Patents

Literature

31results about How to "Raise the initial decomposition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane sealant

InactiveCN107987781AImprove water resistanceGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCarbamateOligomer

The invention relates to a polyurethane sealant. The polyurethane sealant comprises a component A and a component B, wherein the component A adopts a formula as follows: 20-30 parts of a TDI prepolymer, 30-50 parts of an NDI prepolymer, 20-30 parts of hydroxyl-terminated polybutadiene, 60-90 parts of polyether 220 and 10-20 parts of a plasticizer; the component B adopts a formula as follows: 30-50parts of a filler, 10-20 parts of a chain extender, 1-3 parts of a dispersant, 2-5 parts of a heat stabilizer, 0.5-1 part of a light stabilizer, 0.2-0.5 part of a catalyst and 1-3 parts of A-151. Inthe polyurethane sealant, the polyether 220 and the hydroxyl-terminated polybutadiene form a soft segment to improve the elasticity of the sealant; the small molecular chain extender is added and reacts with the TDI prepolymer and the NDI prepolymer to produce an oligomer of carbamate, so that the hardness is achieved, the initial decomposition temperature is increased, and the heat stability of the polyurethane sealant is improved; the polyurethane sealant has the advantages of good water resistance, long service life and high strength.

Owner:苏州炽蓝生物科技有限公司

Method for prepring and modifying high heat-resistant aluminium hydroxide

InactiveCN1915825AImprove heat resistanceRaise the initial decomposition temperatureAluminium oxides/hydroxidesPolymer sciencePhosphate

This invention relates to a method for preparing and modifying Al (OH) 3 flame retardant. The method adopts rare earth coupler as the modifier, or rare earth coupler and phosphate compounds as the composite modifier, and utilizes wet or dry technique to prepare and modify Al (OH) 3 flame retardant. The method can largely improve heat resistance of Al (OH) 3 as well as raise its initial decomposing temperature, and the obtained Al (OH) 3 flame retardant can be widely used in rubber and plastic industiries. The method utilizes one-time surface modification instead of multi-step organic / inorganic modification, thus simplifying the modification process. Besides, the method also raises the activity index of the obtained Al (OH) 3 flame retardant, and reduces its oil-aborbency.

Owner:HUIZHOU UNIV

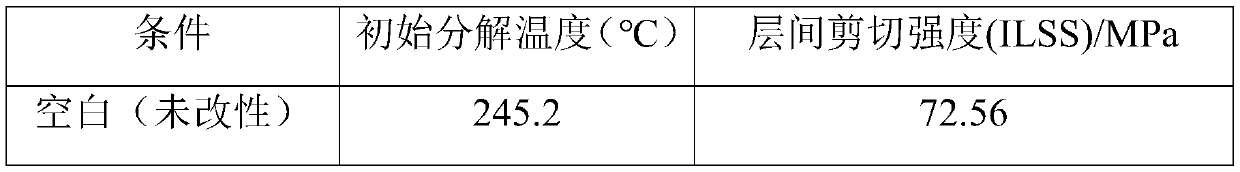

Silicone resin composition for prepregs, carbon fiber prepreg and carbon fiber-silicone resin composite material

The invention provides a silicone resin composition for prepregs, a carbon fiber prepreg and a carbon fiber-silicone resin composite material, relating to a silicone resin composition, a carbon fiber prepreg prepared from the silicone resin composition and a silicone resin composite material. The invention aims to solve the problems of poor high-temperature resistance and single function in the existing silicone resin-carbon fiber composite material. The composition comprises the silicone resin, a phenolic resin, a toughener, a functional filler, a coupling agent and a catalyst. The carbon fiber prepreg comprises a carbon fiber material and the composition for prepregs. The carbon fiber-silicone resin composite material is prepared by curing the carbon fiber prepreg. The curing method comprises winding molding, cast molding or compression molding. The carbon fiber prepreg is cured to obtain the carbon fiber composite material. The carbon fiber composite material has favorable mechanical properties and high-temperature resistance. The silicone resin composition is applicable to the field of silicone resin-carbon fiber composite materials.

Owner:HARBIN INST OF TECH

Method for preparing core-shell type silicon dioxide coated ammonium phosphate based on reversed-phase micro-emulsion method

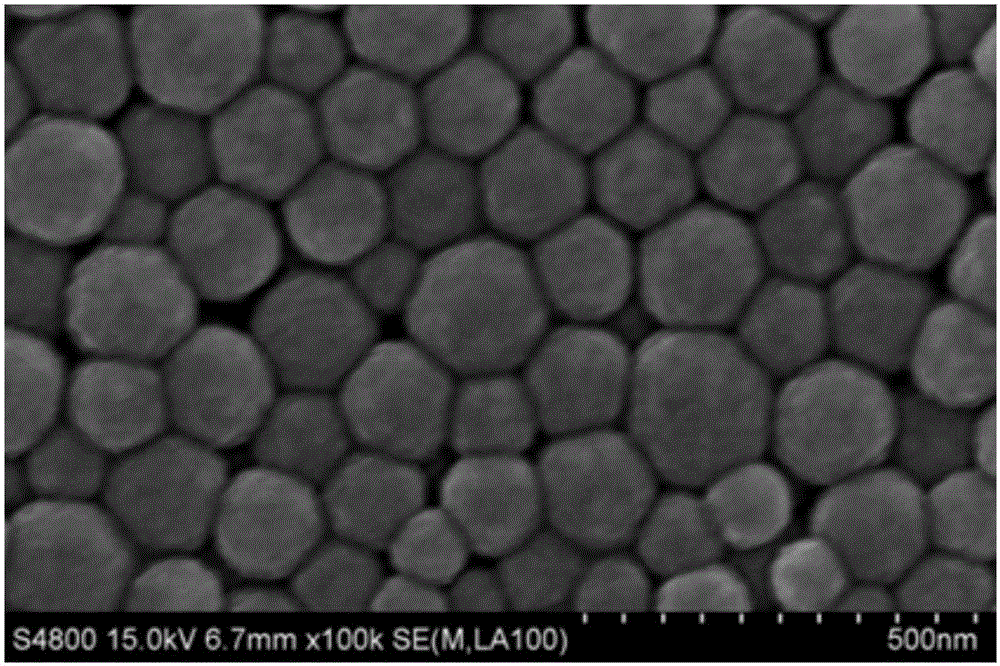

InactiveCN105504879AImprove thermal stabilityLow water solubilityPigment physical treatmentPigment treatment with non-polymer organic compoundsTetraethyl orthosilicateEmulsion

The invention discloses a method for preparing core-shell type silicon dioxide coated ammonium phosphate based on a reversed-phase micro-emulsion method. The method comprises the following steps: (1) preparing reversed-phase micro-emulsion A of non-ionic surfactant / n-hexane / phosphoric acid; (2) preparing reversed-phase micro-emulsion B of non-ionic surfactant / n-hexane / ammonia water; (3) mixing the reversed-phase micro-emulsion A and the reversed-phase micro-emulsion B to obtain dispersion liquid of nano-particles; (4) dropwise adding a n-hexane solution of tetraethyl orthosilicate into the dispersion liquid of the nano-particles to obtain dispersion liquid of core-shell type silicon dioxide coated ammonium phosphate; and (4) dropwise adding a n-hexane solution of a silane coupling agent into the dispersion liquid of the core-shell type silicon dioxide coated ammonium phosphate, and then carrying out emulsion breaking, separation and drying treatments to obtain surface modified core-shell type silicon dioxide coated ammonium phosphate. The particle size of the core-shell type silicon dioxide coated ammonium phosphate prepared by the method disclosed by the invention can be controlled to be 100-800nm, and the core-shell type silicon dioxide coated ammonium phosphate is relatively small in particle size, narrow in distribution and good in dispersity.

Owner:王虹 +1

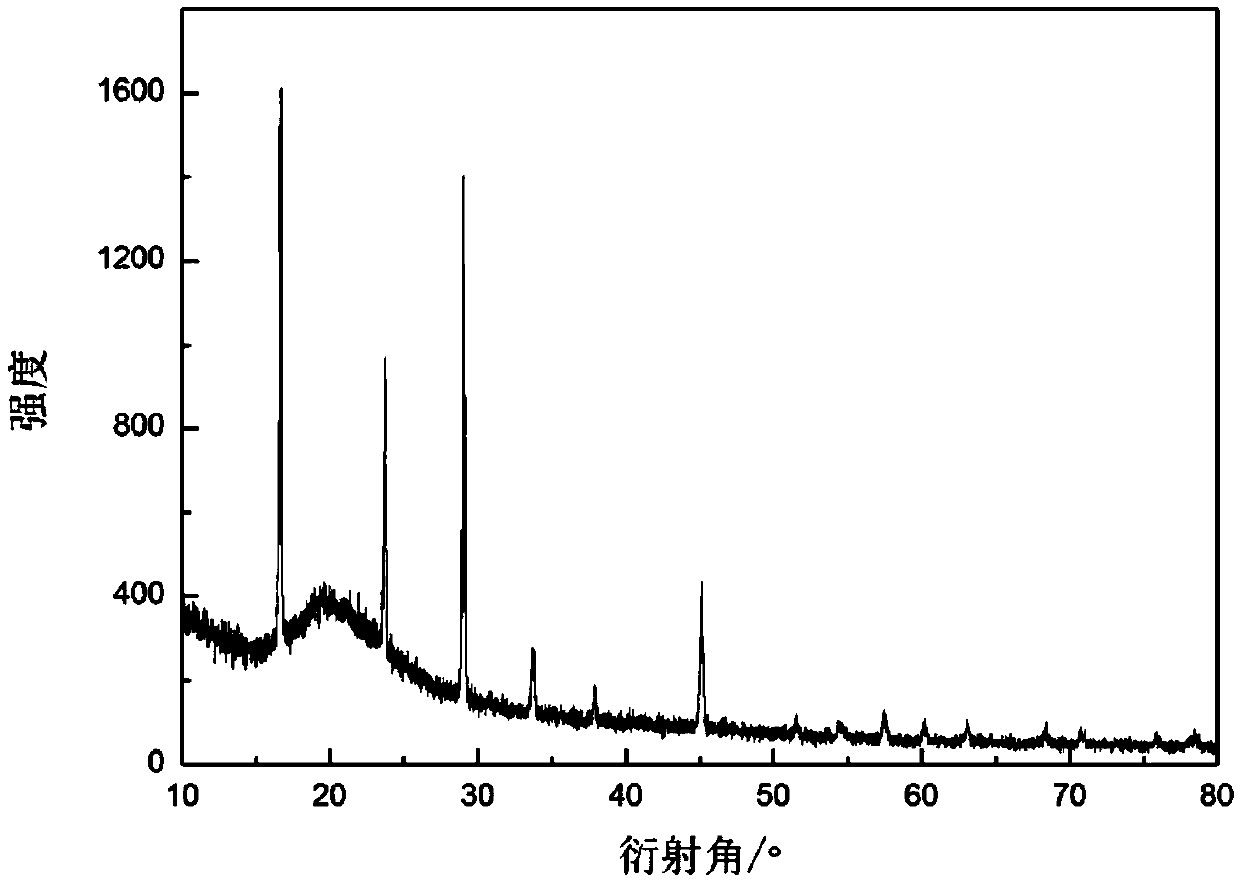

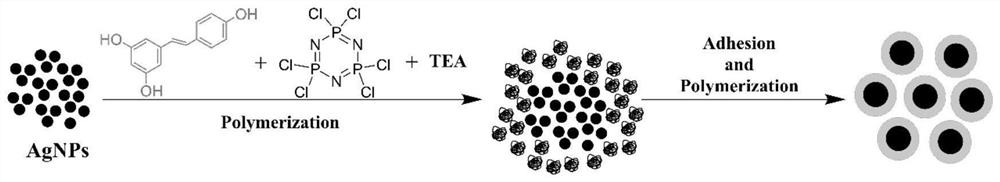

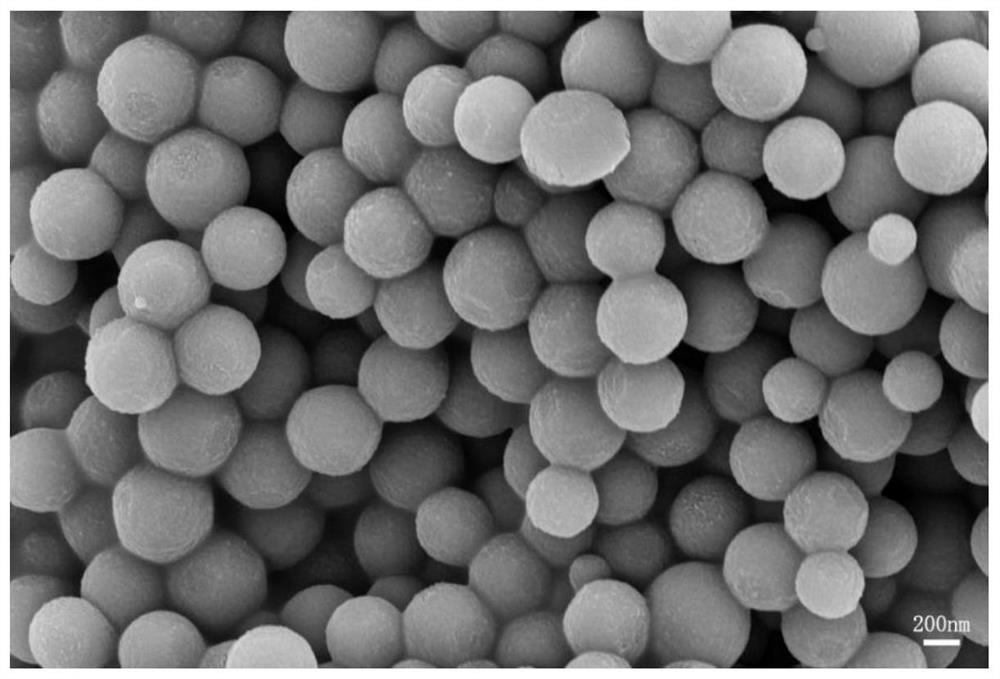

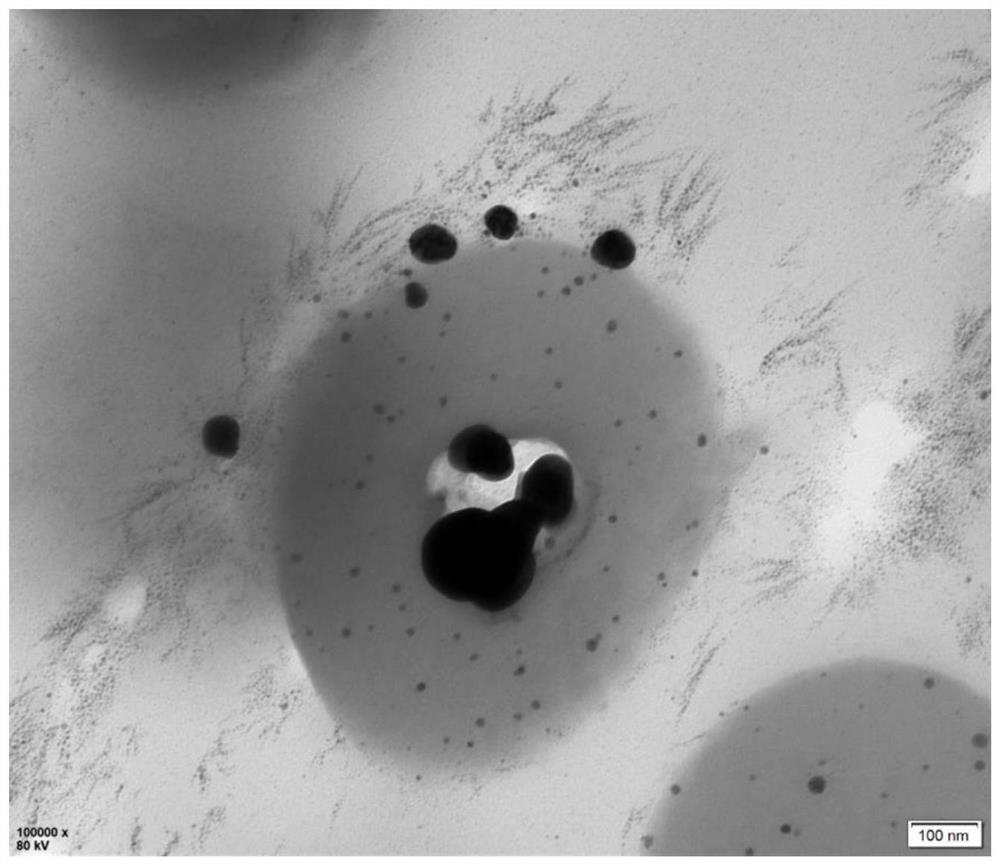

Silver-loaded polyphosphazene microsphere with mesoporous core-shell structure as well as preparation method and application of silver-loaded polyphosphazene microsphere

