A kind of modified concrete water-retaining agent and preparation method thereof

A water-retaining agent and concrete technology, applied in the field of concrete admixtures, can solve the problems of high mud content, poor quality of inferior sand and gravel, limited supply of river sand, etc., and achieve the effects of environmental friendliness, excellent performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

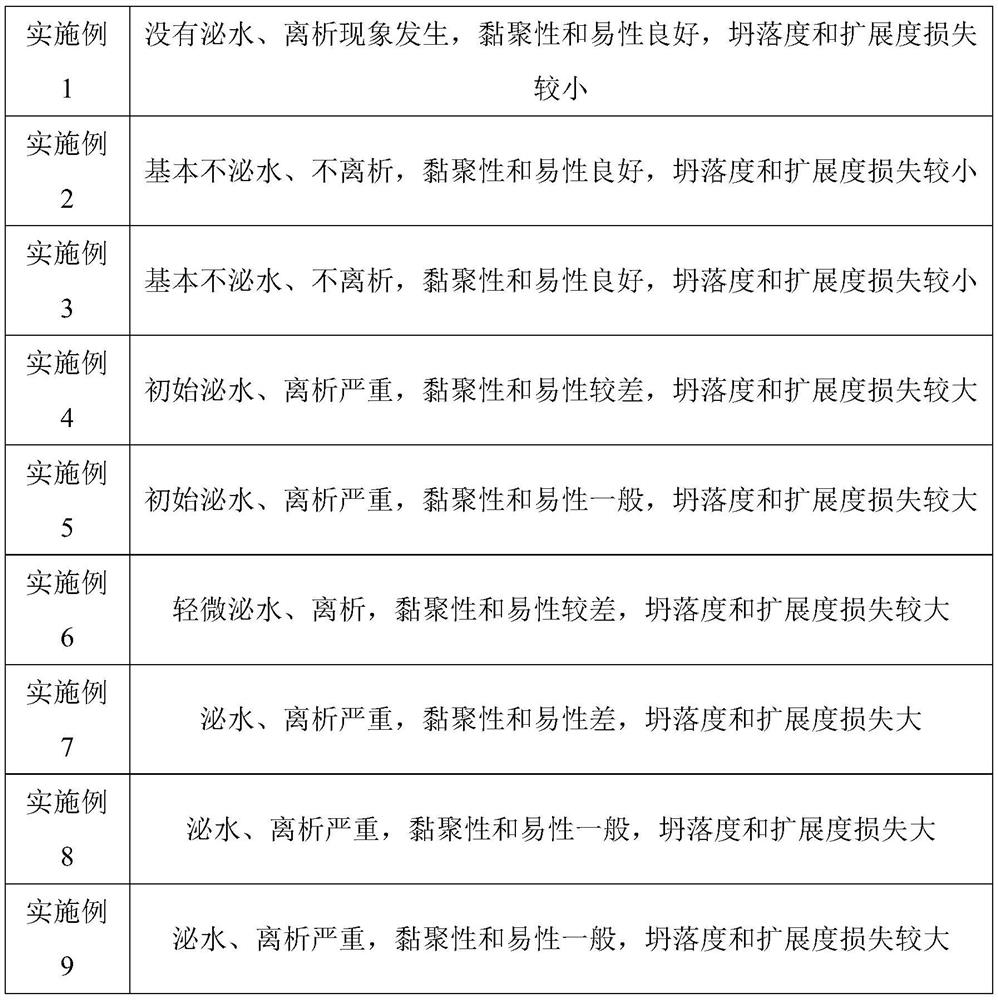

Examples

preparation example Construction

[0072] A second aspect of the present invention provides a method for preparing the modified concrete water-retaining agent, at least including the following steps:

[0073] (1) Dissolve the oxidizing agent in water and configure it into an aqueous solution with a concentration of 0.1-1mol / L, denoted as solution A; dissolve part of the anionic monomer and alkali containing double bonds in water and configure it into an aqueous solution of 0.1-1mol / L , denoted as B solution;

[0074] (1) Mix the reducing agent, the molecular chain regulator, the rest of the double bond-containing anionic monomer and water, heat to 50-60°C while stirring, and continue stirring until completely dissolved;

[0075] (3) At the same time, drop the prepared A solution and B solution into the step (2), the dropping time is 1.5-2.5h, the temperature is 55-65°C, stir and react for 0.5-2h; then cool down to below 40°C , that is.

[0076] In a preferred embodiment, the preparation method of the modified...

Embodiment 1

[0086] Example 1 provides a modified concrete water-retaining agent. The raw materials for the preparation of the water-retaining agent include at least the following components in parts by weight: 50 parts of anionic monomers containing double bonds, 50 parts of ester monomers containing double bonds 20 parts, 10 parts of alkali, 10 parts of molecular chain regulator, 2 parts of oxidizing agent, 4 parts of reducing agent, 500 parts of water.

[0087] The anionic monomer containing a double bond is a mixture of acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid in a weight ratio of 1:4; the acrylic acid was purchased from Aite (Shandong) New Material Co., Ltd. ; The 2-acrylamido-2-methylpropanesulfonic acid was purchased from Jinan Huijinchuan Trading Co., Ltd.

[0088] The ester monomer containing double bonds is vinyl acetate, purchased from Shandong Xinbaihe Chemical Technology Co., Ltd.

[0089] The base is sodium hydroxide.

[0090] The oxidizing agent is ammoni...

Embodiment 2

[0099] Example 2 provides a modified concrete water-retaining agent. The raw materials for the preparation of the water-retaining agent include at least the following components in parts by weight: 30 parts of anionic monomers containing double bonds, 30 parts of ester monomers containing double bonds 10 parts, 5 parts of alkali, 5 parts of molecular chain regulator, 1 part of oxidizing agent, 1 part of reducing agent, 300 parts of water.

[0100] The anionic monomer containing double bonds is a mixture of acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid in a weight ratio of 1:1; the acrylic acid was purchased from Aite (Shandong) New Material Co., Ltd. ; The 2-acrylamido-2-methylpropanesulfonic acid was purchased from Jinan Huijinchuan Trading Co., Ltd.

[0101] The ester monomer containing double bonds is vinyl acetate, purchased from Shandong Xinbaihe Chemical Technology Co., Ltd.

[0102] The base is sodium hydroxide.

[0103] The oxidizing agent is ammonium pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com