Patents

Literature

177results about How to "Improve uniformity and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

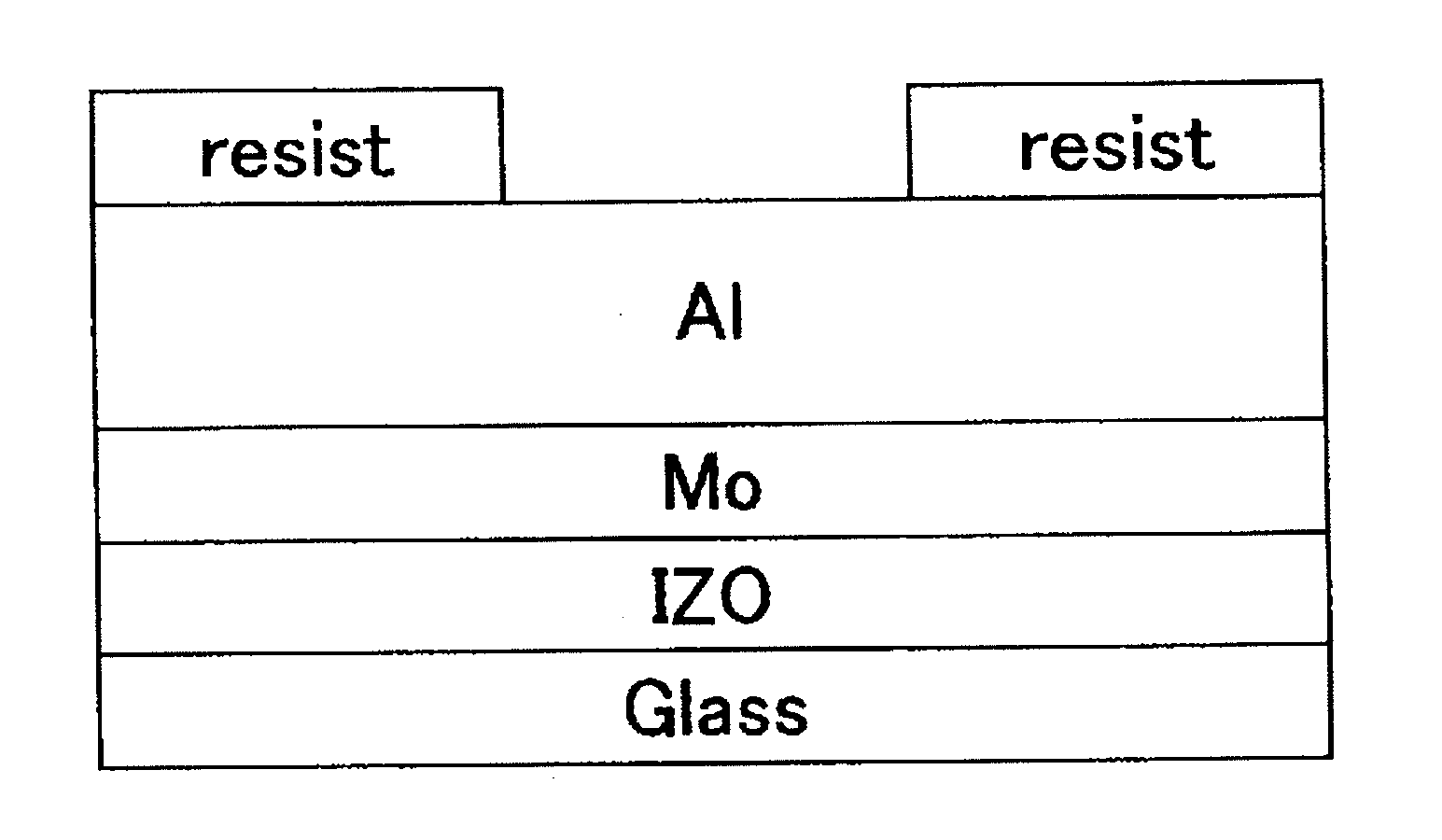

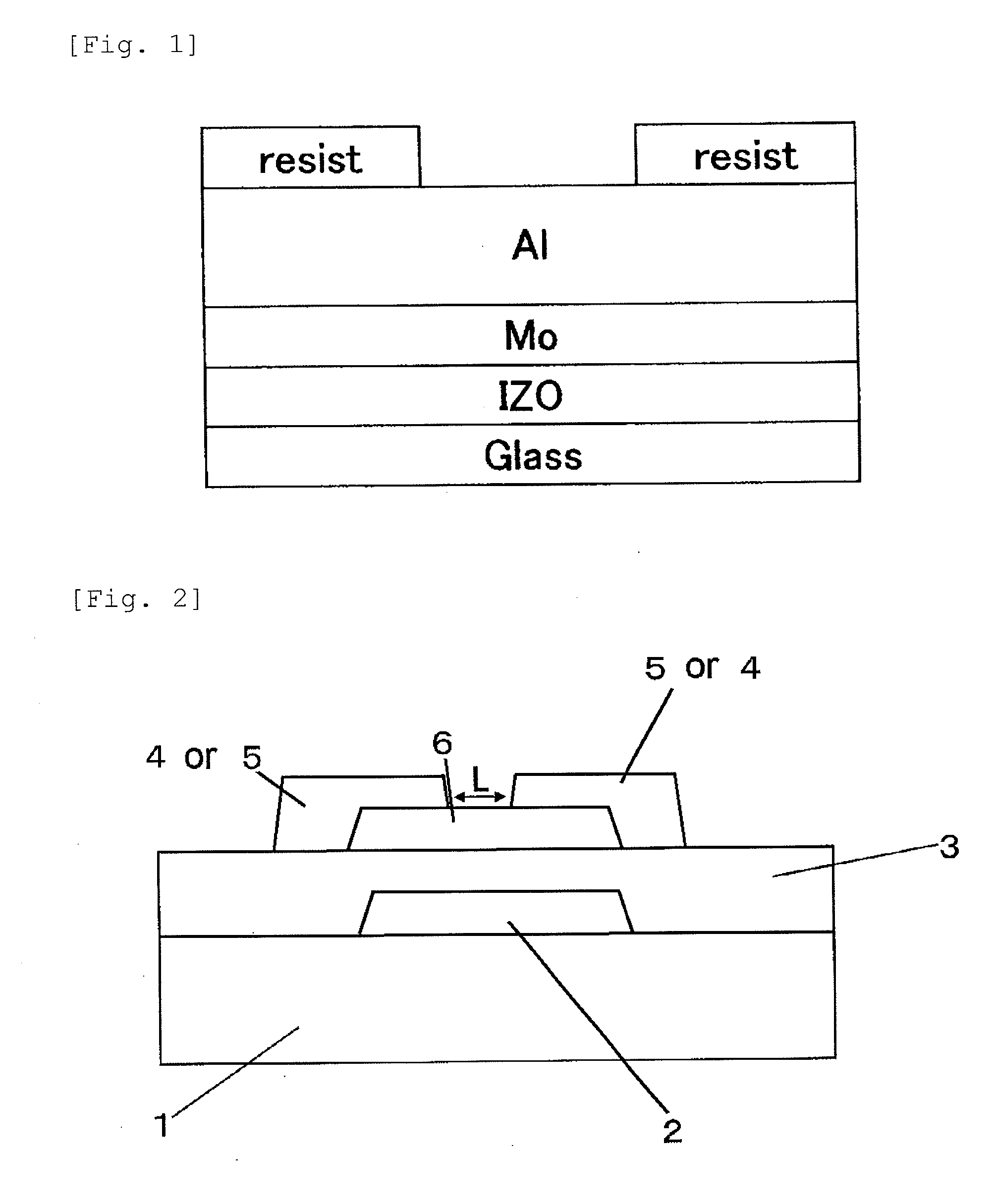

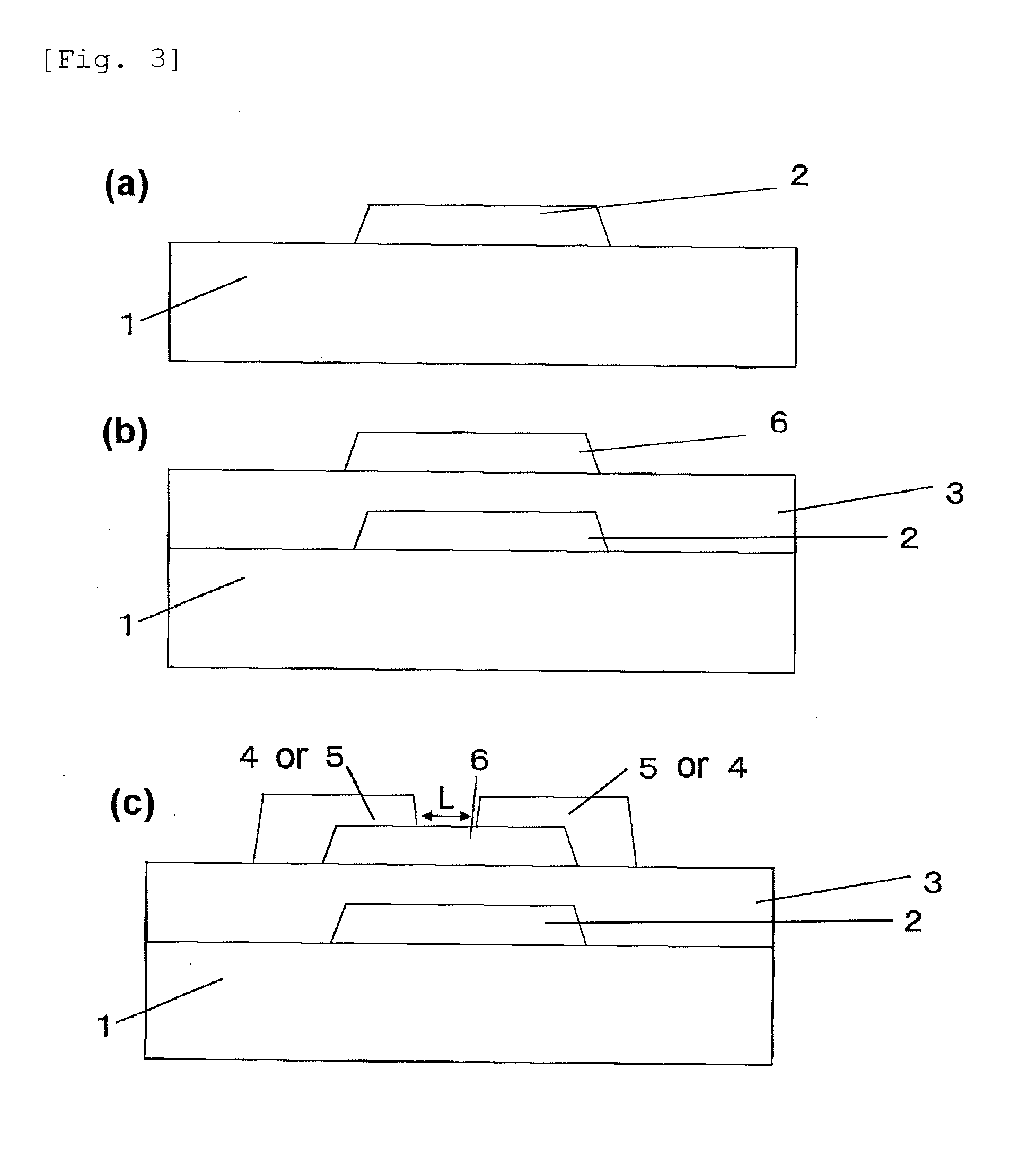

Etching solution composition

InactiveUS20100320457A1High selectivityImprove uniformity and stabilitySemiconductor/solid-state device manufacturingNon-linear opticsMetallurgyAlloy

Provided is an etching solution composition for selectively etching a metal film, which is composed of Al, Al alloy or the like and is arranged on an amorphous oxide film, from a laminated film including the metal film and an amorphous oxide film of various types. The etching solution composition is used for selectively etching the metal film from the laminated film which includes the amorphous oxide film and the metal film composed of Al, Al alloy, Cu, Cu alloy, Ag or Ag alloy, and is composed of an aqueous solution containing an alkali.

Owner:IDEMITSU KOSAN CO LTD +1

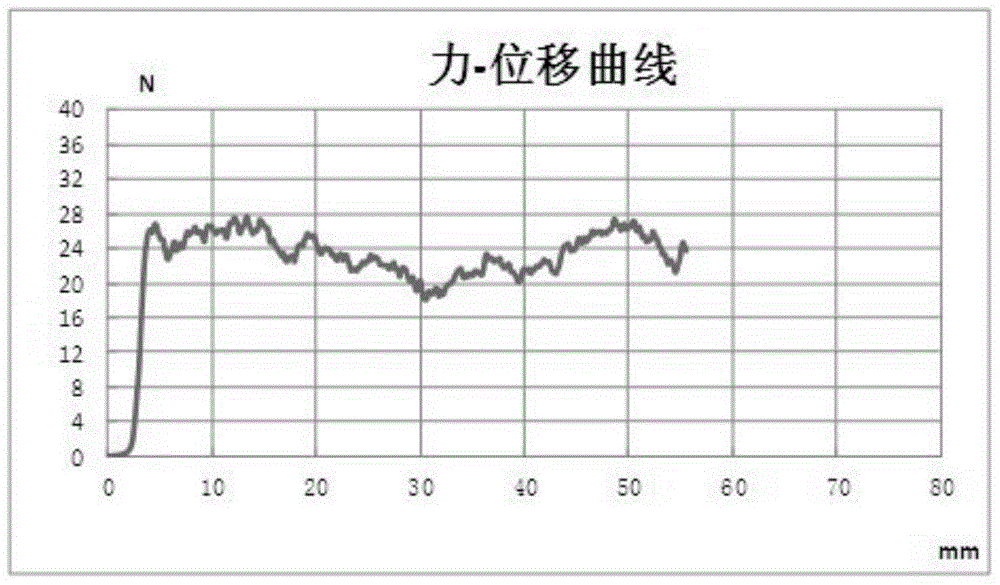

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

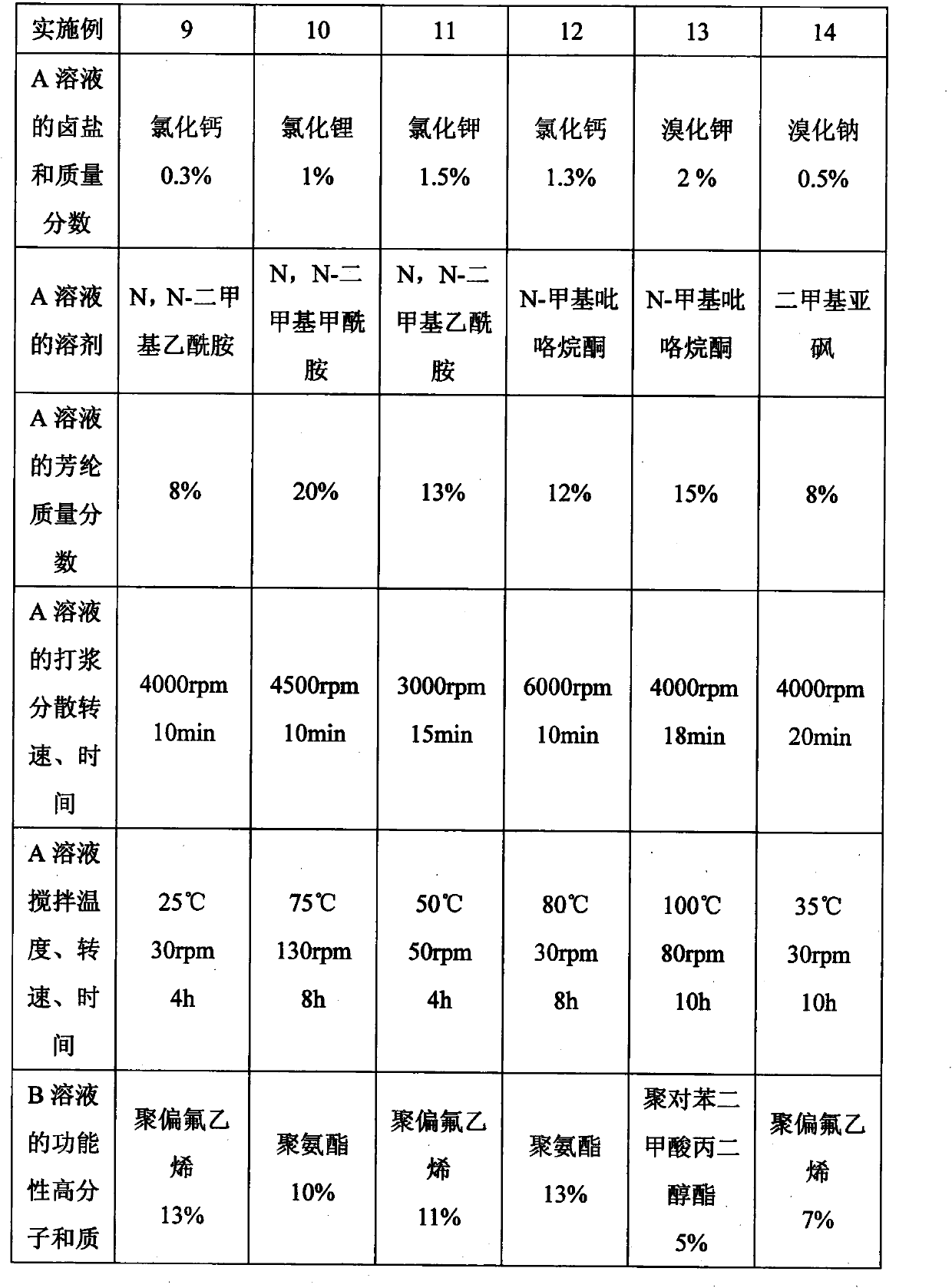

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

Solid waste high temperature aerobic composting method using stereoscopic ventilating apparatus

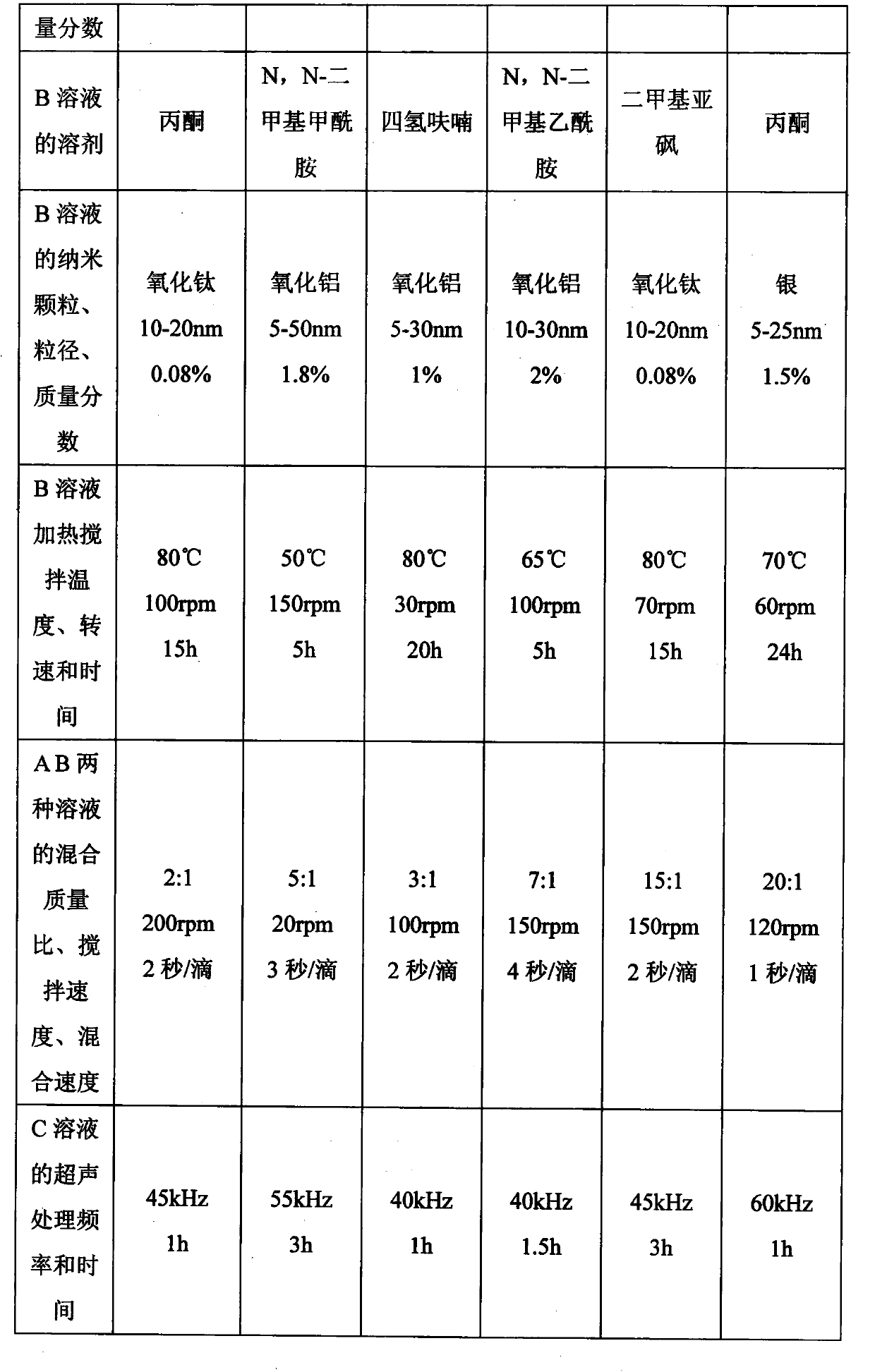

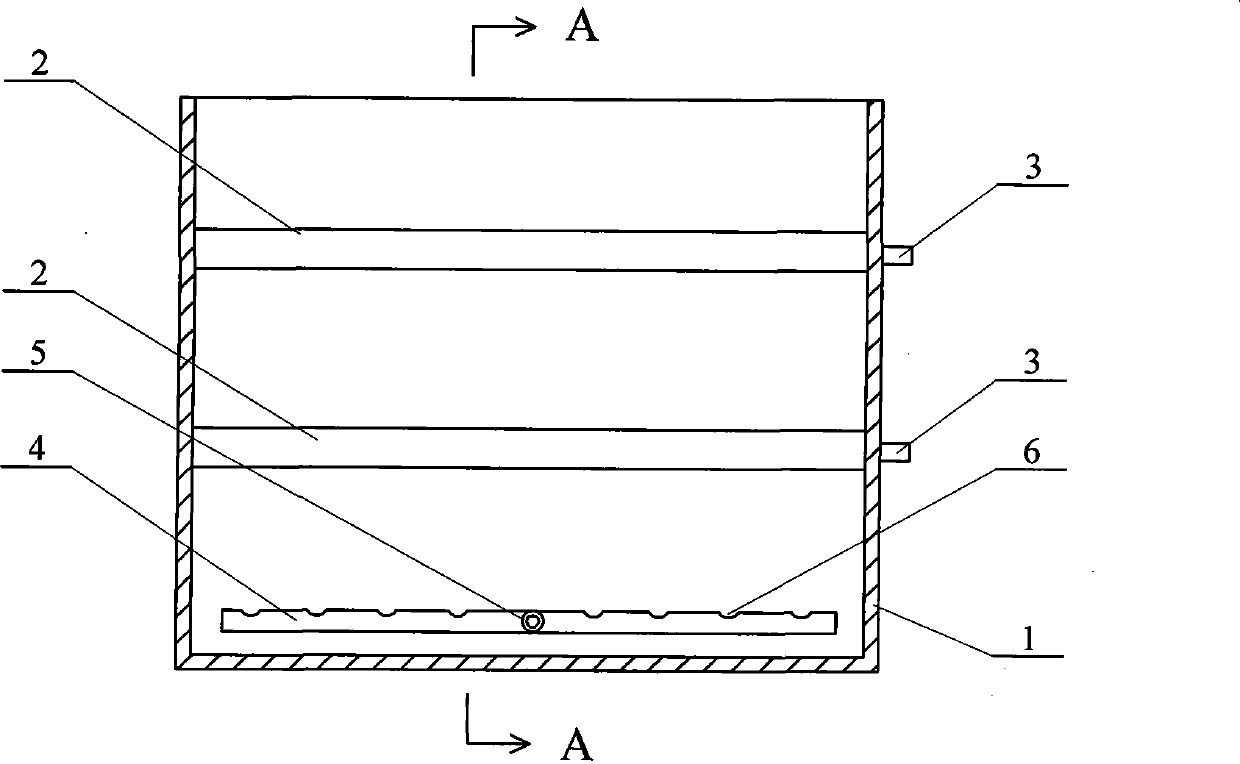

InactiveCN101372427AImprove mass transfer effectImprove uniformity and stabilityBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringCompost

A high-temperature and aerobic composting method for solid wastes which adopts a vertical ventilation device relates to a high-temperature and aerobic composting method for the solid wastes. The composting method aims at solving the problems that in the aerobic fermentation process, the conventional bottom ventilation method causes obvious uneven fermentation at the upper part and the lower part of a stacking body in a fermentation device, thus quality stability and uniformity of the fermented product are affected. In the composting method, middle air distribution pipes are fixed in a fermentation tank arranged at the lower side of an inverted ventilating slot; both the bottom part and the middle part of the fermentation tank adopt intermittent ventilation type, the ventilation time is 5-30 minutes, intermittent time is 15-120 minutes and ventilation rate is 0.03-2m<3> / (min m<3> mixing materials). The composting method increases the contact area between air and materials; air direction forms a reverse rotational flow, which increases residence time of fresh air in the fermentation device, thus improving the mass transfer efficiency, and the operational cycle of a single fermentation is shortened by over 1 / 4.