InactiveCN112841221AUniform particle sizeSimple preparation processBiocideNanotechnologyMicrosphereOrganosolv

The invention relates to the technical field of nano antibacterial materials, in particular to a silver-loaded polyphosphazene microsphere with a mesoporous core-shell structure and a preparation method and an application thereof. The preparation method comprises the following steps that 1, a protective agent and a dispersing agent are added into a silver nitrate solution and stirred to be uniform, heating is conducted to 30-90 DEG C, then a reducing agent is dropwise added, a reaction is conducted in a dark place, centrifugal separation is conducted, obtained sediment is washed with a washing agent, and drying is carried out in vacuum to obtain hard template single-phase nano silver particles; and (2) the hard template single-phase nano-silver particles are ultrasonically dispersed in an organic solvent, a dispersing agent, hexachlorocyclotriphosphazene and resveratrol are sequentially added, uniformly stirred, then an acid-binding agent is added, ultrasonic reaction and centrifugal separation are carried out, the obtained precipitate is washed with a detergent, and vacuum drying is carried out to obtain the silver-loaded polyphosphazene microsphere with the mesoporous core-shell structure. The prepared silver-loaded polyphosphazene microsphere with the mesoporous core-shell structure can achieve a long-acting sterilization effect, can improve the dispersibility of a nano material and reduce the biotoxicity of a silver-series antibacterial material, and can be applied as an antibacterial material.

Owner:ZHEJIANG UNIV OF TECH

Method for prepring and modifying high heat-resistant aluminium hydroxide

InactiveCN100391846CImprove heat resistanceRaise the initial decomposition temperatureAluminium oxides/hydroxidesPolymer sciencePhosphate

This invention relates to a method for preparing and modifying Al (OH) 3 flame retardant. The method adopts rare earth coupler as the modifier, or rare earth coupler and phosphate compounds as the composite modifier, and utilizes wet or dry technique to prepare and modify Al (OH) 3 flame retardant. The method can largely improve heat resistance of Al (OH) 3 as well as raise its initial decomposing temperature, and the obtained Al (OH) 3 flame retardant can be widely used in rubber and plastic industiries. The method utilizes one-time surface modification instead of multi-step organic / inorganic modification, thus simplifying the modification process. Besides, the method also raises the activity index of the obtained Al (OH) 3 flame retardant, and reduces its oil-aborbency.

Owner:HUIZHOU UNIV

High-temperature-resistant water-based environment-friendly adhesive and preparation method thereof

InactiveCN112980381ALow viscosityHigh bonding strengthPolyureas/polyurethane adhesivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses a high-temperature-resistant water-based environment-friendly adhesive and a preparation method thereof. The high-temperature-resistant water-based environment-friendly adhesive comprises the following raw materials in parts by weight: 60-80 parts of a modified polyurethane prepolymer, 30-40 parts of a modified acrylic resin, 10-20 parts of a coupling agent, 15-20 parts of polyvinyl alcohol, 20-30 parts of a cross-linking agent and 300-400 parts of deionized water. The preparation method comprises the following steps: S1, preparing a modified polyurethane base material; and S2, carrying out a cross-linking reaction by using deionized water as a solvent to obtain the high-temperature water-based environment-friendly adhesive. According to the invention, a modified polyurethane prepolymer containing a large number of benzene rings and silicon-oxygen bonds is prepared, so that the prepared adhesive has relatively large crosslinking density, relatively high bond energy and relatively good thermal stability; and the problem that in the prior art, the bonding strength of a waterborne polyurethane adhesive is reduced under the high-temperature condition is solved.

Owner:广州菩曦环保科技有限公司

Three-source intumescent flame retardant, hybrid intumescent flame retardant grafted therewith, and their preparation and application

The invention discloses a three-source intumescent flame retardant, a hybrid intumescent flame retardant formed by grafting layered double hydroxide and their preparation method and application, wherein the three-source intumescent flame retardant The general structural formula of the hybrid intumescent flame retardant or its graft modification is as follows: the three-source intumescent flame retardant or hybrid intumescent flame retardant is used for thermoplastic elastomers, rubber, polyolefin plastics, Aliphatic polyesters, epoxy resins and unsaturated resins not only do not need to be compounded when they are flame retardant, but also have an appropriate proportion of phosphorus, nitrogen, and carbon elements, high flame retardant efficiency, and good char formation, which can greatly reduce the flame retardant. The addition amount reduces the cost, has less influence on the mechanical properties of the substrate, and has better water resistance and higher initial decomposition temperature.

