Patents

Literature

37results about How to "Low temperature impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

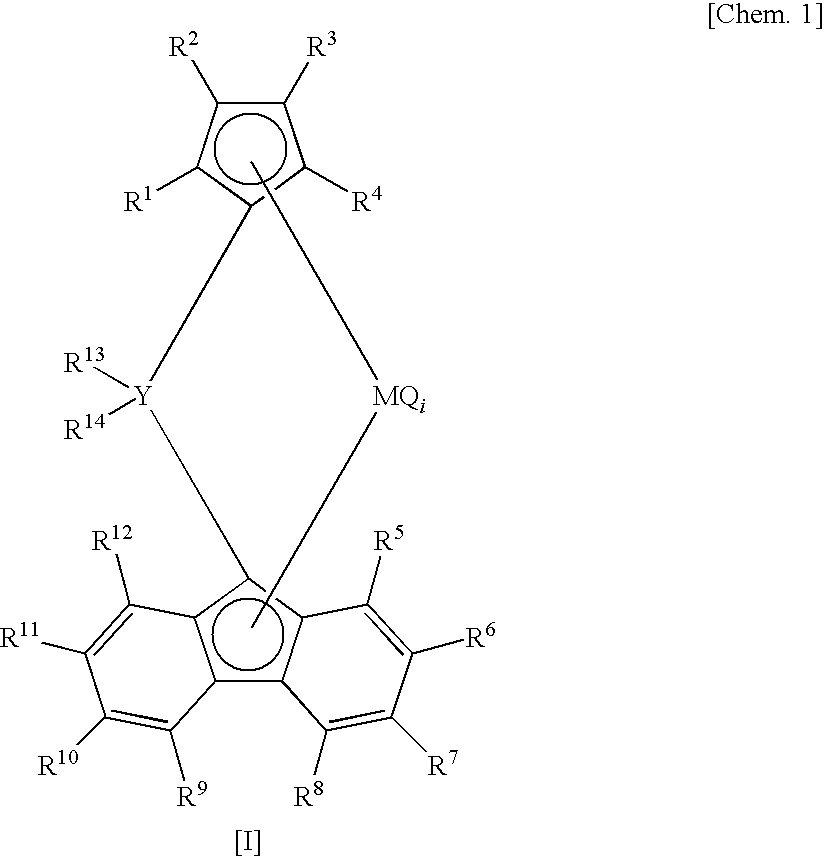

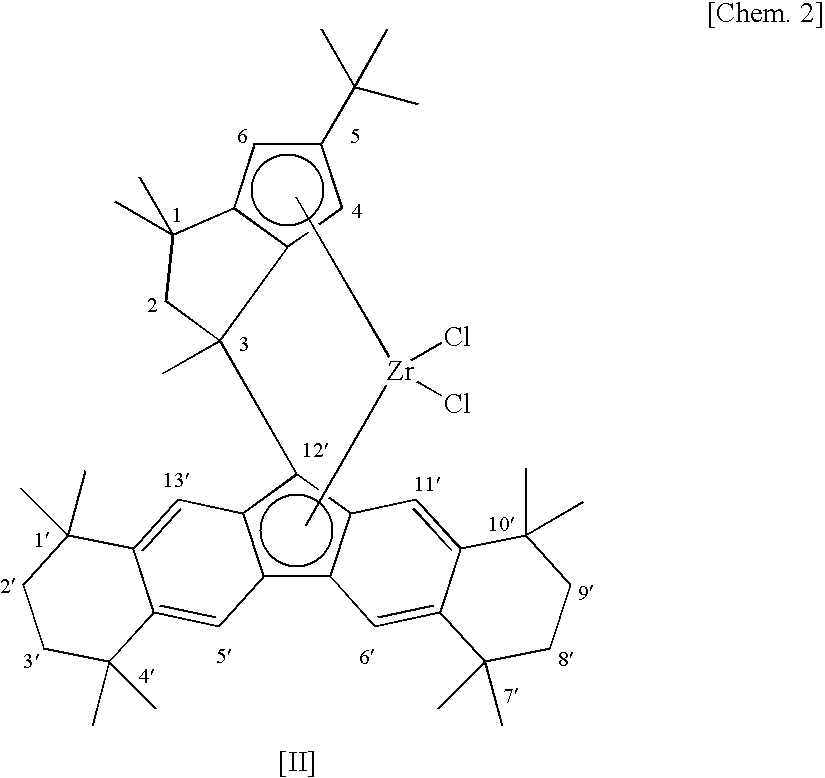

Propylene Random Block Copolymer, Resin Composition Containing the Copolymer and Molded Article Made Thereof

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155° C. and includes 90 to 60% by weight of a portion insoluble (Dinsol) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (Dsol) in n-decane at room temperature, wherein the Dinsol satisfies the following requirements (1) through (3) and the Dsol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the Dinsol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the Dinsol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the Dinsol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the Dsol is from 1.0 to 3.5, (5) the intrinsic viscosity [η] in decalin at 135° C. of the Dsol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the Dsol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

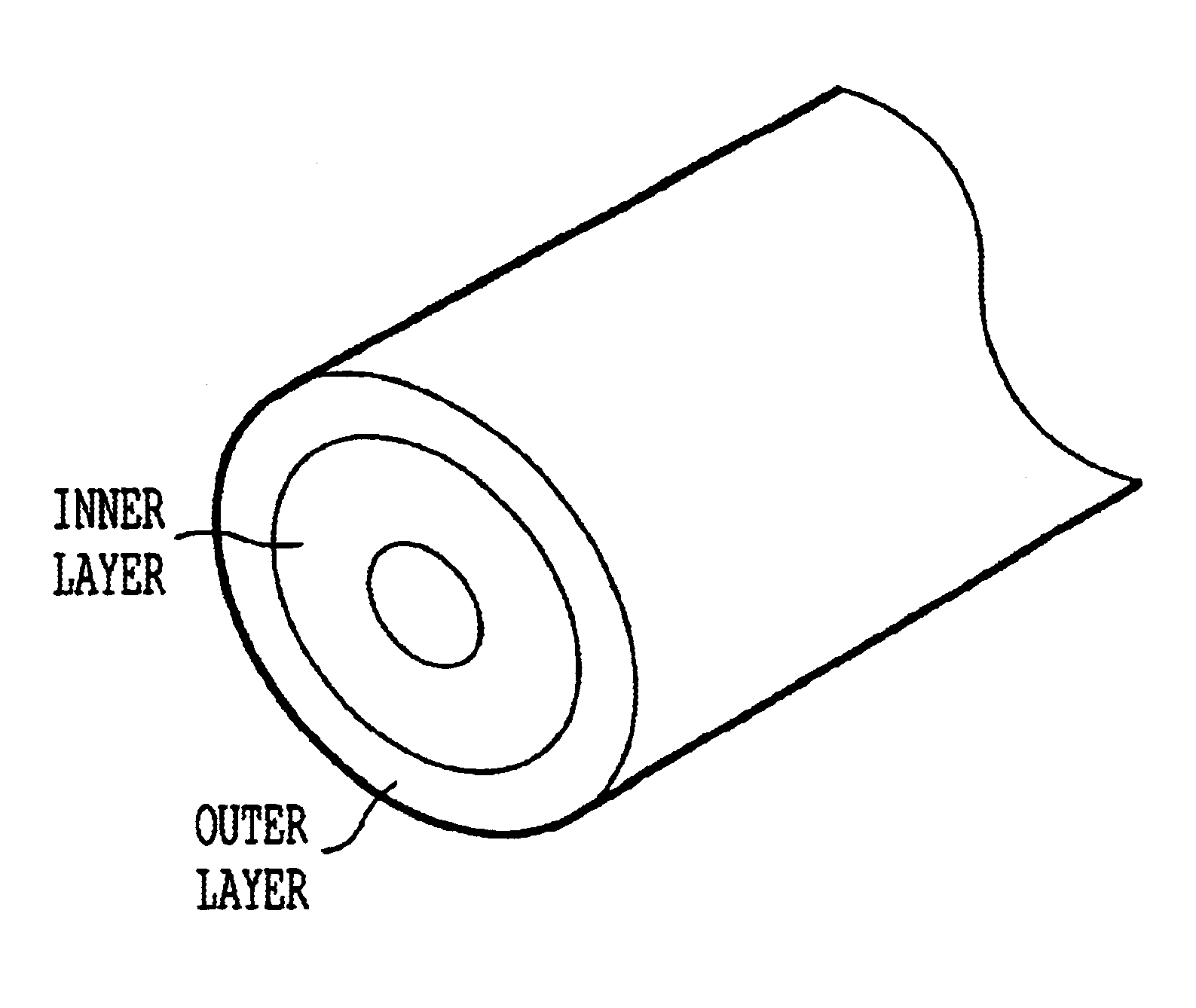

Fuel hose

InactiveUS6655414B2Increase flexibilityIncrease resistanceSynthetic resin layered productsFlexible pipesEngineeringThermodynamics

A fuel hose having a two layer structure comprising an inner layer made of a fluororesin and an outer layer adjacent thereto, made of a thermoplastic resin other than a fluororesin, wherein the fluororesin has a tensile strength at break of higher than 21 MPa, and the fluororesin of the inner layer has a melt adhesiveness with the thermoplastic resin of the outer layer.

Owner:ASAHI GLASS CO LTD

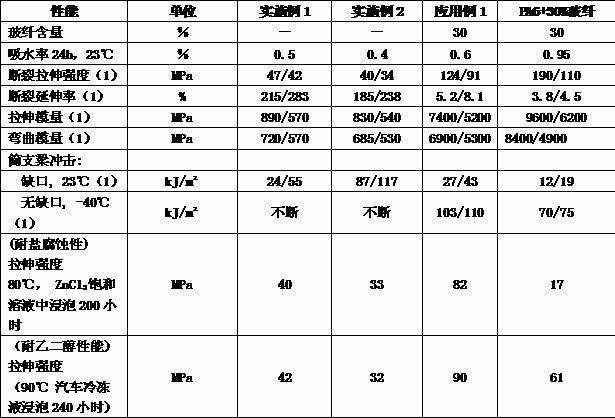

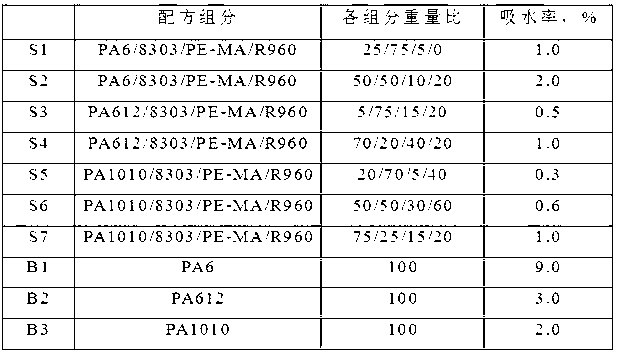

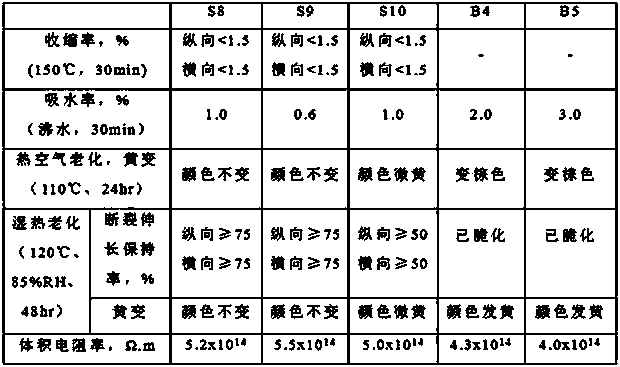

Chemical corrosion resistant high impact long carbon chain nylon master batch and preparation method and application thereof

InactiveCN102643534AGood chemical resistanceImprove low temperature impact resistanceMasterbatchEngineering plastic

The invention relates to a chemical corrosion resistant high impact long carbon chain nylon master batch, which contains long carbon chain nylon, compatible toughening agents and heat stabilizers. The invention further relates to a preparation method and an application of the nylon master batch. The nylon master batch has good impact resistance, chemical corrosion resistance and low humidity absorption, and is good in compatibility with other engineering plastics and capable of improving chemical corrosion resistance, low-temperature impact resistance and dimensional stabilities of composite materials, wherein the chemical corrosion resistance includes corrosion from zinc halide, calcium halide and ethylene glycol.