Owner:李伟光 +1

Slurry-homogenizing process for positive electrode slurry of lithium ion battery, positive electrode plate and lithium ion battery

ActiveCN106654166AImprove uniformity and stabilityReduce evaporationSecondary cellsNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

The invention discloses a slurry-homogenizing process for positive electrode slurry of a lithium ion battery, a positive electrode plate and the lithium ion battery, and belongs to the technical field of manufacturing of the lithium ion battery. The slurry-homogenizing process for the positive electrode slurry of the lithium ion battery comprises the steps of preparing an adhesive solution, stirring by a V-shaped stirrer, performing pre-mixing and stirring, performing high-speed stirring, performing viscosity adjustment, performing vacuum defoaming and the like; the positive electrode plate of the lithium ion battery comprises a positive electrode current collector and the positive electrode slurry for coating the positive electrode current collector; the positive electrode current collector adopts an aluminum foil; the positive electrode slurry is prepared by the slurry-homogenizing process for the positive electrode slurry of the lithium ion battery; and the lithium ion battery adopts the positive electrode plate of the lithium ion battery prepared by the method. By adoption of the slurry-homogenizing process, the solid content of the slurry is increased, so that solid granule friction in stirring can be improved, and the uniformity and the stability of the slurry can be improved; and by lowering a baking temperature in a drying oven in coating and drying, gaps formed between active material granules, conducive carbon granules and a binder can be reduced, thereby enhancing an adhesive effect and improving the performance of the lithium ion battery.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

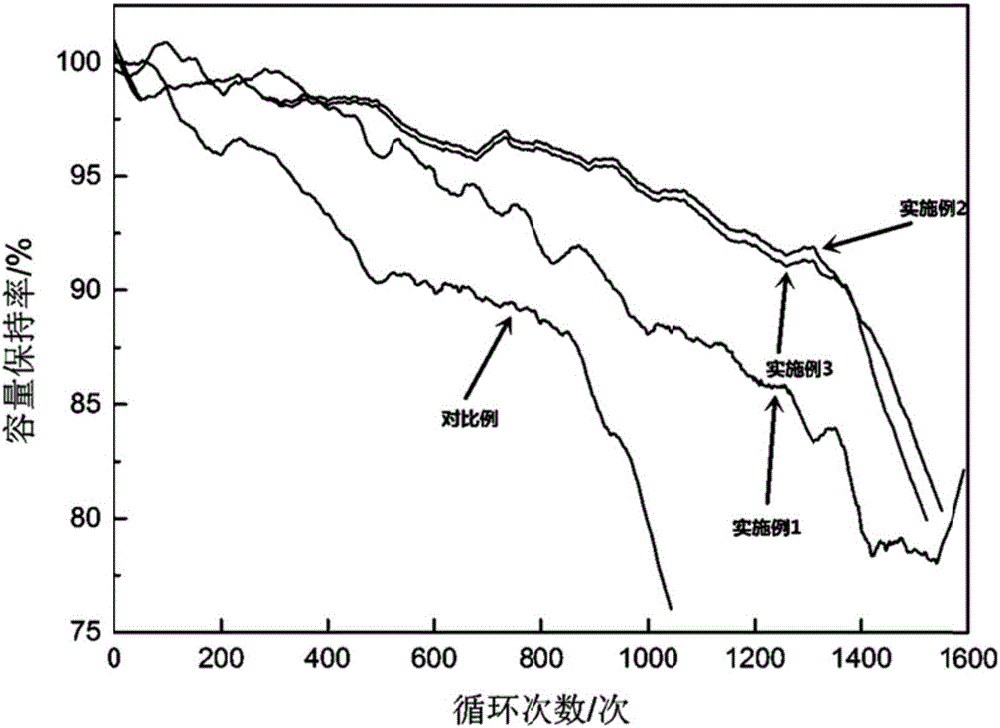

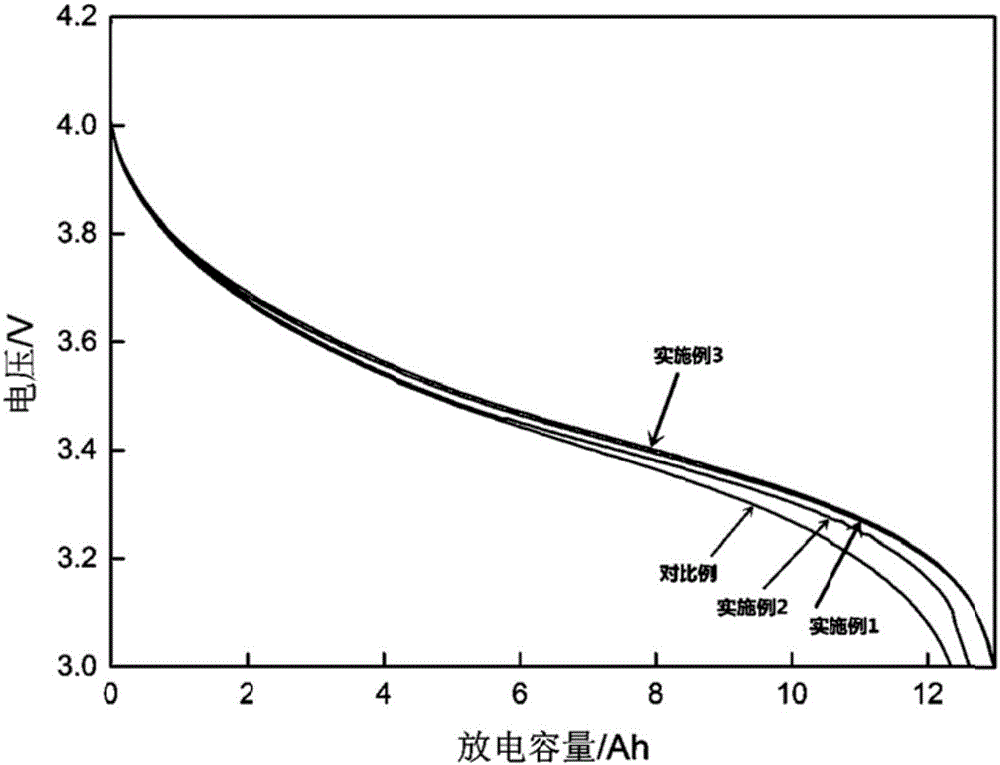

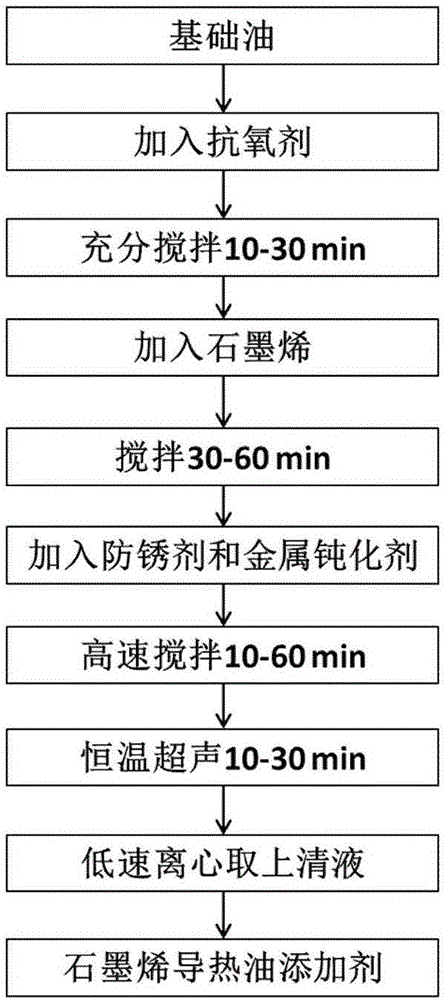

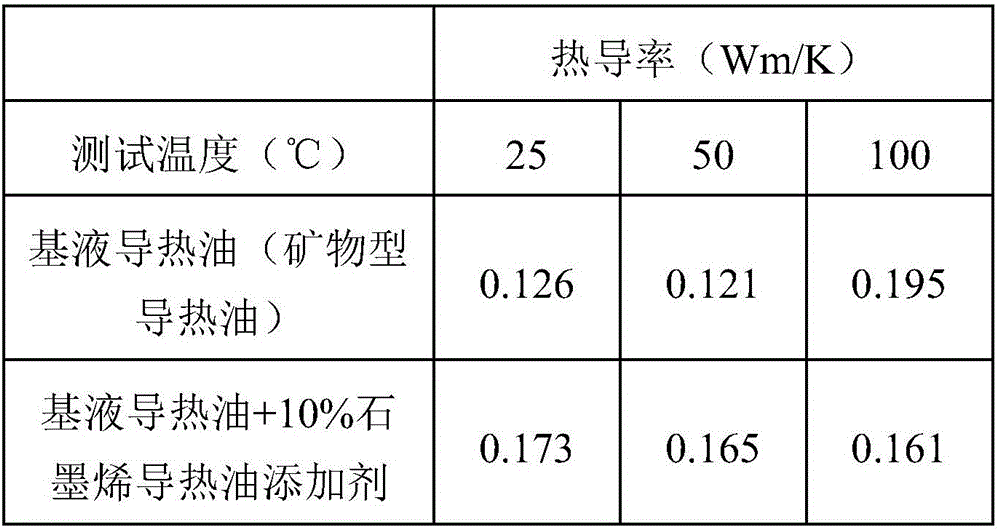

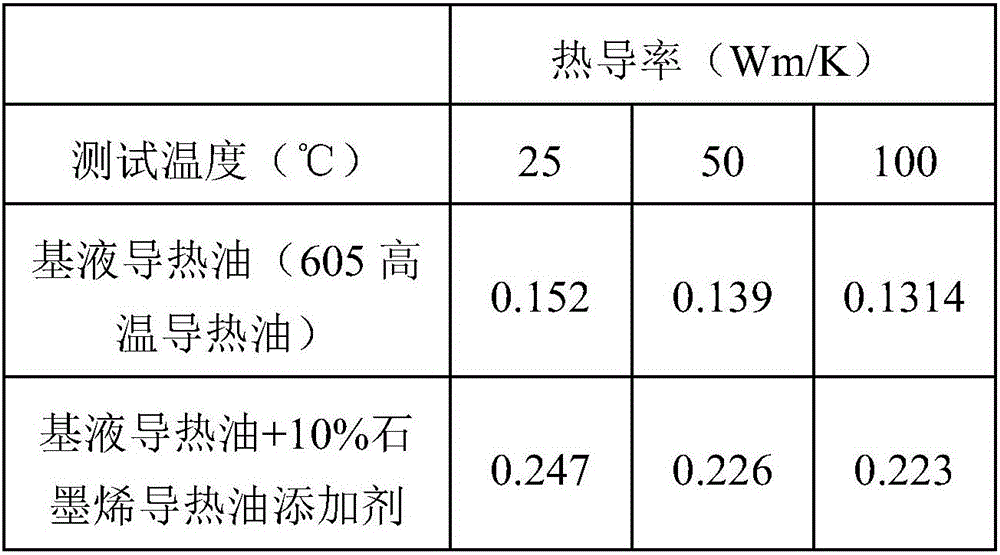

Graphene conduction oil additive and preparation method thereof

InactiveCN106543977AImprove uniformity and stabilityImprove heat transfer efficiencyHeat-exchange elementsLubricant compositionBoiling pointPyrolysis

The invention discloses a graphene conduction oil additive and a preparation method thereof. The graphene conduction oil additive is prepared from the components of base solution conduction oil, graphene, a metal passivator, an antirust agent and antioxygen at a certain proportion and according to the processes of mechanical stirring, high speed stirring and ultrasonic dispersion. The graphene conduction oil additive can be directly added into conduction oil, and the defects of traditional conduction oil that gas or low-boiling-point substances such as micromolecular substances are produced by high temperature pyrolysis, and are polymerized to produce substances with higher molecular weight and even high-boiling-point substances such as coke, combustion is easily caused, and the like can be overcome. The graphene conduction oil additive can be used to effectively improve the heat conduction efficiency of the conduction oil, prevent the conduction oil from being partially over-heated during use, delay ageing and coking of the conduction oil, effectively improve conduction oil indexes such as flash point, pour point, kinematic viscosity and initial boiling point, prolong the service life of the conduction oil, and realize energy conservation and consumption reduction.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

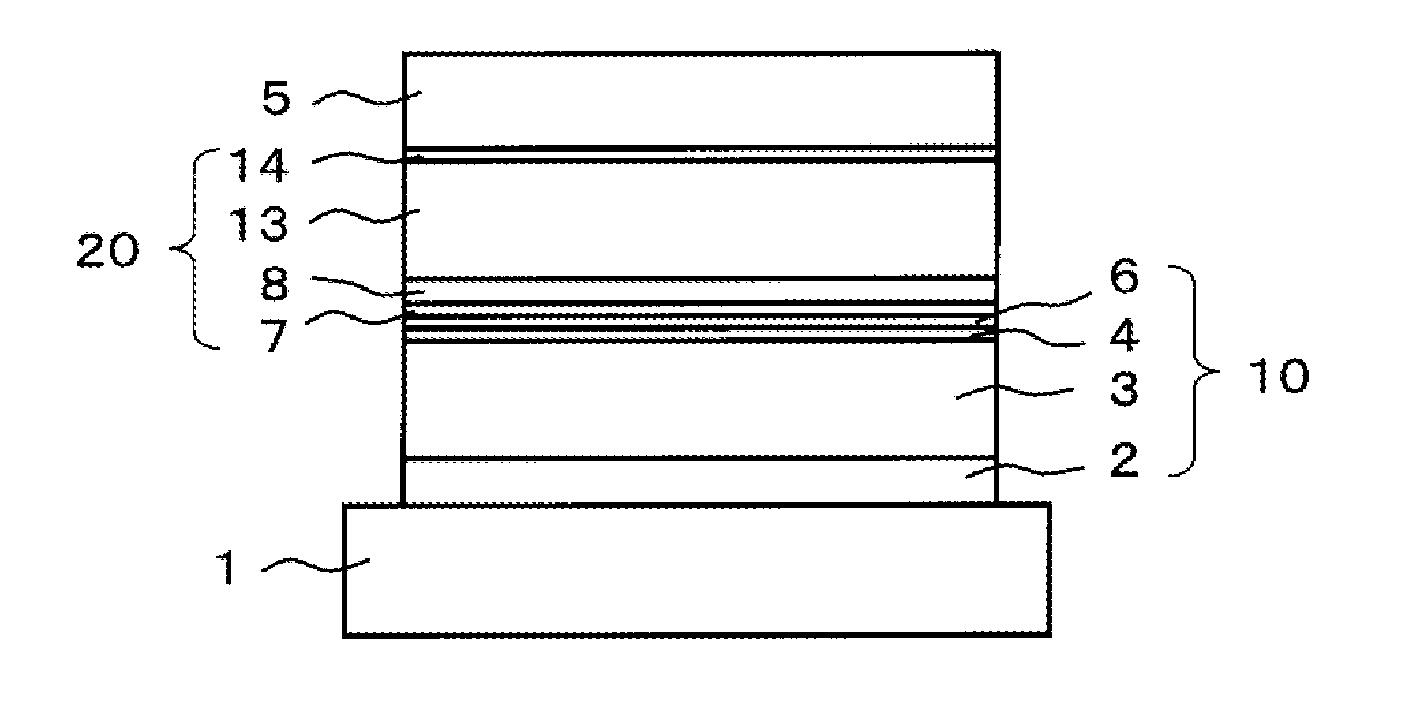

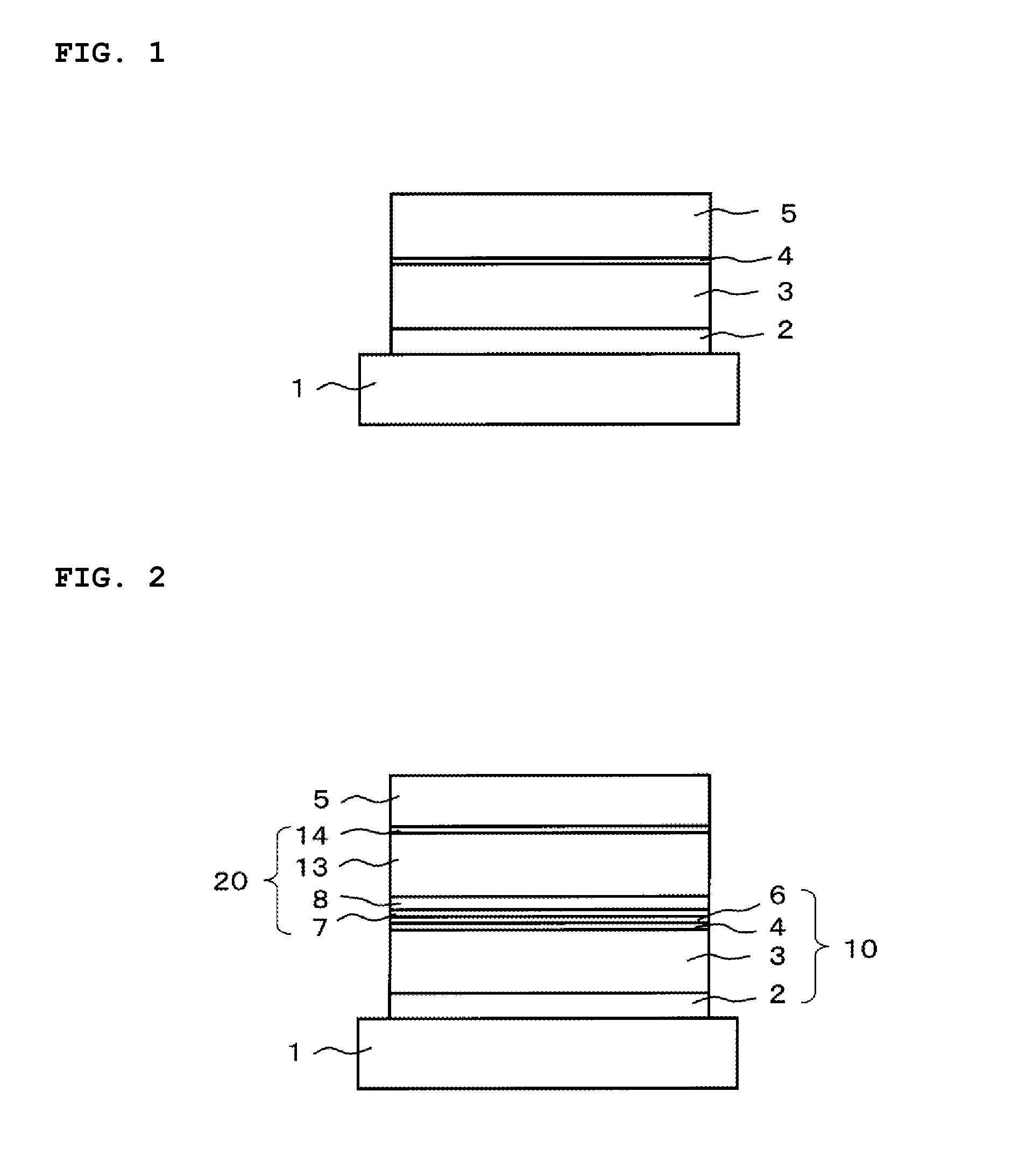

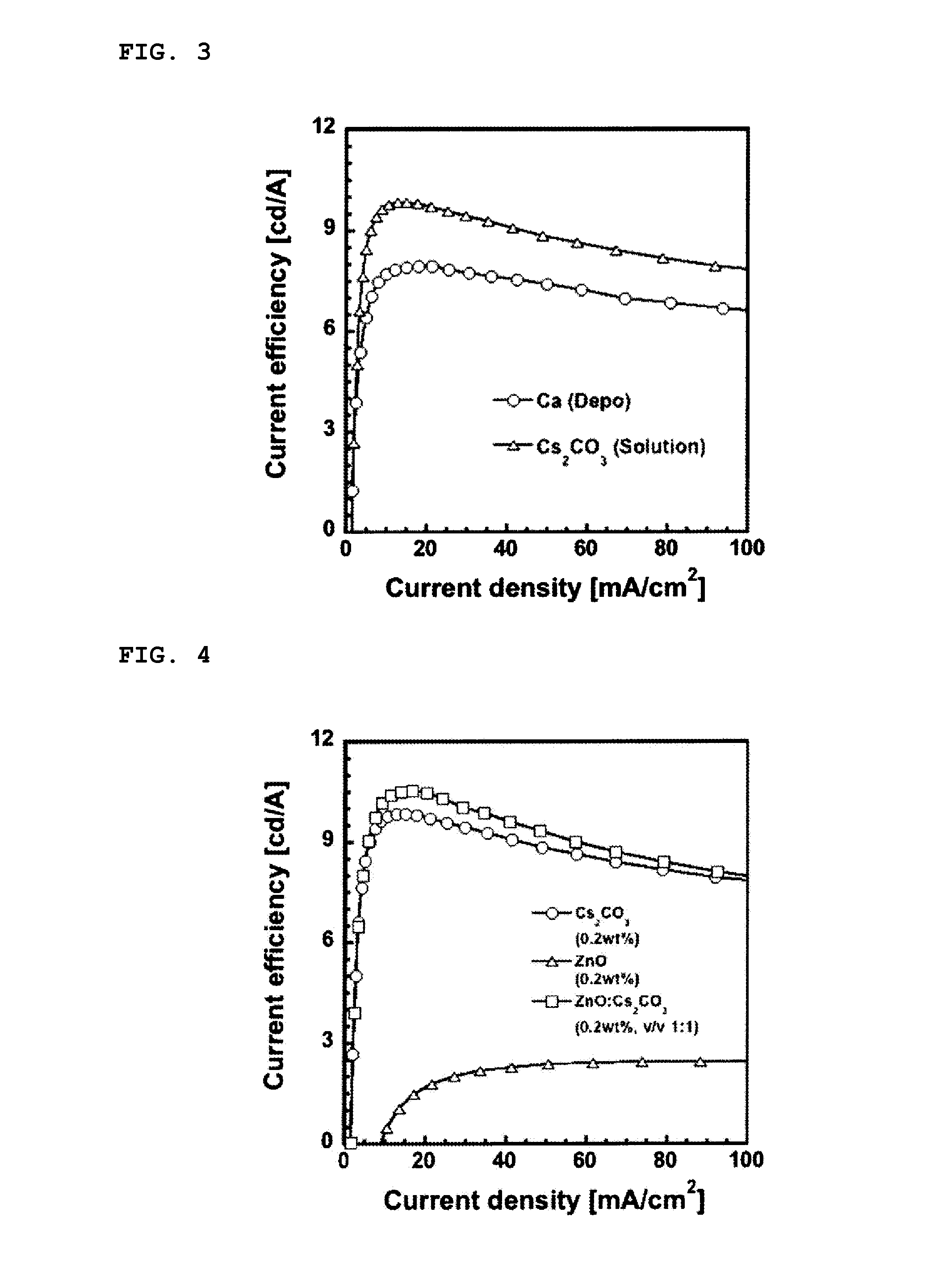

Organic electronic device and method for manufacturing the same

ActiveUS20140084280A1Improve uniformity and stabilityImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing efficiencyOxide

In a coating-type electron injection layer or electron transport layer using a metal oxide, the present invention aims at improving uniformity or stability of composition distribution and adhesion with another adjoining constituent layer, and improving film forming property, to thereby provide an organic electronic device and manufacture of the device whose efficiency is improved. In the organic electronic device having one pair of electrodes on a substrate, and having at least one organic layer between the electrodes, the electron injection layer or the electron transport layer is formed by application of a liquid material in which an alkaline metal salt and zinc-oxide nano particles are dissolved in alcohol.

