Patents

Literature

456 results about "Fibre content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Healthier Baked Goods Containing Microalgae

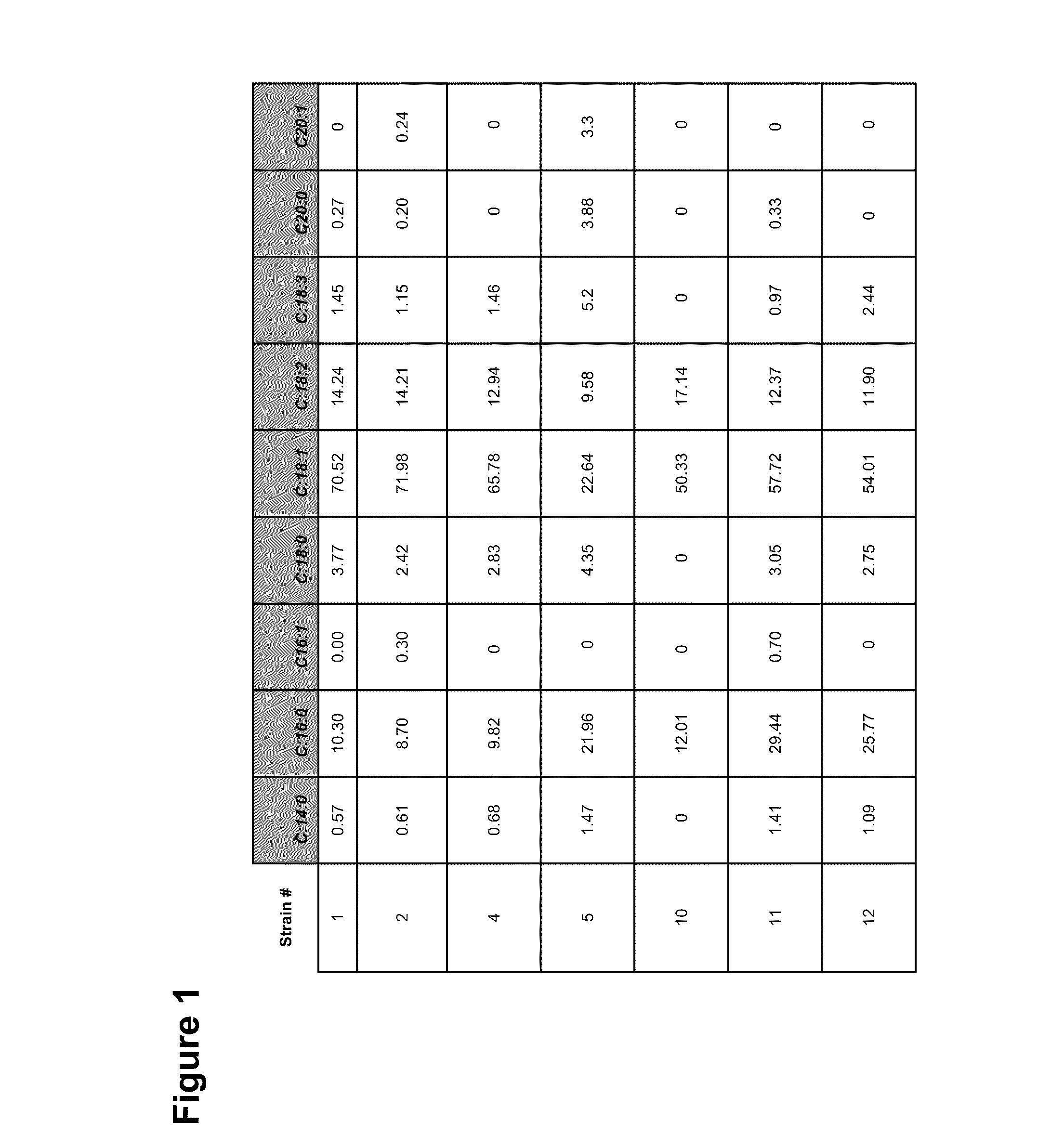

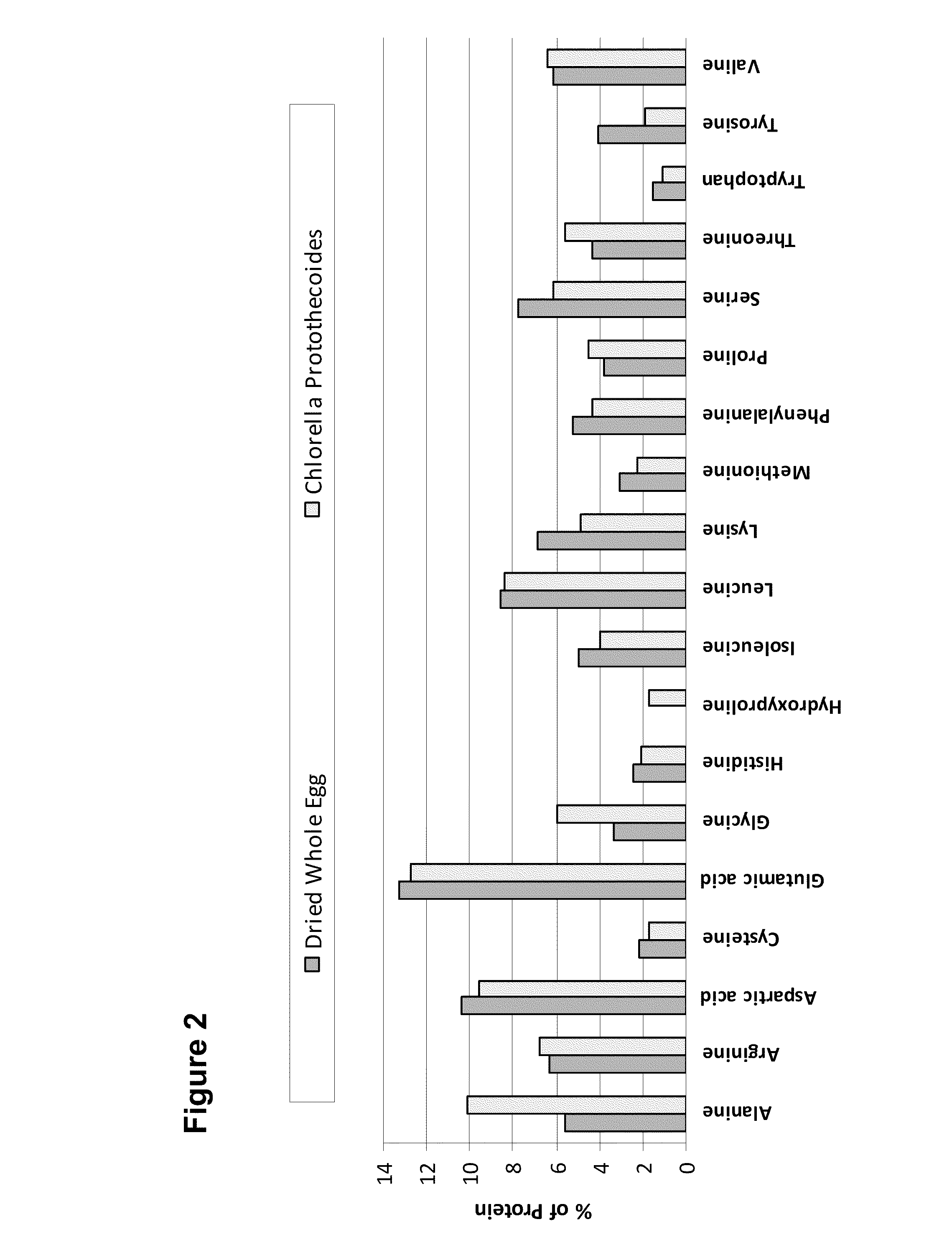

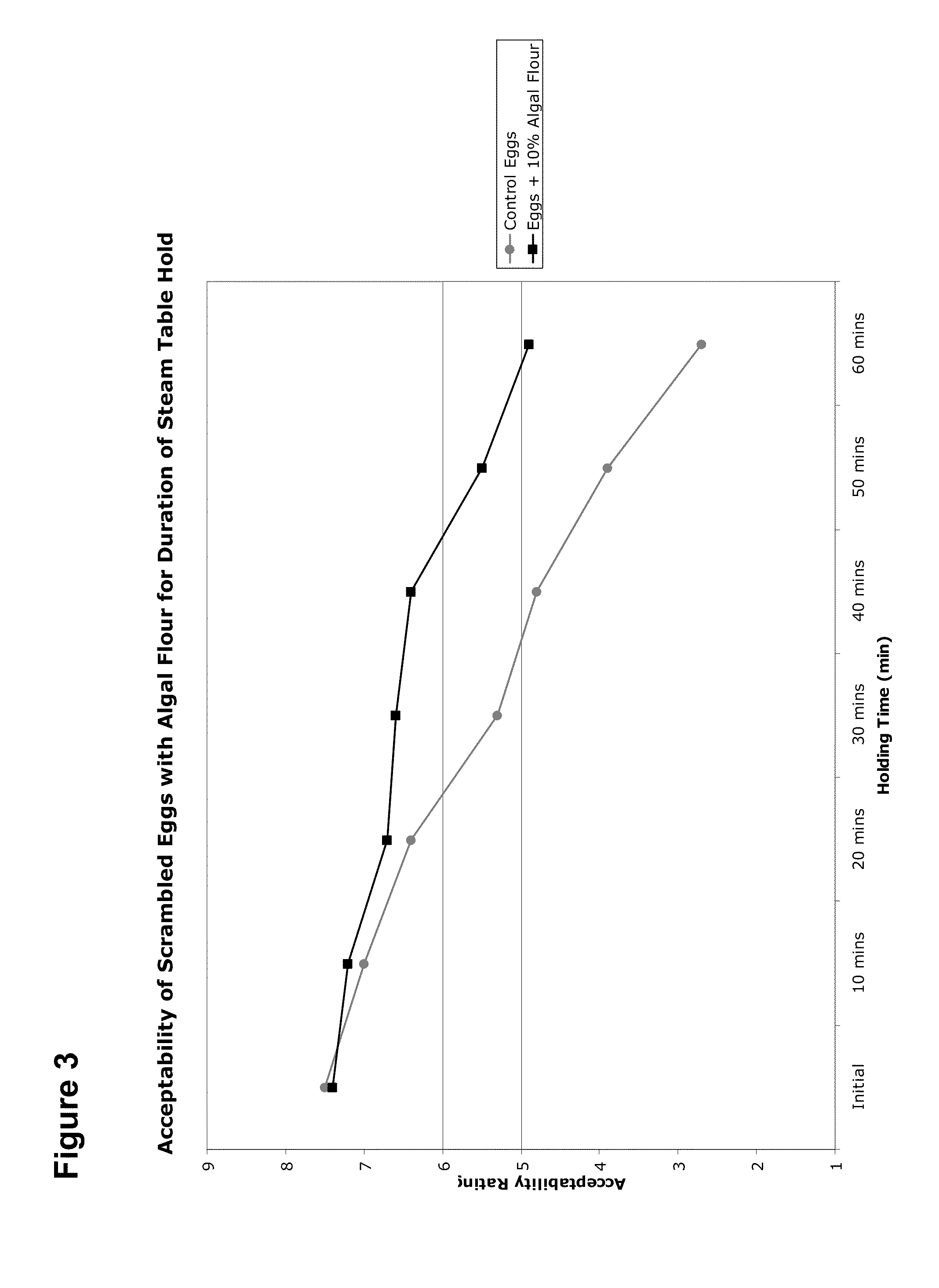

Provided herein are microalgae-containing baked goods with novel properties compared to preexisting products of the same type. Methods of formulating and manufacturing these foods to deliver reduced fat, reduced cholesterol, and increased fiber content are disclosed herein. Various embodiments include elimination or reduction of eggs, butter, animal fat, and saturated oils in favor of healthy oil-containing microalgae biomass and oils, including the manufacture of foods with lower calories than preexisting products of the same type. Methods of producing raw materials for the manufacture of novel processed baked foods and intermediates such as cake and bead mixes are also provided.

Owner:TERRAVIA HLDG INC

High protein puffed food product and method of preparation

Disclosed are ready-to-eat puffed dried food products that are high both in protein and in fiber. The cereals contain sufficient amounts of at least one protein ingredient to provide a total protein content about 50% to 75% (dry weight) of the cooked food product; sufficient amounts of at least one dietary fiber ingredient to provide a total fiber content of about 1-45% (dry weight); and sufficient amounts of a starch containing ingredient to provide a starch content of about 5-45%. The food products have a crush strength raging from about 0.25 to 3.5 kg / cm3.

