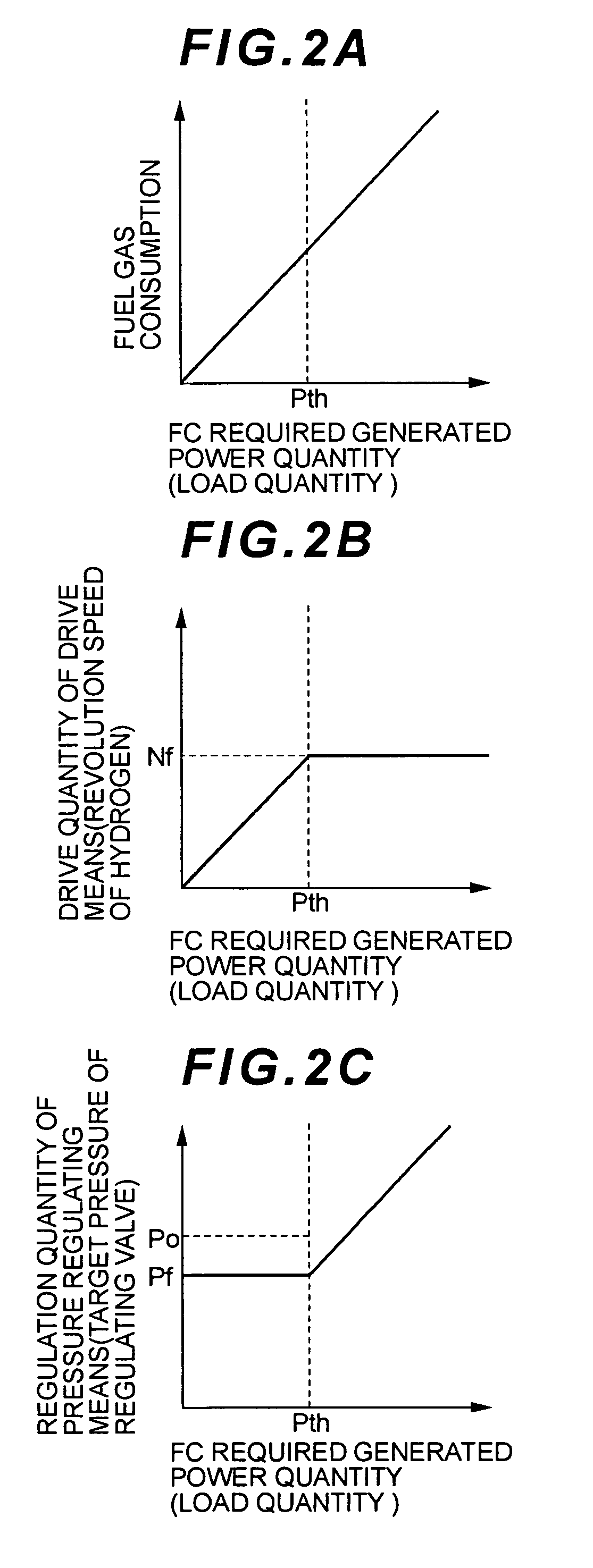

Fuel Cell System And Method For Driving Same

ActiveUS20080038593A1Improve efficiencySmall sizeFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsEngineering

A fuel system with a high power generation efficiency in which drive means can be reduced in size. The fuel cell system of the present invention is equipped with a fuel cell (FC) for generating power by circulating a fuel gas and comprises a circulation route (R) for circulating the fuel gas, drive means (PM) provided in the circulation route (R) and serving to circulate the fuel gas, and pressure regulating means (RG) for regulating the pressure of the fuel gas in the circulatory route (R). A drive characteristic of the drive means (PM) is determined based on the generated power required for the fuel cell, and the pressure regulation quantity of the pressure regulating means (RG) is determined to make up the deficiency of the drive quantity based on the determined drive characteristic of the drive means (PM).

Owner:TOYOTA JIDOSHA KK

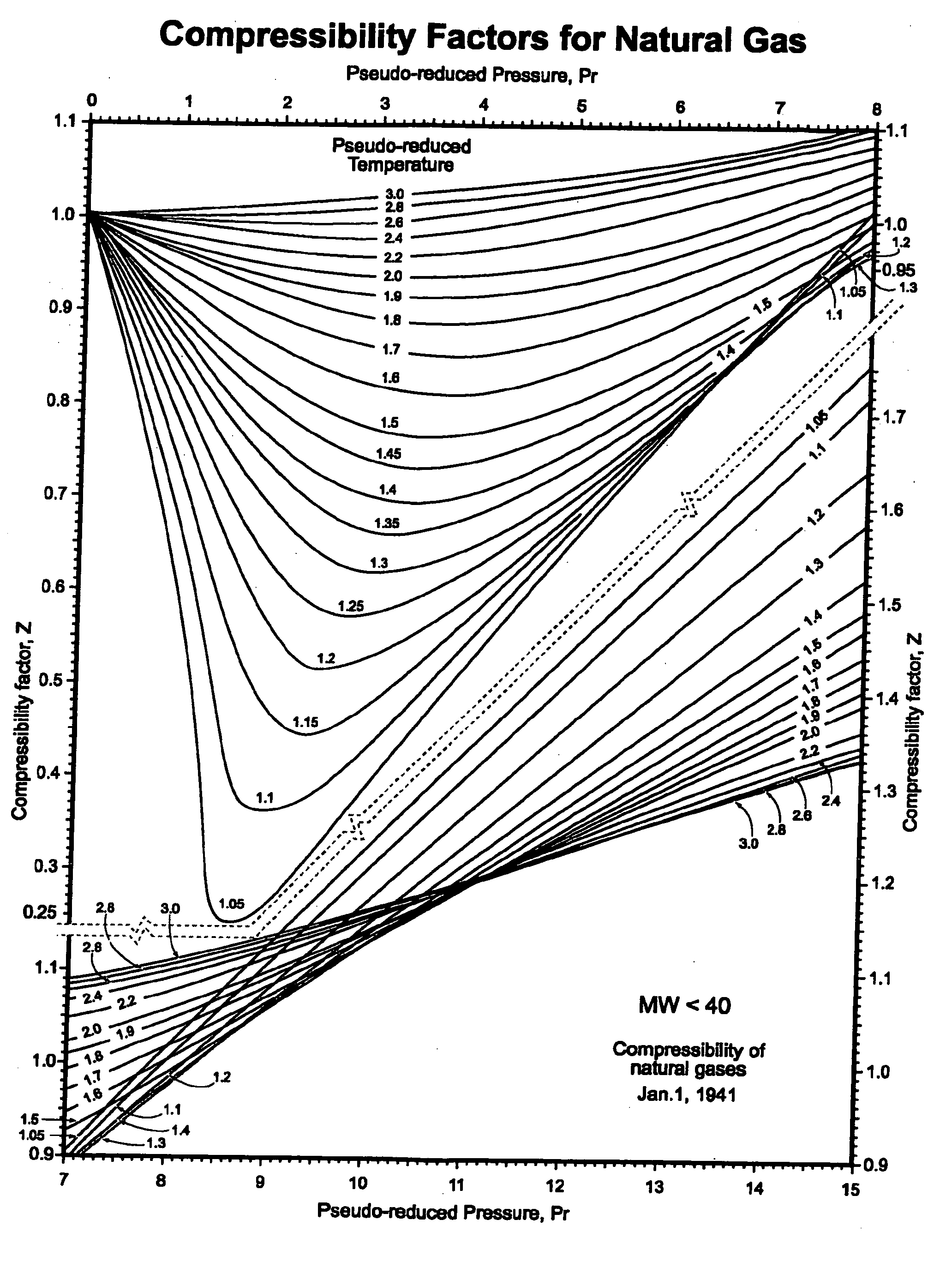

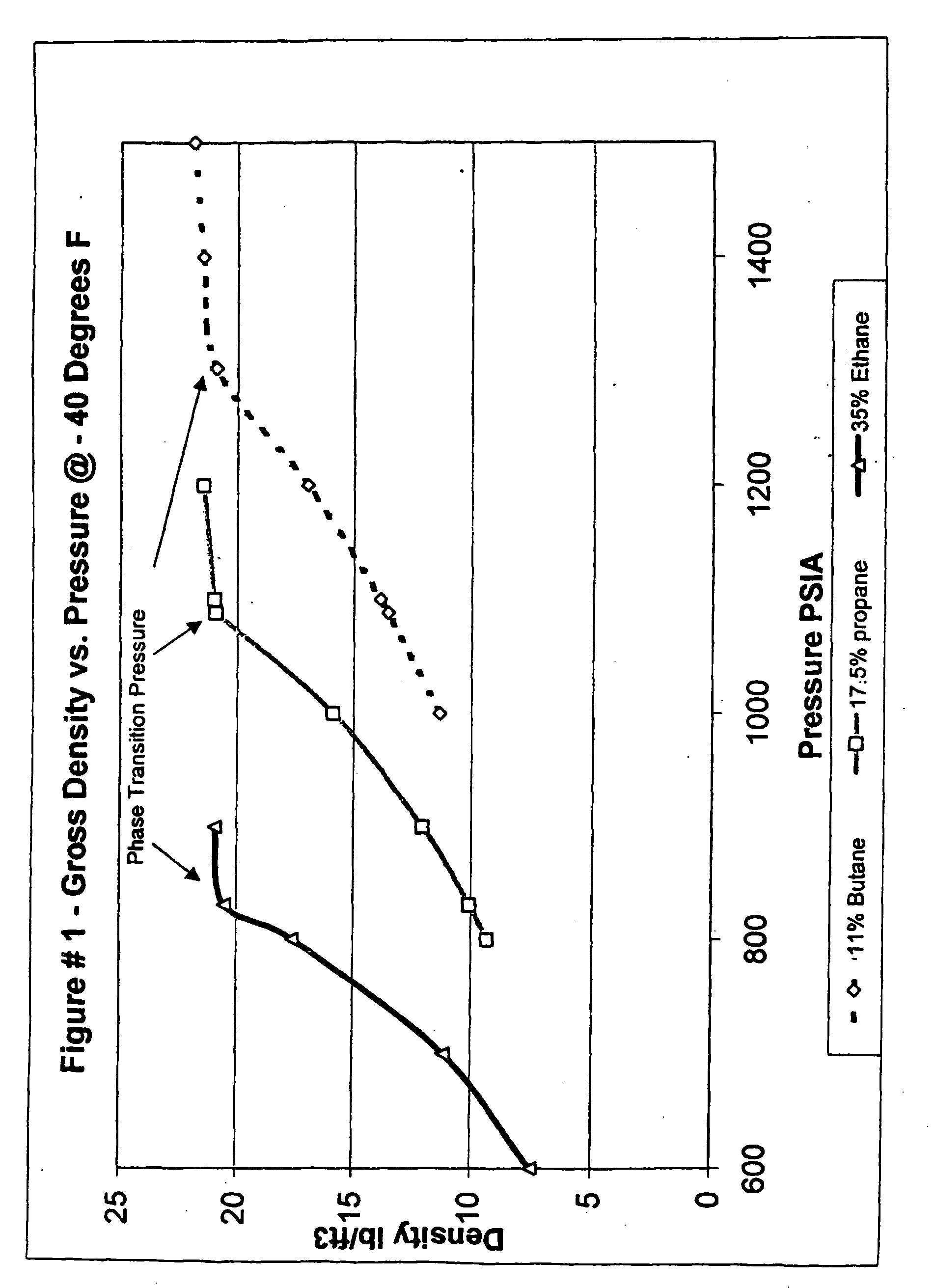

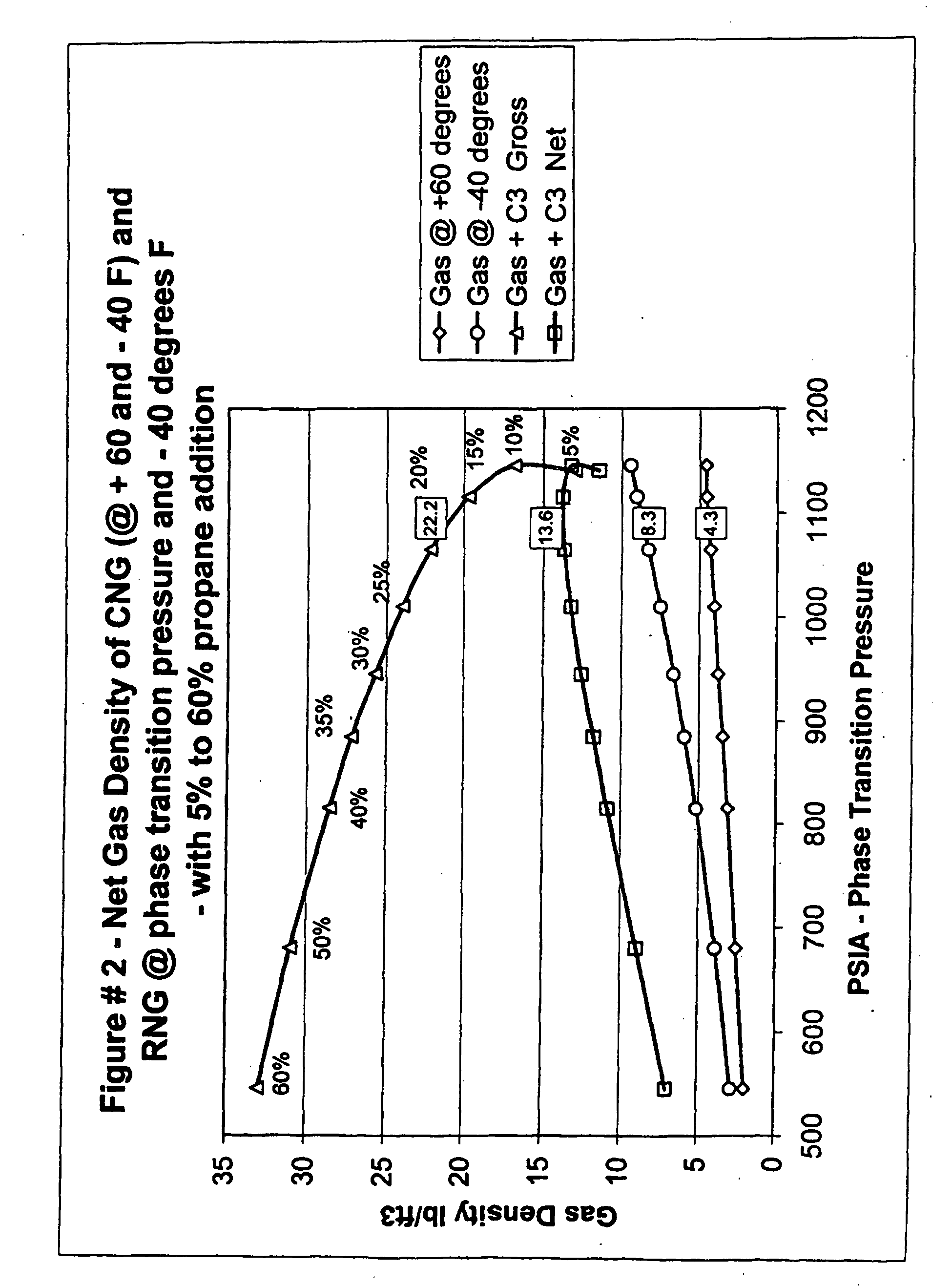

Method and substance for refrigerated natural gas transport

This invention relates to the storage under pressure in a container and subsequent transport of the filled pressurized container of particular natural gas or natural gas-like mixtures that contain methane or natural gas plus an additive, and which mixtures have been refrigerated to less than ambient temperature. (This invention also relates to a similar mixture which has been created by the removal of methane or a lean gas from a richer natural gas mixture.)