Owner:YAMAGATA UNIVERSITY

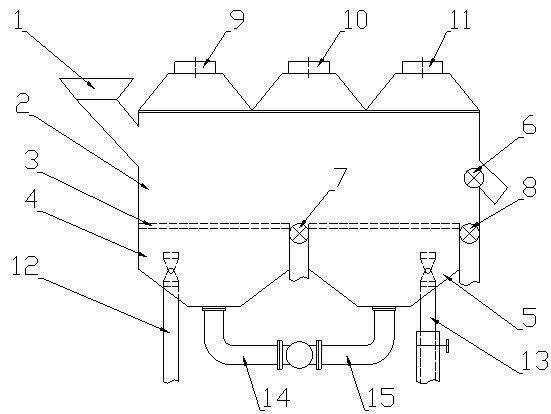

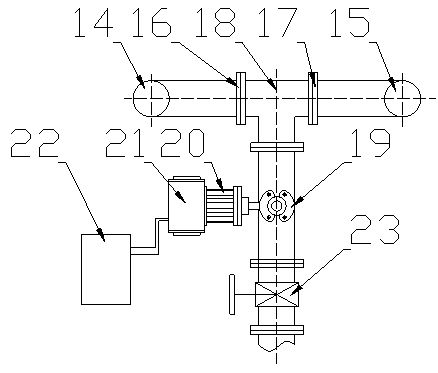

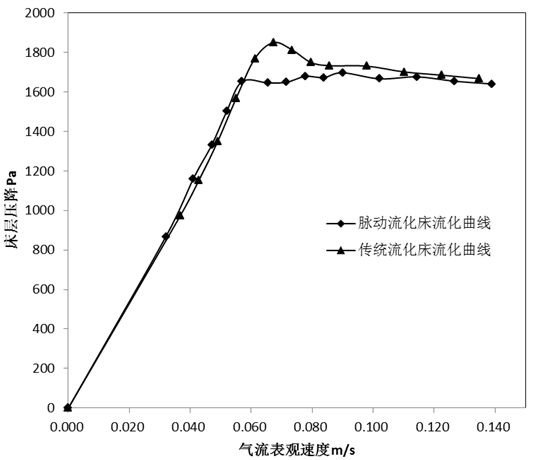

Gas-solid fluidized bed sorting machine based on pulse airflow

InactiveCN102652940AImprove uniformity and stabilitySimple structureGas current separationFluidized bedEngineering

The invention discloses a gas-solid fluidized bed sorting machine based on pulse airflow. The gas-solid fluidized bed sorting machine mainly comprises a sorting groove, an air distributing plate, a dedusting cover and a support, wherein the tail end of the sorting groove is provided with a light product material discharge wheel; the tail end of a rear air distributing chamber is provided with a rear heavy product material discharge wheel; the tail end of a front air distributing chamber is provided with a front heavy product material discharge wheel; the bottom parts of the rear air distributing chamber and the front air distributing chamber are respectively provided with a rear air tube and a front air tube; the rear air tube and the front air tube are connected with an air inlet tube through a three-way connector; and the air inlet tube is provided with a pulse airflow generator and an airflow quantity regulating valve in sequence. According to the invention, the pulse airflow is introduced into a gas-liquid fluidized bed, materials are conveyed forward relying on the oblique angle of the sorting groove and the effect of the pulse airflow; floating materials and sediment materials are respectively discharged through the light product material discharge wheel and the heavy product material discharge wheels, and the medium circulating quantity is reduced effectively; and the height of a front support leg can be adjusted, the front support leg can be used for regulating the oblique angle of the sorting groove, the regulation of coal conveying speed and sorting time can be realized.

Owner:CHINA UNIV OF MINING & TECH

Environment-friendly dust suppressant and preparation method thereof

ActiveCN104449578ARaw materials are easy to getEasy to makeOther chemical processesEconomic benefitsSURFACTANT BLEND

The invention discloses an environment-friendly dust suppressant and a preparation method thereof, belonging to the field of dust suppression control. The dust suppressant consists of the following components: water, a base material, natural starch, a surfactant and a synergist at the mass ratio of 100 to (1-20) to (1-20) to (0.1-5) to (0.1-10). The preparation method of the dust suppressant comprises the following steps: adding 1-20 parts of the base material to 50 parts of the water, continuously stirring, and heating until continuously boiling for 30min; adding 0.1-5 parts of the surfactant to 25 parts of the water, stirring and uniformly mixing; adding the prepared surfactant solution to the boiled base material solution and stirring for 10min; adding 25 parts of the water, adding 1-20 parts of the starch when the temperature is controlled at 60 DEG C, continuously stirring, preserving temperature at 70 DEG C, and stopping heating when the starch is under the state of being completely gelatinized; adding 0.1-10 parts of the synergist and continuing to stir for 10min; and carrying out magnetizing treatment under a magnetic field intensity of 50mT for 1-5min, standing by and cooling to obtain the dust suppressant. The adopted raw materials are excellent in environmental and economic benefits.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

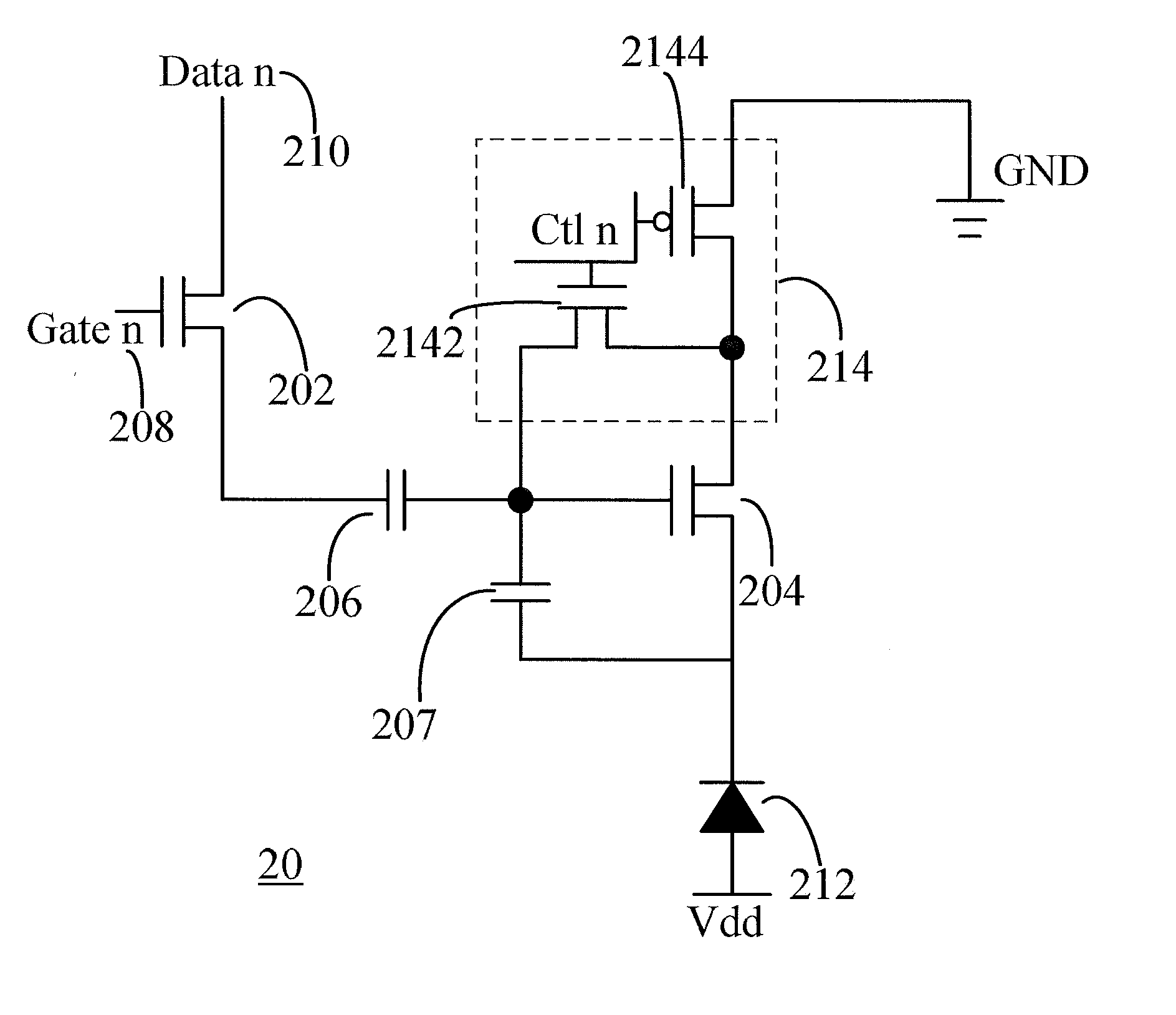

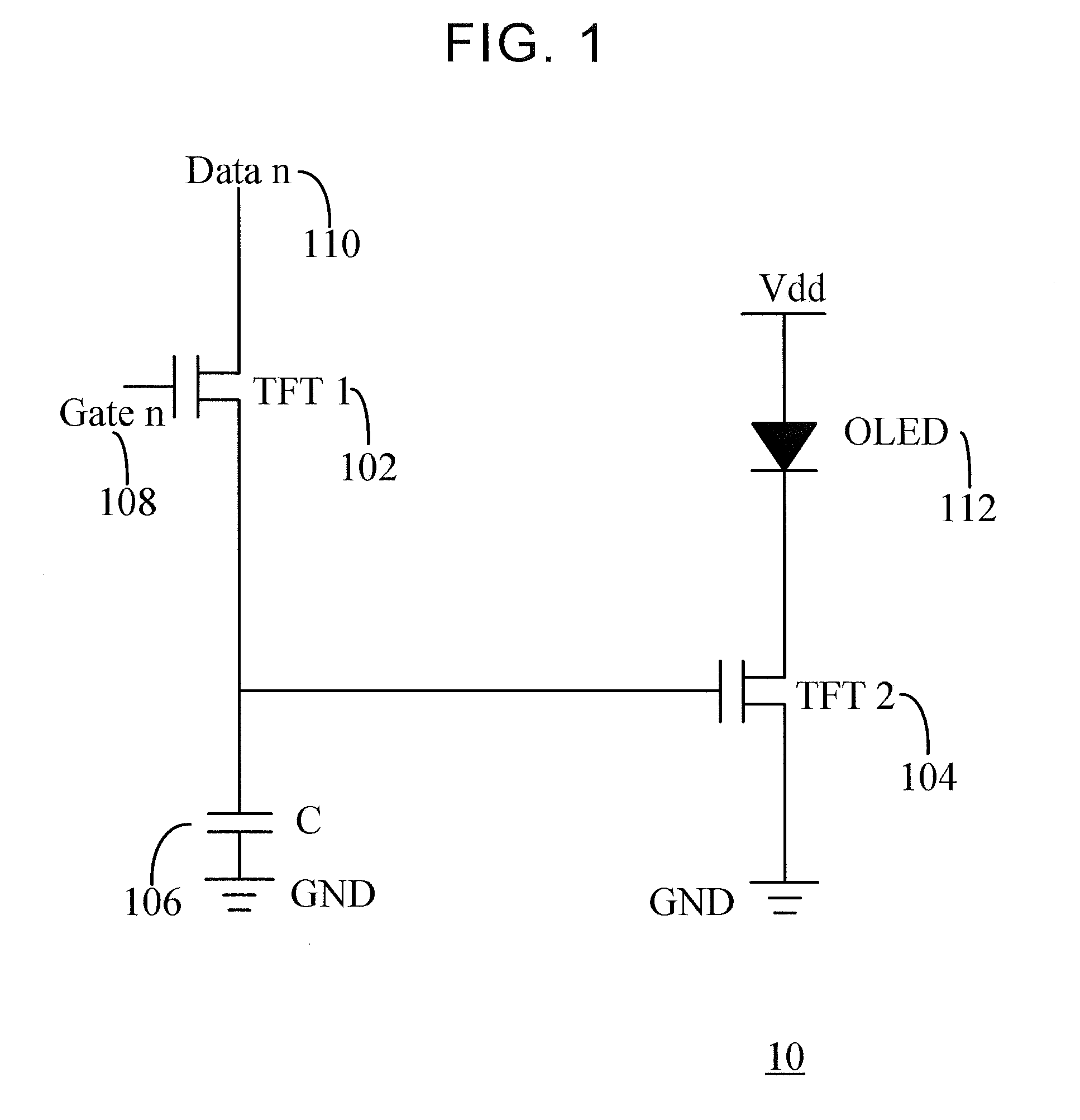

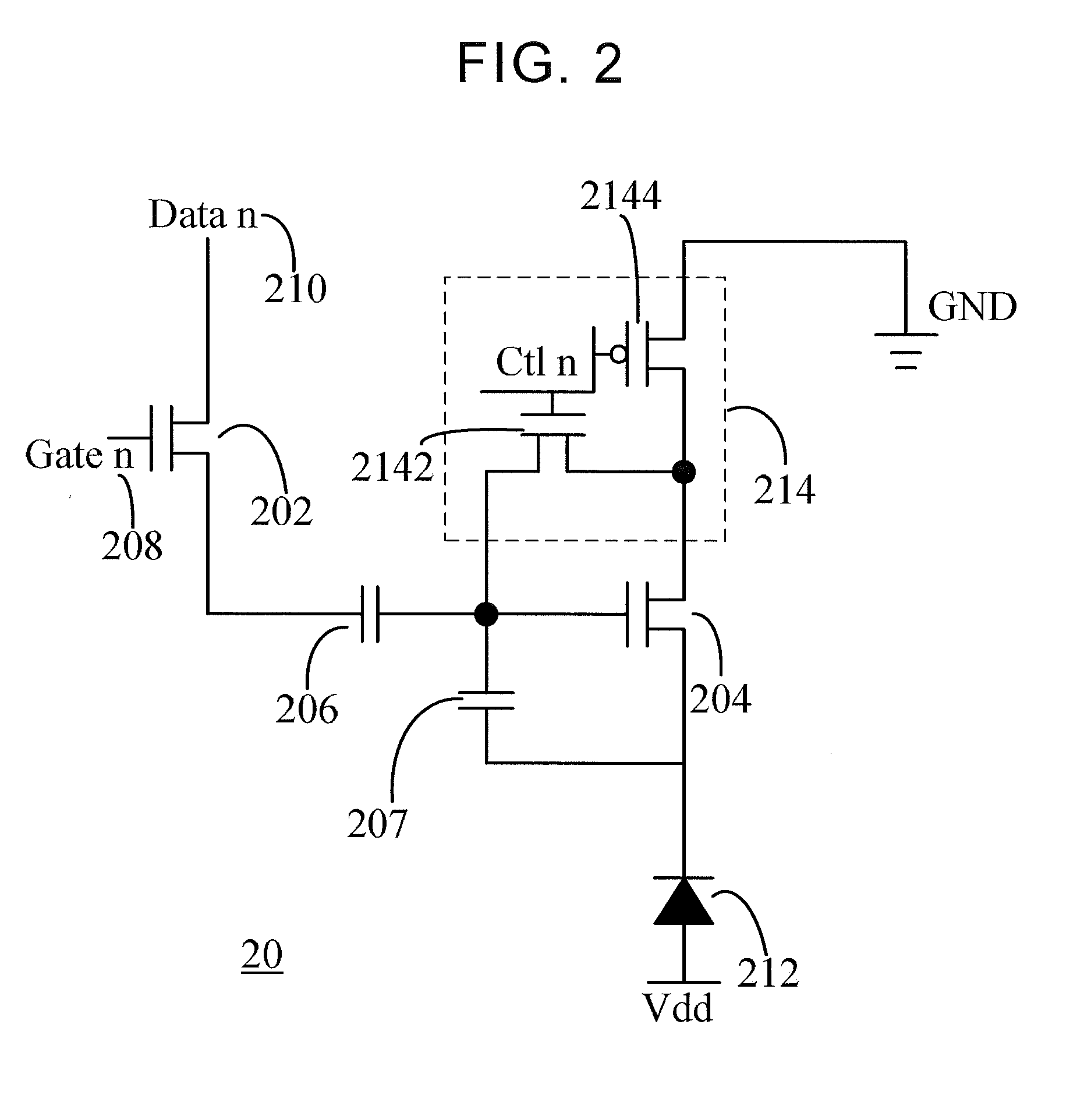

Pixel driver circuit, display panel and driving method therefor

ActiveUS20160240138A1Improve uniformity and stabilityUniform and stable brightnessSolid-state devicesCathode-ray tube indicatorsHemt circuitsEngineering

A pixel driver circuit including a first transistor, second transistor, third transistor, fourth transistor, first capacitor, second capacitor, and organic light-emitting diode is provided. A drain of the second transistor is coupled to a cathode of the organic light-emitting diode, and an anode of the organic light-emitting diode is couple to a power line. A source of the second transistor is respectively coupled to drains of the third transistor and the fourth transistor. A source of the third transistor is coupled to a gate of the second transistor, and gates of the third transistor and the fourth transistor receives a compensation control voltage. A source of the fourth transistor is grounded. A shift of the threshold voltage of an AMOLED can be compensated in an embodiment of the present invention, whereby uniformity between a picture and grayscales of the organic light-emitting diodes can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Lithium ion battery insulating coating, preparation method and pole piece and lithium ion battery using insulating coating

InactiveCN104449011AImprove electrochemical performanceElectrochemical performance does not affectConjugated diene hydrocarbon coatingsSecondary cellsElectrical resistance and conductanceElectrical battery

The invention discloses a lithium ion battery insulating coating, a preparation method and a pole piece and a lithium ion battery using the insulating coating, and belongs to the technical field of lithium ion batteries. The effective components of the lithium ion battery insulating coating disclosed by the invention is formed by inorganic powder, an adhesive and a dispersing agent, wherein the three components generate a synergistic effect to improve the uniformity and stability of the insulating coating and improve the resistance uniformity of an insulating coating layer formed by the insulating coating, and the bonding strength with an aluminum foil matrix for the pole piece is high, thereby being unlikely to drop. The preparation method of the lithium ion battery insulating coating disclosed by the invention is easy to operate and is suitable for industrialized promotion and application, the inorganic powder, the adhesive and the dispersing agent are mixed in a high speed stirring and dispersing manner, so as to improve the uniformity and stability of the insulating coating, and the insulating coating is free of such phenomena as lamination and settlement after being stored for a long term. The lithium ion battery prepared by the insulating coating disclosed by the invention is good in safety performance and is stable in electrochemical performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