Owner:GENERAL MILLS INC

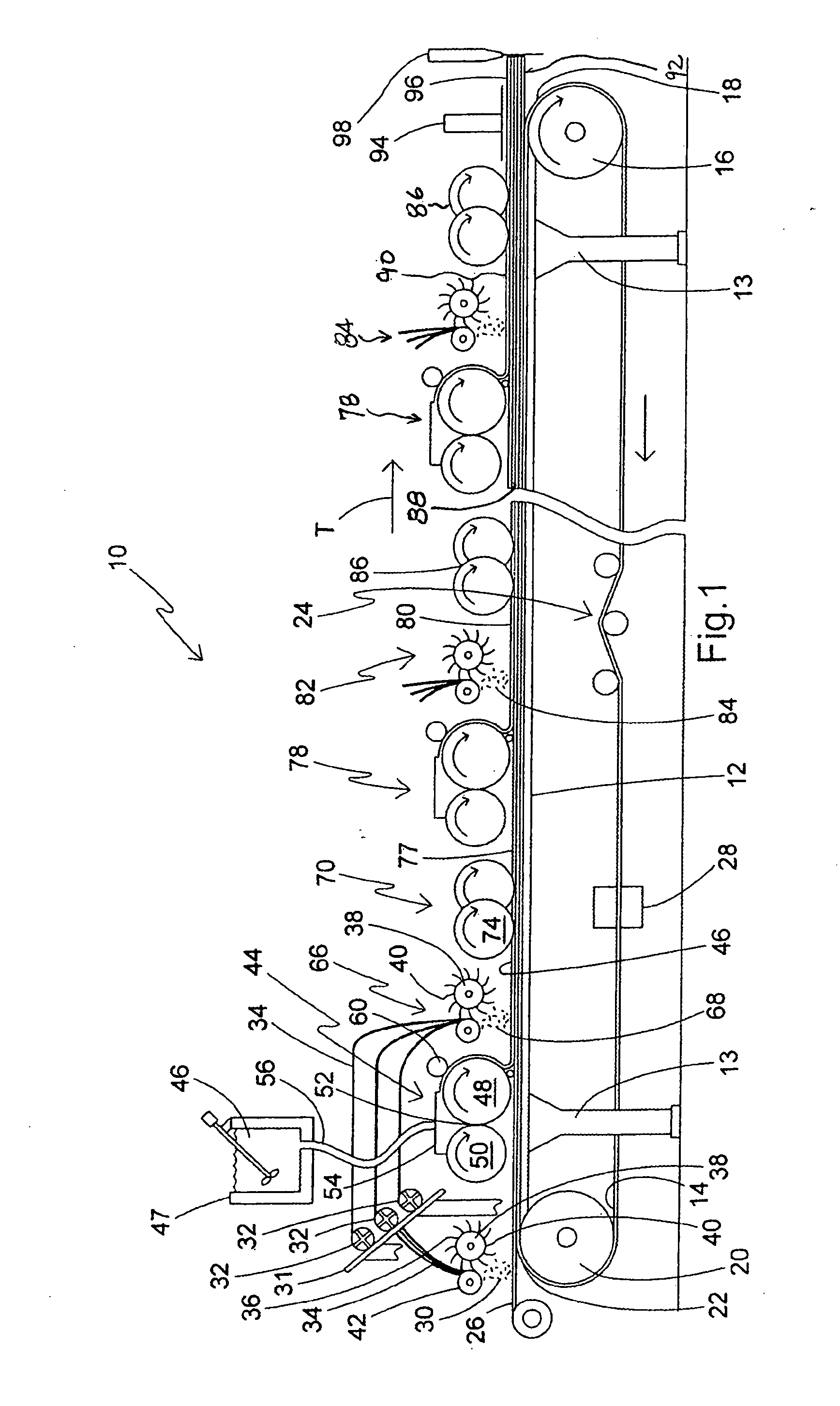

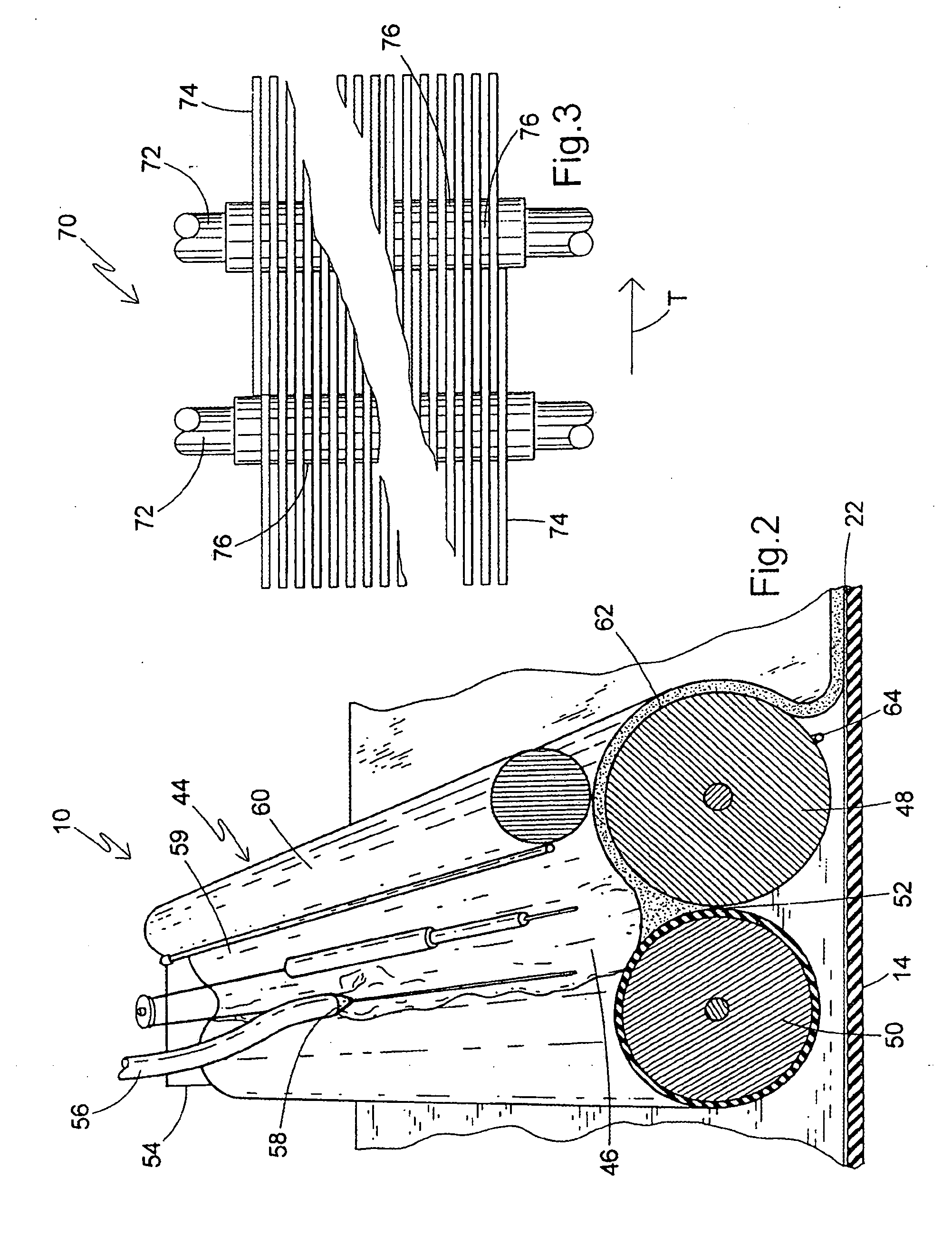

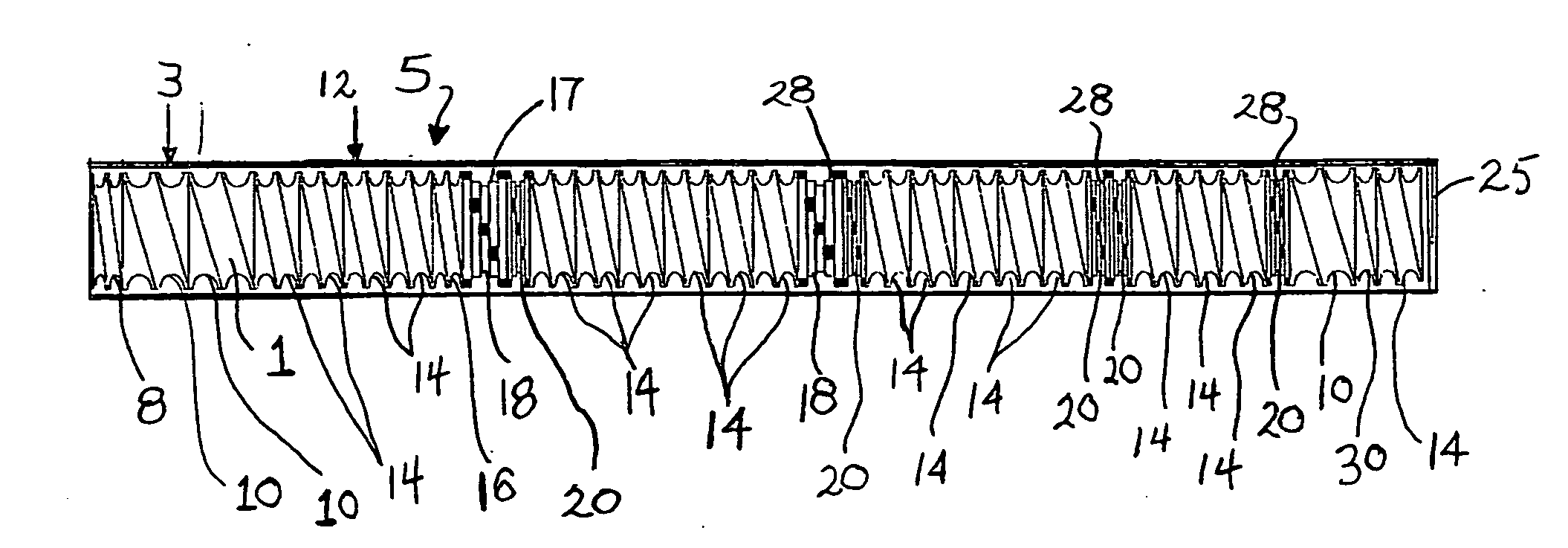

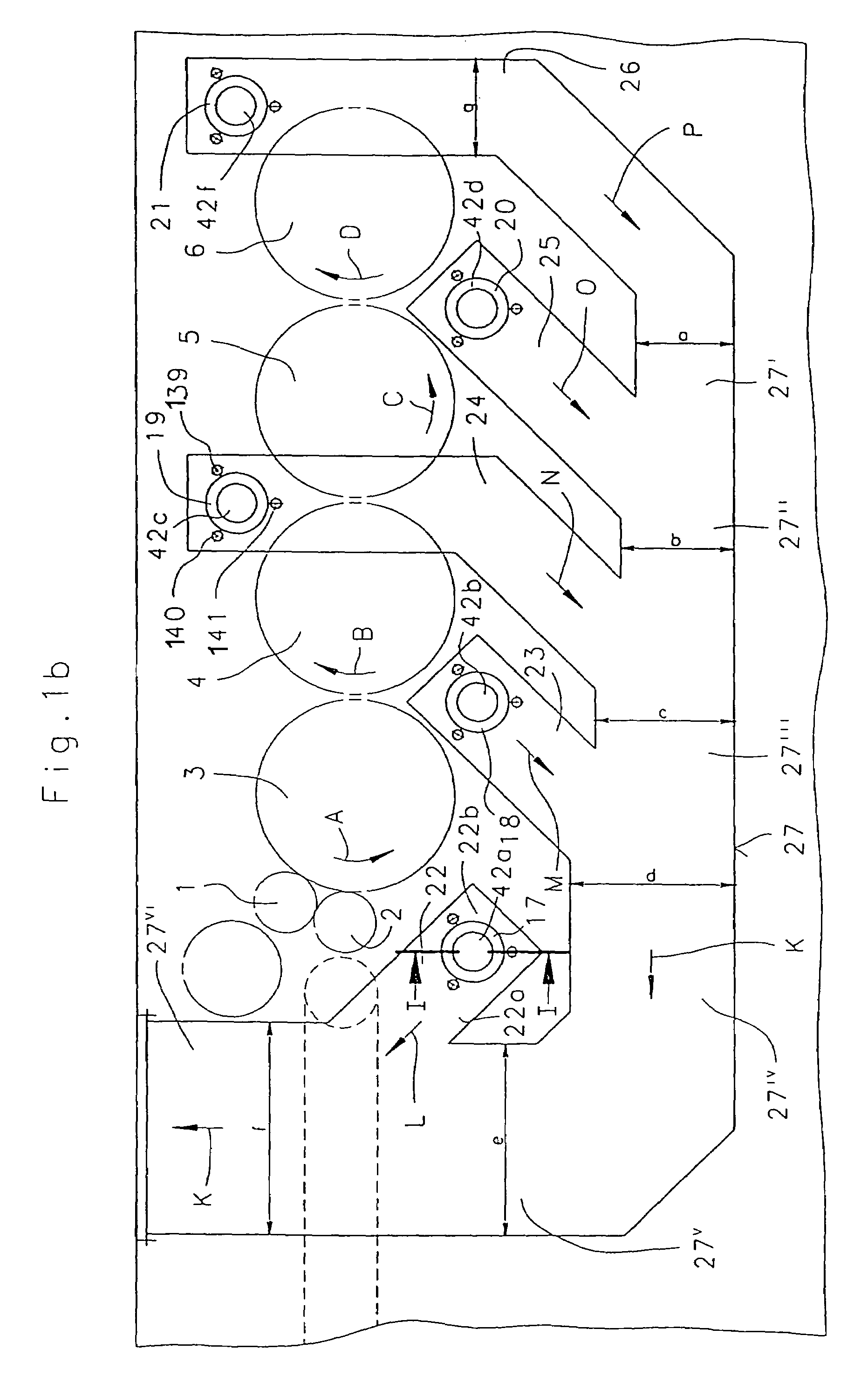

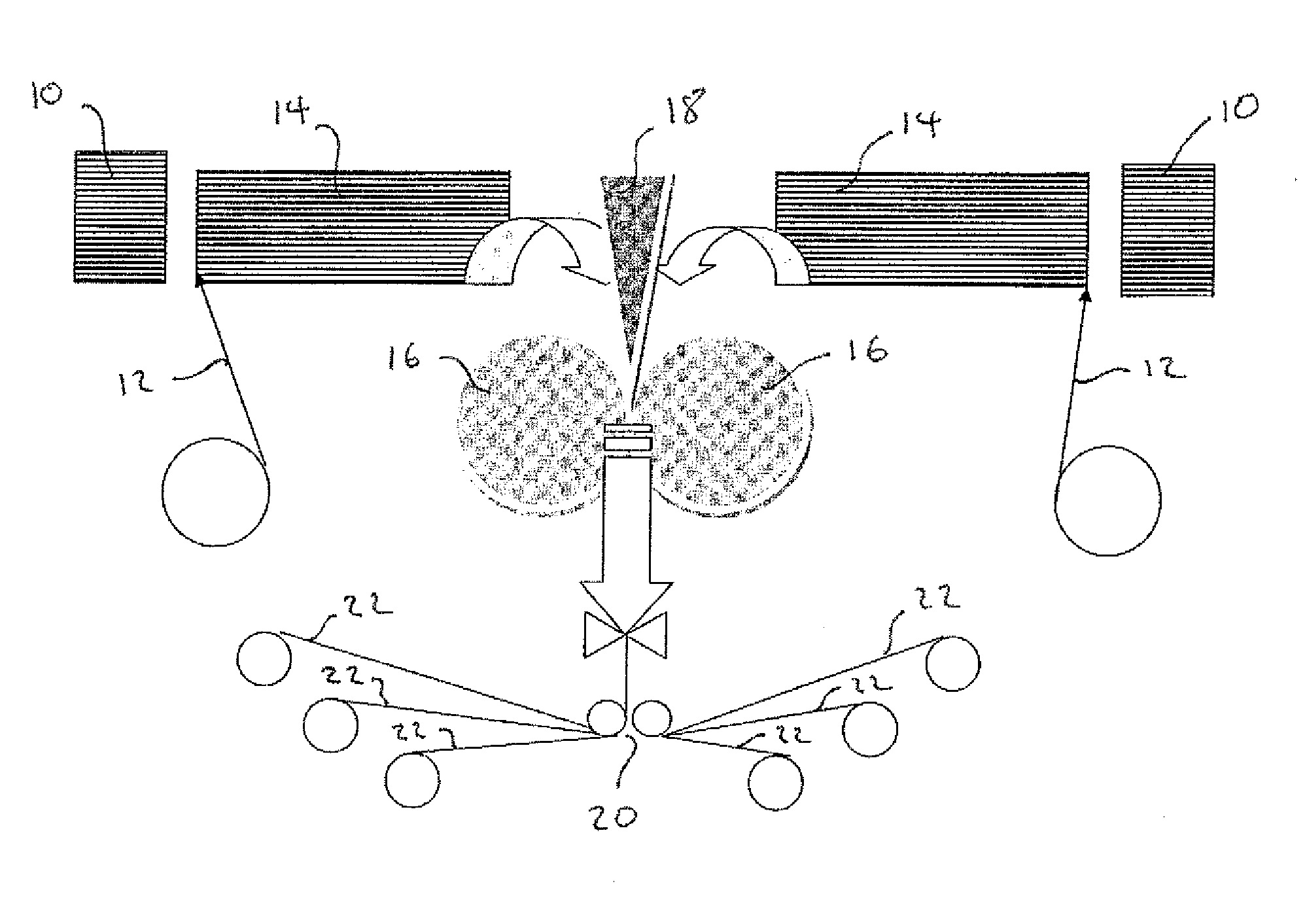

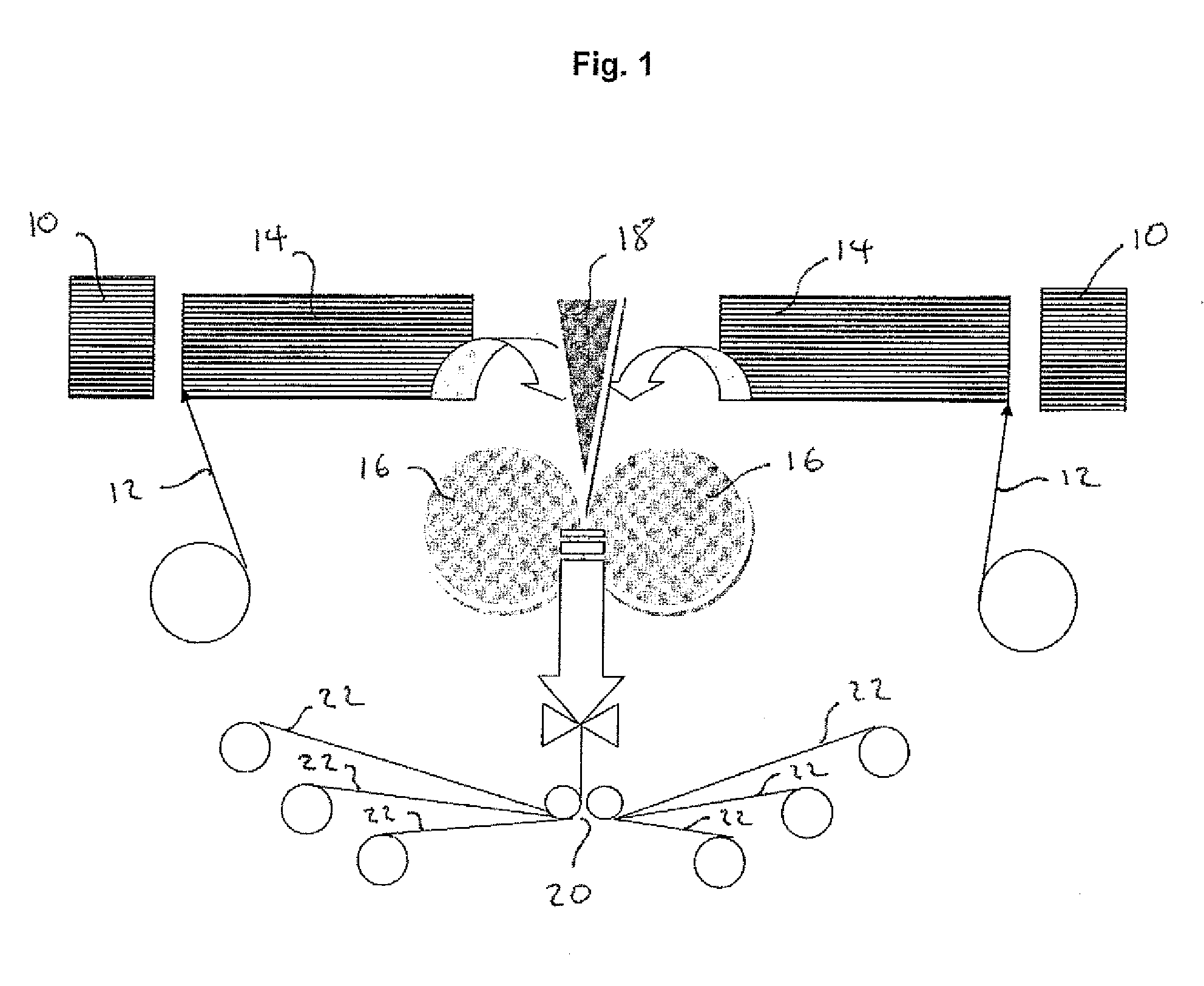

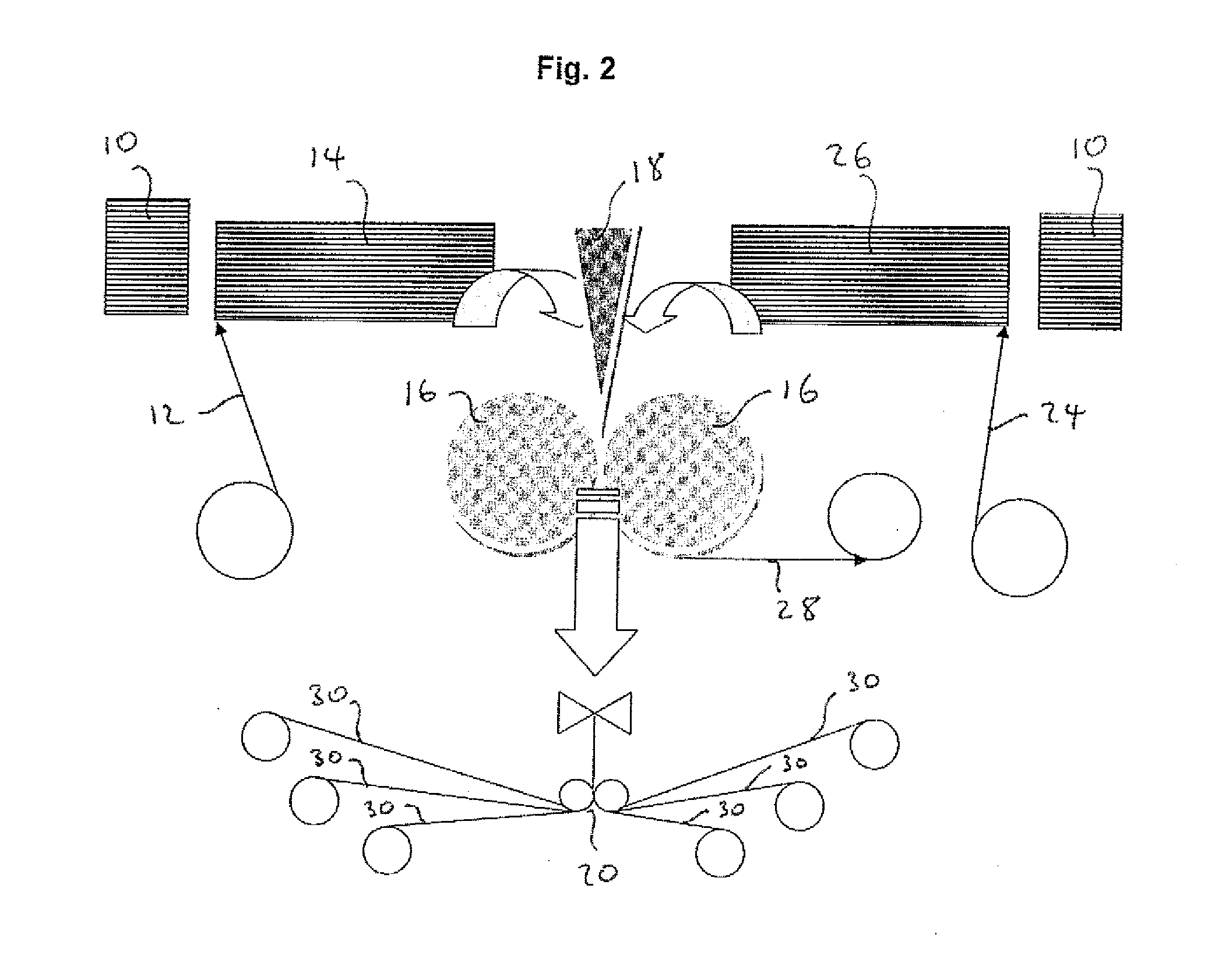

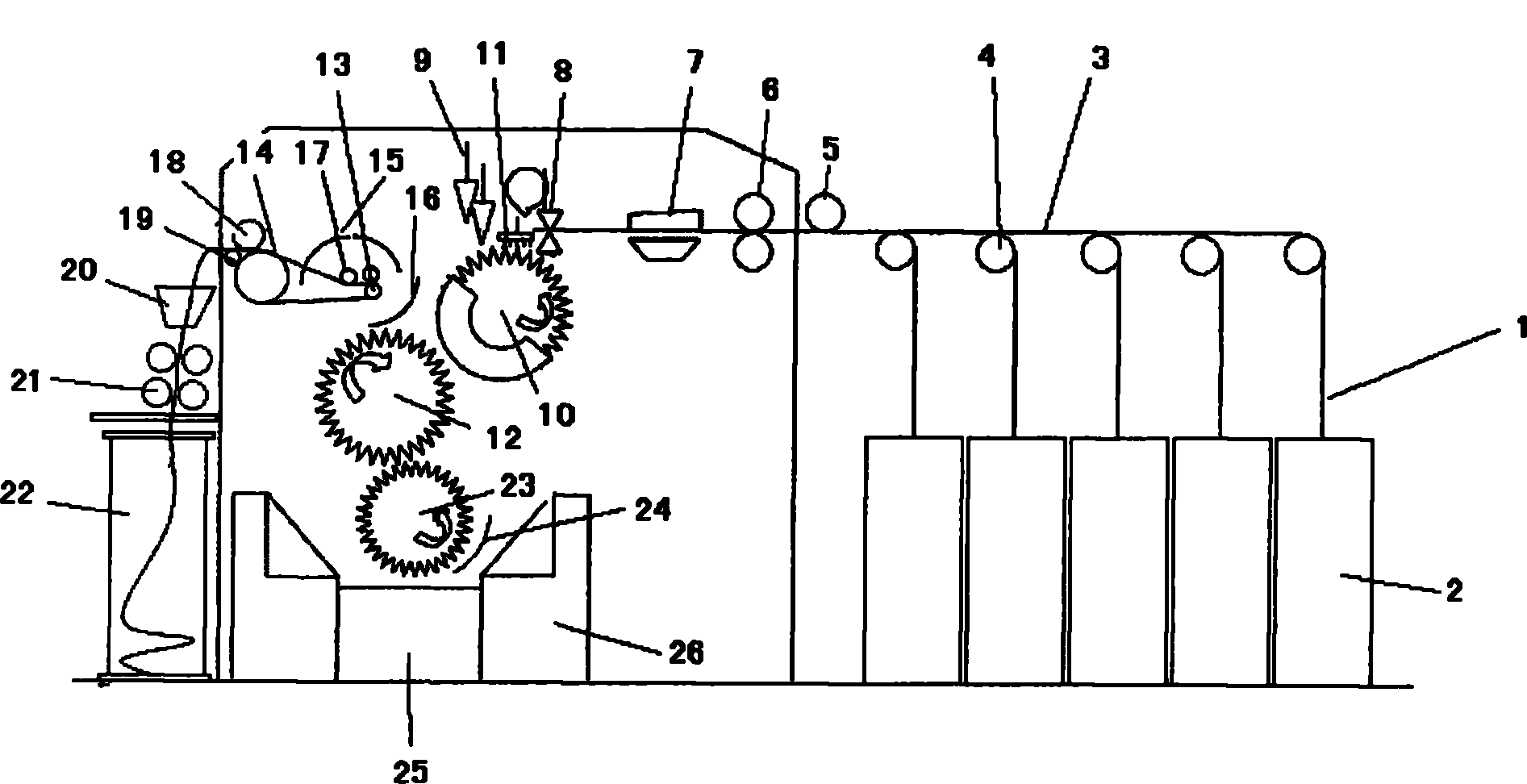

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels with enhanced fiber content

ActiveUS20070110970A1Good strength propertiesA large amountLiquid surface applicatorsConstruction materialCement boardSlurry

A process for producing fiber-reinforced structural cementitious panels made of at least one layer of fiber reinforced cementitious slurry, the process for each such layer of slurry including providing a moving web; depositing a first layer of individual, loose fibers upon the web; depositing a layer of settable slurry upon the deposited first layer of individual, loose fibers; depositing a second layer of individual, loose fibers upon the deposited layer of settable slurry; and actively embedding both layers of individual, loose fibers into the layer of slurry to distribute the fibers throughout the slurry.

Owner:UNITED STATES GYPSUM CO

Process for secondary treating of waste alkali liquid during production of viscose fibers

The invention relates to a process for secondary treating of a waste alkali liquid during production of viscose fibers and belongs to the field of viscose fibers. According to the process, the conventionally-pretreated waste alkali liquid with the sodium hydroxide concentration of 70-90g / L and the hemicellulose content of 60-70g / L and demineralized water are transferred into a diffusion dialyzing membrane stack respectively for diffusion dialyzing, the flow ratio of the waste alkali liquid to the demineralized water is (1-2):1, the alkali liquid with the low hemicellulose concentration is separated from the alkali liquid with the high hemicellulose concentration after diffusion dialyzing, and the alkali liquid with the low hemicellulose concentration is used for production. The process solves the problem that the environment is greatly damaged due to direct discharge of the waste alkali liquid which is recycled once and can still produce the secondary waste alkali liquid in the prior art, the process for treating the secondary waste alkali liquid is provided, sodium hydroxide (NaOH) in the waste alkali liquid can be recovered to the maximum extent, the environmental pollution is reduced, the ecological benefit is improved, and simultaneously, the cost for environmental protection treatment is reduced.

Owner:YIBIN HIEST FIBER +1

Flame Resistant Fabric With Anisotropic Properties

InactiveUS20110010827A1Increased durabilityChemical protectionHeat protectionFiberFire-retardant fabric

