Patents

Literature

39results about How to "Effective compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

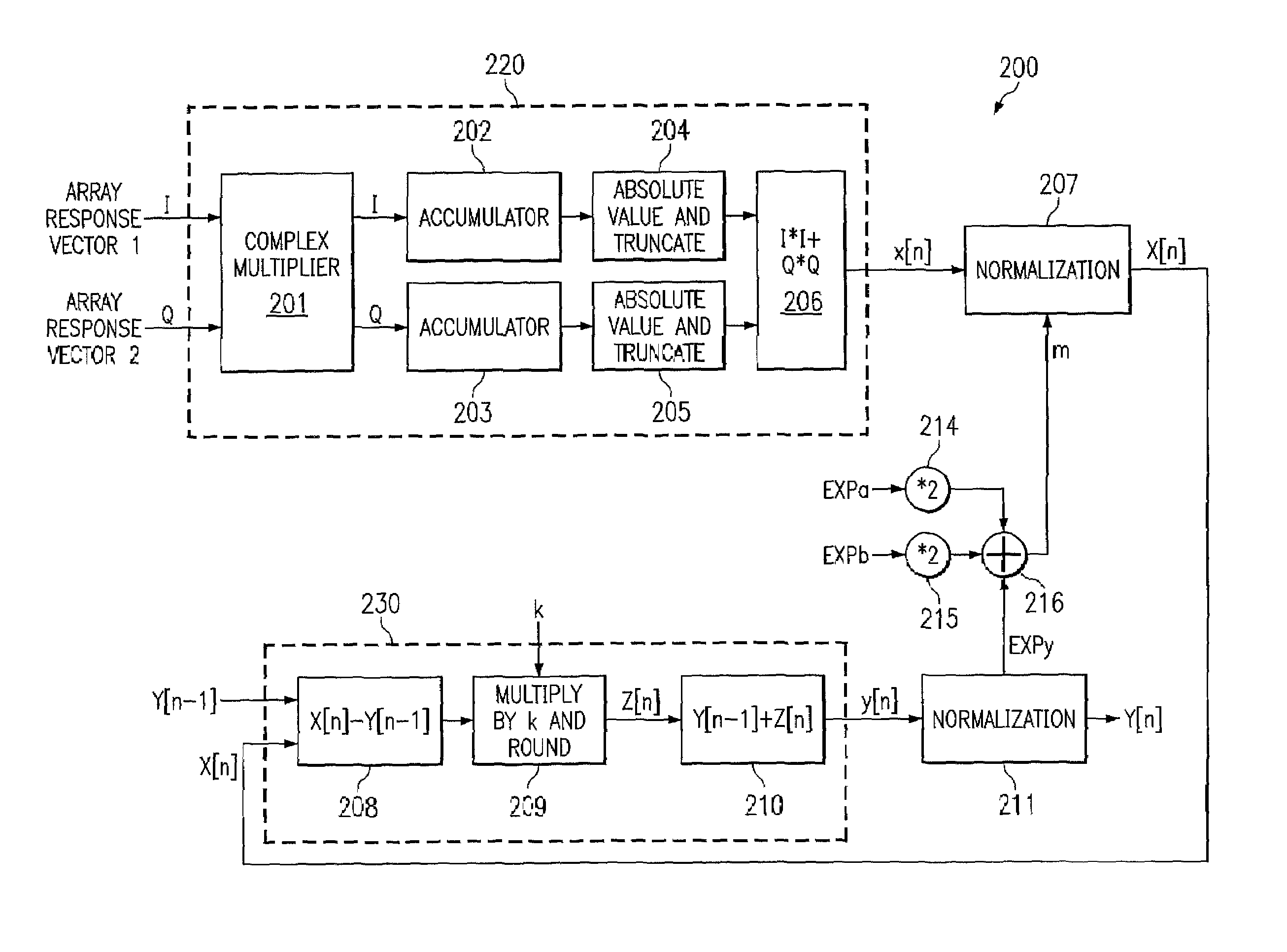

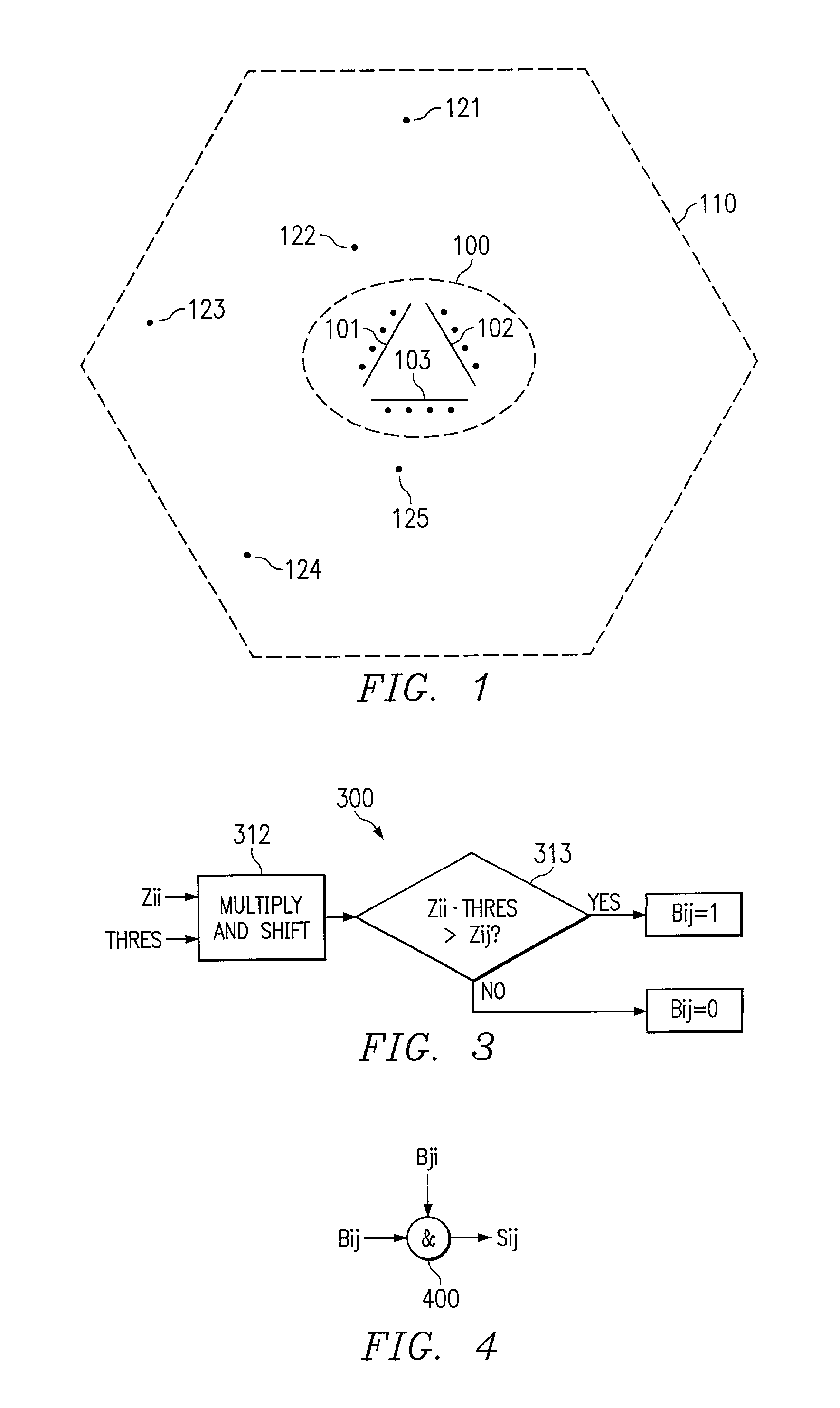

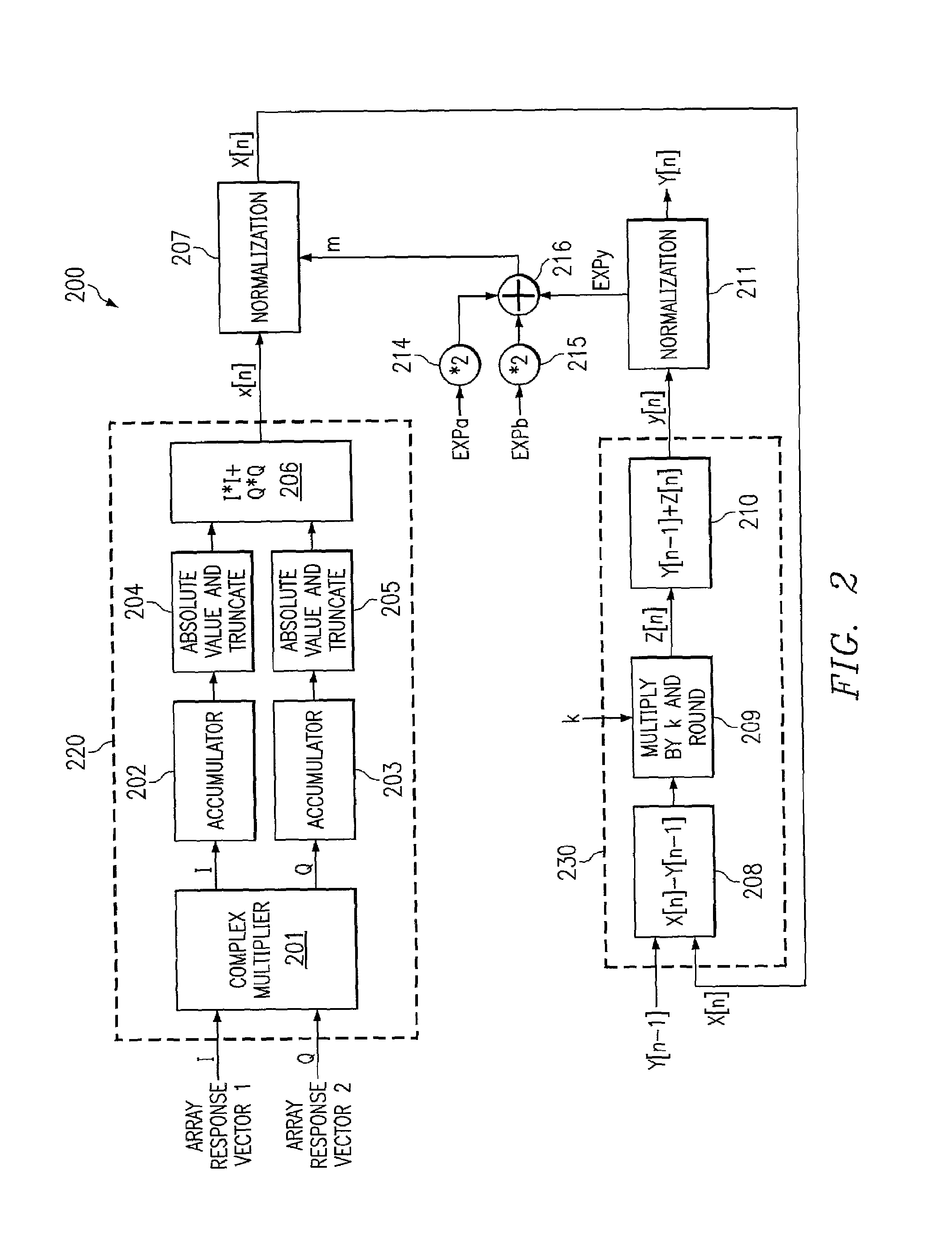

Directed maximum ratio combining and scheduling of high rate transmission for data networks

ActiveUS7085240B2Increase data rateFacilitate data communicationError preventionFrequency-division multiplex detailsHigh rateSelf adaptive

Owner:F POSZAT HU

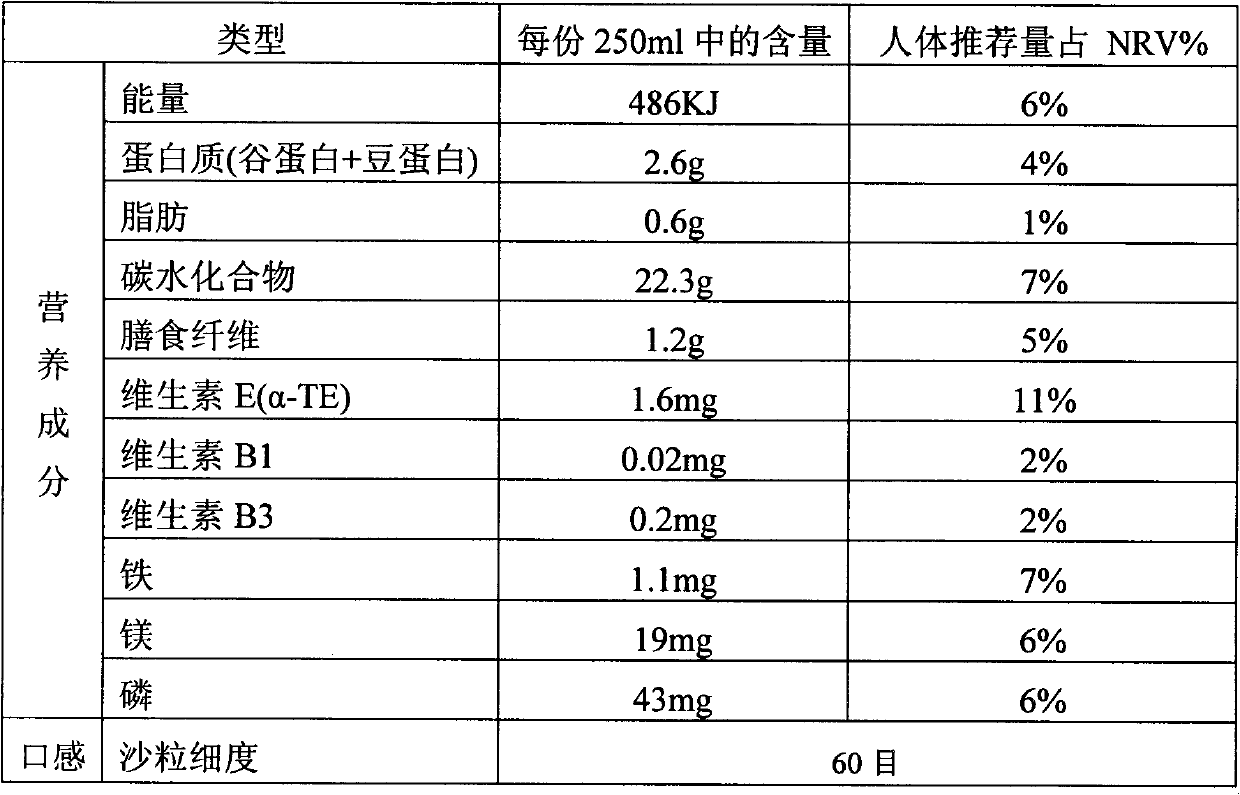

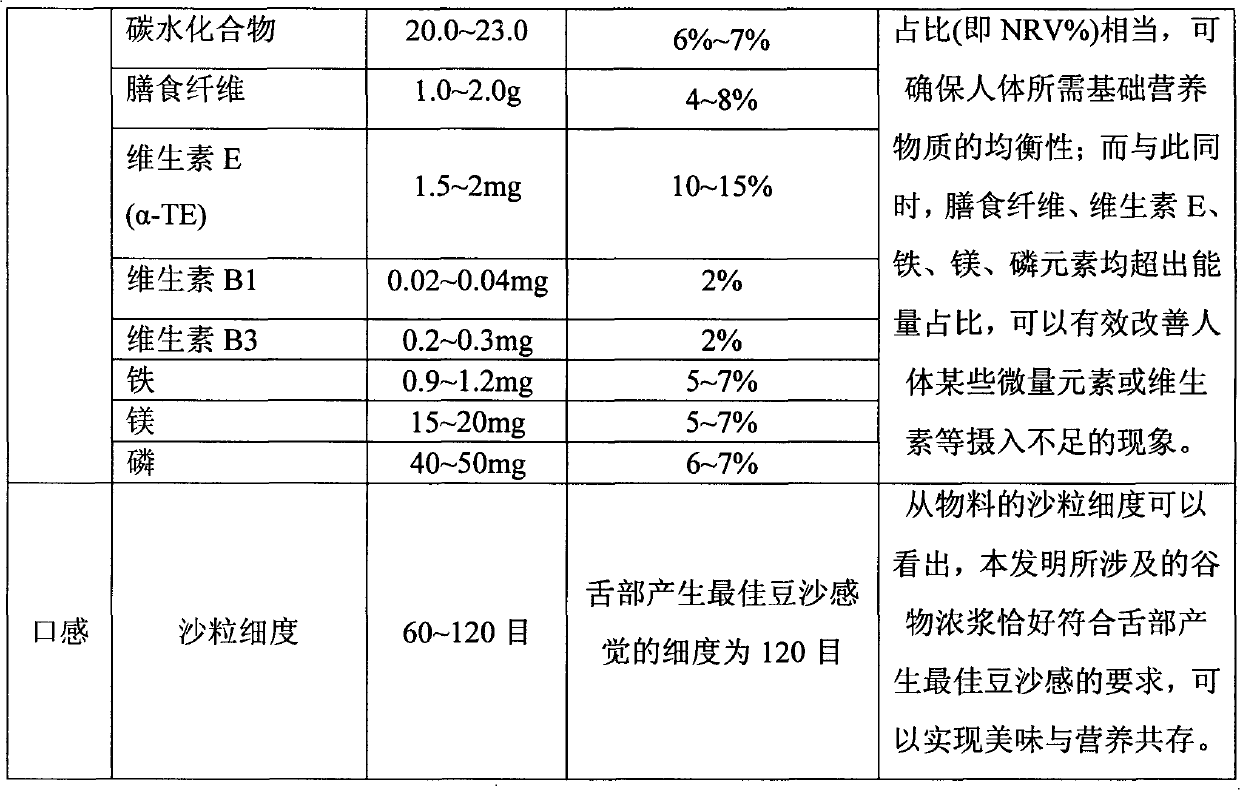

Red bean paste grain concentrated pulp and preparation method thereof

The invention relates to a red bean paste grain concentrated pulp non-alcohol drink and a preparation method thereof. The grain concentrated pulp drink is prepared from the following raw materials: red beans, black beans, dry cowpeas, white sugar, maltodextrin, non-dairy creamer, compound stabilizer and water. The preparation method of the grain concentrated pulp comprises: preparing a grain concentrate; preparing an auxiliary concentrate; blending; sterilizing; and finally, obtaining the red bean paste grain concentrated pulp non-alcohol drink which has a strong bean paste flavor, offers a full and smooth mouthfeel, contains rich dietary fibers, and has long-lasting stability.

Owner:山东朝能福瑞达生物科技有限公司

Mulberry leaf health care beverage and preparation method thereof

InactiveCN102742903AGreen colorAntibacterial and anti-inflammatoryFood preparationAdjuvantBad mouth taste

The invention relates to a beverage and specifically to a mulberry leaf health care beverage prepared with mulberry leaves as a main raw material and a preparation method thereof. Raw materials for the mulberry leaf health care beverage comprise, by mass, 1 part of fresh mulberry leaves, 0.5 part of fresh bamboo leaves, 0.1 part of gypsum powder, 0.015 part of egg white and sugar and 0.02 part of citric acid. The mulberry leaf health care beverage provided in the invention is transparent and clear, has a dark green color, agreeable sweet-sour taste and the unique delicate fragrance of mulberry leaves and bamboo leaves, contains abundant bioactive components, enables effective compatibility of the efficacy of mulberry leaves, bamboo leaves and gypsum powder to be obtained, has the effects of inhibiting bacteria, diminishing inflammation, clearing heat and removing toxins and can be used for prevention and adjuvant treatment of colds and for adjuvant treatment of diseases such as bad breath, toothache, vexation and the like.