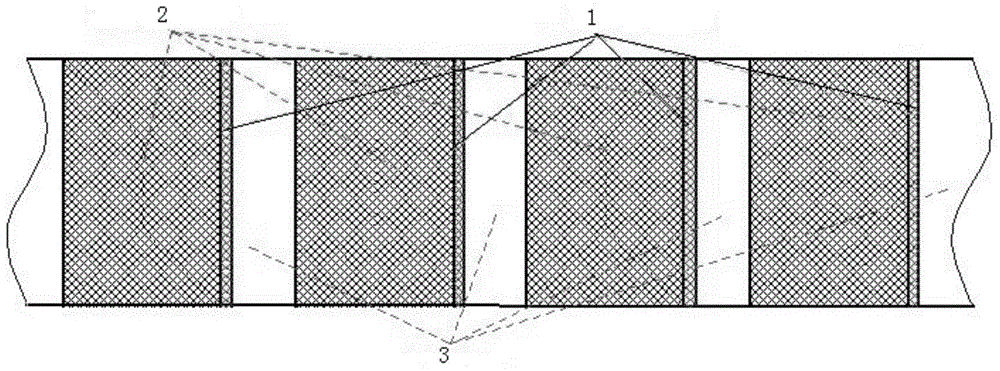

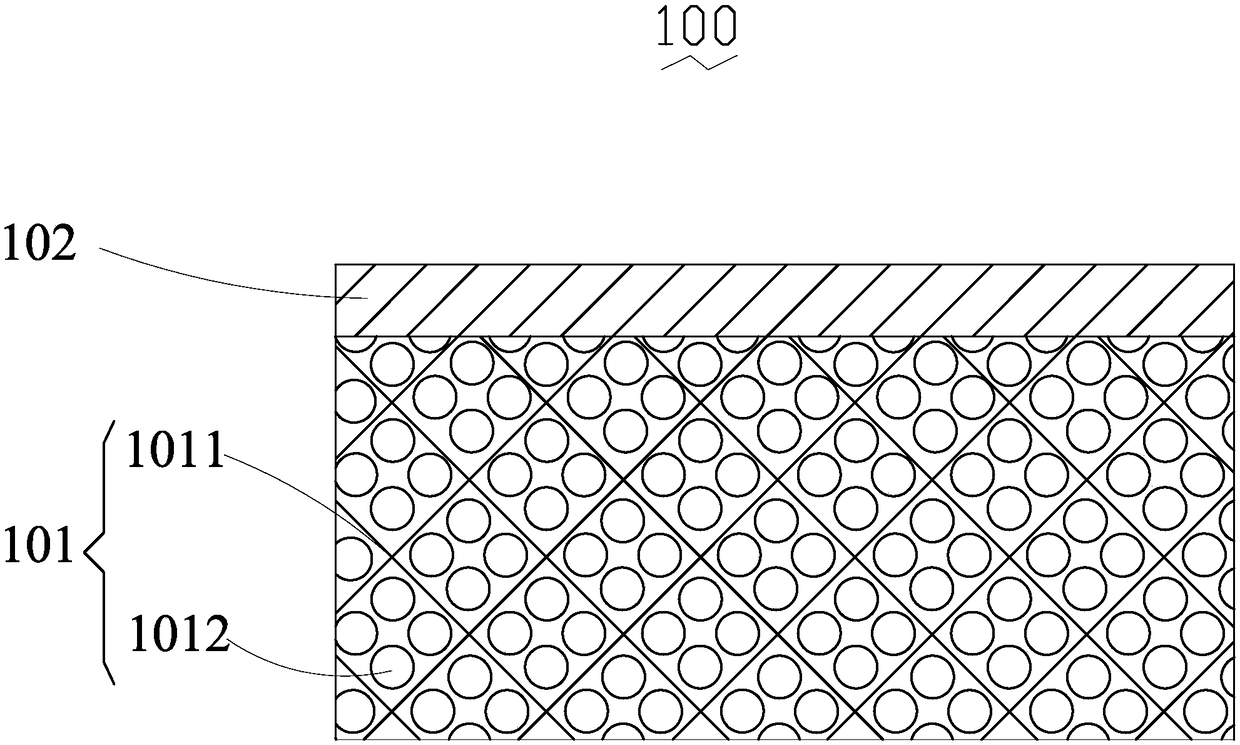

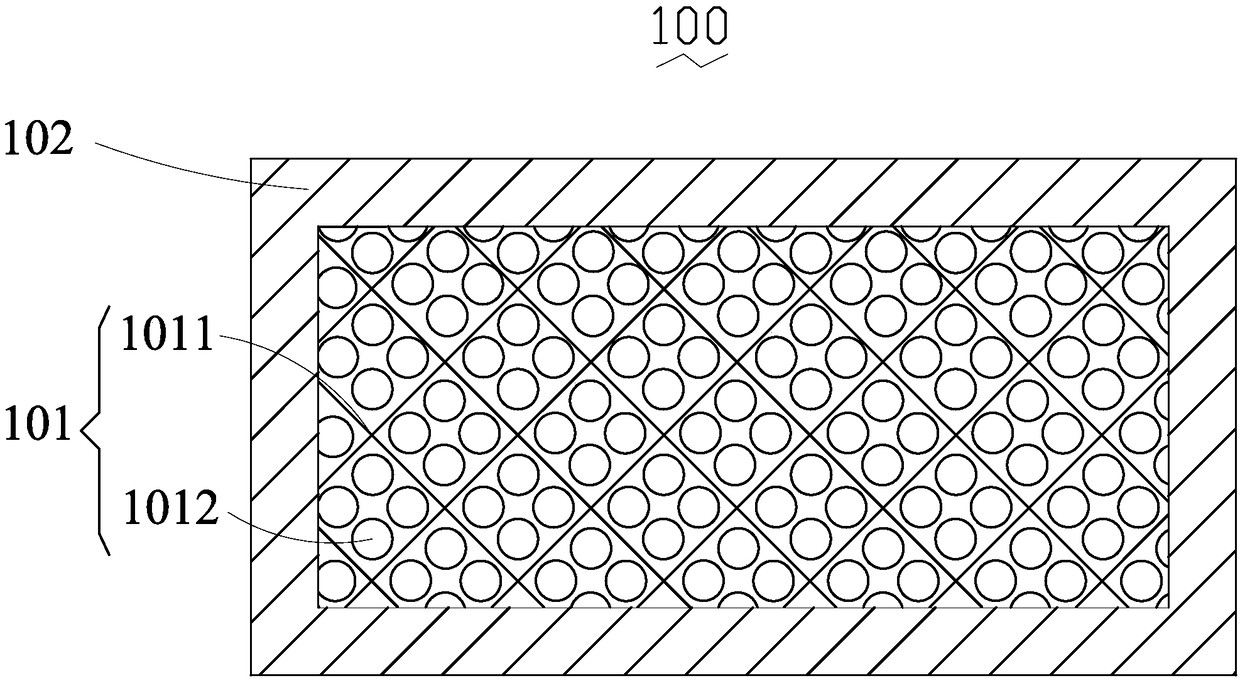

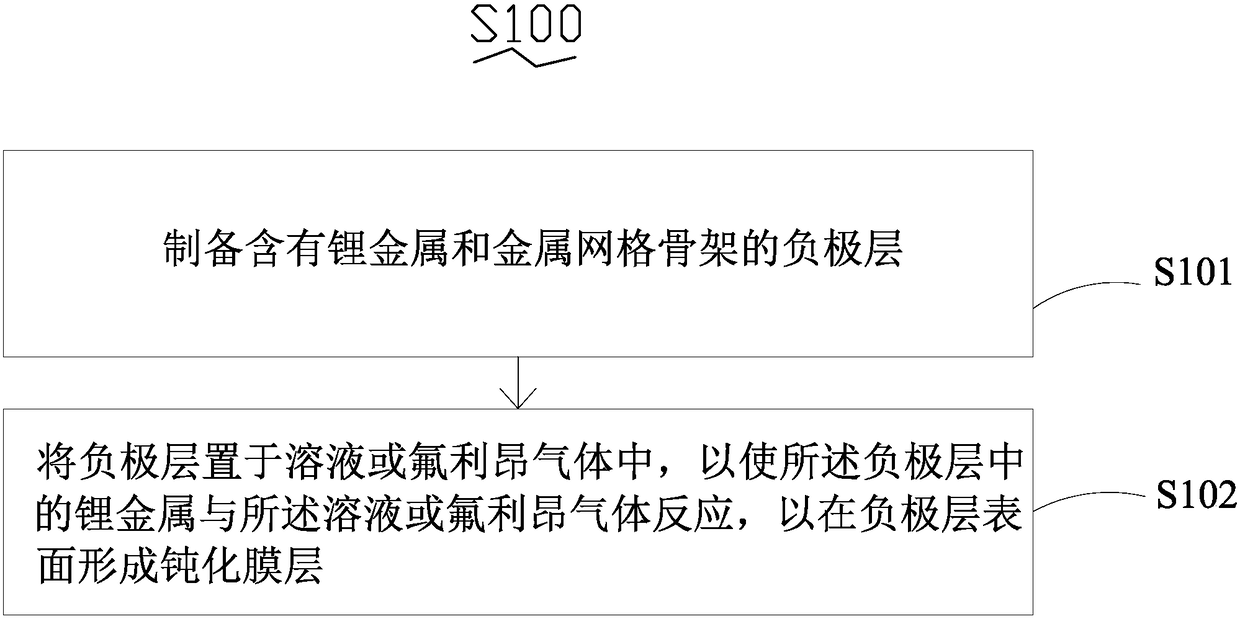

Composite anode structure and preparation method thereof, all-solid-state lithium battery cell and all-solid-state lithium battery

InactiveCN108376763ASmall volume changeImprove uniformity and stabilityCell electrodesFinal product manufactureMetal meshLithium dendrite

The invention relates to the field of lithium batteries, in particular to a composite anode structure and a preparation method thereof, an all-solid-state lithium battery cell and an all-solid-state lithium battery. The composite anode structure comprises an anode layer and a passive coating layer formed on one surface of the anode layer; the anode layer comprises a metal mesh skeleton and lithiummetal composited into the metal mesh skeleton by means hot pressing; the all-solid-state lithium battery cell comprises the composite anode structure; the all-solid-state lithium battery comprises one or multiple all-solid-state lithium battery cells which are in series or parallel connection. According to the technical scheme, the all-solid-state lithium battery has the advantages of small volume change of lithium metal anodes and uniform electro-deposition in charging and discharging, forming of lithium dendrites can be suppressed effectively, and further cycle life and service life of theall-solid-state lithium battery can be prolonged effectively.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

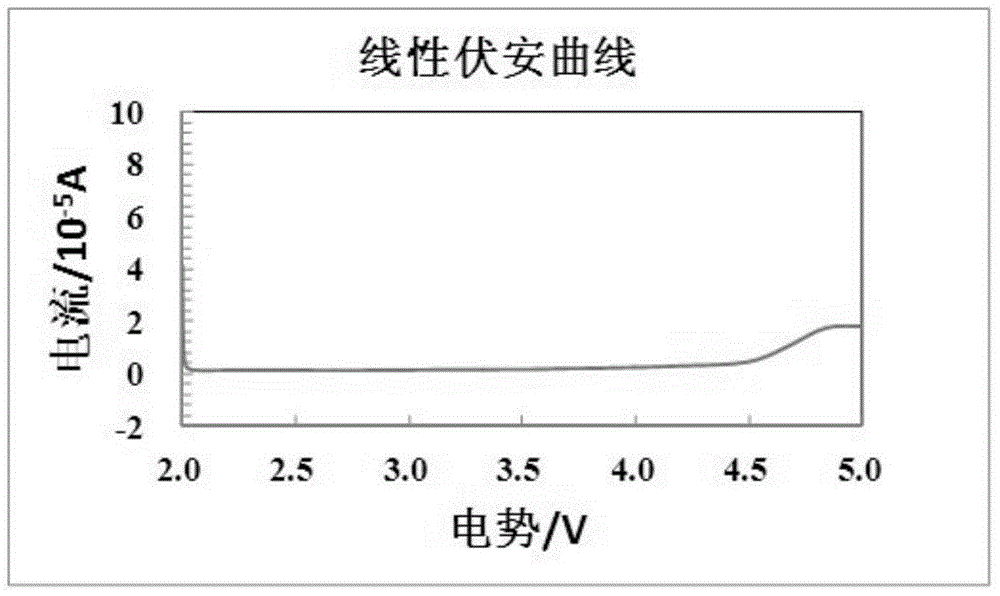

Tin dioxide/porous carbon composite lithium battery negative electrode material and preparation method

The invention discloses a tin dioxide / porous carbon composite lithium battery negative electrode material and a preparation method. The preparation method comprises the following steps: with fibroin and a high molecular polymer PAMAM as precursors, soaking a fibroin / PAMAM composite material after freeze drying treatment in a stannous sulfate aqueous solution for sufficient adsorption; performing high-temperature calcination to obtain the lithium battery negative electrode material. Sn<2+> and amino groups (mainly tertiary amino groups) in the PAMAM dendrimer can generate an effective complexing action so that the SnO2 nanoparticles are in-situ compounded on the surface of the fibroin / PAMAM; therefore, the yield of tin dioxide / porous carbon compound is higher, the uniform stability is better, and a lithium ion battery negative electrode material with high specific capacity and long cycle life is prepared finally.

Owner:赵兵

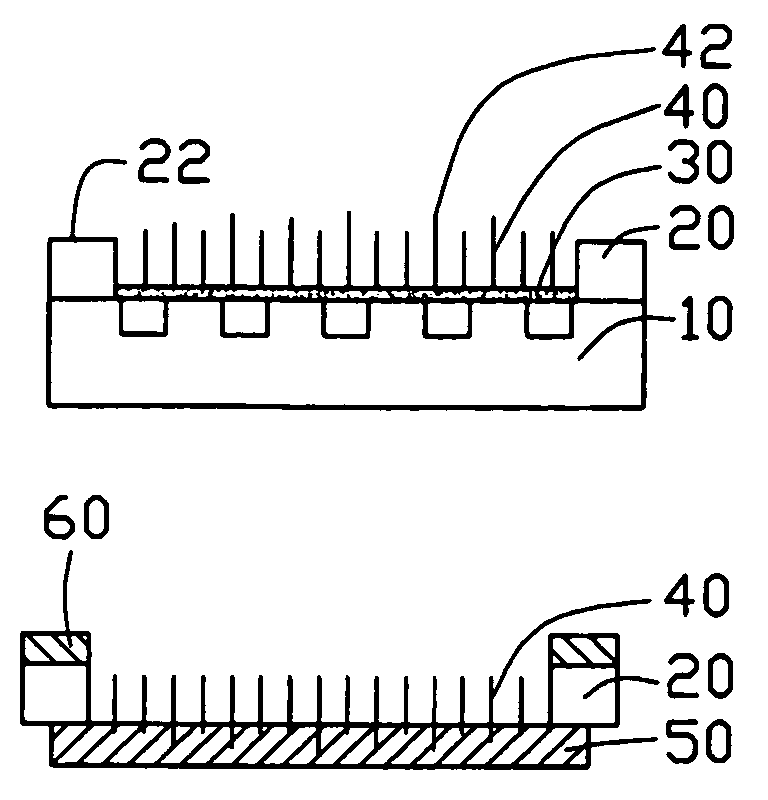

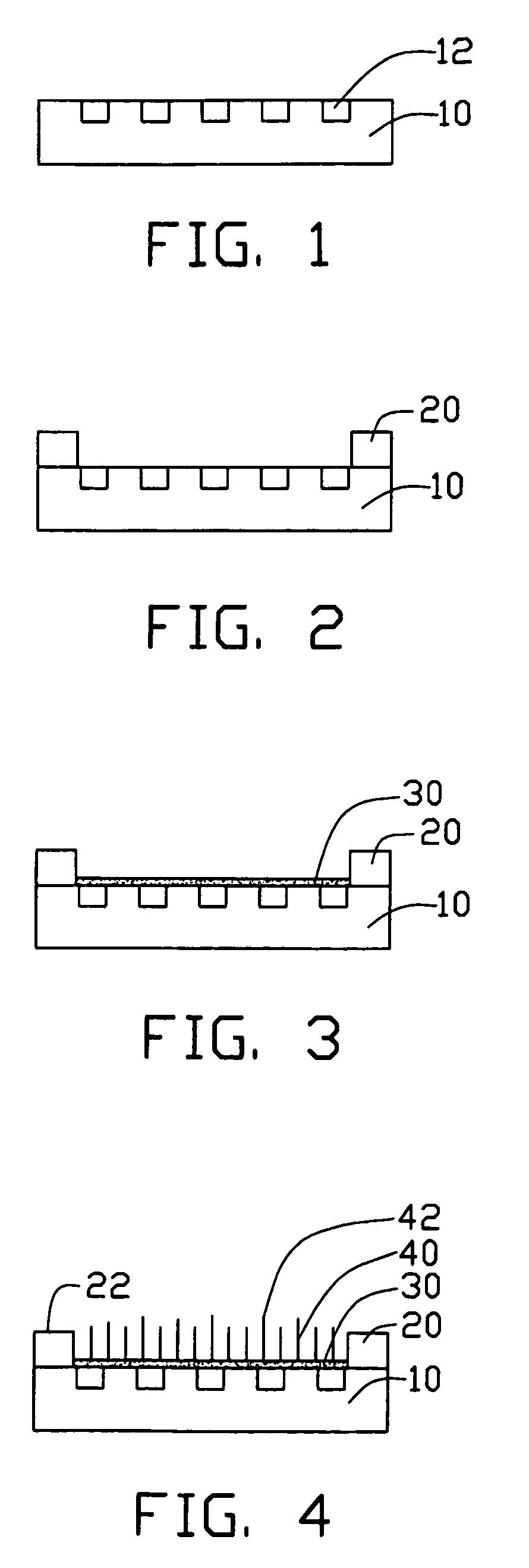

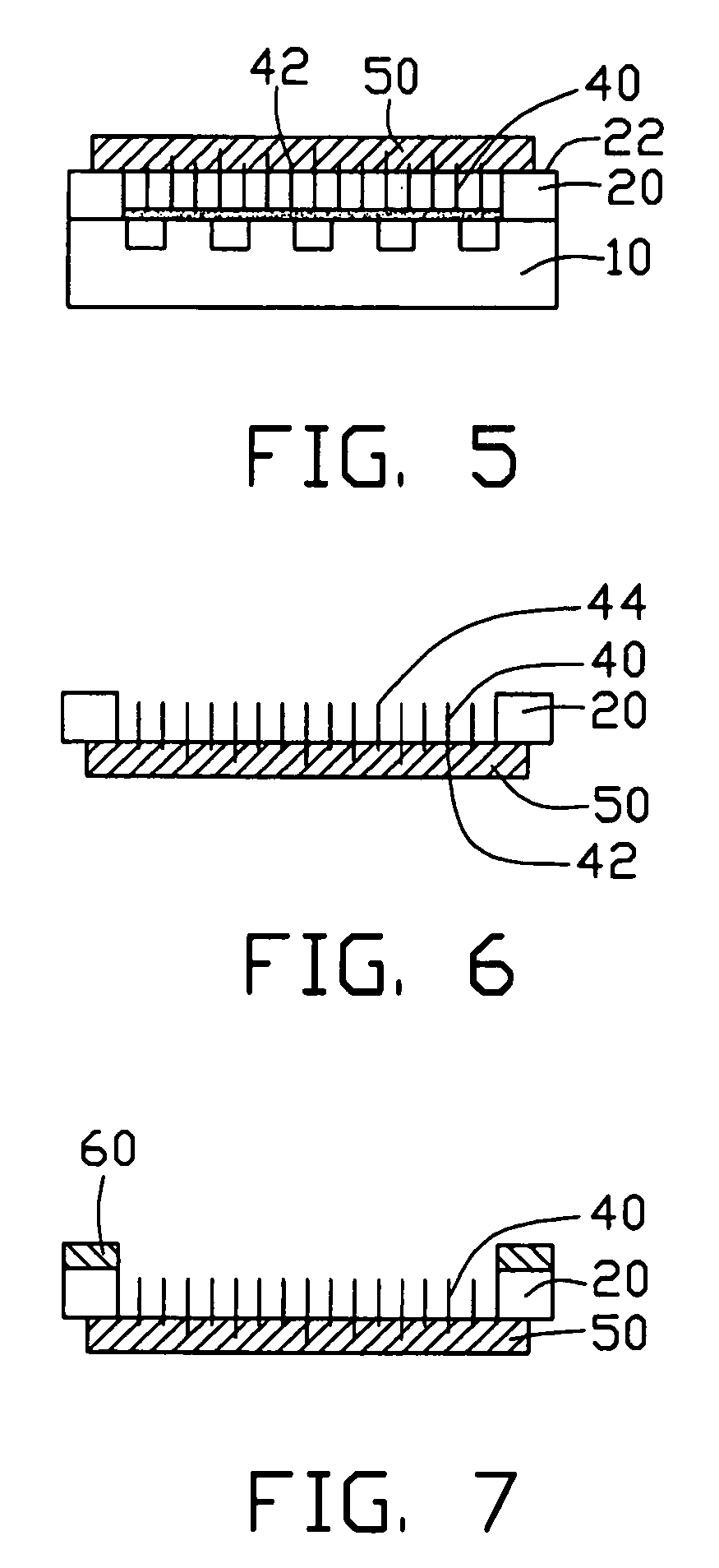

Carbon nanotube-based field emission device

ActiveUS7319288B2Improve uniformity and stabilityUniform and stabile electron emissionDischarge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

A carbon nanotube-based field emission device in accordance with the invention includes: a cathode electrode (50), a carbon nanotube array (40) formed perpendicularly on the cathode electrode, a barrier (20) and a gate electrode (60). The carbon nanotube array has a growth end (42) electrically contacting with the cathode electrode, and an opposite root end (44) for emitting electrons therefrom. The root end of the carbon nanotube array defines a substantially planar surface having a flatness of less than 1 micron.

Owner:TSINGHUA UNIV +1

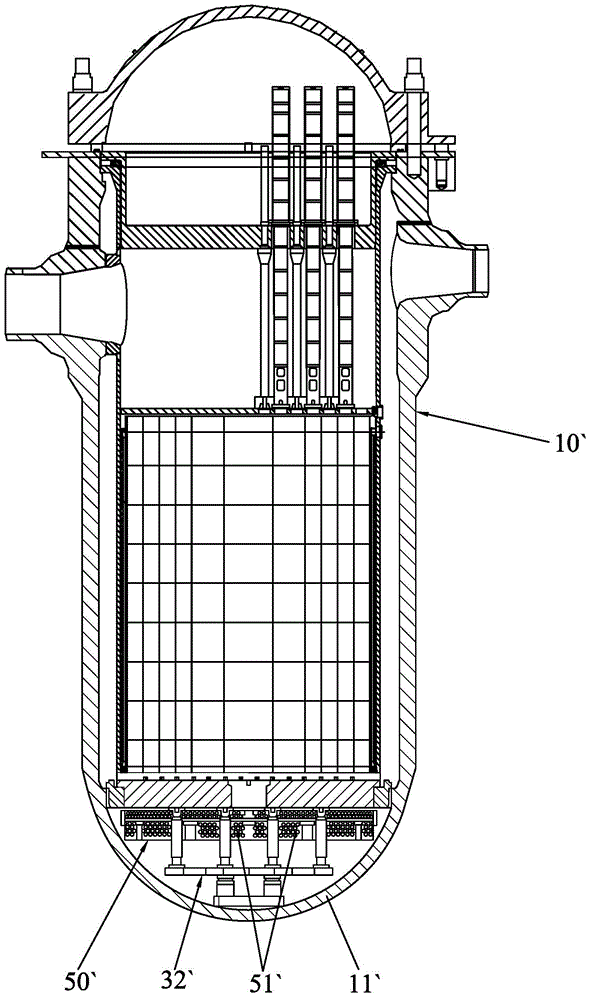

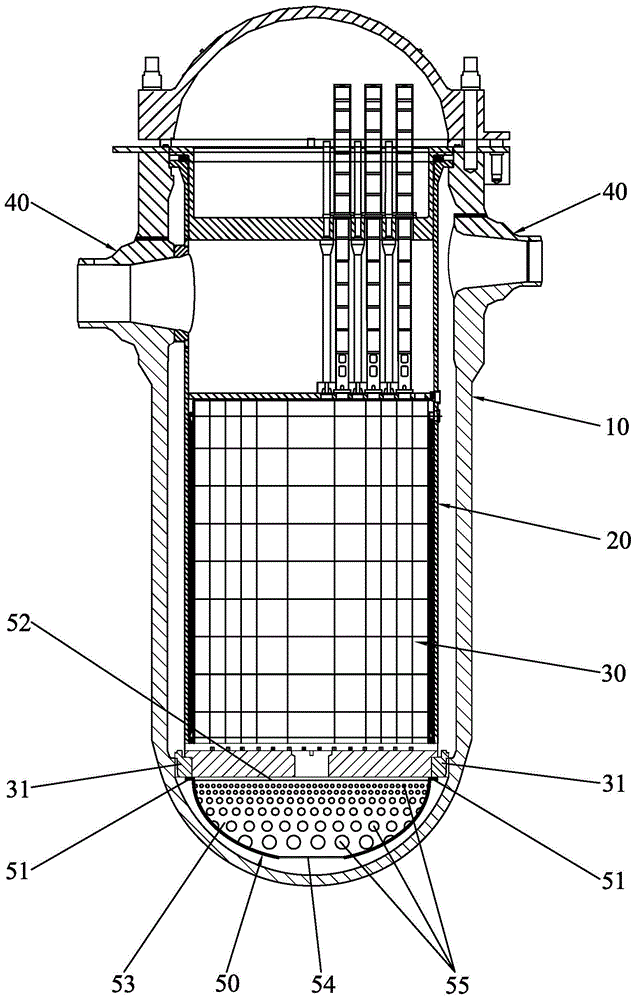

Flow distribution device and nuclear reactor component with same

InactiveCN104637553AAvoid swirlsImprove uniformity and stabilityNuclear energy generationCooling arrangementNuclear reactorNuclear reactor core

The invention discloses a flow distribution device which comprises a flow distributor which is of a concave structure, wherein by virtue of the concave structure, a flow distribution cavity having an opening is formed; the flow distributor is arranged inside a pressure container in a hung mode and is located just below a nuclear reactor core; the opening of the flow distributor faces the nuclear reactor core; a central hole is additionally formed in the center of the bottom of the flow distributor in a penetrating mode and is formed just below the nuclear reactor core; a plurality of shunt holes are additionally formed in the flow distributor in a penetrating mode; under the actions of the central hole and the shunt holes, coolant can uniformly and stably flow into the nuclear reactor core, and the coolant is effectively prevented from generating a vortex under the action of the central hole, so that the uniformity and the stability of coolant flow distribution are further improved; meanwhile, since the vortex is prevented from generating, the safety and the reliability of the nuclear reactor are guaranteed and the probability of nuclear safety accidents is reduced. In addition, the invention also discloses a nuclear reactor component with the flow distribution device.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