Owner:SICHUAN UNIV

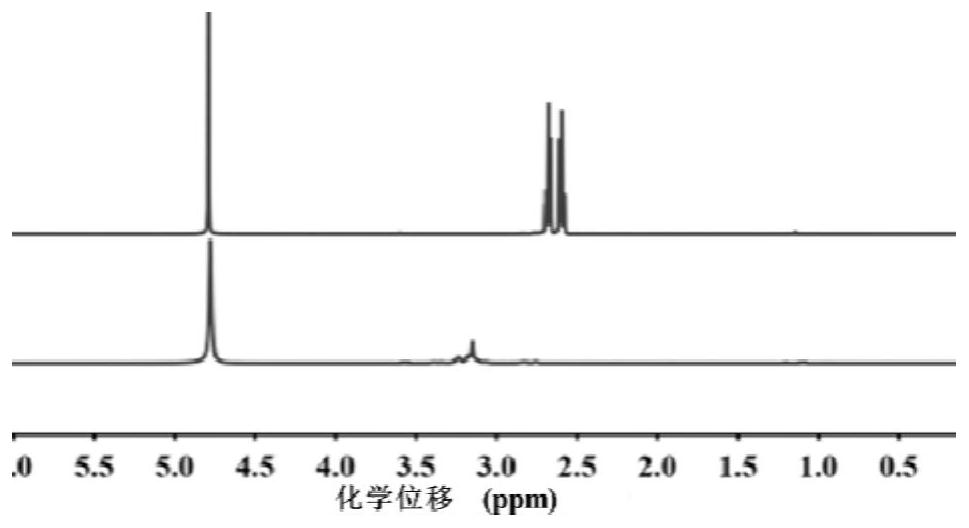

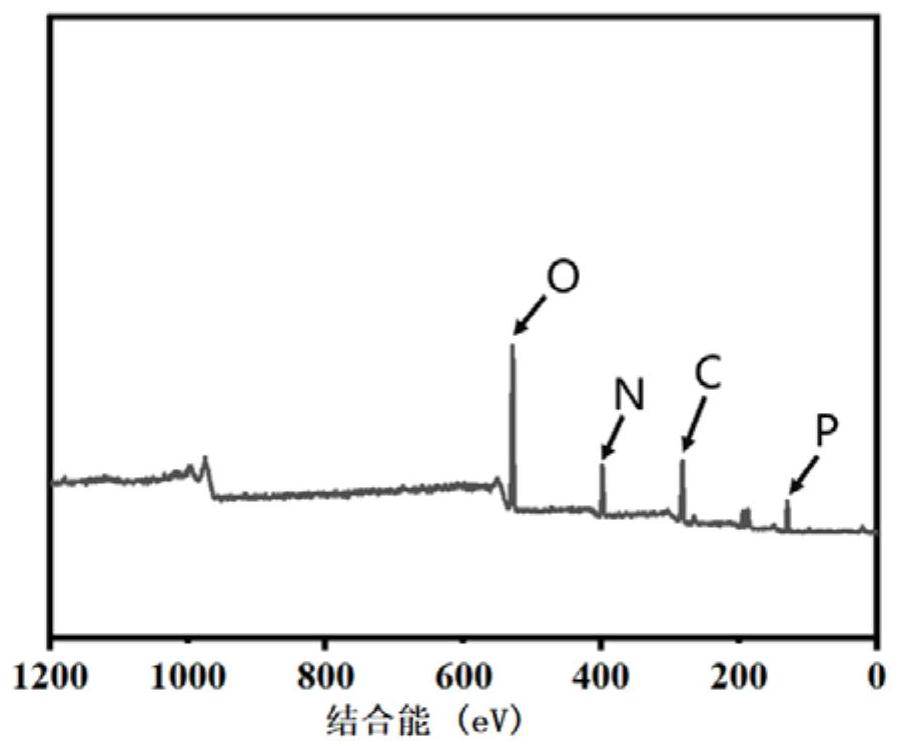

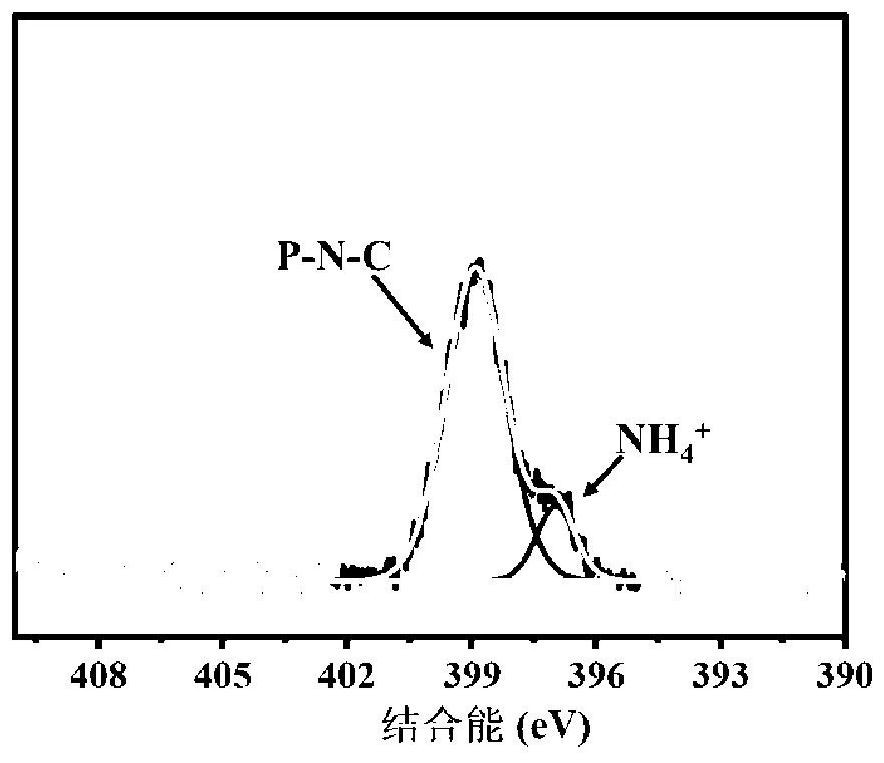

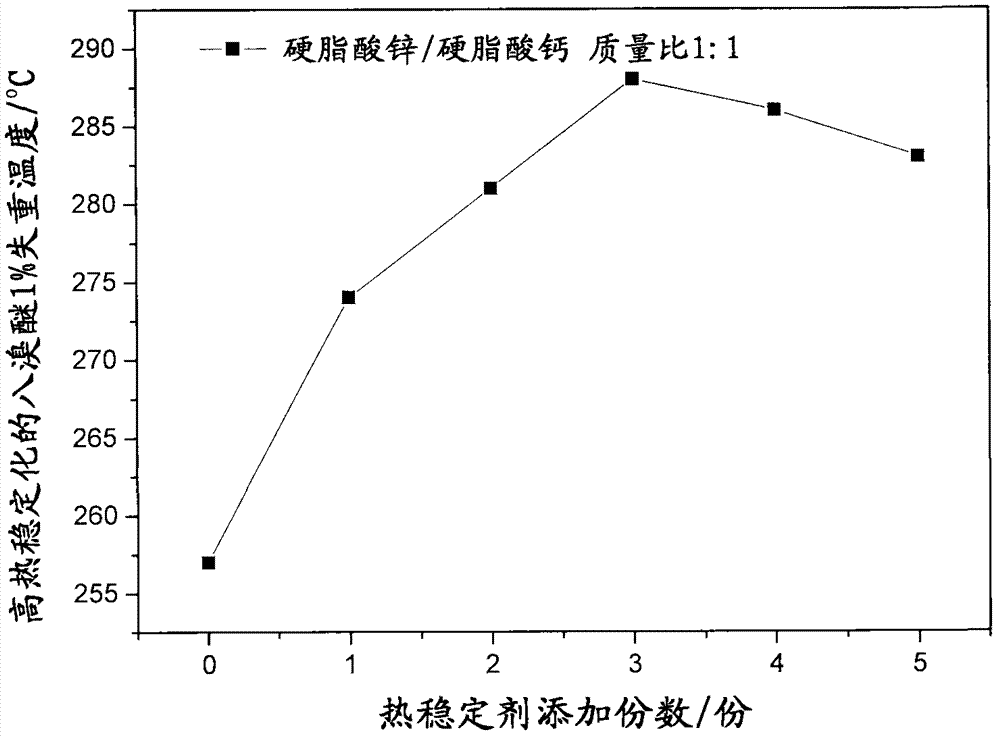

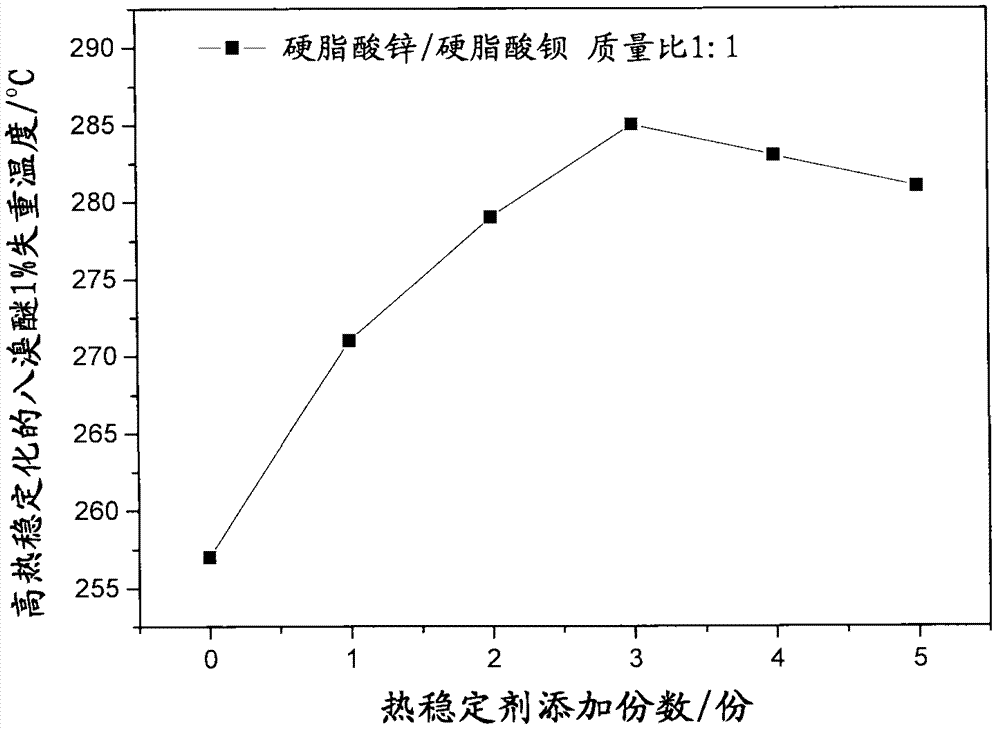

Preparation method of high thermostable eight bromo ether

Belonging to the technical field of preparing high thermostable materials by adding specific thermostable components into ordinary eight bromo ether, the invention relates to a preparation method of high thermostable eight bromo ether. The method of the invention employs a composite thermostable auxiliary agent of zine stearate / barium stearate or zine stearate / calcium stearate in a specific amount and a specific proportion, a composite anti-oxidant in a specific amount and a specific proportion, adds a specific kind of coupling agent, and adopts a high-speed mixer for high-speed stirring and blending so as to prepare a high thermostable eight bromo ether material, the 1% weight loss temperature of which is increased by 20-30DEG C.