Owner:ZEDGAS

Coil pipe type coal pyrolysis device

ActiveCN105219410AIncrease flow rateIncrease gas densityIndirect heating destructive distillationSpecial form destructive distillationCoal pyrolysisCoal tar

The invention discloses a coal pyrolysis device, and particularly relates to a coil pipe type coal pyrolysis device. The coil pipe type coal pyrolysis device comprises a smoke gas inlet, an inner heat insulation layer, an annular narrow cavity, an outer heat insulation layer, a casing and a smoke gas outlet, wherein the annular narrow cavity is defined by the inner heat insulation layer and the outer heat insulation layer; the coil pipe type coal pyrolysis device also comprises a heat exchange coil pipe group, a coil pipe inlet and a coil pipe outlet; the heat exchange coil pipe group is positioned in the annular narrow cavity and is communicated with the coil pipe inlet and the coil pipe outlet. Through the design of installing the heat exchange coil pipe group in the annular narrow cavity in the heat insulation layer and the adoption of an indirect heat exchange form, a product generated through pyrolysis does not directly contact or mix with high-temperature smoke, so that high-temperature semicoke and pyrolysis gaseous products can be conveniently separated; the concentrations of tar, hydrogen and methane in the gaseous products are high; high economic benefits are realized.

Owner:CHANGZHENG ENG

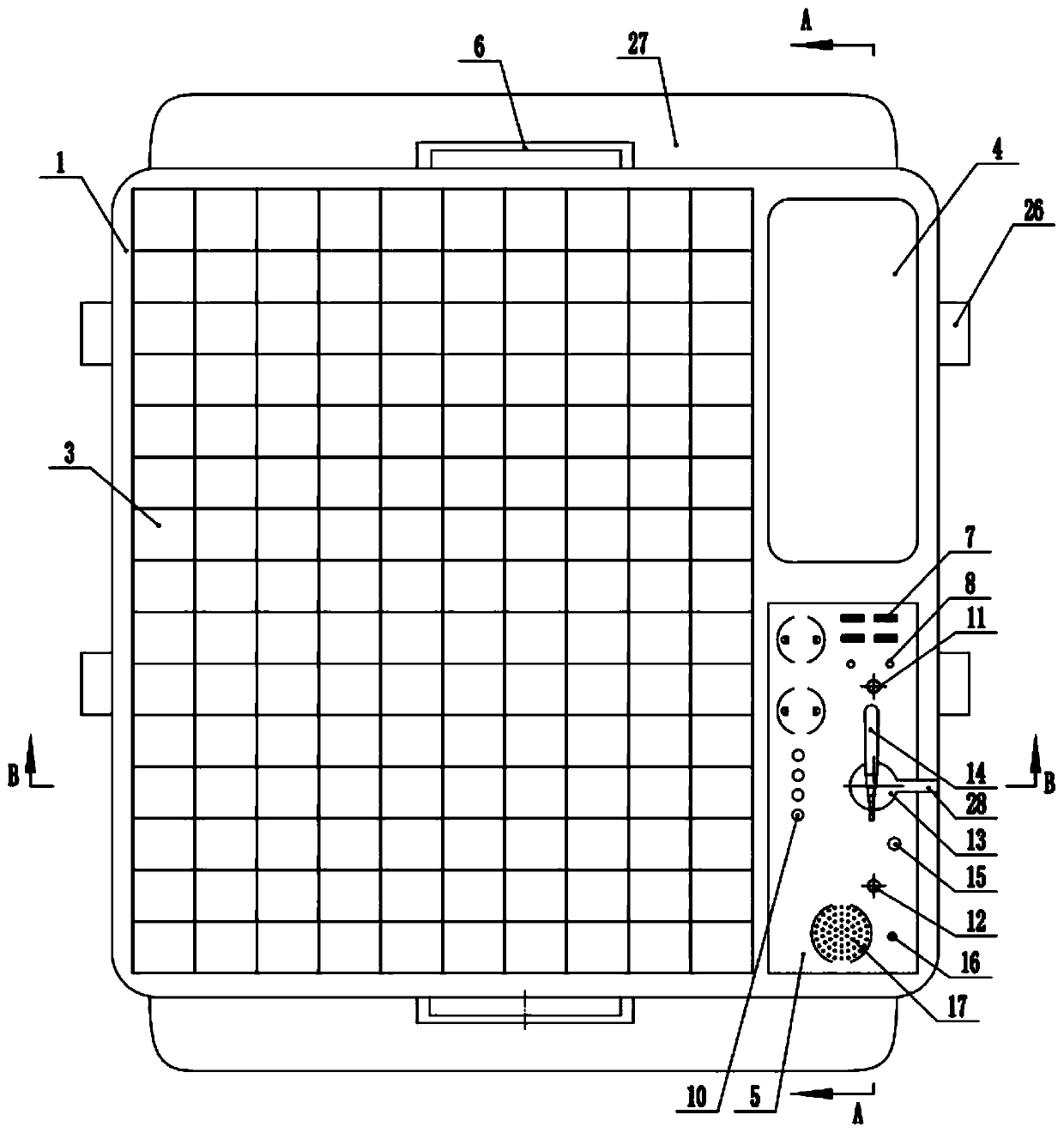

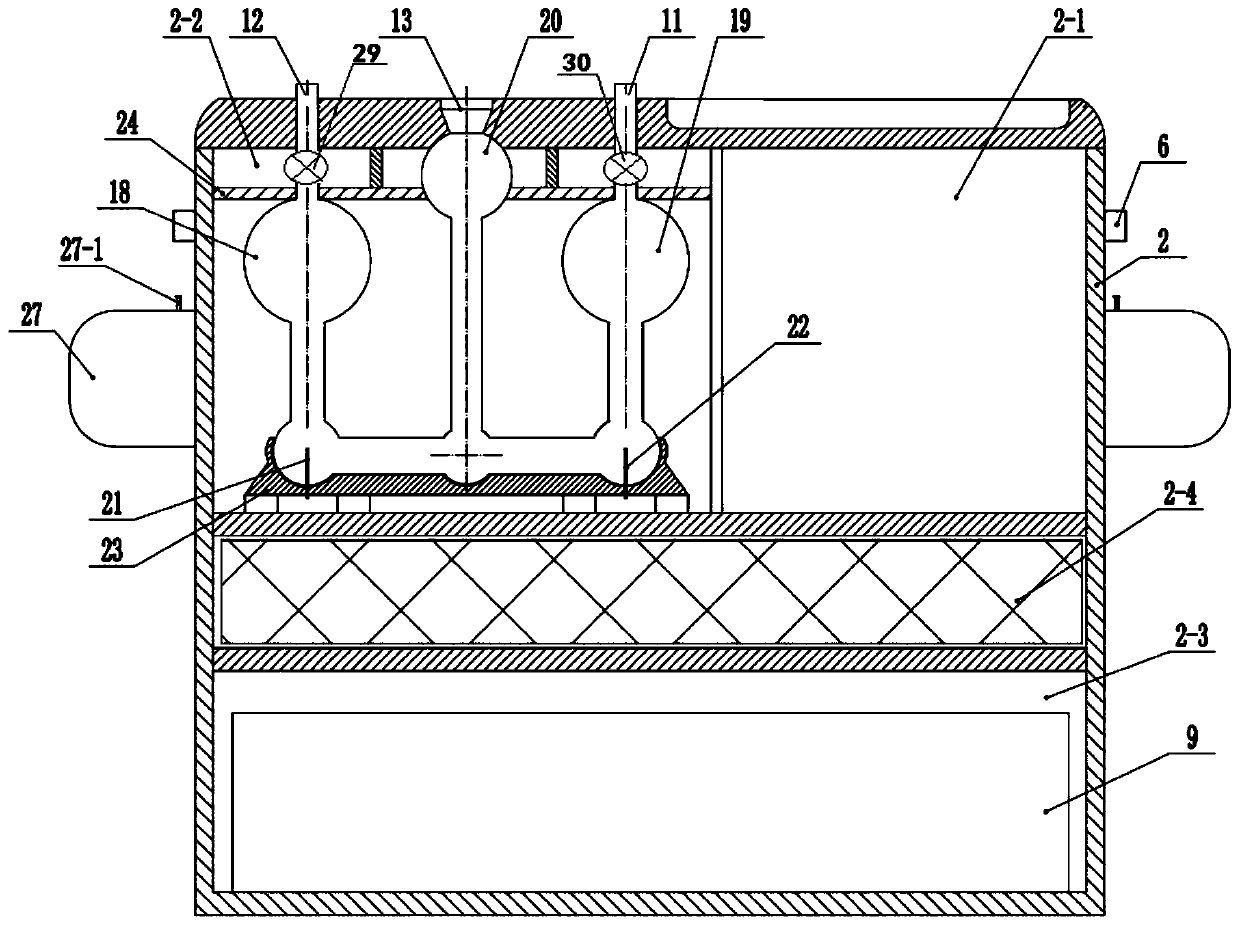

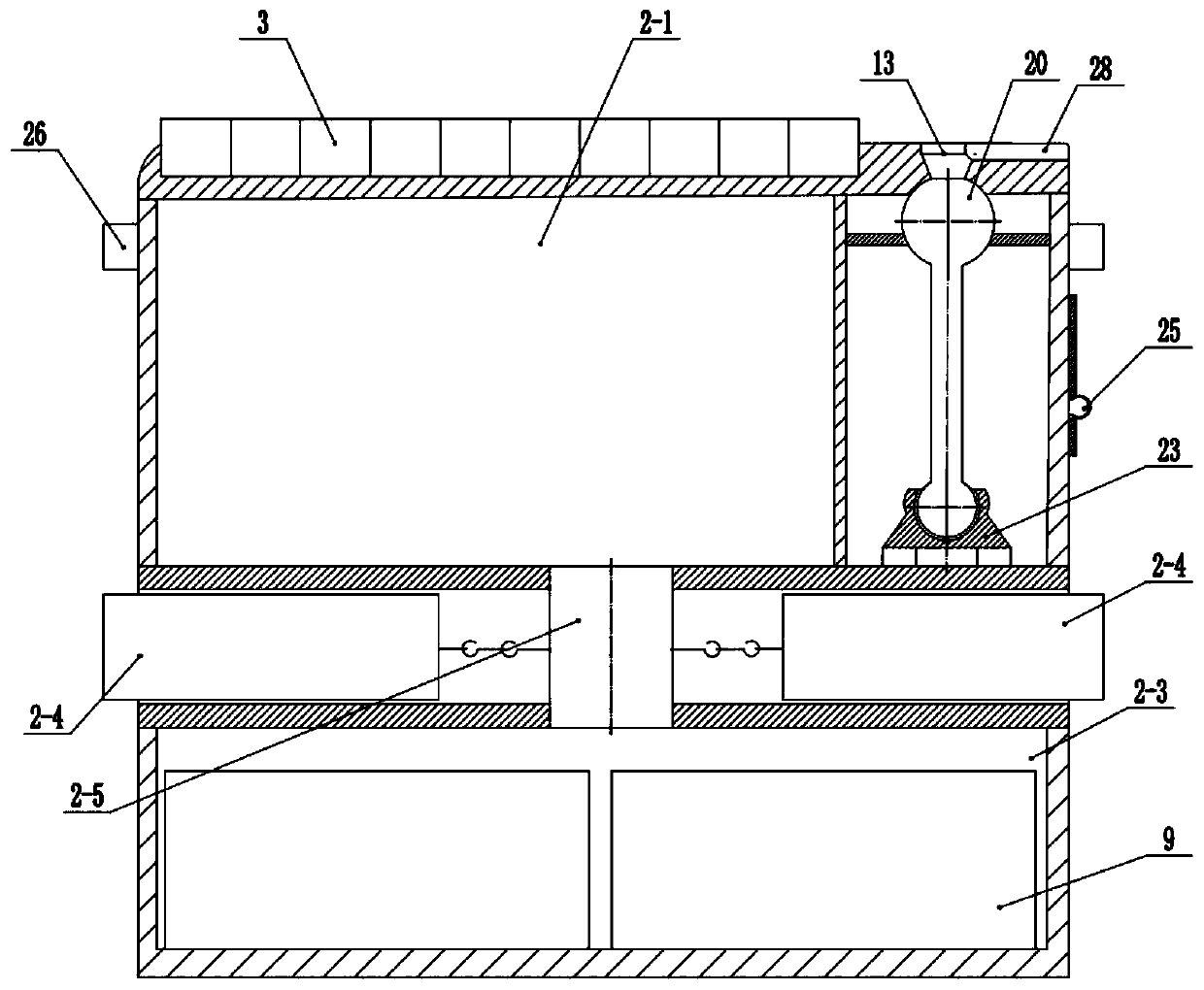

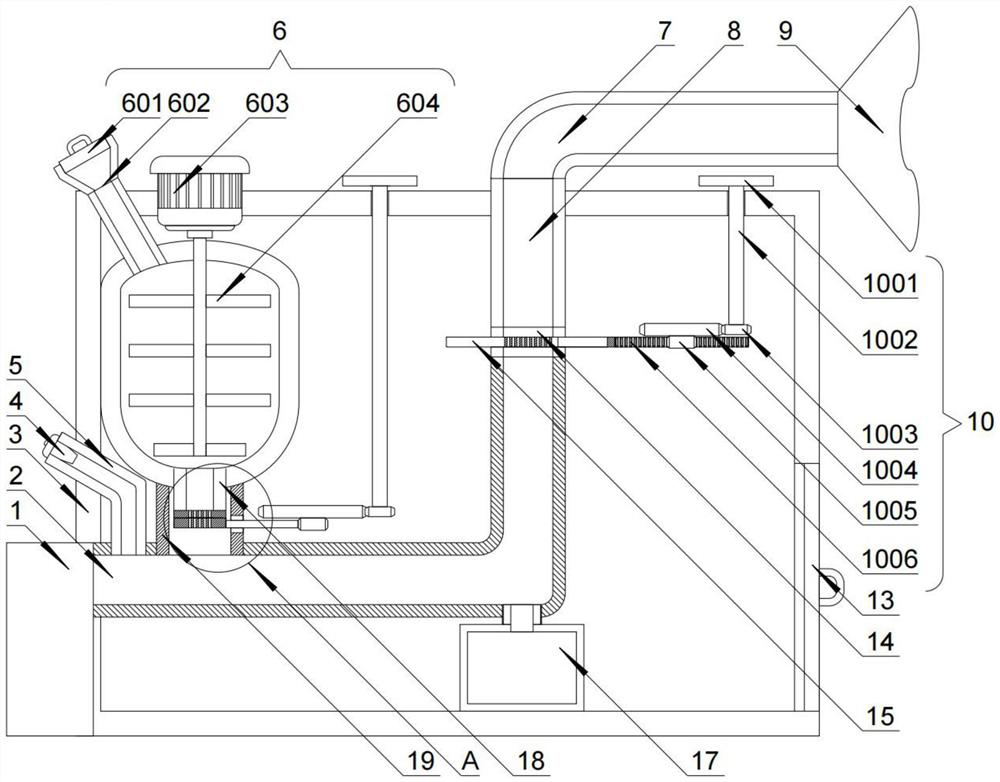

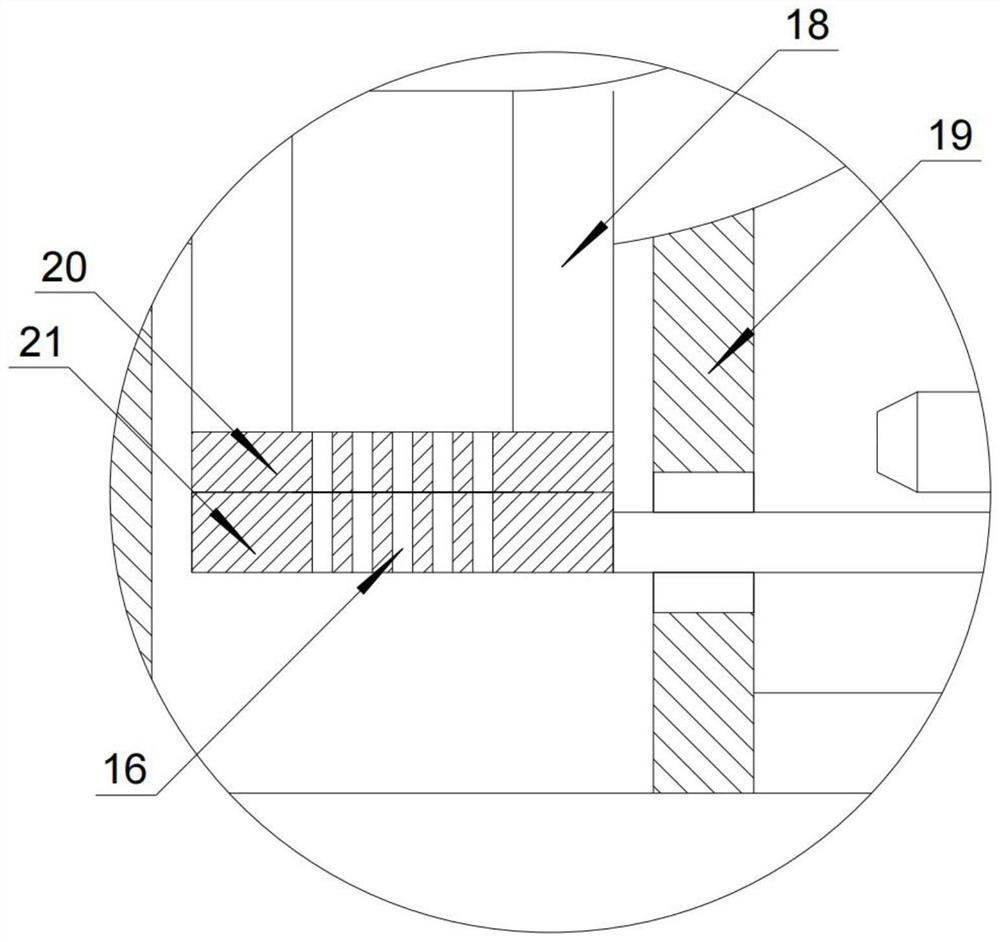

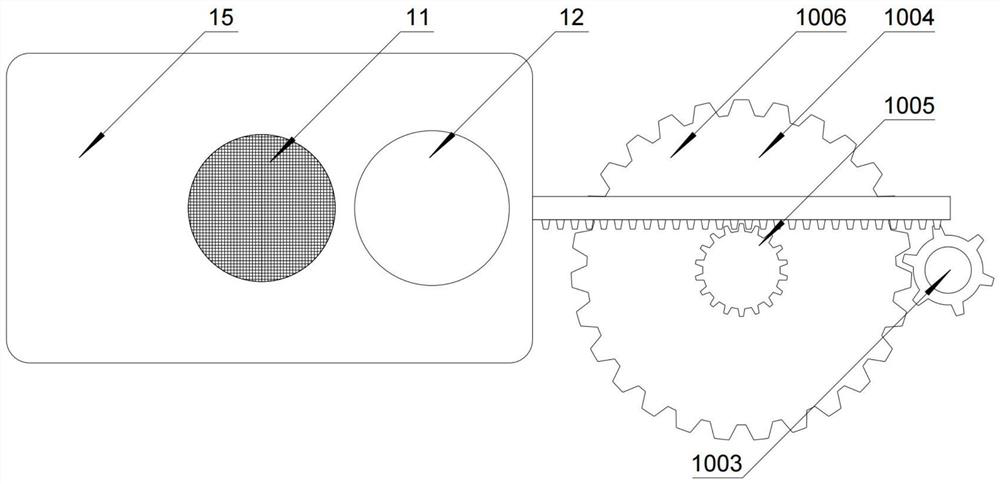

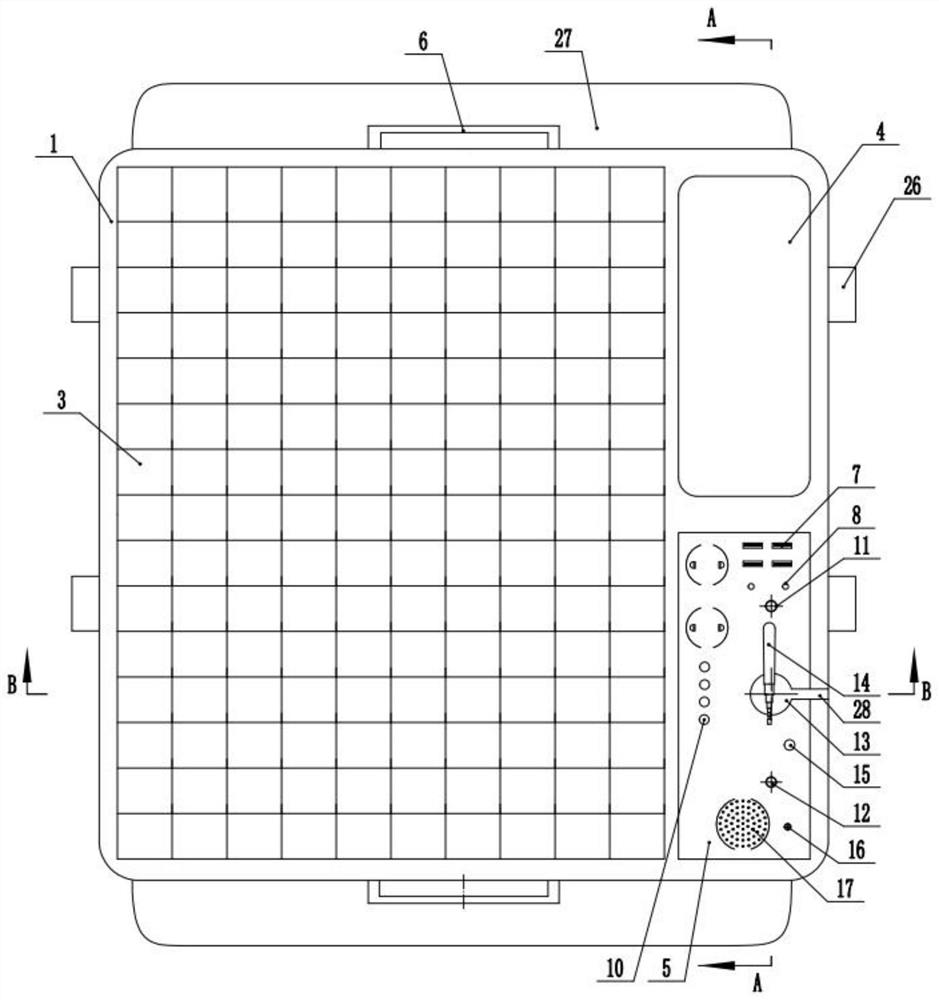

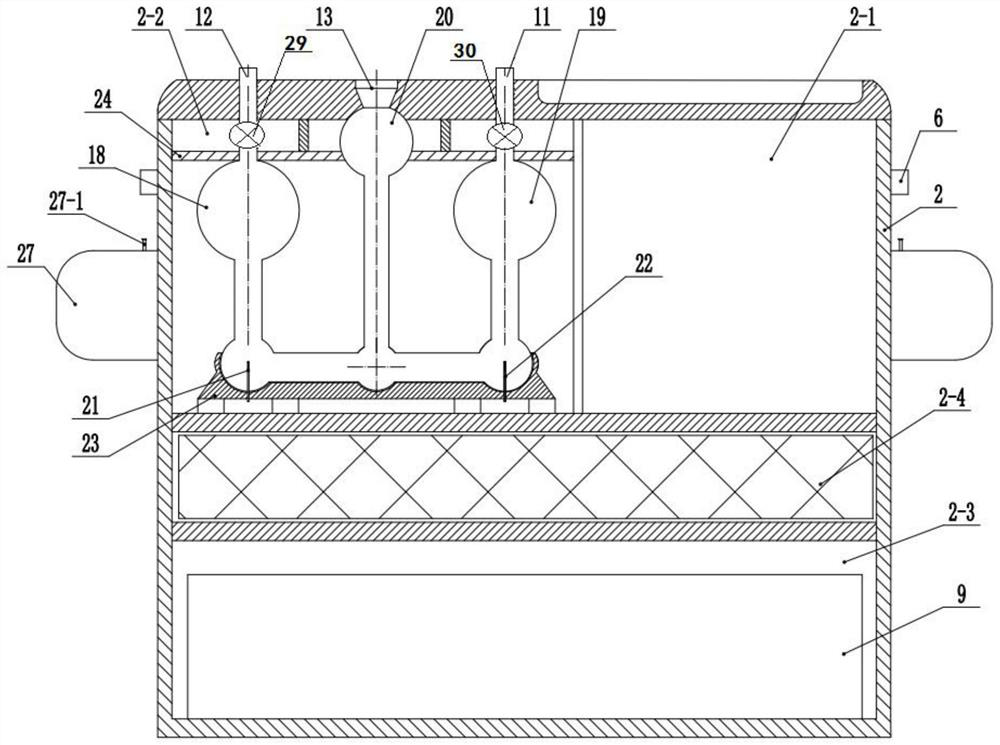

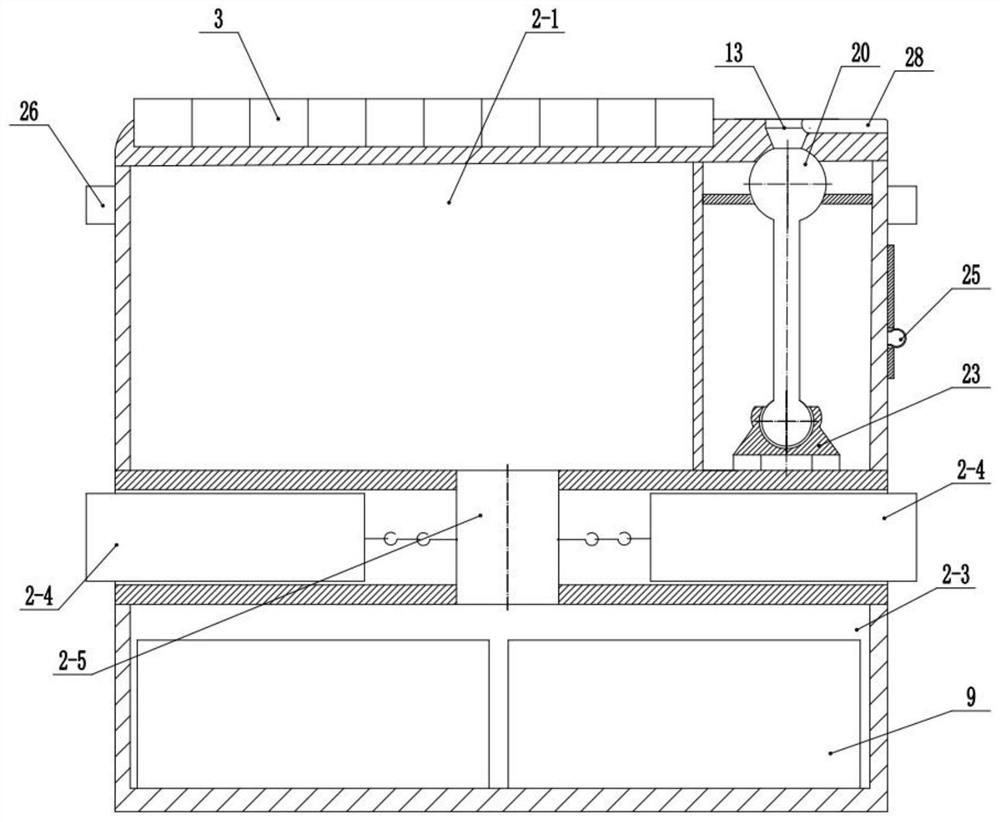

Multifunctional overwater first-aid kit

ActiveCN111284653AIncrease buoyancyEnsure the need to breatheElectrolysis componentsVessel signalling devicesKit first aidElectrolysis

