Long basalt fiber reinforced thermoplastic resin composite master batch and preparation method and application thereof

A technology of basalt fiber and reinforced thermoplastic, which is applied in the field of polymer materials, can solve the problems of difficult to achieve the addition ratio, low fiber content, long fiber length, etc., and achieve the effect of good heat resistance, low price and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

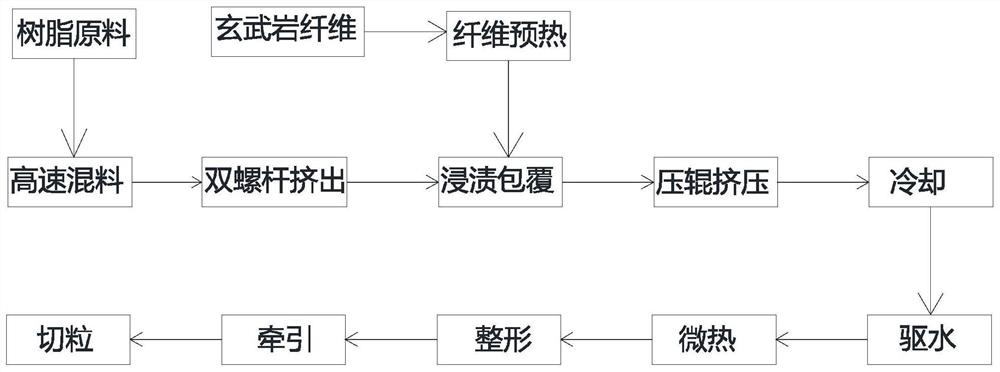

[0031] The present invention also provides a preparation method for the above-mentioned long basalt fiber reinforced thermoplastic resin composite masterbatch, comprising the following steps:

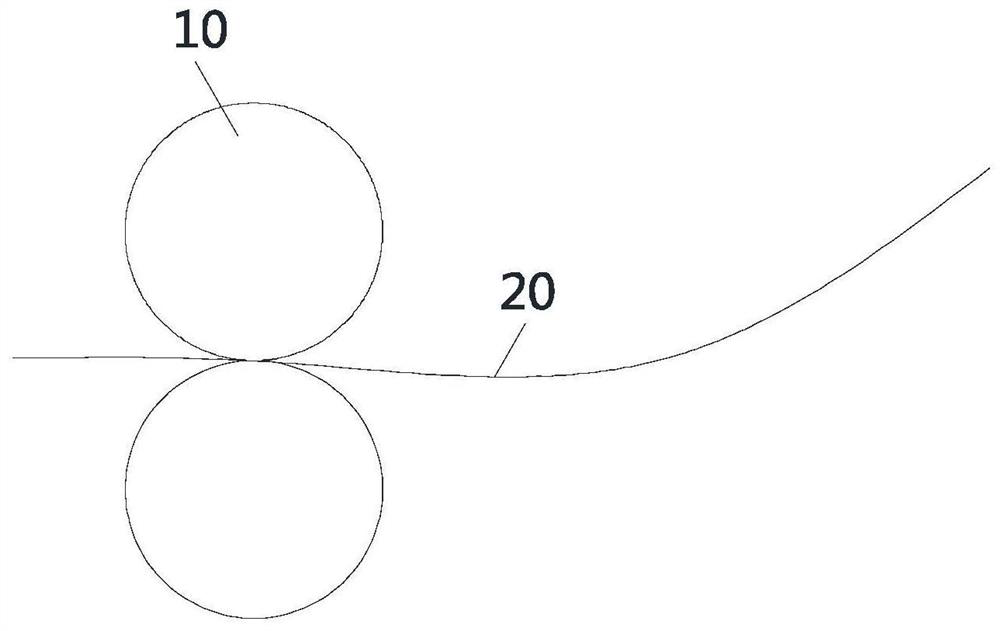

[0032] (1) Weigh each component in proportion, and the weighing amount of other components except basalt fiber is 1.5 to 2.5 times of the formula amount, and add other components except basalt fiber into the mixer and mix at high speed, Obtaining the mixture; (2) adding the mixture into the extruder, pulling the basalt fiber by the traction unit, preheating and fully impregnating the mixture extruded from the extruder in the dipping and coating machine to obtain the impregnating material; (3) The impregnating material is extruded by extrusion rollers to obtain composite materials; (4) The composite materials are subjected to water cooling, shaping, water driving and pelletizing to obtain composite master batches.