Flame resistant fabrics are formed by warp and fill yams having different fiber contents. The fabrics are constructed, for example, by selection of a suitable weaving pattern, such that the body side of the fabric and the face side of the fabric have different properties. The fabrics described herein can be printable and dyeable on both sides of the fabric and are suitable for use in military and industrial garments. Methods of forming flame resistant fabrics, and methods for forming garments from the fabrics, are also described.

Owner:SOUTHERN MILLS

High-dietary fiber five-cereal puffing powder and preparation process thereof

The invention relates to high-dietary fiber five-cereal puffing powder and a preparation method, and belongs to the field of food processing. The five-cereal puffing powder comprises the following raw materials: coarse rice powder, wheat meal, oatmeal, millet meal, glutinous corn meal, soybean meal, wheat bran meal, calcium lactate, ferrous gluconate, zinc gluconate, vitamin B1, vitamin B2 and vitamin B6. A method for processing the five-cereal puffing powder comprises the following steps of: screening coarse cereals, grinding, milling, sieving with an 80-mesh sieve, mixing uniformly in a ratio, adjusting the moisture of materials, balancing the moisture, extruding and puffing by using double screws, drying, crushing, and sieving with a 100-mesh sieve, enhancing mineral elements and the vitamins. The high-dietary fiber five-cereal puffing powder has the characteristics that the puffing powder is prepared from natural grain coarse cereals, emulsifying agents and sweeteners are not added, the mineral elements and the vitamins are enhanced, the content of dietary fibers reaches the specified standard of national high-dietary fiber foods, and the puffing powder can be eaten only by being infused by boiling water, so that the high-dietary fiber five-cereal puffing powder is an ideal nutritional and convenient food which is suitable to be eaten by middle and old-aged people.

Owner:HEFEI UNIV OF TECH

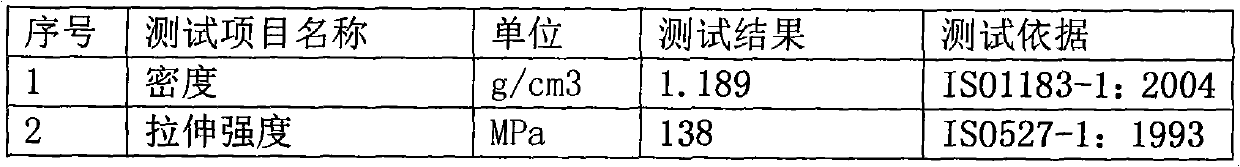

Composite core for power grid transmission line wire and preparation method thereof

The invention provides a composite core for a power grid transmission line wire and a preparation method thereof. The composite core has high strength, high toughness, high glass-transition temperature and surface cleanness. Materials of the composite core comprise a resin material and a strengthening material. The resin material comprises a thermosetting resin, a curing agent, an accelerating agent, a releasing agent, a flexibilizer and nanometer particles. The strengthening material is one kind or a plurality of kinds of carbon fiber, glass fiber, basalt fiber, boron fiber, aramid fiber, silicon carbonate fiber and protein bound iodine (PBI) fiber. The content of composite core fiber Vf=50-80%, tensile strength of the composite core is not lower than 2100MPa, and glass transition temperature of the composite core is not lower than 180 DEG C. The toughness of the composite core is remarkably improved, and breakage and cracking probability caused by brittleness factors in production, transportation and wire hanging construction processes are reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