The invention relates to a multifunctional overwater first-aid kit, which comprises a kit body and a kit cover, a photovoltaic power generation panel and an operation panel are arranged on the kit cover, and the operation panel comprises an air supply assembly, a signal assembly and a power supply assembly; wherein the box body comprises a first chamber, a second chamber and a third chamber; the third chamber is located at the bottom of the box body and is internally provided with a battery connected with the photovoltaic power generation panel; the first chamber and the second chamber are arranged above the third chamber; an oxygen production device is vertically mounted in the second chamber; the oxygen generating device comprises an oxygen pipe, a hydrogen pipe and a water inlet pipe located between the oxygen pipe and the hydrogen pipe. The bottoms of the oxygen pipe and the hydrogen pipe are respectively communicated with the bottom of the water inlet pipe; a positive electrode electrolysis head is arranged at the bottom of the oxygen pipe, a negative electrode electrolysis head is arranged at the bottom of the hydrogen pipe, the oxygen generation device is connected with a gas supply assembly on the operation panel, a wire groove is formed between the third cavity and the first cavity, and floating blocks are symmetrically inserted into the two sides of the wire groove.

Owner:李爱群

Fuel cell system with pressure regulator and method for driving same

ActiveUS8435697B2Improve efficiencySmall sizeFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsFuel gas

A fuel system with a high power generation efficiency in which drive means can be reduced in size. The fuel cell system of the present invention is equipped with a fuel cell (FC) for generating power by circulating a fuel gas and comprises a circulation route (R) for circulating the fuel gas, drive means (PM) provided in the circulation route (R) and serving to