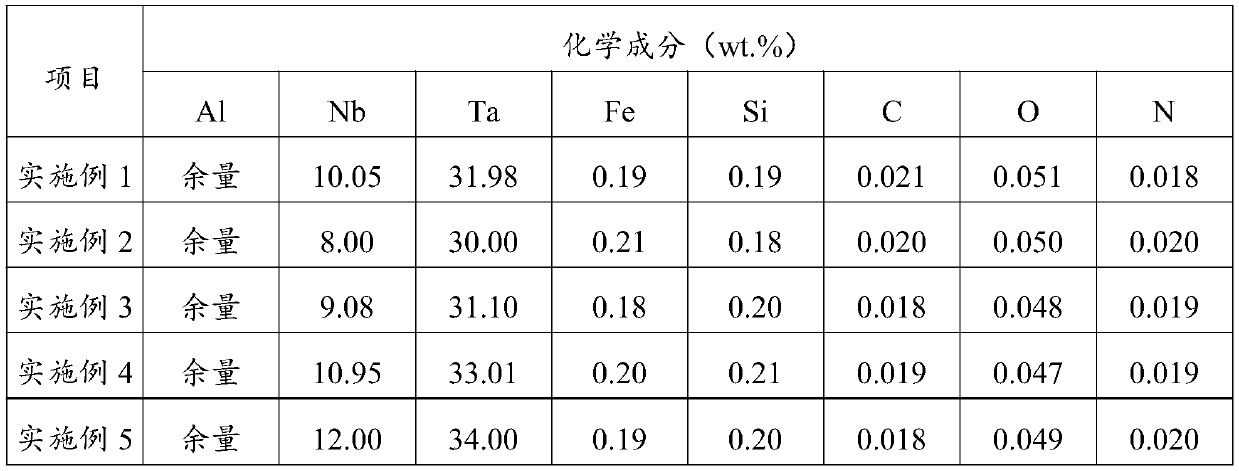

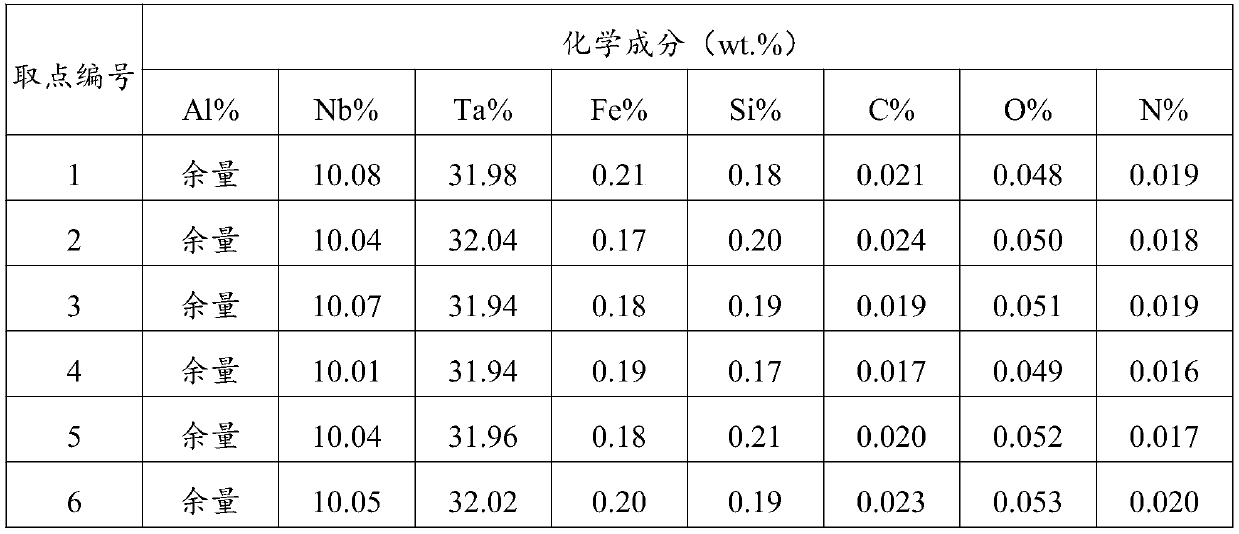

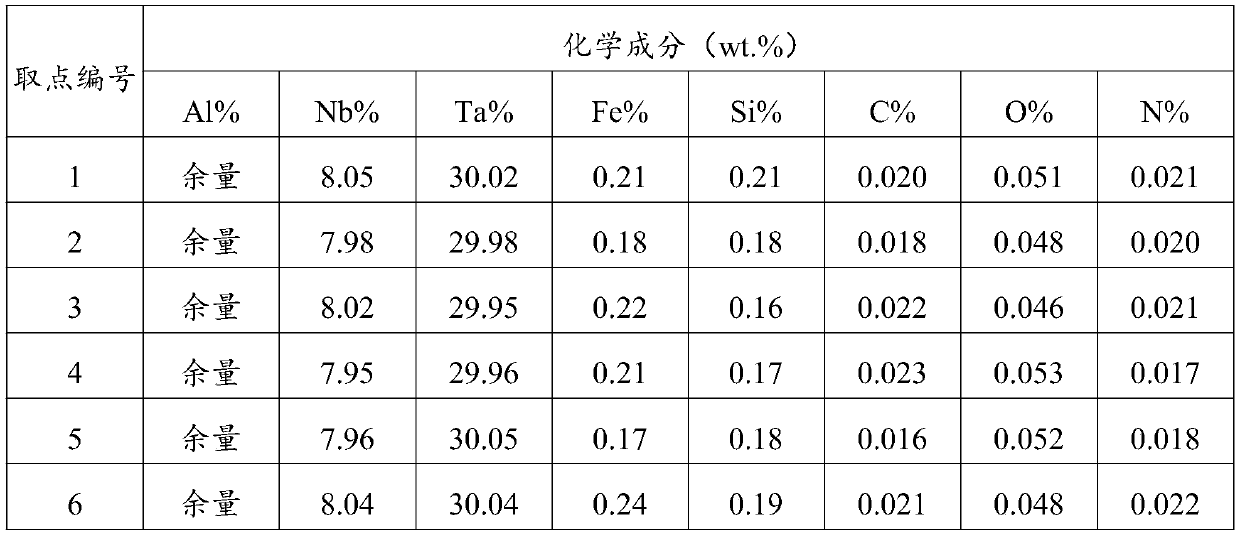

Aluminum-niobium-tantalum intermediate alloy and preparing method thereof

The invention provides an aluminum-niobium-tantalum intermediate alloy and a preparing method thereof and relates to the technical field of metal materials. The aluminum-niobium-tantalum intermediatealloy comprises, by mass, 8.0%-12.0% of Nb, 30.0%-34.0% of Ta and the balance Al. due to component and content control, the components of the aluminum-niobium-tantalum intermediate alloy are uniform,segregation is small, when the titanium alloy is smelted, titanium alloy component homogenization is facilitated, and component segregation is prevented. The preparing method of the aluminum-niobium-tantalum intermediate alloy is provided. The aluminum-niobium-tantalum intermediate alloy is prepared through a two-step method, namely the two steps of the thermit reaction and vacuum smelting are conducted. By means of the preparing method, homogenization stability of the components of the aluminum-niobium-tantalum intermediate alloy can be improved, the content of impurities of O, N and the likeis reduced, and the requirement for titanium alloy production can be better met.

Owner:CHENGDE TIANDA VANADIUM IND

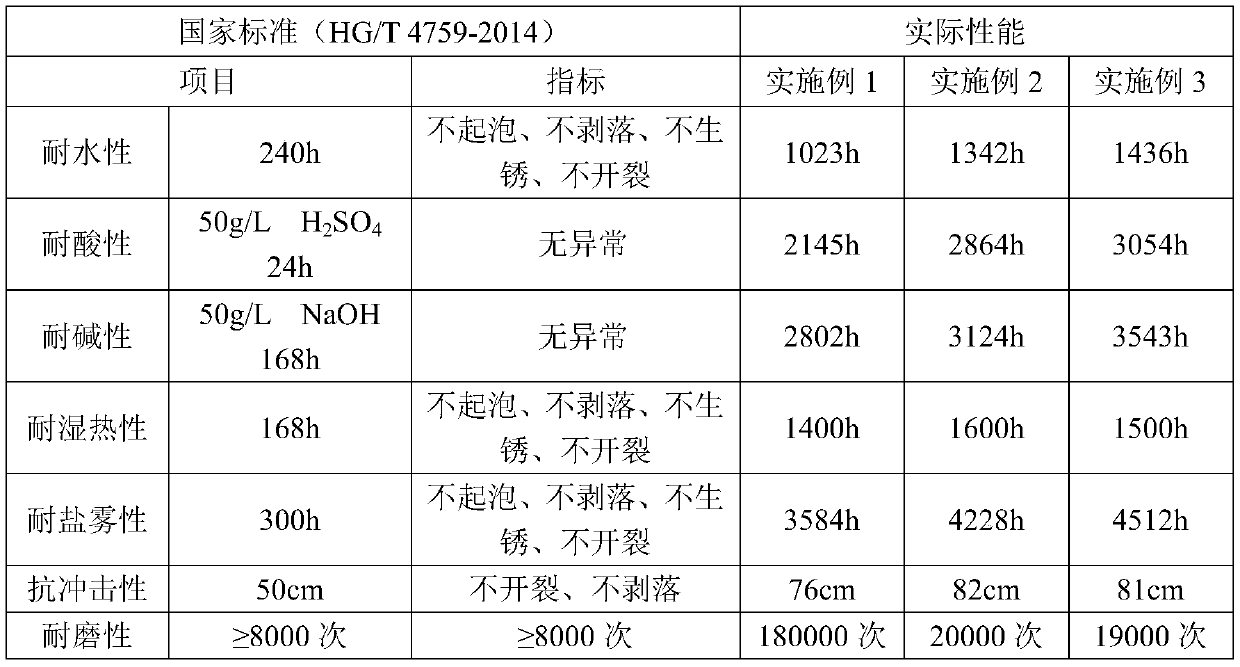

Graphene oxide-carbon quantum dot complex modified anticorrosive coating and preparation method thereof

PendingCN109971323AImprove uniformity and stabilityStrong environmental protectionAnti-corrosive paintsPolyester coatingsCorrosionBarium sulfate

The invention provides a graphene oxide-carbon quantum dot complex modified anticorrosive coating and a preparation method thereof, and belongs to the technical field of coatings. The coating comprises the following raw materials: a graphene oxide-carbon quantum dot nano complex, water-based alkyd resin, titanium dioxide, barium sulfate, a dispersant, a defoaming agent, a thickening agent, an auxiliary agent and a curing agent; and the preparation method comprises the steps of preparing the graphene oxide-carbon quantum dot nano complex, preparing graphene oxide-carbon quantum dot slurry, preparing a pre-prepared coating, and adding the curing agent and performing mixing to obtain the anticorrosive coating. The anticorrosive coating provided by the invention has good corrosion resistance,high mechanical strength and strong environmental protection; and the preparation method has a simple process and is easy to operate.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

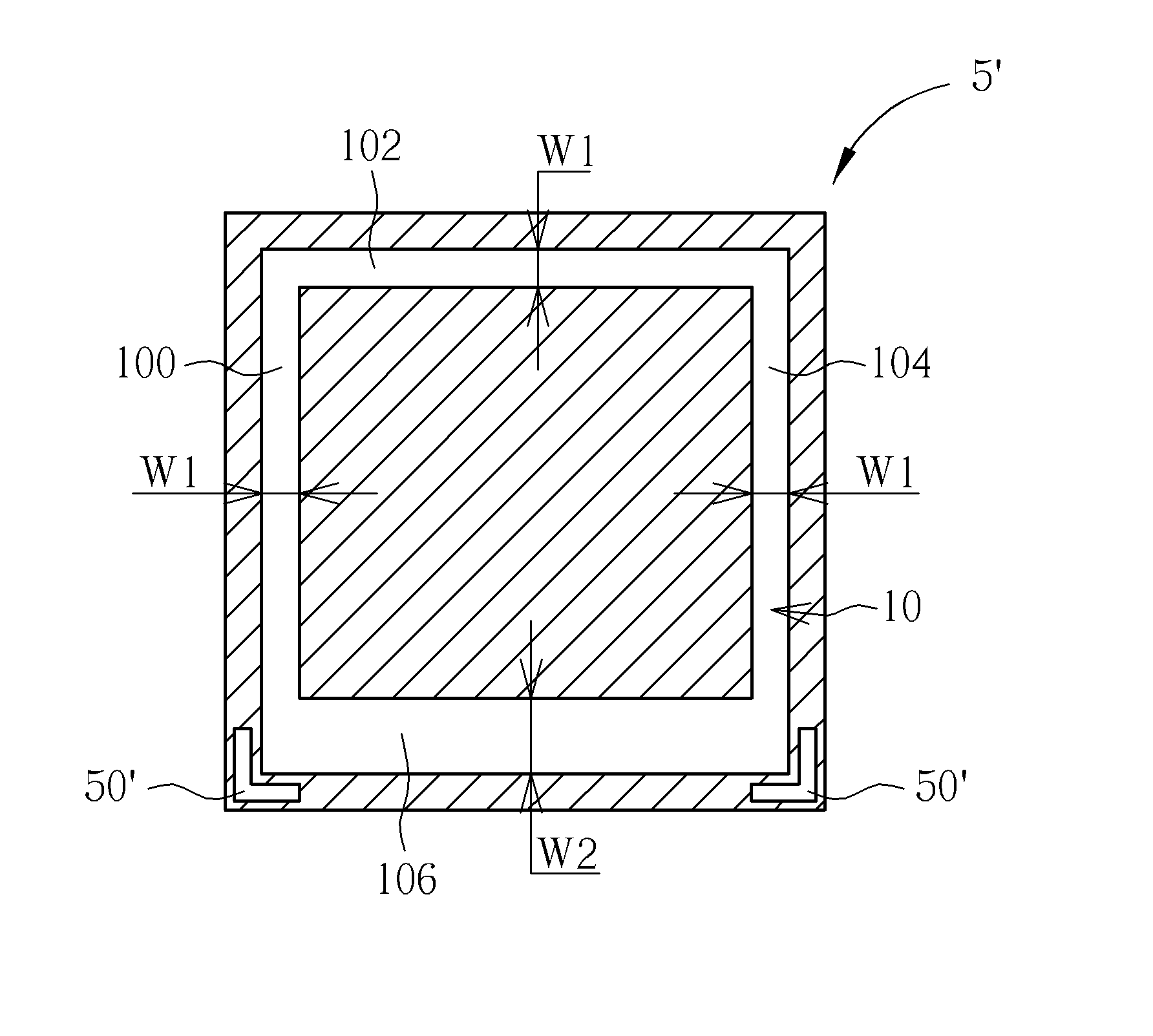

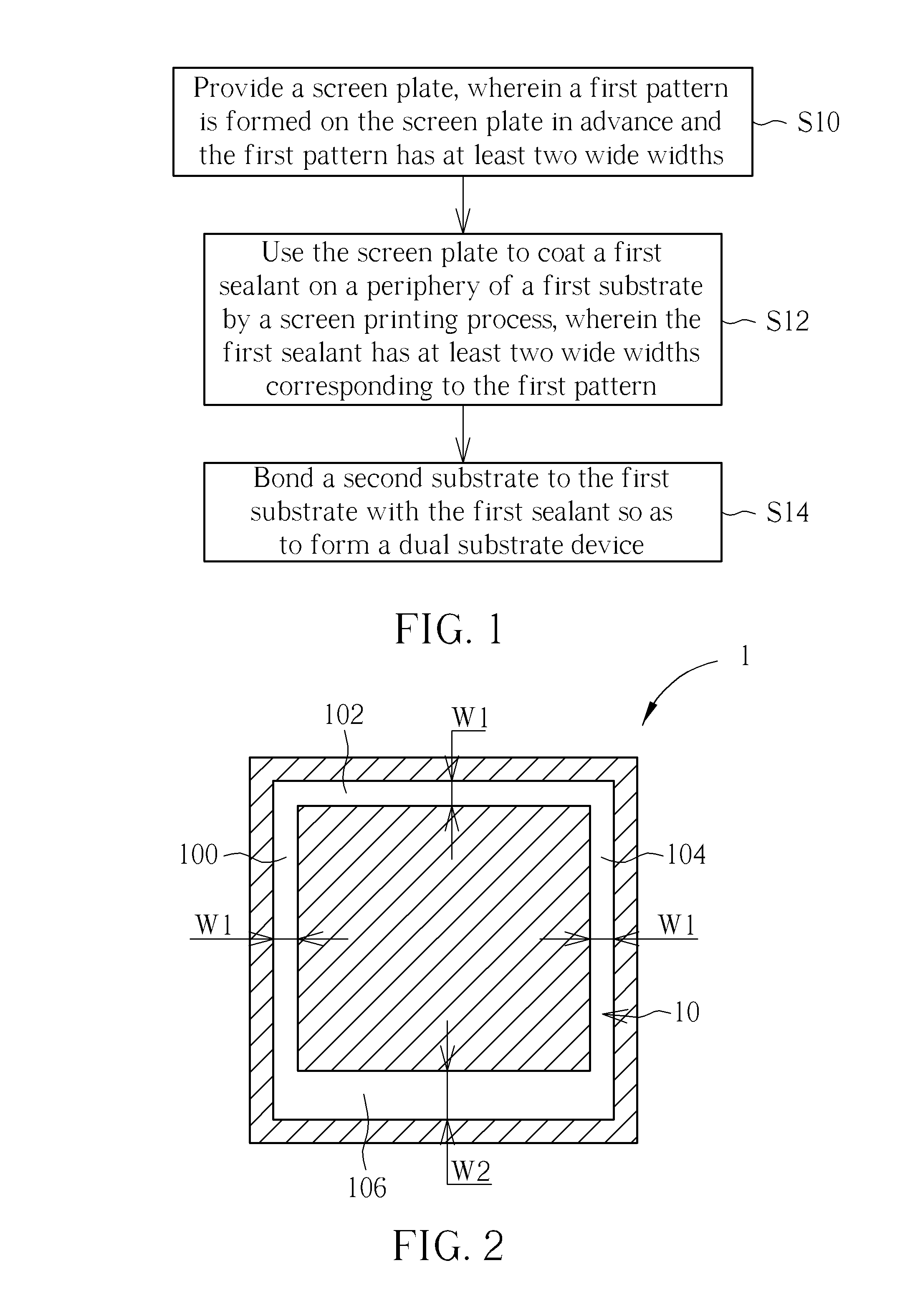

Dual substrate device and dual substrate bonding method

InactiveUS20130273360A1Improve uniformity and stabilityHigh peel strengthLamination ancillary operationsSynthetic resin layered productsSealantElectrical and Electronics engineering