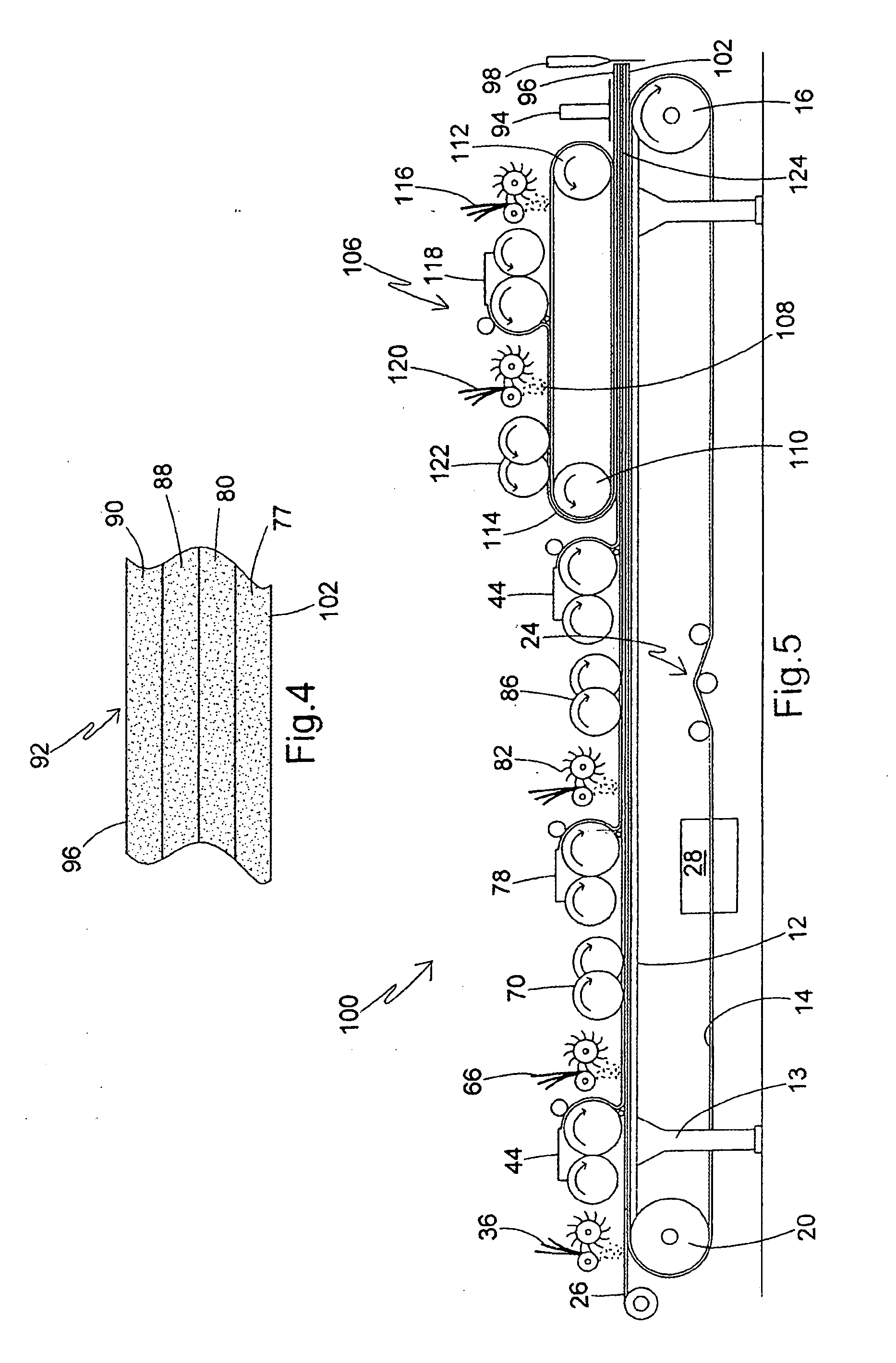

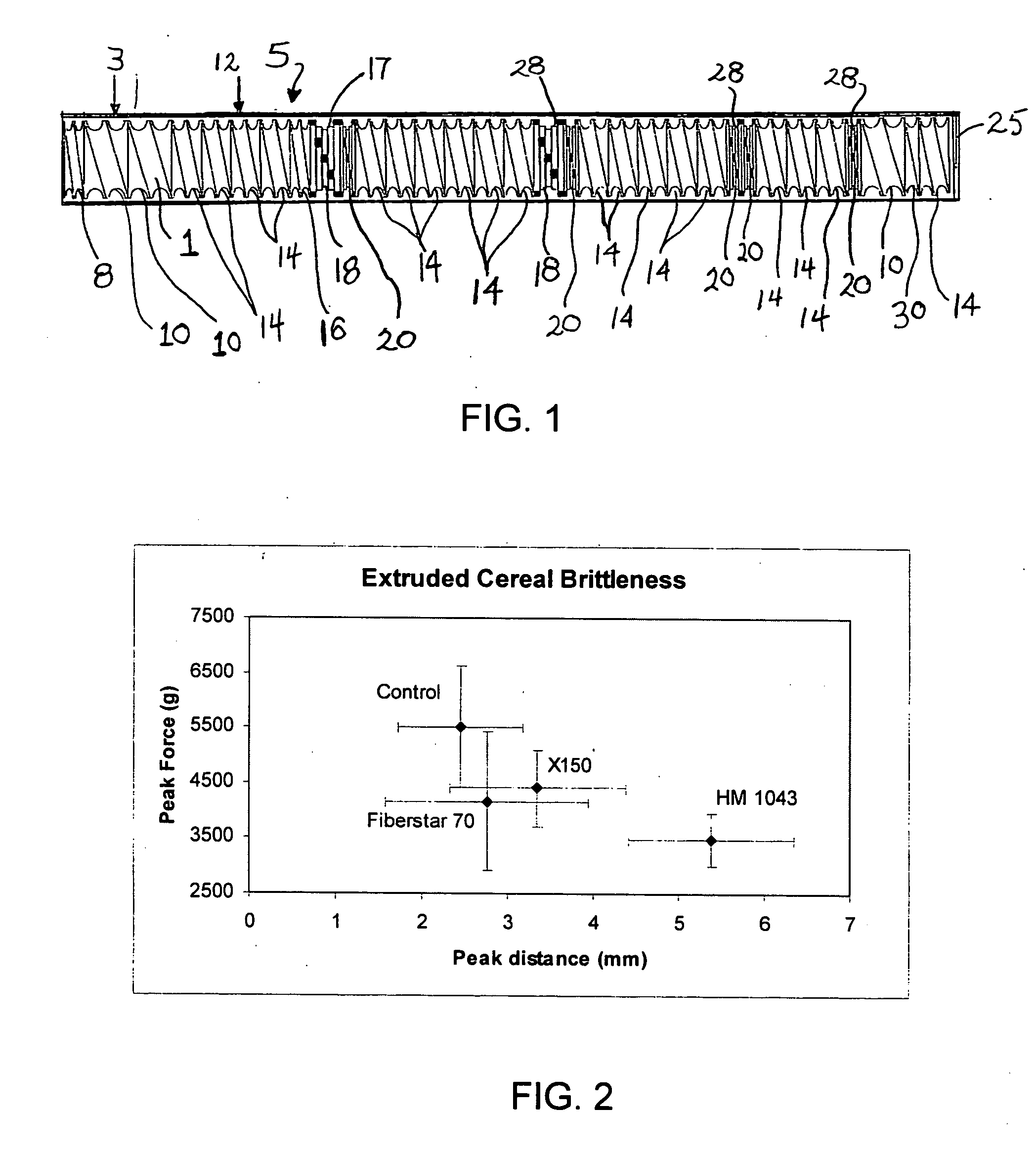

Production of low calorie, extruded, expanded foods having a high fiber content

InactiveUS20070092620A1Reduce water holding capacityBig lossDough treatmentMilk preservationReady to eatAdditive ingredient

An extruded, directly expanded, high fiber reduced calorie food product, such as a ready-to-eat (RTE) cereal or sweet or savory snack, is produced at high production rates without substantial loss of extrusion functionality and extrudability by replacing a substantial portion of at least one flour with a gelatinized, enzyme-resistant starch type III ingredient or bulking agent as a reduced-calorie, high fiber flour replacer. The resistant starch type III ingredient or bulking agent contains an enzyme-resistant starch type III having a melting point with an endothermic peak temperature of at least about 140° C., and may have a water-holding capacity of less than 3 grams water per gram of the starch-based bulking agent. The total dietary fiber retention of the gelatinized, starch-based bulking agent may be at least about 90% by weight after the extrusion using a die temperature of least about 100° C., and a die pressure of at least about 150 psig.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

High fiber rotary molded cookies containing inulin and resistant starch

High fiber cookies containing inulin are produced using rotary molding to achieve a variety of shapes while avoiding inulin lumping and excessive dough stickiness and mold release problems by replacing a substantial portion of the inulin with a resistant starch. The rotary molded cookies have a fiber content derived from the inulin and resistant starch of at least about 7% by weight, possess well-defined embossing and imprinting, exhibit at least substantial homogeneity in color and texture and are at least substantially devoid of undesirable dark spots caused by insufficient dispersion or lumping of inulin. A softer, but crisp texture, calorie reduction, shortening or fat content reduction, and sugar content reduction may also be achieved with the combination of inulin and resistant starch. The rotary molded cookies may be in the form of matching faces and bodies thereby providing play value as well as a healthier product for children.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Production method for adding brewer grain fattening pannage

ActiveCN101779749ARich varietyLow costFood processingAnimal feeding stuffAdditive ingredientCorn meal

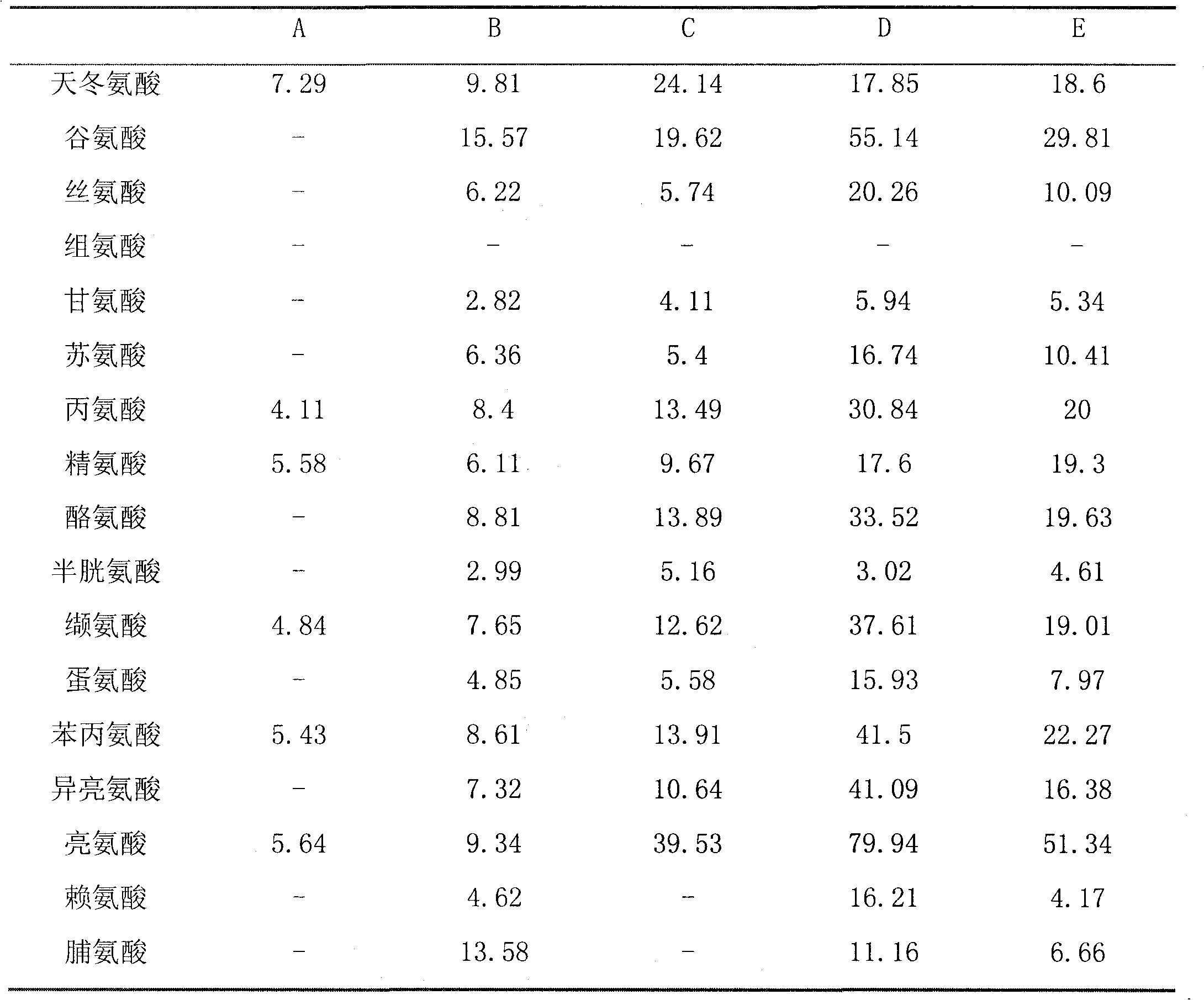

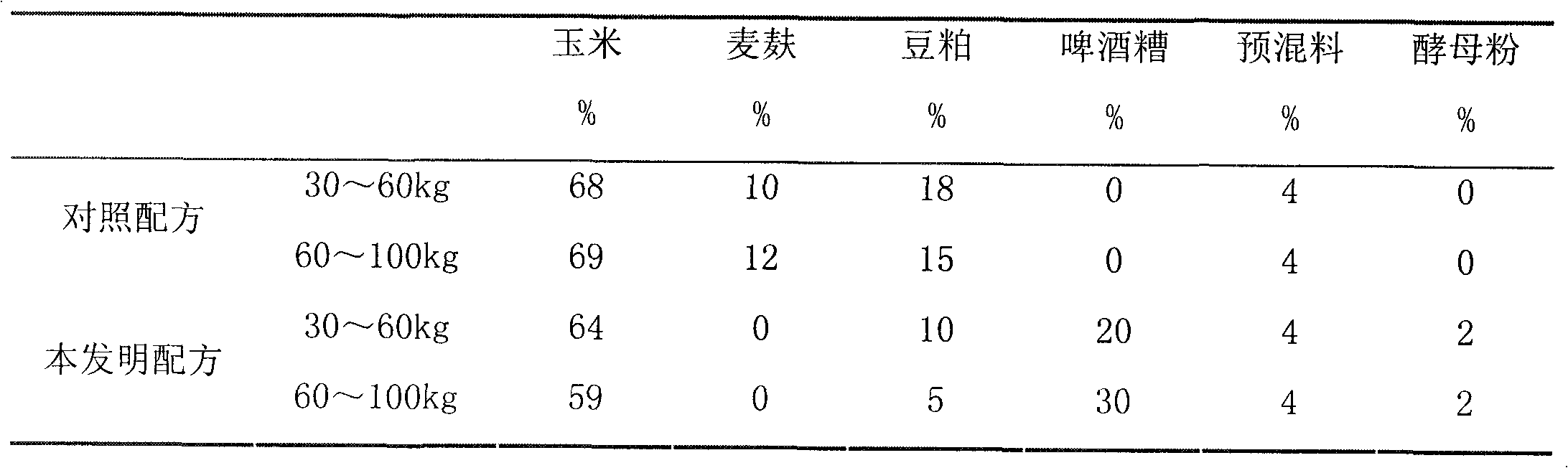

The invention belongs to a production method for adding brewer grain fattening pannage, which belongs to the technical field of the feed processing. The production method comprises the following steps that: the brewer grain is undertaken the steam explosion pretreatment and is added with mixed bacteria and / or complex enzyme to be undertaken the solid anaerobic fermentation so as to degrade the fiber content in the brewer grain and to improve the soluble nitrogen content of the brewer grain, so the quality is better, and the nutrition is more balanced; then the fermented brewer grain, waste yeast powder, corn meal, soybean meal and pre-mixed material are uniformly mixed to obtain the fattening pannage being added with brewer grain. The source of the brewer grain and the waste yeast is abundant, the nutrition for matching the brewer grain and the waste yeast is balanced, and the cost of the feed can be reduced; and the brewer grain is processed with the steam explosion pre-treatment technology, the enzymolysis technology and the biological fermentation technology, so the fiber content is reduced, the protein quality is improved, and the type of the aminoacid is more abundant; and the production method can reduce the grain ratio, improves the daily gain, reduces the feed compositions, and is free from influencing the feed intake and the growth of the fatty pigs.

Owner:BEIJING YANJING BREWERY

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

Fermented beverage of full cereal grains

The invention relates to fermented beverage of full cereal grains. The fermented beverage of full cereal grains is composed of the following ingredients by mass percent: 50-90% of fermentation broth of cereal grains, 8-14% of sucrose, 0.05-0.2% of citric acid, 0.05-0.1% of malic acid and the balance of pure water. The fermented beverage is prepared by mixing the ingredients, fine filtering the ingredients, homogenizing at the pressure of 18-25 Mpa, performing ultrahigh-temperature instant sterilization for 2-6 seconds at 135-137 DEG C, cooling to 80-85 DEG C and sterilely filling. The preparation process of the fermentation broth of cereal grains comprises the following steps of: adding alpha amylase in adjusted cereal grain pulp to perform enzymolysis at 50-65 DEG C, and inoculating specially domesticated lactic acid bacteria culture solution or powder to naturally ferment the zymolytic cereal grain pulp within 35-45 DEG C to obtain the fermentation broth of cereal grains. According to the invention, the development bottle neck of utilizing the cereal grains as food processing raw materials is solved through modern enzyme engineering and fermentation technology; and prebiotics are added in the beverage, and the dietary fiber content is within the range of 0.6-1.3mg / 100ml.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

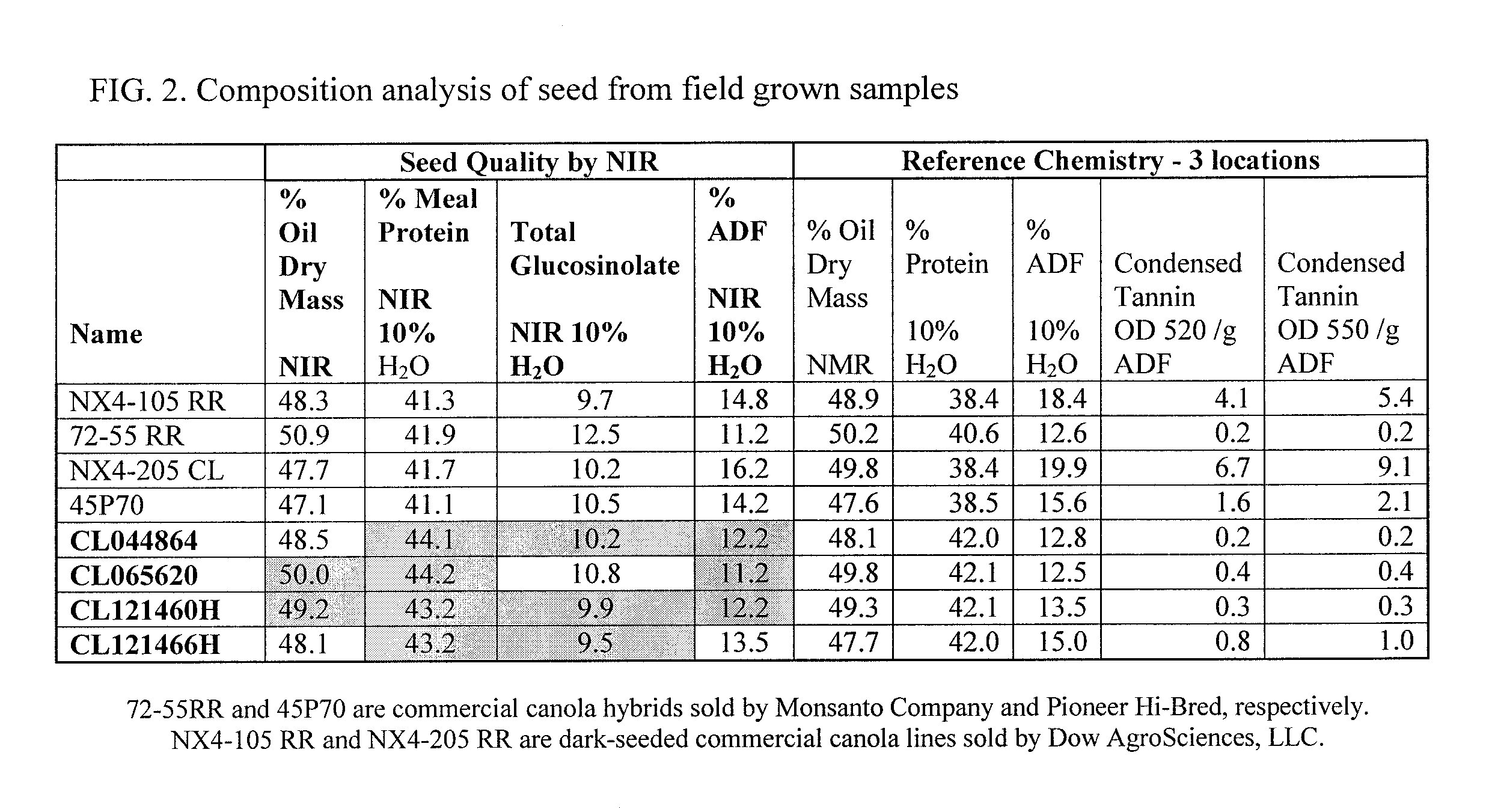

Canola Germplasm Exhibiting Seed Compositional Attributes That Deliver Enhanced Canola Meal Nutritional Value

ActiveUS20120216307A1High nutritional valueIncrease heightFood processingAnimal feeding stuffGermplasmPolyphenol

The present invention concerns a canola germplasm comprising at least 45% crude protein and not more than 18% acid detergent fiber content on an oil-free, dry matter basis. Certain embodiments further comprise one or more traits selected from the group consisting of reduced polyphenolic content and increased phosphorous content. In particular embodiments, the invention concerns canola plants comprising such germplasm and plant commodity products (e.g., seeds) produced therefrom. Canola plants comprising a germplasm of the invention may exhibit favorable seed composition characteristics that make them particularly valuable as a source for canola meal, and for methods of introducing at least one trait selected from the group consisting of high protein content, low fiber content, reduced polyphenolic content and increased phosphorous contentinto a canola variety in a seed coat color-independent manner.