circulate the fuel gas, and pressure regulating means (RG) for regulating the pressure of the fuel gas in the circulatory route (R). A drive characteristic of the drive means (PM) is determined based on the generated power required for the fuel cell, and the pressure regulation quantity of the pressure regulating means (RG) is determined to make up the deficiency of the drive quantity based on the determined drive characteristic of the drive means (PM).

Owner:TOYOTA JIDOSHA KK

Mold and method for foaming a cooling device

Owner:BOSCH SIEMENS HAUSGERATE GMBH

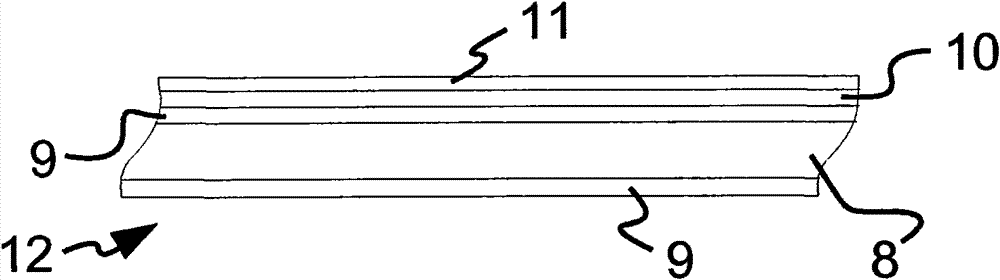

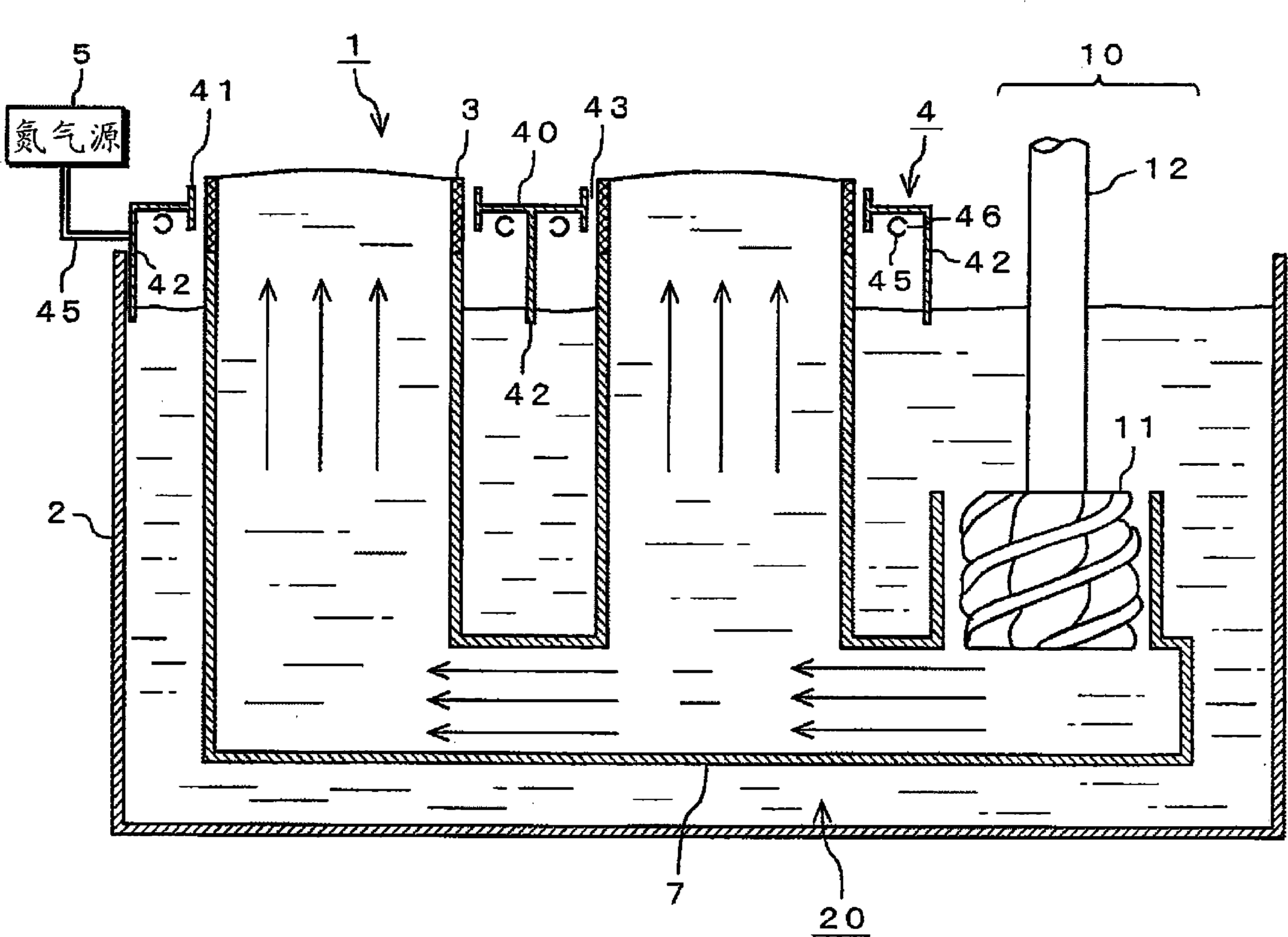

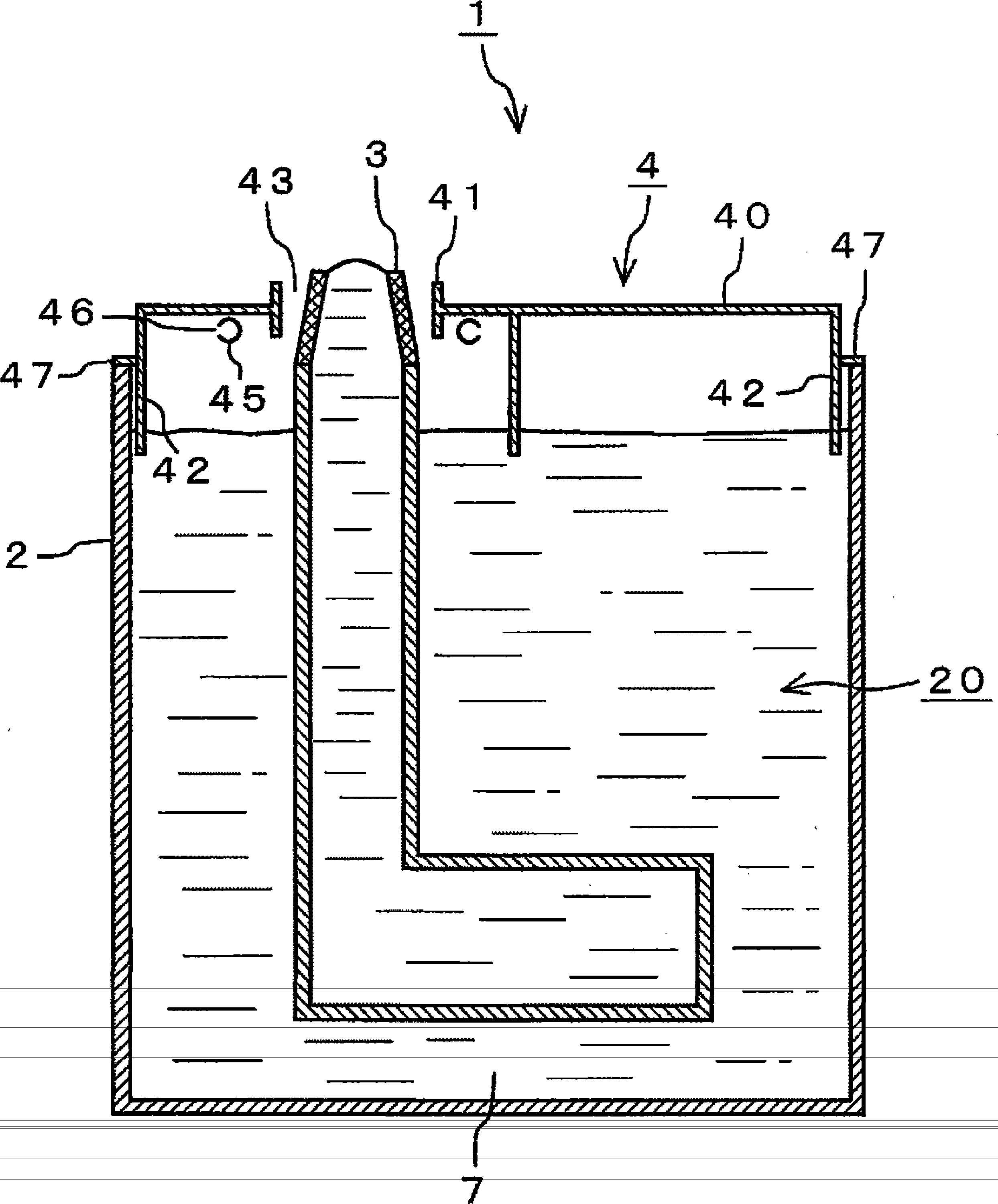

Jet solder vessel

ActiveCN101888746BIncrease gas densityReduce oxygen concentrationPrinted circuit assemblingSolder feeding devicesNitrogenEngineering

The invention provides a Jet solder vessel. The Jet solder vessel can prevent tin soldering oxygenation injected from the nozzle. A cover body part has an opening for inserting of the nozzle part and a lateral wall located at the outside of the opening, the cover body part covers one part of the soldering tin storage part. A supply tube has a plurality of supply ports for supplying nitrogen to the lateral wall side, the supply tube is provided between the opening and the lateral wall in a mode of enclosing the surrounding of the opening. Therefore, the nitrogen supplied from the supply ports faces to the lateral wall to supply, and is stored between the nozzle part, the lateral wall and the liquid level of the soldering tin. The gas density of the stored nitrogen becomes higher. The nitrogen with high gas density ejects from the opening, and injects the nitrogen to the soldering tin injected from the nozzle part. Therefore, the soldering tin oxygenation can be prevented. As a result, imperfect bridging and imperfect solder projection caused by that the soldering tin is adhered outside the prescribed positions.