Owner:苏州隆阁新材料有限公司

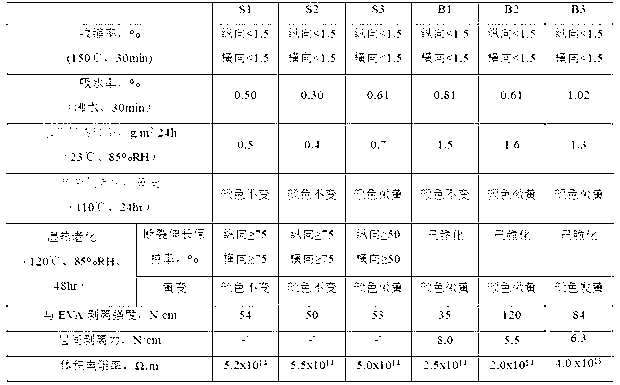

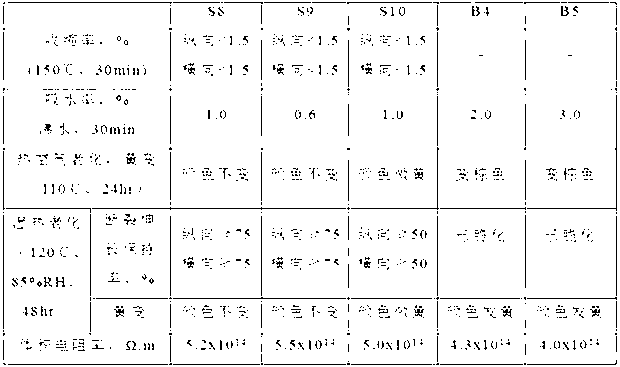

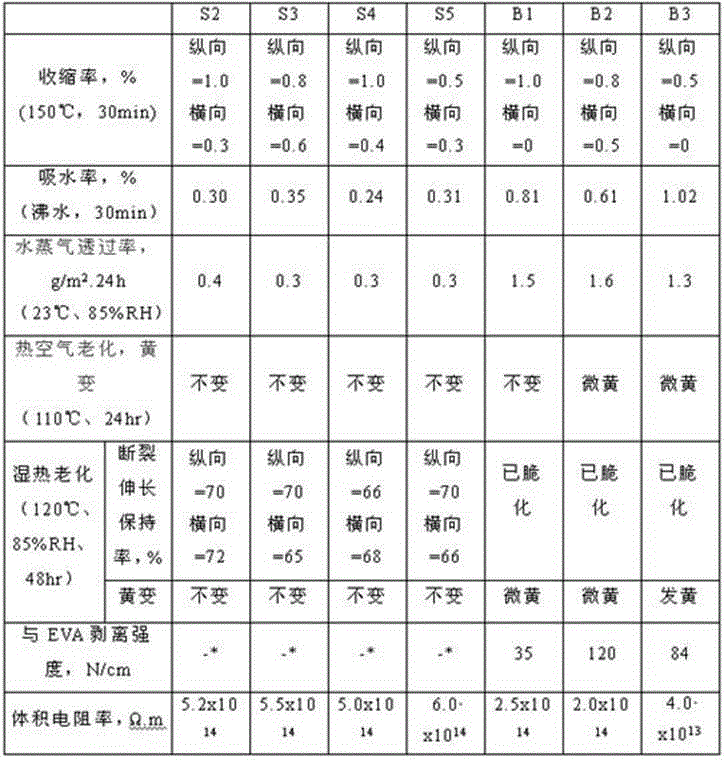

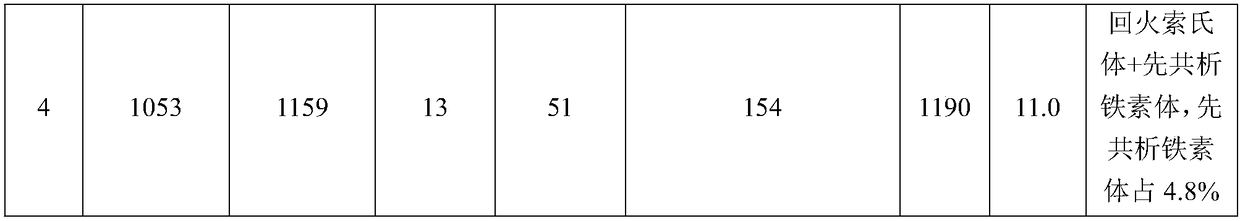

Polyamide backplane for solar energy assembly

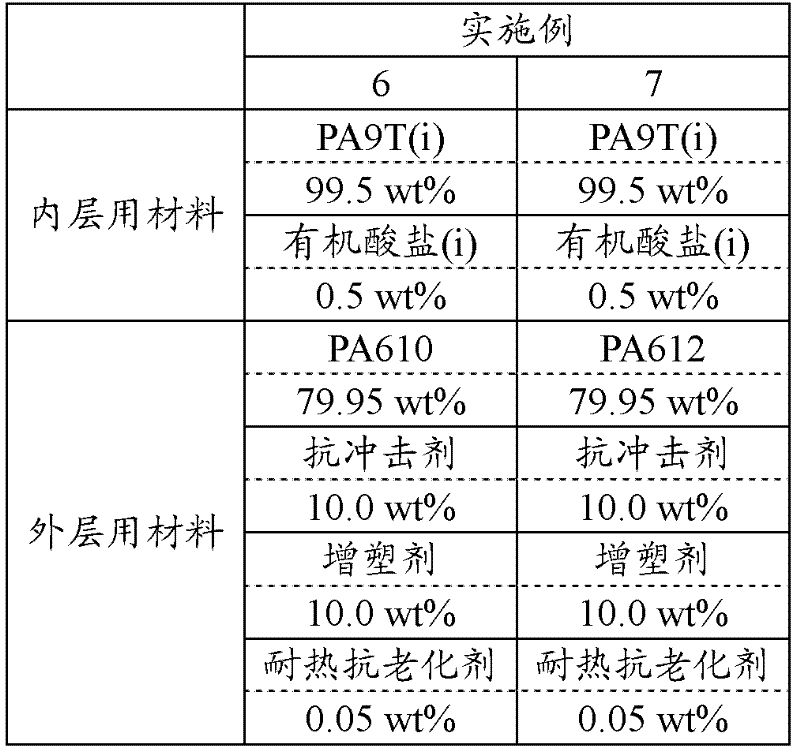

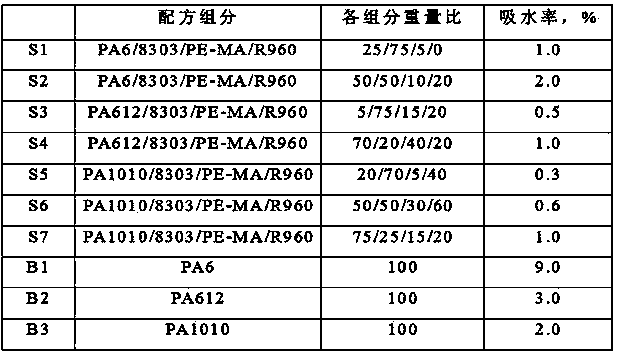

ActiveCN103057223AImprove water absorptionExcellent heat and humidity resistanceFinal product manufactureSynthetic resin layered productsSurface layerWater vapor

The invention discloses a polyamide backplane for a solar energy assembly. The polyamide backplane comprises an inner surface layer, a core layer, and an outer surface layer from the inside to the outside, wherein by mass, the ratio of inner surface layer to the core layer to the outer surface layer is 10-20:60-80:10-20. The inner surface layer and the outer surface layer are made from a polyamide resin, fillers and additives; the core layer is made from a modified polyamide resin composition; and the modified polyamide resin composition comprises a polyamide resin, grafted polyethylene, a polypropylene resin, fillers and additives. The novel polyamide backplane of the present invention is prepared by using coextrusion technology, the final product obtained has excellent adhesion and interlayer peeling force, anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and is easy in preparation and low in cost, suitable for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

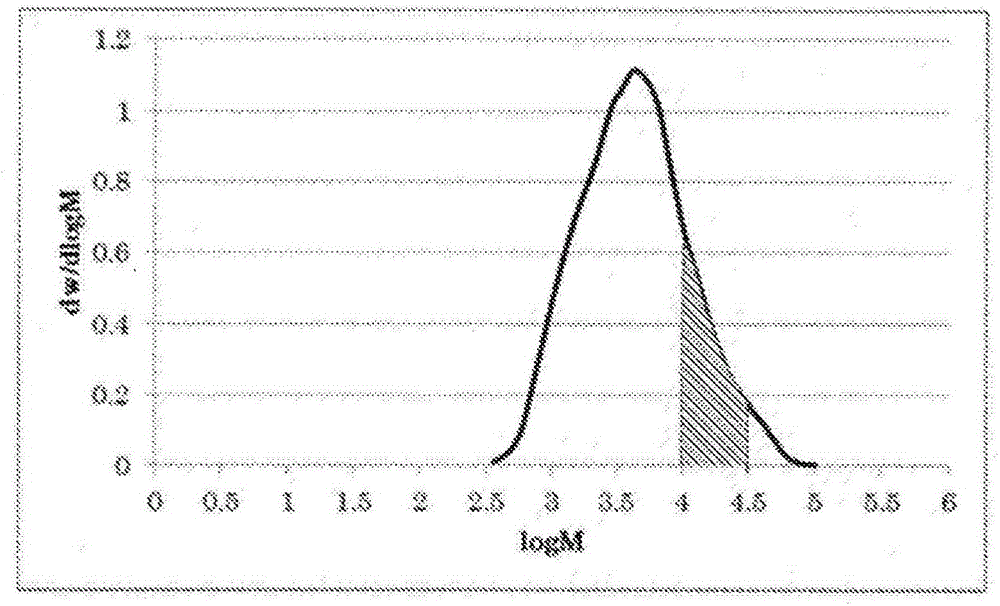

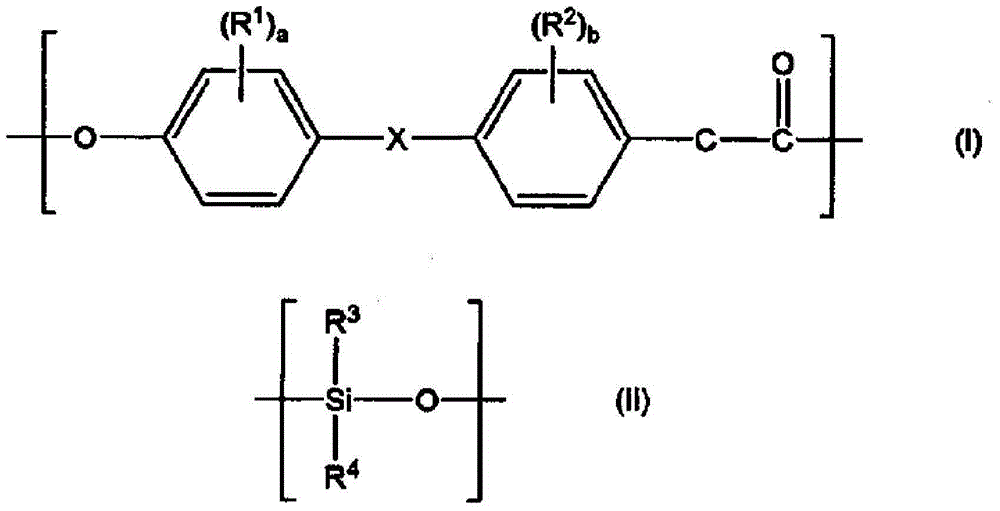

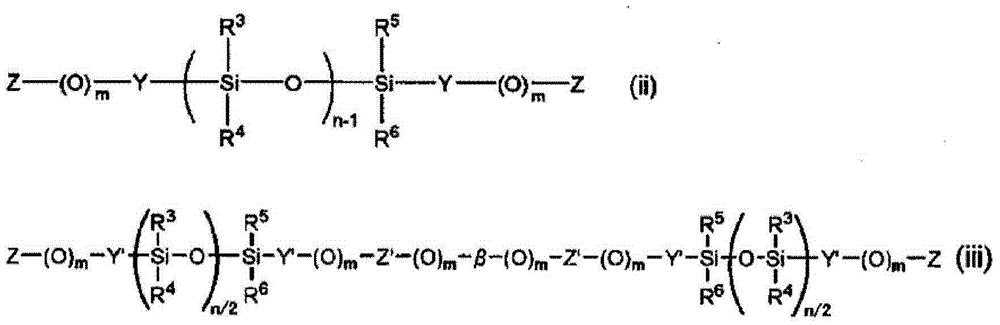

Polycarbonate-polyorganosiloxane copolymer and method for producing same

A polycarbonate-polyorganosiloxane copolymer comprising a specific polycarbonate block unit (A) and a specific polyorganosiloxane block unit (B), wherein in a differential molecular-weight distribution curve obtained by measurements using gel permeation chromatography with polystyrene of the polyorganosiloxane block unit (B) as a conversion basis, the horizontal axis of the distribution curve being the logarithmic value log(M) of molecular weight M and the vertical axis thereof being dw / dlog(M) which is the concentration fraction w differentiated by the logarithmic value log(M) of molecular weight, (1) the value of dw / dlog(M) is the greatest in a range of 3.4≤log(M)≤4.0, and (2) in the differential molecular-weight distribution curve, an integrated value of the dw / dlog(M) value in a range of 4.0≤log(M)≤4.5 is 6 to 40% with respect to an integrated value of the dw / dlog(M) value in the entire range of log (M).

Owner:IDEMITSU KOSAN CO LTD

A modified polyamide resin composition and backplane substrate film prepared by the same

ActiveCN103059558AImprove heat resistanceImprove wear resistancePhotovoltaic energy generationSemiconductor devicesPolypropylenePolyamide