Owner:山东兄弟科技股份有限公司

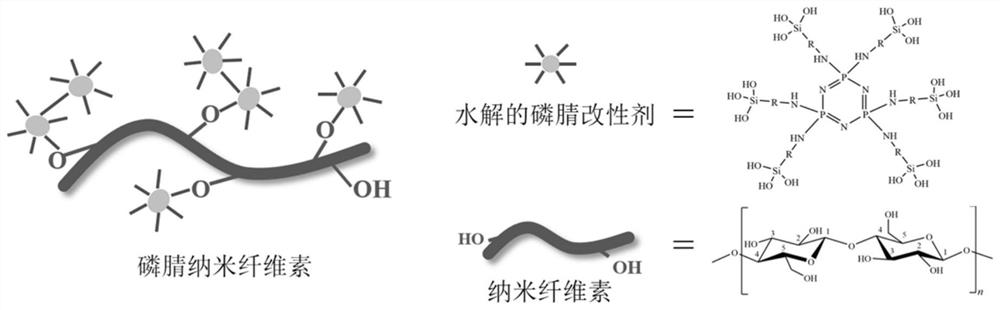

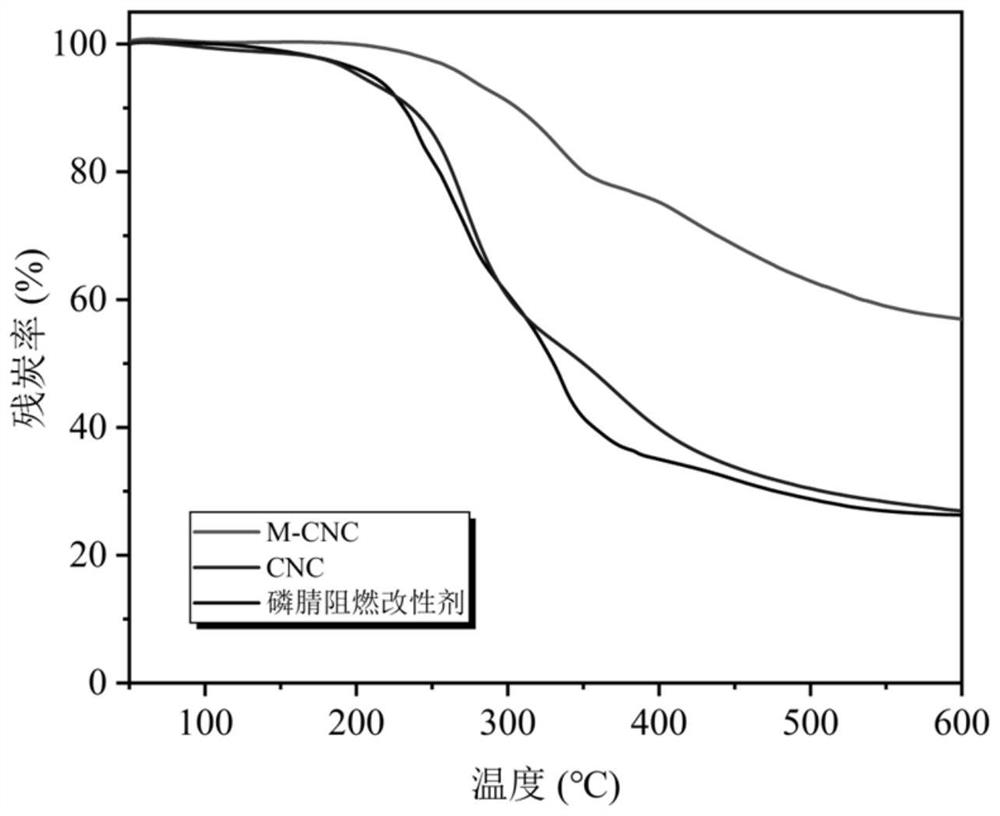

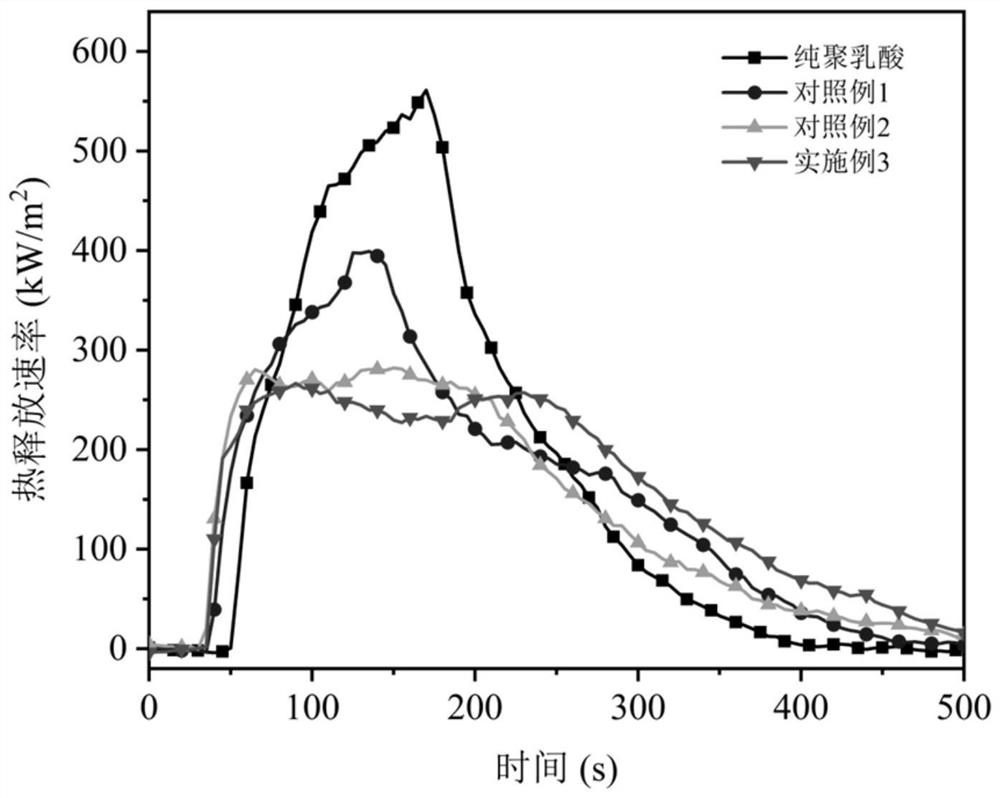

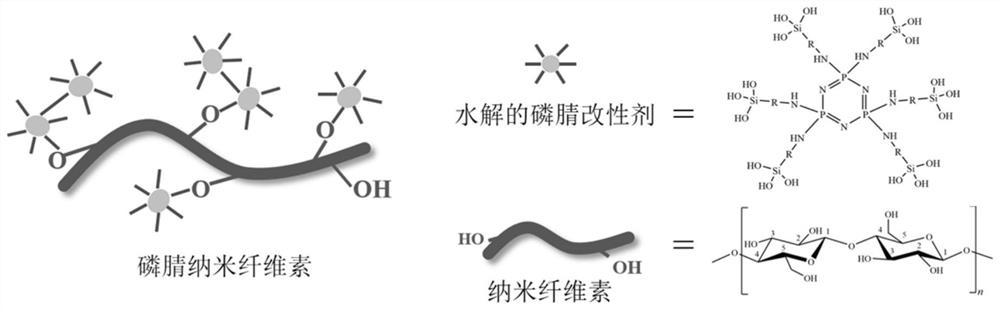

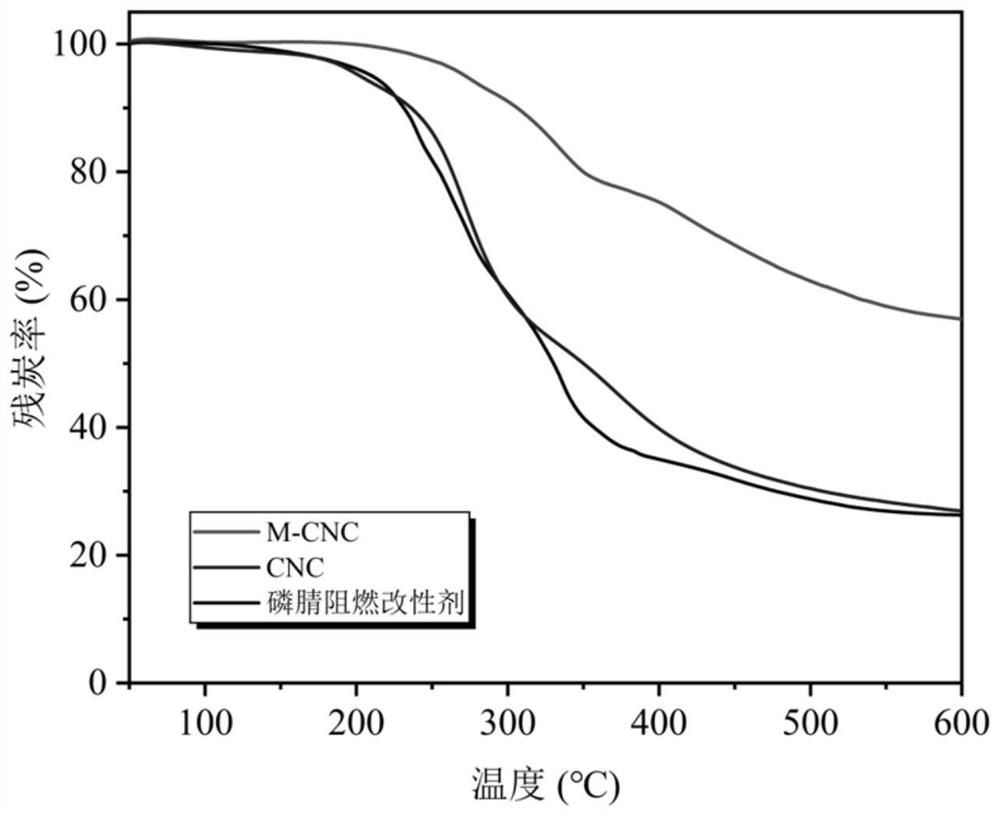

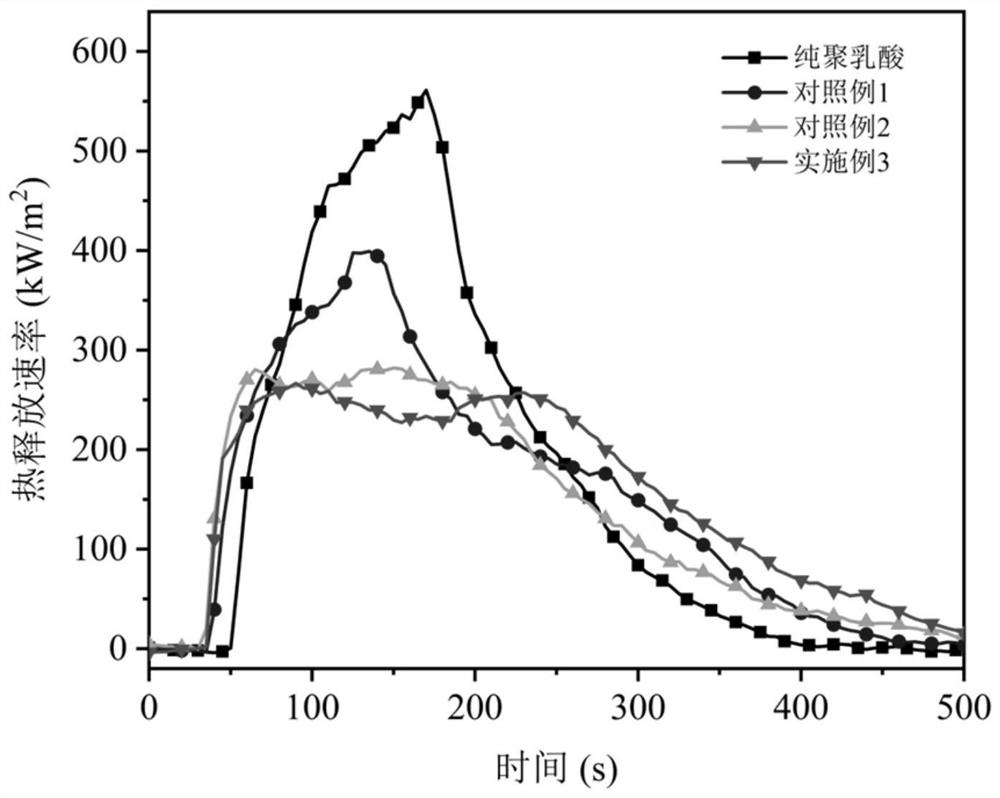

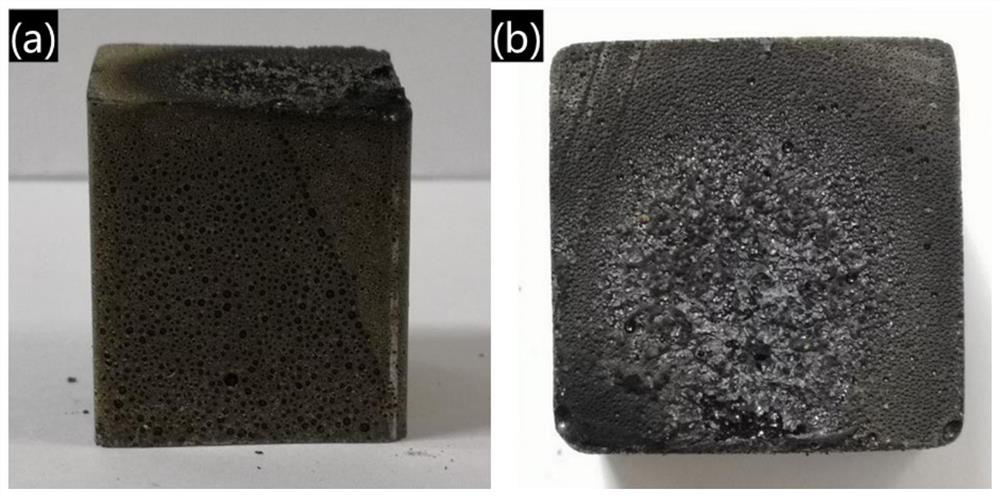

Flame-retardant nano cellulose containing phosphazene group, preparation method and flame-retardant polylactic acid of flame-retardant nano cellulose

ActiveCN113563486ARaise the initial decomposition temperatureImprove thermal stabilityBio-packagingPolymer sciencePolymer chemistry

The invention discloses flame-retardant nano cellulose containing a phosphazene group, a preparation method of the flame-retardant nano cellulose and flame-retardant polylactic acid of the flame-retardant nano cellulose. A phosphazene modifier is chemically grafted on the surface of nanocellulose to obtain the novel flame-retardant nanocellulose containing the phosphazene group. The flame-retardant nano cellulose obtained by the invention has excellent thermal stability and charring ability. The flame-retardant polylactic acid is compounded with a phosphorus-containing flame retardant, so that the flame retardant property of the material can be remarkably improved, and the mechanical property of the material can also be improved.

Owner:杭州志合新材料有限公司

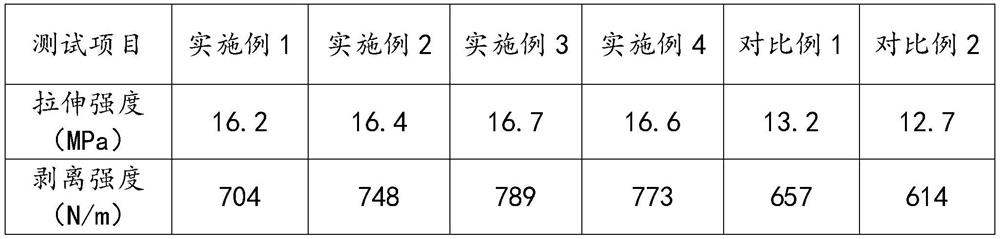

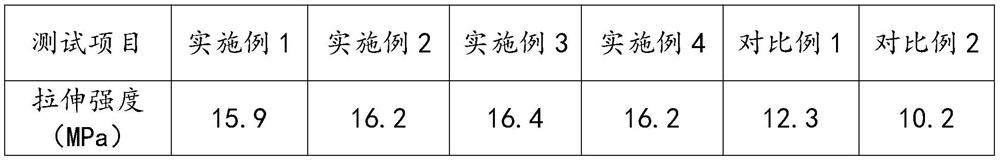

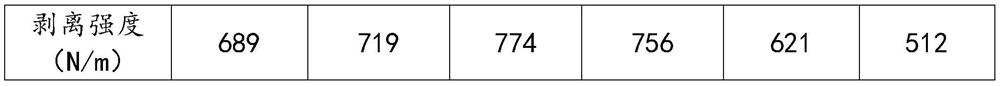

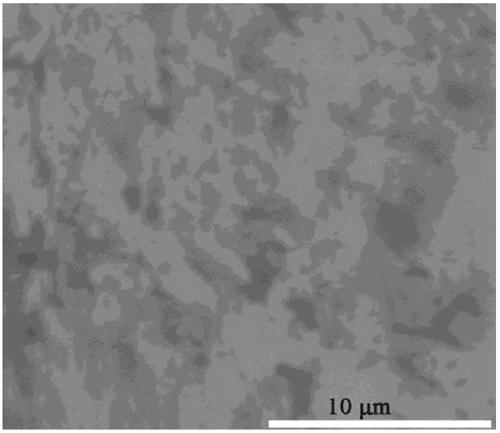

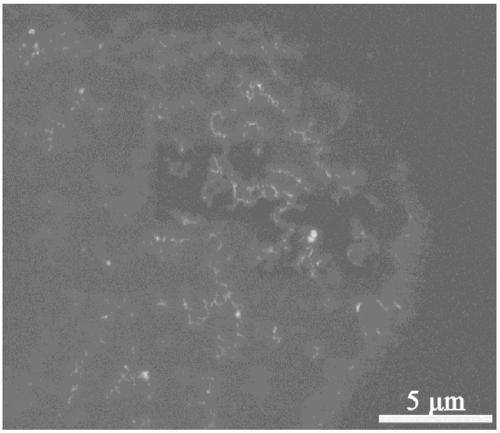

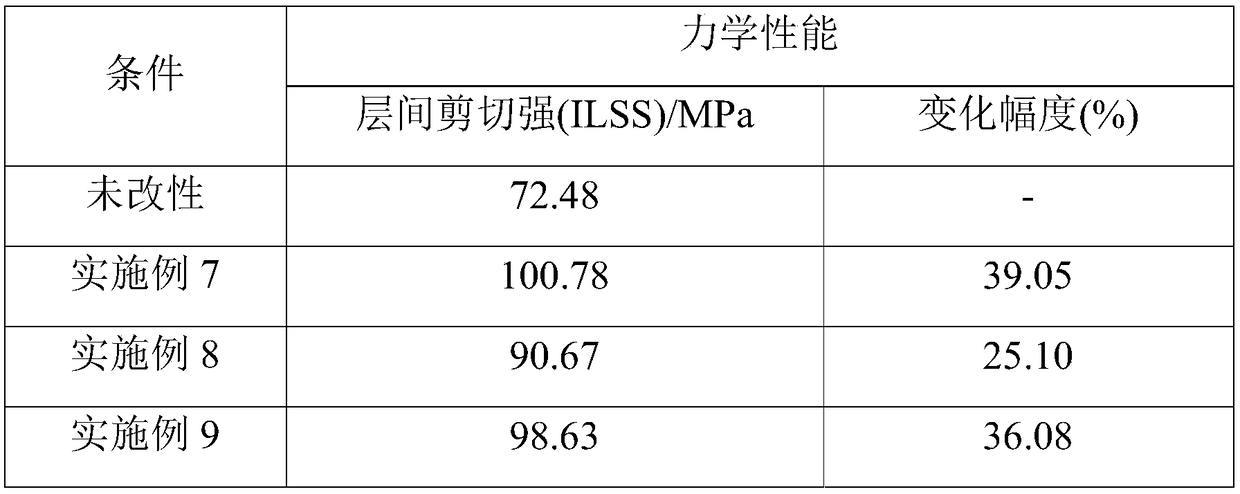

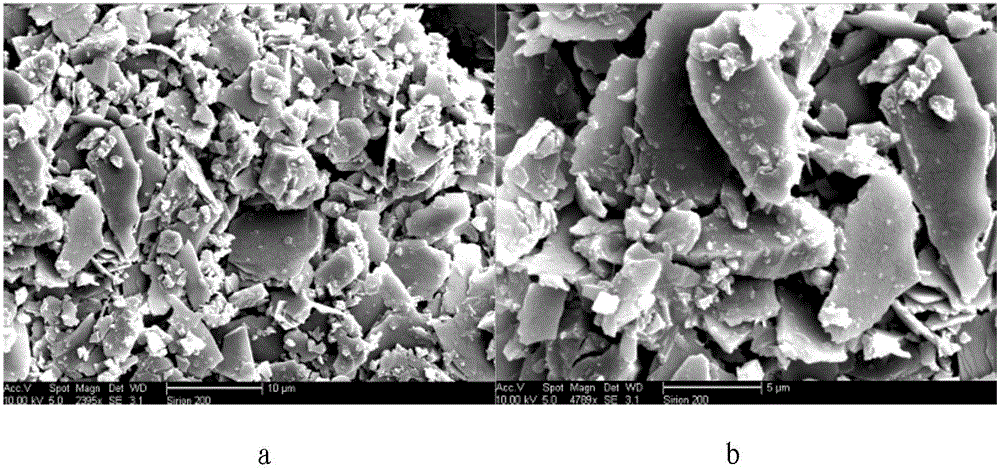

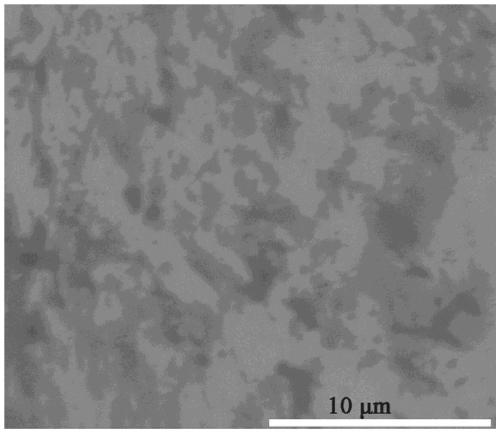

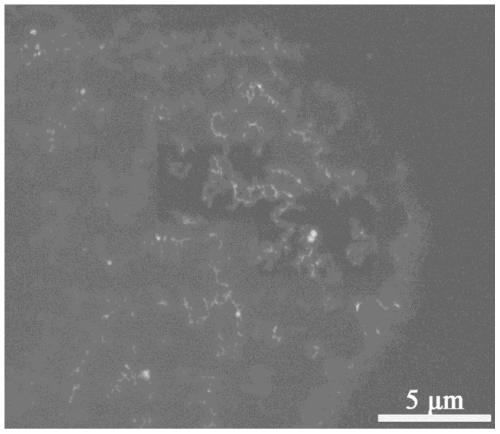

Nanometer laminated boron nitride reinforced carbon fiber sizing agent, and preparation method thereof

The invention discloses a nanometer laminated boron nitride reinforced carbon fiber sizing agent, and a preparation method thereof, and belongs to the technical field of composite material. The preparation method is capable of solving problems in the prior art that at humid hot environment, humidity hot aging is caused by resin chemical degradation and fiber / resin interface cracking. The nanometerlaminated boron nitride reinforced carbon fiber sizing agent comprises 100 parts of an organic resin, 0.3 to 6 parts of an emulsifier, 0.05 to 0.6 part of a dispersant, 0.05 to 1 part of a compatiblymodified nanometer laminated boron nitride dispersion liquid, 20 to 200 parts of an organic solvent, and 20 to 40 parts of deionized water; the compatibly modified nanometer laminated boron nitride dispersion liquid is a dispersion liquid of nanometer laminated boron nitride dispersion liquid processed through polyacrylic acid in-suit polymerization modification. According to the preparation method, raw materials are mixed and stirred until phase transferring is achieved; the compatibly modified nanometer laminated boron nitride dispersion liquid is mixed with the organic resin emulsion, deionized water is added for dilution so as to obtain the nanometer laminated boron nitride reinforced carbon fiber sizing agent. The nanometer laminated boron nitride reinforced carbon fiber sizing agentcan be used for carbon fiber sizing.