Owner:SENJU METAL IND CO LTD

Volute and compressor

PendingCN112943694ASolve the problem of high exhaust temperatureGuaranteed mechanical propertiesPump componentsPumpsEngineeringCooling fluid

The invention discloses a volute and a compressor. An exhaust passage is arranged in the volute, a cooling inlet for injecting cooling liquid is formed in the volute, the cooling inlet communicates with the exhaust passage, and the cooling liquid enters the exhaust passage through the cooling inlet for cooling. According to the volute and the compressor, the problems that in the prior art, due to the fact that the exhaust temperature of a compressor is high, vibration exceeds the standard, noise is large, and the size of the volute of the compressor is large can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Atomization device for pulmonary infection

InactiveCN114652928AIncrease gas densityWon't hinderMedical devicesMedical atomisersPulmonary infectionPharmacy medicine

The atomization device comprises a medicine mixing device for mixing different medicines together, a liquid outlet pipe is arranged at the lower end of the medicine mixing device, a partition plate I is fixedly connected to the lower end of the liquid outlet pipe, a partition plate II is slidably connected to the lower end of the partition plate I, and through holes I are formed in the partition plate I and the partition plate II in a penetrating mode; a high-pressure air pipe is arranged at the lower end of the partition plate II, high-pressure gas is injected into the high-pressure air pipe through a compressor, the amount of the medicine flowing out of the medicine mixing tank and the amount of the medicine flowing into the high-pressure air pipe are controllable through sliding between the partition plate I and the partition plate II, and therefore the amount of the medicine contained in the gas is controlled; the high-pressure air pipe is in an L shape so that high-pressure airflow can carry medicine to impact the inner wall of the high-pressure air pipe so that medicine particles can be dispersed, meanwhile, a dispersing net is arranged at the upper end of the high-pressure air pipe so that the medicine particles can be cut and further dispersed, and it is guaranteed that the medicine particles inhaled by a patient are small enough and cannot be combined with sputum to further block the trachea of the patient.

Owner:HENAN UNIV HUAIHE HOSPITAL

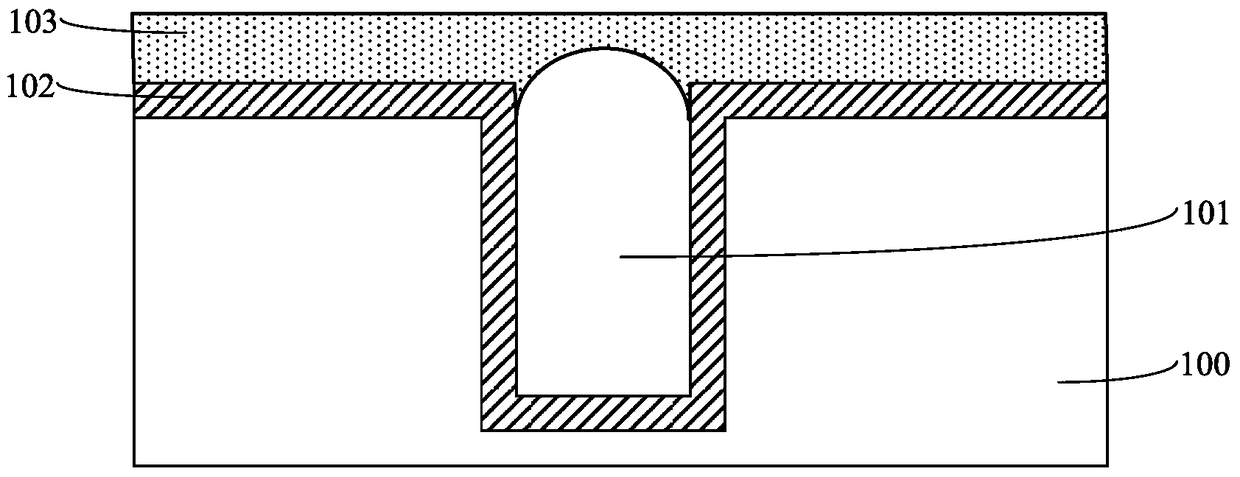

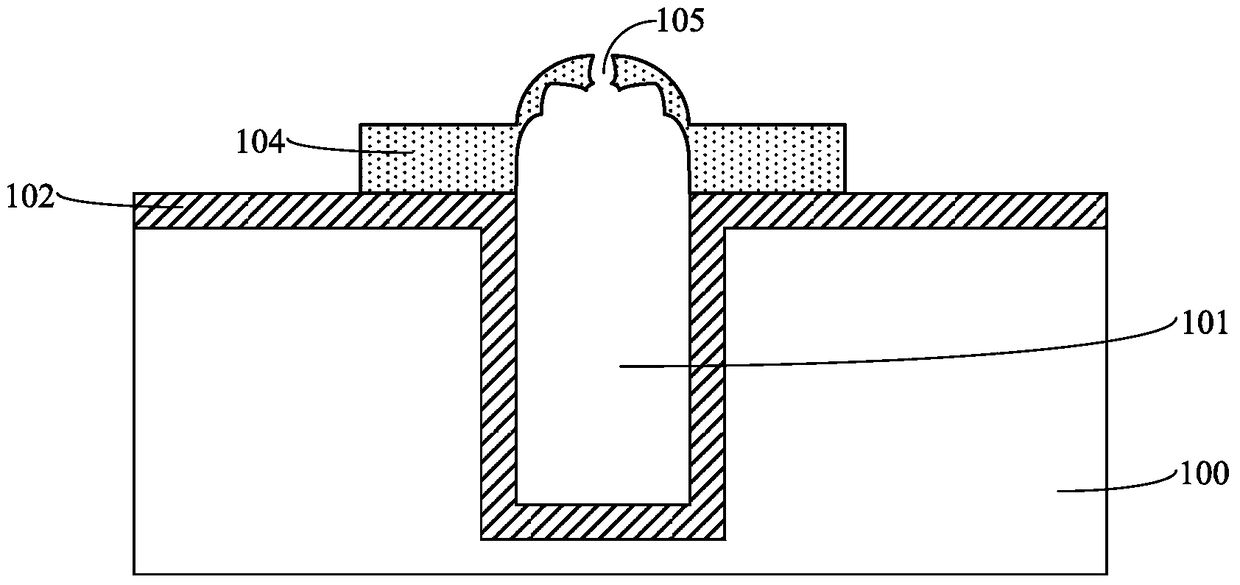

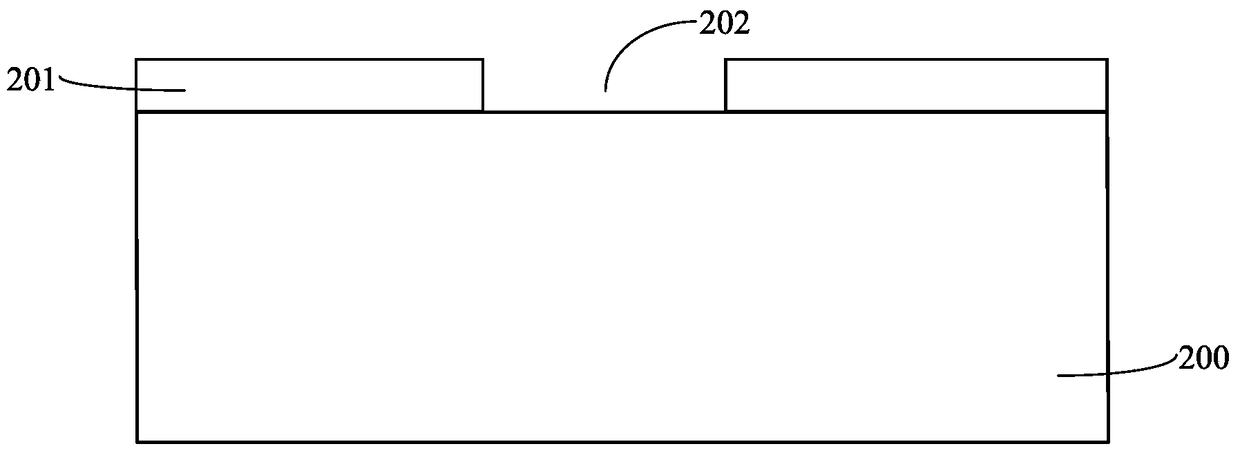

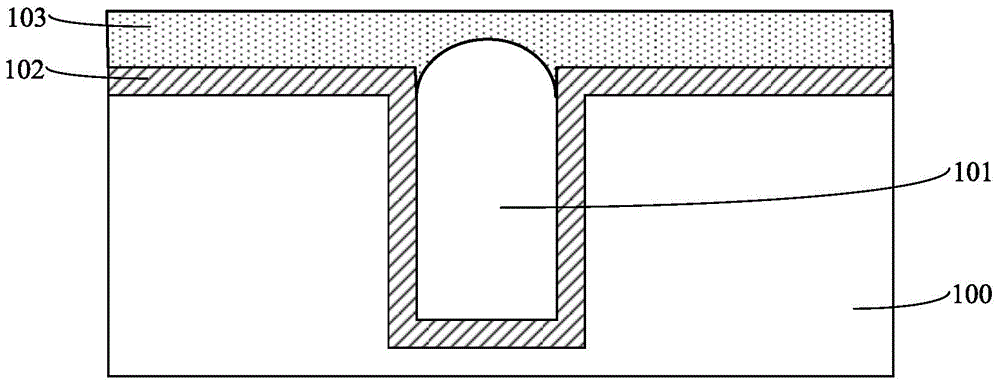

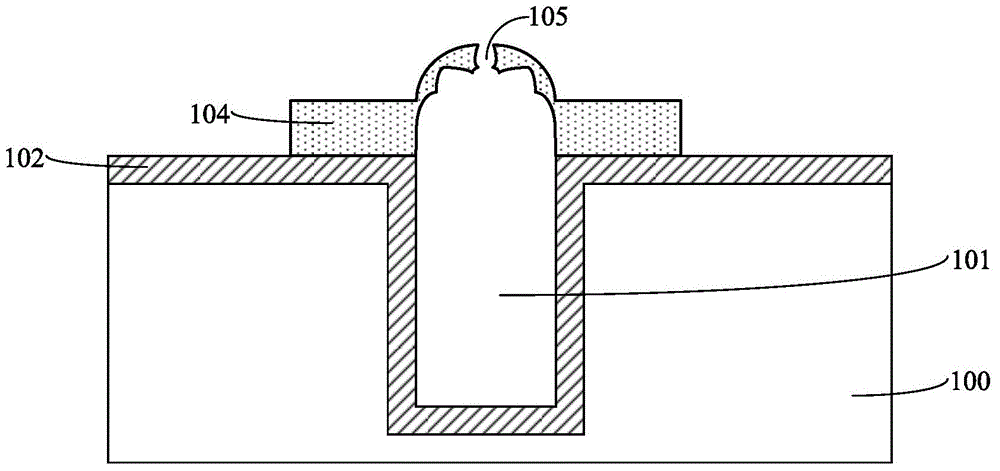

Formation method of semiconductor structure

ActiveCN105374742BImprove reliabilityImprove electrical performanceSemiconductor/solid-state device manufacturingEtchingRedistribution layer

A formation method of a semiconductor structure comprises the following steps of providing a substrate, wherein a through hole is formed in the substrate; forming metal layers on a substrate surface, a through hole bottom and a sidewall surface; providing a lithography processing chamber, wherein pressure in the lithography processing chamber and pressure outside the lithography processing chamber possess a pressure difference, a pressure difference lithography technology is adopted in the lithography processing chamber, a photoresist layer is formed on a part of the metal layer surfaces, the photoresist layer closes the through hole and a gas is arranged in the through hole; taking the photoresist layer as a mask film, etching the metal layers till that a substrate surface is exposed and taking the residual metal layers as a redistribution layer; and removing the photoresist layer. By using the method of the invention, quality of the formed photoresist layer is increased; a thickness of the photoresist layer is avoided to be too thin or fracture is avoided; unnecessary etching to the metal layers of the through hole bottom and the sidewall surface is avoided too; quality of the formed redistribution layer is improved so that reliability and electric performance of the semiconductor structure are increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Sulfur removal method of anhydrous hydrofluoric acid

InactiveCN109019514ASave energyIncrease gas densityHydrogen fluorideHydrofluoric acidHydrogen fluoride

The invention discloses an electric water heater for spraying and an installation method thereof. The method comprises the steps of: 1) preparation of hydrofluoric acid gas; 2) dedusting of gas; 3) sulfur removal of gas; 4) condensation; and 5) cleaning of a desulfurization device. According to the invention, an adjustable desulfurization device is disposed inside a coarse distillation tower for sulfur removal of crude hydrogen fluoride gas, and the sulfur removal efficiency is increased. The method provided by the invention solves the problem that in the existing preparation process of anhydrous hydrofluoric acid, along with the decrease of the furnace gas temperature, the produced sulfur steam can agglutinate in pipelines and equipment, thus resulting in blocking accidents, bringing hidden dangers to production, increasing the maintenance cost and lowering enterprise benefits.