Owner:WINTEK CHINA TECH LTD +1

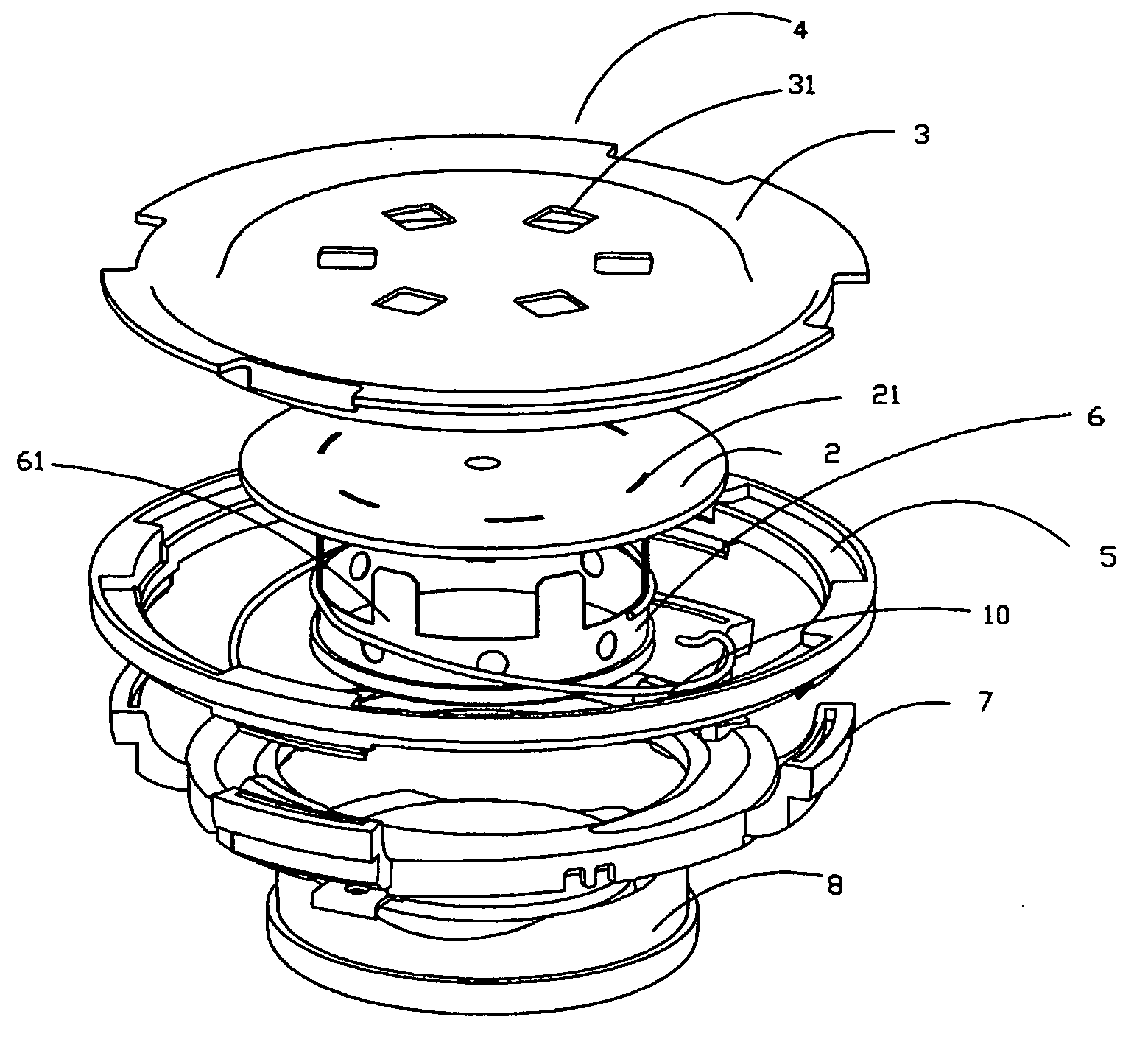

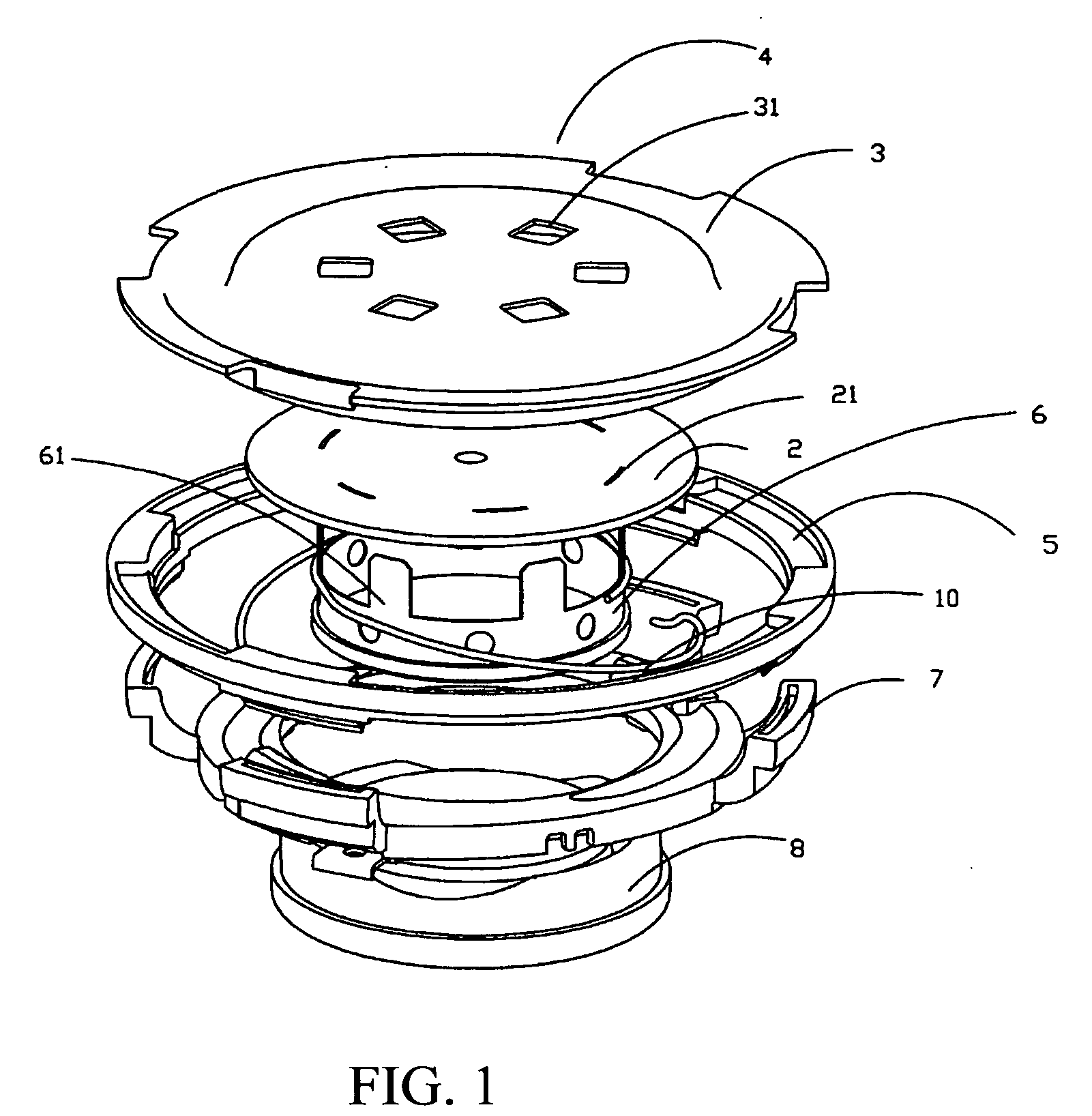

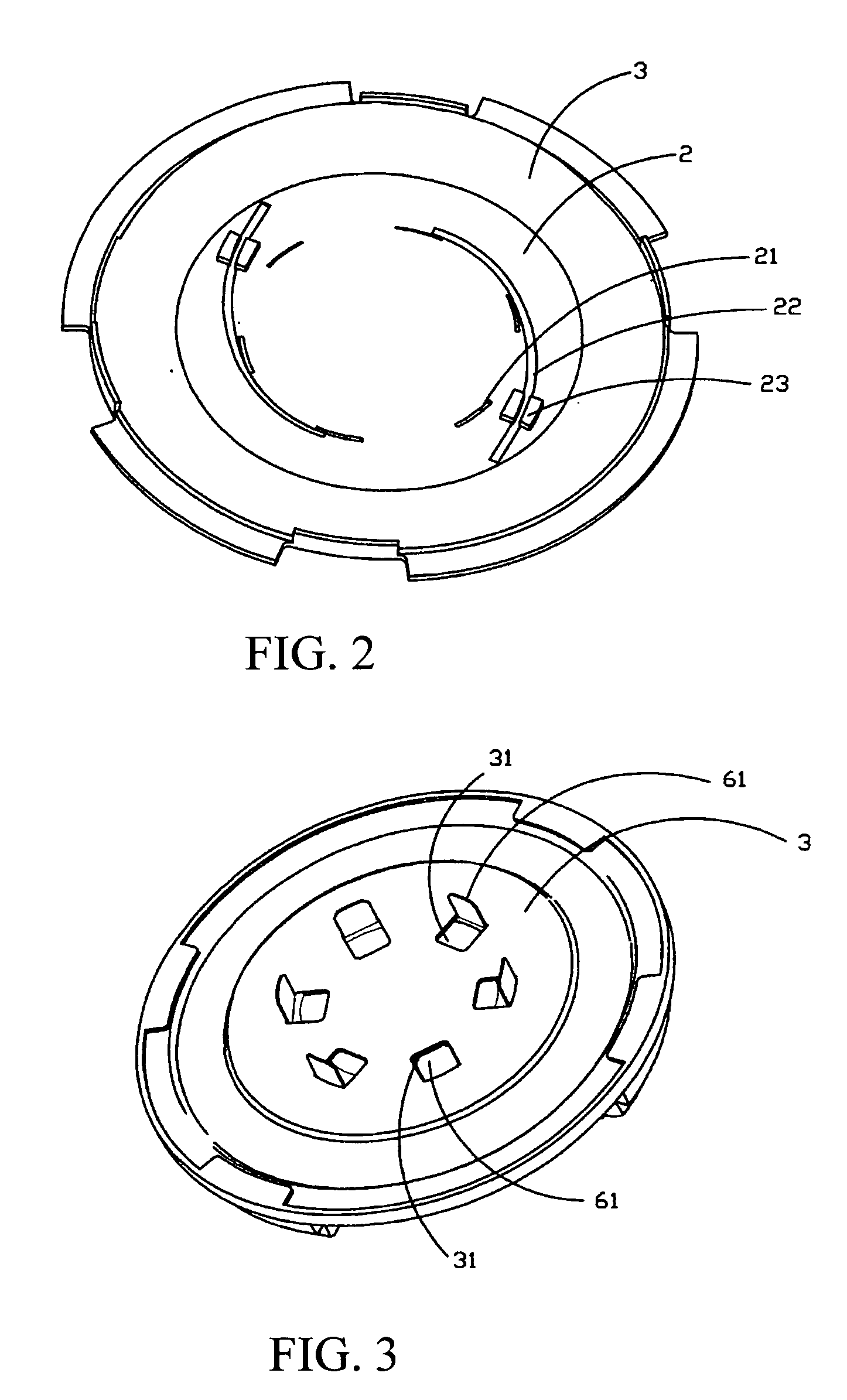

Electromagnetic vibration device and manufacturing method thereof

ActiveUS20110043056A1Improve stabilityImprove uniformitySynchronous generatorsWindingsEngineeringVoice coil

An electromagnetic vibration device includes a vibrating plate, a suspending frame, upper and lower basin frames, a voice coil, and a magnetic loop system. Multiple voice coil fixing slots are uniformly distributed on the circumference of the vibrating plate corresponding to the inserting pieces of the voice coil, and the inserting pieces are passed through the voice coil fixing slots of the vibrating plate and fixed to the vibrating plate. One end of the lead of the voice coil is embedded in a groove on back of the vibrating plate and connected to the terminal of the lower basin frame.

Owner:NINGBO SHENGYA ELECTRONICS

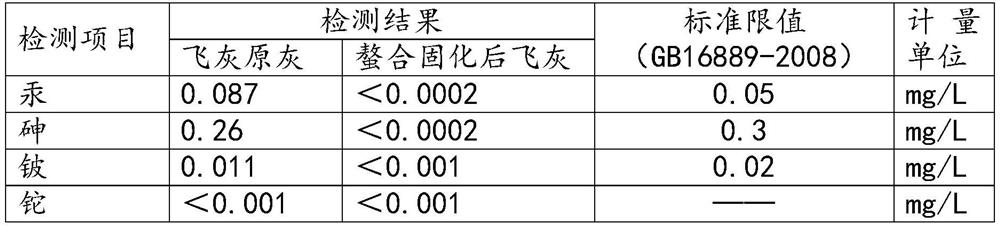

Multi-component composite chelating agent for fly ash treatment and preparation method thereof

InactiveCN111617429AImproved uniformity and stabilityGood dispersionChemical protectionEnvironmental chemistryInorganic phosphate

The invention discloses a multi-component composite chelating agent for fly ash treatment. The multi-component composite chelating agent comprises the following components in percentage by mass: 10-60% of organic sulfide, 1-30% of inorganic sulfide, 1-20% of inorganic phosphate and 1-30% of an organic low-molecular-weight dispersing agent, with the balance being water. The invention provides the heavy metal composite chelating agent for waste incineration fly ash. The chelating agent is simple in preparation method; the composition of the agent is simple and easy to obtain; the chelating agentis comprehensive in component, is homogeneous and stable, can effectively stabilize almost all heavy metal ions in the fly ash for a long time, and allows the fly ash to reach standards for standardlandfill; the purpose of efficiently stabilizing heavy metal ions can be achieved by adopting a small amount of the chelating agent; and the chelating agent has the advantage of high cost performance.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

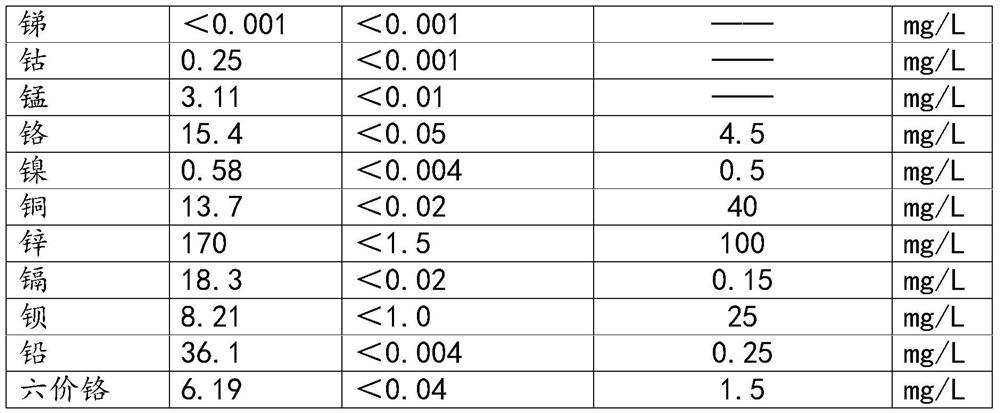

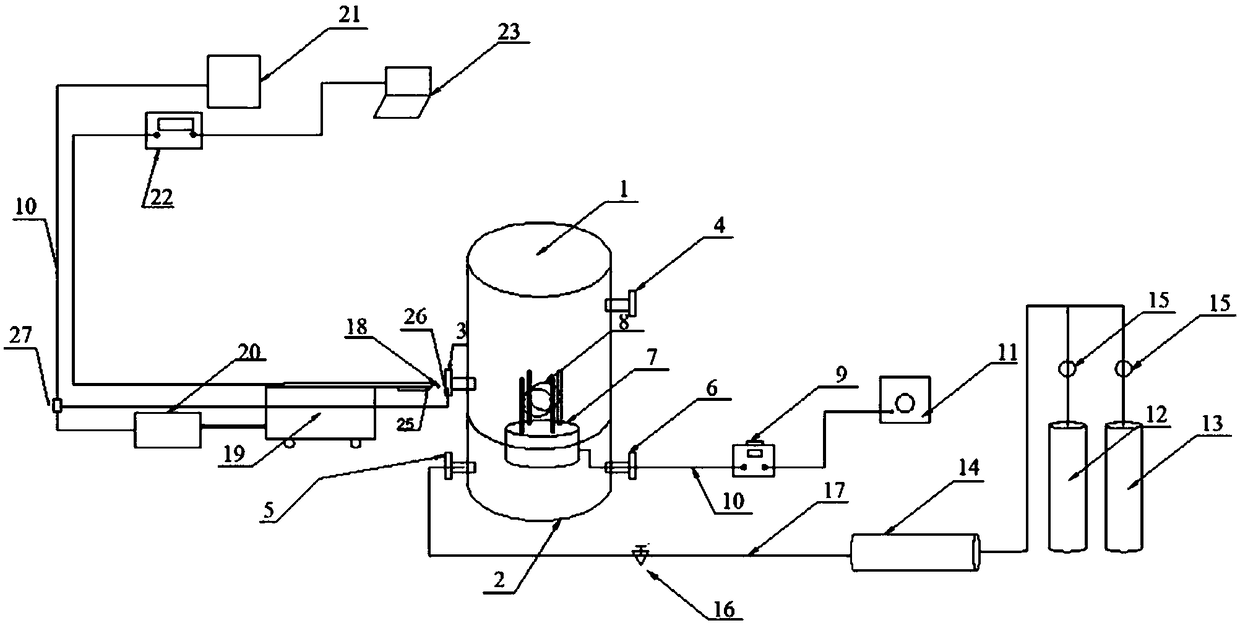

Droplet evaporation and combustion device with observation and shooting convenience and experimental method

ActiveCN108828130AThe same timeGuaranteed accuracyChemical analysis using combustionMaterial thermal analysisExperimental methodsEngineering

The invention discloses a droplet evaporation and combustion device with observation and shooting convenience and an experimental method and belongs to the technical field of combustion experimental devices. The device comprises a sealing device, a gas supply mechanism, an ignition mechanism and a thermocouple propulsion mechanism. The gas supply mechanism provides gas for the sealing device. Theignition mechanism is used for ignition of fuel. The thermocouple propulsion mechanism comprises a thermocouple, a pushing trolley and a driving mechanism. The thermocouple is mounted on the pushing trolley. A sensing end of the thermocouple stretches out of the pushing trolley. The driving mechanism is connected to the pushing trolley and is used for driving and controlling the motion of the pushing trolley. The device is suitable for studying droplet evaporation or flame change during evaporation or combustion of droplets. The device has a simple overall structure, is easy to operate, produces small experimental result errors and produces accurate and reliable results.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hydrophilic coating with high antistatic property and preparation method thereof

ActiveCN107141850AReduce accumulationSolve the pain points of useAlkali metal silicate coatingsElectrically-conductive paintsHydrophilic coatingSolvent

The invention relates to a hydrophilic coating with a high antistatic property and a preparation method thereof. The hydrophilic coating with the high antistatic property is prepared from the following components in parts by weight: 0.3-1.8 parts of conductive filler, 0.5-1.5 parts of conductive auxiliary, 25-50 parts of silicate solution, 10-35 parts of nano sol, 13.4-42 parts of solvent and 0.5-1 part of auxiliary. In preparation, the components are mixed according to a proportion. According to thehydrophilic coating with the high antistatic property and the preparation method thereof provided by the invention, the partial discharge and the dust viscosity caused by poor electrical conductivity of a base material are solved; the hydrophilic coating has the advantages that the hydrophilic property is good, the using experience of a user is improved, the cleaning difficulty is reduced, and the like.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Proportion design method for SMA (stone mastic asphalt) mixture

ActiveCN106082789AAvoid Fiber Quality VariationsImprove uniformity and stabilityStone mastic asphaltAsphalt

The invention relates to a proportion design method for an SMA (stone mastic asphalt) mixture. The proportion design method comprises the following steps: selecting initial testing graduation; calculating a theoretically minimum asphalt-aggregate ratio; determining a maximum asphalt-aggregate ratio; selecting an initial testing asphalt-aggregate ratio; selecting graduation according to the initial testing asphalt-aggregate ratio; determining optimal asphalt-aggregate ratio according to the selected graduation. According to the method, a range of the asphalt-aggregate ratio is obtained through theoretical calculation and testing, the initial testing asphalt-aggregate ratio is determined, the selected graduation is determined from three initial testing graduations, and the optimal asphalt-aggregate ratio is determined according to the selected graduation. The SMA mixture is not doped with fibers, so that the stability of the mixture, the economic efficiency and environmental protection property of construction and the production efficiency are improved.

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST

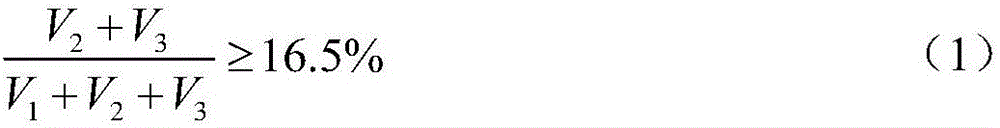

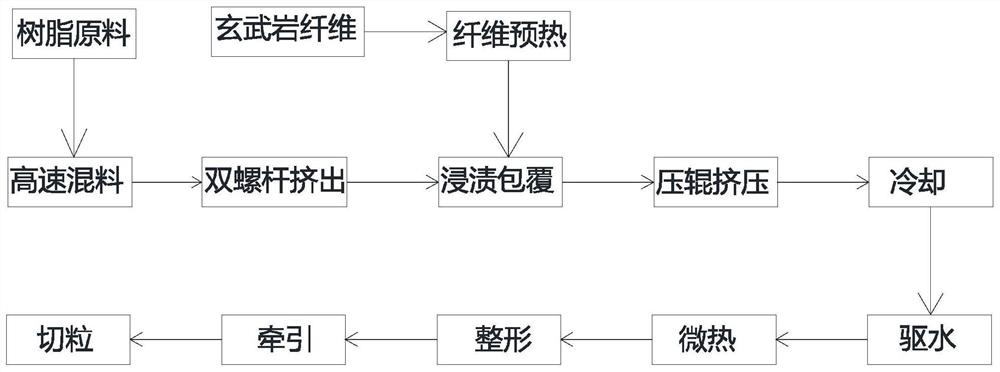

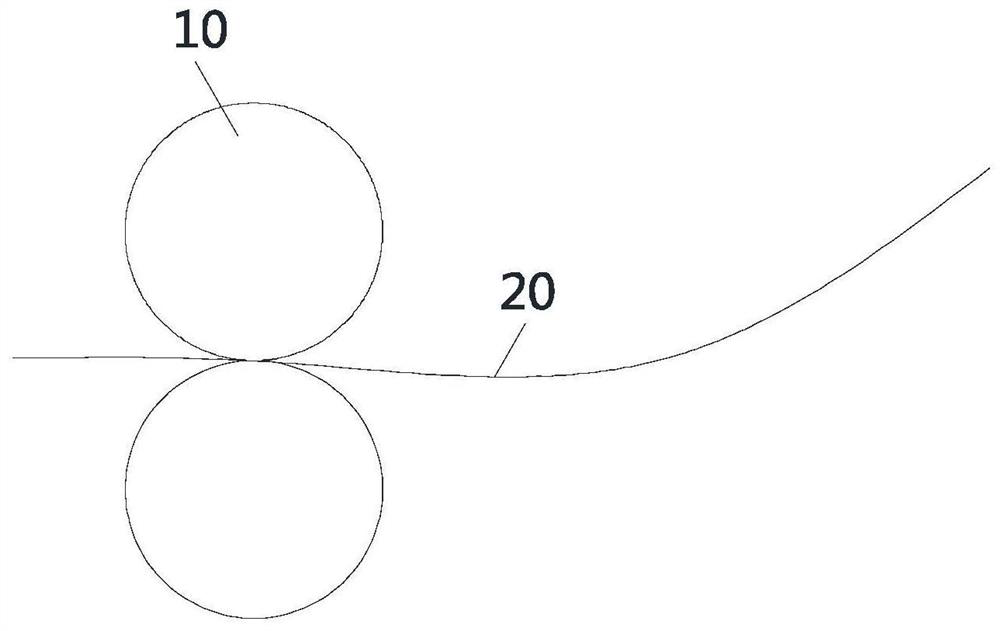

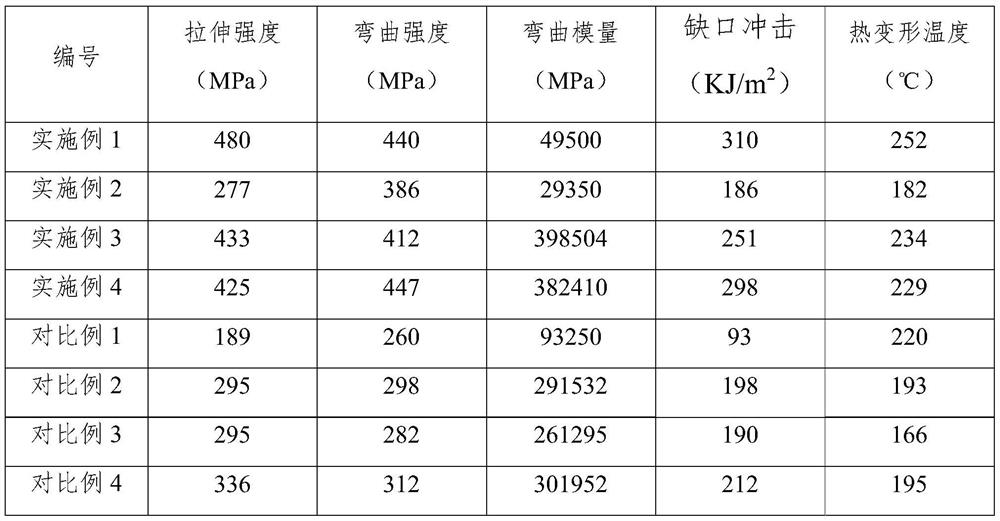

Long basalt fiber reinforced thermoplastic resin composite master batch and preparation method and application thereof

The invention provides a long basalt fiber reinforced thermoplastic resin composite master batch. The long basalt fiber reinforced thermoplastic resin composite master batch comprises the following components in parts by weight: 10-60 parts of thermoplastic resin, 10-85 parts of long basalt fibers and 1-5 parts of a coupling agent, wherein the long basalt fibers in the length direction are distributed along the length direction of the composite master batch and have the same length as the composite master batch; and the length L of the composite master batch is more than or equal to 12mm and less than or equal to 25mm. The composite master batch is high in fiber content and long in fiber length, so that good impact resistance, corrosion resistance, salt spray resistance, vibration resistance and electrical properties can be achieved; the homogenization stability of the fibers and the resin in the composite master batch is good, and the fibers and the resin can be well and uniformly dispersed in the reprocessing process; the invention also provides a preparation method and application of the long basalt fiber reinforced thermoplastic resin composite master batch.