Owner:徐州林泉绿色食品饮料厂

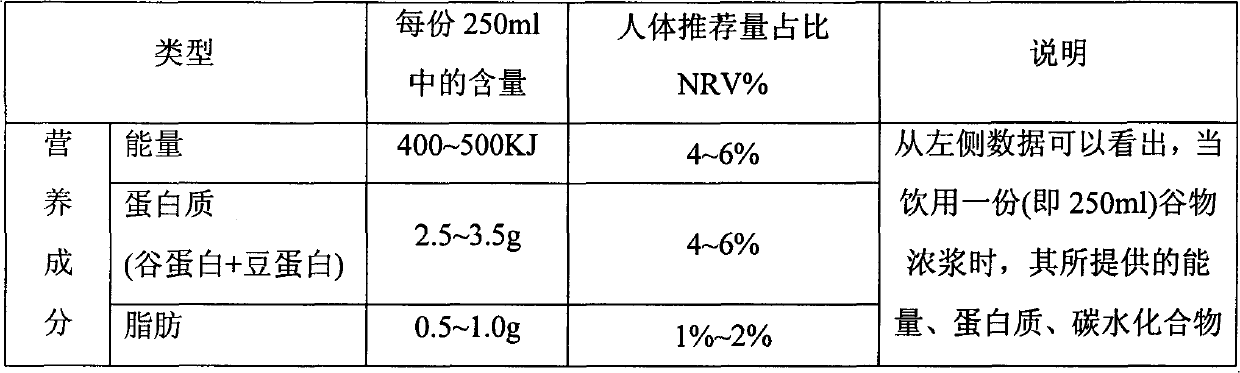

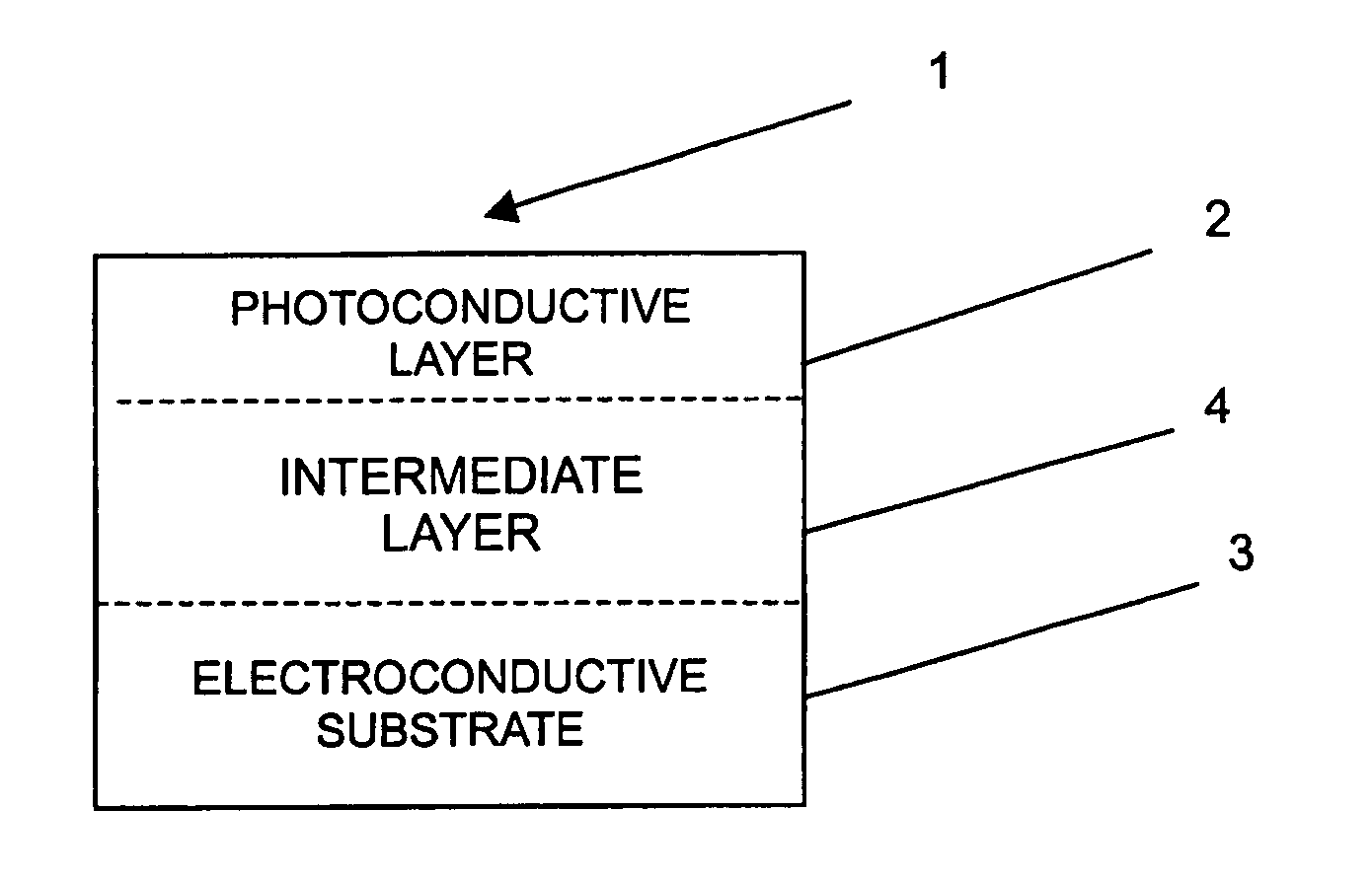

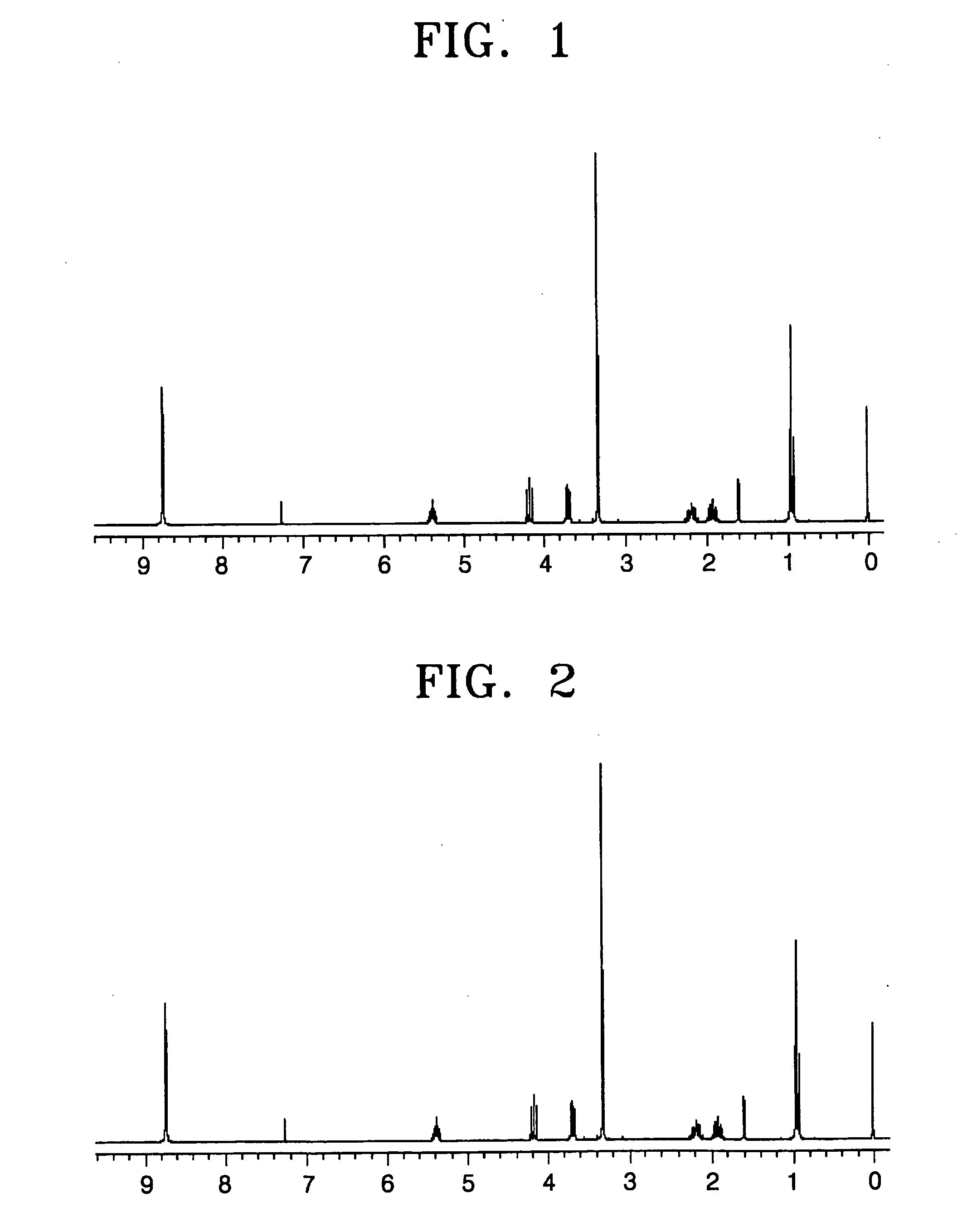

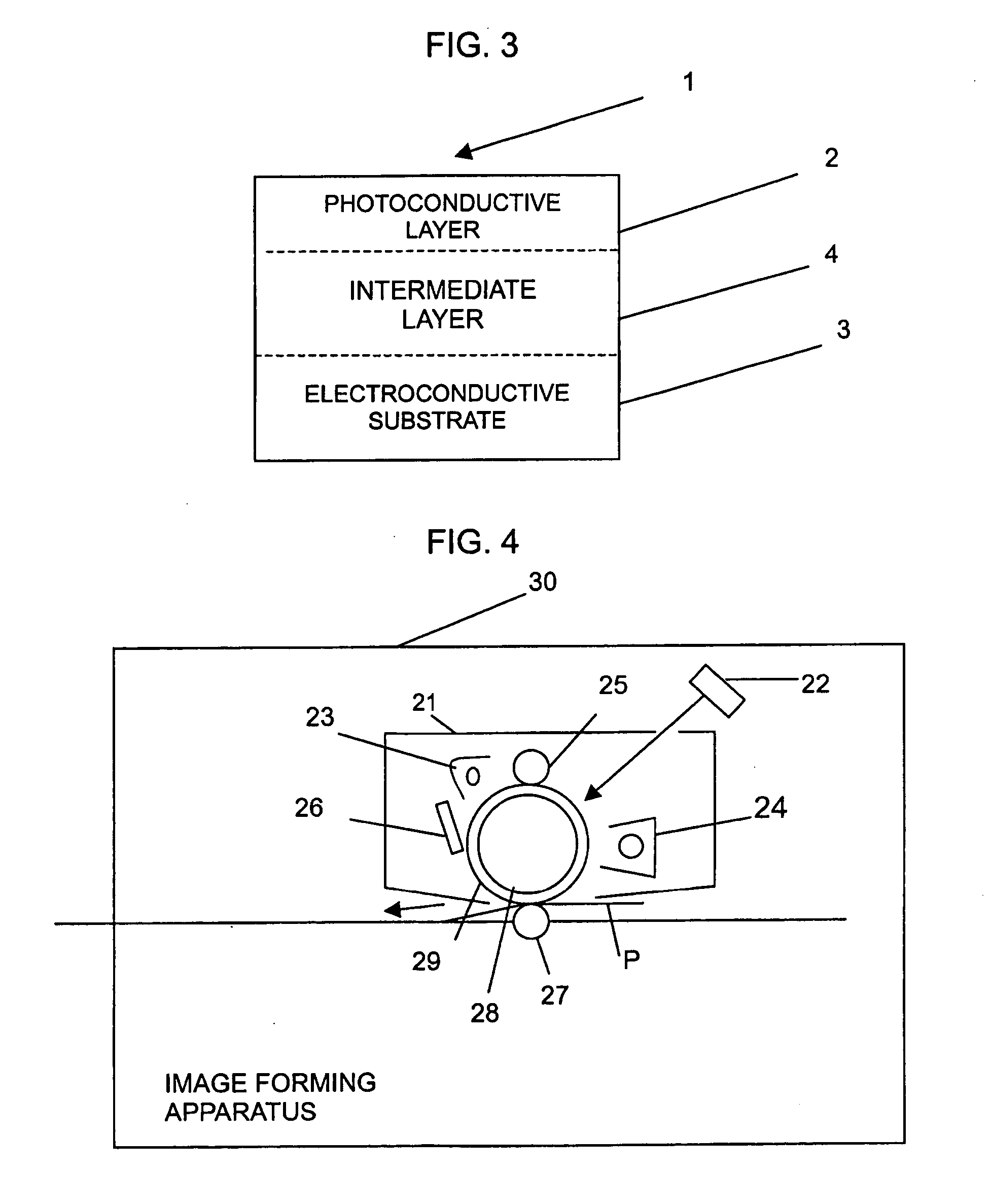

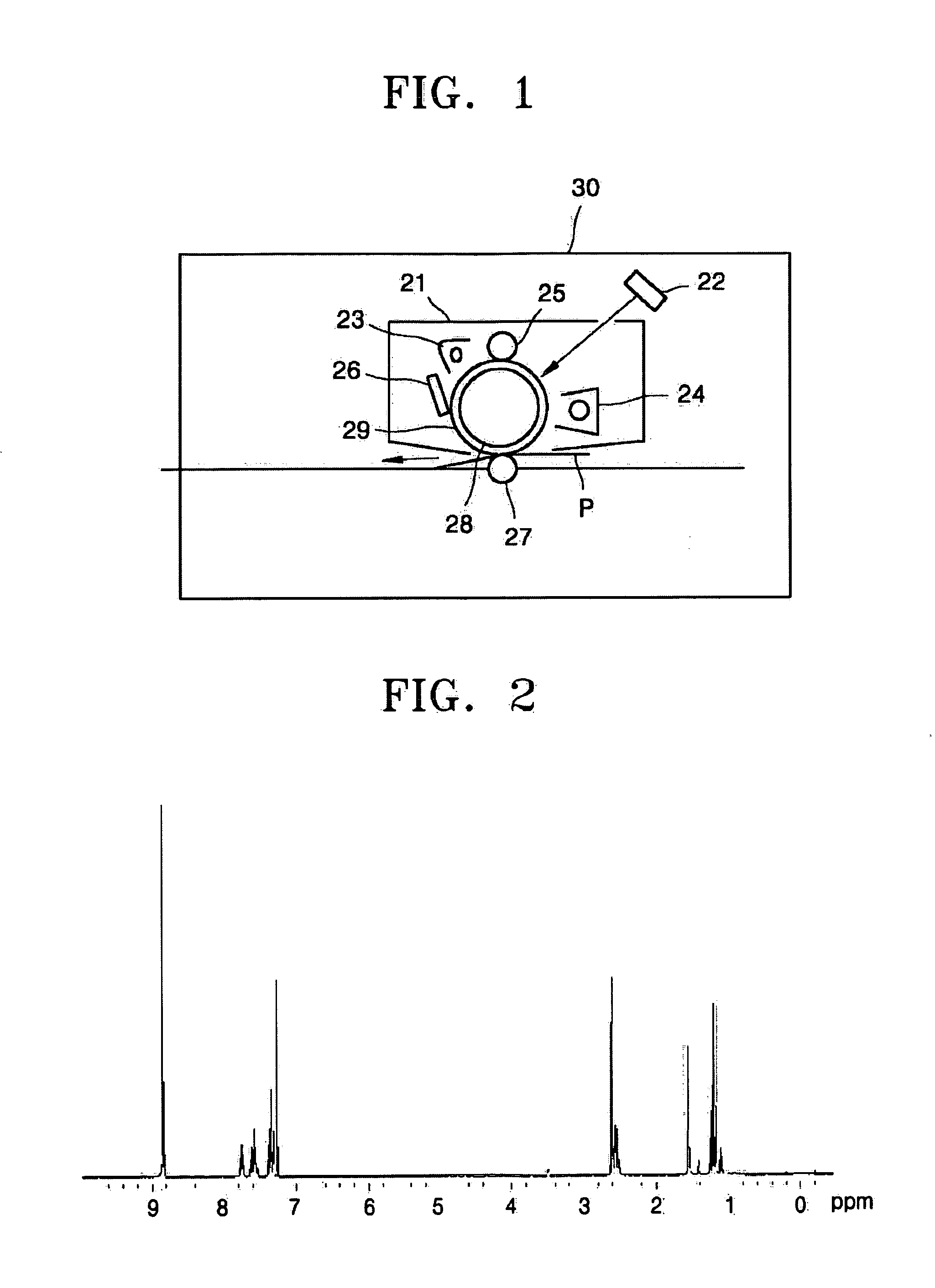

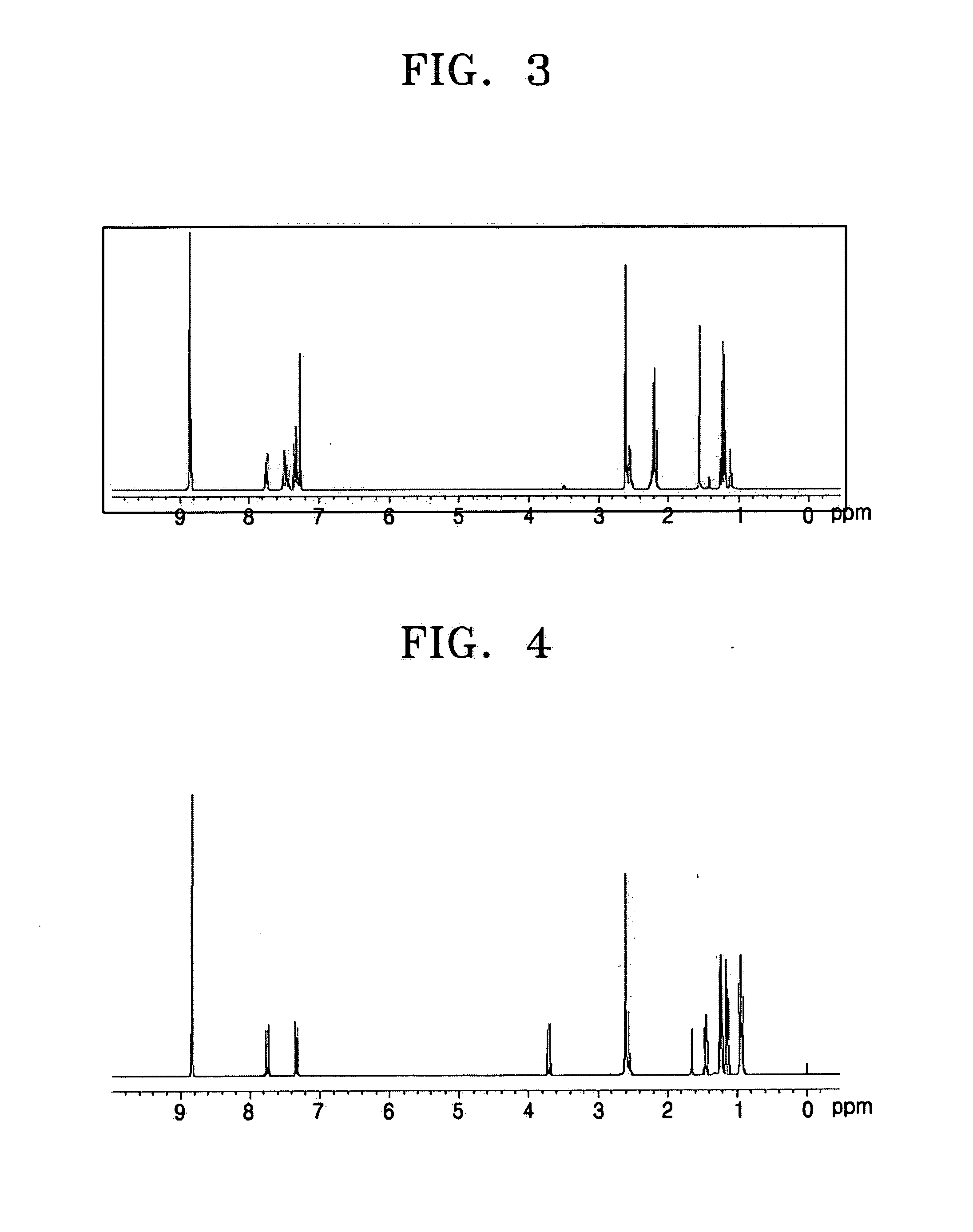

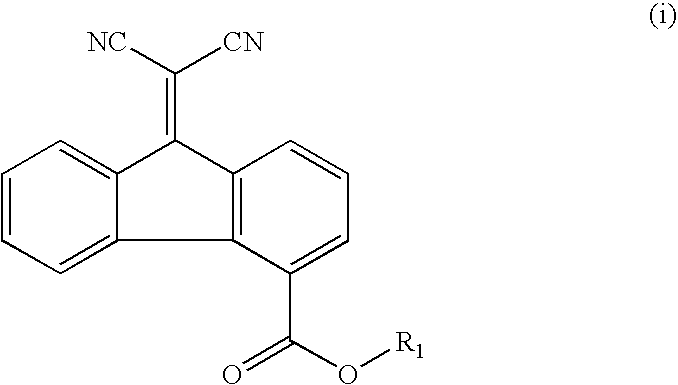

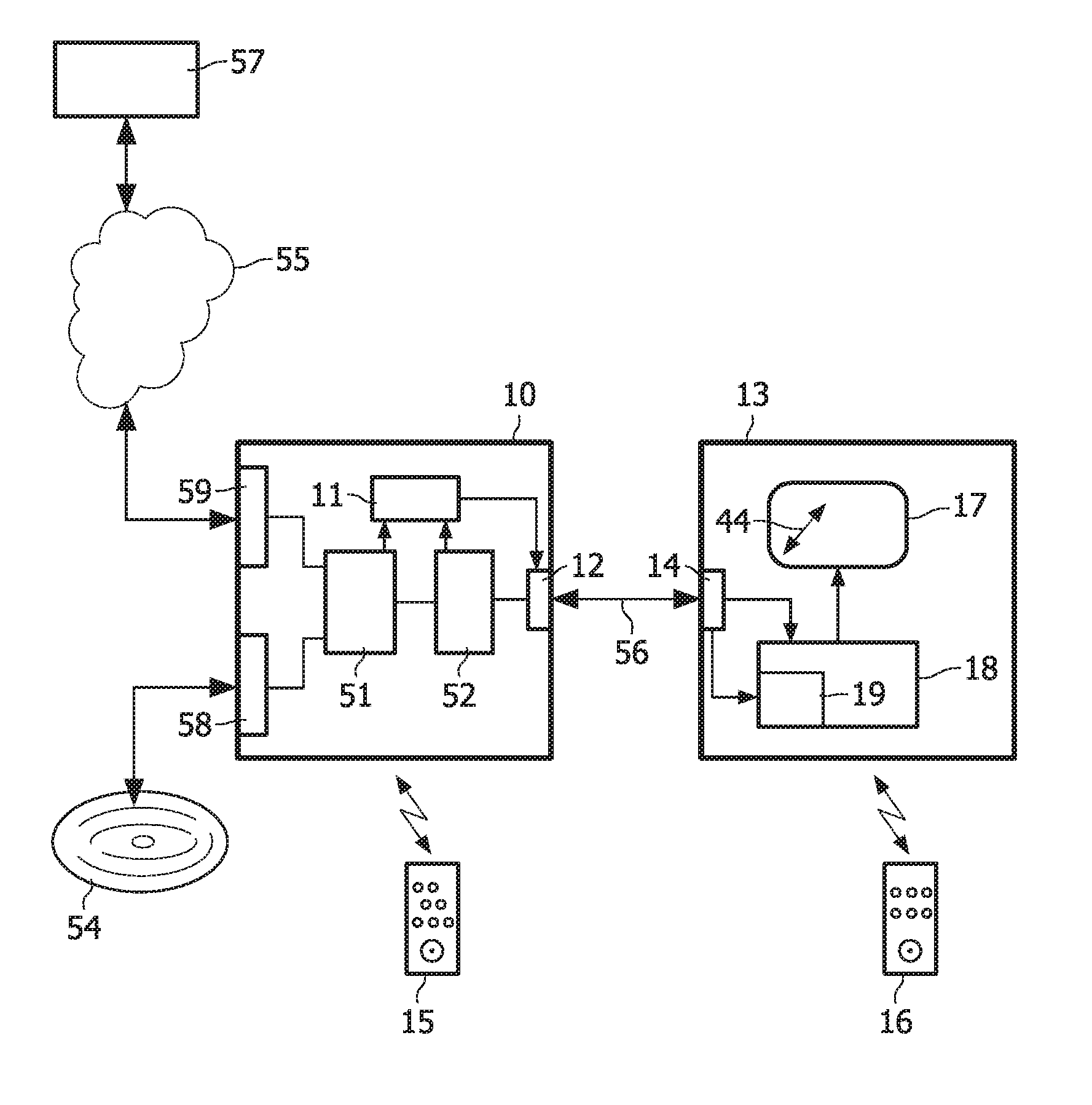

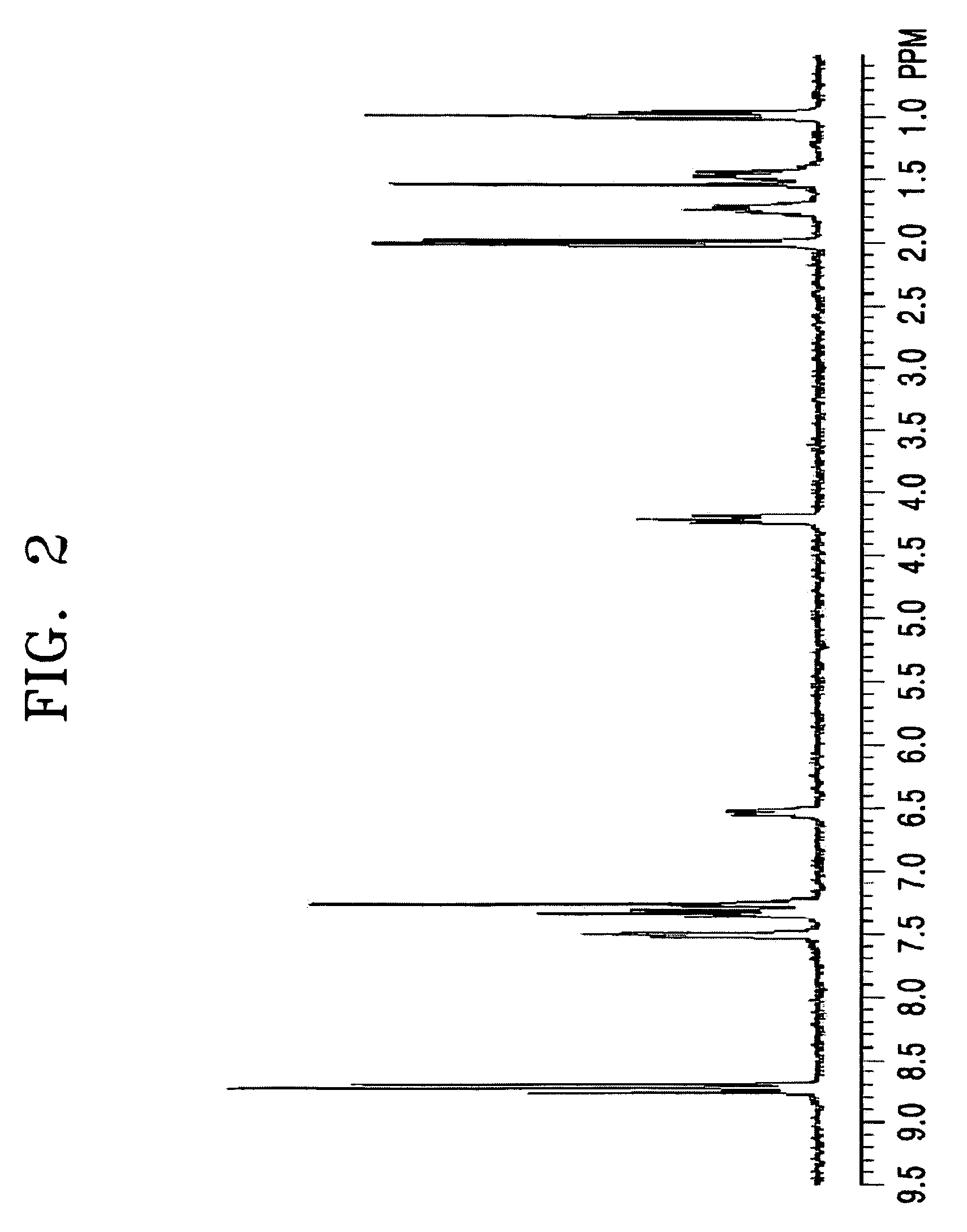

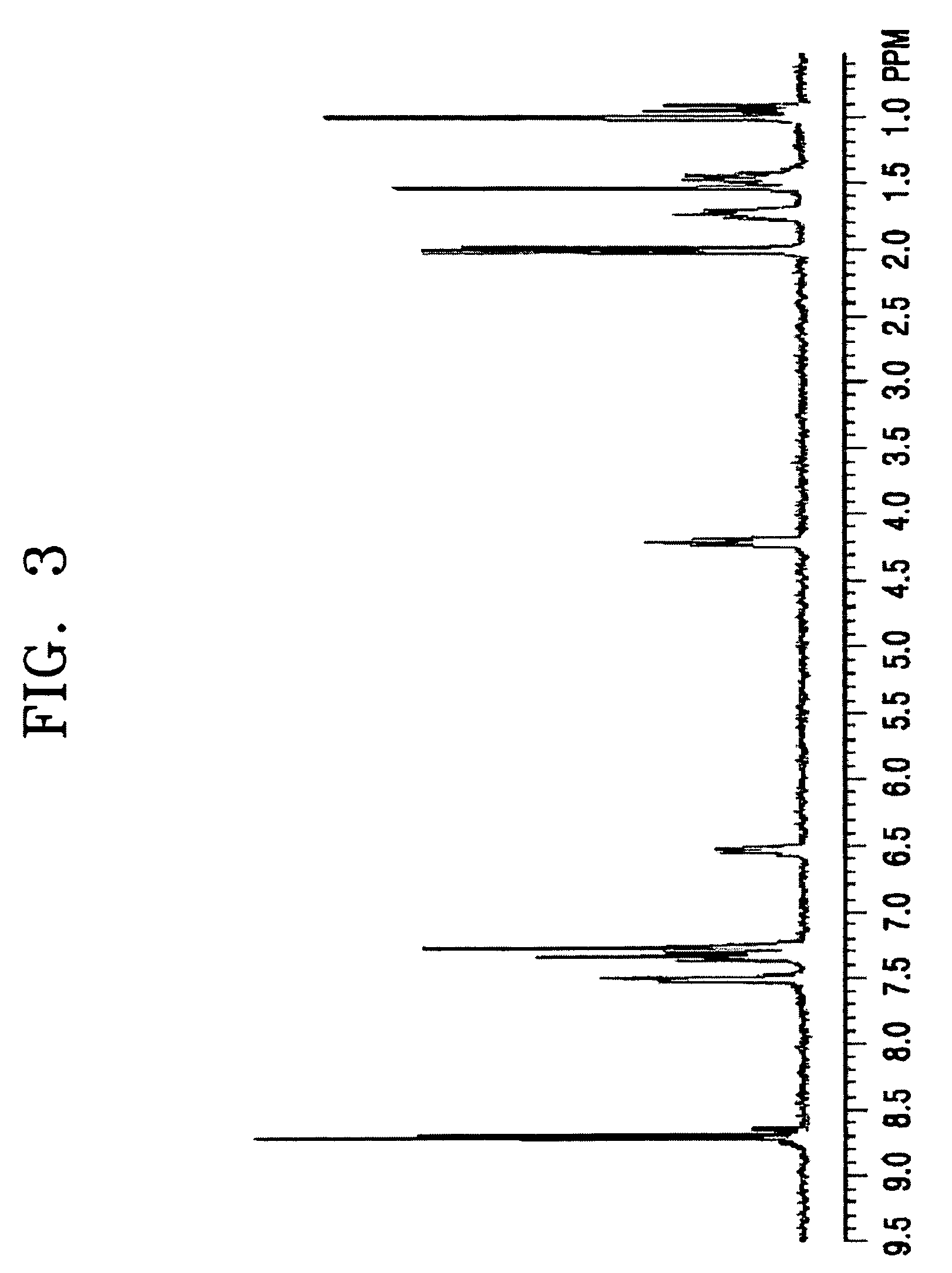

Naphthalenetetracarboxylic diimide derivatives and electrophotographic photoconductor containing the same