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

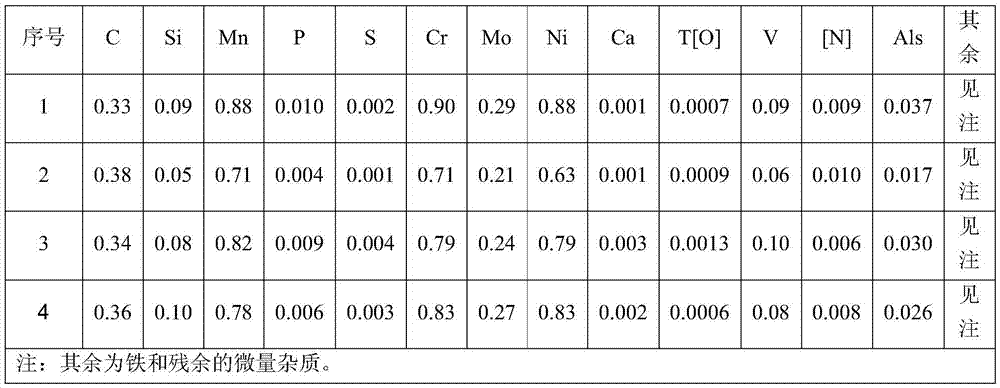

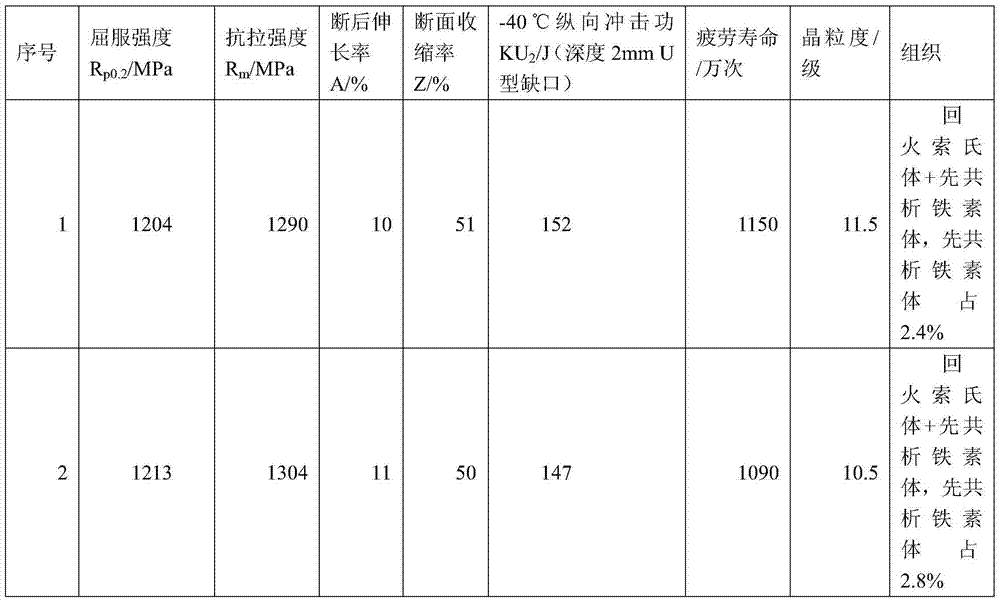

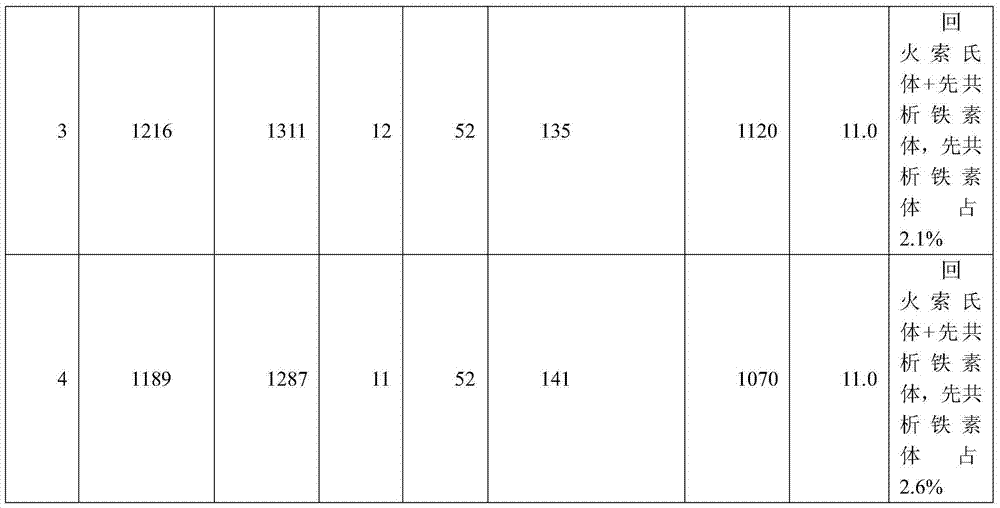

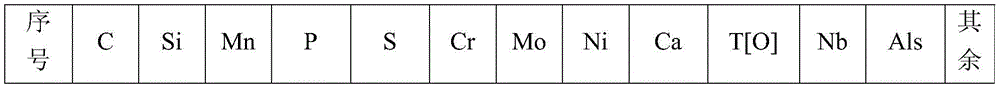

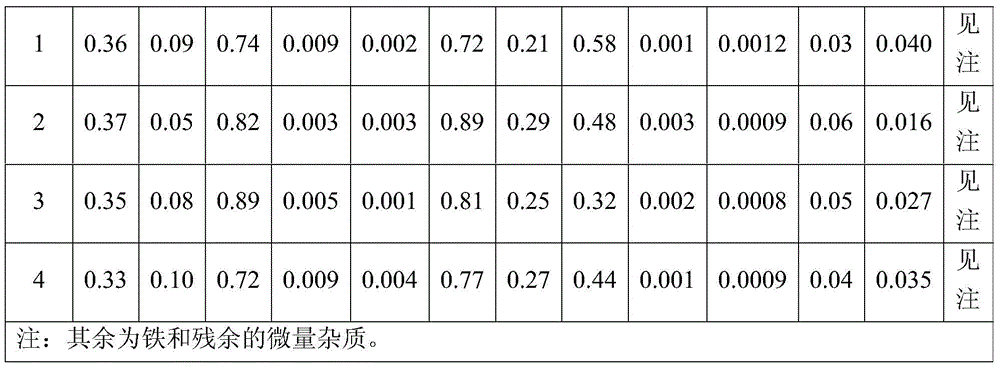

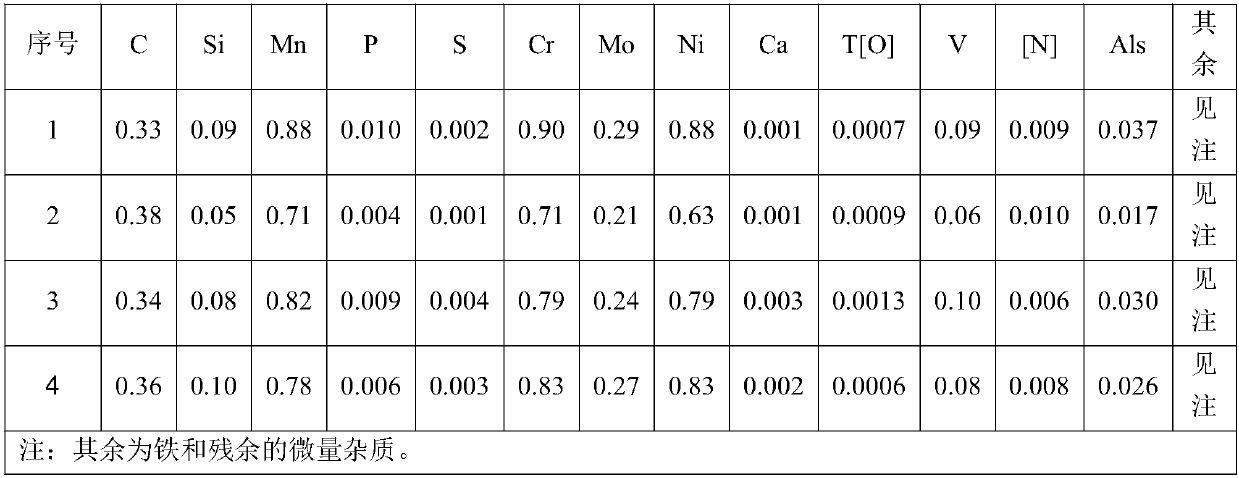

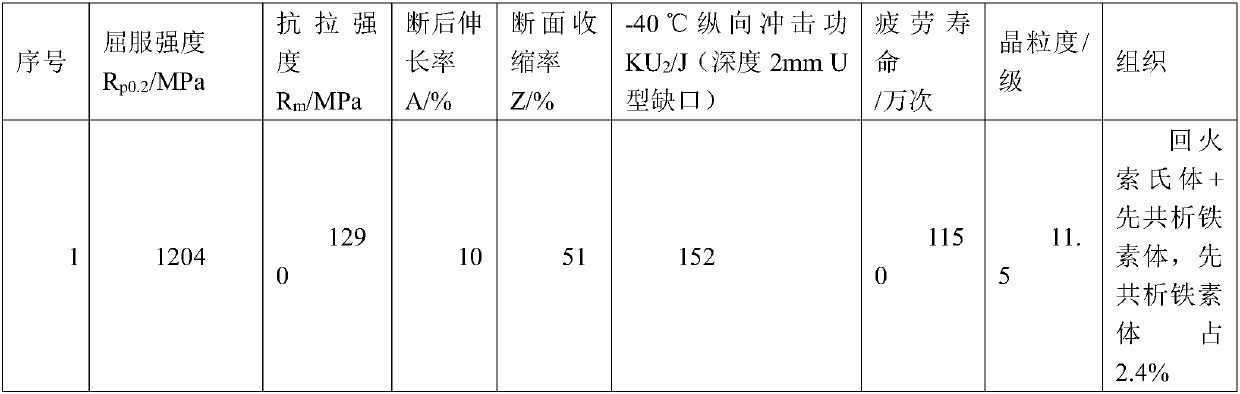

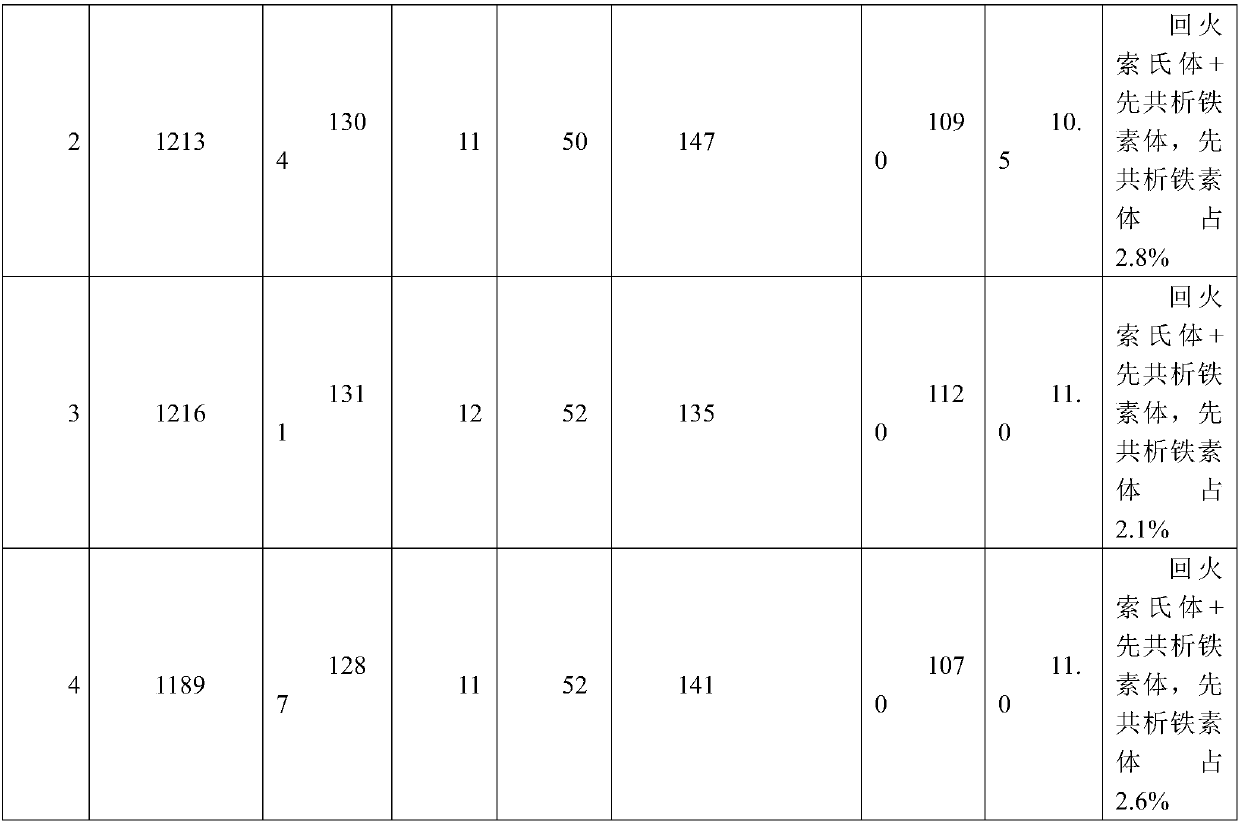

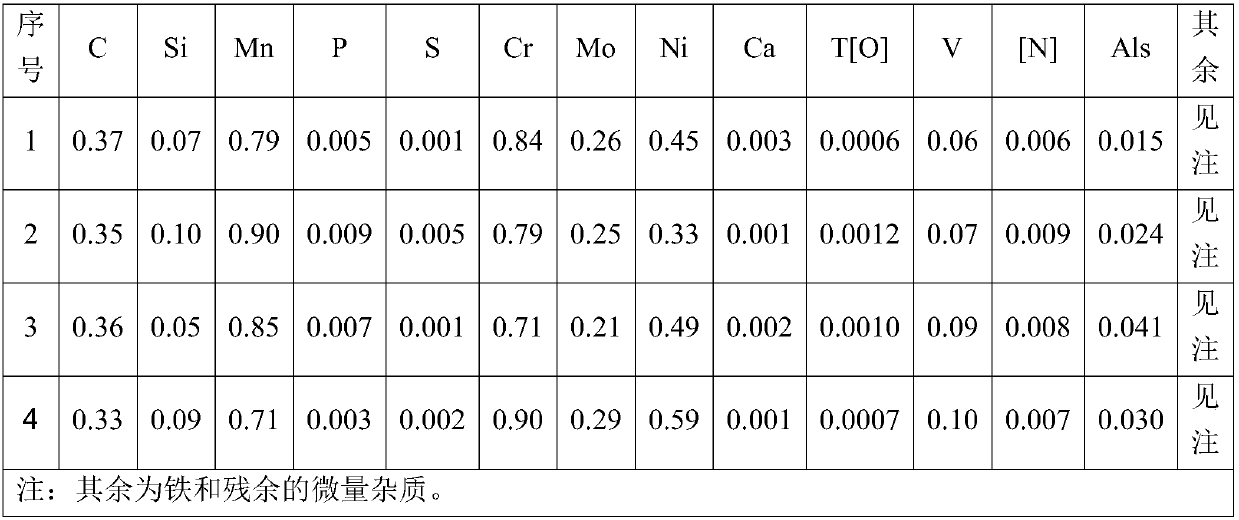

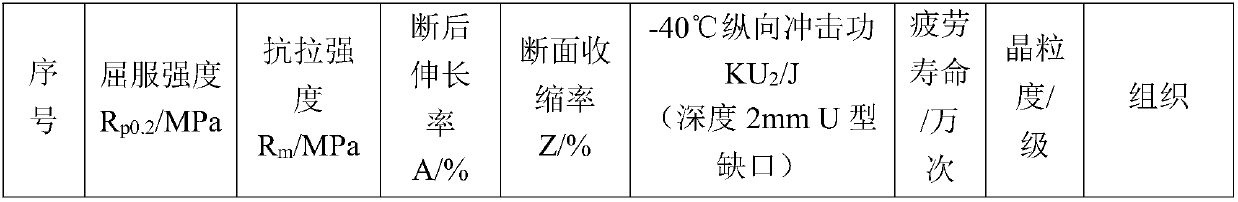

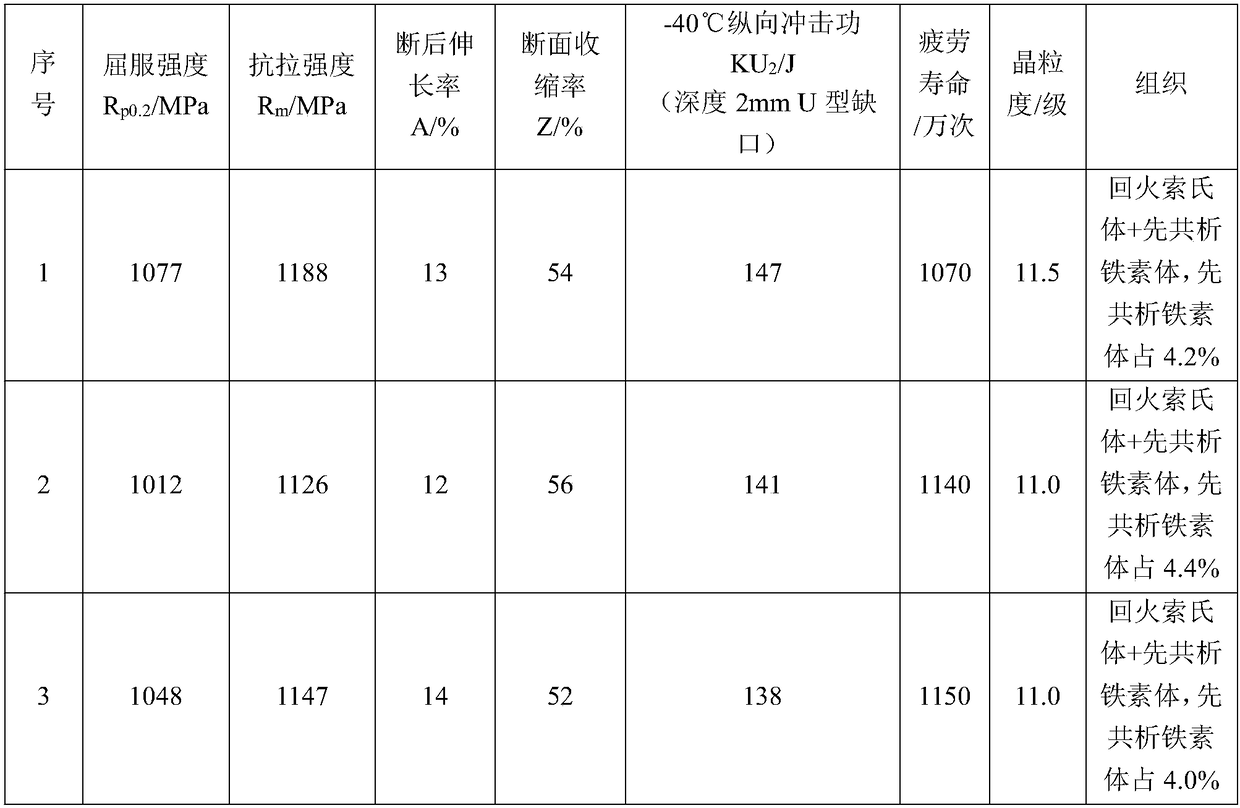

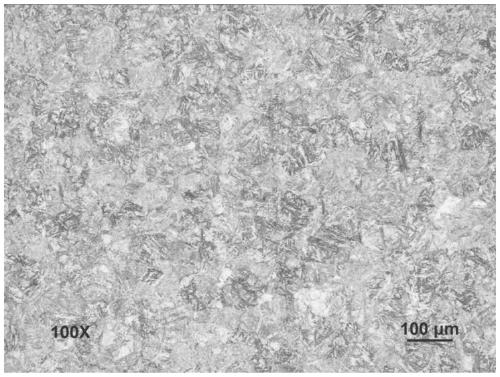

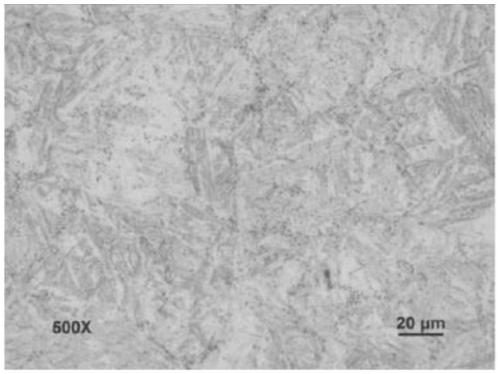

Vanadium-containing 12.9-grade steel for fastener applied to rail transit mobile equipment and thermal treatment process of vanadium-containing 12.9-grade steel

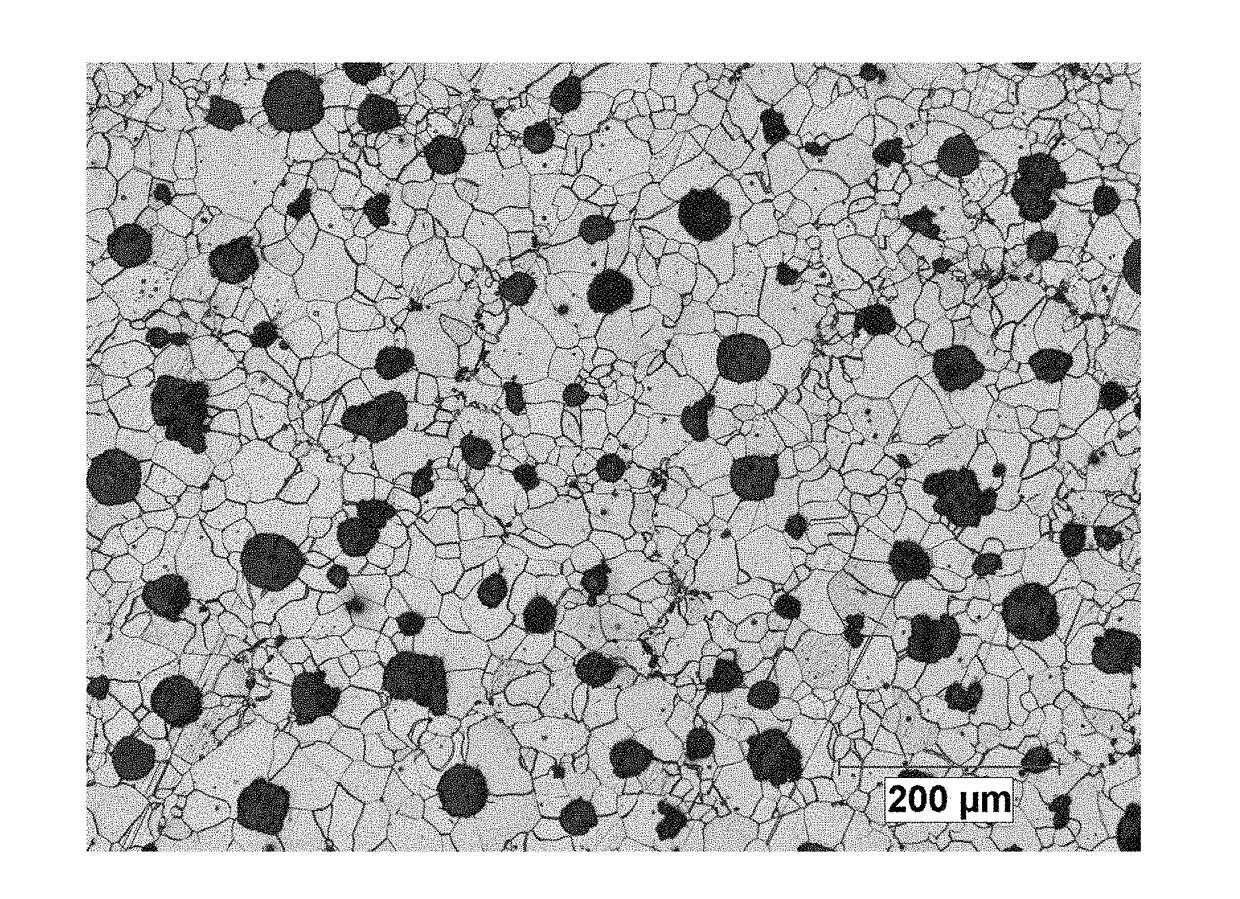

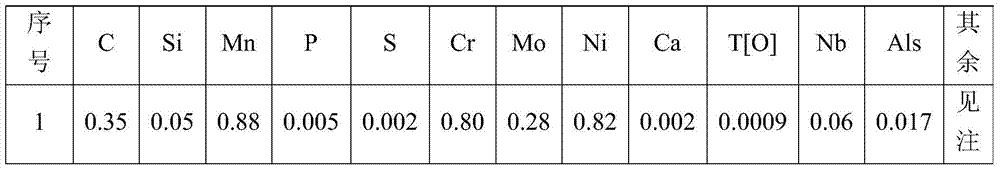

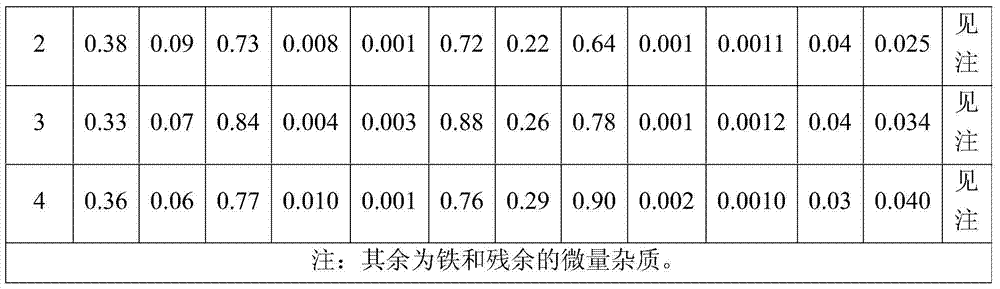

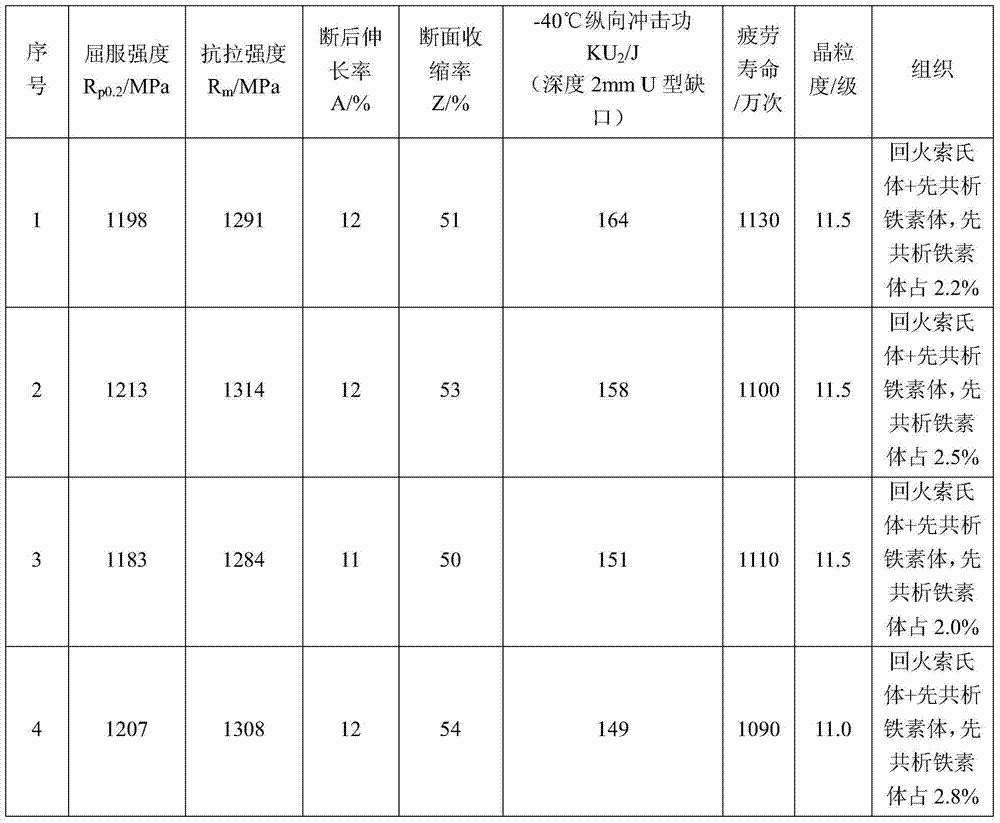

ActiveCN105441788AInhibition of fatigue crack growthImprove fatigue resistanceTemperature control deviceAustenite grainMicrometer

The invention provides a vanadium-containing 12.9-grade steel for a fastener applied to rail transit mobile equipment. The steel mainly comprises the following chemical elements in percentage by mass: 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.60% to 0.90% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.06% to 0.10% of V, 0.006% to 0.010% of [N], smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S and smaller than or equal to 0.0015% of T[O]. The thermally-treated steel is larger than 10.0 grades in austenitic grain size; the structure of the thermally-treated steel is a small amount of small proeutectoid ferrite dispersed on a tempered sorbite base body, wherein the amount of the proeutectoid ferrite is smaller than or equal to 3%, and the size of the proeutectoid ferrite is smaller than or equal to 5 micrometers.

