A kind of reinforcing agent for carbon fiber sizing agent and preparation method thereof

A technology of reinforcing agent and carbon fiber, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of unstable composition and poor compatibility, and achieve the effect of simple preparation method, high thermal stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

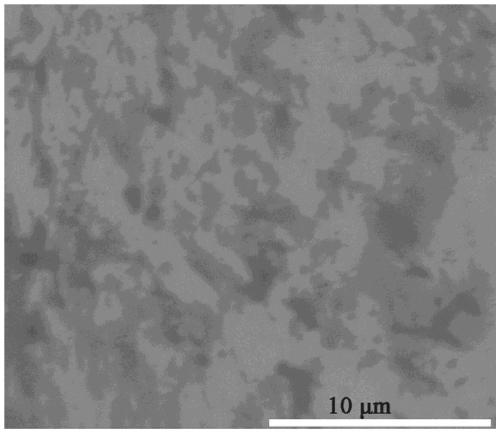

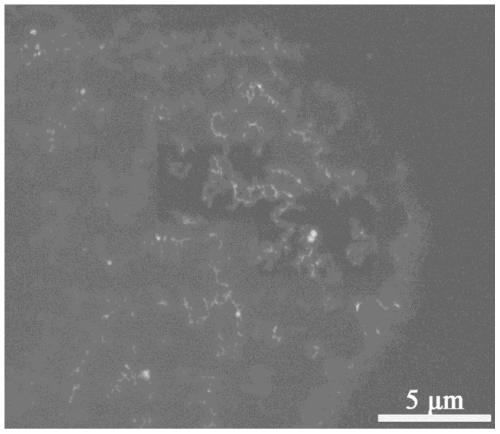

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a reinforcing agent for carbon fiber sizing agent, which is a polyacrylic acid formed by in-situ polymerization of acrylic acid on the surface of effectively stripped nanosheet boron nitride through an ammonium persulfate initiator The modified nano-sheet boron nitride comprises the following steps: weighing a certain amount of polyacrylic acid-modified nano-sheet boron nitride dispersion liquid according to the proportion and mixing it with a dispersant, silicone oil and higher fatty acid at 30°C to 90°C (for example, 50 ℃~80℃), and ultrasonically disperse for 1h~6h.

[0038] Compared with the prior art, the beneficial effect of the method for preparing a reinforcing agent for carbon fiber sizing agent provided by the present invention is basically the same as that of the above-mentioned reinforcing agent for carbon fiber sizing agent, and will not be repeated here.

[0039] In addition, the choice of mixing te...

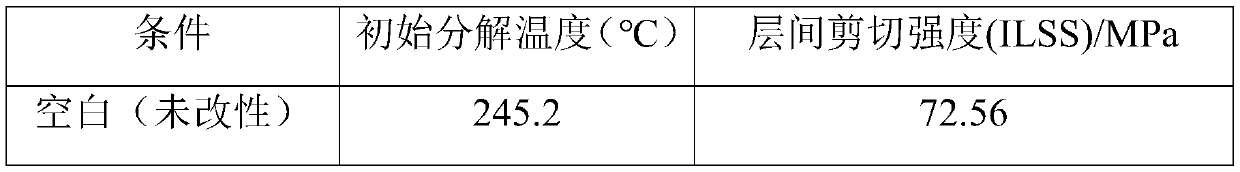

Embodiment 1

[0047] This embodiment provides a polyacrylic acid modified nanosheet boron nitride-based reinforcing agent for carbon fiber sizing agent and its preparation method, wherein the preparation method includes the following steps:

[0048] Step 1: Prepare an aqueous solution of isopropanol, wherein the volume percentage of isopropanol is 30%, boron nitride with an average crystallite size of 50 microns, the concentration of boron nitride is 10 mg / mL, and the dispersion liquid after mixing is 100 grams in total ;

[0049] Step 2: Ultrasonicize the dispersion obtained in Step 1, the ultrasonic power is 50W, and the ultrasonic time is 1 hour; after the ultrasonication is completed, let it stand for 4 hours; then centrifuge at 4000rpm to obtain the upper dispersion;

[0050] Step 3: Modify the dispersion liquid obtained in step 2: add acrylic acid and ammonium persulfate (the mass ratio of acrylic acid, ammonium persulfate, and boron nitride is 10:1:1) at 40°C, and react to obtain mod...

Embodiment 2

[0055] This embodiment provides a polyacrylic acid modified nanosheet boron nitride-based reinforcing agent for carbon fiber sizing agent and its preparation method, wherein the preparation method includes the following steps:

[0056] Step 1: Prepare a mixed solution of water and isopropanol, wherein the volume ratio of isopropanol is 50%, then add boron nitride with an average crystallite size of 50 microns, the concentration of boron nitride is 10mg / mL, mix and disperse 100 grams in total;

[0057] Step 2: ultrasonically treat the dispersion liquid obtained in step 1, the ultrasonic power is 100W, and the ultrasonic time is 8 hours; after the ultrasonic wave is completed, let it stand for 4 hours; then centrifuge at 6000rpm to obtain the upper dispersion liquid;

[0058] Step 3: Modify the dispersion liquid obtained in step 2: add acrylic acid and ammonium persulfate at 60°C (the mass ratio of acrylic acid, ammonium persulfate, and boron nitride is 15:3:5), and react to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com