InactiveUS20050019685A1Effective solubilityEffective compatibilityOrganic chemistryElectrographic process apparatusSolubilityElectronic transmission

A naphthalenetetracarboxylic diimide derivative having formula (1) below, in which flexible ether groups are bonded to nitrogen atoms of diimide, is utilized to yield an effective solubility in organic solvents and compatibility with binder resins, thus providing an effective electron transporting ability:

Owner:SAMSUNG ELECTRONICS CO LTD

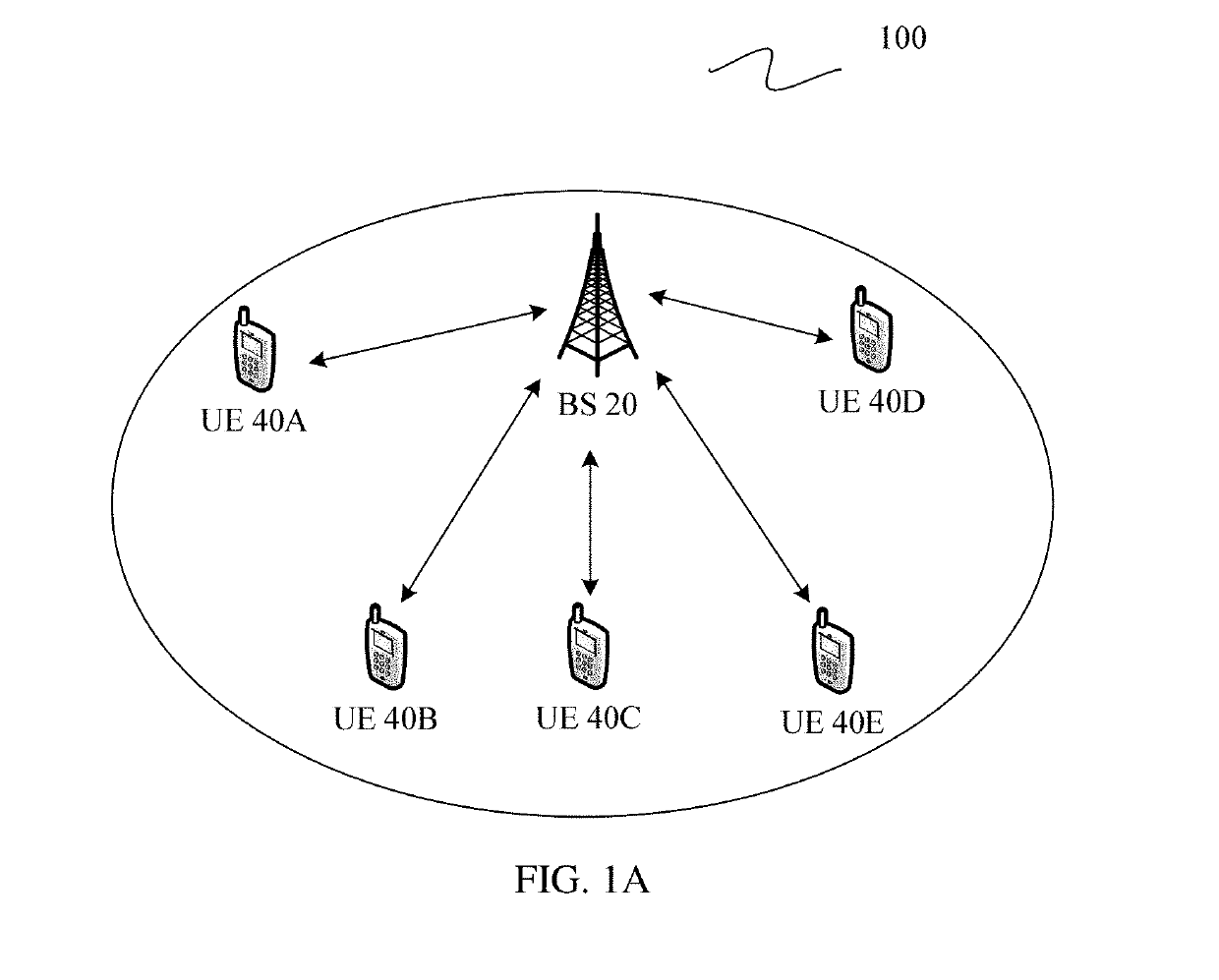

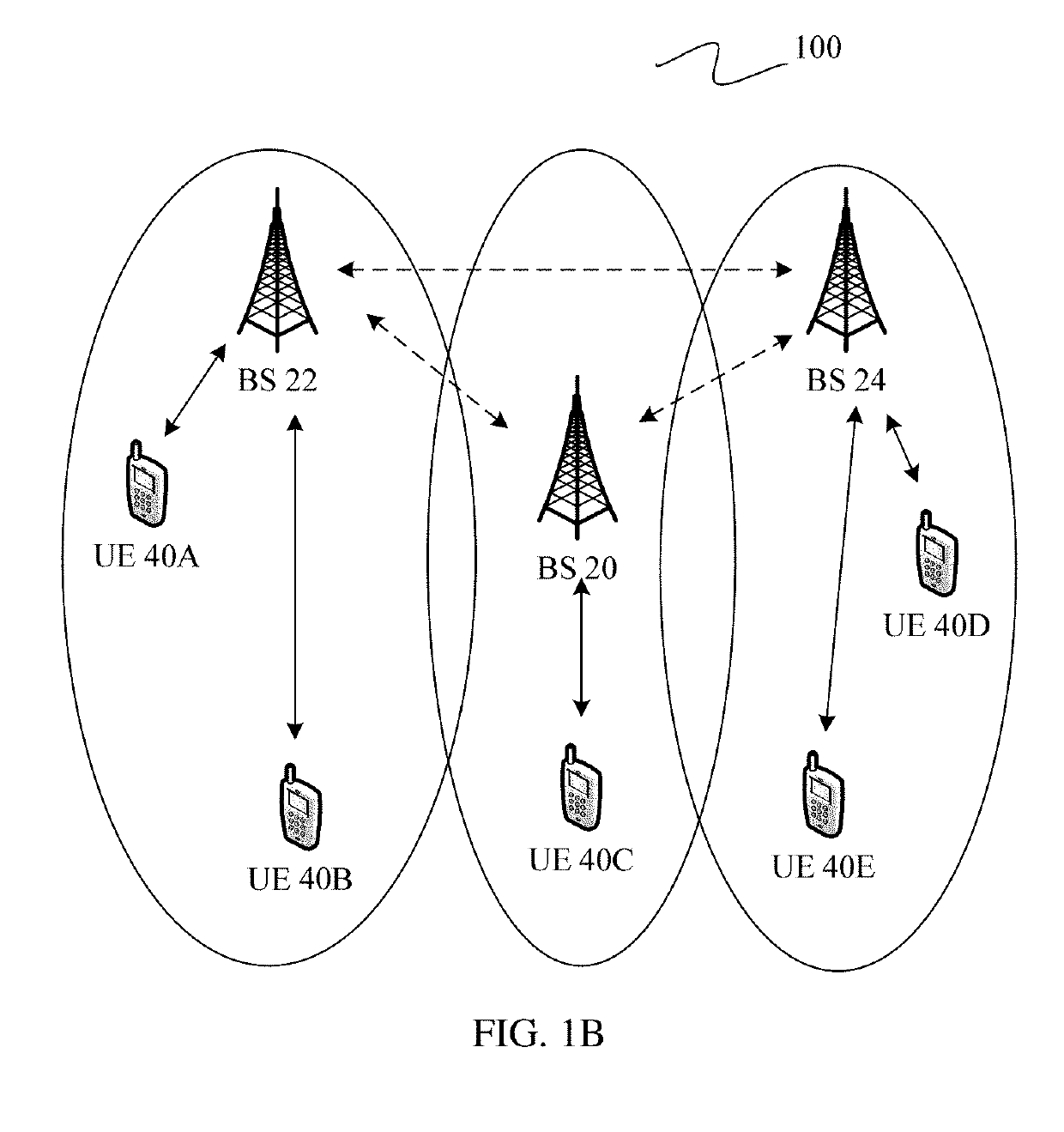

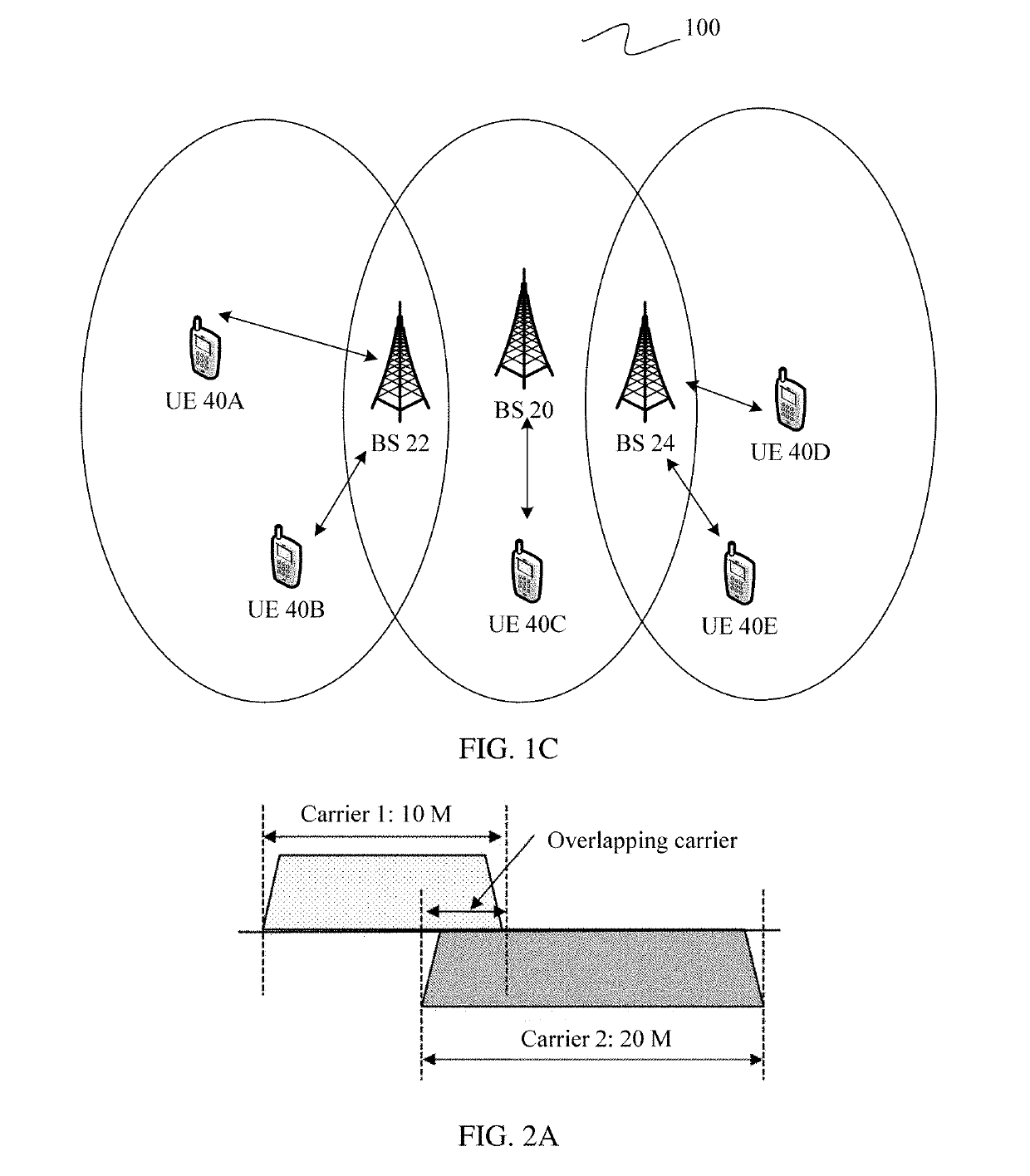

Method for Transmitting Carrier, Base Station, User Equipment, and System

ActiveUS20190261372A1Increase ratingsAvoid interferenceTransmission path divisionPilot signal allocationCommunications systemResource element

The present invention relates to the field of wireless communications technologies, and provides a method for transmitting a carrier, a base station, user equipment, and a system. The method discloses: sending, by a base station, a second carrier, where the second carrier at least partially shares a same resource area with a first carrier, the resource area includes a plurality of resource elements, and the first carrier and the second carrier occupy different resource elements; and sending, by the base station, blank resource element indication information to user equipment that receives the second carrier, where the blank resource element indication information is used to indicate a position of a resource element occupied by the first carrier in the shared resource area. According to the solutions provided in the embodiments, a resource utilization rate of a communications system is improved, and interference between carriers is avoided.

Owner:HUAWEI TECH CO LTD

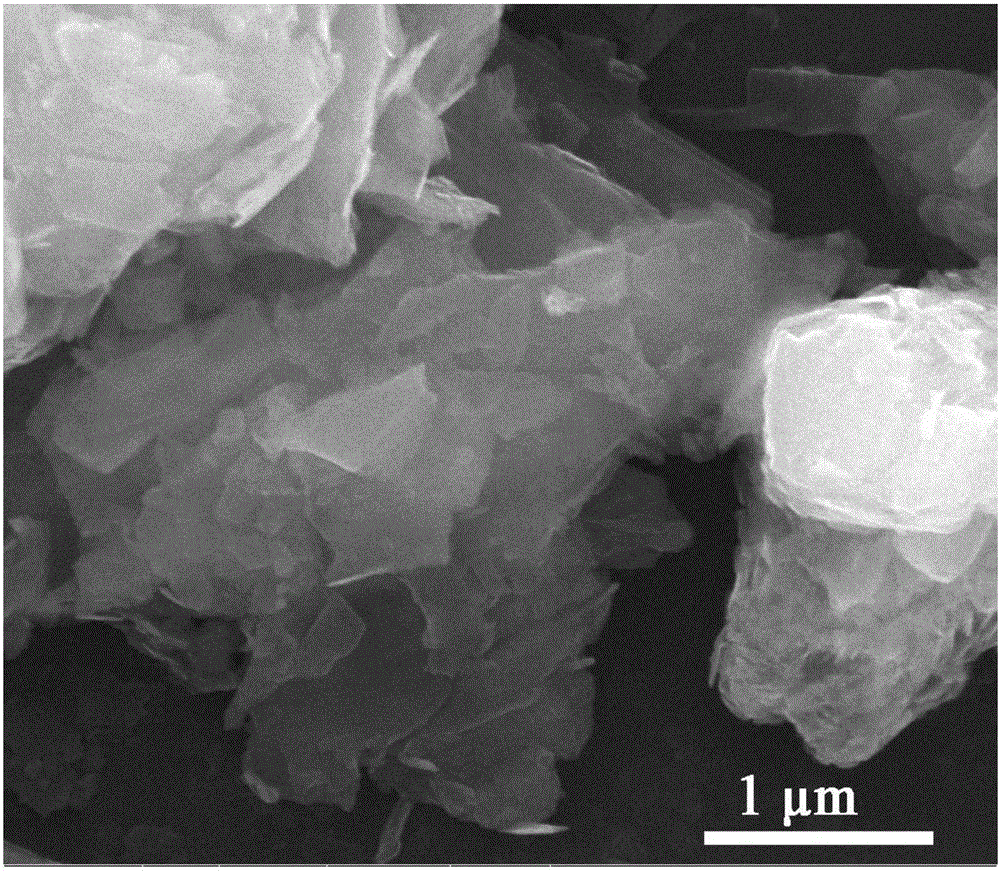

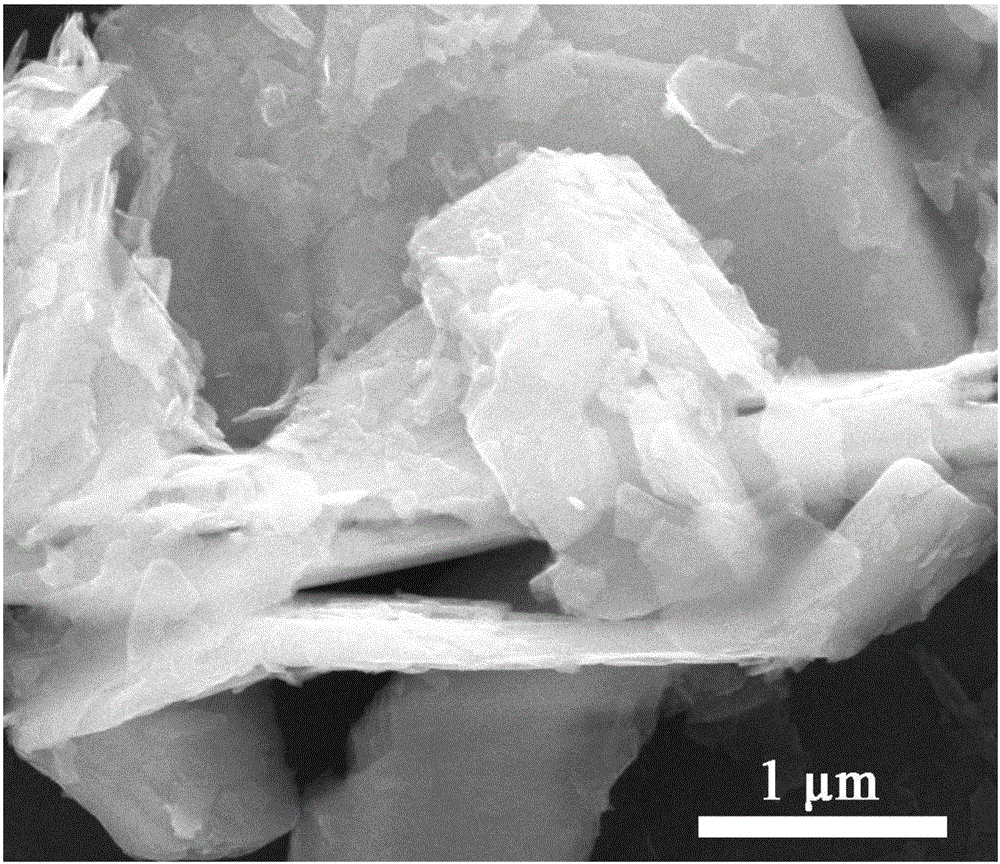

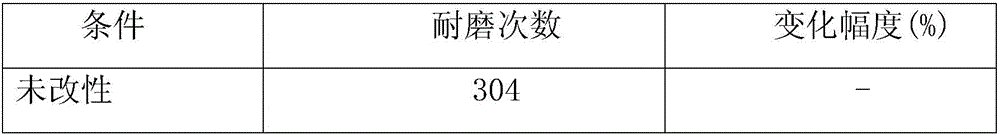

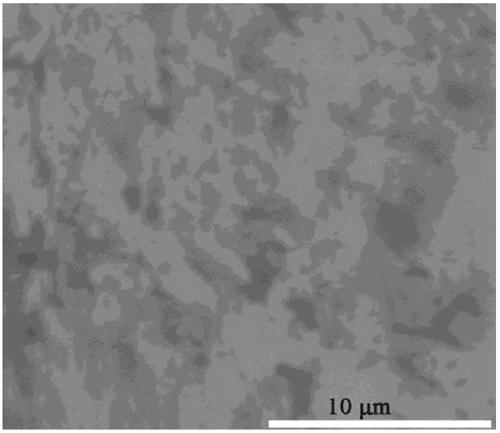

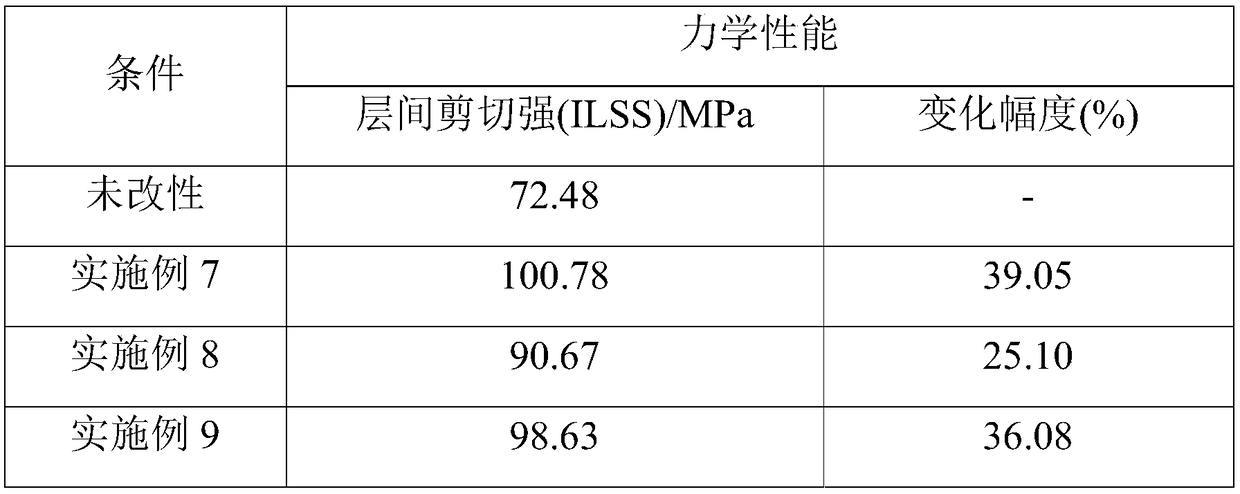

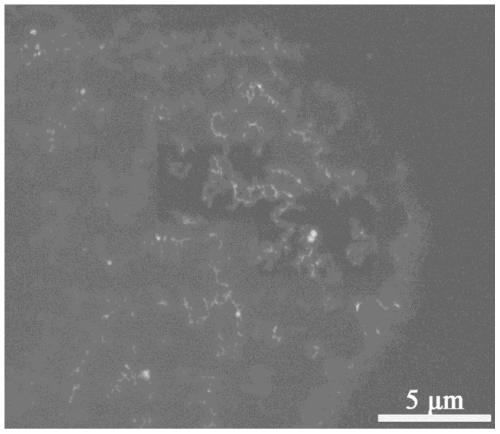

Nanosheet-layer tungsten disulfide reinforced carbon fiber sizing agent and preparation method thereof

InactiveCN105839398AImprove wear resistanceEffective compatibilityCarbon fibresOrganic solventSolid content

The invention relates to a nanosheet-layer tungsten disulfide reinforced carbon fiber sizing agent and a preparation method thereof. The sizing agent is a mixed system consisting of organic resin, an emulsifier, a dispersing agent, nanosheet-layer tungsten disulfide, an organic solvent and deionized water, wherein the organic solvent accounts for 20-200% of the organic resin, the emulsifier accounts for 1-5% of the organic resin, the dispersing agent accounts for 0.1-1% of the organic resin, and the nanosheet-layer tungsten disulfide accounts for 0.05-0.8% of the organic resin all by mass; and the solid content of the obtained mixed system is 25-35%. According to the sizing agent provided by the invention, by adding the nanosheet-layer tungsten disulfide, the wear resistance of the carbon fiber composite material is remarkably improved, the interfacial properties are optimized, and the sizing agent is of important significance to the industrial upgrading of the carbon fiber composite material.