Owner:MAANSHAN IRON & STEEL CO LTD

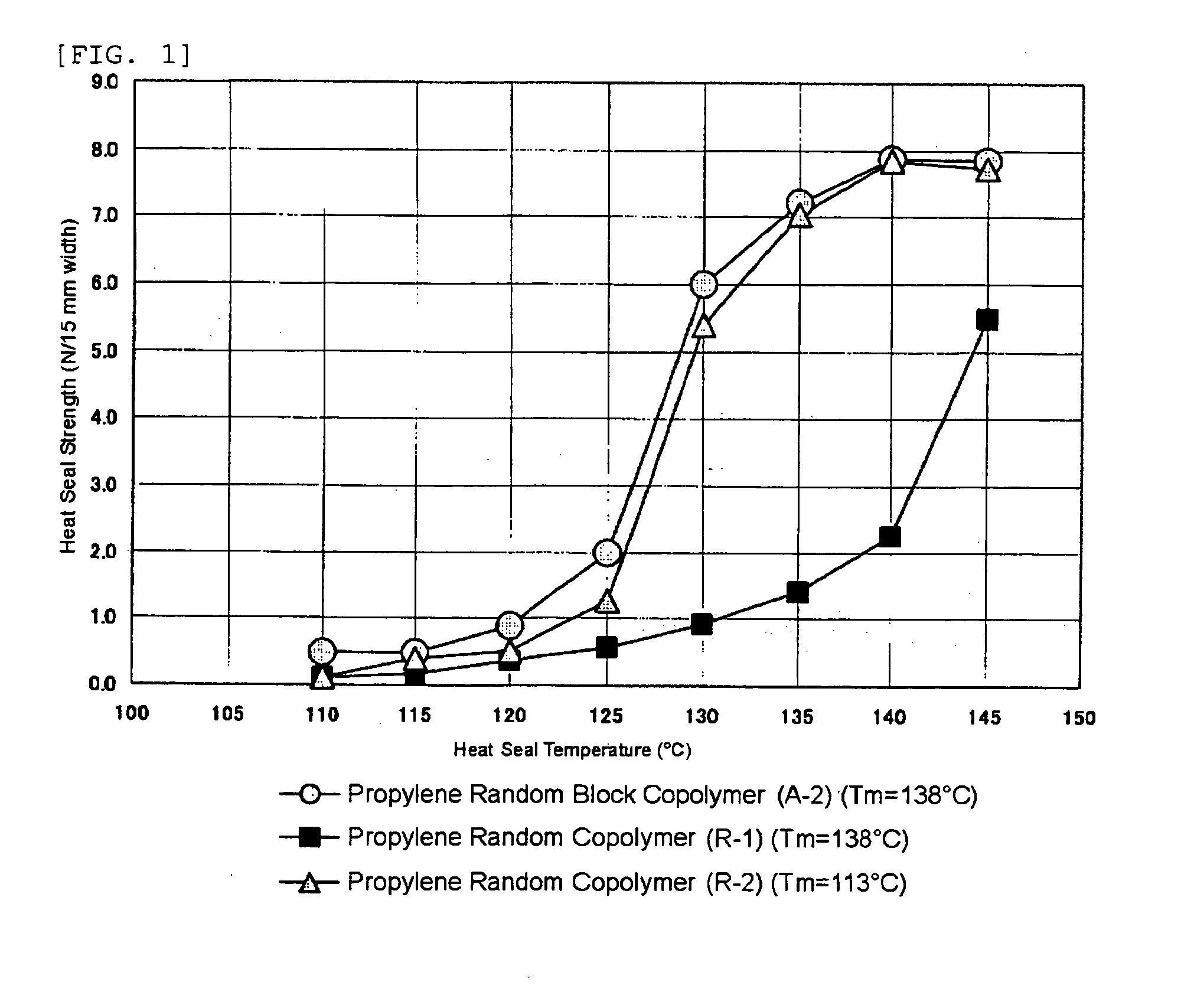

Heat-Sealable Propylene-Based Polymer Composition, Heat-Sealable Film, and Uses Thereof

ActiveUS20090258243A1High heat sealing strengthAvoid resistanceSynthetic resin layered productsPackage sterilisationAlpha-olefinPropylene Polymers

The heat-sealable propylene-based polymer composition of the present invention comprises a propylene polymer composition (A) comprising a propylene polymer component (a1) and a propylene / ethylene random copolymer component (a2) having a propylene unit content of 63 to 77% by mol and an ethylene unit content of 23 to 37% by mol, an ethylene / (α-olefin random copolymer (B), and a soft propylene polymer (C) which has an ethylene content of 0 to 30% by mol and an α-olefin content of 0 to 30% by mol and whose melting point, as measured by a differential scanning calorimeter (DSC), is not higher than 100° C. or is not observed; and this heat-sealable propylene-based polymer composition contains the propylene polymer composition (A) in an amount of 50 to 90% by mass, the ethylene / α-olefin random copolymer (B) in an amount of 3 to 25% by mass and the soft propylene polymer (C) in an amount of 0.5 to 40% by mass ((A)+(B)+(C)=100% by mass). The present invention also provides a heat-sealable film using the composition and a packaging bag comprising the film. The heat-sealable film of the present invention has high heat-seal strength, is little decreased in heat-seal strength even after heat treatment and is excellent in blocking resistance, rigidity and low-temperature impact resistance.

Owner:MITSUI CHEM INC

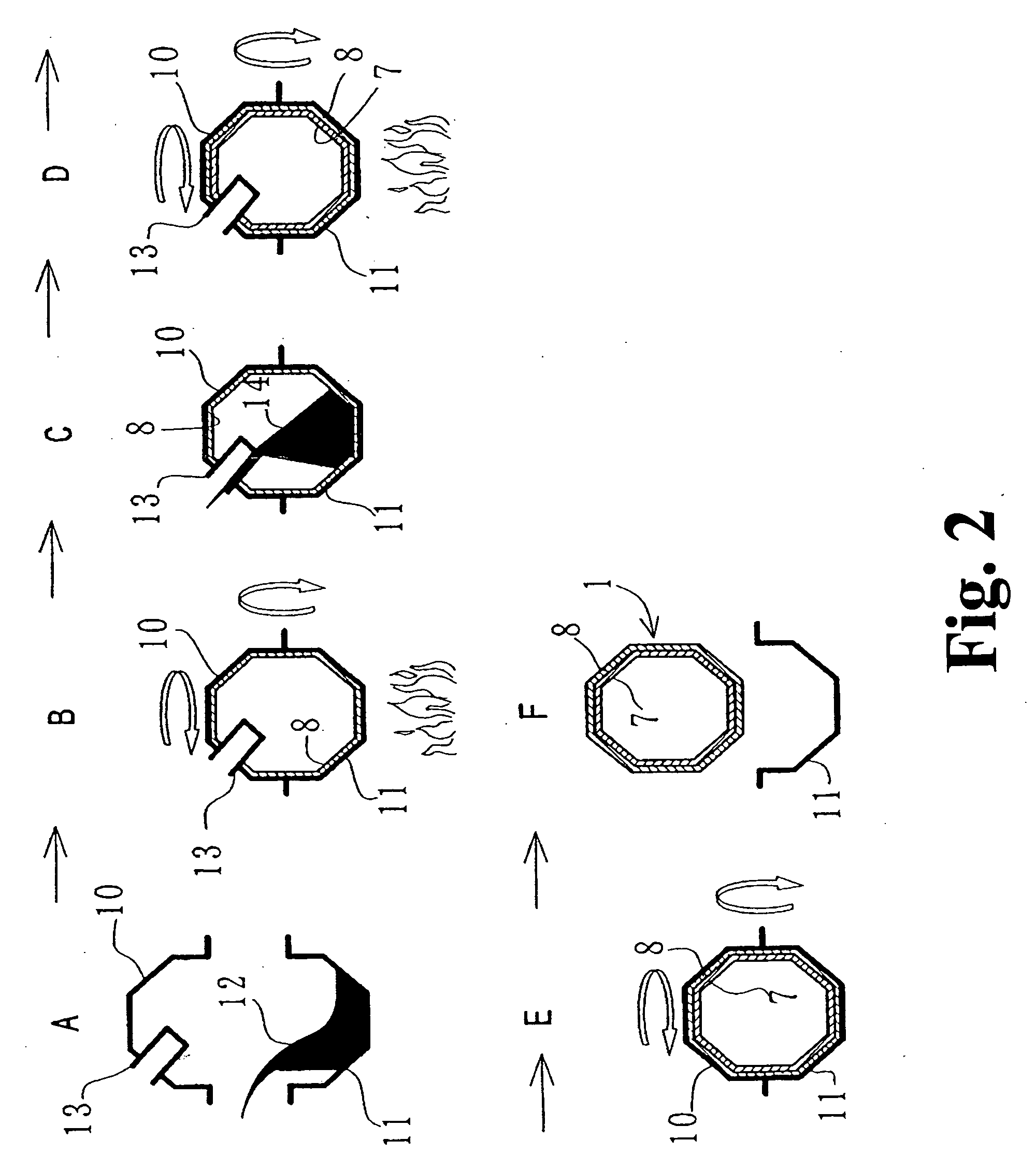

Rotational-molded resin fuel tank

InactiveUS20080203623A1AdhesionImprove adhesionSynthetic resin layered productsVehicle componentsWeather resistanceGasoline

A resin fuel tank having a two-layer structure of inner and outer layers is formed by rotational molding so as to be superior not only in appearance but also in weathering resistance, low temperature impact resistance and resistance to gasoline permeability.