Owner:浙江森田新材料有限公司

A three-gas supercharging system applied to liquid rockets

ActiveCN106194500BImprove reliabilityIncrease independenceRocket engine plantsOxygen tankGas cylinder

The invention relates to a trimix pressurization system applied to a liquid rocket. The trimix pressurization system comprises a helium and hydrogen bottle (1), an oxygen bottle (2), a flow control unit and a catalytic bed (5), wherein mixed helium and hydrogen are stored in the helium and hydrogen bottle (1) in advance; oxygen is stored in the oxygen bottle (2); flow of gas output in the two bottles is controlled through the flow control unit; a mixed gas of output helium, hydrogen and oxygen is subjected to catalytic reaction through the catalytic bed (5); oxygen and hydrogen react to generate water vapor and release hat; and helium, water vapor and oxygen remaining after reaction are heated and enter a storage tank to pressurize the storage tank.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

A kind of multifunctional aquatic first aid kit

ActiveCN111284653BIncrease buoyancyEnsure the need to breatheElectrolysis componentsVessel signalling devicesKit first aidElectrolysis

The invention relates to a multifunctional first aid kit on water, which includes a box body and a box cover, and the box cover is provided with a photovoltaic power generation panel and an operation panel, and the operation panel includes an air supply assembly, a signal assembly and a power supply assembly; the box The body includes a first chamber, a second chamber and a third chamber. The third chamber is located at the bottom of the box and is equipped with a battery connected to a photovoltaic power generation panel. The first chamber and the second chamber The chamber is arranged above the third chamber, and an oxygen generating device is vertically installed in the second chamber, and the oxygen generating device includes an oxygen pipe, a hydrogen pipe and a water inlet pipe between the two, the oxygen pipe and the The bottoms of the hydrogen pipes communicate with the bottoms of the water inlet pipes respectively. The bottom of the oxygen pipes is provided with a positive electrode electrolysis head, and the bottom of the hydrogen pipes is provided with a negative electrode electrolysis head. The oxygen generator is connected with the gas supply assembly on the operating panel. A wire groove is provided between the third chamber and the first chamber, and floating blocks are inserted symmetrically on both sides of the wire groove.

Owner:李爱群

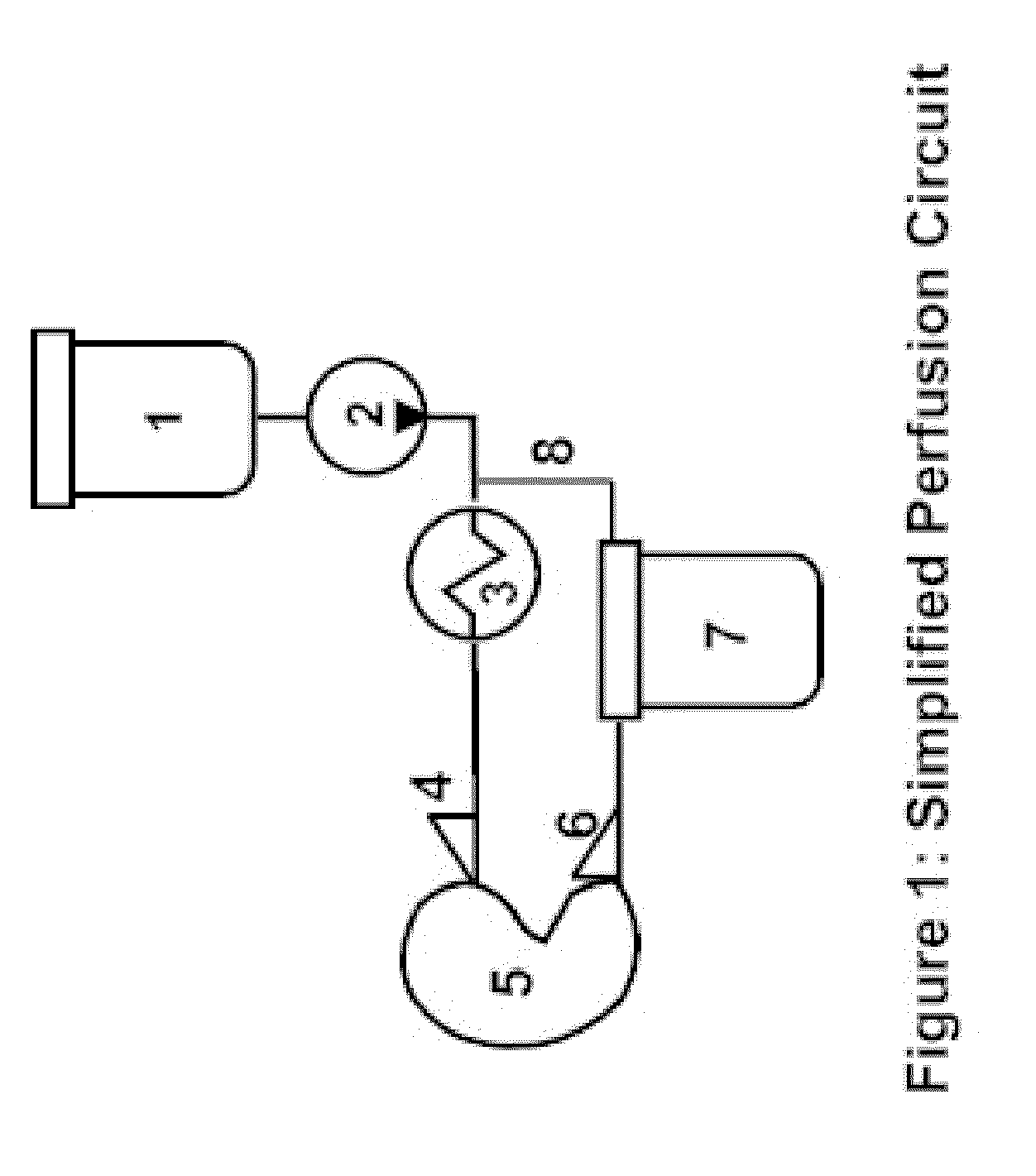

Method and apparatus for prevention of thermo-mechanical fracturing in vitrified tissue using rapid cooling and warming by persufflation

InactiveUS9314015B2Fast coolingRapid warmingDead animal preservationCryoprotectant toxicityHelium gas

A method and apparatus are disclosed for avoiding fracturing, e.g., thermo-mechanical fracturing, in vitrified biological systems via rapid cooling and / or warming persufflation techniques, by reducing the domain size of fracturing and by reducing thermal gradients. Also disclosed is a system adapted to rapidly cool and warm vitrifiable vascular biological tissue by persufflation, significantly reducing cryoprotectant toxicity from that of surface cooled tissue, in which the system is constructed and configured to use one or more of helium gas, hydrogen gas, neon gas, argon gas, krypton gas, xenon gas, oxygen gas, or various gaseous compounds. The system can be operated under pressure to increase the density and heat capacity of the gas relative to its density and heat capacity at atmospheric pressure and to cool the gas by one or more of mechanical action and by the phase change of a material such as a cryogenic gas or solid.