Owner:FUDAN UNIV

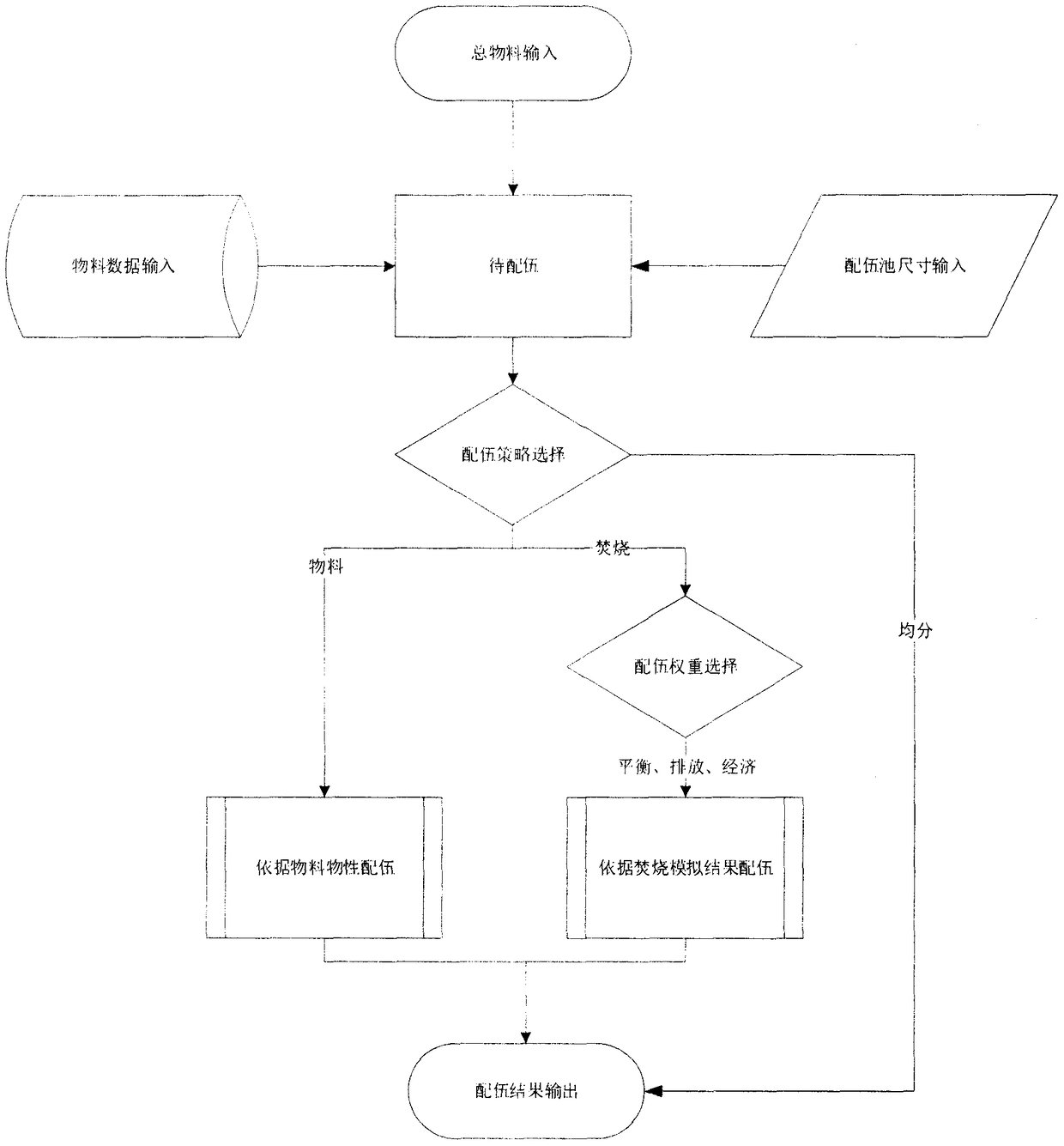

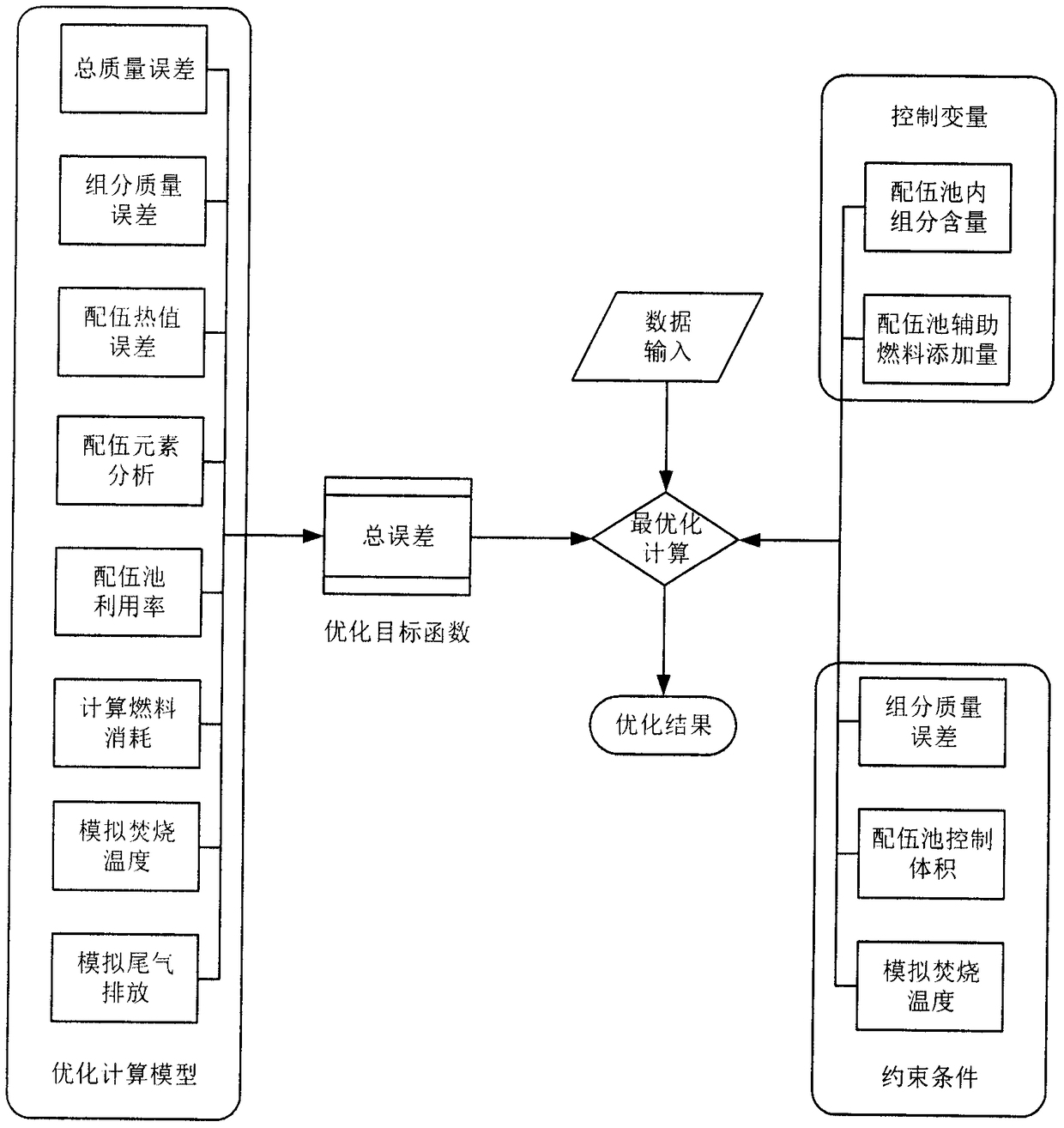

A hazardous waste incineration compatibility system based on off-line operation optimization

PendingCN109359387ACompatibility is simpleEffective compatibilityDesign optimisation/simulationSpecial data processing applicationsEconomic benefitsUser Friendly

The invention relates to a hazardous waste incineration compatibility system based on off-line operation optimization, including a hazardous waste databases, a module to be compatible, a compatibilitystrategy selection module and a compatibility module; by using the mixed integer nonlinear optimization method, the optimal compatibility scheme is calculated under the given limited conditions, Theresulting compatibility scheme can be exported as a user-friendly document for practical reference, The system can assist operators to quickly and simply carry out effective compatibility of various materials, thereby improving equipment operation efficiency, reducing temperature fluctuation caused by improper feed compatibility and equipment unplanned shutdown, and effectively improving the economic benefits of hazardous waste incineration.

Owner:TIANJIN UNIV OF SCI & TECH

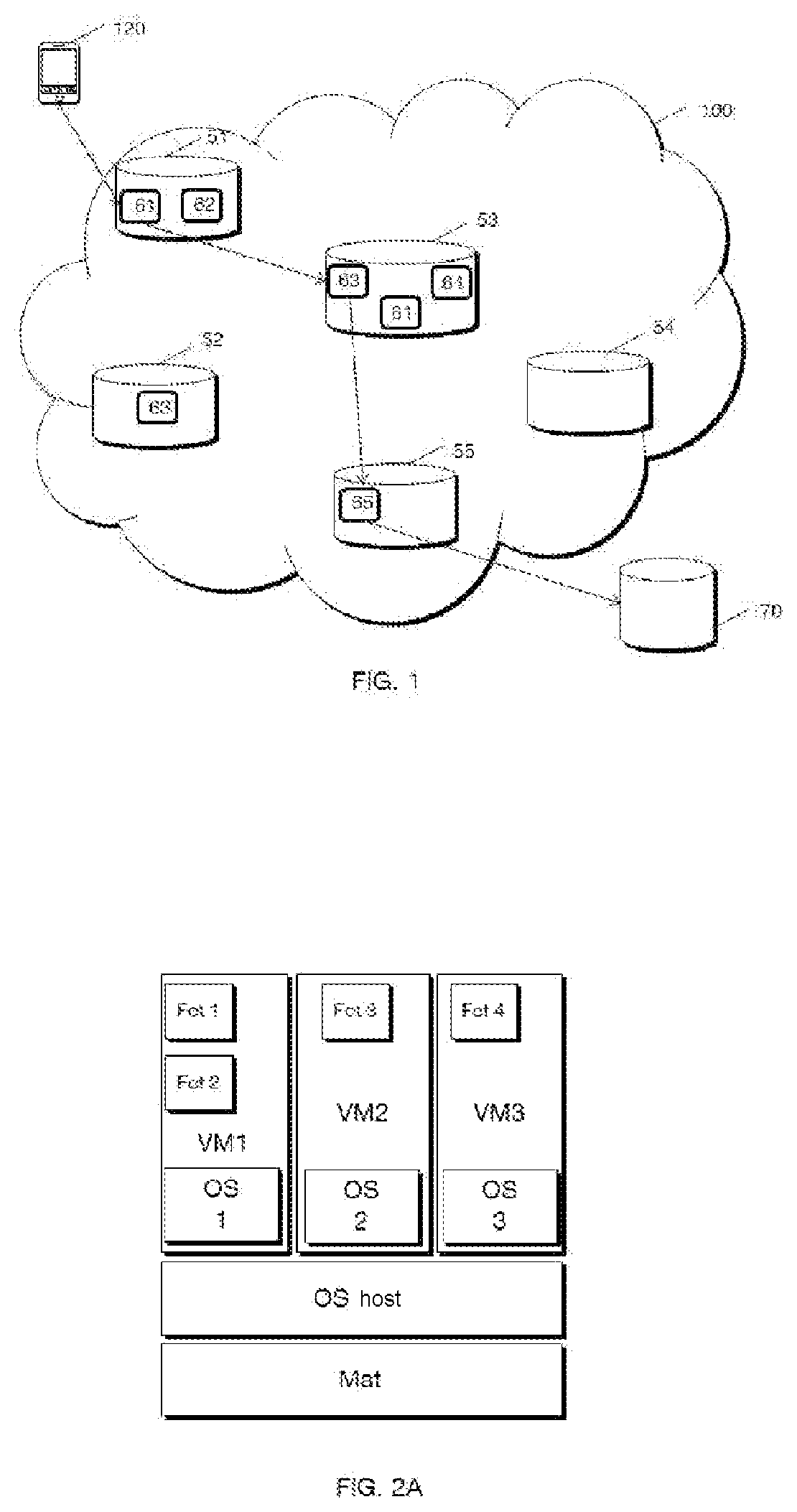

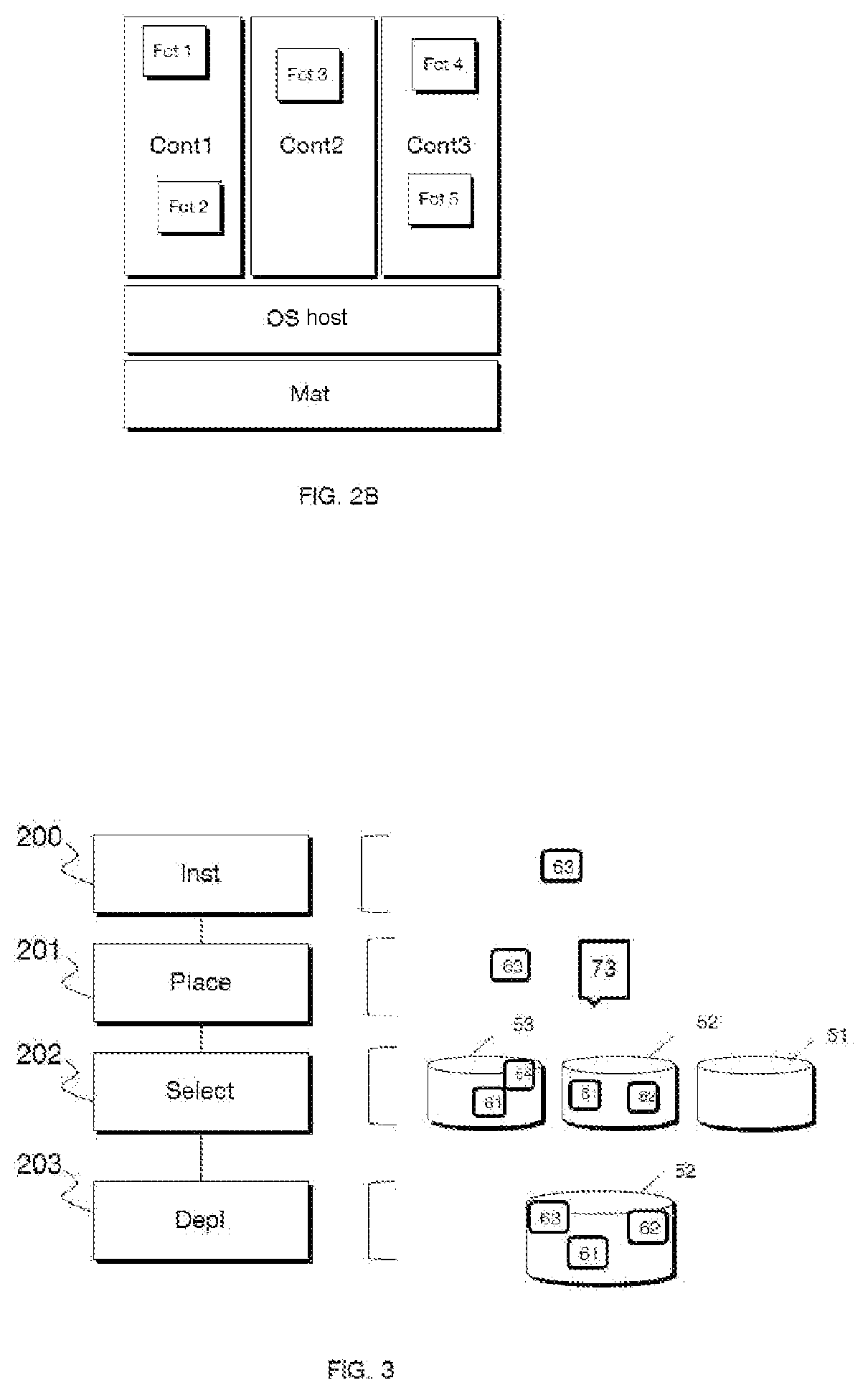

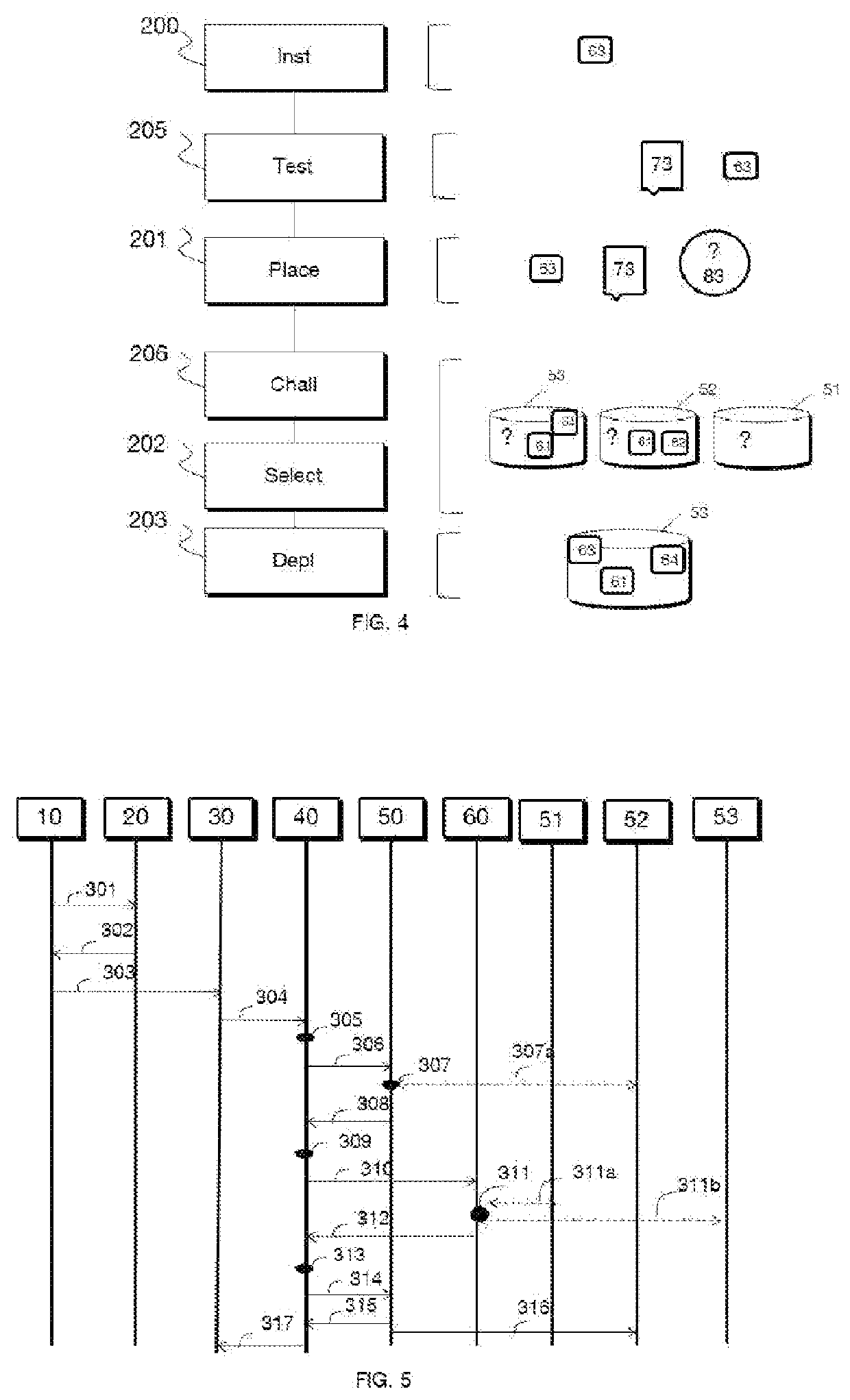

Method for evaluating the devices of a network infrastructure for deploying a virtualised function

PendingUS20220174588A1Good conditionEffective compatibilityError detection/correctionAssess restrictionVirtualizationComputer network

A method for determining a hosting device of a network infrastructure of an operator for the installation of a virtualized function. The virtualized function contributes to transmission and processing of at least one item of information relating to a service. The method is implemented by a management entity of the infrastructure and includes: transmitting to a virtualization entity a compatibility request including at least one datum relating to a test of a resource of the hosting device; receiving from the virtualization entity at least one first variable derived from the test, relating to the transmitted datum, executed on the resource; and determining an aptitude of the hosting device to accommodate the virtualized function as a function of the at least one first variable received.

Owner:ORANGE SA (FR)

Electrophotographic photoreceptor containing pyridine-substituted asymmetric naphthalenetetracarboxylic acid diimide derivatives and electrophotographic imaging apparatus

InactiveUS20060183043A1Effective solubilityEffective compatibilityOrganic chemistryElectrographic process apparatusSolubilityOrganic solvent

An electrophotographic photoreceptor includes a pyridine-substituted asymmetric naphthalenetetracarboxylic acid diimide derivative. The pyridine-substituted asymmetric naphthalenetetracarboxylic acid diimide derivative has increased solubility in organic solvents, improved compatibility with binder resins and enhanced resistance for nitrogen oxides. The electrophotographic photoreceptor containing the asymmetric naphthalenetetracarboxylic acid diimide compound according to the present invention can maintain a constant surface potential and durability after being repeatedly used for an extended time. The electrophotographic photoreceptor according to the present invention can provide a high image quality for an extended time. The invention is also directed to an electrophotographic imaging apparatus, an electrophotographic cartridge and to novel pyridine-substituted asymmetric naphthalenetetracarboxylic acid diimide derivatives.