Owner:HONDA MOTOR CO LTD

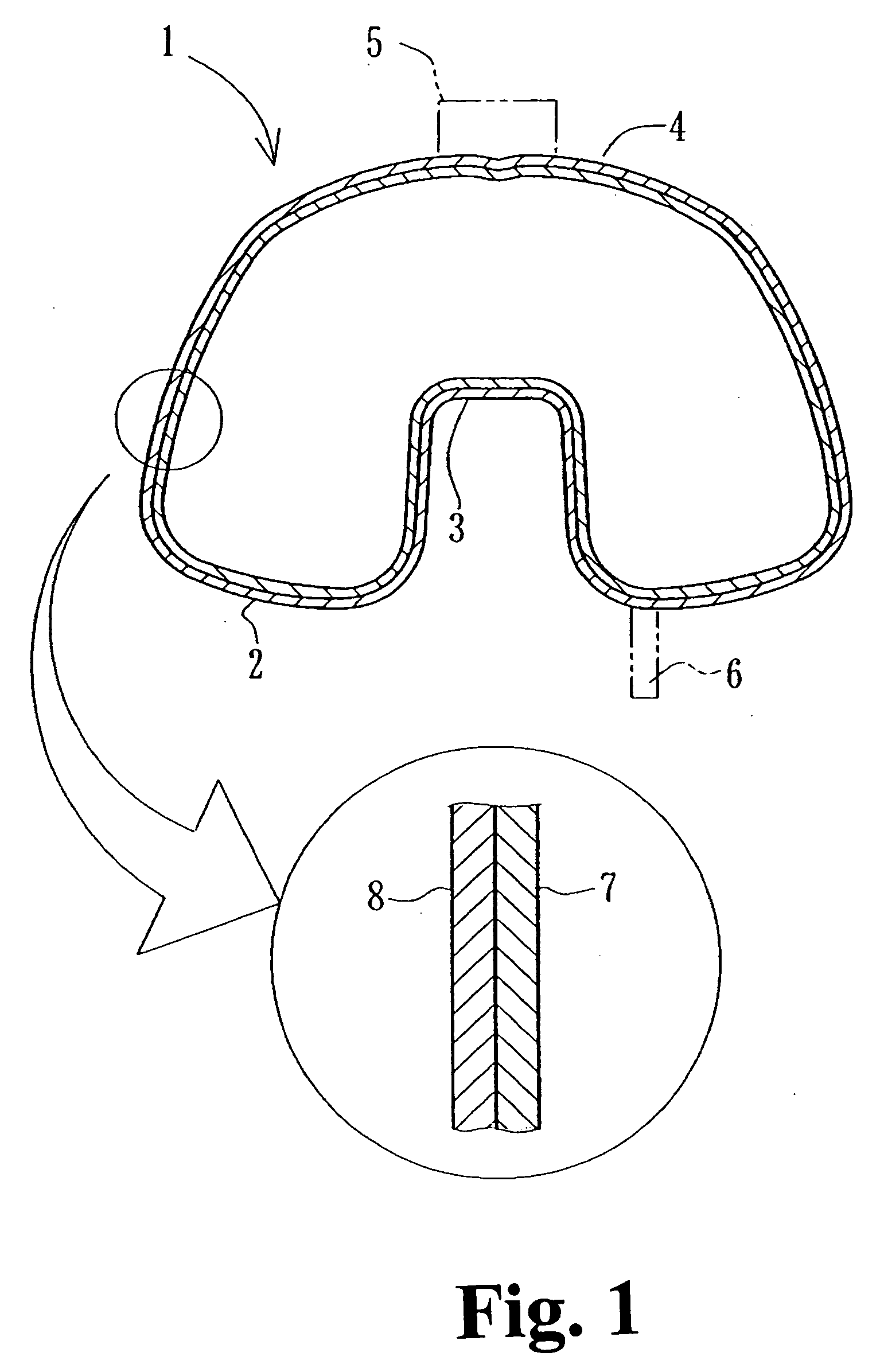

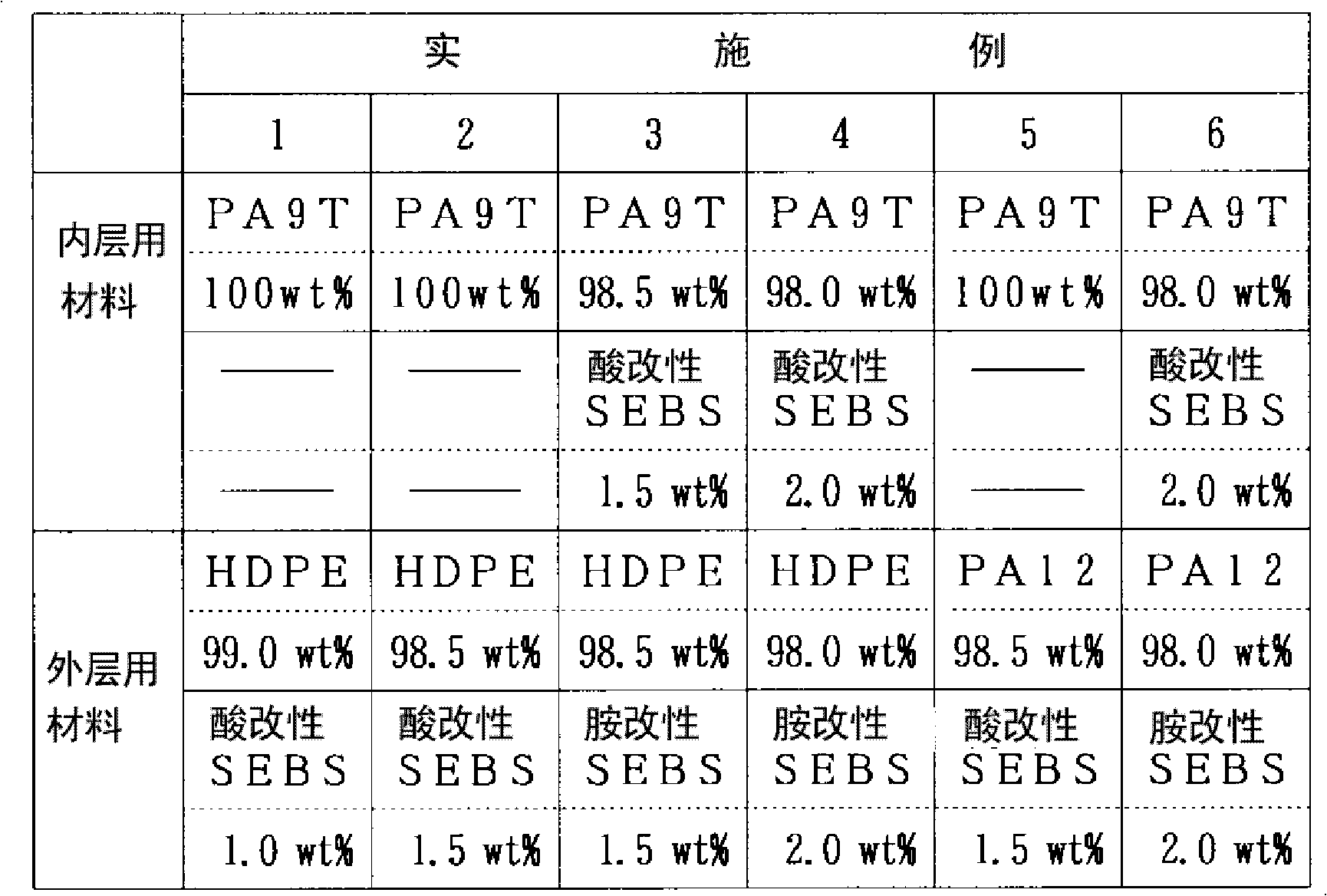

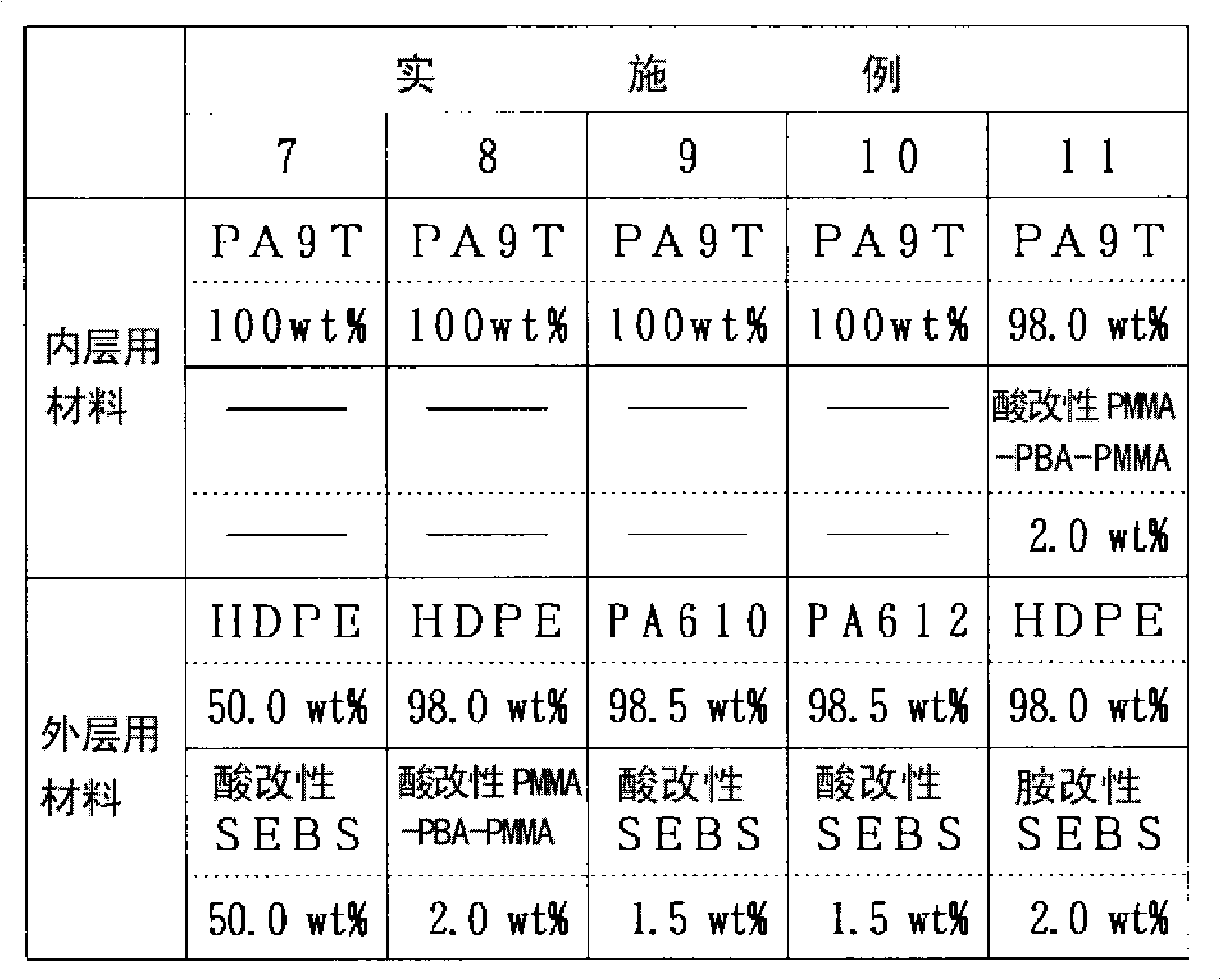

Multilayer tube

ActiveUS20170261133A1Deteriorated fuel resistanceImprove adhesionSynthetic resin layered productsLaminationAramidesFluorine containing

Provided is a multilayer tube that has a layer containing an aliphatic polyamide (such as Polyamide 11 or Polyamide 12), a layer containing a Polyamide 6 composition or Polyamide 6 / 66 / 12 composition, a layer containing a saponified ethylene-vinyl acetate copolymer, and a layer containing a semi-aromatic polyamide composition that contains a semi-aromatic polyamide having a specific structure, and further has a fluorine-containing polymer in which a functional group having reactivity with an amino group is introduced into the molecular chain thereof.

Owner:UBE IND LTD

Fuel Hose

InactiveCN102596555ALight in massReduce permeabilitySynthetic resin layered productsFlexible pipesPolyolefinHeat resistance

Owner:SUMITOMO RIKO CO LTD

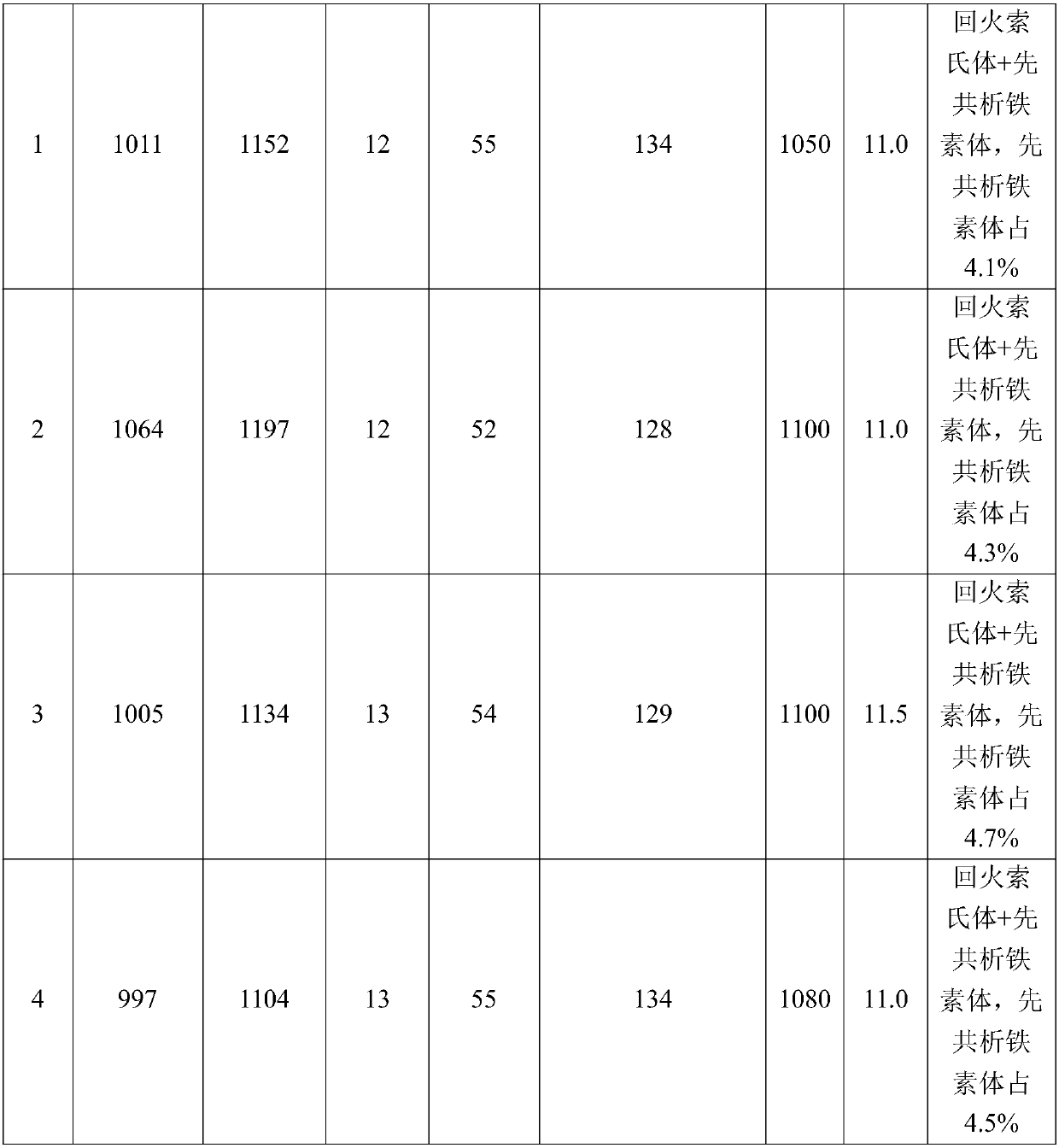

Vanadium-contained 10.9-level steel for fastener for rail transit mobile equipment and heat treatment technology of steel

ActiveCN105543654AInhibition of fatigue crack growthImprove fatigue resistanceAustenite grainMicrometer

The invention provides vanadium-contained 10.9-level steel for a fastener for rail transit mobile equipment. The steel mainly comprises following chemical elements including, by mass percentage, 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.30% to 0.60% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.03% to 0.06% of Nb, not larger than 0.010% of P, not larger than 0.005% of S and not larger than 0.0015% of T[O]. The autstenitic grain size of steel obtained after heat treatment of the fastener is larger than 10.0 level, and according to the structure of the steel obtained after heat treatment of the fastener, a small amount of small pro-eutectoid ferrite is dispersed and distributed on a tempered sorbite base body, wherein, the amount of the pro-eutectoid ferrite is smaller than or equal to 5%, and the size of the pro-eutectoid ferrite is smaller than or equal to 5 micrometers. The longitudinal mechanical property of the fastener obtained after heat treatment can meet the standard requirement.

Owner:MAANSHAN IRON & STEEL CO LTD

Formula and processing technology of PP-R pipe

The invention discloses a formula and processing technology of a PP-R pipe. The PP-R pipe comprises the following components: 97%-99.65% of polypropylene randon coplymer, 0.1%-1% of pentaerythritol ester, 0.2%-1.5% of auxiliary antioxygen DLTP and 0.05%-0.5% of a nucleator TMB-4. According to the formula and the processing technology of the PP-R pipe, the melting temperature range is wide during processing, and the forming machinability is good. Besides, the PP-R pipe has the advantages of good toughness and cold-resistance, high impact property and better transparency, and also has the following properties of a polypropylene pipe including resistance to acid, alkali, chemical corrosion, heat, low temperature, impact, ageing and light.

Owner:ANHUI WEIXING PIPE IND

Multilayer tubes

ActiveUS20200262188A1Good adhesivenessIncreased durabilitySynthetic resin layered productsMachines/enginesElastomerPolymer science

It is provided a multilayer tube having a layer containing a specific aliphatic polyamide composition and a layer containing a semi-aromatic polyamide composition which contains a semi-aromatic polyamide having a specific structure or a mixture thereof, and the both layers being disposed adjacent to each other, wherein the aliphatic polyamide composition contains an aliphatic polyamide having a melting point of a specific value or less, and a ratio of the number of the methylene groups to the number of the amide groups is a specific value or more, an aliphatic polyamide having an absolute value of a difference in solubility parameter SP values to that of the aliphatic polyamide being a specific range, and an elastomer polymer containing a constitutional unit derived from an unsaturated compound having a carboxyl group and / or an acid anhydride group.

