Low-pressure flash pyrolysis flow tube reaction device based on continuous molecular beam source

A technology of reaction device and flow tube, which is applied in the field of low-pressure flash pyrolysis flow tube reaction device, can solve the problems of high complete decomposition temperature, failure to reach pyrolysis reaction, easy annihilation, etc., achieve high initial decomposition temperature and reduce secondary The effect of short reaction and residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

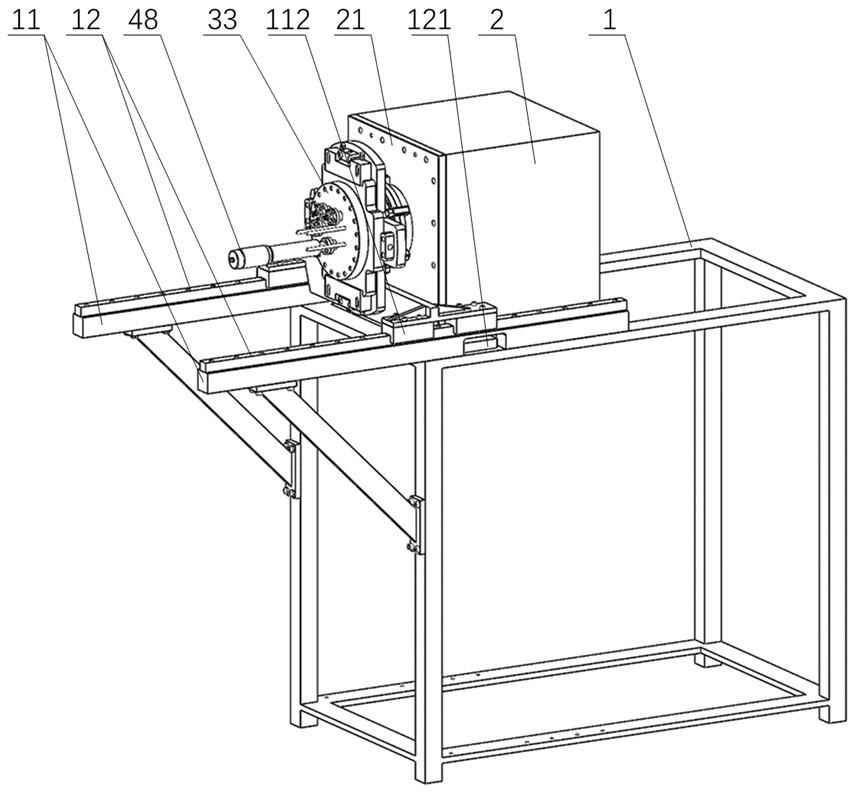

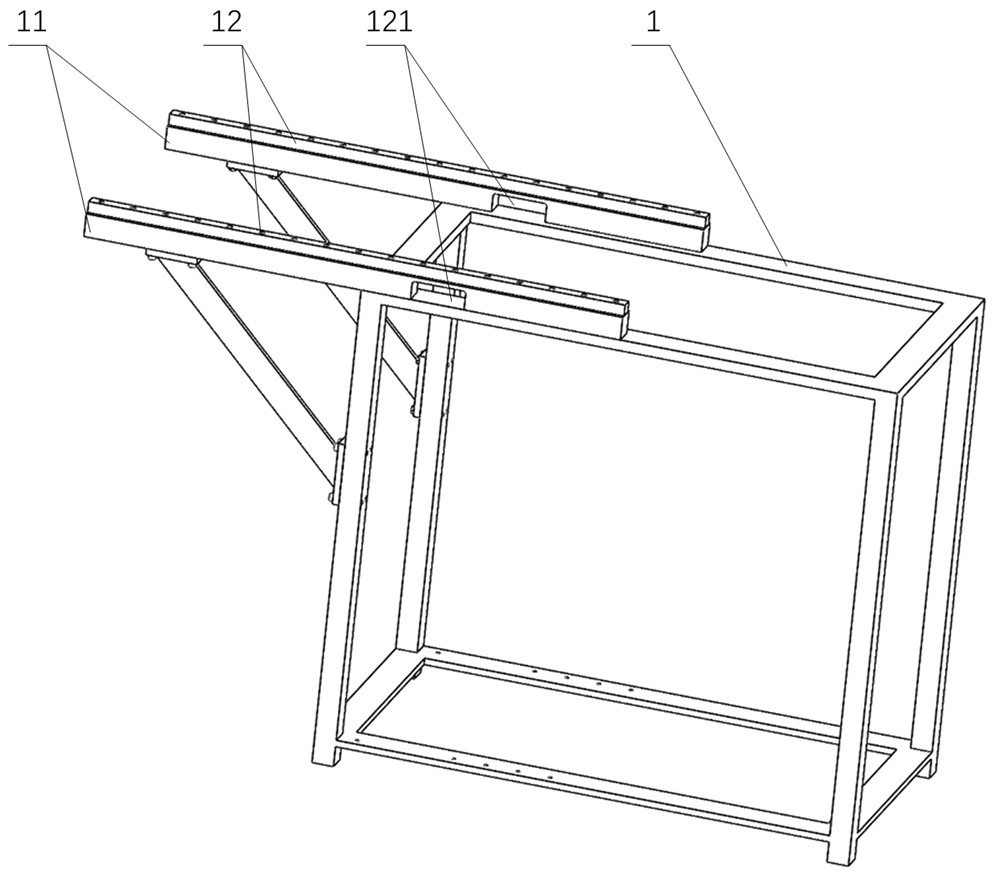

[0044] See figure 1 , figure 2 and image 3 , a low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source, comprising a cube-shaped test bench 1, a mounting mechanism, a flash pyrolysis mechanism and a vacuum box 