Owner:FUDAN UNIV

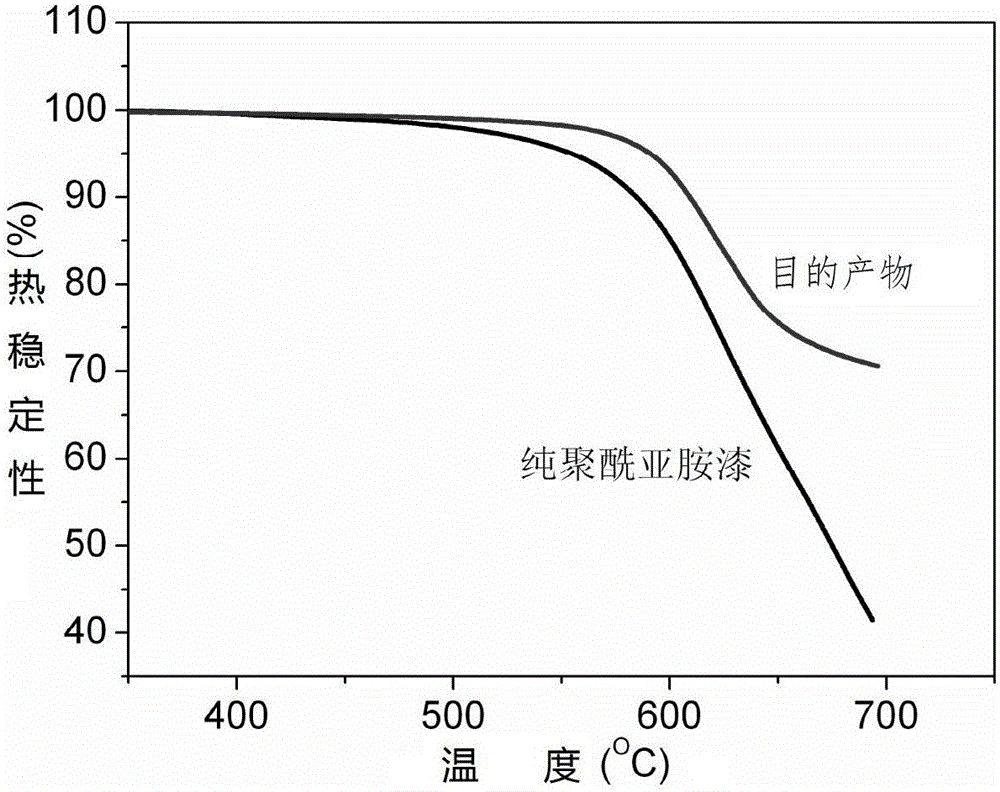

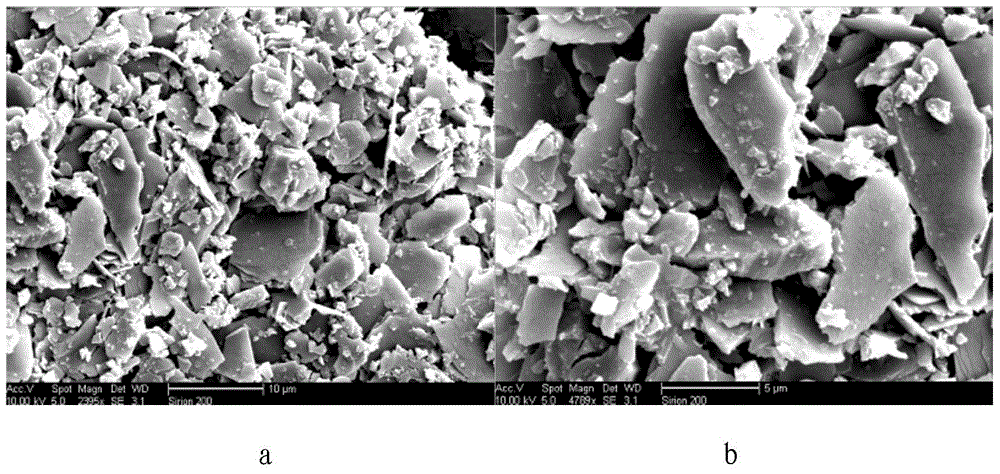

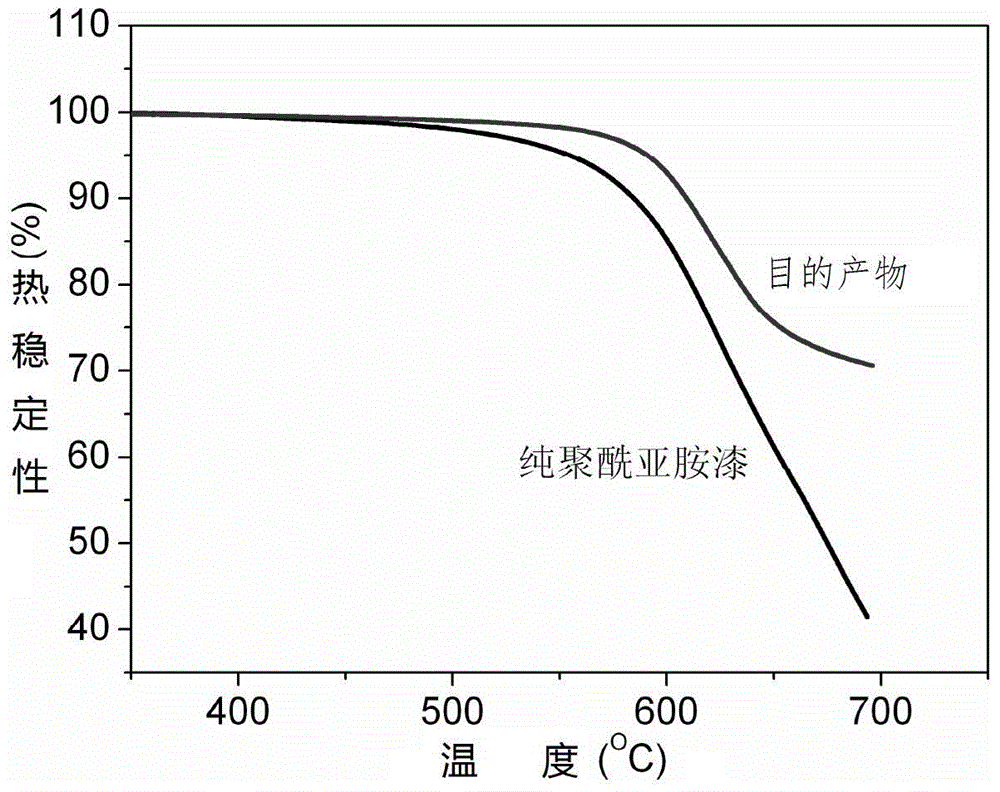

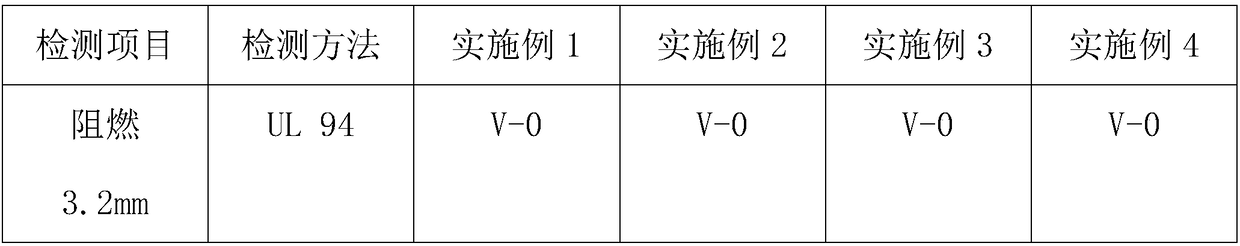

Composite insulating paint and preparation method thereof

ActiveCN105017958AHigh resistivityImprove impact performanceFireproof paintsPolyurea/polyurethane coatingsDecompositionTemperature resistance

The invention discloses a composite insulating paint and a preparation method thereof. The insulating paint consists of an organic insulating paint and a silicate-silicon dioxide hybrid in a weight ratio of (90-99):(1-10), wherein the silicate-silicon dioxide hybrid is obtained by loading silicon dioxide particles on the surface of a silicate sheet, the length and the width of the silicate sheet are 1-20 microns, the thickness of the silicate sheet is less than or equal to 1 micron, the silicate sheet is one of or a mixture of two of sericite and kaolin, and the particle size of the silicon dioxide particles is 0.1-2 microns. The preparation method comprises the following steps: firstly, dropwise adding tetraethyl orthosilicate into an aqueous solution of the silicate sheet to obtain a mixed solution; secondly, adding hydrochloric acid into the mixed solution, and then performing hydrolysis to obtain a precursor solution; thirdly, drying the precursor solution, and then milling to obtain the silicate-silicon dioxide hybrid; and finally, adding the silicate-silicon dioxide hybrid into the organic insulating paint while stirring to prepare the target product. The composite insulating paint has relatively high initial decomposition temperature and thermal stability, and can be widely applied to insulating places needing high temperature resistance and fireproof performance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Composite insulating varnish and preparation method thereof

ActiveCN105017958BHigh resistivityImprove impact performanceFireproof paintsPolyurea/polyurethane coatingsDecompositionTemperature resistance

The invention discloses a composite insulating paint and a preparation method thereof. The insulating paint consists of an organic insulating paint and a silicate-silicon dioxide hybrid in a weight ratio of (90-99):(1-10), wherein the silicate-silicon dioxide hybrid is obtained by loading silicon dioxide particles on the surface of a silicate sheet, the length and the width of the silicate sheet are 1-20 microns, the thickness of the silicate sheet is less than or equal to 1 micron, the silicate sheet is one of or a mixture of two of sericite and kaolin, and the particle size of the silicon dioxide particles is 0.1-2 microns. The preparation method comprises the following steps: firstly, dropwise adding tetraethyl orthosilicate into an aqueous solution of the silicate sheet to obtain a mixed solution; secondly, adding hydrochloric acid into the mixed solution, and then performing hydrolysis to obtain a precursor solution; thirdly, drying the precursor solution, and then milling to obtain the silicate-silicon dioxide hybrid; and finally, adding the silicate-silicon dioxide hybrid into the organic insulating paint while stirring to prepare the target product. The composite insulating paint has relatively high initial decomposition temperature and thermal stability, and can be widely applied to insulating places needing high temperature resistance and fireproof performance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Binder with strong high-temperature resistance

InactiveCN109694674ARaise the initial decomposition temperatureHigh maximum thermogravimetric rate temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolystyreneTemperature resistance

The invention discloses a binder with strong high-temperature resistance, and belongs to the field of binders, wherein the binder comprises, by weight, 250-300 parts of aluminum hydroxide, 100-250 parts of an ethylene-vinyl acetate-acrylate copolymer, 100-200 parts of polyethylene powder, 100-150 parts of an ethylene-vinyl chloride copolymer, 90-100 parts of a polyester resin, 70-80 parts of a polyamide resin, 60-70 parts of a polystyrene resin, 30-40 parts of a xylene resin, 30-35 parts of talc powder, 20-35 parts of dibutyl phthalate, 20-30 parts of a bisphenol A type epoxy resin, 10-20 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 10-20 parts of 2,6-di-tert-butyl-p-cresol, 10-15 parts of a rosin resin, 5-10 parts of bis(2-ethylhexyl) phthalate, and 1-5 parts of a Tween type emulsifier. According to the present invention, with the binder of the present invention, the problems of low high-temperature tolerance and easy shedding at a high temperature of the common binder can be effectively solved.

Owner:朱岳丹

High flame-retardant material for mobile phone shell

InactiveCN108690342AExcellent interfacial interactionImprove interfacial interactionPentaerythritolPhosphate

The invention discloses a high flame-retardant material for a mobile phone shell. The high flame-retardant material is prepared from the following raw materials in parts by weight: 65 to 75 parts of PC (polycarbonate), 27 to 33 parts of ABS (acrylonitrile butadiene styrene), 4 to 7 parts of compound compatilizer, 13 to 17 parts of compound flame retardant, 0.2 to 0.7 part of polytetrafluoroethylene, 0.5 to 1.2 parts of diisobutyl phthalate, 0.3 to 0.7 part of pentaerythritol stearate, 0.4 to 1 part of zinc stearate, 0.2 to 0.8 part of phosphate, and 0.3 to 0.8 part of 2,6-ditert butyl-4-methylphenol. The prepared high flame-retardant material has excellent flame-retardant property and flowing property.

Owner:安徽酷米智能科技股份有限公司

A kind of full deuterated ammonium dinitramide and preparation method thereof

ActiveCN111620351BWill not cause poisoningEasy to purifyExplosivesAmmonia compoundsPtru catalystPhysical chemistry

The invention discloses a fully deuterated ammonium dinitramide and a preparation method thereof, belonging to the technical field of synthesis of deuterated energetic materials. The invention is simple in purification, and high-purity products can be obtained without adsorption and solvent elution; the product does not contain metal ions such as potassium ions, does not cause catalyst poisoning during use, and can increase the application range of the product. The invention judges the progress of the reaction by measuring the pH of the solution, and the judgment method of the reaction end point is simple; the deuterated ammonia gas can be recycled after being collected, the waste of deuterated raw materials is reduced, and the production cost is reduced. Compared with ordinary ammonium dinitramide, the initial decomposition temperature of perdeuterated ammonium dinitramide is increased to about 150°C, and the thermal stability is significantly increased; the crystal density is increased, and the energy characteristics are also significantly improved. The invention can realize the preparation of perdeuterated ammonium dinitramide, and provides a reference for the industrial production of perdeuterated ammonium dinitramide.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

polyurethane sealant

InactiveCN107987781BIncrease elasticityImprove thermal stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

This case involves a polyurethane sealant. The polyurethane sealant is composed of component A and component B. The formula of component A is as follows: 20-30 parts of TDI prepolymer, 30-50 parts of NDI prepolymer, terminal hydroxyl 20-30 parts of polybutadiene, 60-90 parts of polyether 220; 10-20 parts of plasticizer; the formula of component B is as follows: 30-50 parts of filler, 10-20 parts of chain extender, 1-3 parts of dispersant 1 part, heat stabilizer 2‑5 part, light stabilizer 0.5‑1 part, catalyst 0.2‑0.5 part, A‑151 1‑3 part. In the present invention, polyether 220 and hydroxyl-terminated polybutadiene form a soft segment to increase the elasticity of the sealant, and the oligomer composition of carbamate is formed by adding a small molecule chain extender, TDI prepolymer, and NDI prepolymer to react Hardness, increase the initial decomposition temperature, and improve the thermal stability of polyurethane sealant; it has the advantages of good water resistance, long service life and high strength.