Owner:UBE CORP

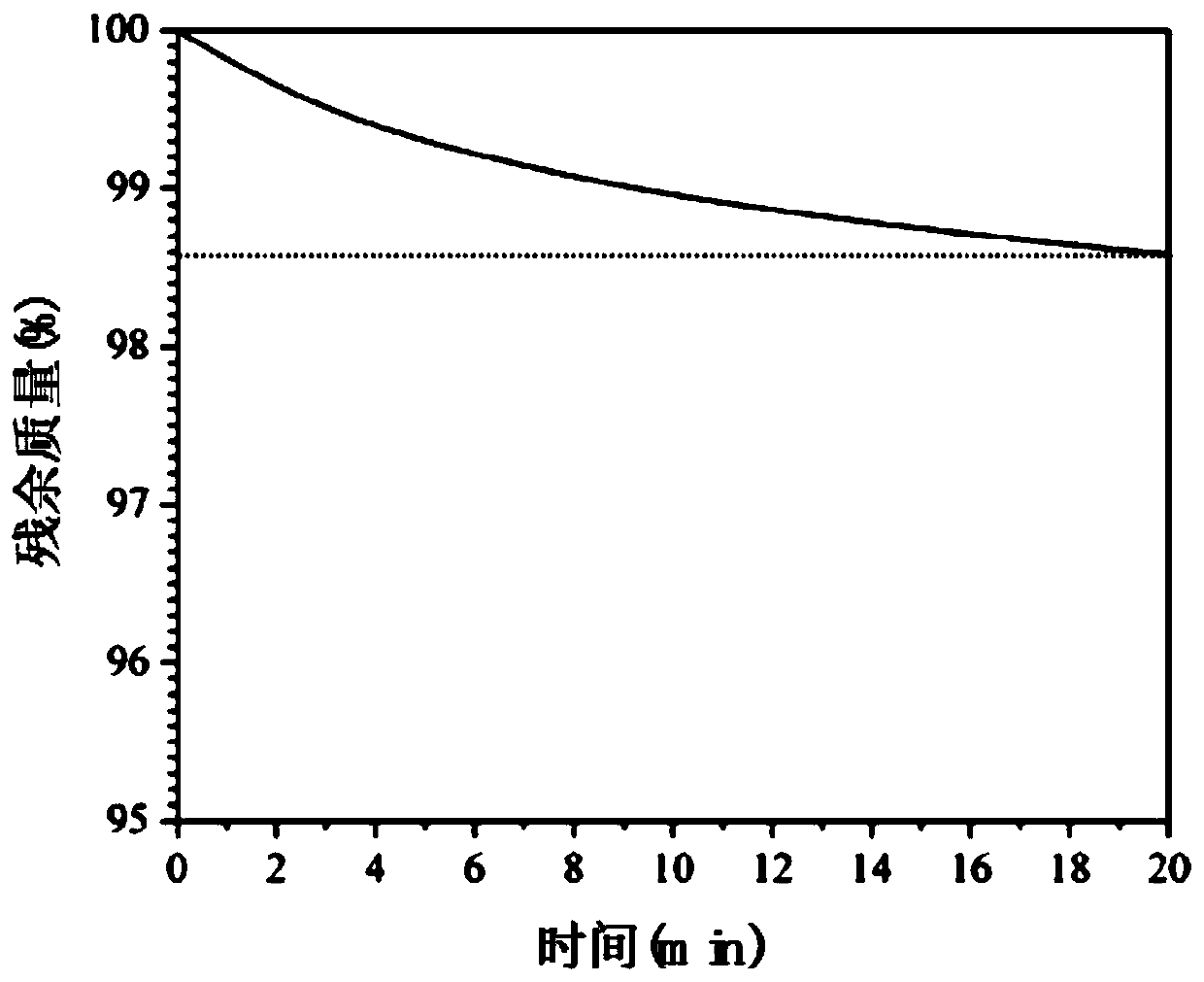

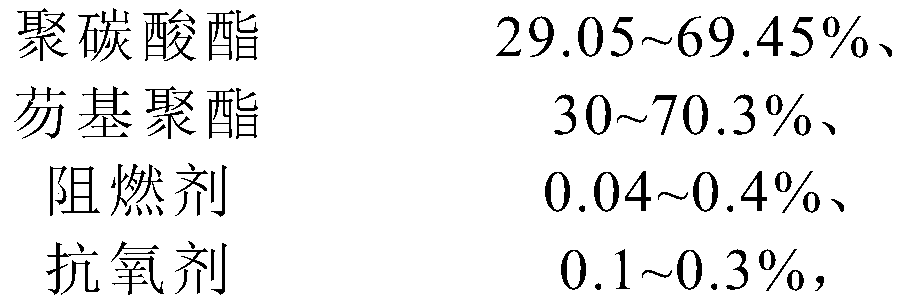

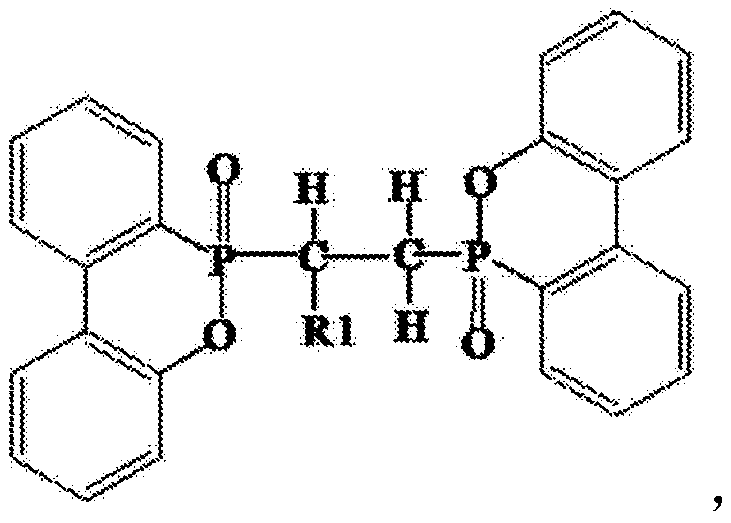

Low-temperature-impact-resistant high-transmittance flame-retardant polycarbonate composite material and preparation method thereof

The invention relates to a low-temperature-impact-resistant high-transmittance flame-retardant polycarbonate composite material and a preparation method thereof, and belongs to the technical field ofhigh polymer materials. The composite material comprises the following components in percentage by weight: 29.05-69.45% of polycarbonate, 30-70.3% of fluorenyl polyester, 0.04-0.4% of flame retardantand 0.1-0.3% of antioxidant, wherein the fluorenyl polyester is aromatic polyester resin with a main chain containing at least one fluorenyl group; the polycarbonate composite material disclosed by the invention is resistant to low-temperature impact, high in transparency, good in flame-retardant effect and low in birefringence.

Owner:宁波坚锋新材料有限公司

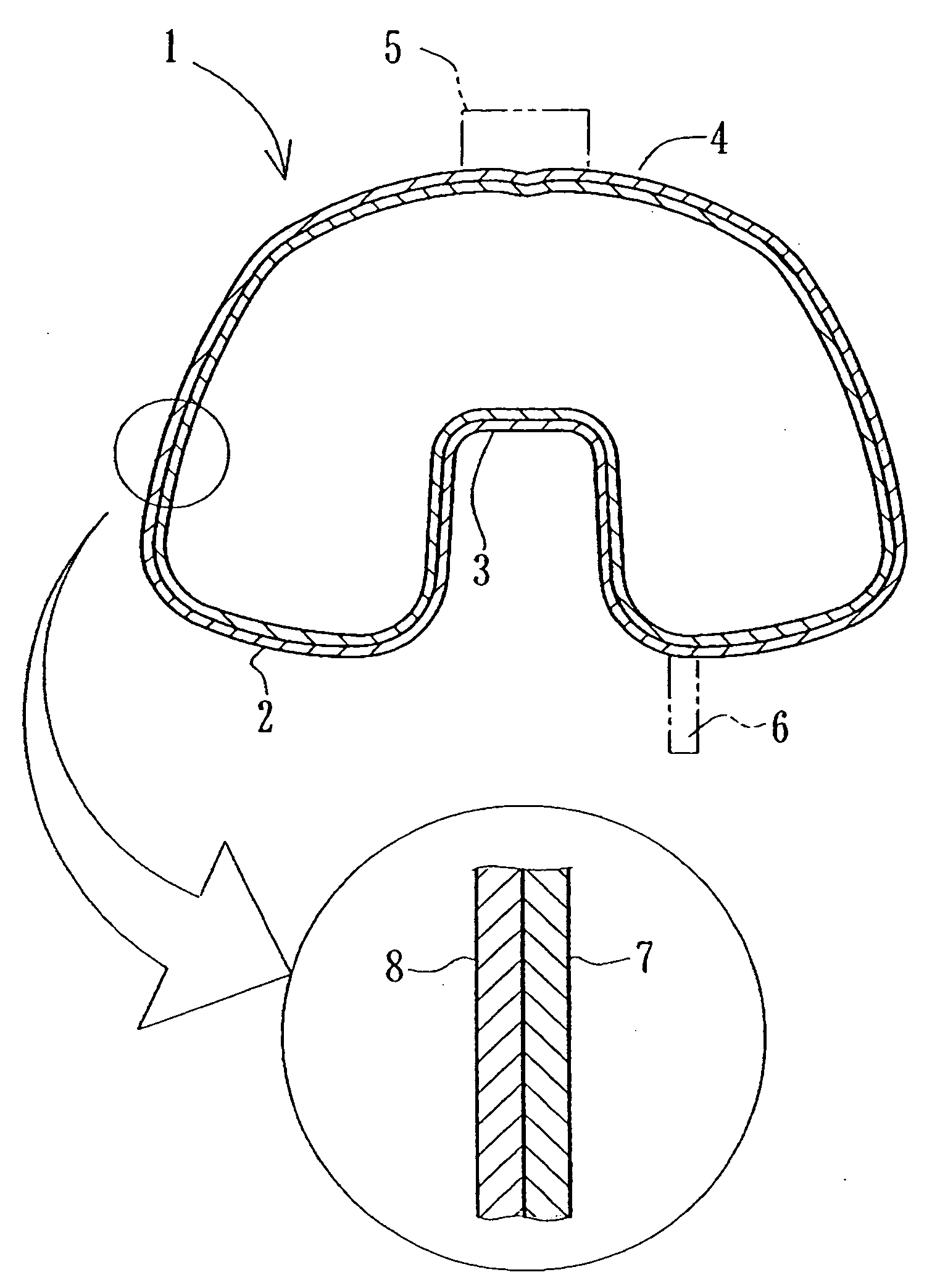

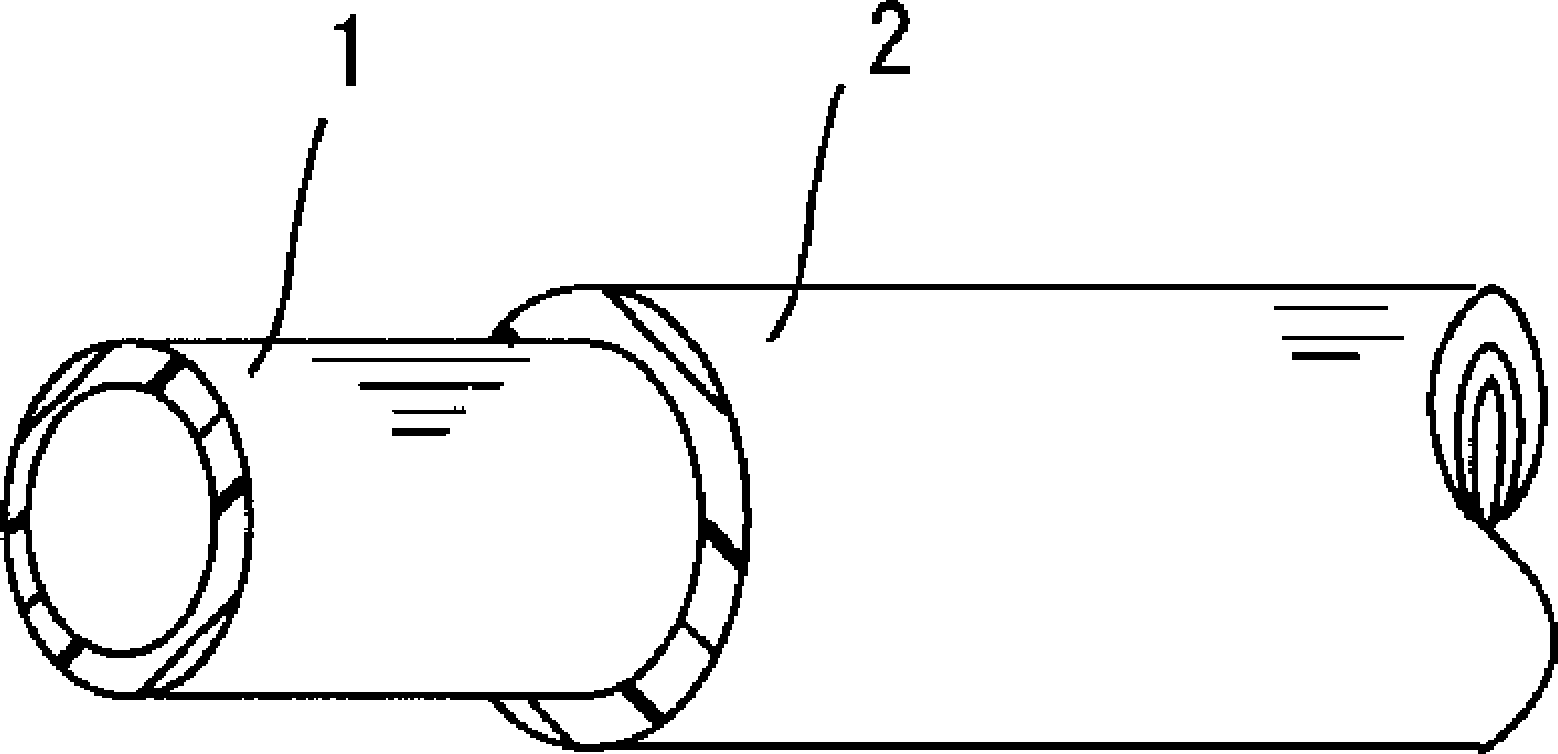

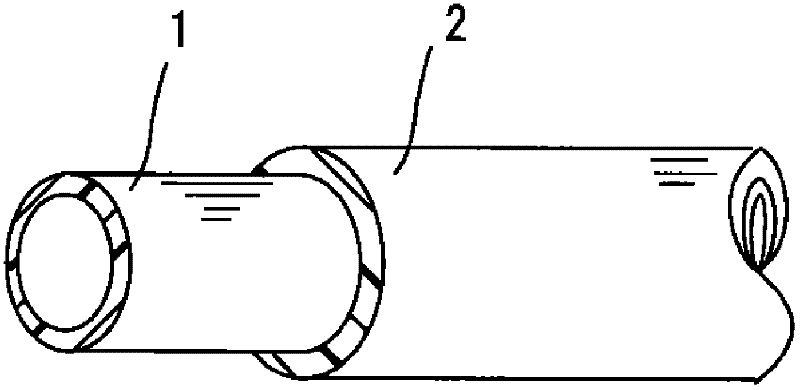

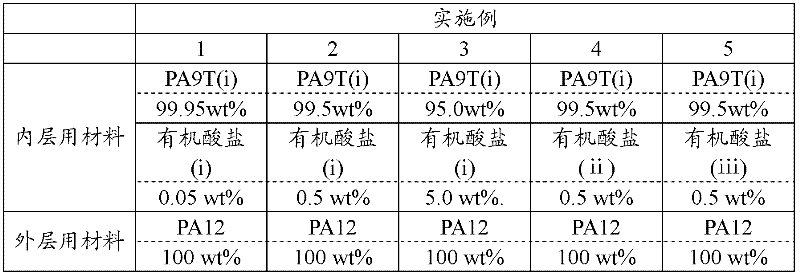

Fuel hose and method for producing same

ActiveCN102483185AImprove interlayer adhesionLight in massSynthetic resin layered productsFlexible pipesCarbon numberOrganic acid

Disclosed is a fuel hose provided with a tubular inner layer (1) composed of a resin composition (A) which is mainly composed of an aromatic polyamide resin and which contains an organic acid salt having a carbon number of 10-28, and an outer layer (2) which is provided on the outer peripheral surface of the inner layer and which is composed of a resin composition (B) mainly composed of an aromatic polyamide resin, wherein both layers are bonded to each other. Thus, the fuel hose has a low fuel permeability and an excellent bonding property between the layers.