Owner:ARIGOS BIOMEDICAL

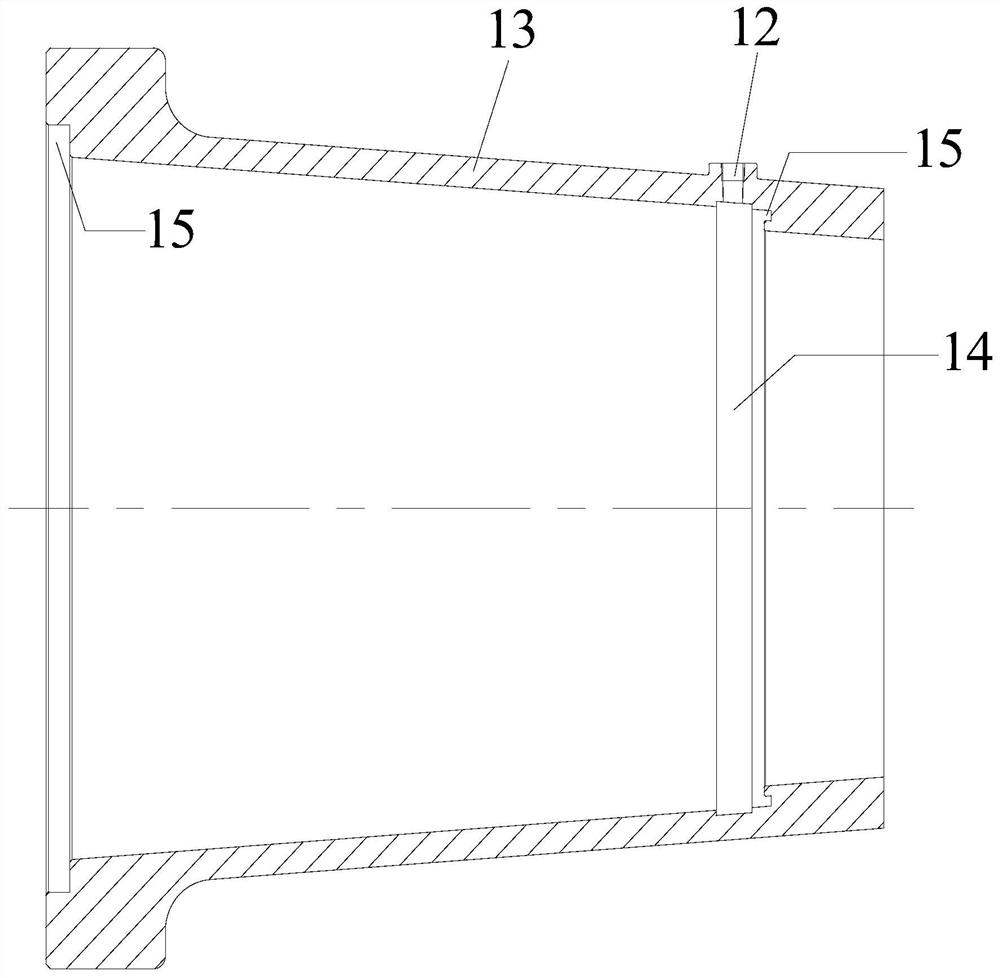

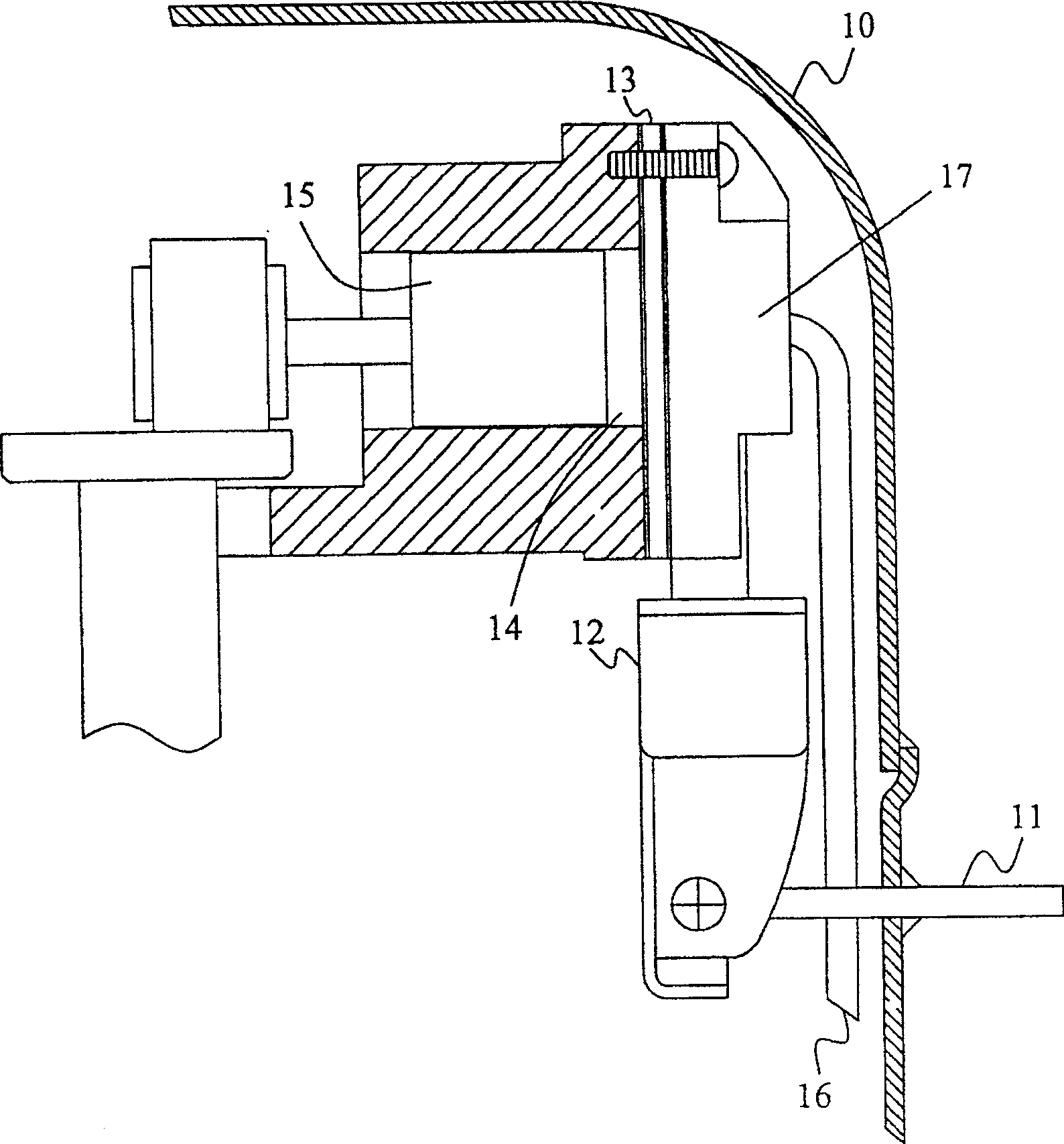

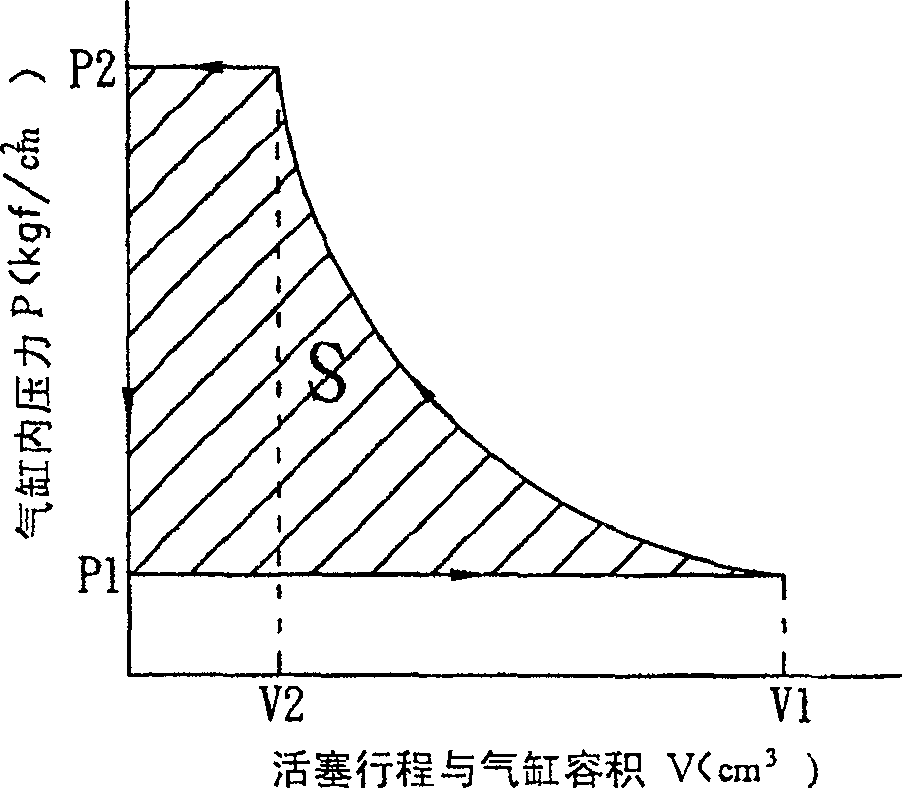

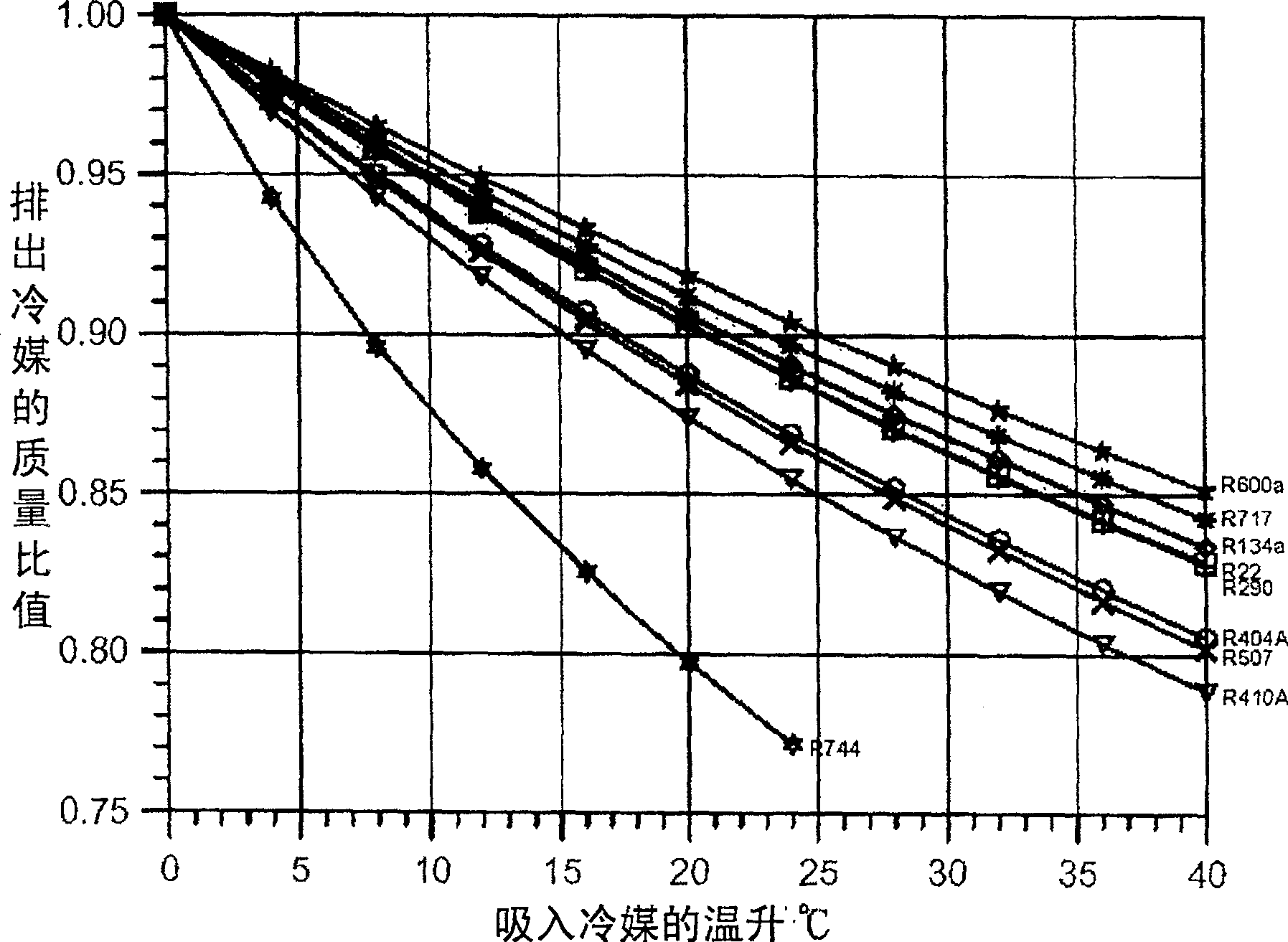

Air inlet structure of reciprocating compressor

ActiveCN100491723CIncrease gas densityIncrease the amount of refrigerantPositive displacement pump componentsMulti-stage pumpsEngineeringHigh pressure

An air inlet structure for the reciprocating compressor in order to decrease the power needed by compression and the load of condenser features that the low-temp and -pressure cold medium gas coming from evaporator can flow through low-pressure cold medium inlet tube, is then directly and quickly sucked into a compressing cylinder, and finally is compressed. It is not mixed with the high-temp cold medium gas in compressor.