Owner:SAMSUNG ELECTRONICS CO LTD

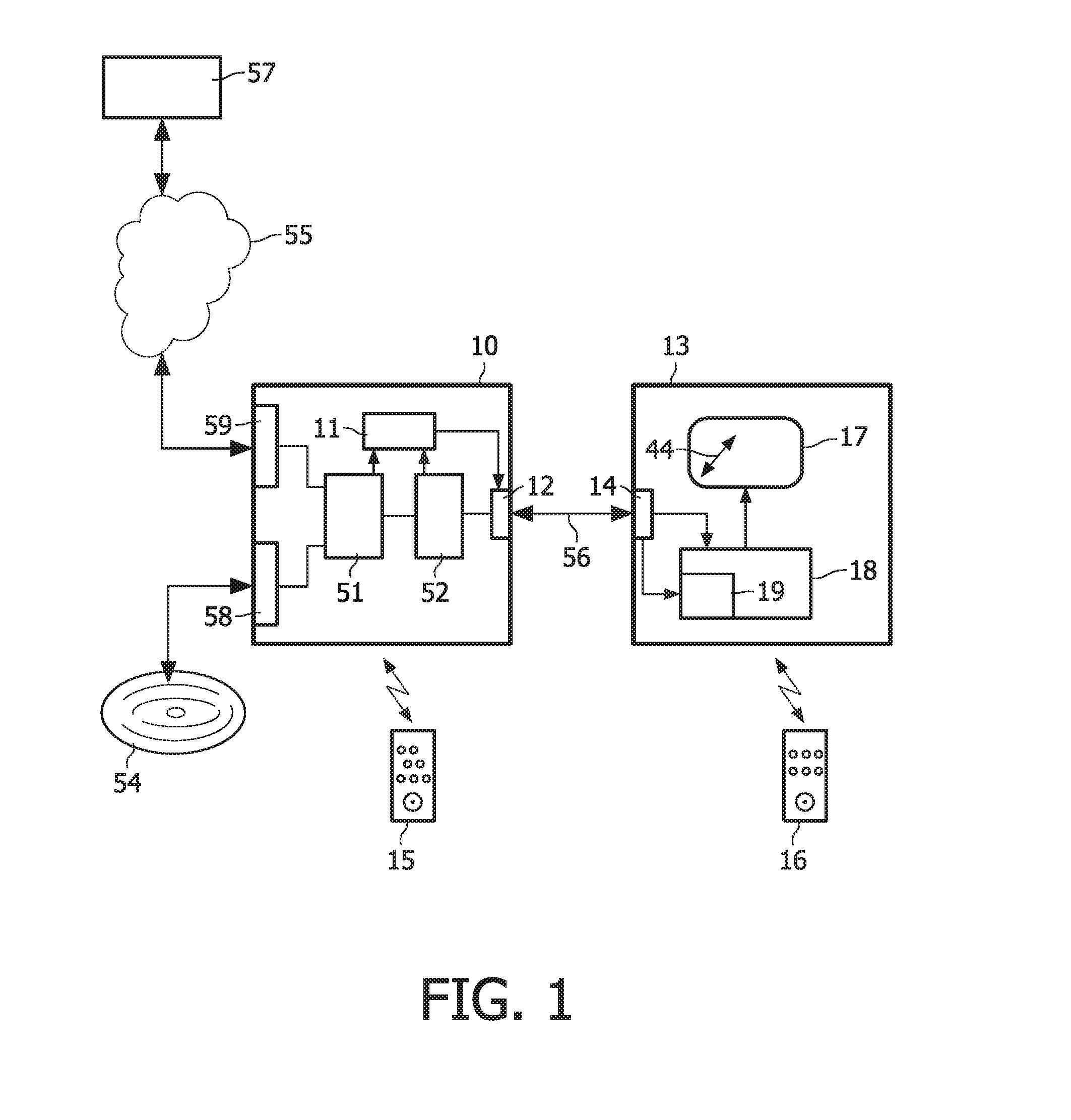

Extending 2d graphics in a 3D GUI

A system of providing a three-dimensional [3D] graphical user interface on a 3D image device (13) is provided for controlling a user device (10) via user control means (15). The user control means are arranged for receiving user actions and generating corresponding control signals. A graphical data structure is provided representing a graphical control element for display in the 3D graphical user interface. The graphical data structure has two dimensional [2D] image data for representing the graphical control element, and also at least one depth parameter for positioning the 2D image data at a depth position in the 3D graphical user interface.

Owner:KONINKLJIJKE PHILIPS NV

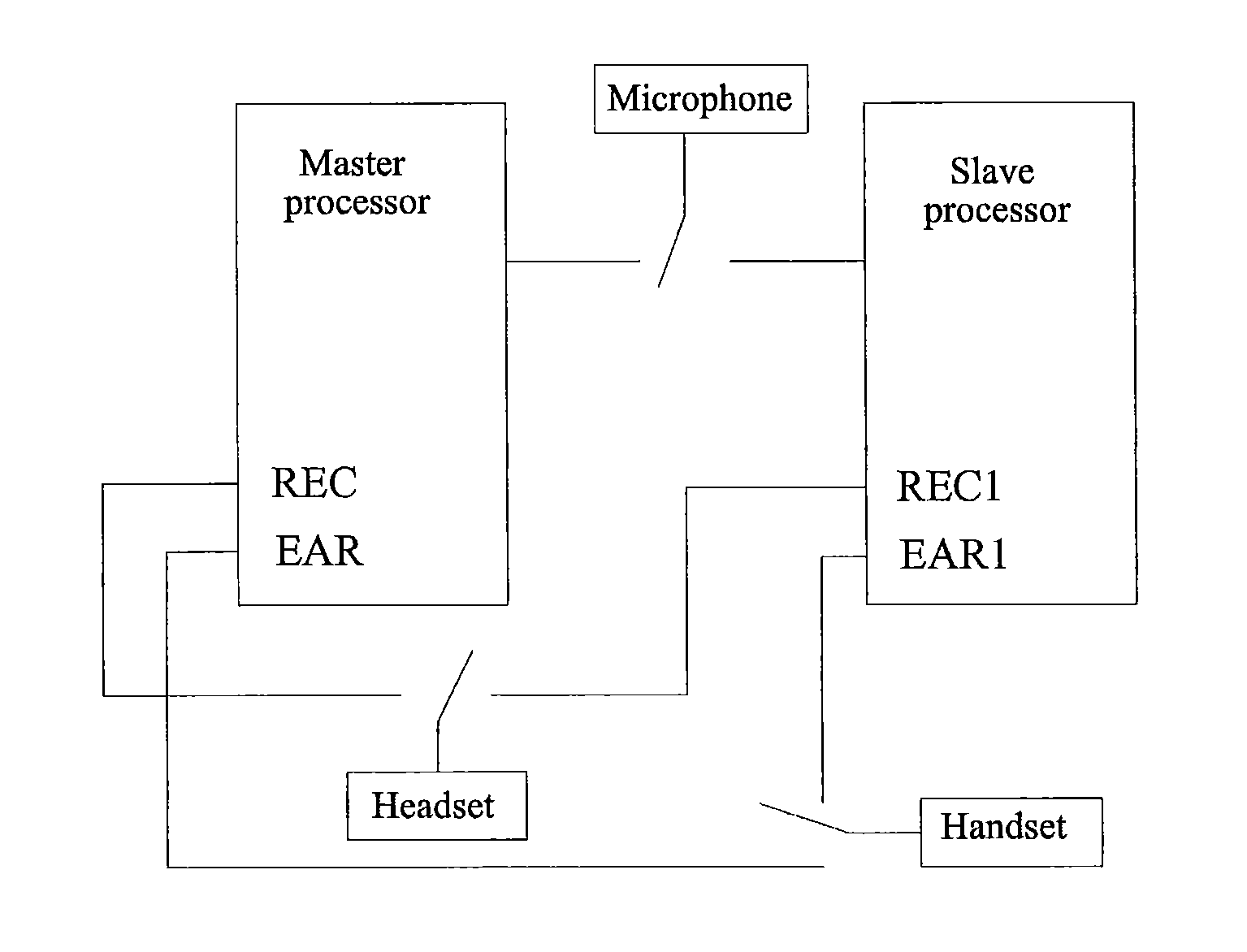

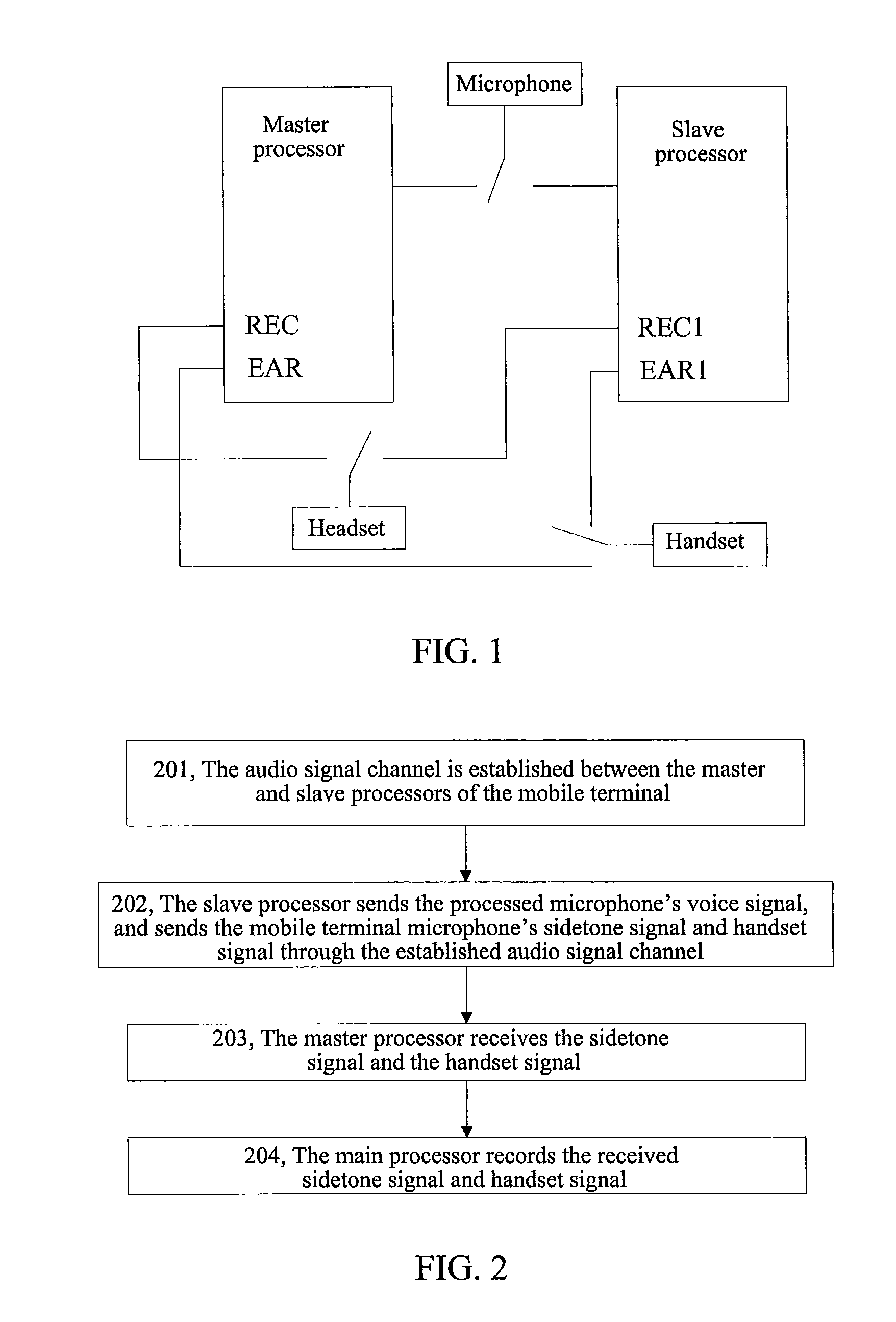

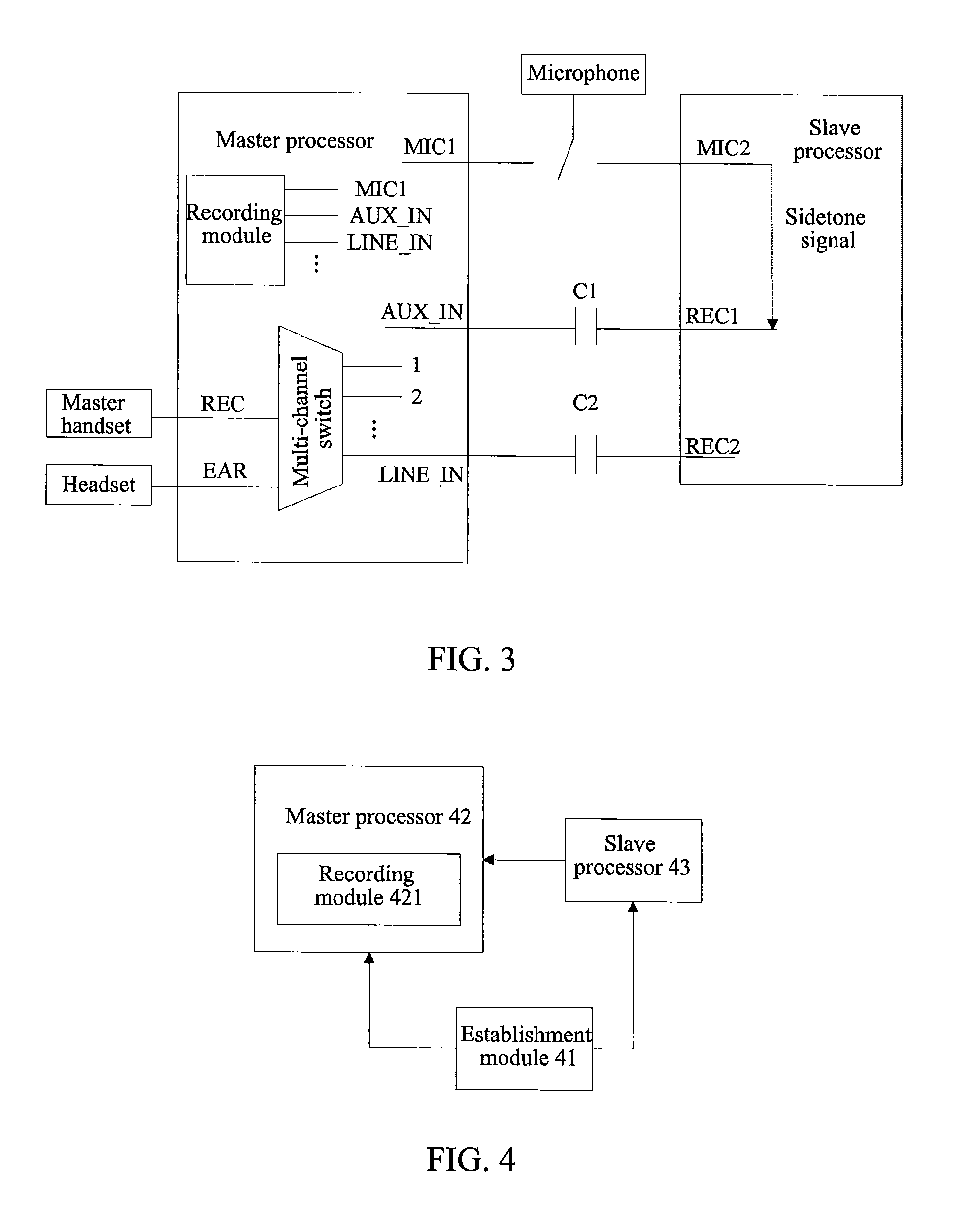

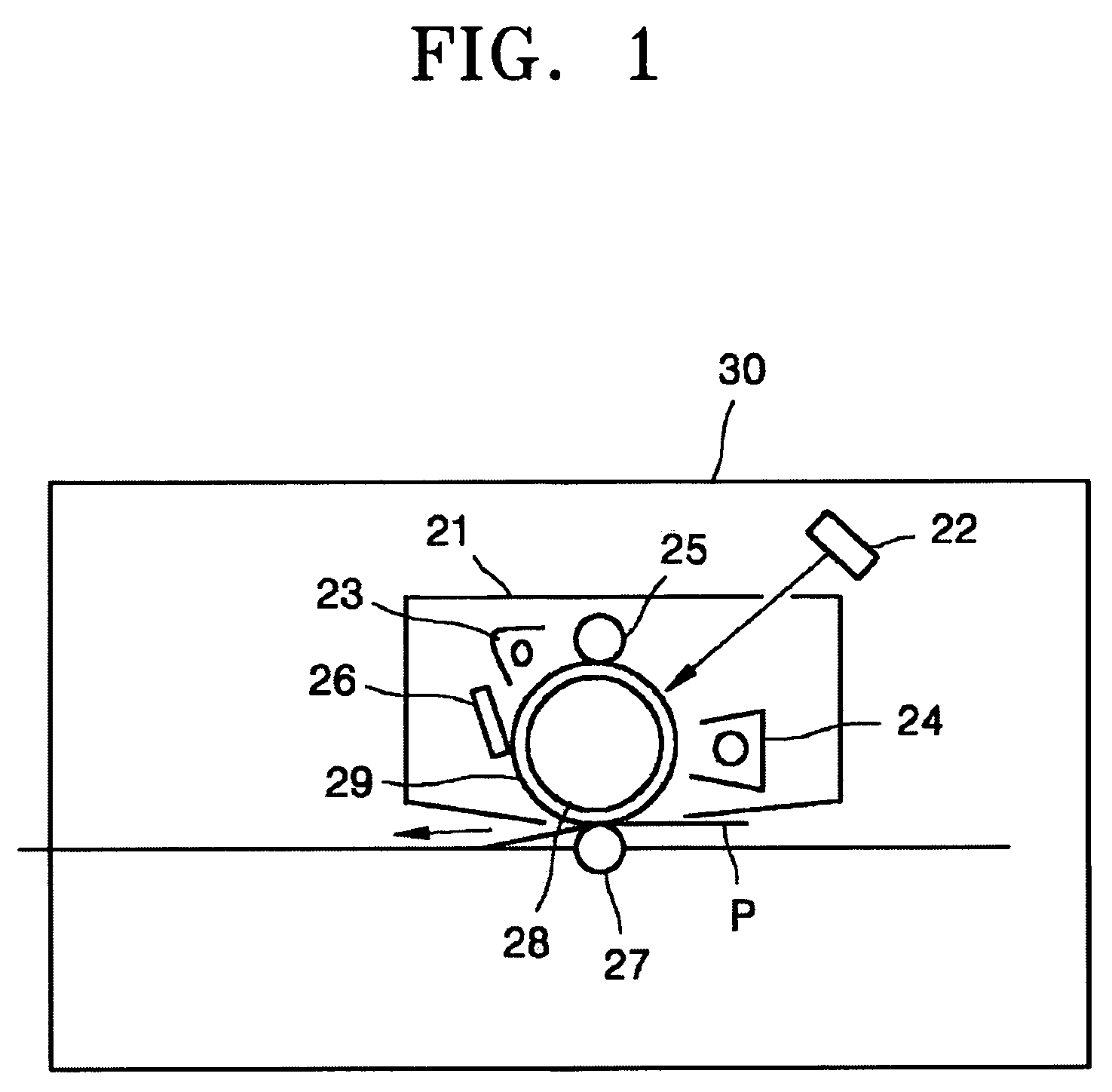

Method and terminal for talk recording implementation

InactiveUS20120329434A1Reduce data volumeImplementation is simple and convenientSpecial service for subscribersSubstation equipmentSidetoneComputer terminal

The present invention discloses a method for implementing call recording. Said method includes: establishing an audio signal channel between a master processor and a slave processor of a mobile terminal. Said method also includes: the slave processor sending the mobile terminal microphone's sidetone signal and headphone signal through the established audio signal channel; the master processor receiving and recording said sidetone signal and headphone signal; the present invention also discloses a terminal for implementing call recording. According to the technical solution of the present invention, the master processor can record the slave processor's sidetone signal and headphone signal in real time.

Owner:ZTE CORP

Electrophotographic photoreceptor containing asymmetric naphthalenetetracarboxylic acid diimide derivatives and electrophotographic imaging apparatus employing the same

InactiveUS7494754B2Effective solubilityEffective compatibilityOrganic chemistryElectrographic process apparatusSolubilityOrganic solvent

Owner:SAMSUNG ELECTRONICS CO LTD

Heat-resistant graphene conductive thin film and preparation method thereof

The invention discloses a heat-resistant graphene conductive thin film. The heat-resistant graphene conductive thin film is prepared from the following raw materials in parts by weight: 10 to 14 partsof graphene, 1 to 2 parts of diethylene glycol dibenzoate, 0.8 to 1 part of alkanolamide, 1 to 2 parts of silane coupling agent kh550, 2 to 3 parts of barium stearate, 0.1 to 0.2 part of stannous sulfide, 5 to 7 parts of heat-resistant polyethylene wax, 0.1 to 0.2 part of alkylphenol polyoxyethylene, 60 to 70 parts of polyaniline, 1 to 2 parts of ammonium polyphosphate, 3 to 4 parts of aluminiumdihydrogen phosphate, and 2 to 3 parts of triethanolamine. The heat-resistant graphene conductive thin film has the advantages that by adding the aluminium dihydrogen phosphate, calcium acetylacetonate and the like, the heat-resistant stability of the finished thin film is improved; by adding the aluminium dihydrogen phosphate, the viscosity between the raw materials can be enhanced in the calendering and filming process, thereby further improving the uniform stability of filming.

Owner:查公祥

Aqueous environmentally-friendly nano-copolymer multifunctional defoamer and preparation method thereof

ActiveCN110327665AImprove performanceGood shear stabilityFoam dispersion/preventionHazardous substanceWater source

The embodiment of the invention provides an aqueous environmentally-friendly nano-copolymer multifunctional defoamer and a preparation method thereof. The raw materials of the defoamer comprise, by mass, 20-26% of a natural vegetable fatty alcohol, 10-15% of a higher fatty alcohol, 5-10% of an amide, 5-8% of a nano-hydrophobic agent, 0.5-1% of a fluorine monomer, 3-6% of a silane, 2-5% of an initiator, 1-2% of an active polymerization agent, 0.5-1% of a catalyst, 1-2% of a thickener, 1-2% of an antifreeze agent and 30-45% of deionized water. The defoamer provided by the embodiment of the invention is prepared by raw material selection and a copolymerization synthesis mode, a nano-material group is introduced to change the polymer structure, and harmful substances such as a conventional emulsifier, formaldehyde and silicone oil are not used, so the versatility, the weather resistance, the stain resistance, the high corrosion resistance and the auto-cleaning property are improved. The product can be decomposed by hydrolysis, photodegradation and biodegradation without causing cumulative effects, so the product is very safe to water sources and the environment.

Owner:安徽广成新材料科技有限公司

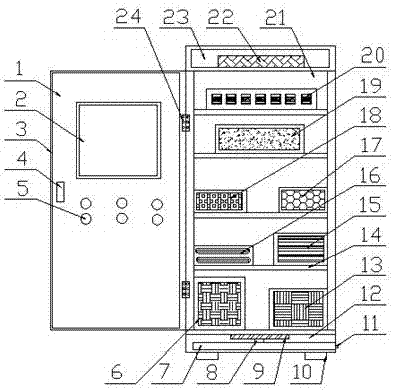

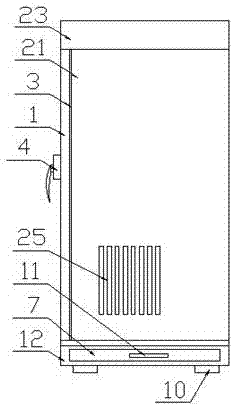

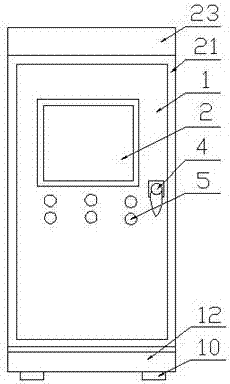

Power distribution cabinet having functions of heat radiation and dust absorbing

InactiveCN107453258AWith vacuum functionAvoid enteringSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTime delaysEngineering

The invention provides a distribution box capable of dissipating heat and having a dust collection function, and relates to the technical field of heat dissipation of distribution boxes. The distribution box includes a box body, the box body and the box door are rotatably connected by hinges, the edge of the box door is provided with a sealing strip, the surface of the box door is provided with an observation window, the lower end of the observation window is provided with an indicator light, and one side of the indicator light is provided There is a handle with a fingerprint reader on the surface of the handle, a vent on one side of the box, a contactor inside the box, a frequency converter on one side of the contactor, a fixing plate on the upper end of the frequency converter, and a Relay, there is a water-cooled radiator on one side of the relay, because the distribution box is closed, so if you want to check the distribution box, you can only open the distribution box to check, not only the process is cumbersome, but also a waste of time, and the distribution box is cooling There are also great deficiencies in this aspect, so when the distribution box is burned due to excessive temperature, it can only be remedied later, which not only wastes money, but also delays time.