Owner:苏州炽蓝生物科技有限公司

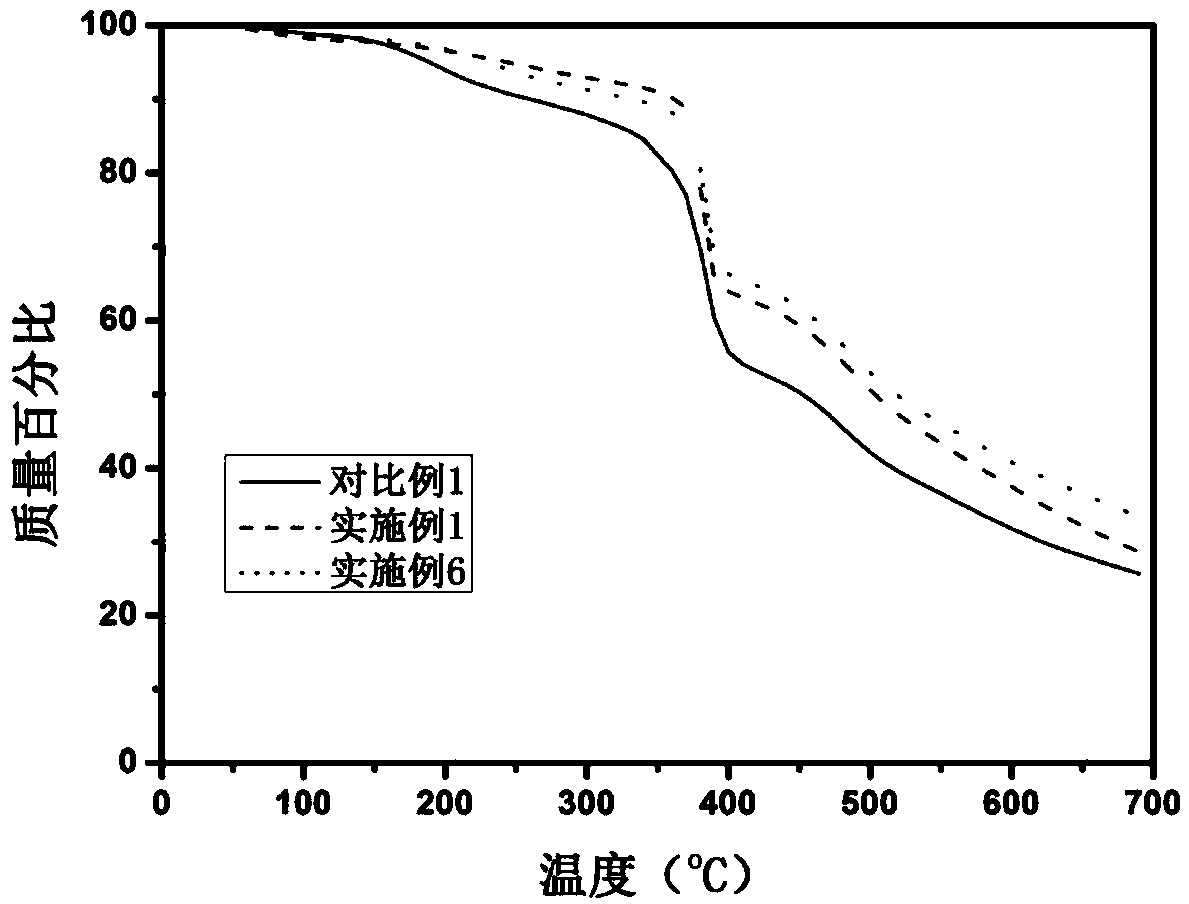

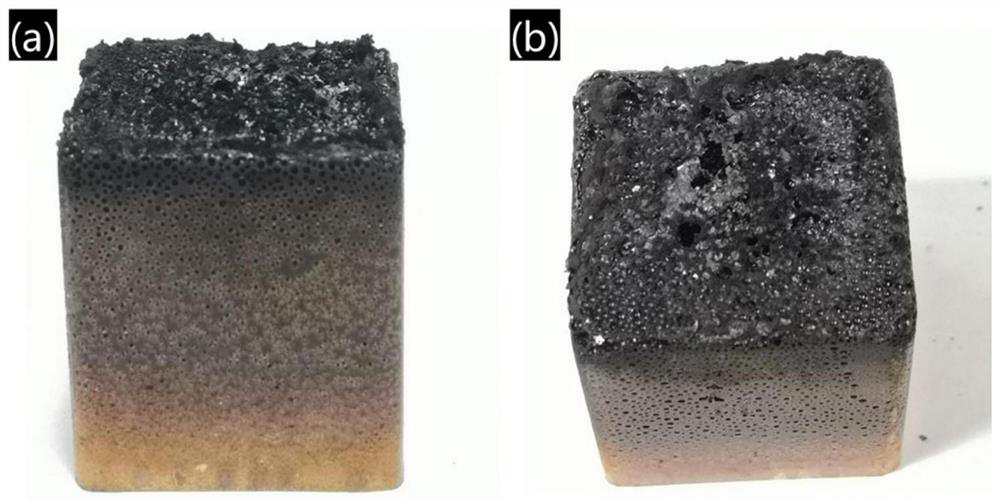

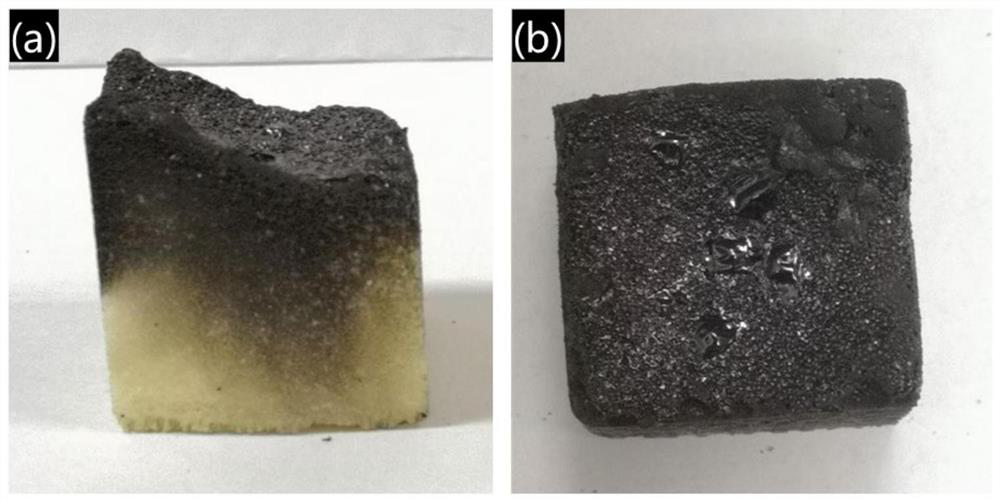

High-efficiency flame-retardant modified melamino-formaldehyde foams and preparation method thereof

The invention discloses high-efficiency flame-retardant modified melamino-formaldehyde foams. The high-efficiency flame-retardant modified melamino-formaldehyde foams are obtained by performing layer-by-layer self assembling through an alternating reaction formed by soaking or spraying of a positive electrolyte aqueous solution and a negative electrolyte aqueous solution based on a layer-by-layer self-assembling technology, and are deposited on the surface of a foam hold skeleton to form multiple layers of stable flame-retardant films, wherein the limit oxygen index is 35.5 to 46.5%; thermogravimetric residual weight at 700 DEG C and under nitrogen atmosphere is 26.7 to 32.8%; under the condition of cone calorimetric test with the power of 50 kW and in the process of from that the foam can be ignited to that the foam cannot be ignited, heat release peak value is 9.8 to 78.8 kW / m<2>; the foam is difficult to shrink at continuous high temperature of 750 DEG C. The flame-retardant films on the obtained melamino-formaldehyde foams have a strong adhesive force, are washable and have high flame-retardant efficiency and excellent flame-retardant performance. The thickness of each of the flame-retardant films is less than 2 microns, so other properties of the foams are not influenced. The high-efficiency flame-retardant modified melamino-formaldehyde foams are simple to prepare, environment-friendly, and easy for industrialized large-scale production.

Owner:SICHUAN UNIV

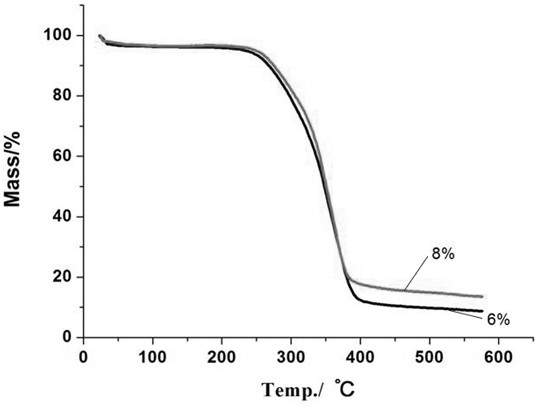

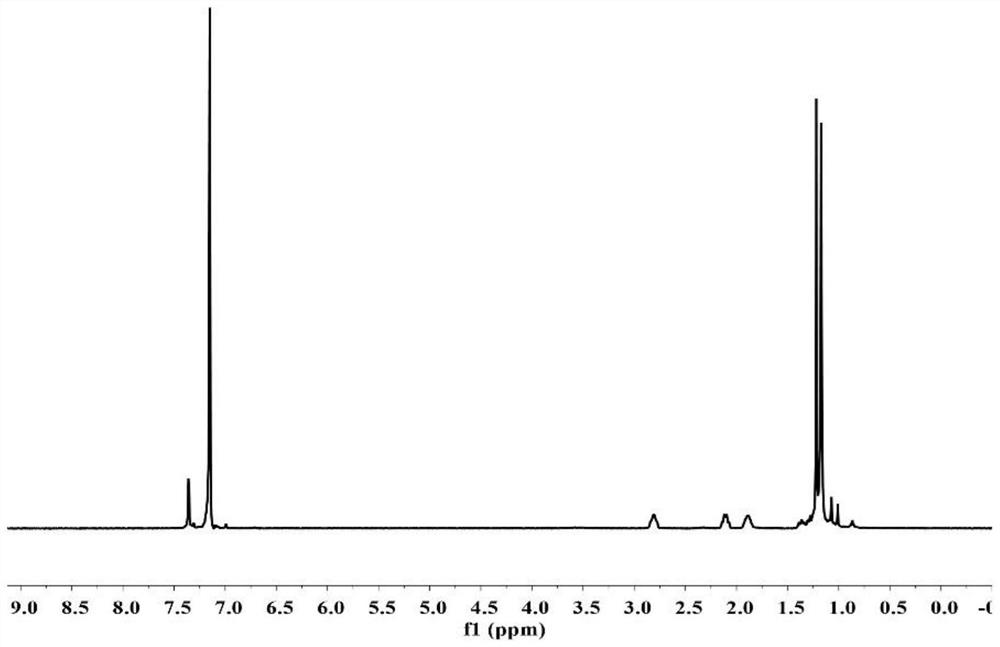

A kind of preparation method of phosphorus-nitrogen flame retardant waterborne polyurethane

ActiveCN110078886BImprove flame retardant performanceImprove thermal stabilityPolymer sciencePropanoic acid

The invention relates to a preparation method of phosphorus-nitrogen flame-retardant water-based polyurethane, comprising: reacting the product prepared after phosphorus oxychloride and pentaerythritol, and then reacting with piperazine ethanol and triethylamine to prepare a solid small molecular phosphorus -Nitrogen flame retardant; add polyether polyol, isophorone diisocyanate, and catalyst into the there-necked flask, heat, heat and stir for a period of time, then add the prepared phosphorus-nitrogen flame retardant, and continue to heat and stir for a period of time at a certain temperature time, then continuously add 2,2-dimethylolpropionic acid and 1,4-butanediol to react, then cool down to 60°C, add triethylamine to neutralize, continue stirring for 30 minutes, then add a certain amount of distilled water, and stir quickly 30min, the reaction is over. The invention prepares a reactive flame-retardant water-based polyurethane, which has good flame-retardant effect, simple synthesis method, low cost, good practicability and economy, and good market prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of reinforcing agent for carbon fiber sizing agent and preparation method thereof

ActiveCN109487538BHigh mechanical strengthRaise the initial decomposition temperatureCarbon fibresPolymer scienceCarbon fibers

The invention discloses a strengthening agent for carbon fiber sizing agents and a preparation method of the strengthening agent, belongs to the technical field of composite materials, and solves theproblems of instable component and poor compatibility of a strengthening agent in the prior art. The strengthening agent comprises polyacrylic acid modified nano-lamella boron nitride dispersion liquid, a dispersing agent, silicone oil and higher fatty acid, nano-lamella boron nitride dispersion liquid is modified by polyacrylic acid to form the polyacrylic acid modified nano-lamella boron nitridedispersion liquid, and a modified mode of the polyacrylic acid includes that acrylic acid is polymerized on the surface of effectively peeled nano-lamella boron nitride in situ. The preparation method includes the steps: mixing the polyacrylic acid modified nano-lamella boron nitride dispersion liquid, the dispersing agent, the silicone oil and the higher fatty acid; ultrasonically dispersing mixture to obtain the strengthening agent for the carbon fiber sizing agents. The strengthening agent and the preparation method can be used for strengthening the carbon fiber sizing agents.

Owner:FUDAN UNIV

Intramolecular trifunctional Lewis acid-base pair catalyst, cyclic topology pmmbl polymer and preparation method and application

ActiveCN113896875BEasy to operateSuitable for industrial productionGroup 5/15 element organic compoundsChemical recyclingPolymer sciencePtru catalyst

The invention relates to the technical field of catalysts, in particular to intramolecular trifunctional Lewis acid-base pair catalysts, preparation methods and applications, ring topology PMMBL polymers, preparation methods and applications. The intramolecular trifunctional Lewis acid-base pair catalyst provided by the present invention has any one or several structures shown in formulas I to III. The catalyst provided by the present invention adopts the chain growth mechanism of "bimolecular synergy". Two Lewis acid sites of B and one Lewis base site of P of the catalyst simultaneously exist in the same molecular structure through covalent bonding and acidic The application of the weaker B-site Lewis acid is favorable for the ω-end of one polymer chain to attack the α-terminus of the other chain, so that the catalyst structure leaves and the two polymer chains connect end-to-end to form a ring to prepare a high initial heat Degradation temperature and narrow thermal degradation temperature window for ring topology PMMBL polymers.

Owner:JILIN UNIV

Perdeuterated ammonium dinitramide and preparation method thereof

ActiveCN111620351AWill not cause poisoningEasy to purifyExplosivesAmmonia compoundsPtru catalystPhysical chemistry

The invention discloses perdeuterated ammonium dinitramide and a preparation method thereof, belonging to the technical field of synthesis of deuterated energetic materials. According to the invention, purification is simple, and a high-purity product can be obtained without adsorption and solvent elution; the product does not contain metal ions such as potassium ions, does not cause catalyst poisoning in the use process, and is widened in application range; reaction process is judged by measuring the pH value of a solution, and the reaction endpoint judgment method is simple; and deuterated ammonia gas can be recycled after being collected, so the waste of deuteration raw materials is reduced, and production cost is reduced. Compared with common ammonium dinitramide, the initial decomposition temperature of the perdeuterated ammonium dinitramide is increased to about 150 DEG C, and the thermal stability of the perdeuterated ammonium dinitramide is obviously improved; and crystalline density is increased, and meanwhile, energy characteristic is obviously improved. According to the preparation method disclosed by the invention, the preparation of the perdeuterated ammonium dinitramide can be realized, and a reference is provided for industrially producing the perdeuterated ammonium dinitramide.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A preparation method of high ortho boron modified thermosetting phenolic-based hollow nano-gradient activated carbon fiber membrane

Owner:ZHONGYUAN ENGINEERING COLLEGE

Three-source one-body intumescent flame retardant, hybrid intumescent flame retardant grafted by using three-source one-body intumescent flame retardant as well as preparation method and application of three-source one-body intumescent flame retardant and hybrid intumescent flame retardant

The invention discloses a three-source one-body intumescent flame retardant, a hybrid intumescent flame retardant grafted by using the three-source one-body intumescent flame retardant as well as a preparation method and application of the three-source one-body intumescent flame retardant and the hybrid intumescent flame retardant, wherein the structural general formulas of the three-source one-body intumescent flame retardant and the hybrid intumescent flame retardant are respectively as shown in the specification, and the three-source one-body intumescent flame retardant or the hybrid intumescent flame retardant is used for a thermoplastic elastomer, rubber, polyolefin plastic and aliphatic polyester, the epoxy resin and the unsaturated resin are not required to be compounded when used in flame retardancy, the proportion of phosphorus, nitrogen and carbon elements is appropriate, the flame-retardant efficiency is high, the addition amount of the flame retardant can be greatly reduced, the cost is reduced, the influence on the mechanical property of the base material is small, the water resistance is better, and the initial decomposition temperature is higher.