Owner:SUMITOMO RIKO CO LTD

A modified polyamide resin composition and backplane substrate film prepared by the same

ActiveCN103059558BImprove water absorptionGood moisture and heat aging resistancePhotovoltaic energy generationSemiconductor devicesWater vaporGraft reaction

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Multilayer tube

ActiveUS10663092B2Improve adhesionImprove impermeabilitySynthetic resin layered productsLaminationPolymer sciencePolyamide

Provided is a multilayer tube that has a layer containing an aliphatic polyamide (such as Polyamide 11 or Polyamide 12), a layer containing a Polyamide 6 composition or Polyamide 6 / 66 / 12 composition, a layer containing a saponified ethylene-vinyl acetate copolymer, and a layer containing a semi-aromatic polyamide composition that contains a semi-aromatic polyamide having a specific structure, and further has a fluorine-containing polymer in which a functional group having reactivity with an amino group is introduced into the molecular chain thereof.

Owner:UBE CORP

Manufacturing method of steel

The invention provides a manufacturing method of steel, comprising the following steps: smelting the molten steel to ensure that the content of P in the molten steel is less than or equal to 0.035%, the content of S is less than or equal to 0.015% and the content of V is less than or equal to 0.15%; then adding Cu element and Ni element to the molten steel to ensure that the content of Cu in the molten steel is 0.20-0.60% and the content of Ni is 0.15-0.55%; tapping to a steel ladle when the content of C in the molten steel is below 0.05%; adding physical mixture of lime and fluorite and predeoxidizing agent to the steel ladle in the tapping process to ensure that the content of S in the molten steel is less than or equal to 0.012%; adding Cr element, Si element and Mn element to the molten steel to ensure that the content of Si in the molten steel is 0.25-0.60%, the content of Mn is 0.80-1.60% and the content of Cr is 0.20-0.80%; feeding Al simple substance to the molten steel to carry out final deoxidation; heating the molten steel in the condition of argon blowing to lead the steel slag to melt; then adding Al simple substance to the steel ladle to ensure that the content of S in the molten steel is less than or equal to 0.010%; and then adding C element to the molten steel to ensure that the content of C in the molten steel is 0.08-0.16%; feeding Al simple substance and alloy containing Ti, V and N to the molten steel to control that the content of acid-soluble aluminium in the molten steel is 0.025-0.040%, the content of Ti is 0.005-0.015%, the content of V is 0.08-0.15% and the content of N is 0.010-0.020%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Polypropylene composite material and preparation method thereof

The invention provides a polypropylene composite material, comprising the following components in percentage by weight: 35 to 80 percent of polypropylene, 7 to 45 percent of polyethylene, 10 to 30 percent of inorganic nano-particles, 0.1 to 1 percent of antioxidant, and 0.1 to 1 percent of lubricant. The polypropylene composite material provided by adopting the method has the characteristics of low cost and good low-temperature impact resistance. The invention also provides a method for preparing the polypropylene composite material, comprising the following steps: mixing and plasticating the polypropylene, the polyethylene, the antioxidant and the lubricant to prepare a plasticated product; mixing, compacting and molding the plasticated product with the inorganic nano-particles to prepare the polypropylene composite material. The polypropylene composite material with good low-temperature impact resistance can be prepared by adopting the method in lower cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Propylene block copolymer

A propylene block copolymer satisfying the following requirements, which is obtained by producing in the step 1 a propylene polymer component (1), producing in the step 2 a propylene copolymer component (2) in the presence of the component (1), and producing in the step 3 an ethylene copolymer component (3) in the presence of the components (1) and (2):the component (1) has a melting temperature of 155° C. or higher;the component (2) contains 40 to 50% by mol of ethylene, and has an intrinsic viscosity of 2.0 to 8.0 dl / g;the component (3) contains 45 to 70% by mol of ethylene, and has an intrinsic viscosity of 3.0 to 8.0 dl / g, provided that the ethylene content is larger than the ethylene content in the propylene polymer component (2);a ratio by weight of the component (2) to the component (3) is 1 / 10 to 1 / 1;the propylene block copolymer has a glass transition temperature of −55.0° C. or lower; anddispersed particles contained in an injection molded article of the block copolymer have a volume-average particle diameter of 1.0 μm or less, provided that the above particles have a round shape in their cross-section.

Owner:SUMITOMO CHEM CO LTD

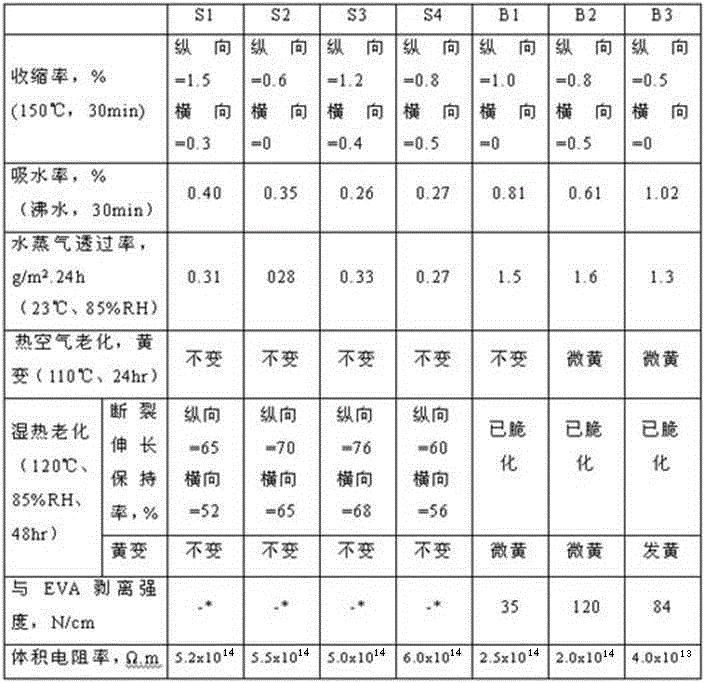

Impact resistant ductile iron castings

ActiveUS9945003B2High low temperature impact resistanceHigh elongationFurnace typesHeat treatment furnacesDuctile ironImpact resistance

A highly impact resistant ductile iron casting is made from a specified high nickel content ductile iron composition and post-treated with a specified heating and cooling profile to achieve an elongation exceeding the ASTM A536 (“60-40-18”) standard, and meeting or exceeding Charpy V Notch impact resistance at −20° F. of greater than 11.0 ft.lbs.

Owner:STRATO AG

Steel for Fasteners Containing Niobium 12.9 Grade Rail Transit Mobile Equipment and Its Heat Treatment Process

Owner:MAANSHAN IRON & STEEL CO LTD

A kind of solar backboard and preparation method thereof

ActiveCN103895304BGood adhesionExcellent interlayer peeling forceSynthetic resin layered productsLaminationPolyolefinSurface layer

The invention discloses a solar energy back panel. The solar energy back panel comprises an upper surface layer, a core layer and a lower surface layer from top to bottom, wherein the mass ratio of the upper surface layer to the core layer to the lower surface layer is (10-20):(60-80):(10-20), the upper surface layer is a polyethylene resin composition layer, the lower surface layer is a polypropylene resin composition layer, and the core layer is a polyolefin resin composition layer. The new solar energy back panel is developed, and experiments prove that the solar energy back panel has good adhesion and interlayer stripping properties, ageing resistance, high-temperature and damp-heat aging resistance, low saturated water absorptivity, low low-temperature impact resistance, low water vapor permeability and excellent electrical insulating property, and can completely meet the requirement of the back panel of a solar cell module.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Heat-sealable propylene-based polymer composition, heat-sealable film, and uses thereof

ActiveUS8003223B2High heat sealing strengthAvoid resistanceSynthetic resin layered productsPackage sterilisationPropylene PolymersAlpha-olefin

The present invention is directed to a heat-sealable propylene-based polymer composition comprising a propylene polymer composition including a propylene polymer component and propylene / ethylene random copolymer component; an ethylene / α-olefin random copolymer; and a soft propylene polymer composition. The present invention also provides a heat-sealable film using the composition and a packaging bag comprising the film. The heat-sealable film of the present invention has high heat-seal strength, with little decrease in heat-seal strength even after heat treatment. The heat-sealable film also has excellent blocking resistance, rigidity and low-temperature impact resistance.

Owner:MITSUI CHEM INC

Vanadium-containing 12.9 grade steel for fasteners used in rail transit mobile equipment and its heat treatment process

ActiveCN105441788BLow temperature impact resistanceHigh strengthTemperature control deviceAustenite grainMicrometer

The invention provides a vanadium-containing 12.9-grade steel for a fastener applied to rail transit mobile equipment. The steel mainly comprises the following chemical elements in percentage by mass: 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.60% to 0.90% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.06% to 0.10% of V, 0.006% to 0.010% of [N], smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S and smaller than or equal to 0.0015% of T[O]. The thermally-treated steel is larger than 10.0 grades in austenitic grain size; the structure of the thermally-treated steel is a small amount of small proeutectoid ferrite dispersed on a tempered sorbite base body, wherein the amount of the proeutectoid ferrite is smaller than or equal to 3%, and the size of the proeutectoid ferrite is smaller than or equal to 5 micrometers.

Owner:MAANSHAN IRON & STEEL CO LTD

Steel for Fasteners Containing Vanadium 10.9 Grade Rail Transit Mobile Equipment and Its Heat Treatment Process

Owner:MAANSHAN IRON & STEEL CO LTD

Steel for Fasteners Containing Niobium Grade 10.9 Rail Transit Mobile Equipment and Its Heat Treatment Process

The invention provides vanadium-contained 10.9-level steel for a fastener for rail transit mobile equipment. The steel mainly comprises following chemical elements including, by mass percentage, 0.33% to 0.38% of C, 0.05% to 0.10% of Si, 0.70% to 0.90% of Mn, 0.70% to 0.90% of Cr, 0.30% to 0.60% of Ni, 0.20% to 0.30% of Mo, 0.015% to 0.045% of Als, 0.03% to 0.06% of Nb, not larger than 0.010% of P, not larger than 0.005% of S and not larger than 0.0015% of T[O]. The autstenitic grain size of steel obtained after heat treatment of the fastener is larger than 10.0 level, and according to the structure of the steel obtained after heat treatment of the fastener, a small amount of small pro-eutectoid ferrite is dispersed and distributed on a tempered sorbite base body, wherein, the amount of the pro-eutectoid ferrite is smaller than or equal to 5%, and the size of the pro-eutectoid ferrite is smaller than or equal to 5 micrometers. The longitudinal mechanical property of the fastener obtained after heat treatment can meet the standard requirement.

Owner:MAANSHAN IRON & STEEL CO LTD

A kind of resin composition and solar backboard prepared therefrom

ActiveCN103897322BImprove low temperature impact resistanceAging resistantSynthetic resin layered productsSemiconductor devicesWater vapor permeabilityAging resistance

The invention discloses a resin composition, which comprises the following components in terms of mass: 100 parts of silane-grafted polyethylene resin, 10-100 parts of pretreated filler, 0-1.5 parts of additive, and 0.05-0.5 part of catalyst; The silane-grafted polyethylene resin is prepared by grafting and cross-linking the following components: 100 parts of component A, 0.2-5 parts of silane, and 0.05-0.5 parts of initiator; wherein, the component A is selected from homopolymerization One or more of ethylene, copolymerized polyethylene and metallocene polyethylene. And a backboard prepared from the resin composition. The back sheet of the present invention not only has excellent adhesion and interlayer peeling force, but also has aging resistance, especially high temperature and heat aging resistance, and has low saturated water absorption, low temperature impact resistance, and low water vapor permeability. High efficiency and excellent electrical insulation, fully meet the requirements of the back sheet of solar cell modules.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

A high strength and toughness martensitic stainless steel

The invention discloses martensite stainless steel with high strength and toughness. The stainless steel is prepared from the following components in percentage by mass: 0.06-0.3% of C, 11-15% of Cr,1.5-3% of Ni, less than 0.08% of P, less than 0.008% of S, less than 30 ppm of O and the balance of Fe and impurities. The martensite stainless steel has the characteristics of corrosion resistance, high strength, high toughness and low temperature impact resistance, overcomes the problem that martensite stainless steel and ferrite stainless steel are not high in strength, overcomes the problem that the conventional martensite stainless steel is poor in toughness and low-temperature performance, overcomes the high-cost problem of duplex stainless steel, and overcomes the defects that sorbite high-strength stainless structural steel has yield strength commonly smaller than 800 MPa, and breaking strength lower than 1000 MPa.

Owner:前海索新发展科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com