Nanometer laminated boron nitride reinforced carbon fiber sizing agent, and preparation method thereof

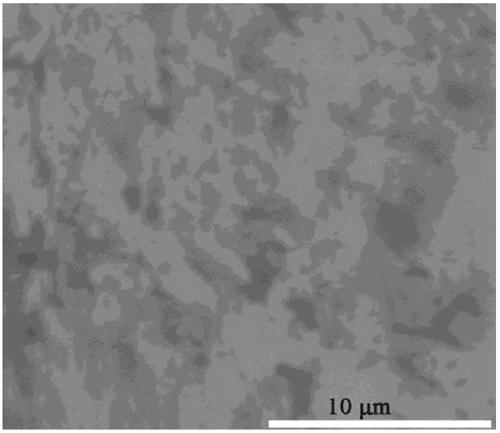

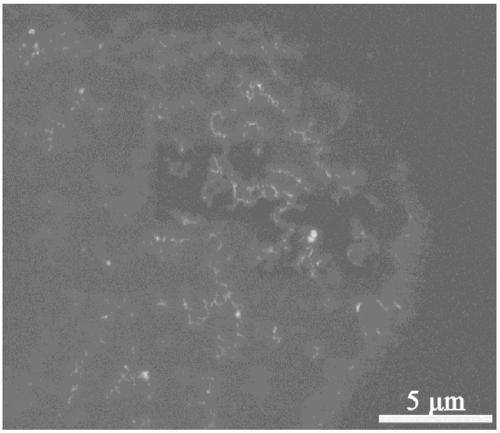

A nano-sheet, boron nitride technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of damp heat aging, fiber/resin interface cracking, etc., to enhance the interaction force, increase the decomposition temperature, and reduce the aggregation phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

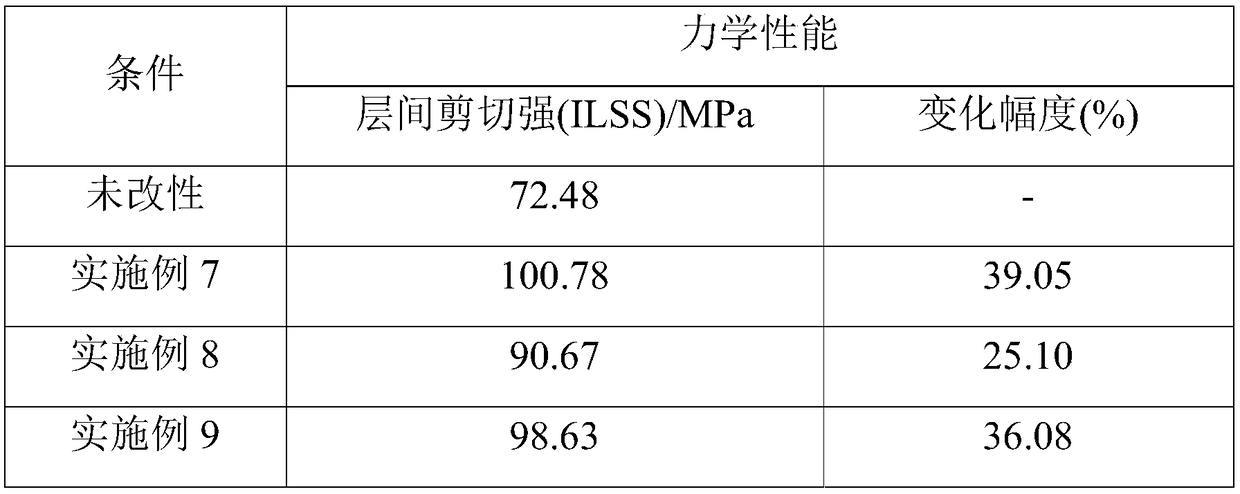

[0041] The present invention also provides a preparation method of a nanosheet boron nitride reinforced carbon fiber sizing agent, which is used to prepare the above nanosheet boron nitride reinforced carbon fiber sizing agent, comprising the following steps: organic resin, organic solvent, emulsified Mix and stir the solvent, dispersant and deionized water until phase transfer occurs to obtain an organic resin emulsion; mix the dispersion of compatible modified nanosheet boron nitride with the organic resin emulsion, add deionized water to dilute, and obtain nanosheets Layer boron nitride reinforced carbon fiber sizing.

[0042] Compared with the prior art, the preparation method of the nanosheet boron nitride reinforced carbon fiber sizing agent provided by the present invention is simple, reliable and low in cost, and the prepared compatible modified nanosheet boron nitride can play a role in carbon fiber To a very good protective effect, while improving the mechanical prop...

Embodiment 1

[0057] This embodiment provides a method for preparing a dispersion of compatible modified nanosheet boron nitride, comprising the following steps:

[0058] Step 1: Prepare an aqueous solution of isopropanol, wherein the volume percentage of isopropanol is 30%, boron nitride with an average crystallite size of 50 microns, the concentration of boron nitride is 10 mg / mL, and the dispersion liquid after mixing is 100 grams in total ;

[0059] Step 2: Ultrasonicize the dispersion obtained in Step 1, the ultrasonic power is 50W, and the ultrasonic time is 1 hour; after the ultrasonication is completed, let it stand for 4 hours; then centrifuge at 4000rpm to obtain the upper dispersion;

[0060] Step 3: Modify the dispersion liquid obtained in step 2: add acrylic acid and ammonium persulfate (the mass ratio of acrylic acid, ammonium persulfate, and boron nitride is 10:1:1) at 40°C, and react to obtain modified polyacrylic acid. Nano-sheet layer boron nitride dispersion liquid, poly...

Embodiment 2

[0063] This embodiment provides a method for preparing a dispersion of compatible modified nanosheet boron nitride, comprising the following steps:

[0064] Step 1: Prepare a mixed solution of water and isopropanol, wherein the volume ratio of isopropanol is 30%, then add boron nitride with an average crystallite size of 50 microns, the concentration of boron nitride is 1mg / mL, mix and disperse 100 grams in total;

[0065] Step 2: Ultrasonicize the dispersion obtained in Step 1, the ultrasonic power is 50W, and the ultrasonic time is 1 hour; after the ultrasonication is completed, let stand for 3 hours; then centrifuge at 1500rpm to obtain the upper dispersion;

[0066] Step 3: Modify the dispersion liquid obtained in step 2: add acrylic acid and ammonium persulfate at 30°C (the ratio is acrylic acid:ammonium persulfate:boron nitride=15:3:5), and react to obtain polyacrylic acid modified The dispersion liquid of nano-sheet boron nitride, after reacting for 5 hours, obtains th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com