Owner:斯迈德智能装备(新昌)有限公司

Polymer intercalation zirconium phosphate proton exchange membrane and preparation method thereof

InactiveCN108306036AEffective compatibilityImprove stabilityFuel cellsPhosphoric acid8-Hydroxyquinoline

The invention discloses a polymer intercalation zirconium phosphate proton exchange membrane. The polymer intercalation zirconium phosphate proton exchange membrane is prepared from the following rawmaterials in parts by weight: 30-40 parts of phosphoric acid solution with the concentration of 96-98%, 20-22 parts of zircon, 10-15 parts of acrylamide, 0.3-0.4 parts of initiator, 110-120 parts of modified polyphenyl ether, 2-3 parts of lauryl dimethyl amine oxide, 0.4-1 parts of 8-hydroxyquinoline, and 1-2 parts of aminopropyl triethoxysilane. By virtue of alloying of the amino-intercalation solution and oleic acid-doped antioxidant polyphenyl ether, and through a reaction between amino and oleic acid, effective compatibility between intercalation zirconium phosphate and polyphenyl ether isrealized, thereby improving uniform stability and mechanical strength of the finished proton membrane.

Owner:温州市赢创新材料技术有限公司

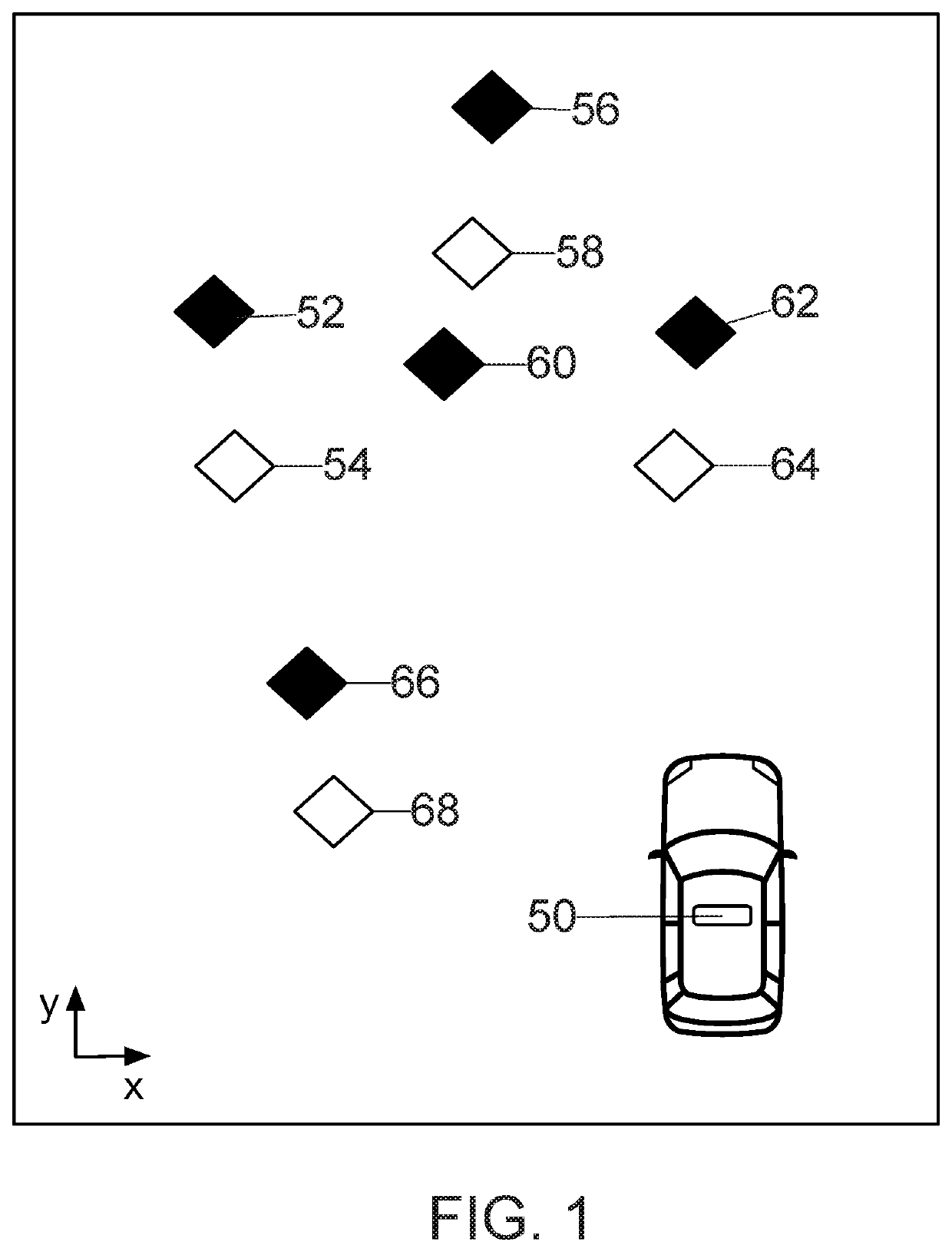

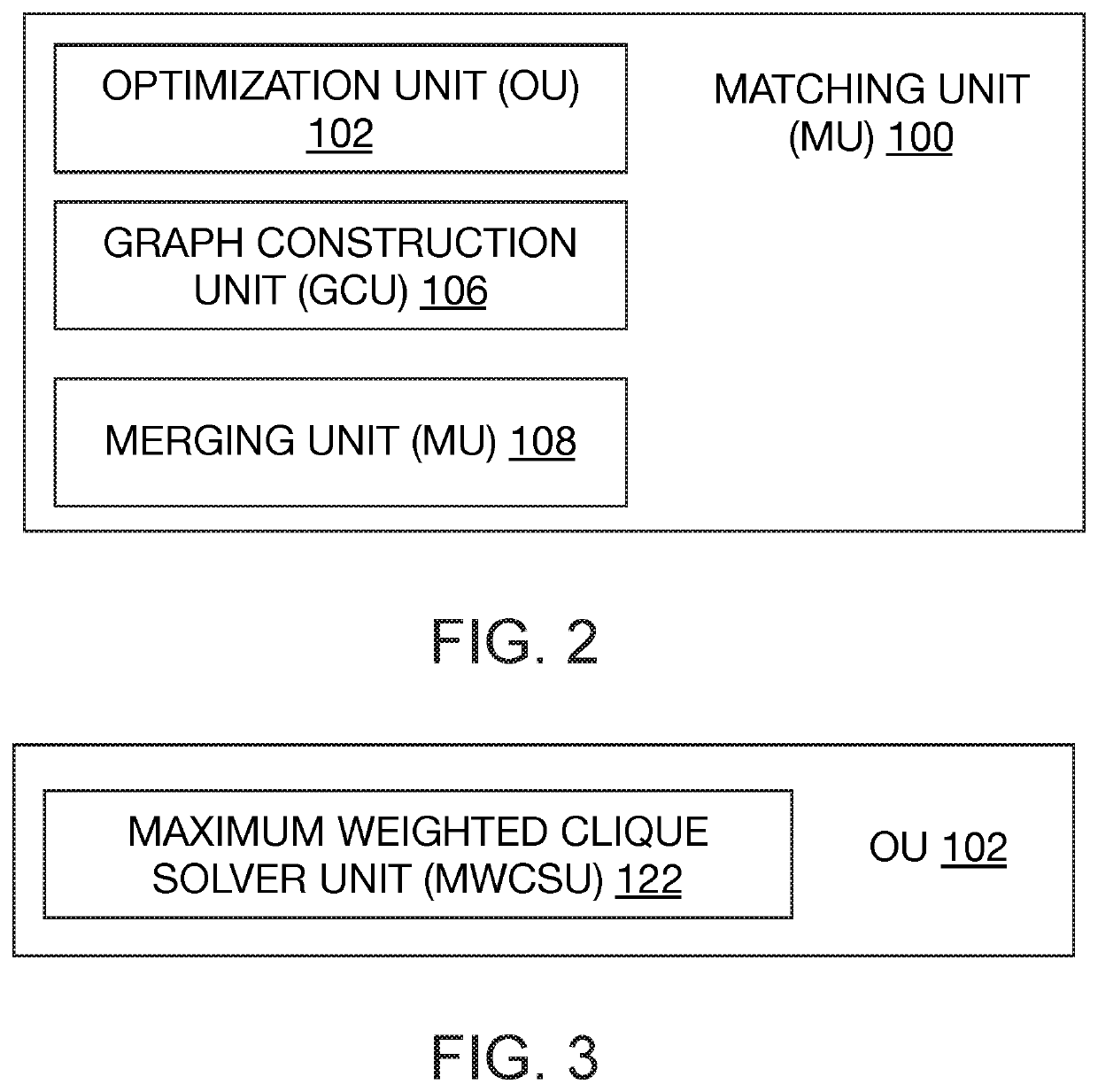

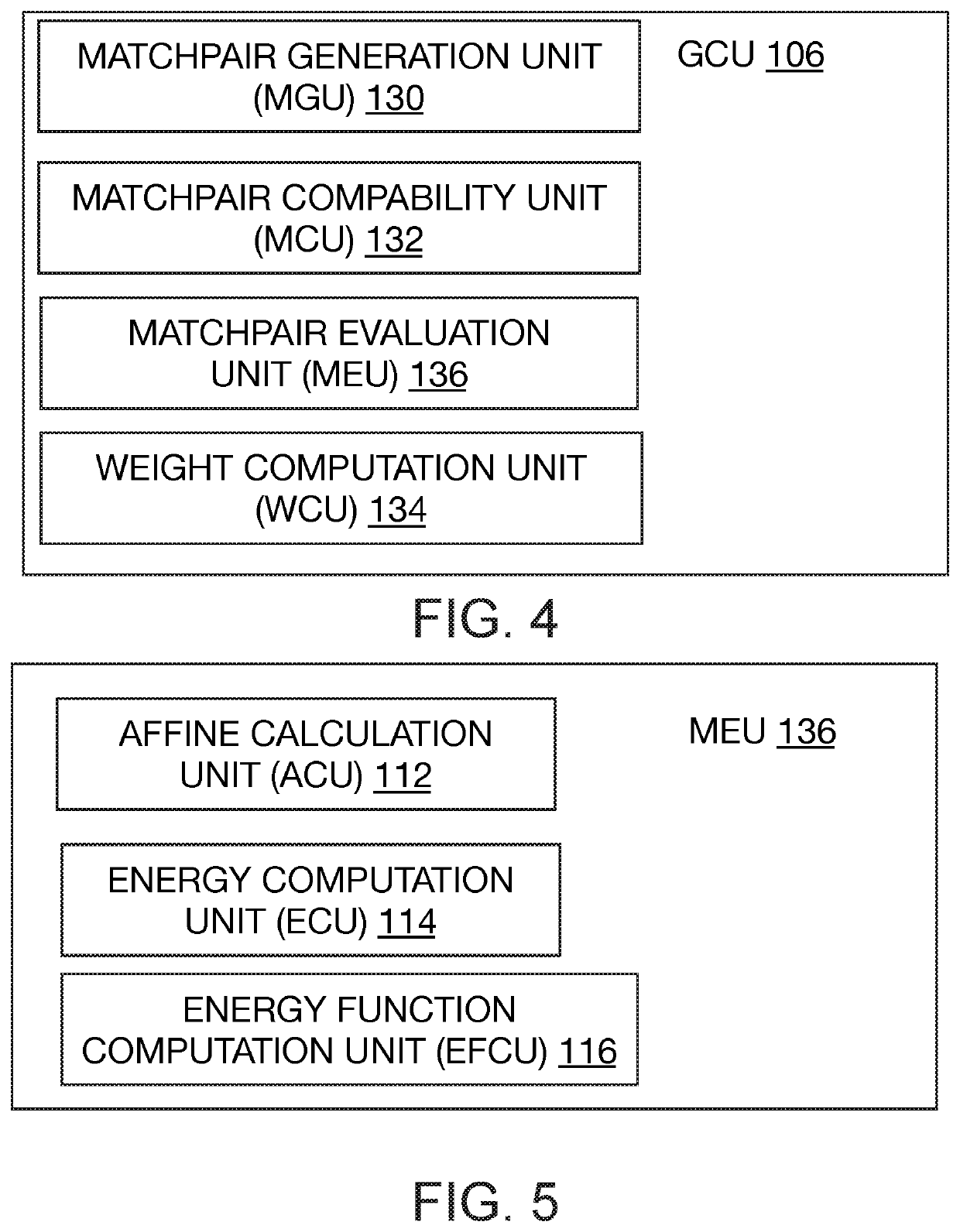

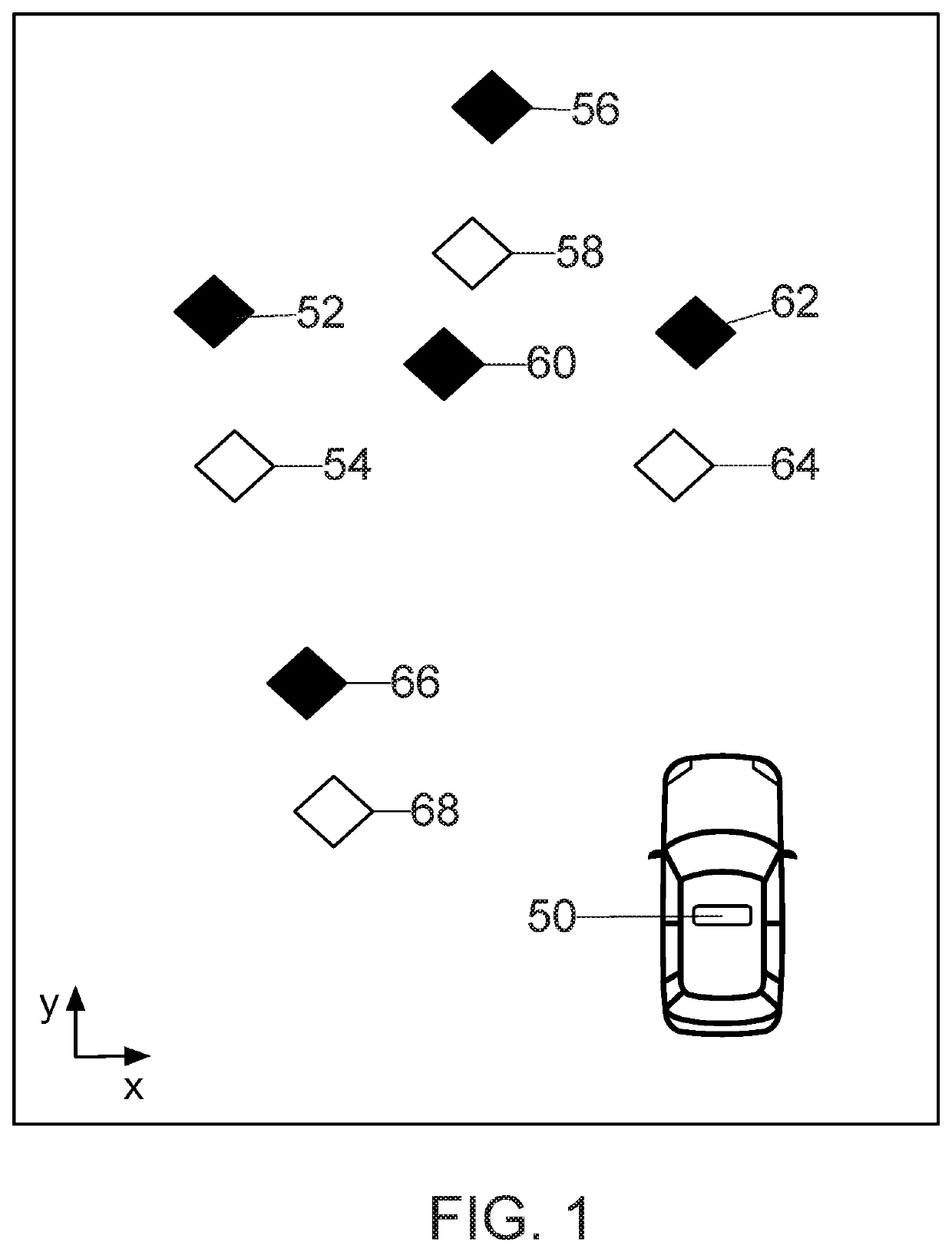

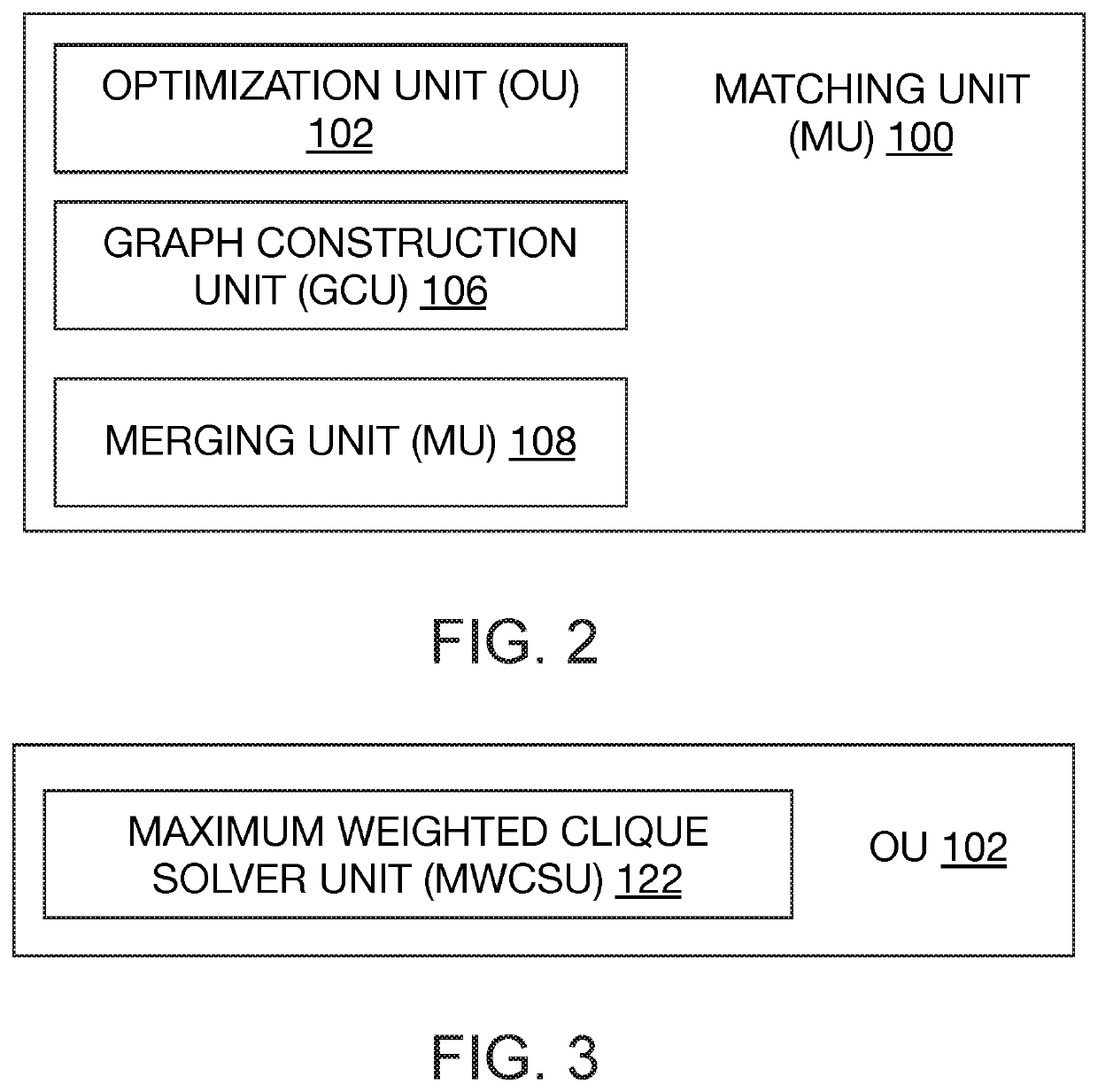

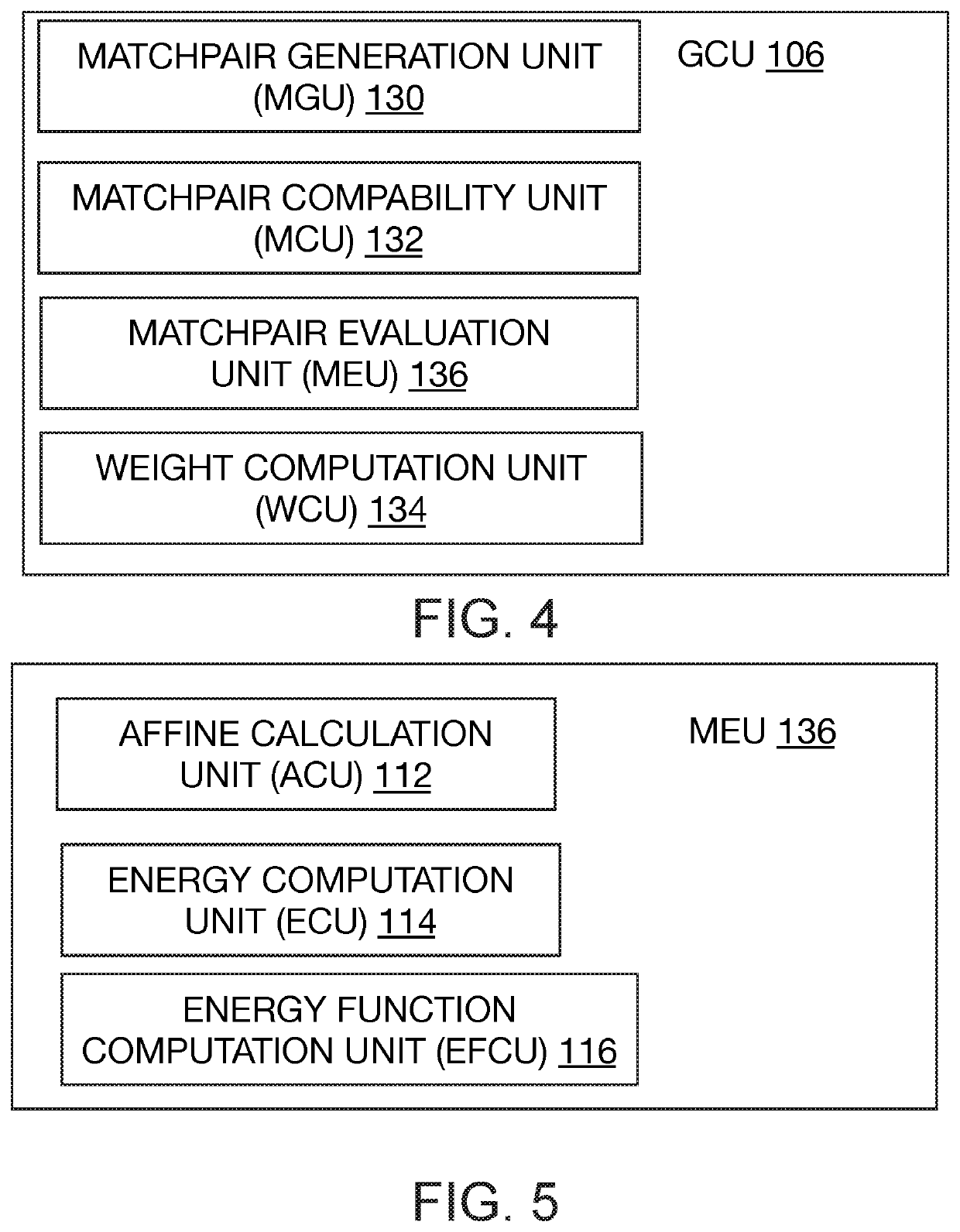

Associating spatial point sets with candidate correspondences

ActiveUS20200394444A1Effective compatibilityScene recognitionComplex mathematical operationsUndirected graphTheoretical computer science

A computer implemented method for generating a one-to-one mapping between a first spatial point set and a second spatial point set in nD comprising receiving a first and a second spatial point sets in nD and a plurality of candidate correspondences; computing conflict lists for the candidate correspondences; generating one or more MatchPairs between the first and the second point sets using the Cartesian Products of the plurality of candidate correspondences; computing local distance measures for the MatchPairs; converting the local distance measures to weights; computing conflict lists for pairs of the MatchPairs by taking the bitwise UNIONs of their candidate correspondences' unit conflict lists; computing correspondence lists for the MatchPairs; computing compatibilities between pairs of the MatchPairs by examining for each pair of said pairs the bitwise AND of one's correspondence list and the other's conflict list; constructing an undirected graph with its nodes corresponding to the MatchPairs, its edges representing the compatibilities, and its graph vertices assigned the weights; computing a maximum-weight clique of the graph; and merging the maximum-weight clique to generate the one-to-one mapping.