[0033] The long basalt fiber reinforced thermoplastic resin composite ma...

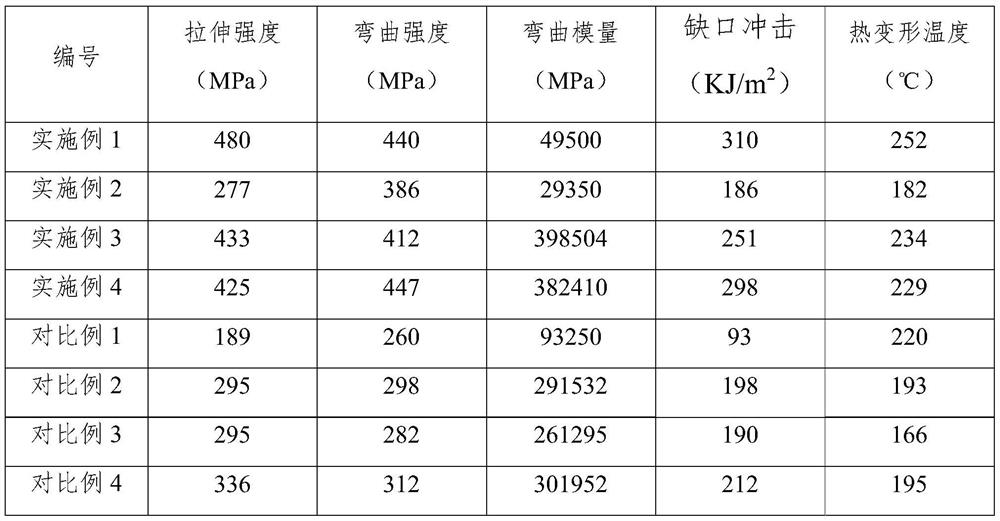

Embodiment 1

[0053] This embodiment provides a kind of long basalt fiber reinforced thermoplastic resin composite masterbatch, including the following components in weight percentage: 10 parts of nylon (PA), 85 parts of long basalt fibers of 2400tex, 5 parts of silane coupling agent; The length of the grains was 12 mm.

[0054] The present embodiment also provides the preparation method of above-mentioned composite masterbatch, comprises the following steps:

[0055] (1) Weigh the raw materials in proportion, and the weighing amount of other components except basalt fiber is 2.5 times of the formula quantity, and add other components except basalt fiber into the mixer for high-speed mixing. The rotation speed is 500r / min, the mixing time is 10min, and the mixing temperature is 90°C to obtain the mixture;

[0056] (2) Put the mixture into the twin-screw extruder, the screw speed is 400r / min, the temperature of the extrusion section is 240°C, the basalt fiber is pulled by the traction unit,...

Embodiment 2

[0060] This embodiment provides a kind of long basalt fiber reinforced thermoplastic resin composite master batch, including the following components in weight percentage: 60 parts of nylon (PA), 39 parts of long basalt fiber of 2400tex, 1 part of titanate coupling agent; The length of the composite masterbatch is 25mm.

[0061] The present embodiment also provides the preparation method of above-mentioned composite masterbatch, comprises the following steps:

[0062] (1) Weigh the raw materials in proportion, and the weighing amount of other components except basalt fiber is 1.5 times of the formula amount, and add other components except basalt fiber to the mixer for high-speed mixing. The rotation speed is 1500r / min, the mixing time is 10min, and the mixing temperature is 60°C to obtain the mixture;

[0063] (2) Put the mixture into the twin-screw extruder, the screw speed is 220r / min, the temperature of the extrusion section is 180°C, the basalt fiber is pulled by the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com