Owner:SICHUAN UNIV

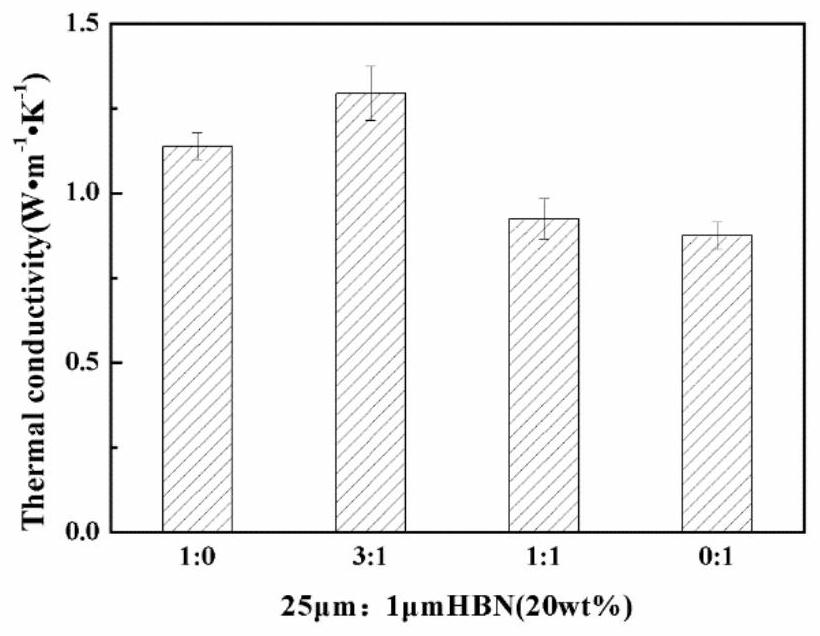

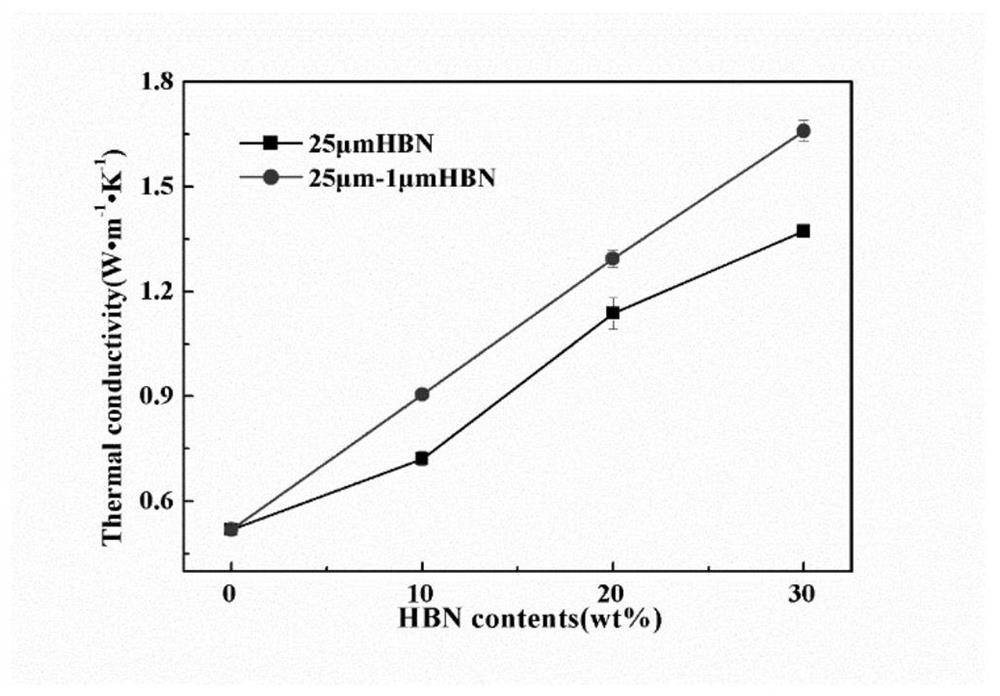

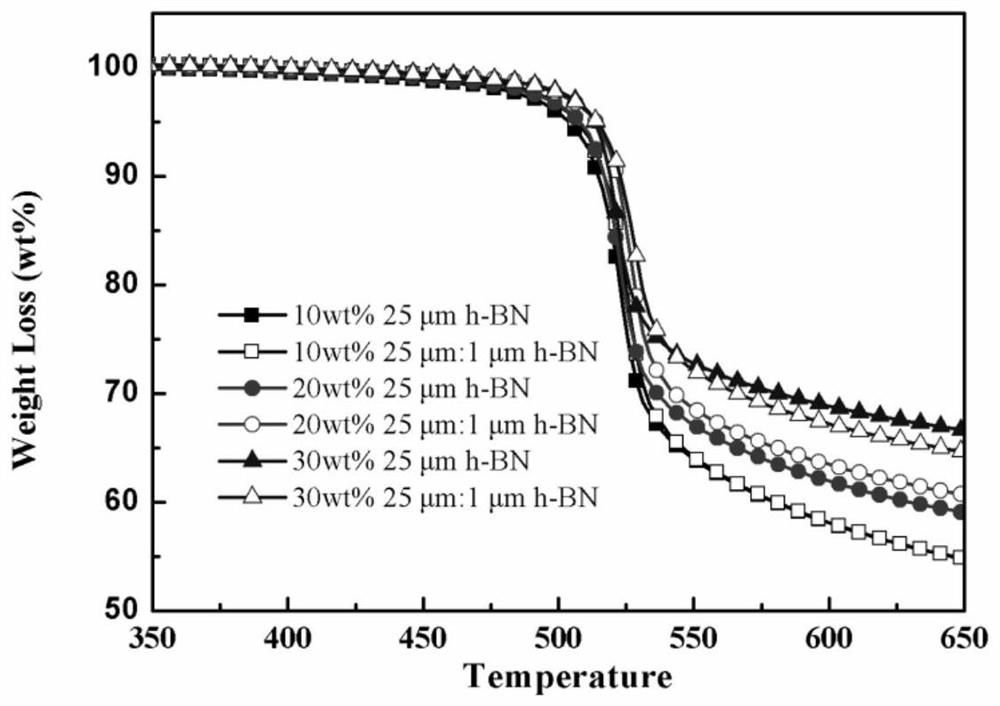

LCP/HBN composite material and preparation method thereof

The invention discloses an LCP / HBN composite material and a preparation method thereof. The heat-conducting polymer composite material is prepared by compounding and filling the heat-conducting fillers, compounding of the heat-conducting fillers with different particle sizes has a heat-conducting synergistic effect, and the heat conductivity coefficient of the composite material is improved. Meanwhile, high polymer material plasticizing and transporting equipment based on extensional rheology is used for processing, and the composite material has better dispersing and mixing efficiency in a flow field dominated by extensional deformation than in a flow field dominated by shear deformation. The preparation method of the LCP / HBN composite material is simple, additives and chemical reagents do not need to be added, and pollution to the environment can be reduced while the cost is reduced. The heat conductivity of the composite material is improved, the heat stability of the composite material is also improved, the mechanical property of the material can be maintained, the use scene of the material is greatly widened, and the composite material has wide application prospects in the fields of packaging materials, electronic substrates and the like.

Owner:SOUTH CHINA UNIV OF TECH

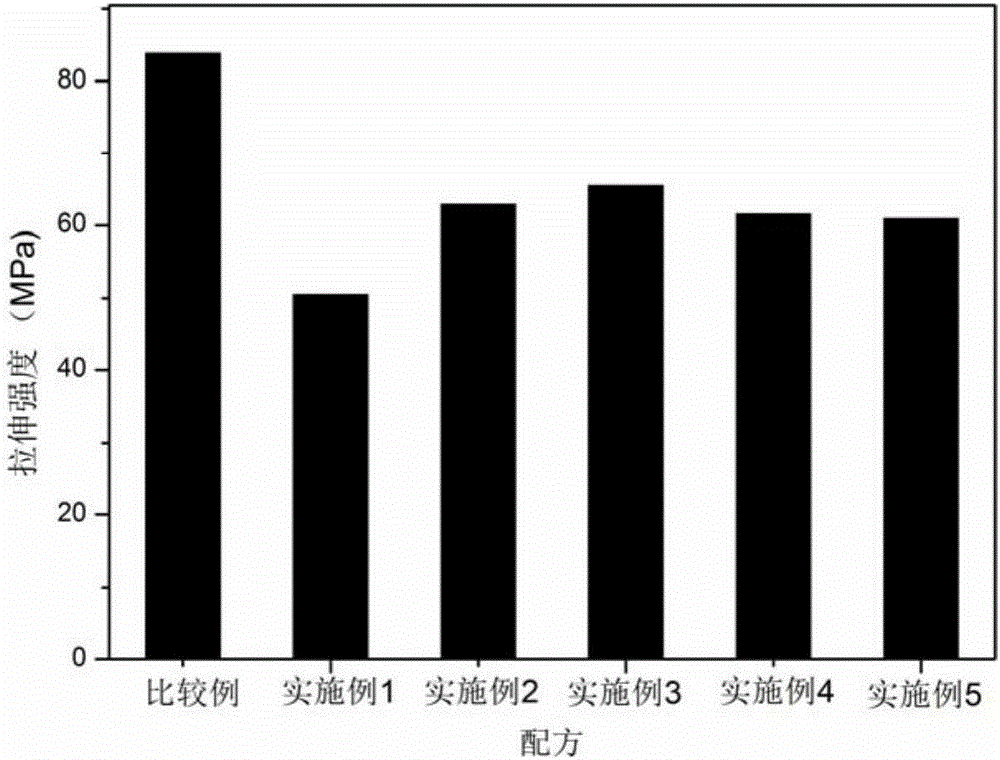

A flame-retardant heat-resistant reinforced polylactic acid composition and its preparation method

The invention discloses a flame-retardant heat-resistant reinforced polylactic acid composition and a preparation method thereof. The polylactic acid composition is prepared from the following components by mass percent: 85% of polylactic acid, 0% to 12% of vinyl silicone resin and 3% to 15% of halogen-free phosphate ester flame retardant. The preparation method comprises the following steps: mixing the polylactic acid, the vinyl silicone resin and the halogen-free phosphate ester flame retardant in proportion; adding the mixture into a double-screw extruder under a conventional feeding speed, a conventional feeding temperature and a conventional rotating speed of screw rods; and extruding, cooling and cutting into granules. The flame-retardant heat-resistant reinforced polylactic acid composition is simple in formula and free of halogen, wherein the formula proportion of the polylactic acid, the vinyl silicone resin and the halogen-free phosphate ester flame retardant is reasonably regulated, so that the polylactic acid has flame-retardant and heat-resistant effects; in addition, the tensile strength of the polylactic acid can be improved. Thus, the harms and the pollutions of the polylactic acid composition to human bodies and environments are low.