Owner:IND TECH RES INST

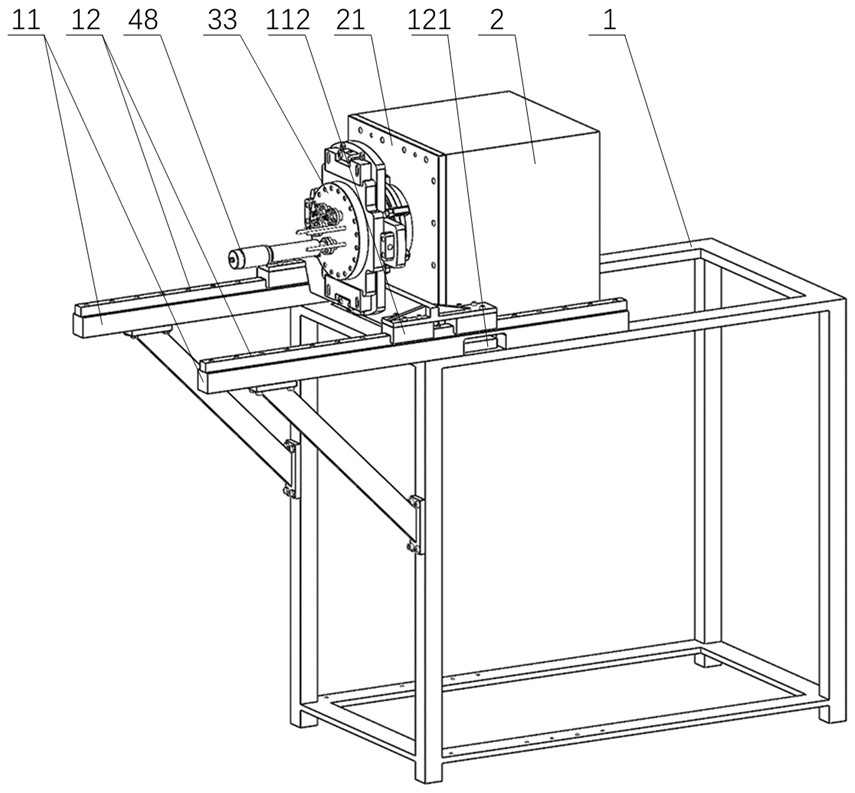

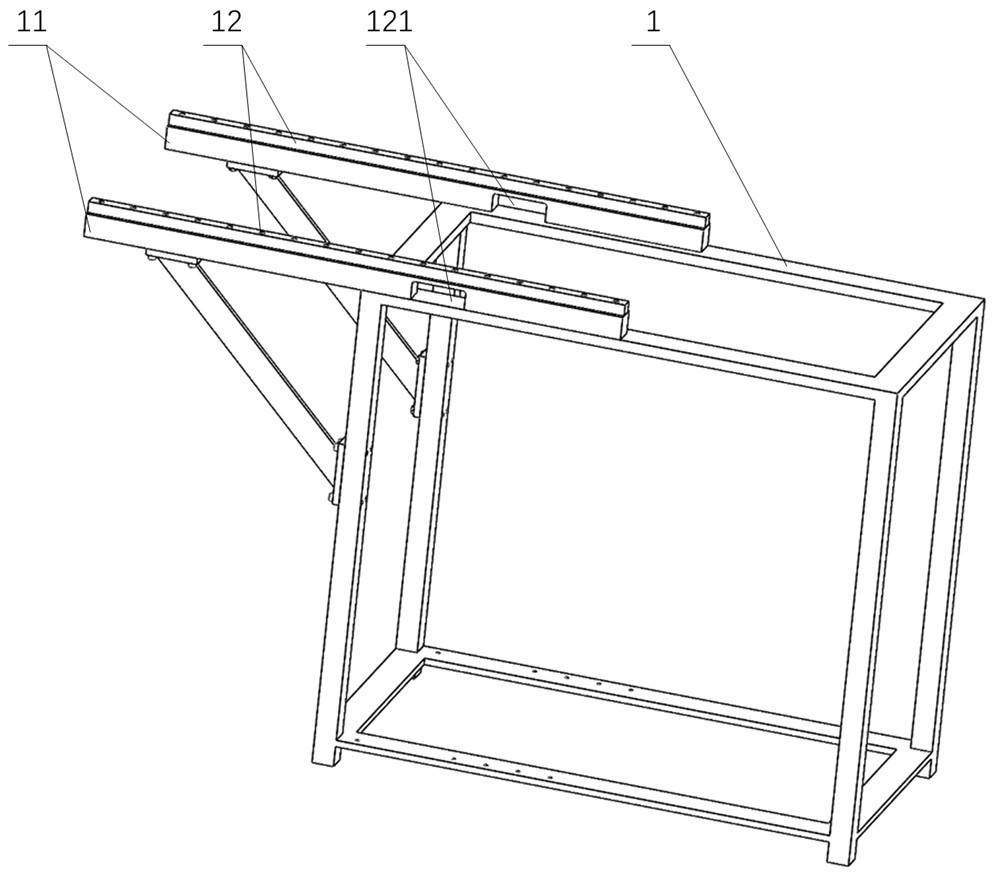

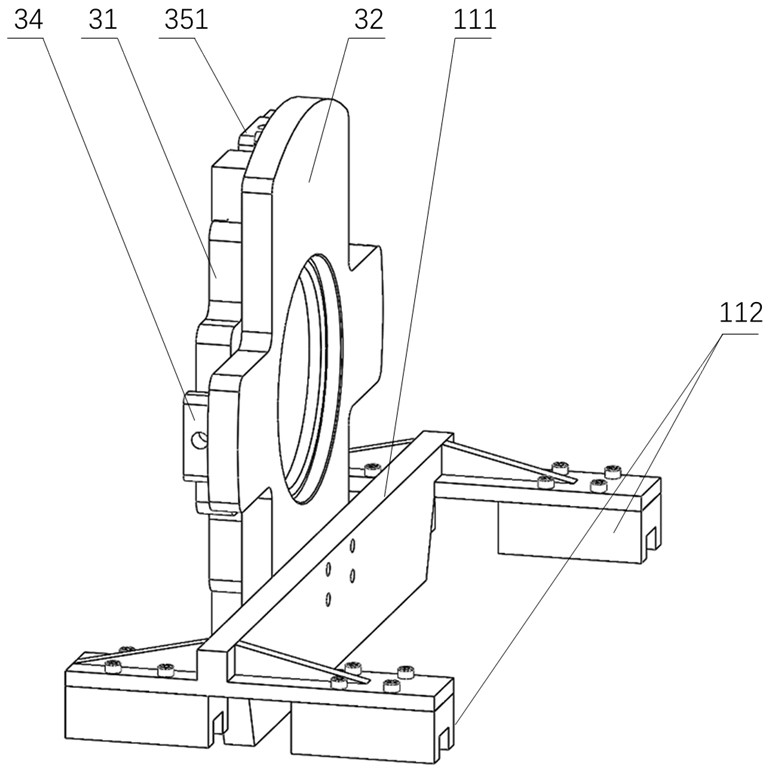

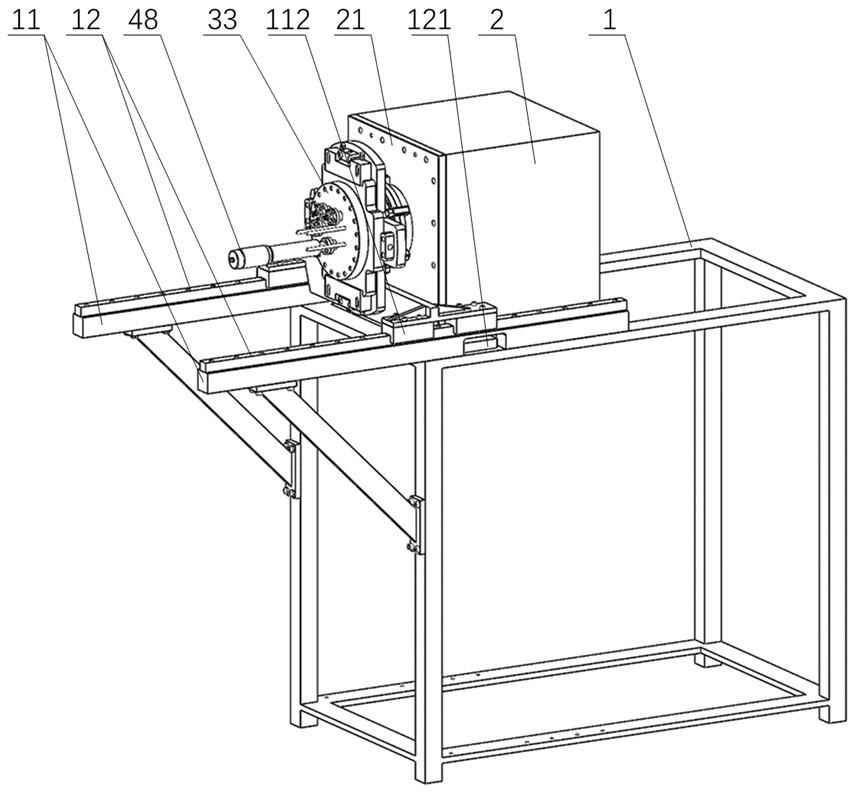

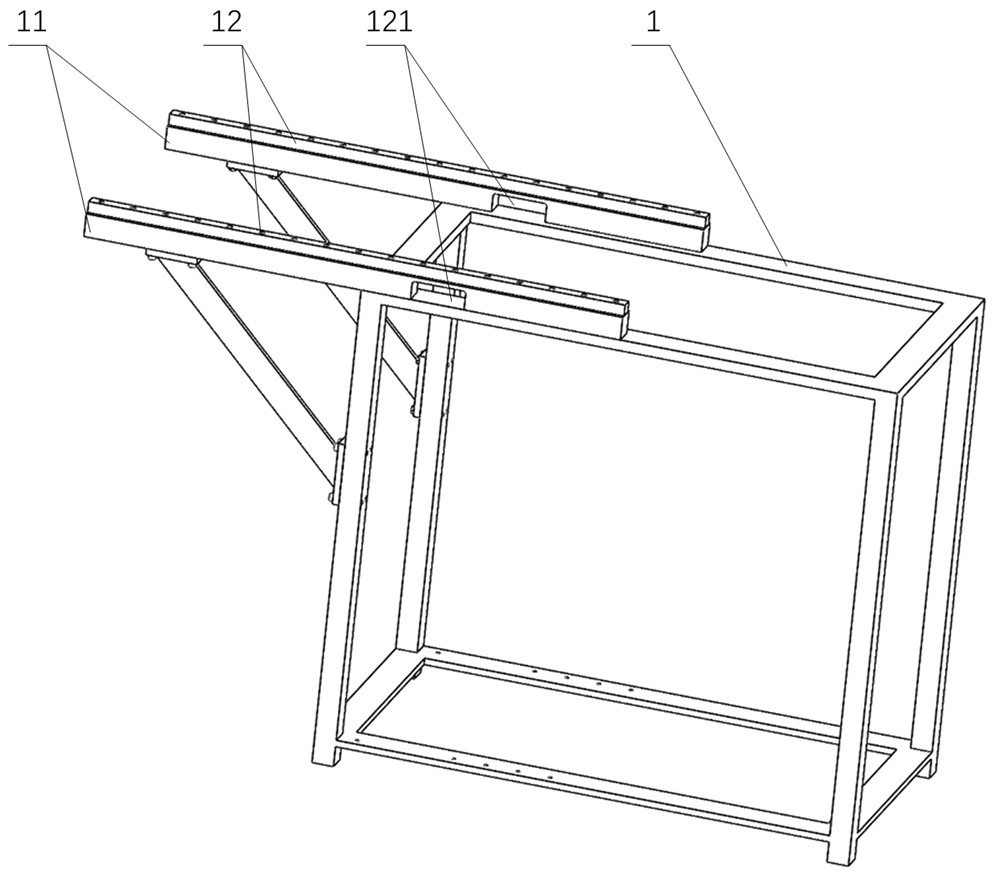

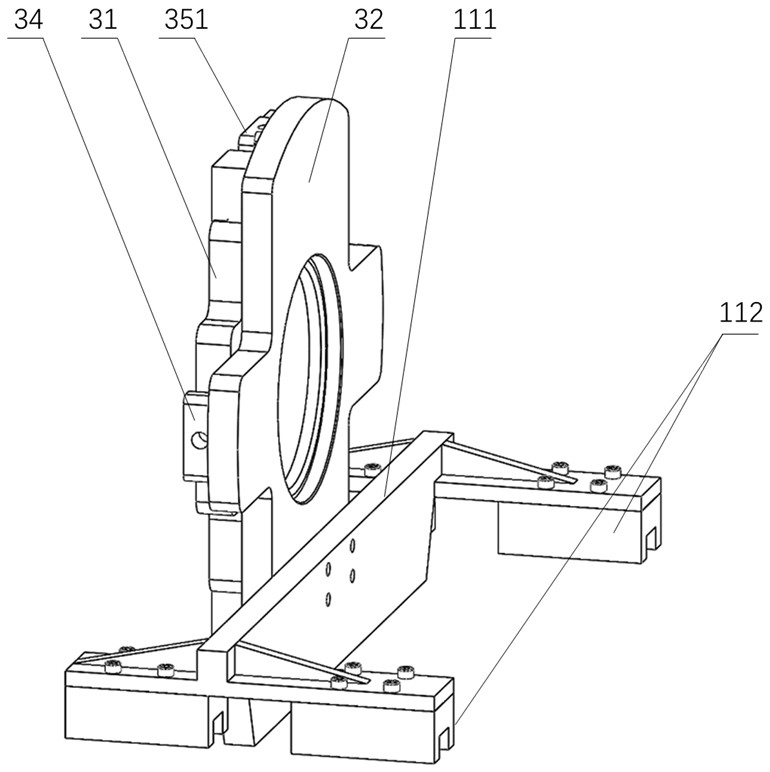

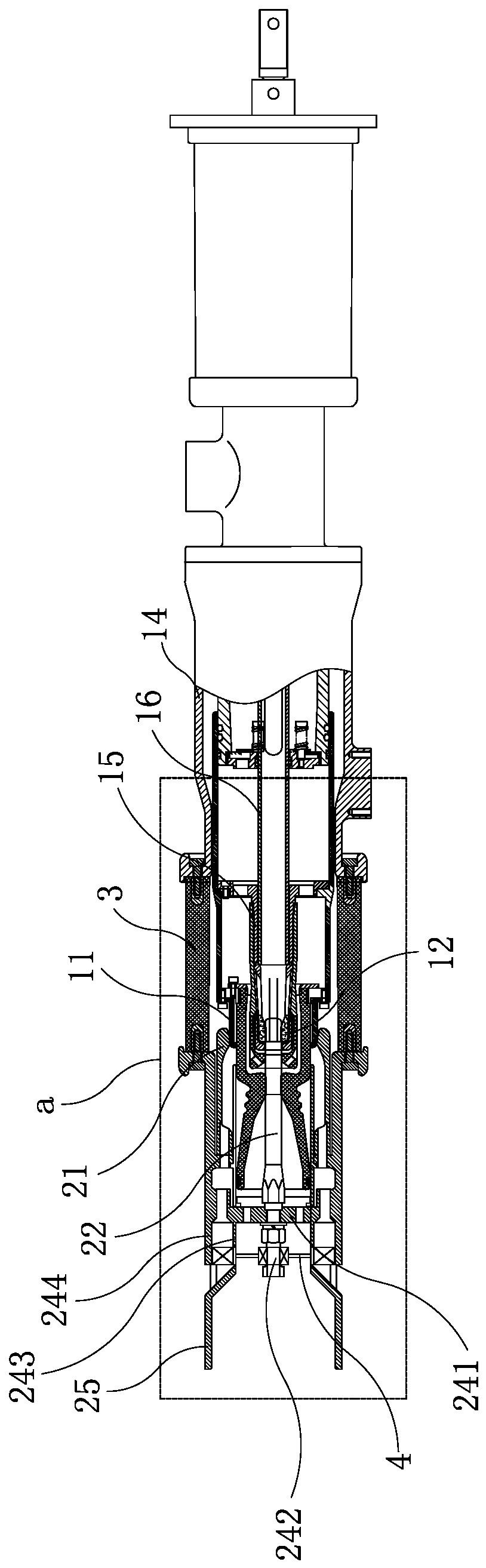

A low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source

ActiveCN113908771BShort stayFast heating ratePressure vessel componentsSub-atmospheric pressure processesGraphite electrodeGraphite

The invention belongs to the technical field of pyrolysis instruments, in particular to a low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source. It includes a test bench, an installation mechanism, a flash pyrolysis mechanism and a vacuum box; the flash pyrolysis mechanism includes a cylindrical cavity horizontally arranged in the vacuum box, and a sample injection pipe, a water inlet pipe and a water outlet pipe arranged in the cylindrical cavity, and a water cooling chamber It is slidably arranged in the cavity at the other end of the cylindrical cavity, the other end of the injection tube penetrates the water cooling cavity, and the extension end is connected with a silicon carbide tube, and a pair of graphite electrodes is sleeved on the silicon carbide tube; the extension end of the push rod of the linear introducer A sliding table is arranged in the corresponding cylindrical cavity, the extension end of the push rod is fixedly connected with the sliding block, and the upper end of the sliding block is fixedly connected with the corresponding sampling tube. The silicon carbide tube of the invention is used as a reactor, and the graphite electrode is heated to realize rapid temperature rise and reduce secondary reactions, and can reduce the annihilation of active and important reaction intermediates such as free radicals under low pressure, and can realize continuous sampling and improve the reaction power of pyrolysis samples. study research.

Owner:UNIV OF SCI & TECH OF CHINA

Low-pressure flash pyrolysis flow tube reaction device based on continuous molecular beam source

ActiveCN113908771AShort stayLow residence time for shorter, gas densityPressure vessel componentsSub-atmospheric pressure processesCarbide siliconGraphite electrode

The invention belongs to the technical field of pyrolysis instruments, and particularly relates to a low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source. The device comprises a test bed, a mounting mechanism, a flash pyrolysis mechanism and a vacuum box; the flash pyrolysis mechanism comprises a cylindrical cavity horizontally arranged in the vacuum box, and a sample injection pipe, a water inlet pipe and a water outlet pipe which are arranged in the cylindrical cavity, the water cooling cavity is slidably arranged in a cavity body at the other end of the cylindrical cavity, the other end of the sample injection pipe penetrates through the water cooling cavity, the extending end of the sample injection pipe is connected with a silicon carbide pipe, and the silicon carbide pipe is sleeved with a pair of graphite electrodes; and a sliding table is arranged in the cylindrical cavity corresponding to the extension end of a push rod of the linear introducer, the extension end of the push rod is fixedly connected with a sliding block, and the upper end of the sliding block is fixedly connected with a corresponding sample injection pipe. The silicon carbide tube is used as a reactor, the graphite electrode is used for heating, rapid heating is achieved, secondary reaction is reduced, annihilation of active and important reaction intermediates such as free radicals can be reduced under low pressure, continuous sampling can be achieved, and reaction kinetics research of pyrolysis samples can be perfected.

Owner:UNIV OF SCI & TECH OF CHINA

Arc extinguishing chamber insulation auxiliary structure

PendingCN109935495AExtended service lifeHigh dielectric strengthHigh-tension/heavy-dress switchesAir-break switchesImpellerEngineering

The invention discloses an arc extinguishing chamber insulation auxiliary structure, which comprises a moving end part, a static end part, an impeller and an insulating support seat connecting the moving end part and the static end part. The two ends of the insulating support seat are respectively connected with a static contact seat and a pressure cylinder. The insulating support seat sleeves a nozzle of the moving end part, and a chamber is formed between the insulating support seat and the nozzle. A fixed plate of the static contact seat is provided with an air outlet communicated with thenozzle, and the fixed plate of the static contact seat is also provided with an air inlet communicated with the chamber and located outside the air outlet. The impeller rotationally fits the outer endface of the fixed plate, and the air outlet and the air inlet of the fixed plate correspond to the inner blade and the outer blade of the impeller respectively. The decline of the insulation performance of the insulating support seat can be avoided.

Owner:XUJI XIAMEN INTELLIGENT SWITCHGEAR MFG +1

Formation method of semiconductor structure

ActiveCN105374742ALow densityPrevent from being etchedSemiconductor/solid-state device manufacturingEtchingLithographic artist

A formation method of a semiconductor structure comprises the following steps of providing a substrate, wherein a through hole is formed in the substrate; forming metal layers on a substrate surface, a through hole bottom and a sidewall surface; providing a lithography processing chamber, wherein pressure in the lithography processing chamber and pressure outside the lithography processing chamber possess a pressure difference, a pressure difference lithography technology is adopted in the lithography processing chamber, a photoresist layer is formed on a part of the metal layer surfaces, the photoresist layer closes the through hole and a gas is arranged in the through hole; taking the photoresist layer as a mask film, etching the metal layers till that a substrate surface is exposed and taking the residual metal layers as a redistribution layer; and removing the photoresist layer. By using the method of the invention, quality of the formed photoresist layer is increased; a thickness of the photoresist layer is avoided to be too thin or fracture is avoided; unnecessary etching to the metal layers of the through hole bottom and the sidewall surface is avoided too; quality of the formed redistribution layer is improved so that reliability and electric performance of the semiconductor structure are increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com