Owner:四川拜赛特高新科技有限公司

Preparation method for slurry of super capacitor

InactiveCN103400705AShorten preparation timeImprove uniformity and stabilityHybrid/EDL manufactureSolventActive carbon

The invention relates to a preparation method for slurry of a super capacitor. The method comprises the steps of a) initial slurry preparation, wherein active carbon, conductive carbon, binder and solvent are placed in a double-planet mixer with a constant temperature system and stirred and mixed for 0.5 to 5 hours; b) slurry emulsification, wherein the prepared initial slurry is transferred into an emulsifying machine for emulsification; and c) vacuum bubble removal, wherein the emulsified slurry is transferred into a turnover tank with a rotating disk to carry out vacuum bubble removal. The preparation method for the slurry of the super capacitor can uniformly mix different substances in the super capacitor, is excellent in uniformity and high in stability, is not likely to be layered, and is free of bubbles.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

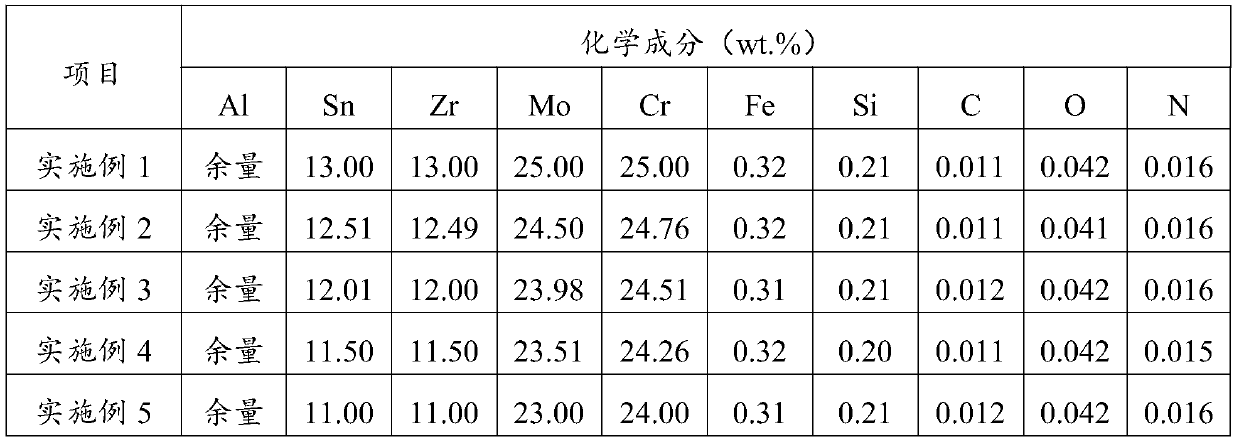

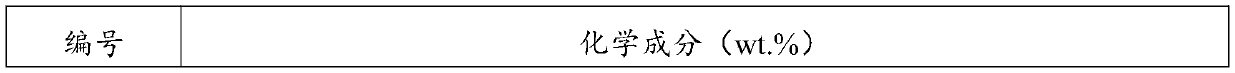

Aluminum-tin-zirconium-molybdenum-chromium intermediate alloy and preparation method thereof

InactiveCN110760708AImprove uniformity and stabilityLow impurity contentMetallic materialsTitanium alloy

The invention belongs to the technical field of metal materials, and particularly relates to an aluminum-tin-zirconium-molybdenum-chromium intermediate alloy and a preparation method thereof. The aluminum-tin-zirconium-molybdenum-chromium intermediate alloy comprises the following components of, by mass, 11.0-13.0% of Sn, 11.0-13.0% of Zr, 23.0-25.0% of Mo, 24.0-25.0% of Cr, and the balance Al andinevitable impurities. According to the aluminum-tin-zirconium-molybdenum-chromium intermediate alloy and the preparation method thereof, through control over the raw material components and the content, the aluminum-tin-zirconium-molybdenum-chromium intermediate alloy has small component segregation, when a titanium alloy is smelted, homogenization of the titanium alloy components is facilitated, the component segregation is prevented, the batching process during titanium alloy smelting is optimized, and accurate batching in the production process can be realized; and the preparation methodcan improve the uniformity and stability of the aluminum-tin-zirconium-molybdenum-chromium intermediate alloy components, the content of impurities such as O and N is reduced, the process is simple, control is easy, and the preparation method is suitable for large-scale industrial production.

Owner:CHENGDE TIANDA VANADIUM IND

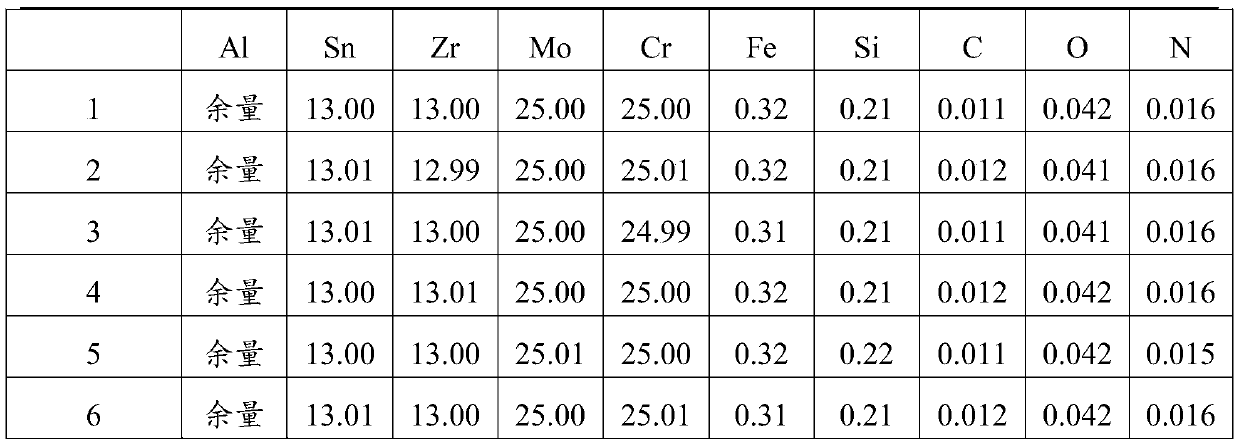

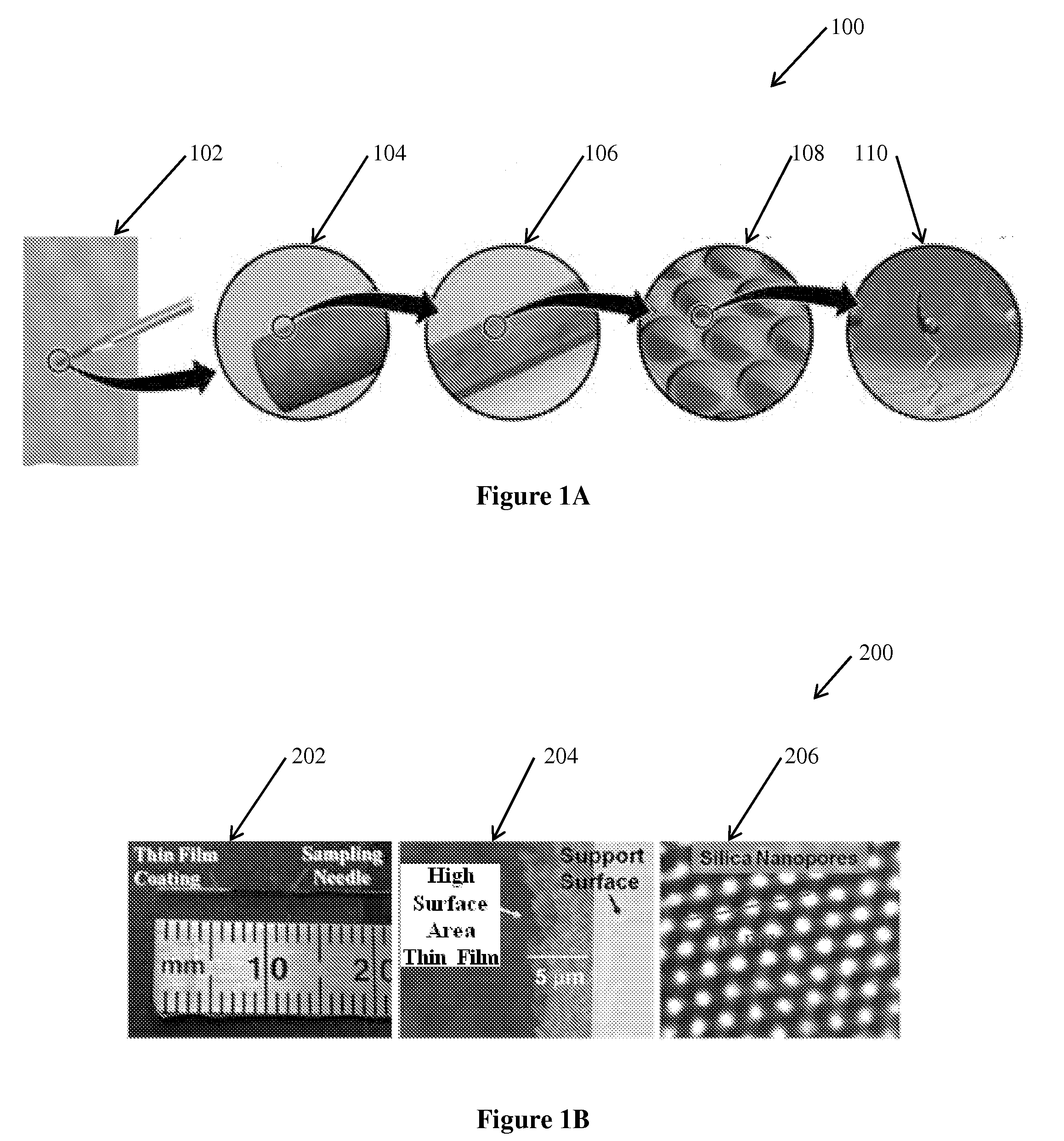

Device and method for enhanced collection and assay of chemicals with high surface area ceramic

ActiveUS20140017805A1Easy to collectEnhances capture of such targetWithdrawing sample devicesPreparing sample for investigationTarget analysisAnalyte

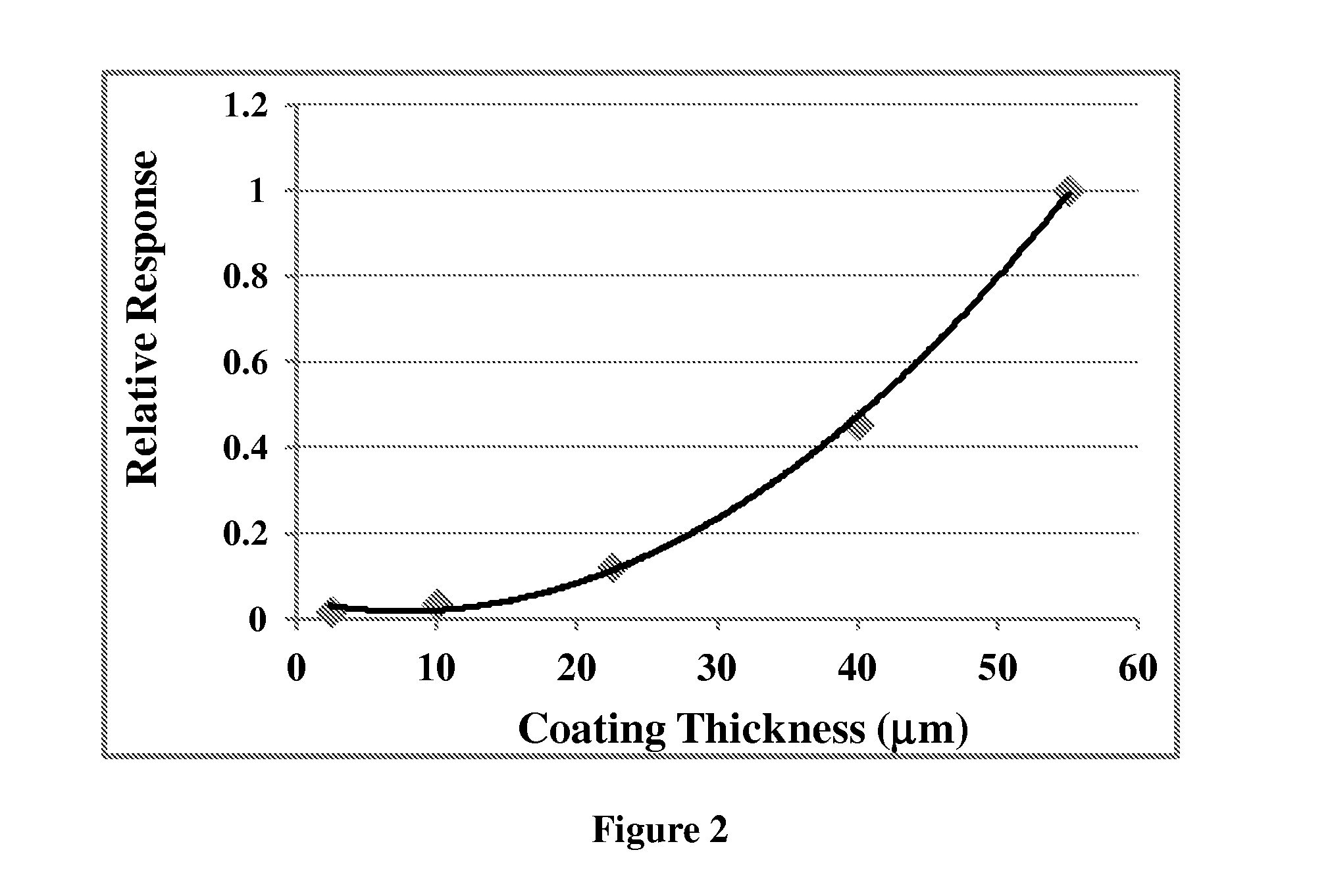

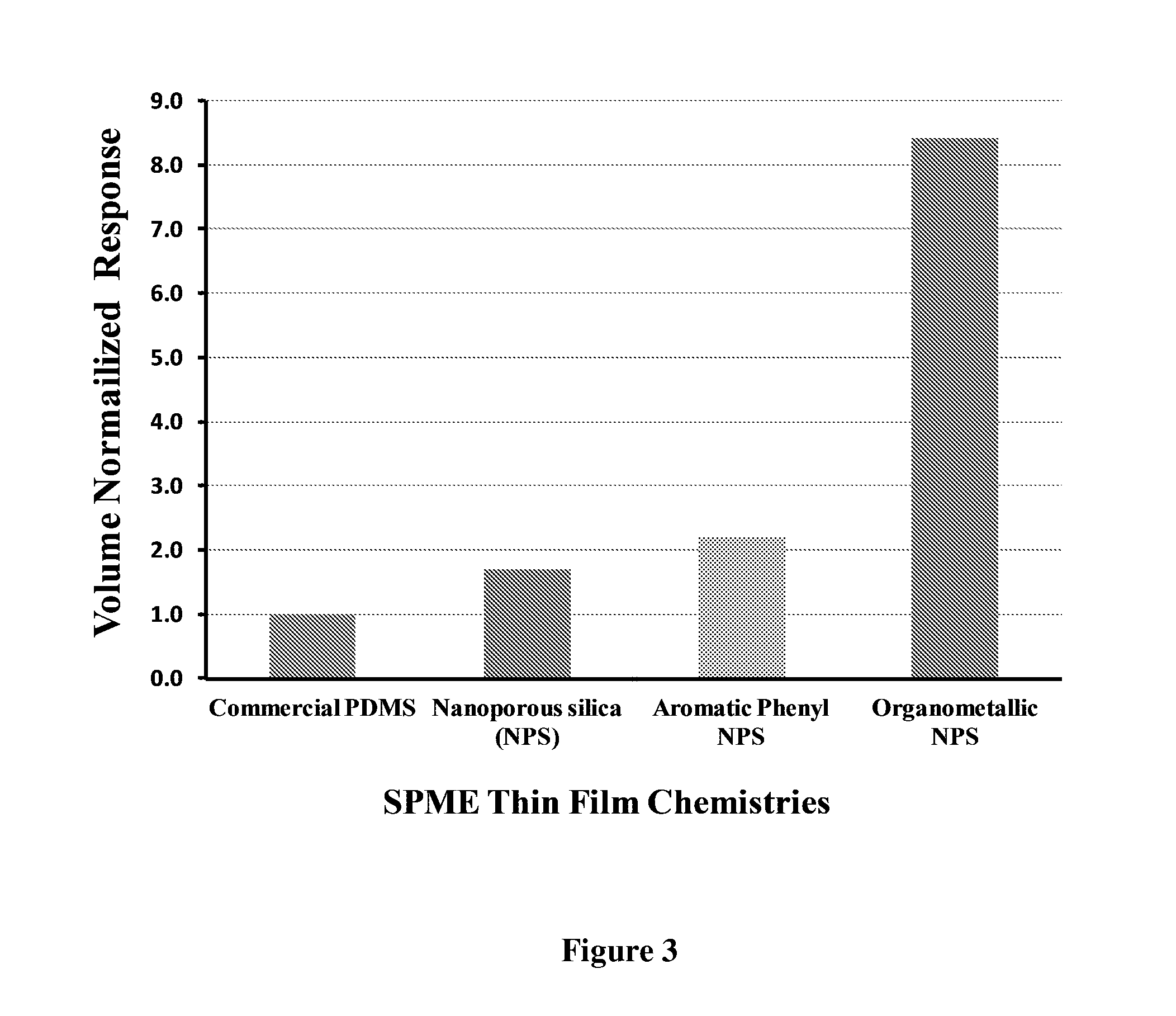

A method and device for enhanced capture of target analytes is disclosed. This invention relates to collection of chemicals for separations and analysis. More specifically, this invention relates to a solid phase microextraction (SPME) device having better capability for chemical collection and analysis. This includes better physical stability, capacity for chemical collection, flexible surface chemistry and high affinity for target analyte.

Owner:BATTELLE MEMORIAL INST

Shock tunnel

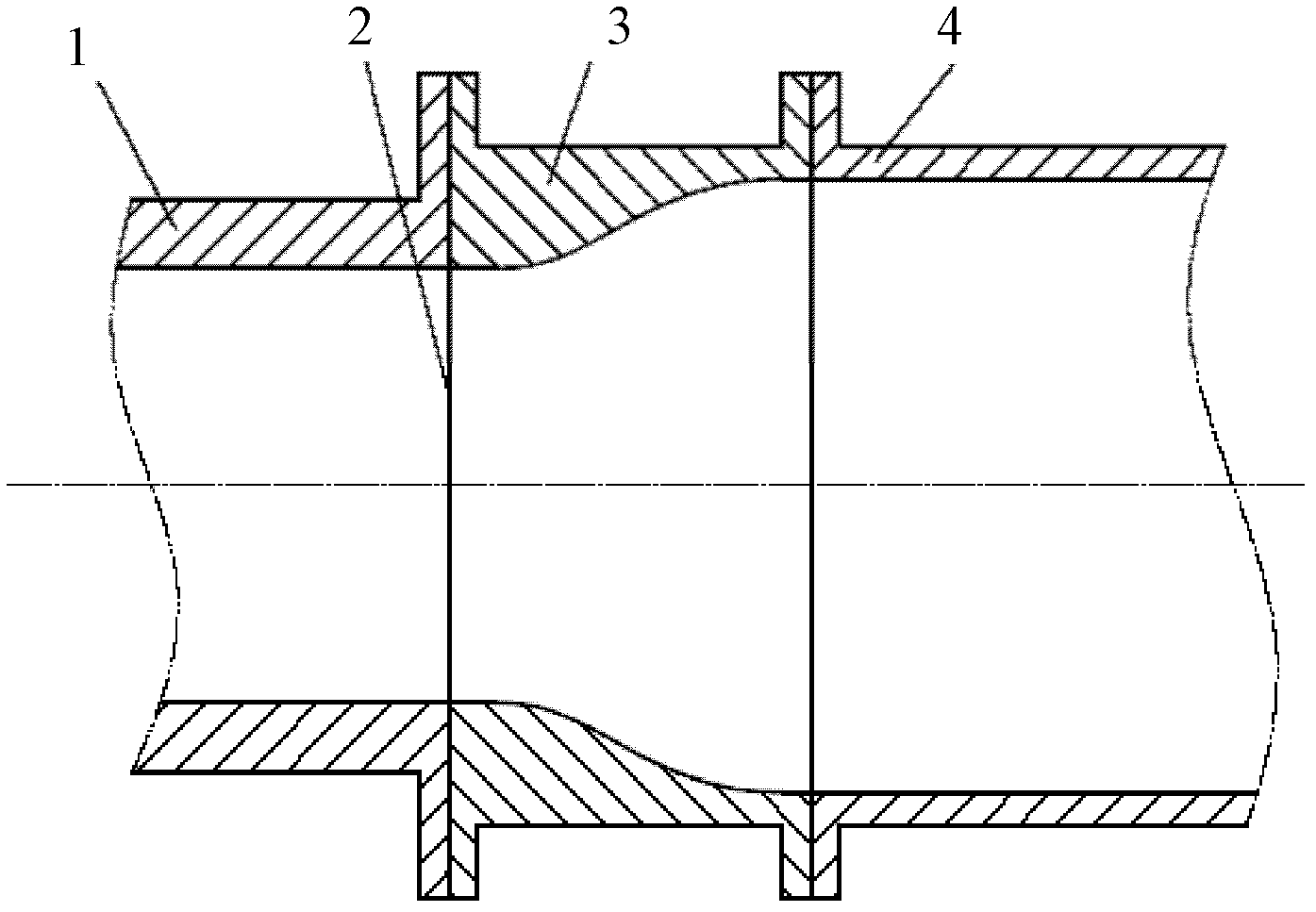

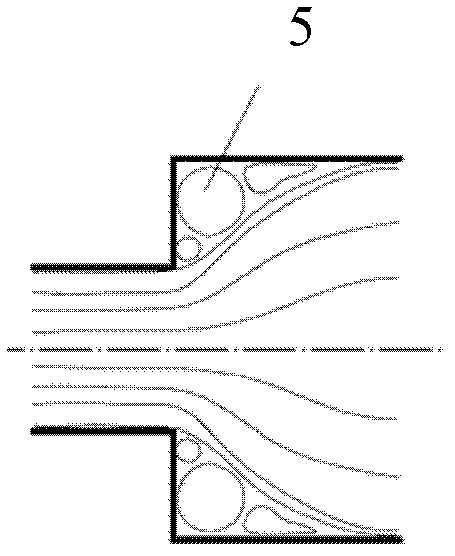

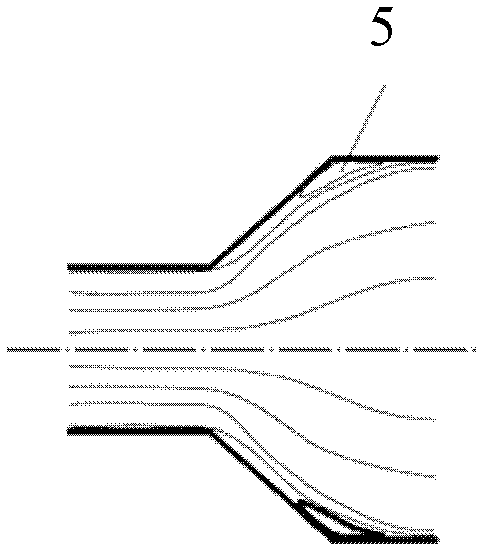

The invention discloses a shock tunnel which comprises a driving section and a driven section, wherein the diameter of a channel in the driven section is larger than that of a channel in the driving section; a transition section is arranged between the driving section and the driven section; the diameter of a channel in the transition section is gradually enlarged from the driving section to the driven section; the diameter of a channel which is arranged in the transition section and is connected with one end of the driving section is the same as that of the channel in the driving section; and the diameter of a channel which is arranged in the transition section and is connected with one end of the driven section is the same as that of the channel in the driven section. The transition section is adopted to connect the driving section with smaller internal diameter and the driven section with larger internal diameter, and a streamlined gradient curved surface is adopted as the shape of the channel in the transition section, so that boundary layer separation, large separation and the formation of instable vortex can be avoided; therefore, the uniform stability of flow can be improved, the flow loss is less, and the flow quality is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