Owner:YANG TIANZHI

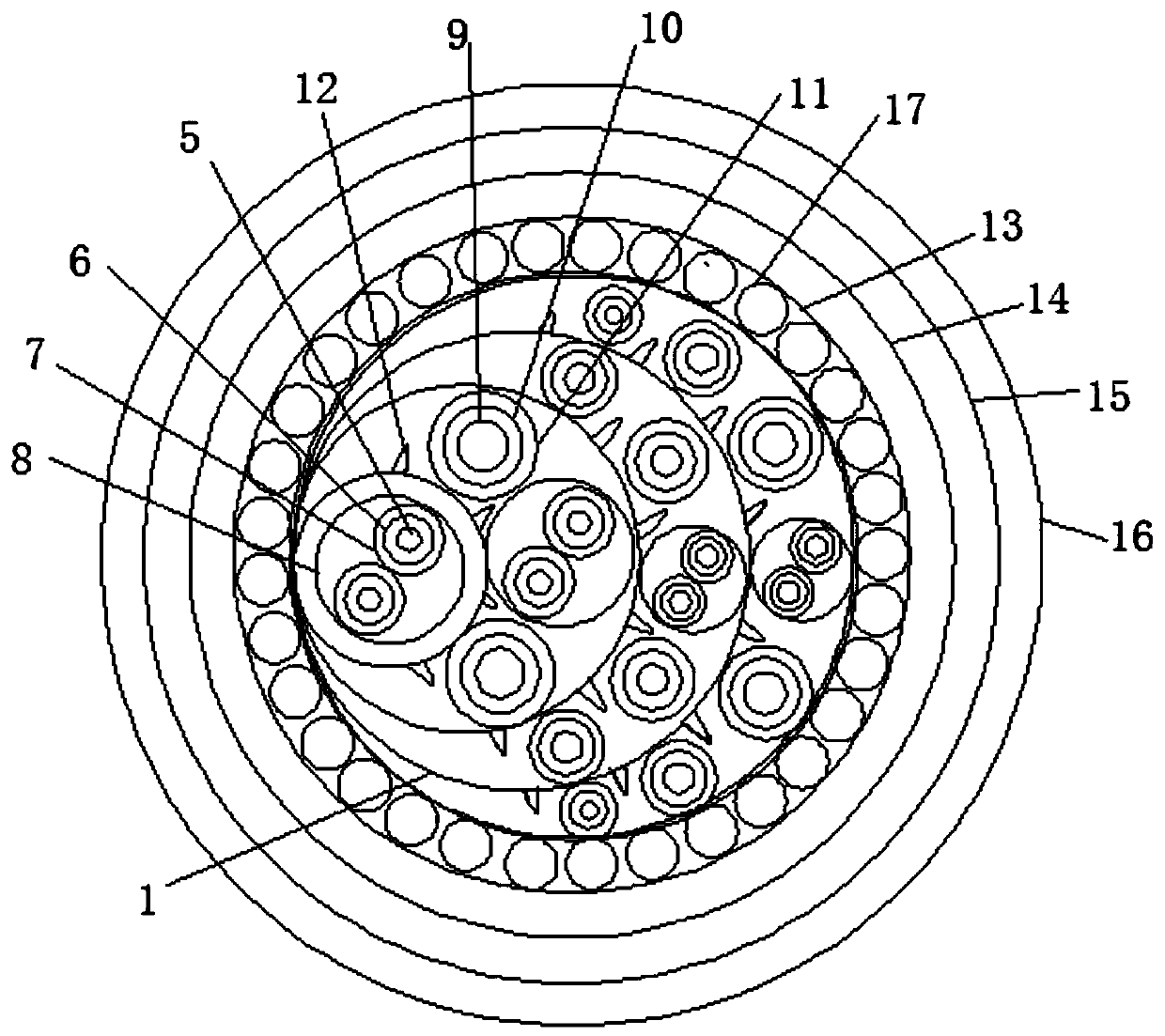

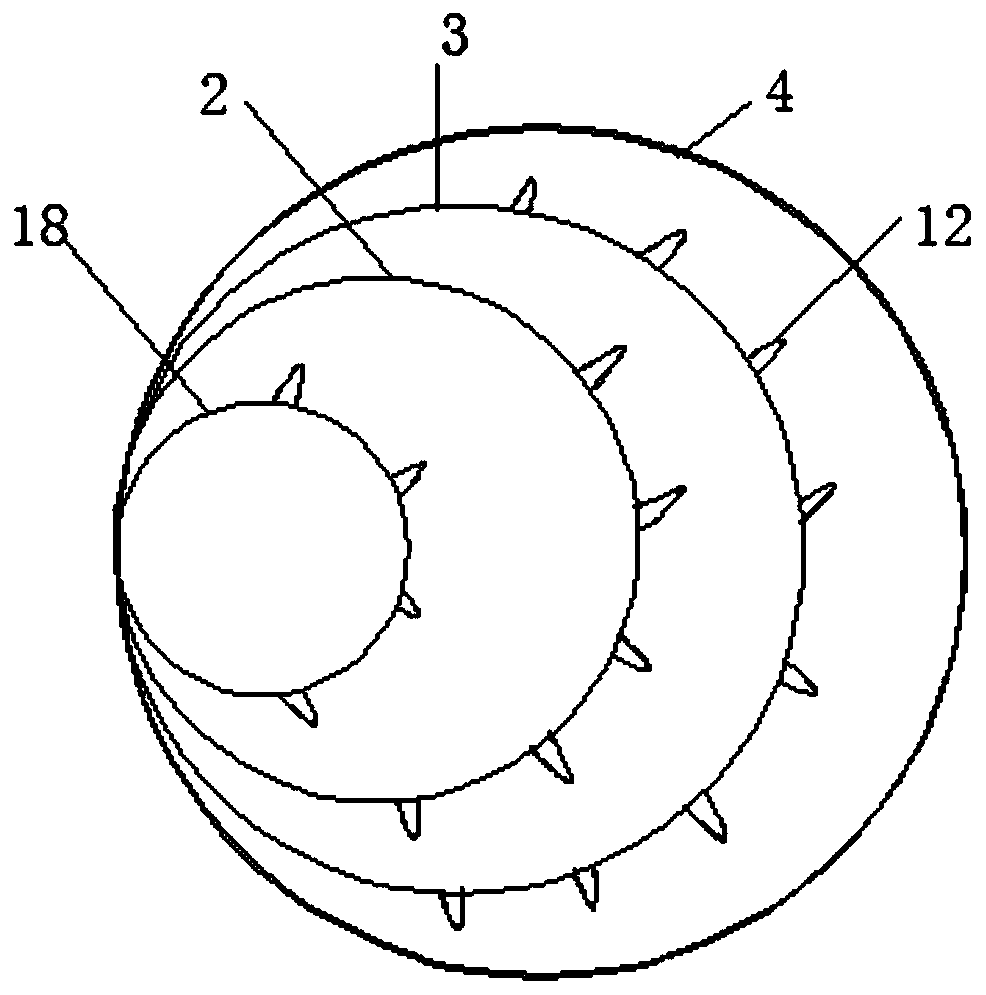

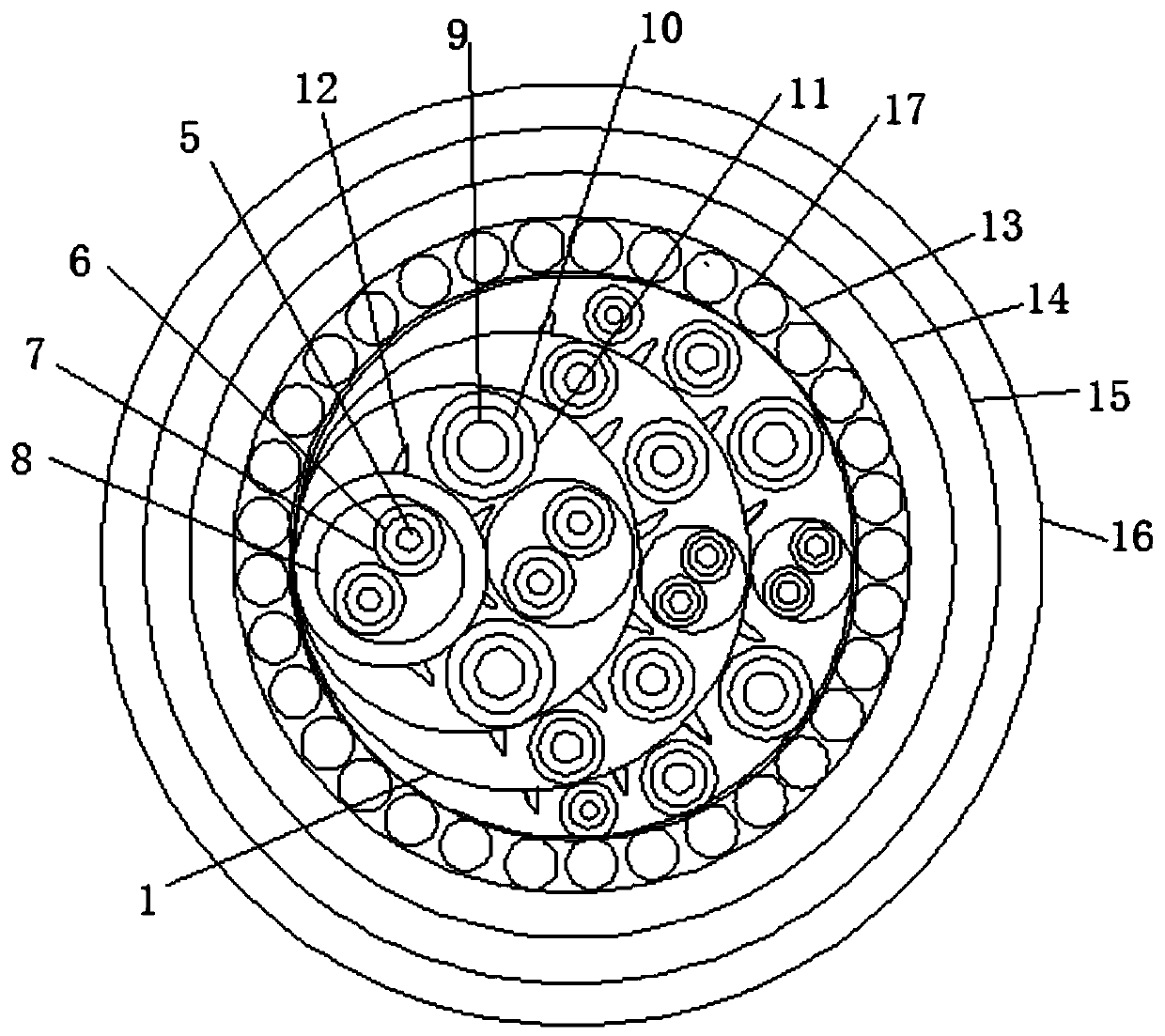

Waterproof fireproof control cable

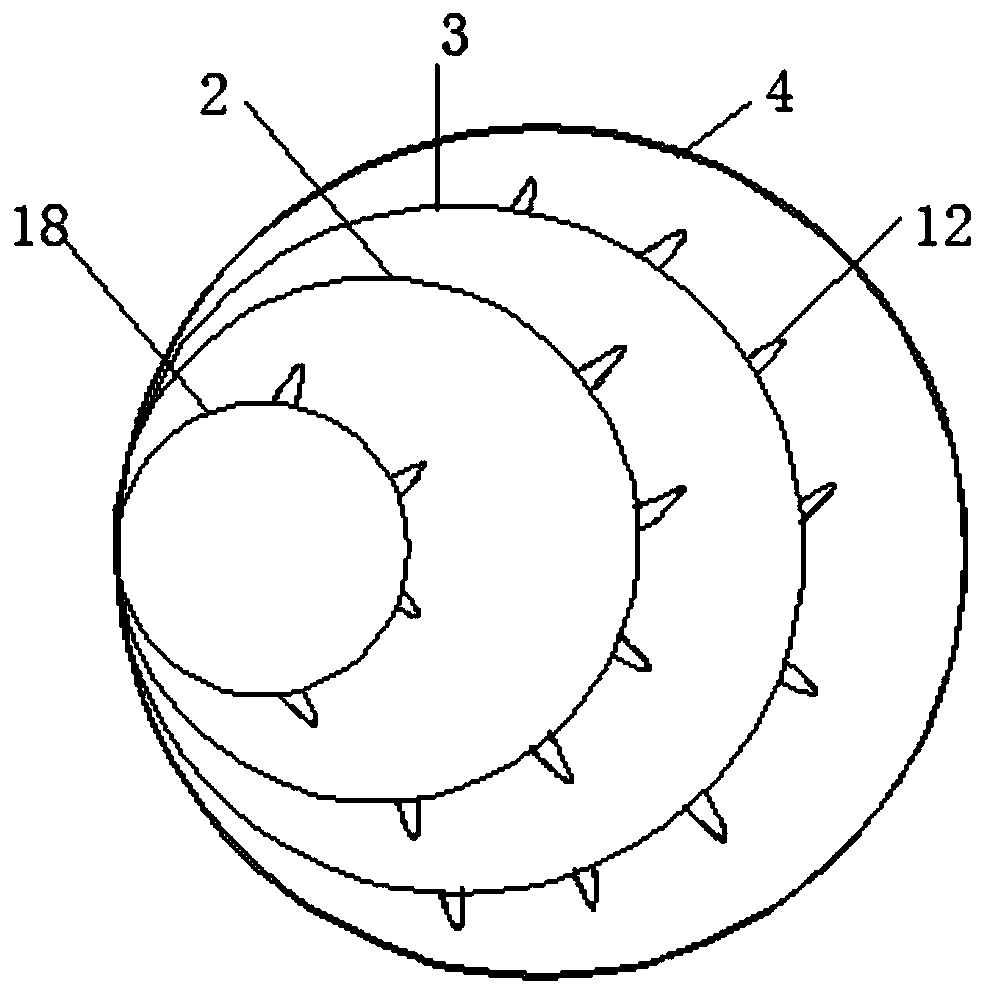

ActiveCN109830336AThe internal structure of the cable is compact and stableGood wire core protectionInsulated cablesInsulated conductorsEngineeringEthylene propylene rubber

The invention discloses a waterproof fireproof control cable comprising a rubber skeleton, wherein the rubber skeleton comprises four circular skeletons with different radiuses; the left side surfacesof the four circular skeletons are fixedly connected together and then the four circular skeletons are successively stacked according to the radiuses; first wire cores are disposed in the four circular skeletons; a plurality of second wire cores are disposed in each of the second circular skeleton, the third circular skeleton and the fourth circular skeleton; each first wire core includes a firstconductor; and the outer side of the first conductor is successively coated with a thermoplastic vulcanized rubber insulating layer and a halogen-free glass fiber wrapping layer. The outer side of the rubber skeleton is successively coated with a glass fiber belt and ceramic silicone rubber belt wrapping layer, a lead alloy inner sheath layer, a waterproof expansion filling layer and an outer sheath. Thus, the cable is good in waterproof and fireproof effect, simple in structure, good in insulation effect, long in service life, stable in operation and low in production cost. An ethylene propylene rubber elastic rod enhances the softness of the cable.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

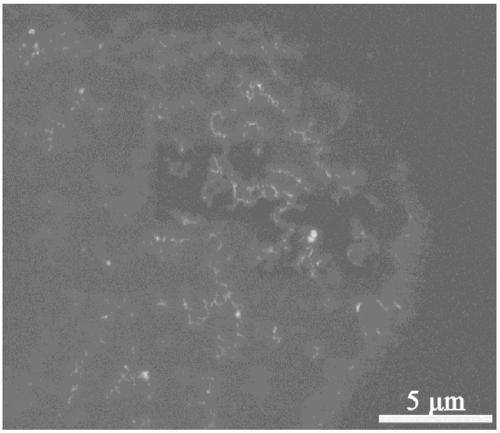

Nanometer laminated boron nitride reinforced carbon fiber sizing agent, and preparation method thereof

The invention discloses a nanometer laminated boron nitride reinforced carbon fiber sizing agent, and a preparation method thereof, and belongs to the technical field of composite material. The preparation method is capable of solving problems in the prior art that at humid hot environment, humidity hot aging is caused by resin chemical degradation and fiber / resin interface cracking. The nanometerlaminated boron nitride reinforced carbon fiber sizing agent comprises 100 parts of an organic resin, 0.3 to 6 parts of an emulsifier, 0.05 to 0.6 part of a dispersant, 0.05 to 1 part of a compatiblymodified nanometer laminated boron nitride dispersion liquid, 20 to 200 parts of an organic solvent, and 20 to 40 parts of deionized water; the compatibly modified nanometer laminated boron nitride dispersion liquid is a dispersion liquid of nanometer laminated boron nitride dispersion liquid processed through polyacrylic acid in-suit polymerization modification. According to the preparation method, raw materials are mixed and stirred until phase transferring is achieved; the compatibly modified nanometer laminated boron nitride dispersion liquid is mixed with the organic resin emulsion, deionized water is added for dilution so as to obtain the nanometer laminated boron nitride reinforced carbon fiber sizing agent. The nanometer laminated boron nitride reinforced carbon fiber sizing agentcan be used for carbon fiber sizing.

Owner:FUDAN UNIV

Heat-resistant graphene conductive film and preparation method thereof

PendingCN108597643AImprove uniformity and stabilityEffective compatibilityNon-insulated conductorsConductive materialPhosphateAlkylphenol

The invention discloses a heat-resistant graphene conductive film, which is composed of the following raw materials by weight: 10-14 parts of graphene, 1-2 parts of diethylene glycol dibenzoate, 0.8-1part of alkanolamide, 1-2 parts of silane coupling agent kh550, 2-3 parts of barium stearate, 0.1-0.2 part of stannous sulfide, 5-7 parts of heat-resistant polyethylene wax, 0.1-0.2 part of alkylphenol ethoxylate, 60-70 parts of polyaniline, 1-2 parts of ammonium polyphosphate, 3-4 parts of aluminum dihydrogen phosphate, and 2-3 parts of triethanolamine. The aluminum dihydrogen phosphate, calciumacetylacetonate and the like added by the invention may improve the heat stability of the finished film, and the aluminum dihydrogen phosphate may also enhance the viscosity between the raw materialsin the cast film forming process, thereby further improving the uniform stability of the film formation.

Owner:戚明海

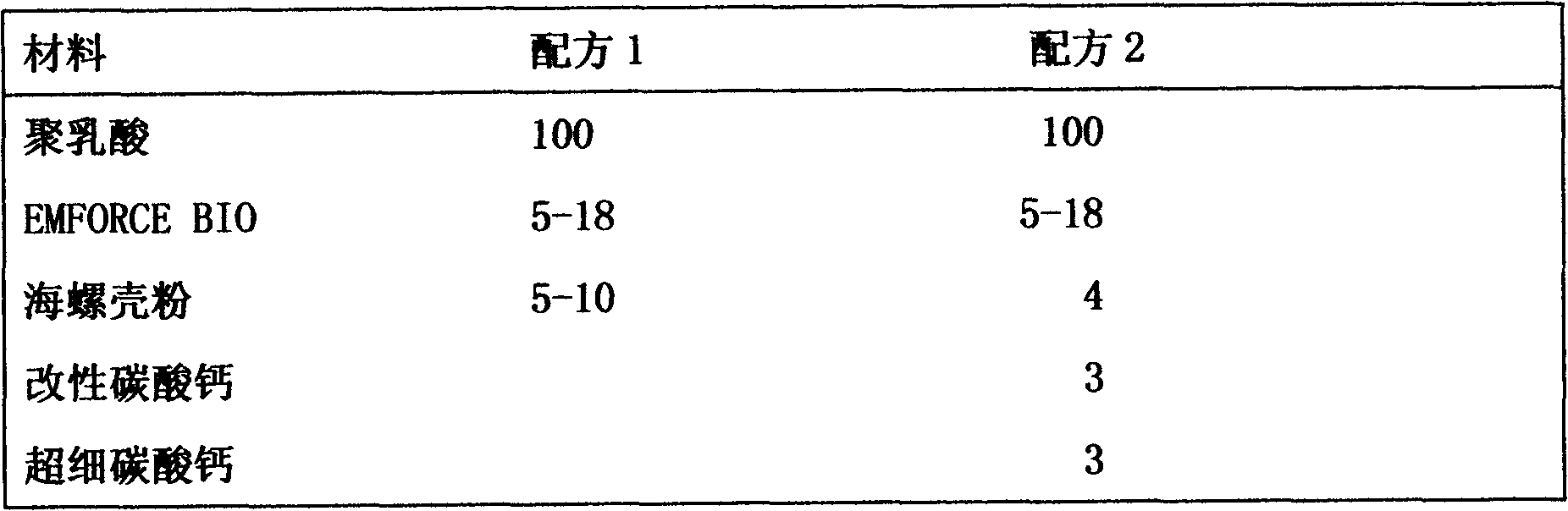

Degradable material for tubal extraction hook and manufacturing method

The present invention provides a degradable material for tubal extraction hooks and a manufacturing method. The degradable material is prepared by polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression segment is of 160-170 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 165-175 DEG C, the mold temperature is 20-45 DEG C, the injection pressure is 45-85 Mpa, the injection time is 40-55 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The performances of the degradable tubal extraction hook are in line with the requirements of national industry standard YY91024 1999. The degradable tubal extraction hook can completely replace a metal tubal extraction hook. The waste degradable tubal extraction hook does not pollute the environment by burning, and can completely degrade by landfilling in the natural environment. The degradable tubal extraction hook is especially suitable for disposable use, and helps to prevent iatrogenic disease cross-infection and achieve environmental-protection and energy-saving purposes.