Owner:AGRI GENETICS

Method for preparing dietary fiber from bean dregs serving as raw material by combining steam explosion and enzymolysis

The invention discloses a method for preparing dietary fiber from bean dregs serving as a raw material by combining steam explosion and enzymolysis. In the method, a pure natural and fully water-soluble dietary fiber product is obtained through pretreatment of the bean dregs, steam explosion, ultrafine grinding, enzymolysis and drying of enzymolysis slurry. In the method, conversion rate of the soluble dietary fiber can be quickly and effectively increased by performing the steam explosion before the enzymolysis. Other chemical substances are not required to be added due to the adoption of the steam explosion, and the product is the pure natural dietary fiber. Cellulase, pectinase or xylanase can be separately used as an enzyme used in the method. Compared with a method for producing the fully water-soluble dietary fiber, the method for producing the mixed dietary fiber with high water-soluble dietary fiber content has the advantages of reduced investment, low production cost and capability of solving the problem of pollution of three wastes (waste water, waste gas and industrial residues).

Owner:GUANGXI UNIV

Fine-denier Modal fiber blended color yarn and its production method

The fine-dentier modal fiber mixed-color spinning yarn comprises two or more fibers with different color special with 40-100% fine-dentier modal fiber that has bright and variable color, soft hand feeling, and well warmth retention property. Compared with prior art, this invention needs no special device, solves the color-float and other problems and special the reduction of high tenacity.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

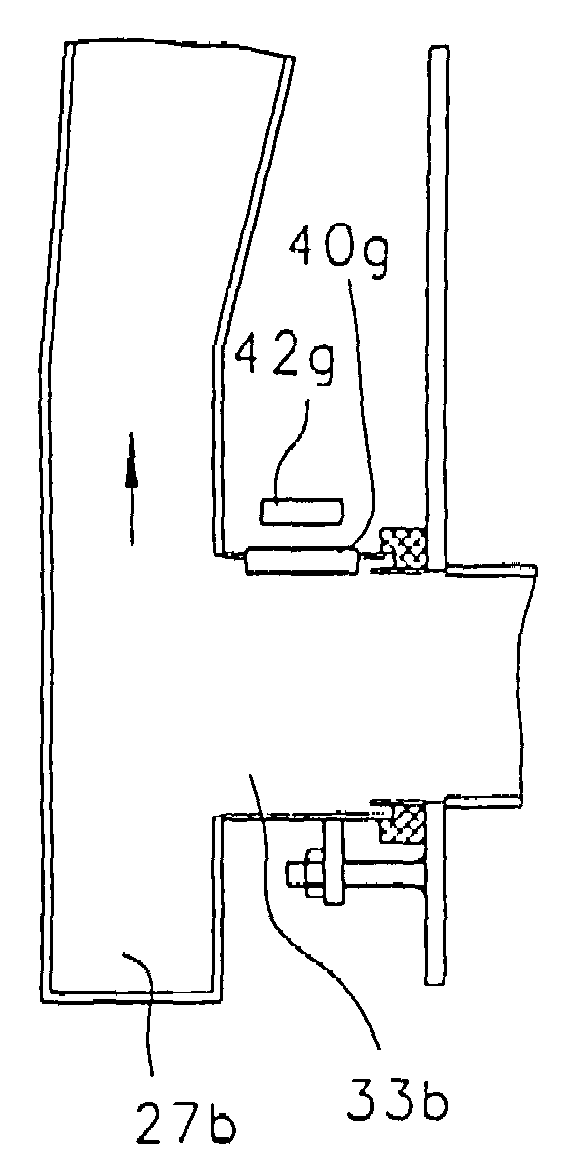

Apparatus at a spinning preparation machine for detecting waste separated out from fibre material

InactiveUS7173207B2Automatic detectionEasy to adjustSafety devices for fibre treatmentCarding machinesForeign matterEngineering

In an apparatus at a spinning preparation machine, for example a cleaner, opener, carding machine or the like, for detecting waste which is separated out from fibre material, for example cotton, and consists of foreign matter and good fibres and which is collected in a collecting device, there is provided an optical measuring device having a brightness sensor, which measuring device examines the waste.In order to make it possible, by simple means, for the content of good fibres in the waste to be detected and to allow optimum adjustment of the composition of the waste, especially with a high content of trash and low content of good fibres, the waste material is moved past at least one sensor arrangement responding to good fibres, and the sensor arrangement comprises a light source, the light reflected by the moving good fibres being detected by the brightness sensor and being converted into electrical signals, from which the good fibre content can be determined.

Owner:TRUETZSCHLER GMBH & CO KG

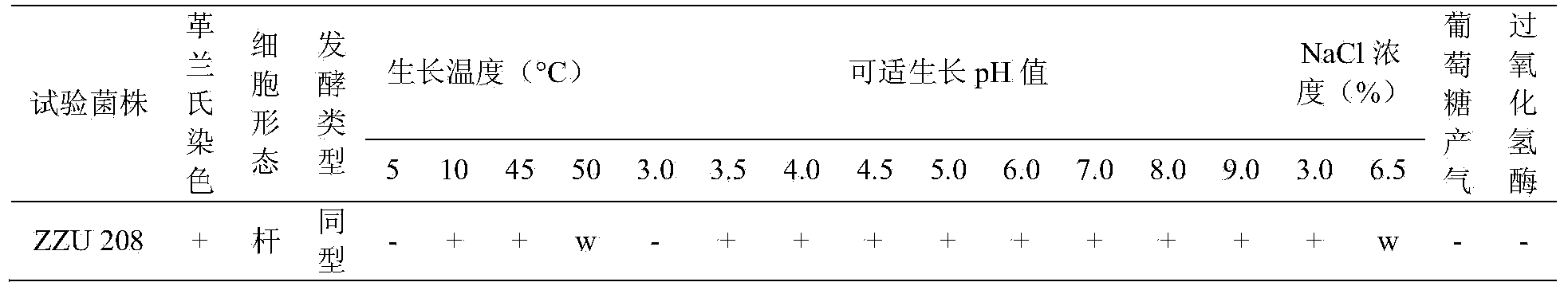

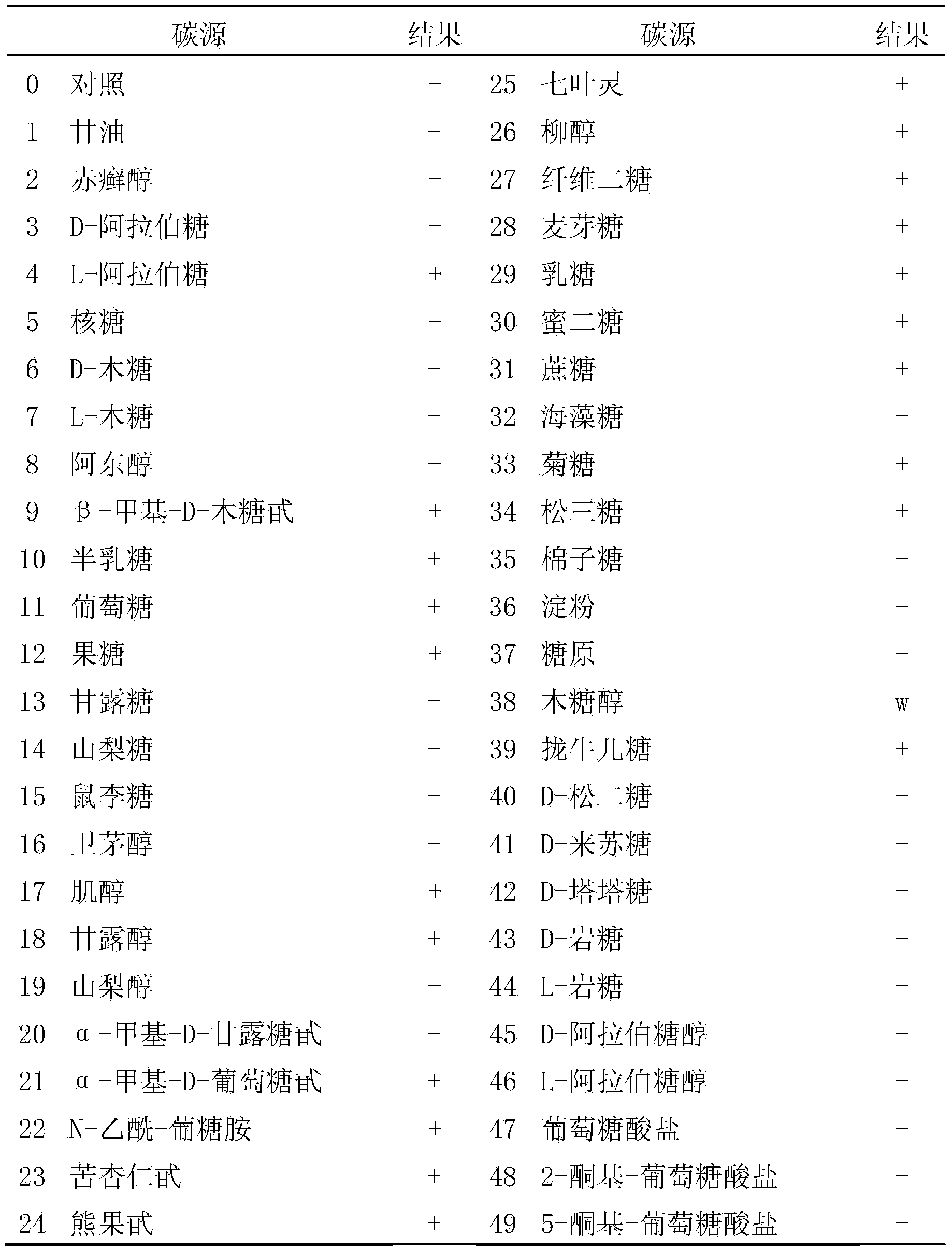

Lactobacillus plantarum and application thereof to alfalfa silage

ActiveCN104336416AHigh antibacterial activityLower pHBacteriaMicroorganism based processesMicrobiologySugar

The invention discloses lactobacillus plantarum and application thereof to alfalfa silage. The invention provides application of lactobacillus plantarum ZZU 208 CGMCC No.8990 or a fermentation product thereof or a bacterium suspension thereof or a culture solution thereof as an alfalfa silage additive or to preparation of the alfalfa silage additive. As proved by experiments, lactobacillus ZZU 208 which is separated from a corn silage fodder and is purified can grow and produce acid in an environment of low soluble sugar content, and has high bacteriostatic activity to pathogenic bacterium. In the alfalfa silage, the pH can be effectively lowered, the fiber content is lowered, and crude fat and crude protein content are increased; the lactobacillus plantarum has a potential application value on the aspect of silage additives.

Owner:ZHENGZHOU UNIV +1

Composite materials

ActiveUS20120114899A1High in fiberEliminate the problemFinal product manufactureBaby linensTurbine bladeWork in process

A curable prepreg or semipreg material comprising a layer of fibres and a substantially non-flowable curable resin having a layer of porous sheet material on an outer surface, the material allows automatic lay-up of high fibre content prepregs or semiprepregs typically used in industrial applications such as wind turbine blades.

Owner:HEXCEL COMPOSITES LTD (GB)

Preparation method of biological feed of banana stem leaves

InactiveCN101579041AHas a clear fragranceLower pHFood processingAnimal feeding stuffBiotechnologyFully developed

The invention discloses a preparation method of a biological feed of banana stem leaves, which comprises the following steps of: cutting up the banana stem leaves, then pre-drying till the water content is 70 to 75 percent, adding minor ingredients into the banana stem leaves, then adding cellulase, tannase and third class seed liquid of lactobacillus plantarum, mixing evenly, extracting air, sealing, storing and preparing to obtain the biological feed of banana stem leaves; and the minor ingredients are pineapple peels, papaya peels or molasses. The preparation method uses the banana stem leaves as major raw materials, generates an acid environment by fermentation of lactobacillus to inhibit spoilage micro-organisms, and can fully develop and utilize by products of fruits, reduce tannin content and coarse fibre content of the by product of banana and improve the palatability, digestibility and nutritional value of the feed.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI +1

