Air inlet structure of reciprocating compressor

A technology of air intake structure and compressor, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of reduced refrigerant volume, increased refrigerant temperature, and decreased compressor efficiency, and achieves increased refrigeration. ability, the effect of increasing the amount of working fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

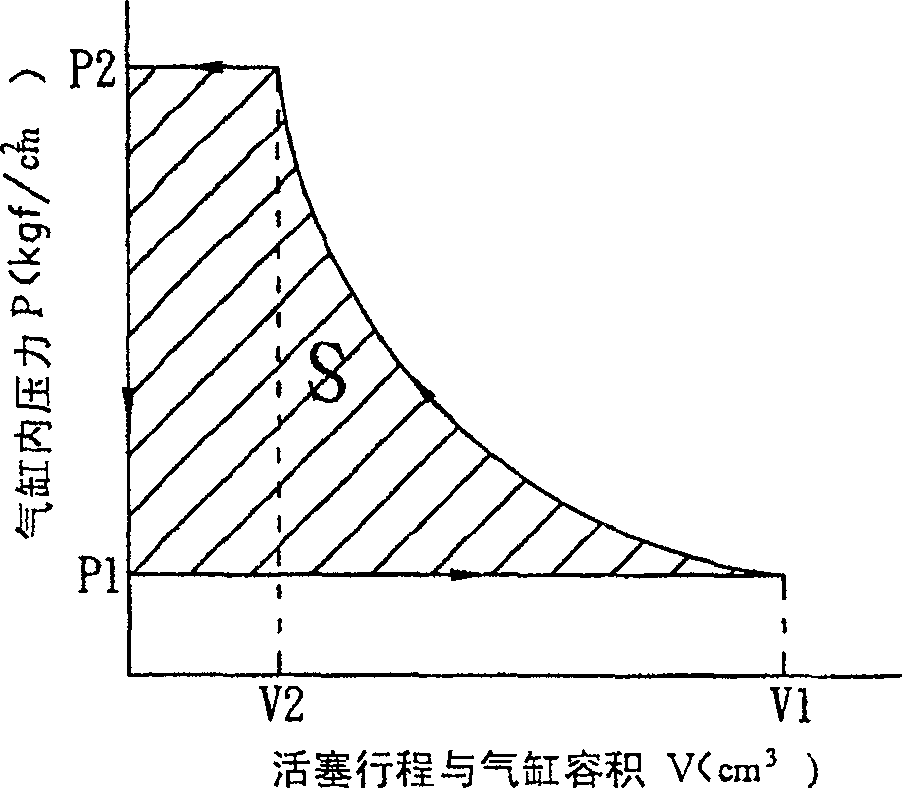

[0035] According to the intake structure of the reciprocating compressor disclosed in the present invention, firstly, according to the theoretical compression work of piston compression, please refer to figure 2 As shown, the compression work required for one compression of the piston is roughly the same no matter whether the temperature of the sucked refrigerant is higher or lower. In a reciprocating compressor, the low-temperature and low-pressure refrigerant gas entering the cylinder becomes high-temperature and high-pressure refrigerant gas after being compressed by the piston. The compression work required for one piston compression is the area of the cross-sectional area S in the figure. The state of the refrigerant gas during the piston compression movement:

[0036] ( P 2 P 1 ) = ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com