Owner:江苏奥博金医药科技有限公司

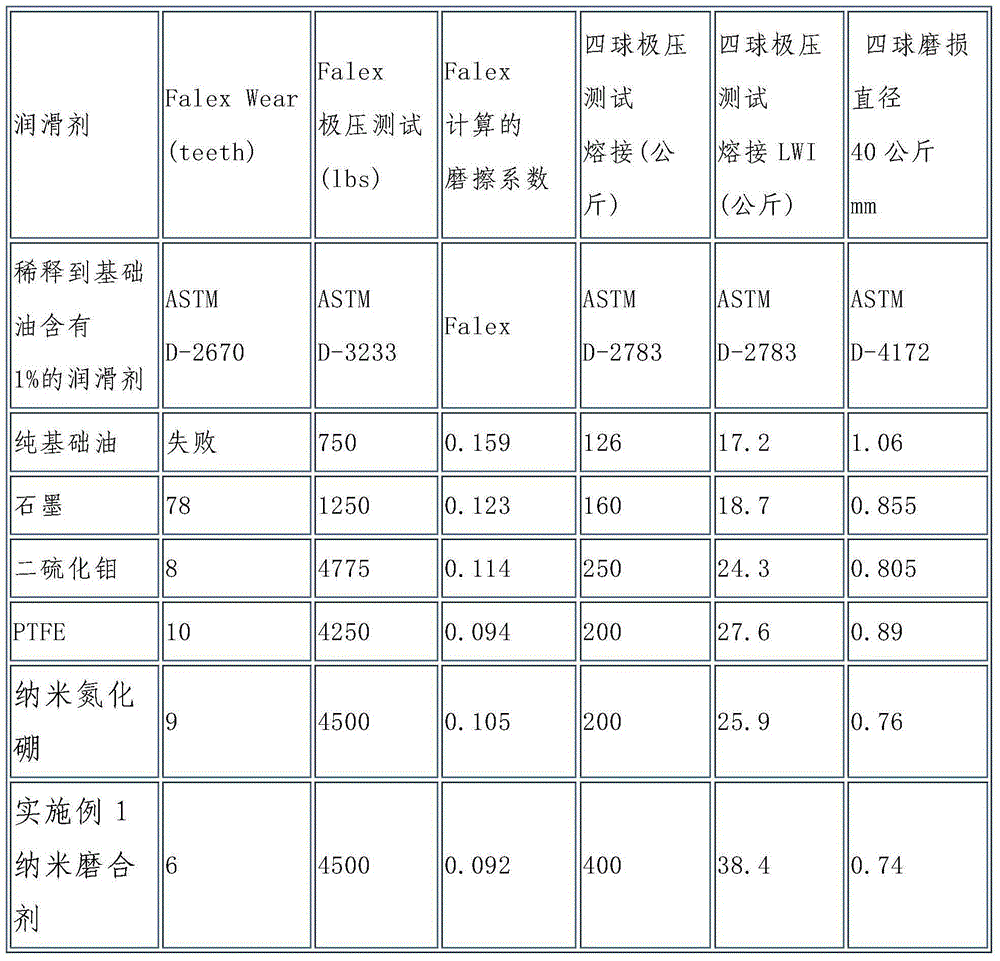

Nanometer running-in agent

InactiveCN105199812AOvercome limitationsOvercome the limitations of immiscibilityAdditivesBeef TallowPetroleum

A disclosed nanometer running-in agent is composed of the following compositions in percent by weight: 10-20 parts of heavy alkyl benzene, 10-20 parts of alkyl naphthalene, 20-50 parts of boronized polyisobutylene succinimide, 20-40 parts of molybdenum dialkyldithiophosphate, 1-2 parts of oil-modified phenolic resin, 1-4 parts of hydroxyl silicone oil emulsion 305, 1-4 parts of beef tallow, and 1-4 parts of detergent LD-1. The agent is prepared according to the following steps: (1) putting heavy alkyl benzene into a blending kettle, heating to 60 DEG C, and stirring for 30 min; (2) then adding boronized polyisobutylene succinimide, and continuing to stir for 30 min; (3) then adding molybdenum dialkyldithiophosphate, cyclically stirring for 120 min, then adding oil-modified phenolic resin, hydroxyl silicone oil emulsion 305, beef tallow and the detergent LD-1, keeping a constant temperature of 60 DEG C for 60 min, and then slowly cooling to 40 DEG C or less, loading a barrel, and capping, so as to obtain the agent. Compared with the prior art, the agent possesses the substantial advantages that the agent is applicable to lubrication systems of various vehicles, ships, petroleum chemical machinery, mine machinery and other large-scale equipment, and possesses multiple functions of reducing wear, reducing oil consumption, restoring wear surface, improving bearing capability, reducing noise and the like.

Owner:胡波

Preparation method of sundew film coating agent

InactiveCN108969546AImprove liquidityLiquidityNervous disorderHydroxy compound active ingredientsMentholMedicine

The invention concretely discloses a preparation method of a sundew film coating agent. The sundew film coating agent is prepared from 200g of sundew extracts, 30g of borneol, 20g of menthol, 30g of dibutyl phthalate, 12.5g of poly(vinyl formalacetal), 100g of acetone and the balance ethanol being 75 v / v percent after the constant volume reaching to 1000g. The prepared external use film coating agent is coated onto the affected part when being used; after solvents are volatilized, a film is formed so as to protect the focus surface; meanwhile, the contained medicine is released to achieve thetreatment effect. The preparation process is very simple; mounting materials are not used; the use is convenient; the film coating agent is coated onto the affected part; after the film coating agentis dried after the coating, the film formed in the affected part has certain anti-tearing performance; the contained medicine can be absorbed in a balanced way to generate the curative effect.

Owner:PIZHOU GAXING MEDICINE TECH SERVICE CO LTD

Associating spatial point sets with candidate correspondences

ActiveUS10963733B2Effective compatibilityScene recognitionComplex mathematical operationsUndirected graphTheoretical computer science

Owner:YANG TIANZHI

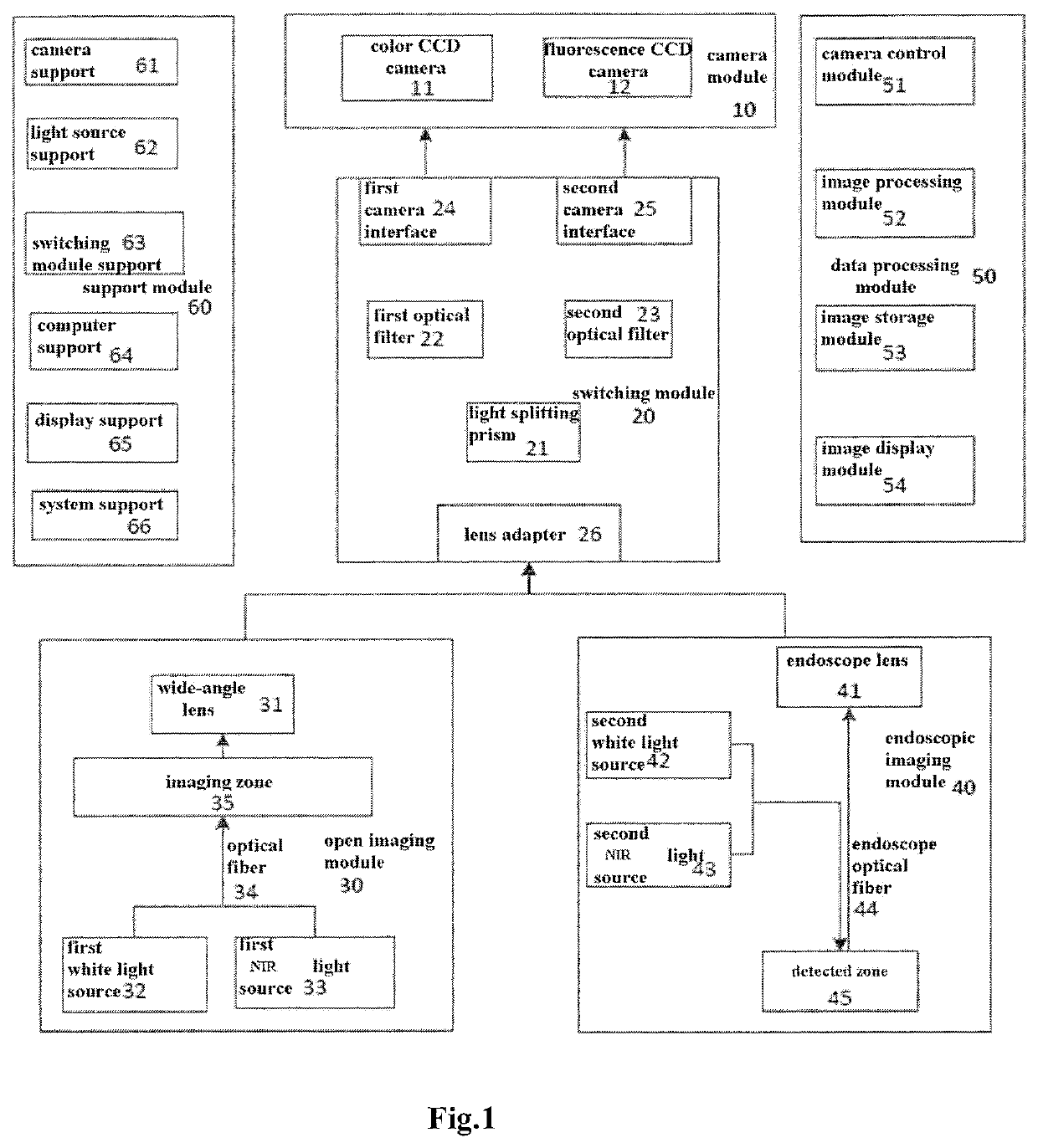

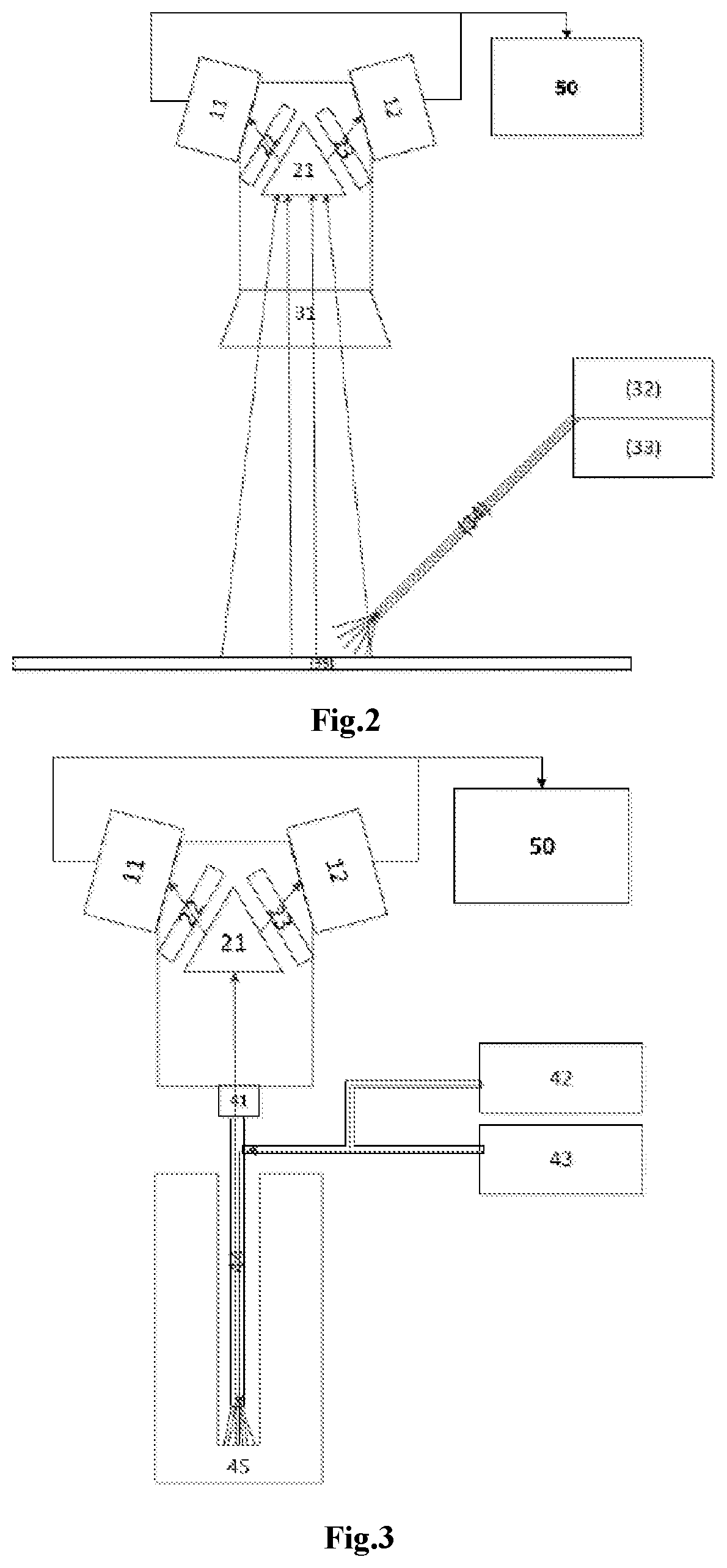

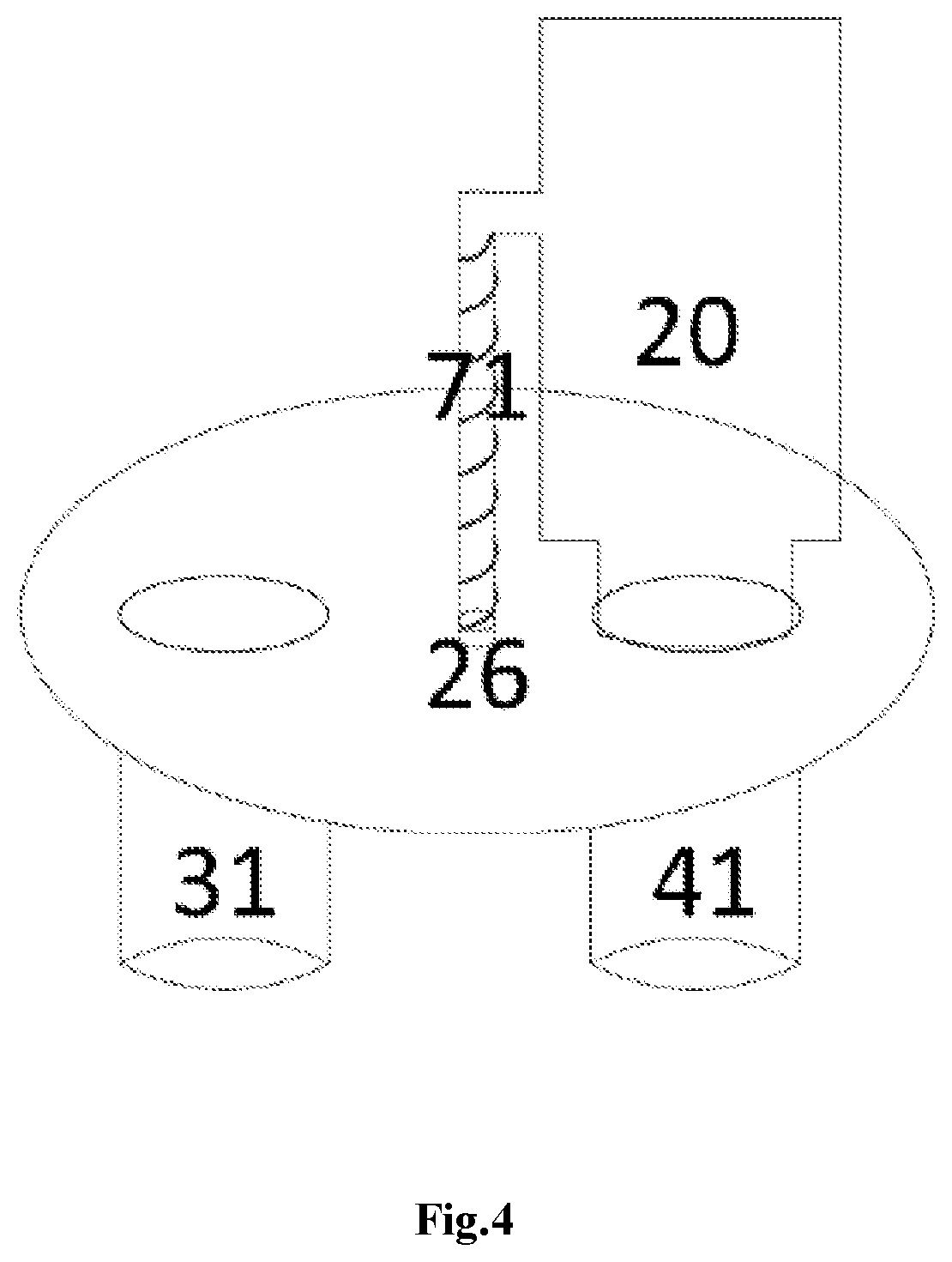

Dual-mode optical molecular imaging navigation apparatus with a switchable field of view and imaging method thereof

ActiveUS10564103B2Effective compatibilityEasy to operateTelevision system detailsColor television detailsCamera controlImaging data

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

A waterproof and fireproof control cable

ActiveCN109830336BImprove protectionCompact and stable structureInsulated cablesInsulated conductorsGlass fiberElectrical conductor

The invention discloses a waterproof fireproof control cable comprising a rubber skeleton, wherein the rubber skeleton comprises four circular skeletons with different radiuses; the left side surfacesof the four circular skeletons are fixedly connected together and then the four circular skeletons are successively stacked according to the radiuses; first wire cores are disposed in the four circular skeletons; a plurality of second wire cores are disposed in each of the second circular skeleton, the third circular skeleton and the fourth circular skeleton; each first wire core includes a firstconductor; and the outer side of the first conductor is successively coated with a thermoplastic vulcanized rubber insulating layer and a halogen-free glass fiber wrapping layer. The outer side of the rubber skeleton is successively coated with a glass fiber belt and ceramic silicone rubber belt wrapping layer, a lead alloy inner sheath layer, a waterproof expansion filling layer and an outer sheath. Thus, the cable is good in waterproof and fireproof effect, simple in structure, good in insulation effect, long in service life, stable in operation and low in production cost. An ethylene propylene rubber elastic rod enhances the softness of the cable.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

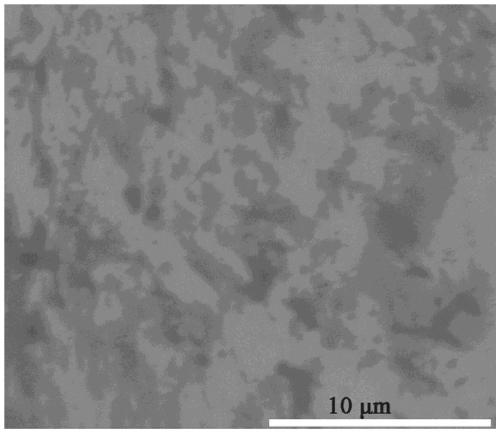

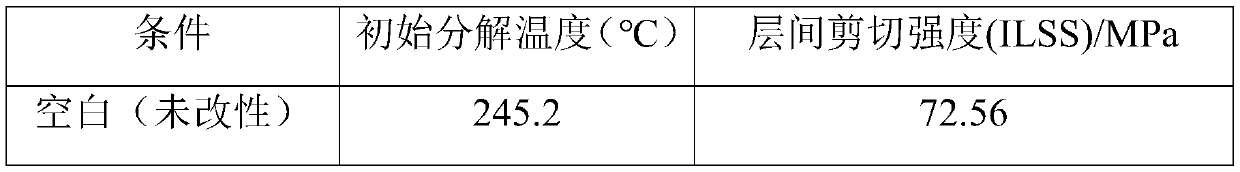

A kind of reinforcing agent for carbon fiber sizing agent and preparation method thereof

ActiveCN109487538BHigh mechanical strengthRaise the initial decomposition temperatureCarbon fibresPolymer scienceCarbon fibers

The invention discloses a strengthening agent for carbon fiber sizing agents and a preparation method of the strengthening agent, belongs to the technical field of composite materials, and solves theproblems of instable component and poor compatibility of a strengthening agent in the prior art. The strengthening agent comprises polyacrylic acid modified nano-lamella boron nitride dispersion liquid, a dispersing agent, silicone oil and higher fatty acid, nano-lamella boron nitride dispersion liquid is modified by polyacrylic acid to form the polyacrylic acid modified nano-lamella boron nitridedispersion liquid, and a modified mode of the polyacrylic acid includes that acrylic acid is polymerized on the surface of effectively peeled nano-lamella boron nitride in situ. The preparation method includes the steps: mixing the polyacrylic acid modified nano-lamella boron nitride dispersion liquid, the dispersing agent, the silicone oil and the higher fatty acid; ultrasonically dispersing mixture to obtain the strengthening agent for the carbon fiber sizing agents. The strengthening agent and the preparation method can be used for strengthening the carbon fiber sizing agents.

Owner:FUDAN UNIV

Environmentally-friendly halogen-free knitting material

InactiveCN108250619AEffective compatibilityImprove mechanical stability and strengthPolyvinyl chlorideToughness

The invention discloses an environmentally-friendly halogen-free knitting material. The environmentally-friendly halogen-free knitting material is characterized in that modified polyvinyl chloride isprepared through the following raw materials in parts by weight: 100-110 parts of polyvinyl chloride, 10-14 parts of light calcium carbonate, 1-2 parts of oleic diethanolamide, 0.1-0.3 part of butyltin tricaprylate, 20-30 parts of thionyl chloride, 3-4 parts of ricinoleic acid, and 1-2 parts of calcium stearate. According to the method, cyanopropyl methylcellulose is doped for modifying, so that the toughness of the knitting material is effectively improved. The knitting material is safe, high in environmental protection performance, and free from toxic and harmful volatile materials, and canbe processed into various decorative parts.

Owner:史敏强

Plastic pencil holder material

The invention discloses a plastic pencil holder material which comprises the following raw materials in parts by weight: 0.1-0.4 part of octyl mercaptan tin, 130-150 parts of polystyrene, 50-70 partsof talcum powder modified rubber powder and 3-7 parts of ethylene-bis-stearamide. Effective compatibility of talcum powder with waste rubber powder is achieved, furthermore the dispersion performanceof the talcum powder modified rubber powder in polystyrene is improved, and the mechanical stability of a finished product material is improved.

Owner:蒙城县金元达制笔有限公司

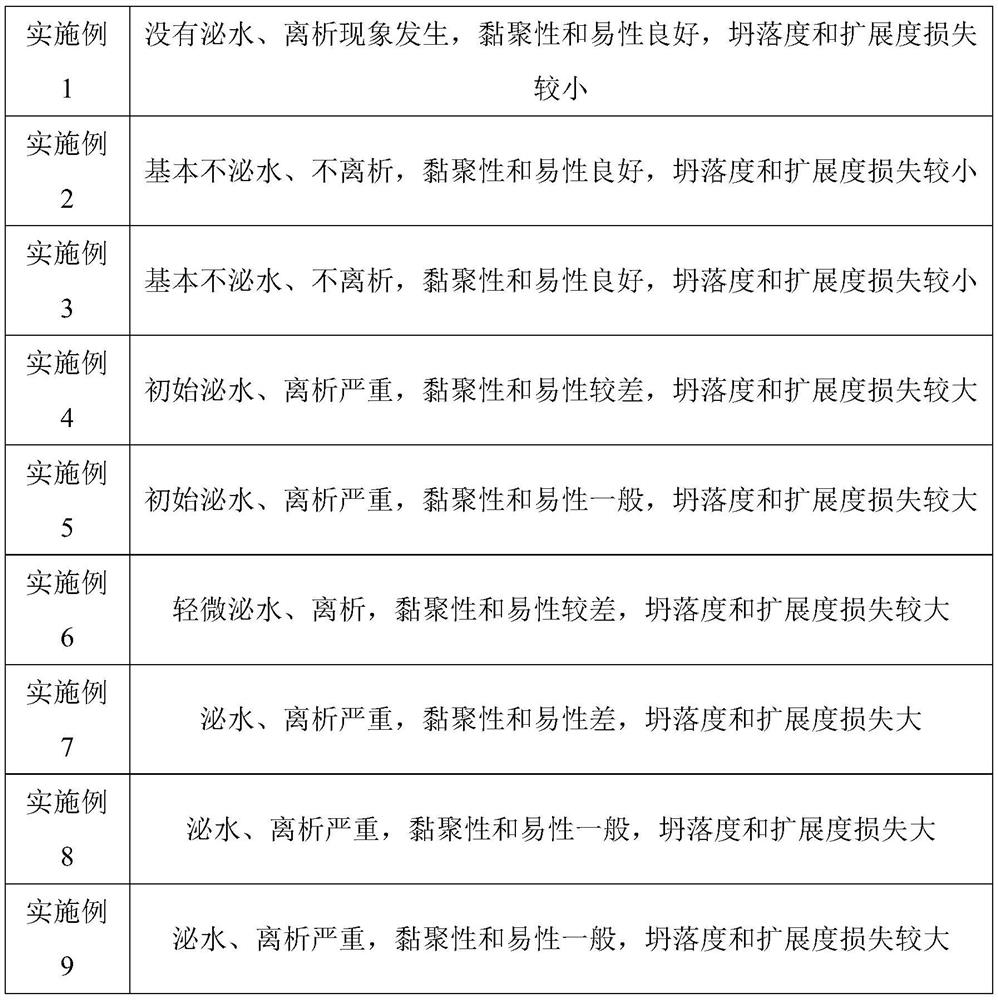

A kind of modified concrete water-retaining agent and preparation method thereof

ActiveCN111533844BAddressing Adaptive IssuesSolve the adaptability problem with large mud contentProcess engineeringCarboxylic acid

The invention relates to the technical field of concrete admixtures, in particular to a modified concrete water-retaining agent and a preparation method thereof. A modified concrete water-retaining agent, the preparation raw materials of the water-retaining agent, by weight, at least include the following components: 30-60 parts of anionic monomers containing double bonds, 10-30 parts of ester monomers containing double bonds 5-15 parts of alkali, 5-15 parts of molecular chain regulator, 1-5 parts of oxidizing agent, 1-5 parts of reducing agent, 300-600 parts of water. The invention provides a modified concrete water-retaining agent, which effectively solves the adaptability of polycarboxylate high-performance water-reducing agent to sand and gravel materials, especially the adaptability of sand and gravel materials with large mud content, and the production process is simple and suitable for Environmentally friendly and excellent in performance, it can be used effectively in combination with polycarboxylate high-performance water reducer.

Owner:JIANGSU WANBANG BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com