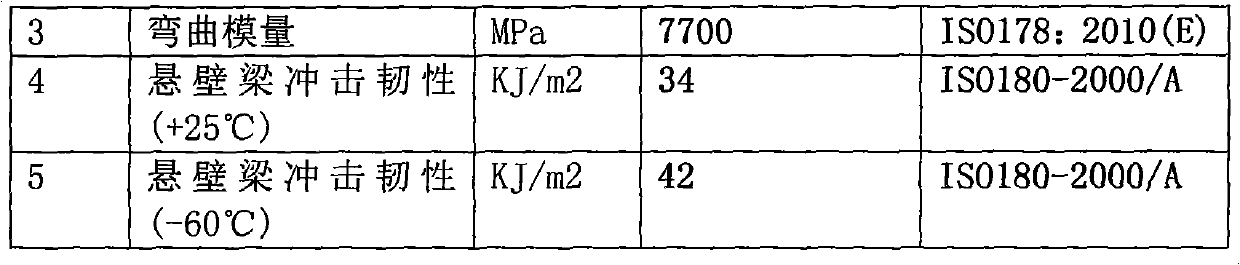

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

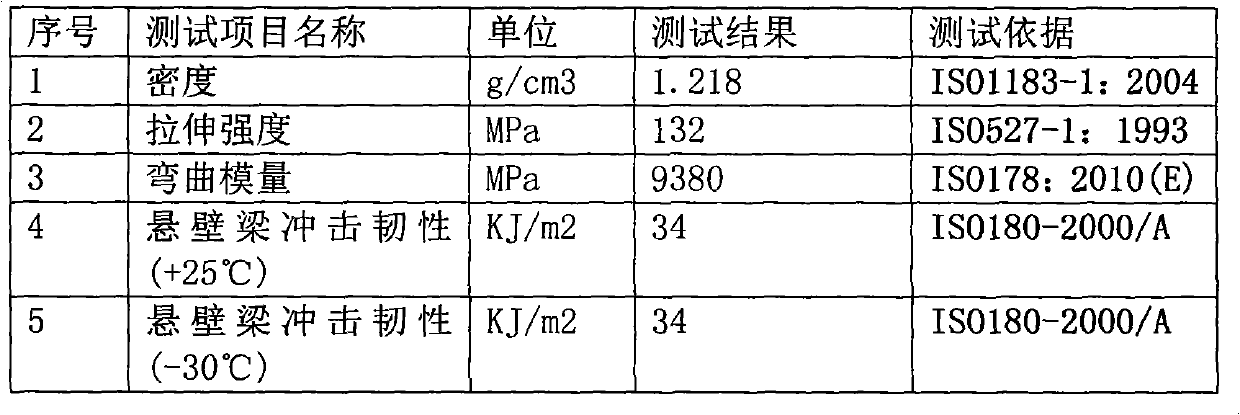

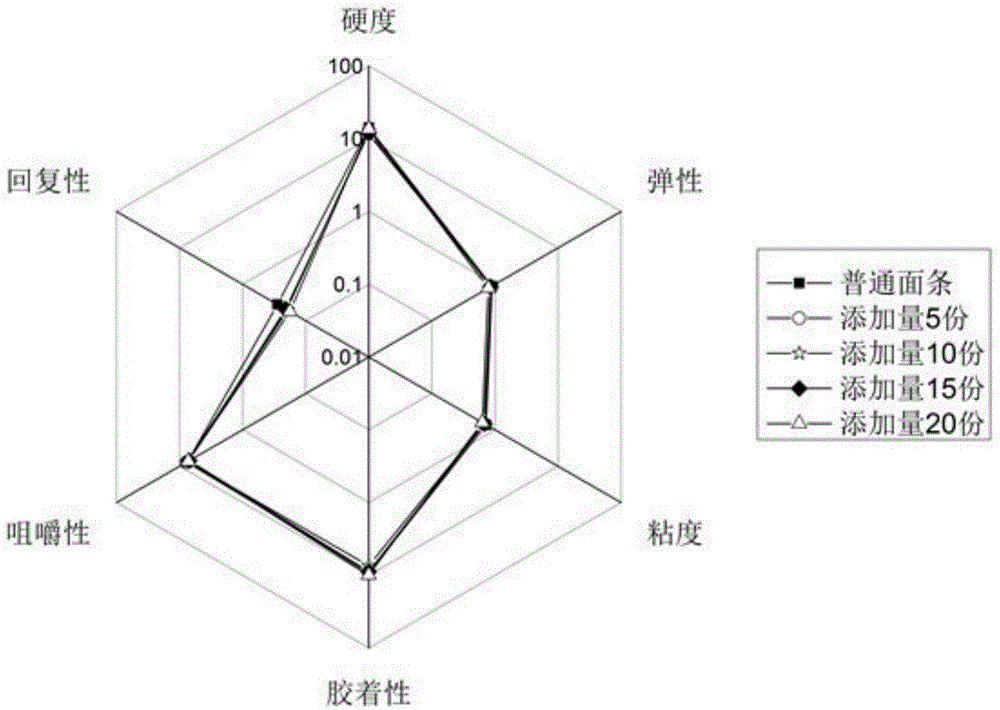

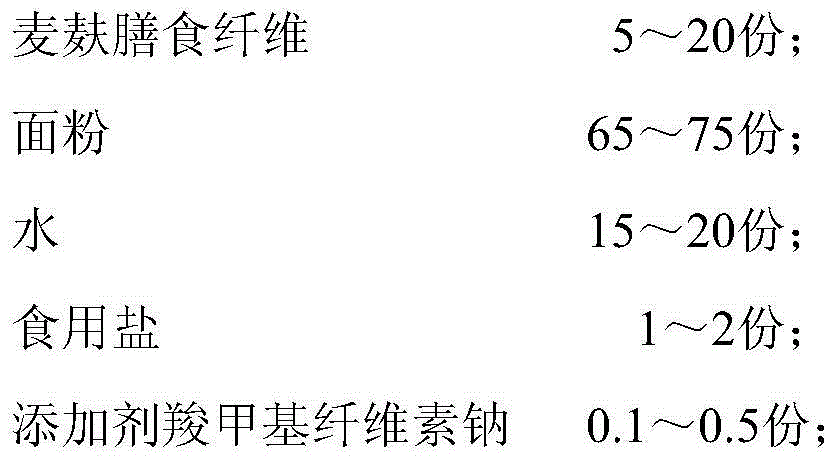

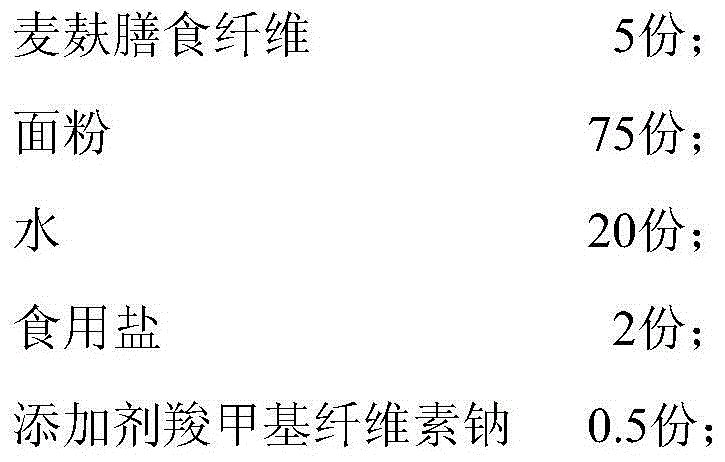

High dietary fiber noodles and method for preparing high dietary fiber noodles by fully utilizing wheat bran and wheat middling

ActiveCN104431771ANo significant difference in viscosityThere was no significant difference in adhesivenessFood ingredientsFood preparationSodium carboxymethylcelluloseWater soluble

The invention relates to high dietary fiber noodles and a method for preparing the high dietary fiber noodles by fully utilizing wheat bran and wheat middling. The high dietary fiber noodles comprise the following ingredients in parts by weight: 5-20 parts of wheat bran dietary fiber, 65-75 parts of flour, 15-20 parts of water, 1-2 parts of table salt and 0.1-0.5 part of an additive, namely sodium carboxymethylcellulose. The high dietary fiber noodles have no obvious differences in textures and properties as compared with the ordinary noodles without added dietary fiber, and is excellent in taste; by adopting the method, the problem about the full utilization of wheat by-product bran and wheat middling is effectively solved, the additional value of wheat bran and wheat middling is improved, and the problems that wheat bran is low in content of water-soluble dietary fiber, low in processing adaptability, great in influences on the textures of flour products and the like are solved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Secondary fermentation and production method of rehydration flexible package dried bamboo shoot

InactiveCN101803713ASolve the poor flavor of lactic acidSolve the problem of high crude fiber contentFood preparationAcid waterLiquid ratio

The invention discloses a secondary fermentation and production method of rehydration flexible package dried bamboo shoot, relating to the production method of dried bamboo shoot. The secondary fermentation and production method comprises the following working procedures for the dried bamboo shoot: adsorbing water, softening, slitting, boiling with water for swelling, rinsing to remove acid water, and packaging the bamboo product in vacuum. The secondary fermentation and production method is characterized in that: 1) secondary fermentation is carried out after rinsing to remove acid water, Lactobacillus acidophilus is added into the flaky and strip bamboo body processed in the previous working procedure for secondary pure breed fermentation at the fermentation inoculum size amount of 1.2-1.8%, lactic acid bacteria density of 2.9-3.5%, solid-to-liquid ratio of 2-4 and fermentation time of 13-18%; meanwhile, the pH value of the fermented bamboo body is controlled to be 3.7-4.6; and 2) the working procedure of rinsing is carried out after secondary fermentation, and the working procedure of packaging in vacuum is carried out. The invention has the advantages of solving the technical problems of poor lactic acid bacteria flavour, high coarse fibre content, low tenderness and the like caused by the method of once fermentation. The bamboo acidity is controlled to be that the pH is 3.7-4.6, coarse fibre content is controlled to be within 3.5%, and the tenderness, the tough-brittle taste and the chewing taste of the bamboo body can be improved.

Owner:福建建宁孟宗笋业有限公司

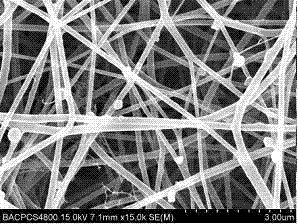

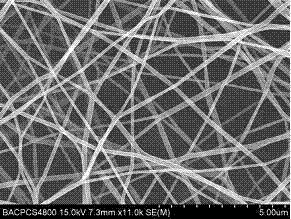

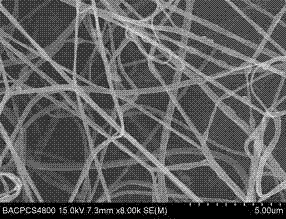

Preparation method of nano bamboo fiber composite material

InactiveCN103173892AImprove solubilitySystem stabilityArtificial filaments from cellulose solutionsConjugated cellulose/protein artificial filamentsElectrospinningSlurry

The invention discloses a preparation method of a nano bamboo fiber composite material. The method comprises the following steps of: respectively preparing bamboo slurry and a polymer solution; then mixing the bamboo slurry and the polymer solution according to a certain proportion so as to obtain blend spinning liquid with different bamboo fiber content; and successfully preparing the nano bamboo fiber composite material from the blend spinning liquid by an electrostatic spinning technology. By the method, bamboo fibers can be prepared by the electrostatic spinning technology; the diameter of composite nano fiber obtained by the method is 50-250 nm; the bamboo fibers account for 0.1-99.9 percent of composite fibers; polymers account for 99.9-0.1 percent of the composite fibers; the nano bamboo fiber composite material is attractive in appearance and uniform in thickness; the preparation method is simple; raw materials are readily available and low in cost; and the method is favorable for electrostatic spinning industrialization and has wide application prospect.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

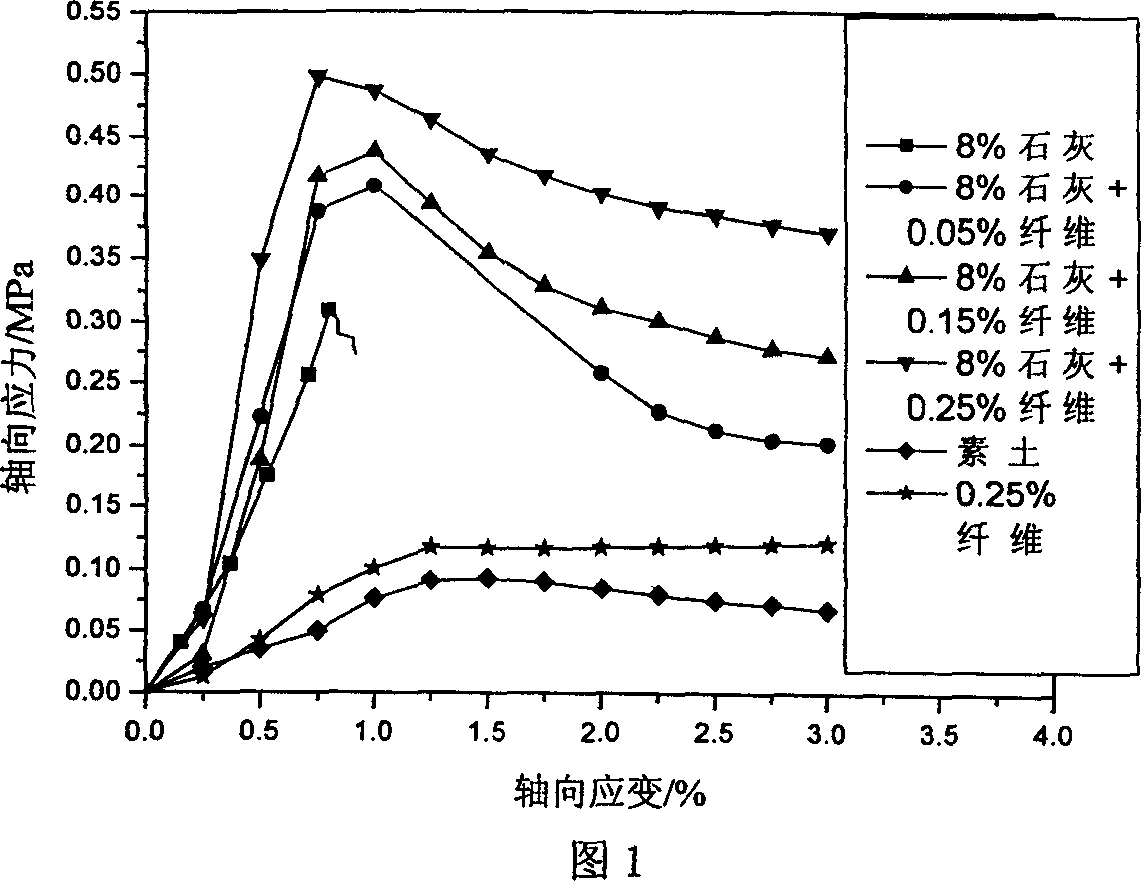

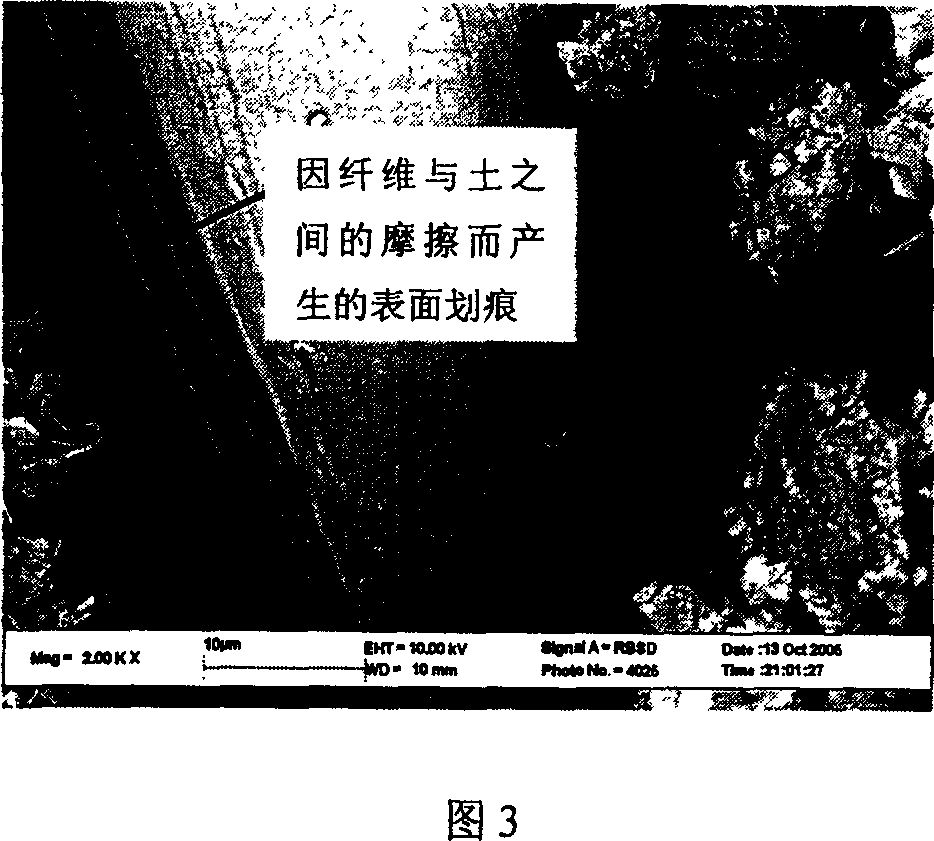

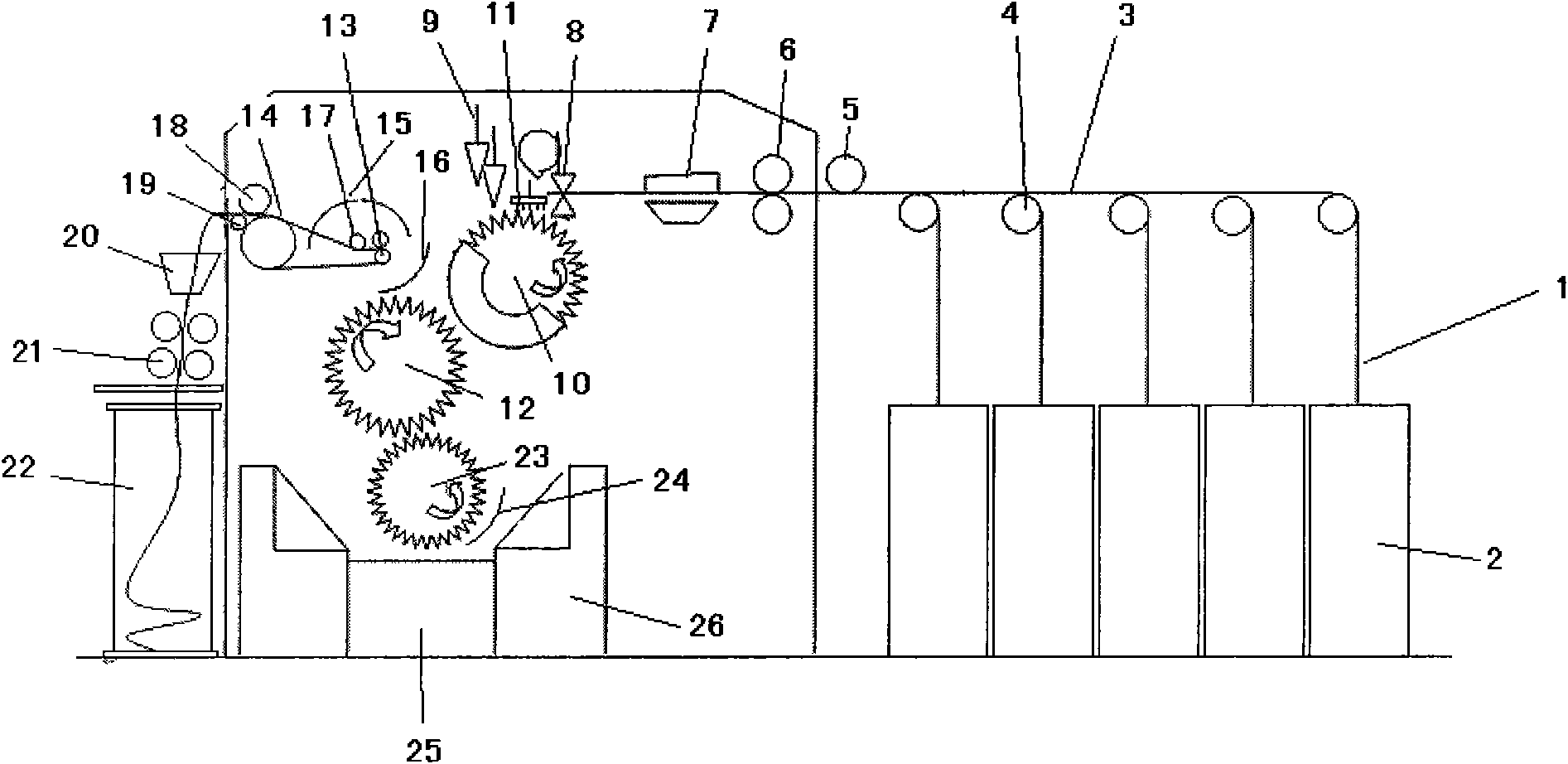

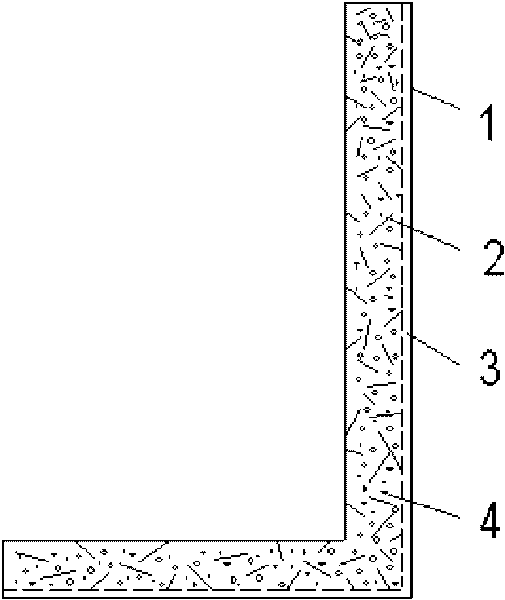

Chopped fiber reinforced rendzinas ground treatment method

InactiveCN1932167ASmall expansion and contractionReduce dosageSoil preservationDry soilMaterials science

The present invention relates to a short fibre reinforced lime soil ground base treatment method. It is characterized by that it makes the short fibre and lime be mixed in the engineering soil so as to improve the engineering property of soil, and can be used for making ground base treatment. The fibre content is 0.05-0.5% of dried soil weight and the lime content is 1-10% of dried soil weight, the fibre length is 2mm-30mm. Said soil in which the short fibre and lime are mixed is undergone the processes of stirring, stacking and rolling so as to form the invented short fibre reinforced lime soil ground base.

