A hazardous waste incineration compatibility system based on off-line operation optimization

A hazardous waste, offline computing technology, applied in the field of hazardous waste incineration, can solve the problems of the service life of the rotary kiln, damage to the insulation layer, coking and slagging, lack of guidance, etc., so as to reduce unplanned downtime of equipment and improve equipment operation efficiency. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Taking a hazardous waste treatment plant as an example, a batch of waste to be treated includes three tons of A / B / C;

[0018] Determine the physical properties, calorific value data, industrial analysis and elemental analysis data of A / B / C three kinds of materials to be processed through the test report of the feeding unit and the laboratory sampling test data, and establish the physical property database of the three materials;

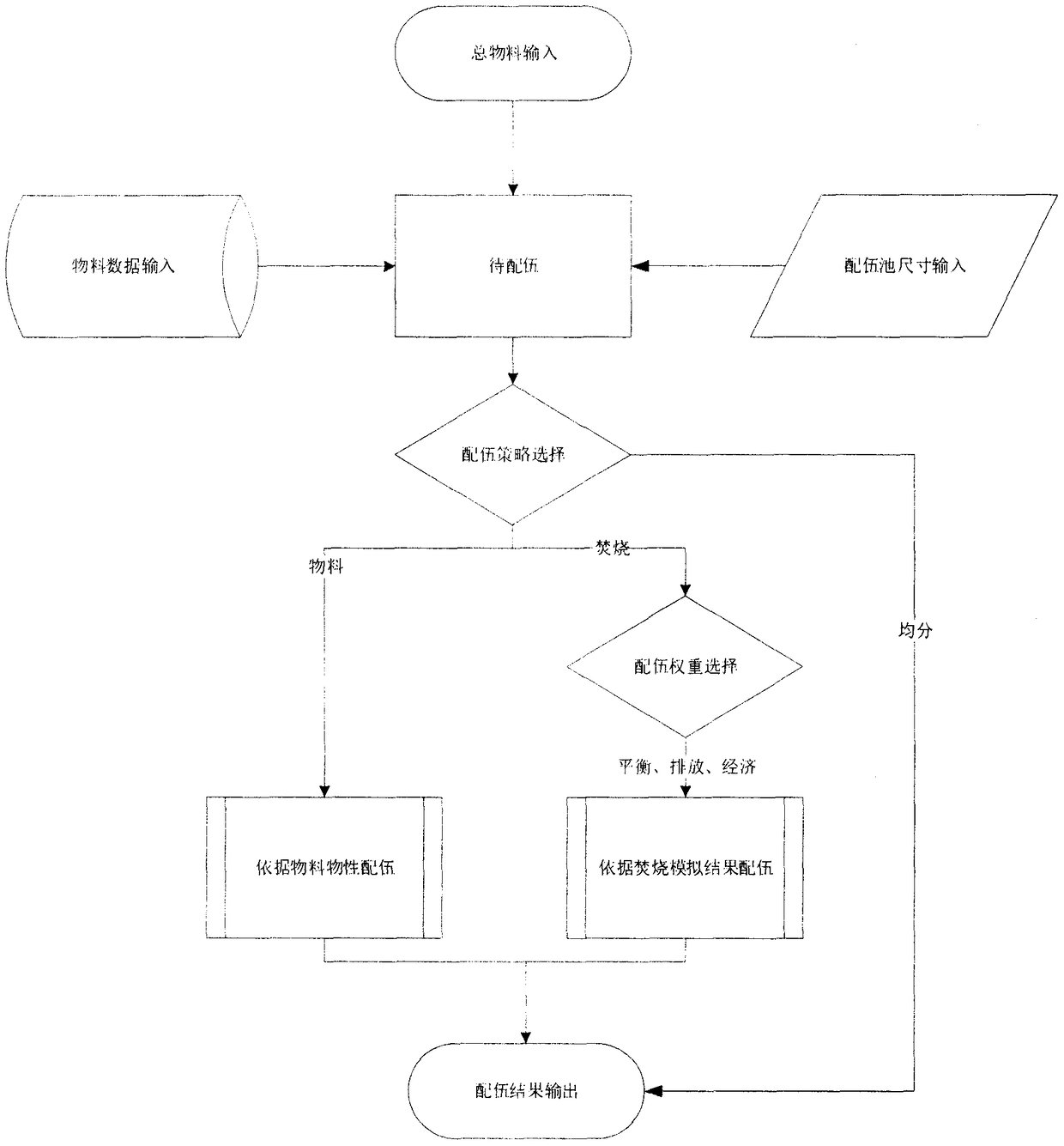

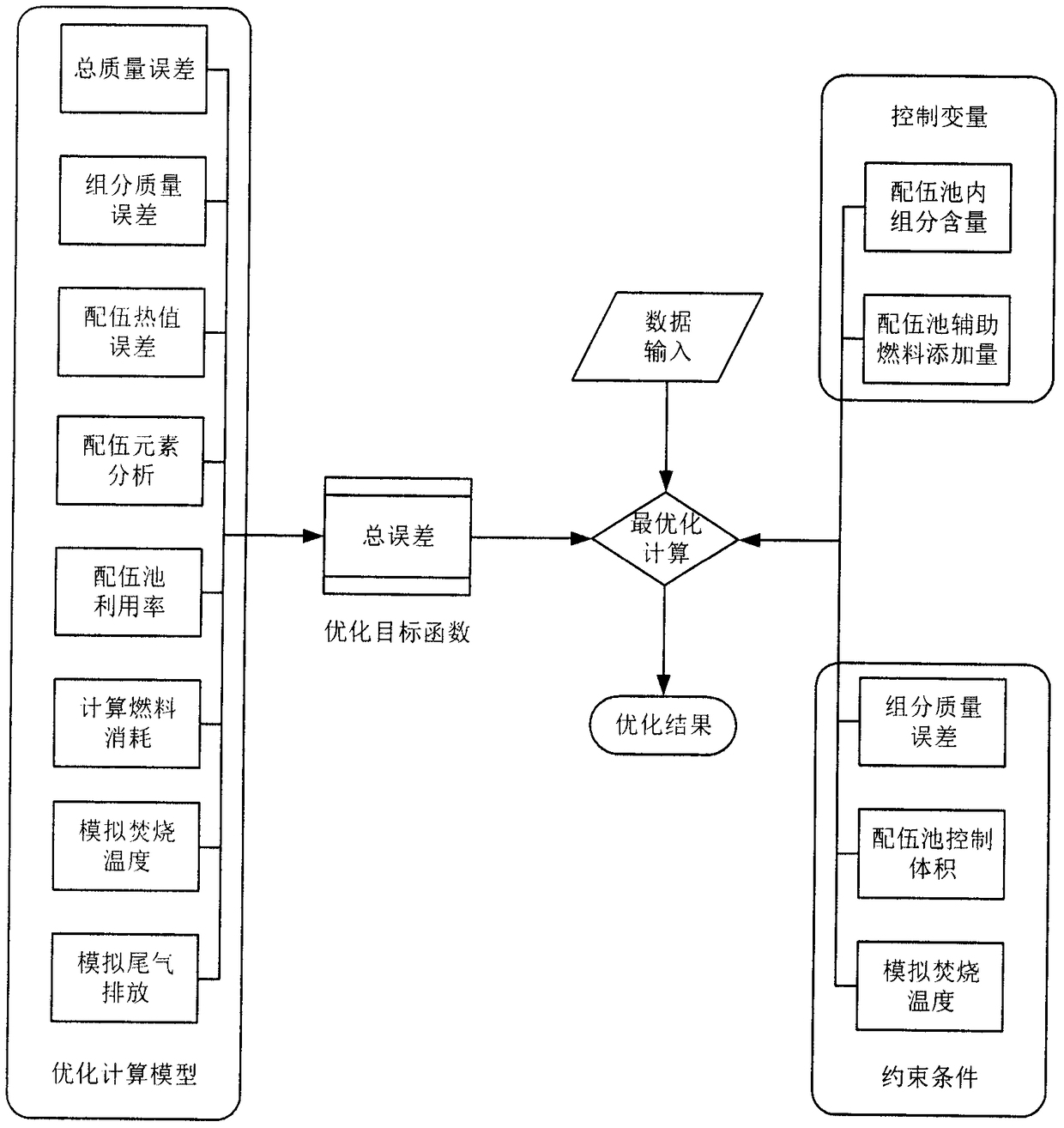

[0019] Input the type and total amount of materials to be processed into the compatibility module, and the compatibility module will call the physical property data of the relevant materials from the physical property database according to the input material type, and calculate the suitable compatibility pool in combination with the pre-set size of the compatibility pool of the treatment plant Quantity n, the above input and generated data are transferred to the compatibility module to be calculated and called;

[0020] The operator selects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com