A high strength and toughness martensitic stainless steel

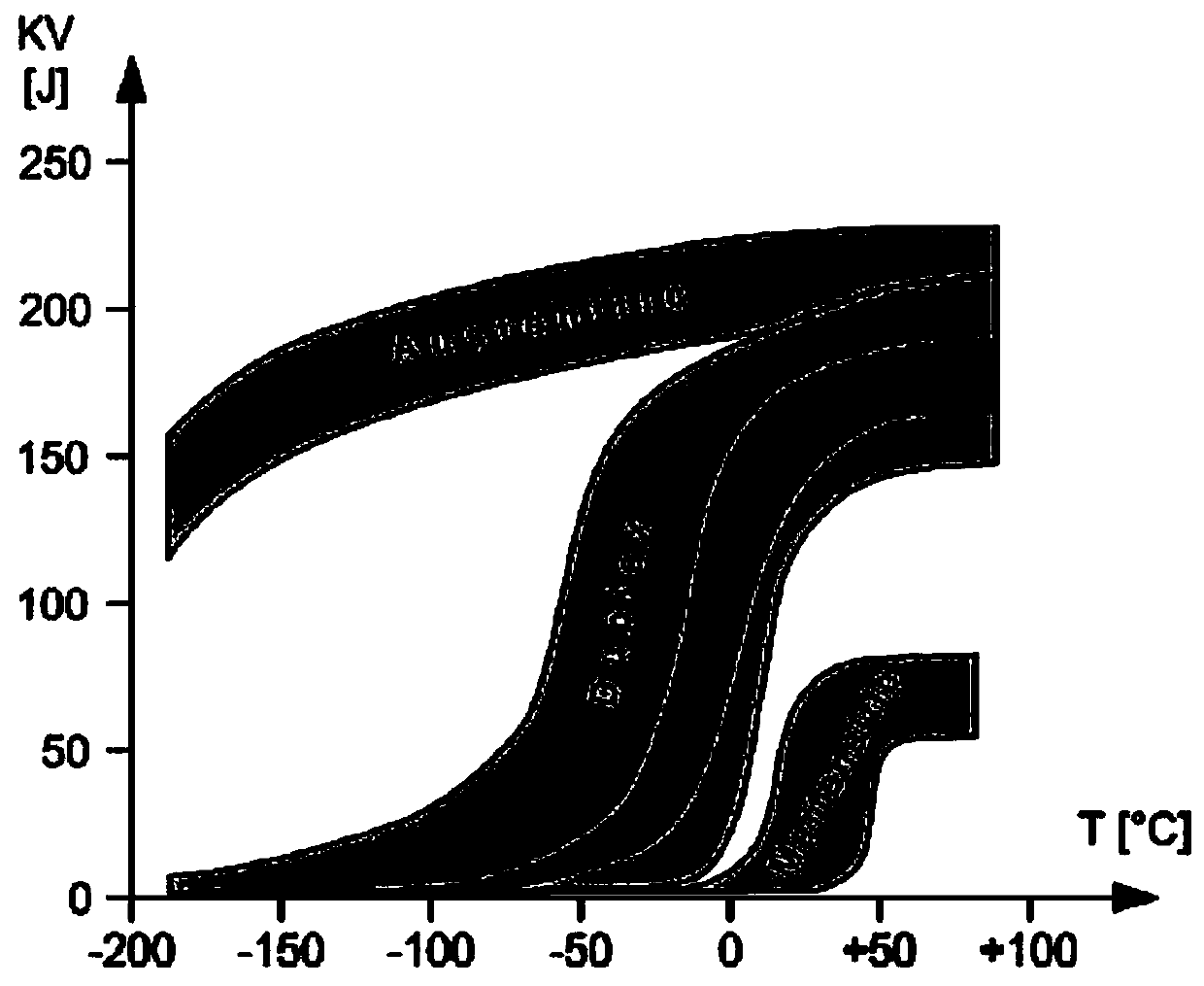

A martensitic stainless steel and molten steel technology, applied in the field of high-strength and tough martensitic stainless steel, can solve the problems of increased dosage, disappearance of low-temperature impact performance, low strength, etc., to expand the application field, good comprehensive performance, overcome toughness and low temperature poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

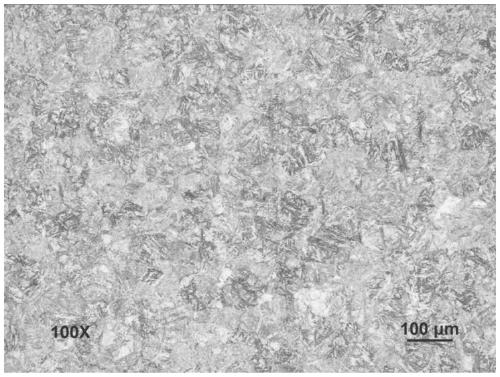

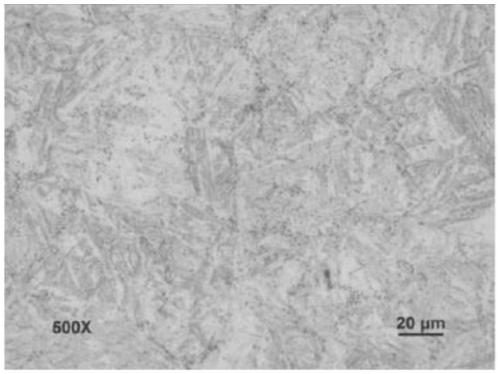

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] The technical problem to be solved by the present invention is to provide a martensitic stainless steel. The mass percentage of the components contained in the stainless steel is: C content 0.06-0.3%, Cr content 11-15%, Ni content 1.5-3%, P content less than 0.08%, the S content is less than 0.008%, the O content is less than 30ppm, and the balance is Fe and impurities.

[0025] In some preferred embodiments, the content of silicon and manganese elements should be as small as possible.

[0026] As a preferred embodiment, the C content can be: 0.06%, 0.08%, 0.11%, 0.12%, 0.16%, 0.18%, 0.25%;

[0027] Cr content can be: 11%, 12%, 13%, 13.51%, 14.58%, 14.98%, 15%;

[0028] Ni content can be: 1.5%, 1.6%, 1.83%, 1.98%, 2.05%, 2.48%, 2.89%, 3%;

[0029] P content can be: 0.079%, 0.06%, 0.0597%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com