Owner:NANJING UNIV

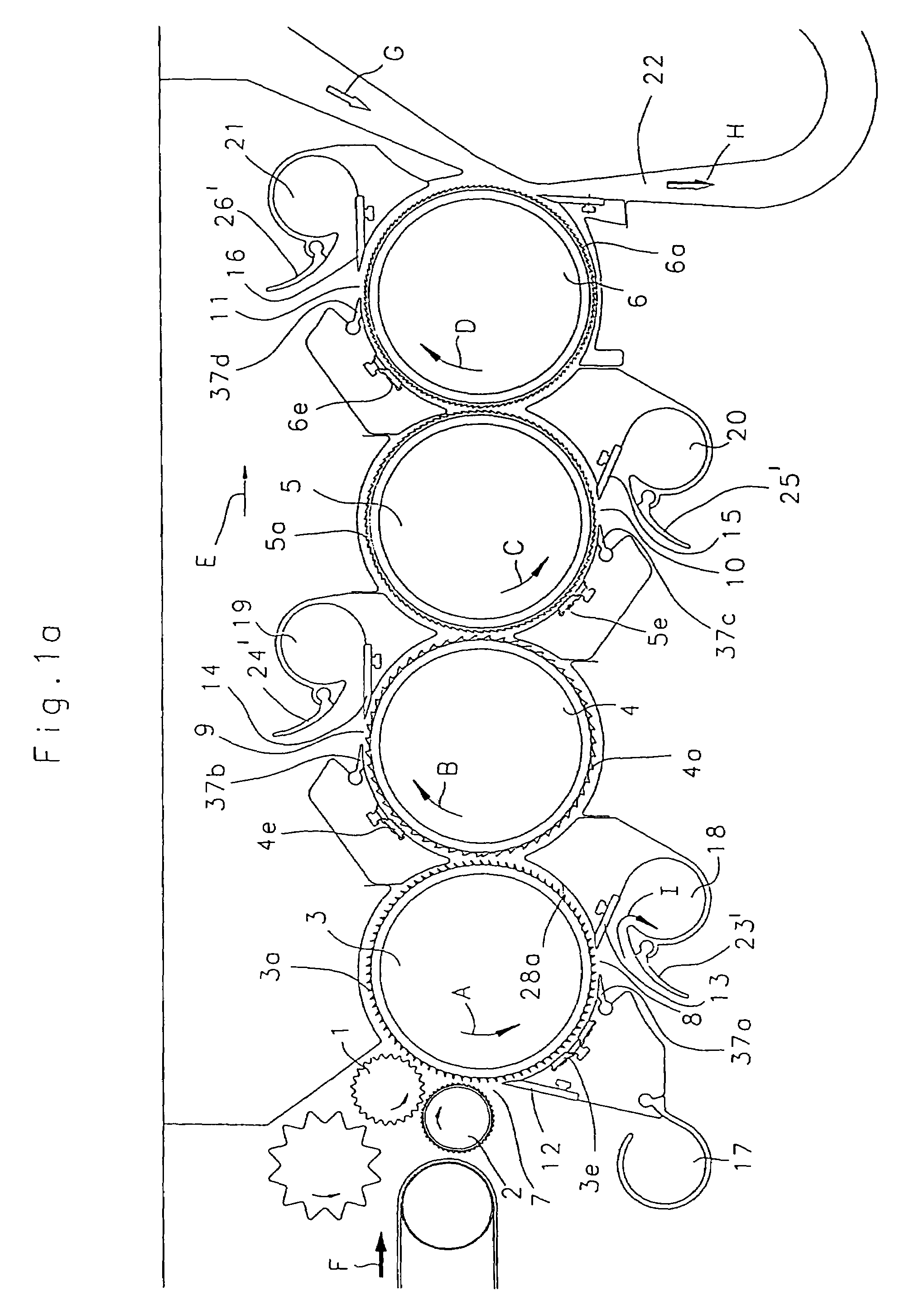

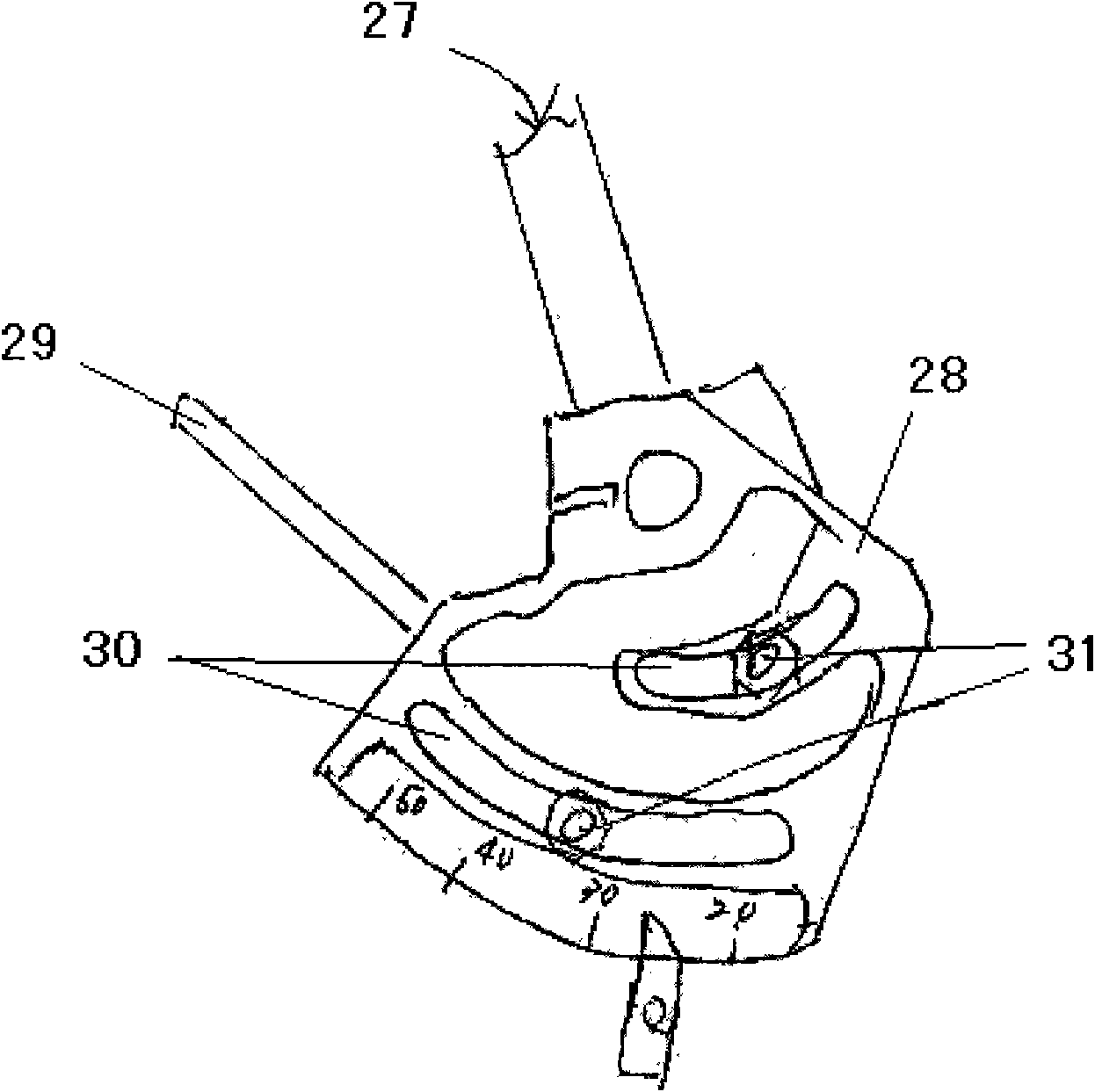

Sesaron combing and sorting method and device

ActiveCN101824676AEfficient removalIncrease the degree of splittingSafety devices for fibre treatmentCombing machinesCombingEngineering

The invention relates to a sesaron combing and sorting method and a device; combed ramie stripes with different specifications and lengths are obtained through a plurality of layers of combing; the split degree of the ramie stripes is decided by comb needle models used in all the layers of combing; and the lengths of the ramie stripes are changed by adjusting a pulling vehicle. In a combing and sorting mechanism of the device, circular comb needle strips are lined in a circumference of 0 to 270 degrees respectively through a rack method and a rack and needle row combined method, and top combs are in a single row or a plurality of rows. A pulling separation mechanism comprises the pulling vehicle, the pulling vehicle is arranged on a regulation frame, the regulation frame is provided with a rod and a circular arc-shaped chute, a bolt is inserted into the circular arc-shaped chute, the bolt is fastened on a frame, the bolt is loosened, and the regulation frame can slide along the circular arc-shaped chute by triggering the rod. At least two pairs of curl rollers are arranged in a strip discharge mechanism. The ramie stripe fibers processed by the method and the device are even and uniform, have short fiber rate, uniform fiber length and low ultra-long length fiber content, so that the fibers are more parallel and straighter, the operation is convenient, the efficiency is high, and the labor intensity is low.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

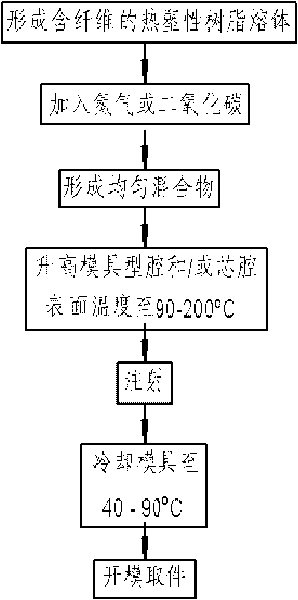

Fiber reinforcement injection molding product and injection molding method thereof

ActiveCN101712789AHigh strengthGood dimensional stabilityBulk chemical productionCarbon dioxidePlasticizer

The invention relates to an injection molding product, in particular to a thermoplastic resin thin-wall product which has fiber content ranging from 10% to 30% and the injection molding method thereof. The product of the invention has a wall thickness ranging from 1.5mm to 2.5mm, and one or more than one surface of the product is provided with a layer of resin surface layer free from fiber, which has a thickness ranging from 5 mu to 15 mu; the product is composed of thermoplastic resin, thermoplastic fiber and nitrogen or carbon dioxide and the raw materials are calculated according to proportion by weight, wherein the content of the thermoplastic resin ranges from 69.95% to 89.95%, the content of the fiber ranges from 10% to 30%, the rest is nitrogen or carbon dioxide. The product and the method of the invention have the advantages of adopting supercritical nitrogen or carbon dioxide as plasticizer, further improving flowability by raising the surface temperature of the tool cavity before injection and obtaining lighter and thinner product by cooling the surface temperature of the tool cavity to relatively low temperature after the completion of injection; in addition, the product features fine apparent mass, high strength and high dimensional stability.