2, and the vacuum box 2 passes through a slide frame 11 and a The cooperating sliding of slide rail 12 is arranged on the upper end of test bench 1; test bench 1 is quite convenient for moving the instruments, and a pair of slide rails 12 can reduce a large amount of disassembly workload and reduce the time wasted due to disassembly and assembly of instruments.

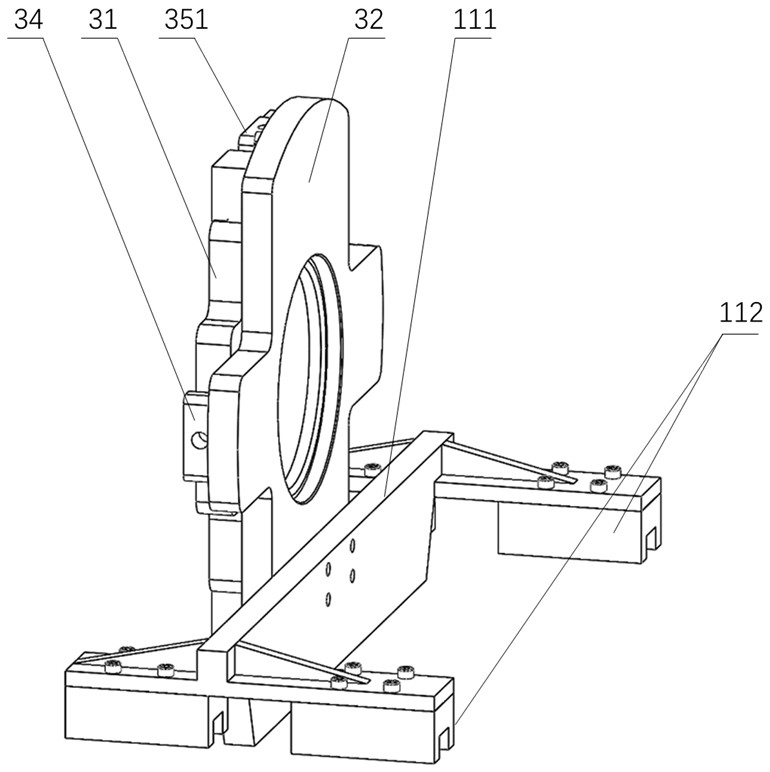

[0045] See Figure 4 and Figure 5 , the installation mechanism includes a first support plate 31, a second support plate 32 and an adjustment mechanism, and the first support plate 31 is adjustable on one side of the second support plate 32 through the adjustment mechanism, and the second support plate 32 The other side is fixedly installed on the front end face ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com