Owner:NANJING UNIV OF SCI & TECH

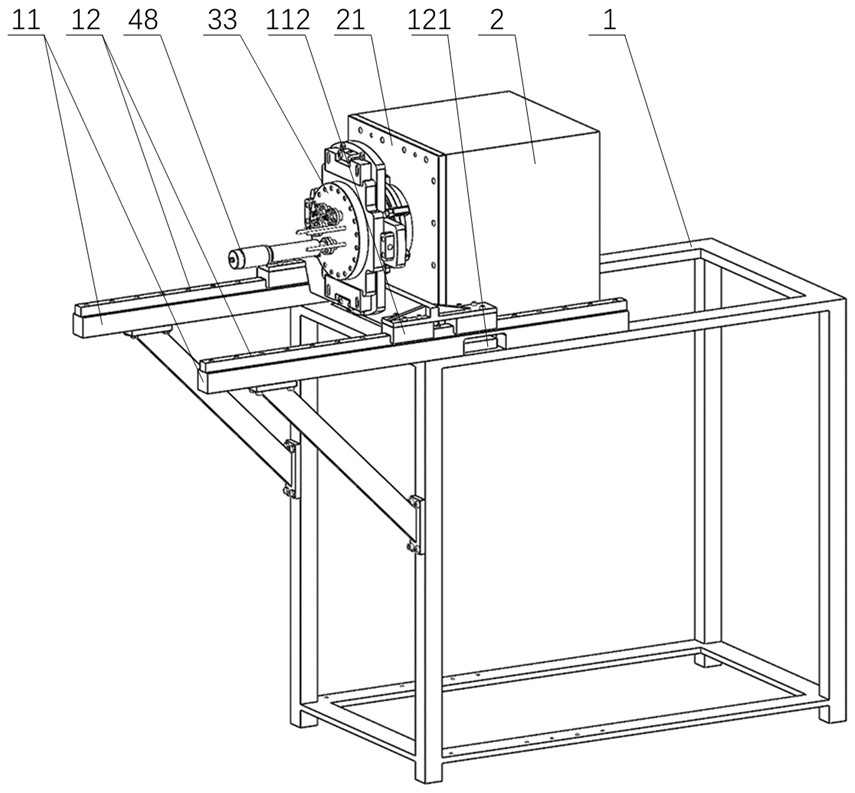

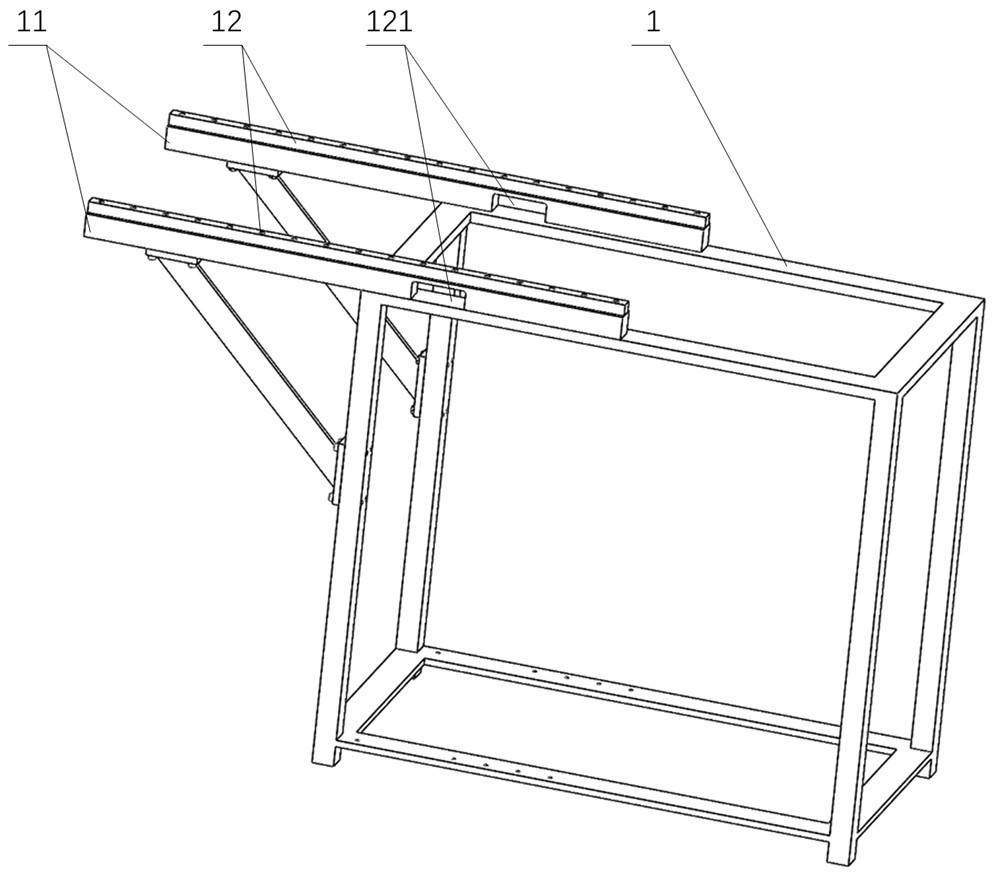

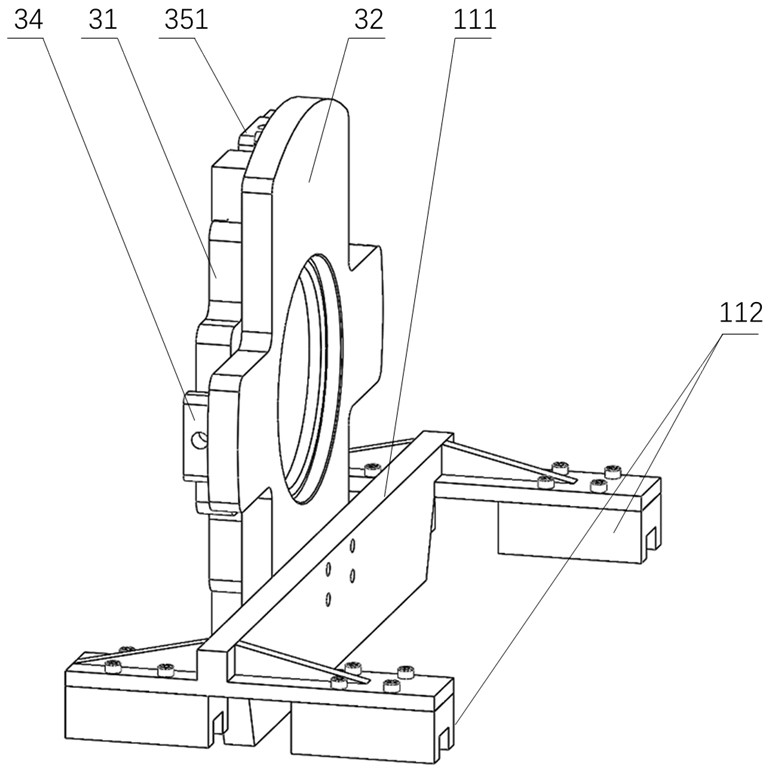

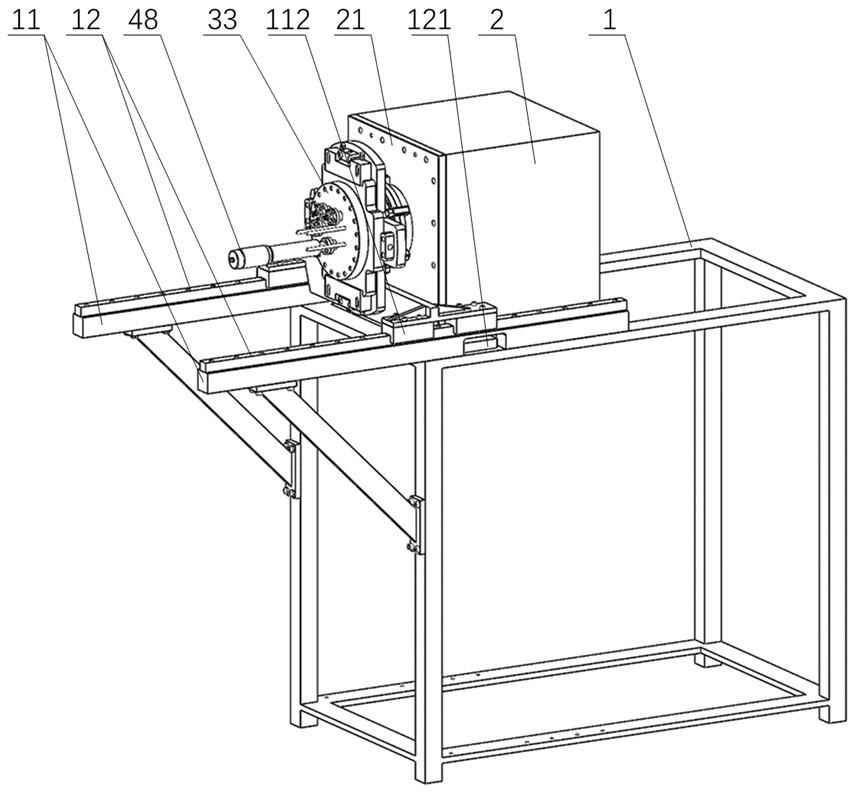

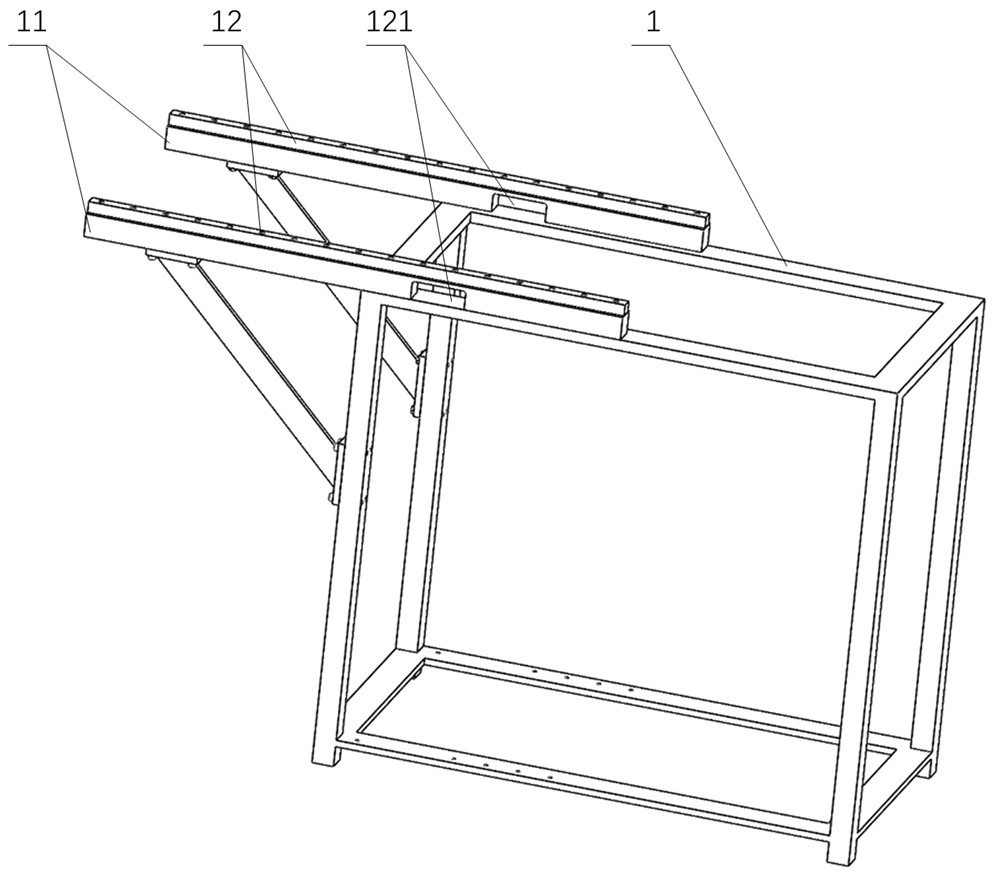

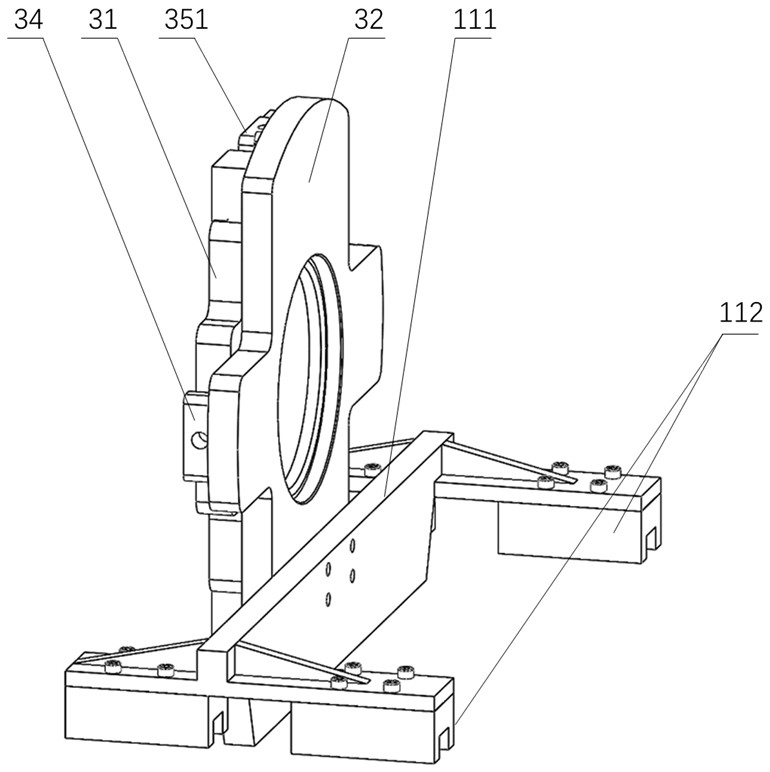

A low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source

ActiveCN113908771BShort stayFast heating ratePressure vessel componentsSub-atmospheric pressure processesGraphite electrodeGraphite

The invention belongs to the technical field of pyrolysis instruments, in particular to a low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source. It includes a test bench, an installation mechanism, a flash pyrolysis mechanism and a vacuum box; the flash pyrolysis mechanism includes a cylindrical cavity horizontally arranged in the vacuum box, and a sample injection pipe, a water inlet pipe and a water outlet pipe arranged in the cylindrical cavity, and a water cooling chamber It is slidably arranged in the cavity at the other end of the cylindrical cavity, the other end of the injection tube penetrates the water cooling cavity, and the extension end is connected with a silicon carbide tube, and a pair of graphite electrodes is sleeved on the silicon carbide tube; the extension end of the push rod of the linear introducer A sliding table is arranged in the corresponding cylindrical cavity, the extension end of the push rod is fixedly connected with the sliding block, and the upper end of the sliding block is fixedly connected with the corresponding sampling tube. The silicon carbide tube of the invention is used as a reactor, and the graphite electrode is heated to realize rapid temperature rise and reduce secondary reactions, and can reduce the annihilation of active and important reaction intermediates such as free radicals under low pressure, and can realize continuous sampling and improve the reaction power of pyrolysis samples. study research.

Owner:UNIV OF SCI & TECH OF CHINA

Low-pressure flash pyrolysis flow tube reaction device based on continuous molecular beam source

ActiveCN113908771AShort stayLow residence time for shorter, gas densityPressure vessel componentsSub-atmospheric pressure processesCarbide siliconGraphite electrode

The invention belongs to the technical field of pyrolysis instruments, and particularly relates to a low-pressure flash pyrolysis flow tube reaction device based on a continuous molecular beam source. The device comprises a test bed, a mounting mechanism, a flash pyrolysis mechanism and a vacuum box; the flash pyrolysis mechanism comprises a cylindrical cavity horizontally arranged in the vacuum box, and a sample injection pipe, a water inlet pipe and a water outlet pipe which are arranged in the cylindrical cavity, the water cooling cavity is slidably arranged in a cavity body at the other end of the cylindrical cavity, the other end of the sample injection pipe penetrates through the water cooling cavity, the extending end of the sample injection pipe is connected with a silicon carbide pipe, and the silicon carbide pipe is sleeved with a pair of graphite electrodes; and a sliding table is arranged in the cylindrical cavity corresponding to the extension end of a push rod of the linear introducer, the extension end of the push rod is fixedly connected with a sliding block, and the upper end of the sliding block is fixedly connected with a corresponding sample injection pipe. The silicon carbide tube is used as a reactor, the graphite electrode is used for heating, rapid heating is achieved, secondary reaction is reduced, annihilation of active and important reaction intermediates such as free radicals can be reduced under low pressure, continuous sampling can be achieved, and reaction kinetics research of pyrolysis samples can be perfected.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of flame-retardant nanocellulose containing phosphazene group, preparation method and flame-retardant polylactic acid thereof

ActiveCN113563486BRaise the initial decomposition temperatureImprove thermal stabilityBio-packagingPolymer sciencePolymer chemistry

The invention discloses a flame-retardant nanocellulose containing a phosphazene group, a preparation method and a flame-retardant polylactic acid thereof. The phosphazene modifier was chemically grafted on the surface of nanocellulose to obtain a novel flame-retardant nanocellulose containing phosphazene groups. The flame-retardant nanocellulose obtained by the invention has excellent thermal stability and carbon-forming ability. Combining it with a phosphorus-containing flame retardant to compound flame retardant polylactic acid can not only significantly improve the flame retardant properties of the material, but also improve its mechanical properties.

Owner:杭州志合新材料有限公司

Preparation method of high-compression-resistance fire-resistant composite epoxy foam

The invention relates to the technical field of preparation of epoxy foam materials, and mainly relates to a preparation method of high-pressure-resistant fire-resistant composite epoxy foam. On the basis of the controllable benzyl hydroxyl activity principle, the benzyl hydroxyl activity in the boron novolac epoxy resin synthesis process is reduced by taking ammonia water as a catalyst and adopting a stepped heating method, so that the problems of epoxy value reduction and boric acid residue caused by over-high benzyl hydroxyl activity in resin synthesis are solved; the boron-containing high-temperature-resistant foaming resin matrix is successfully prepared; a bifunctional foaming agent with a synergistic curing effect is added in the foaming process, so that the problem that resin gel and foaming agent decomposition are not matched is solved; boron novolac epoxy resin grafted and modified graphene oxide is added into epoxy foam, so that the size of a foam hole is reduced, the wall of the foam hole is enhanced, the surface of the epoxy foam is promoted to form a stable graphitized carbon layer in flame, the heat conductivity is reduced, and finally the epoxy foam material integrating compression resistance, heat insulation and flame resistance functions is prepared.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com