Owner:BEIJING CHN TOP MACHINERY

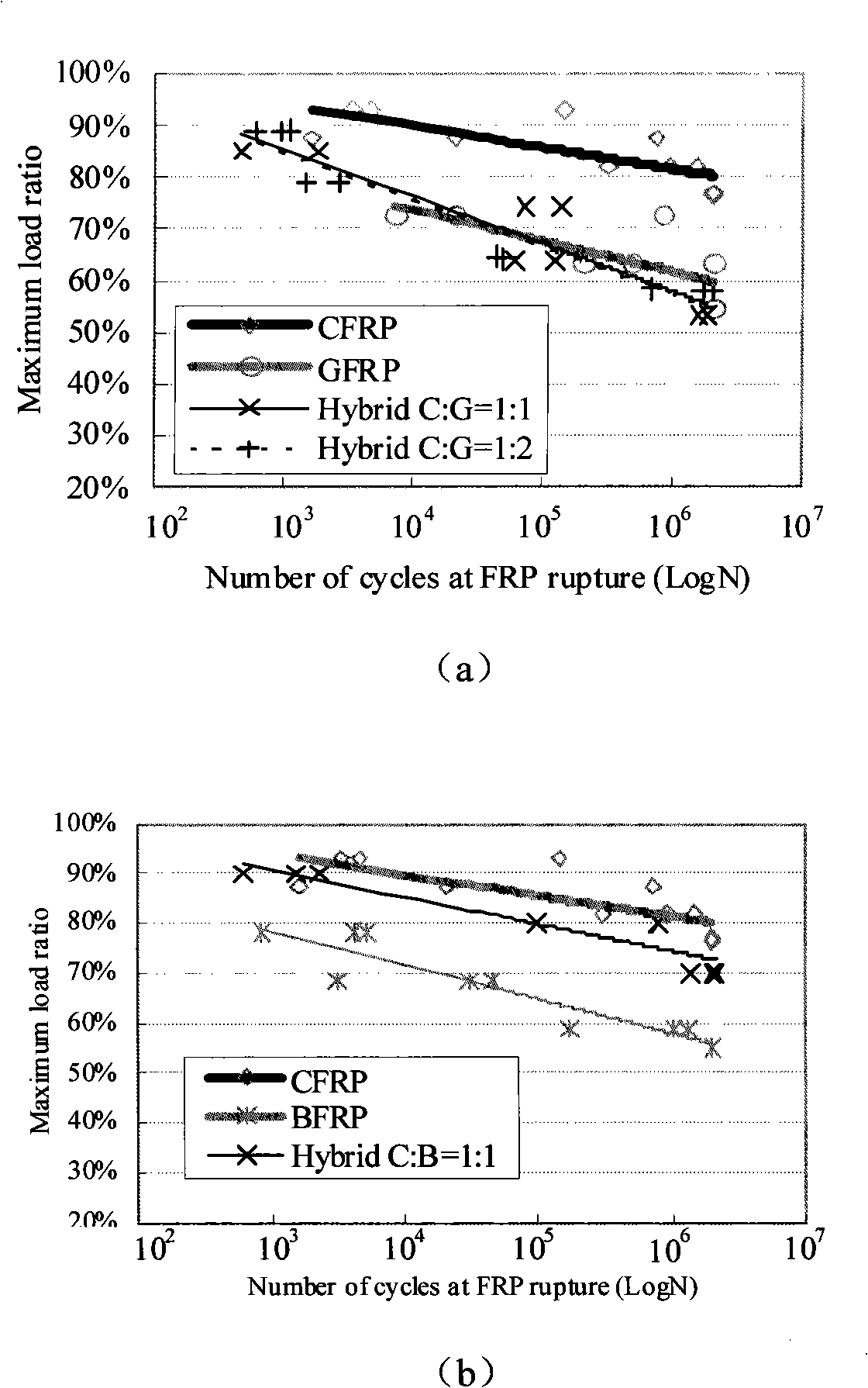

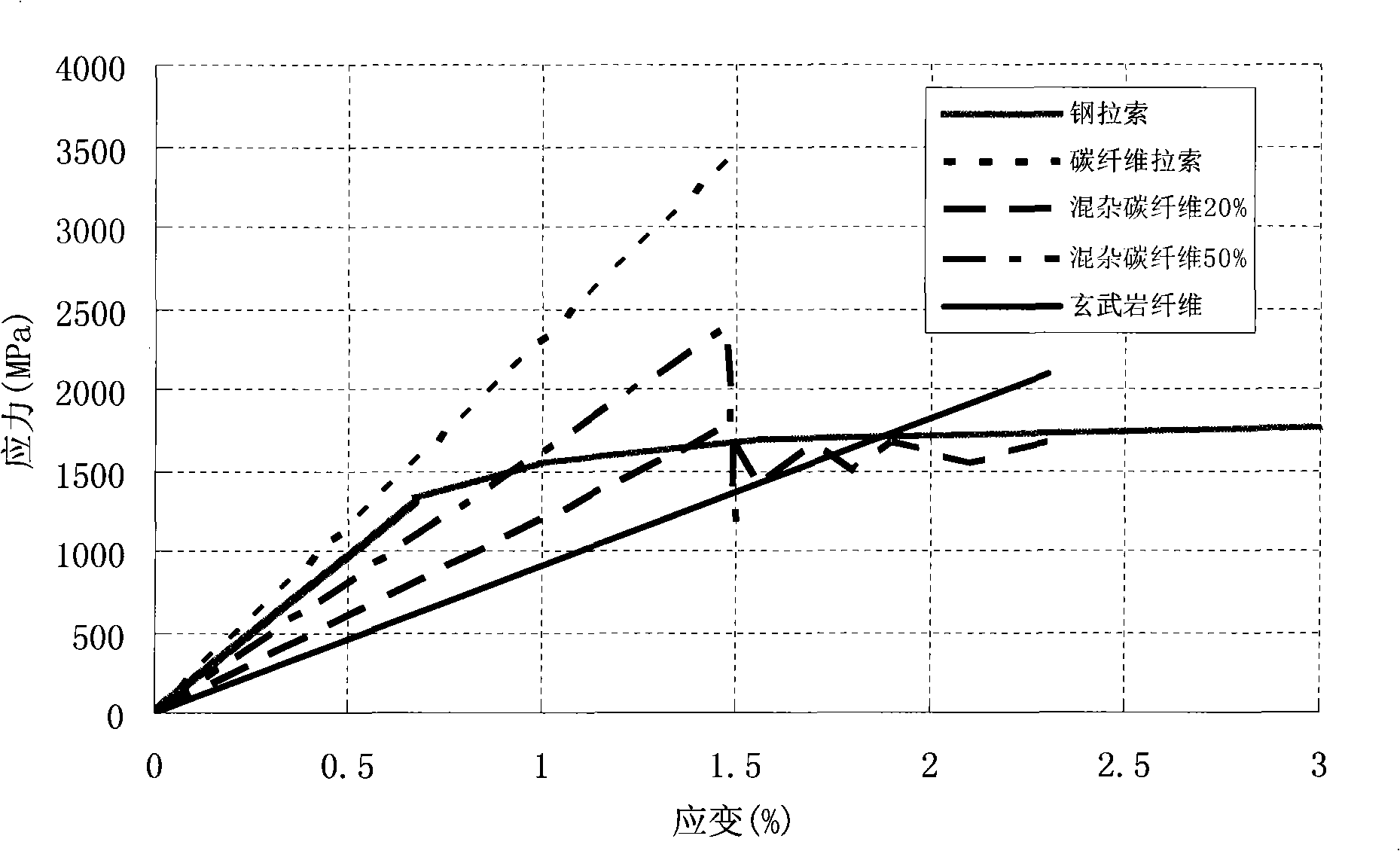

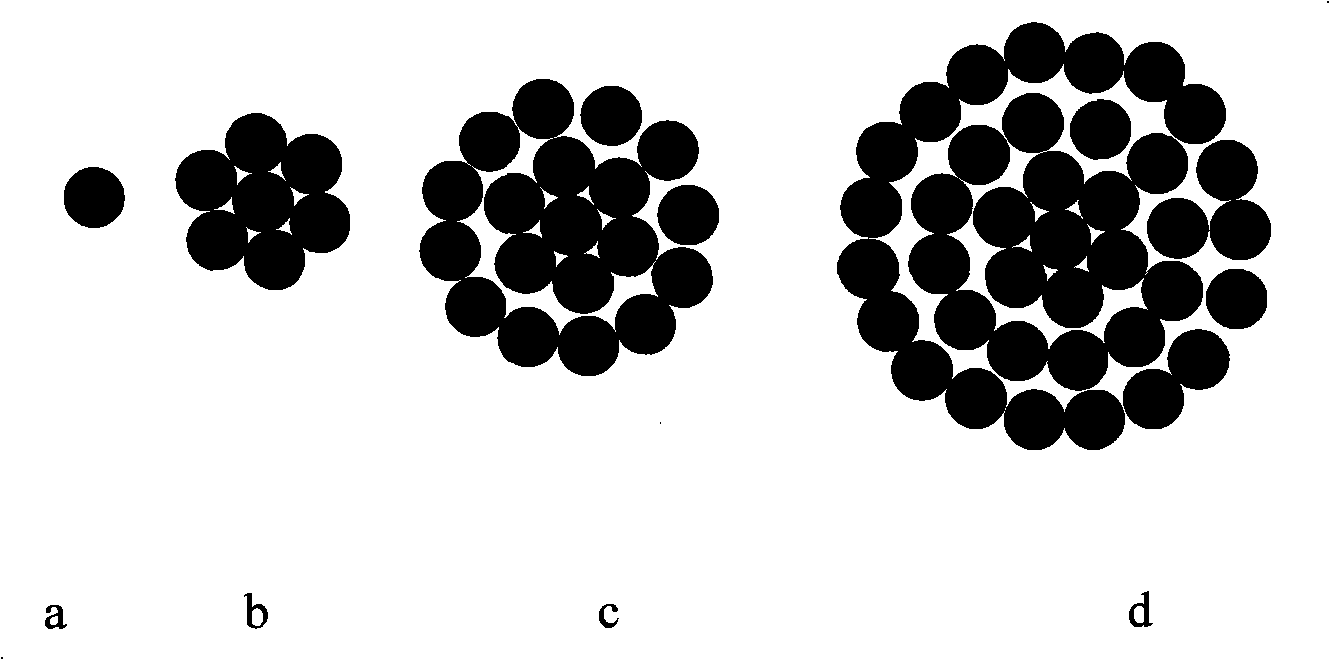

Basalt fibre composite rib and basalt fibre composite inhaul cable

ActiveCN101525864ASmall sag effectImprove air stabilityBridge structural detailsCarbon fibersBasalt fiber

The invention discloses a basalt fibre composite rib and a basalt fibre composite inhaul cable. The composite rib is formed by drawing, extruding, molding and compounding basalt fibre and carbon fibre under the pretension action, and fibre volume ratio is 4:1-1:1; the basalt fibre composite inhaul cable comprises an outer protecting layer and fibre reinforcement material arranged in the outer protecting layer, the fibre reinforcement material comprises a center rib and an outer rib, the center rib is composed of a basalt fibre rib or carbon fibre rib, the outer rib is composed of the basalt fibre composite rib, an adhesive elastic filling layer and an inner sleeve are arranged between the center rib and the outer rib, the inner side of the inner sleeve is connected with the adhesive elastic filling layer, and the outer side of the inner sleeve is connected with the outer rib. In the composite inhaul cable, the carbon fibre content occupies 25-40 percent of total fibre content of the inhaul cable. Compared with the prior art, the composite carbon fibre of the basalt fibre composite inhaul cable in the basalt fibre enables short-period and long-period mechanical property and chemical property of the inhaul integer to be better, and has remarkable economy.

Owner:SOUTHEAST UNIV +2

High protein, low carbohydrate pasta

The present invention provides high protein, low carbohydrate pastas that are also low in fiber. Specifically, a pasta comprising, by weight, at least about 55% protein, about 10% or less fiber, and at least about 4% fat is provided. The pastas also comprise less than about 30% total carbohydrate by weight. The pastas provided herein include a rapid-cook pasta, a rice substitute, a gluten-free pasta, and a soy-milk based pasta. The present invention further provides a pasta having at least about 55% protein, by weight, and having a firmness value that does not differ by more than 40% from that of 100% durum semolina wheat pasta. Also, the present invention provides food compositions from which the pastas are made. Further provided are farinaceous food products, including, but not limited to, pastas, made from the food compositions provided herein.

Owner:KERRY GRP SERVICES INT

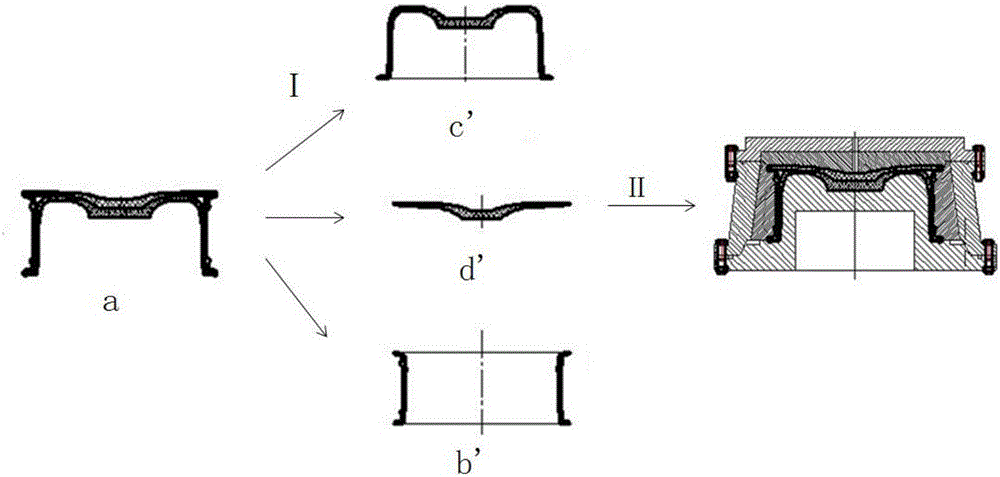

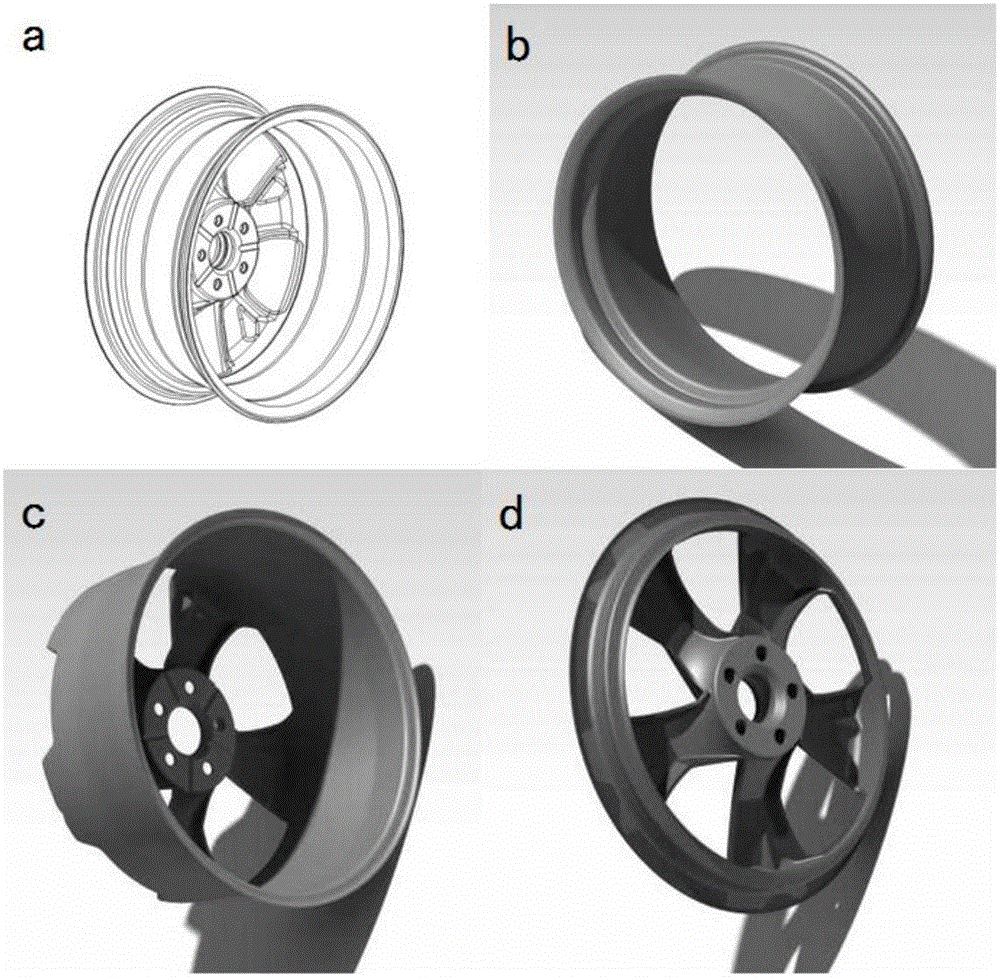

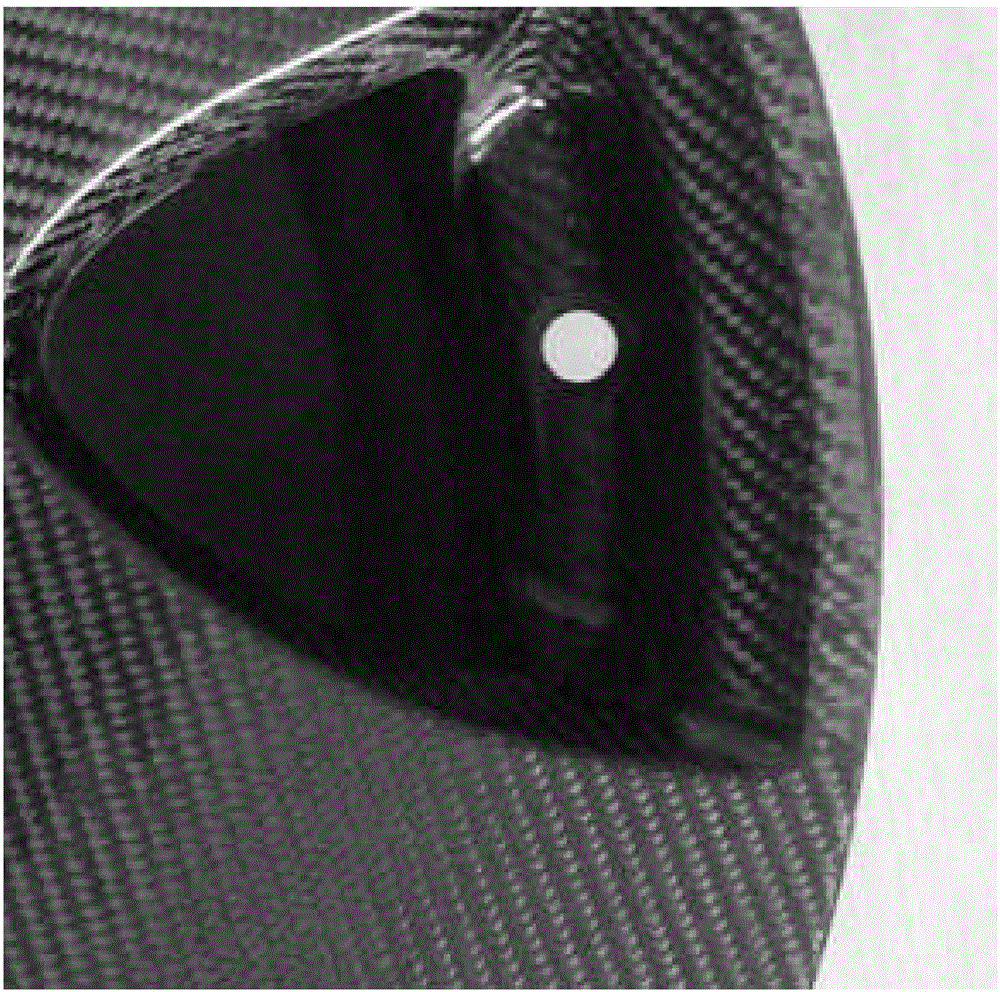

Manufacturing method for composite hub

The invention relates to a manufacturing method for a composite hub. The manufacturing method comprises the following steps that a reinforced fiber perform is manufactured in advance; a sealed die cavity is filled with the reinforced fiber perform, and then is vacuumized; a resin system is injected in the die cavity with compressed air; and the composite hub is obtained after curing. The resin system is injected in a die with the compressed air, and pressure is maintained for a certain time after injection is completed, so that the acceptable volume content of a reinforced material is increased, the purpose that the volume content of the reinforced material is controllable is achieved, and the mechanical strength of the hub is controlled and improved. The composite hub, manufacturing according to the manufacturing method, is extremely low in void ratio and high in fiber content, fibers are uniformly distributed in a composite material structure, without folds, and since the perform is manufactured in a blocked manner, a complex product is split into simple components, the production efficiency is high, and the quality is controllable and stable.

Owner:HARBIN FRP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com