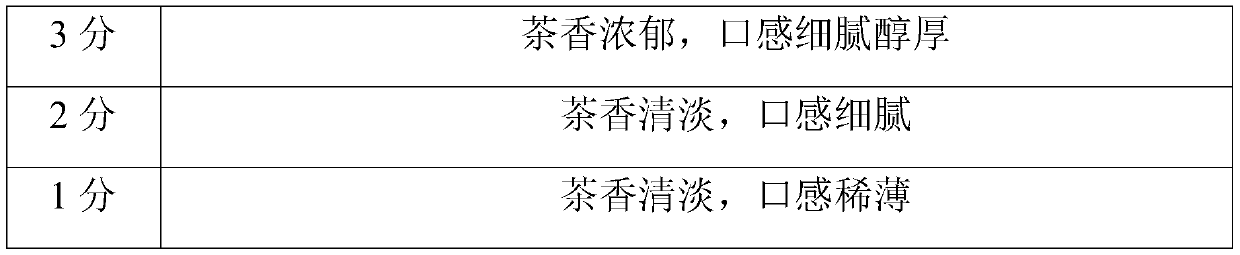

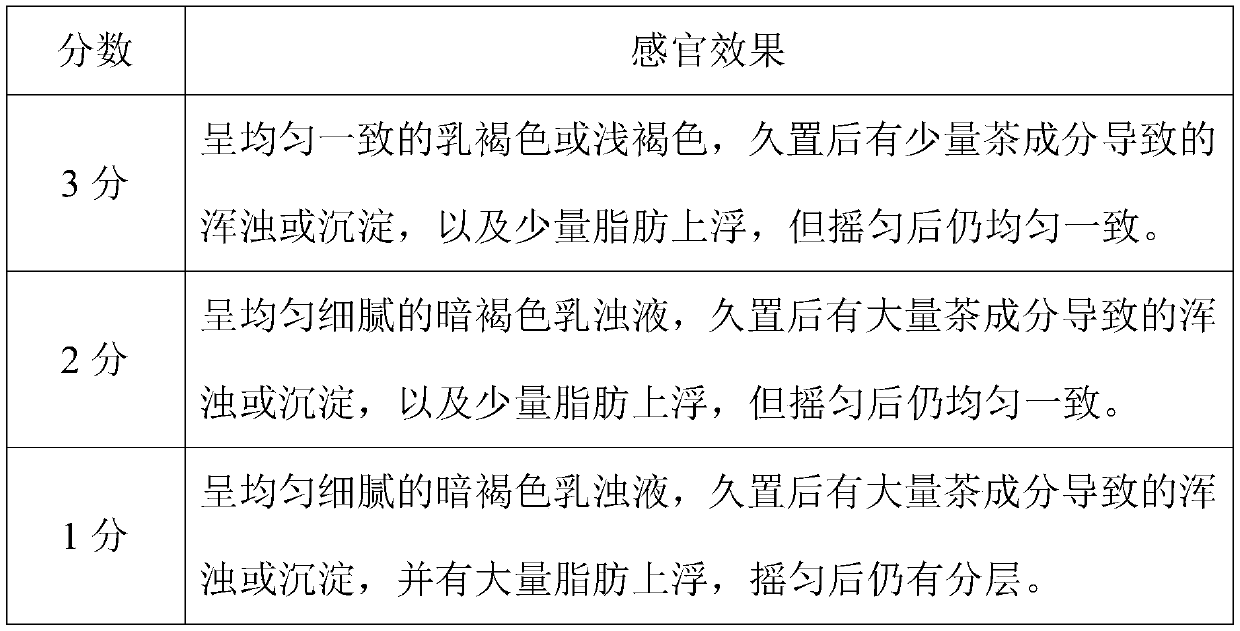

Walnut black tea beverage and preparation method thereof

InactiveCN110583823AAvoid harmMeet the needs of general healthTea extractionBlack teaVegetable Proteins

The invention relates to a walnut black tea beverage and a preparation method thereof. The walnut black tea beverage is a vegetable protein beverage combining walnut kernels and black tea, meets demands of people for fashion, taste and nutrition and meets the demand of massive health. The preparation method of the walnut black tea beverage comprises the following steps: (1), preparing walnut pulp,a black tea solution, a compound emulsified thickener solution and a sweet solution; and (2), mixing the solutions prepared in step (1), and performing constant-volume processing and homogenization to obtain the walnut black tea beverage. According to the preparation method, the black tea solution is prepared from black tea leaves with a three-time soaking method, damage of nutrient components ofthe black tea leaves due to traditional ground black tea powder or black tea concentrated liquor is avoided, the nutrient components in the black tea leaves can be sufficiently extracted, and the walnut black tea beverage has the advantages of simple process, low cost and high cost performance.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

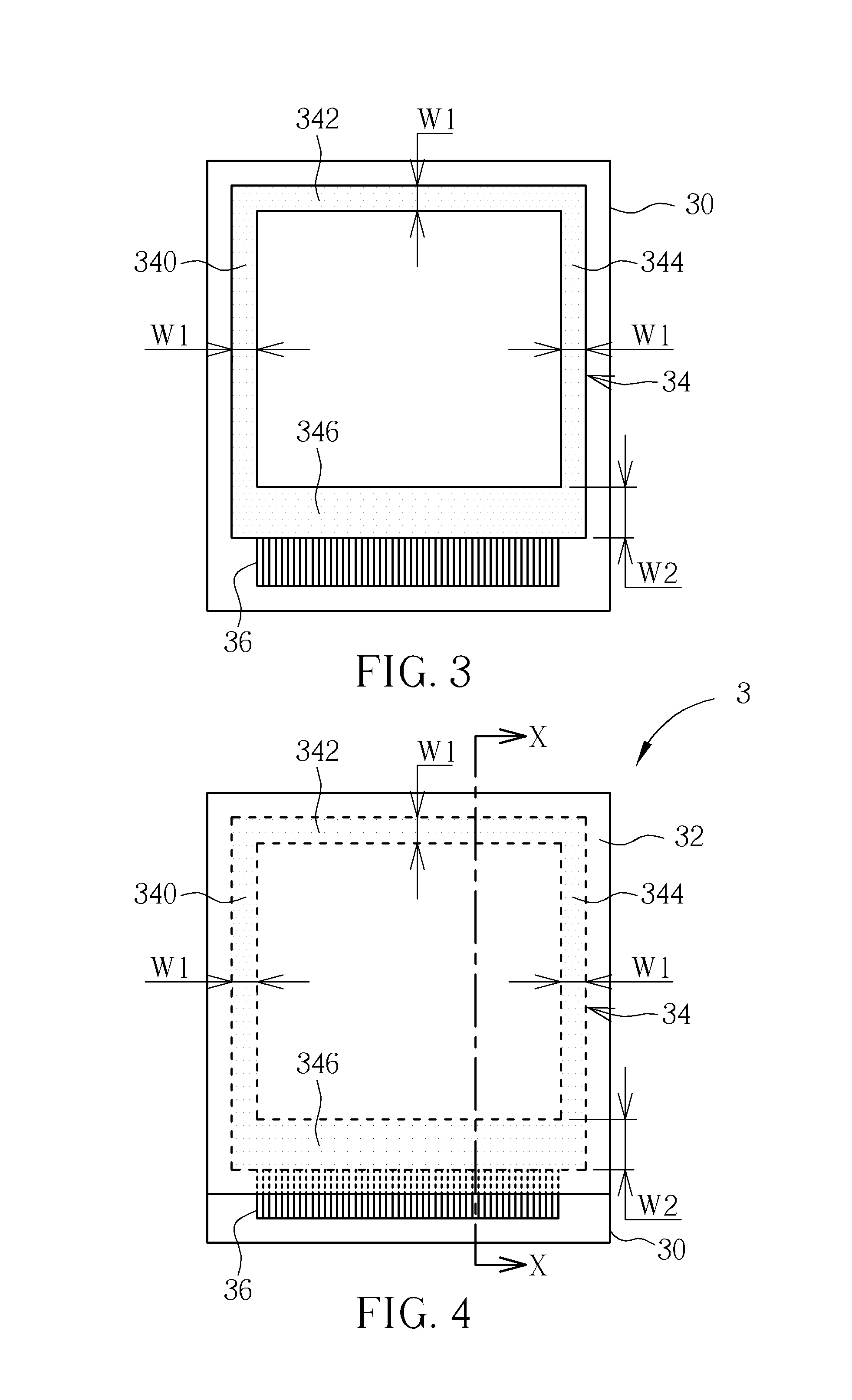

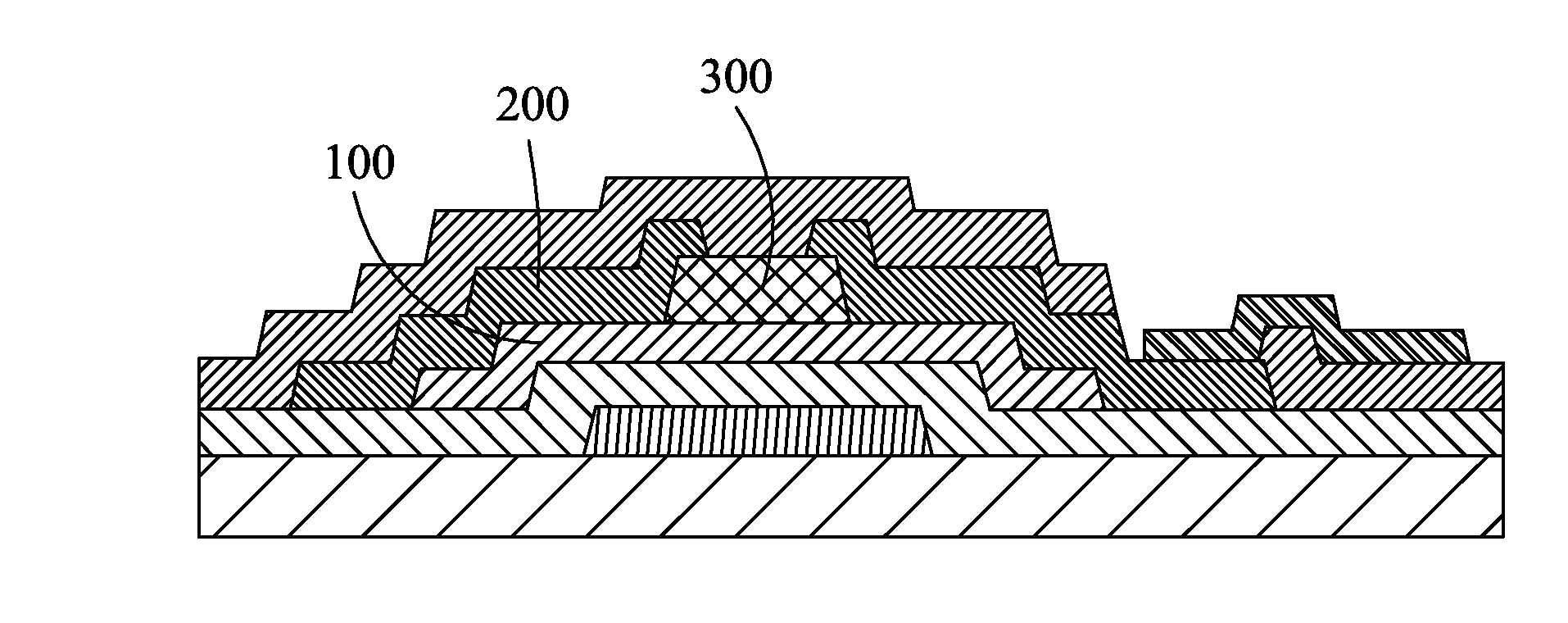

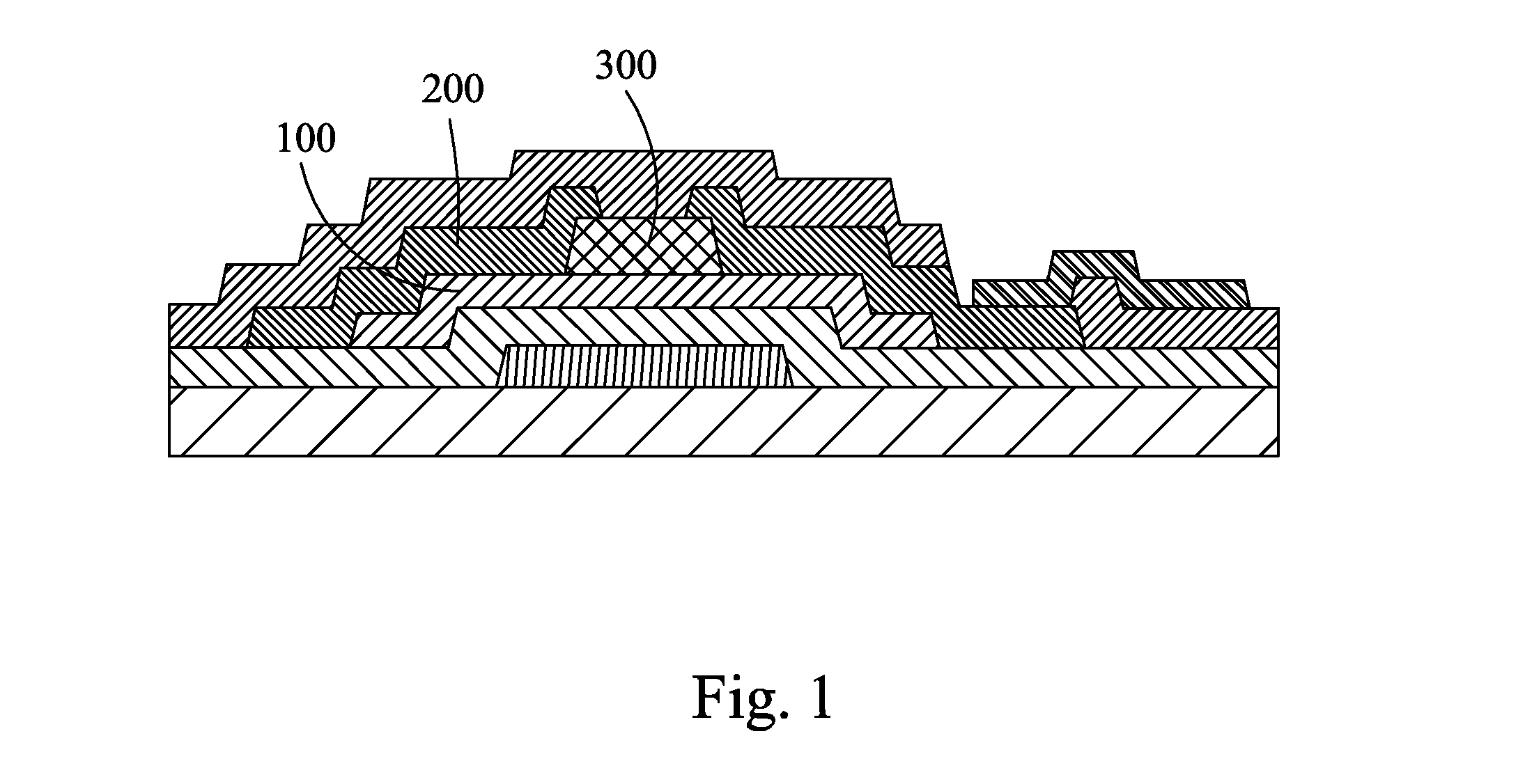

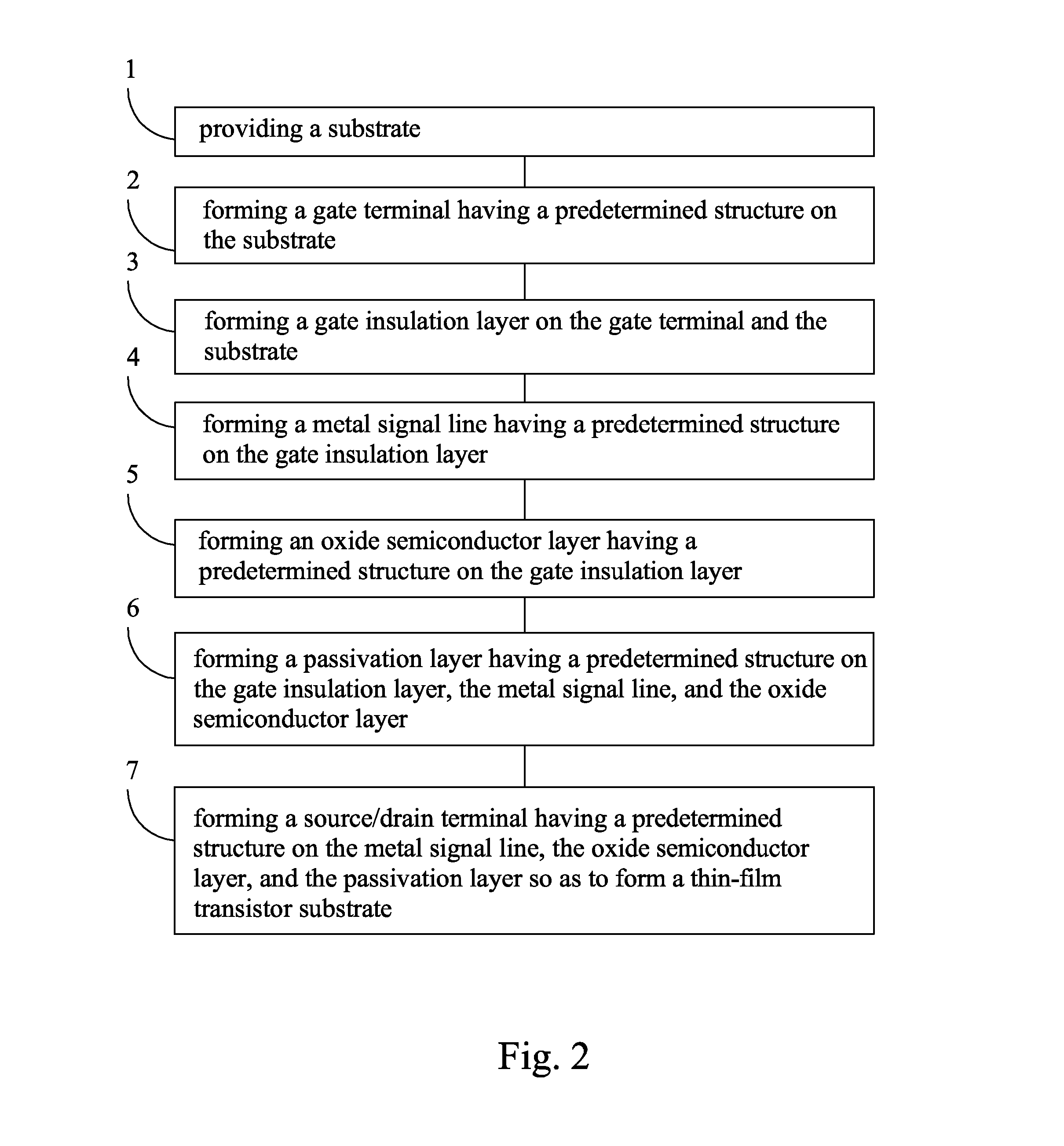

Method For Manufacturing Thin-Film Transistor Substrate And Thin-Film Transistor Substrate Manufactured With Same

InactiveUS20150129863A1Improve stabilityImprove uniformityTransistorSolid-state devicesInsulation layerEngineering

The present invention provides a method for manufacturing a thin-film transistor substrate and a thin-film transistor substrate manufactured with the method. The method includes: (1) providing a substrate (20); (2) forming a gate terminal (22) having a predetermined structure on the substrate (20); (3) forming a gate insulation layer (24) on the gate terminal (22) and the substrate (20); (4) forming a metal signal line (26) having a predetermined structure on the gate insulation layer (24); (5) forming an oxide semiconductor layer (28) having a predetermined structure on the gate insulation layer (24); (6) forming a passivation layer (32) having a predetermined structure on the gate insulation layer (24), the metal signal line (26), and the oxide semiconductor layer (28); and (7) forming a source / drain terminal (34) having a predetermined structure on the metal signal line (26), the oxide semiconductor layer (28), and the passivation layer (32) so as to form a thin-film transistor substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

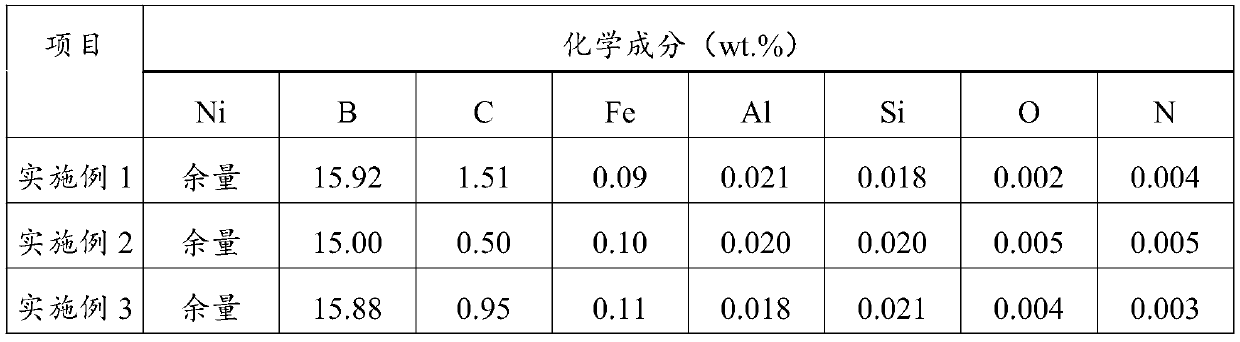

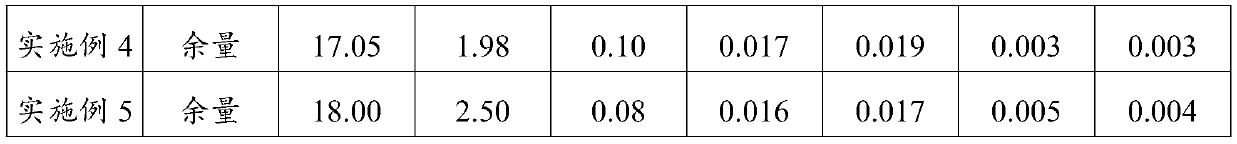

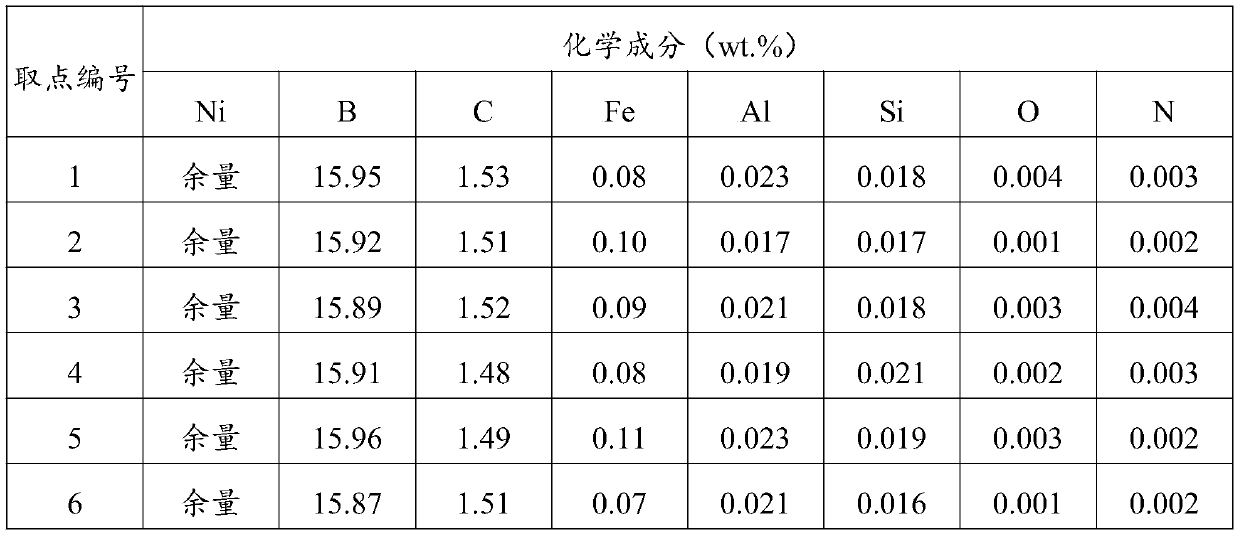

Nickel boron carbon intermediate alloy and preparation method thereof

The invention provides nickel boron carbon intermediate alloy and a preparation method thereof, and relates to the technical field of a metal material. The nickel boron carbon intermediate alloy comprises the following components measured by mass content: 15.0-18.0% of B, 0.5-2.5% of C and the allowance of Ni. The alloy components and content are reasonably designed, so that the components of thenickel boron carbon intermediate alloy is uniform and stable, the proportion of alloying elements in the final product of nickel-base superalloy can be controlled better, and alloying can be improvedbetter. The invention provides the preparation method of the nickel boron carbon intermediate alloy. The preparation method can prepare the intermediate alloy by an aluminothermic method and vacuum smelting method, can improve the uniform stability of the components of the nickel boron carbon intermediate alloy and reduce the impurity content, and therefore obtains the nickel boron carbon intermediate alloy with accurate chemical components, high purity, low density and a low melting point.

Owner:CHENGDE TIANDA VANADIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com