Fuel hose and method for producing same

A hose and fuel technology, applied in the direction of hoses, applications, pipes, etc., can solve the problems of expensive hoses and increase the thickness of the fluororesin layer, and achieve excellent heat resistance, light weight, and low fuel permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

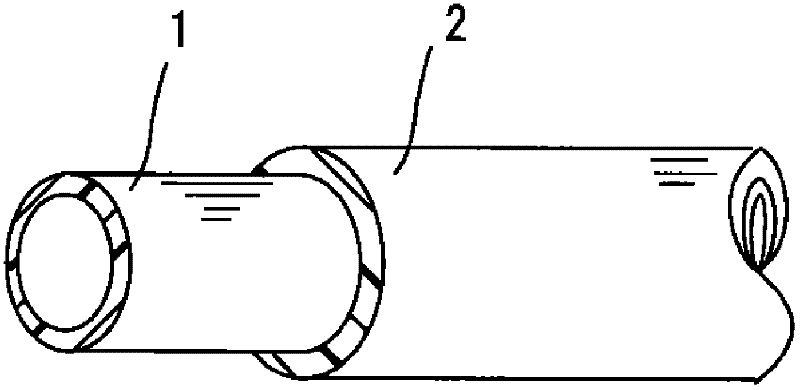

Image

Examples

Embodiment 1~21、 comparative example 1~2

[0088] Prepare the materials for the innermost layer (only Examples 16 to 21), the materials for the inner layer, and the materials for the outer layer shown in the following Tables 1 to 5, and use an extrusion molding machine (a multi-layer extrusion molding machine manufactured by Plastic Engineering Research Institute Co., Ltd.) extruder) melted and kneaded these, and co-extruded them to produce a smooth hose with an inner diameter of 6 mm. In addition, when the smooth hose produced above has a 2-layer structure, the thickness of the inner layer is 0.3mm / the thickness of the outer layer is 0.7mm; mm / thickness of outer layer 0.7mm.

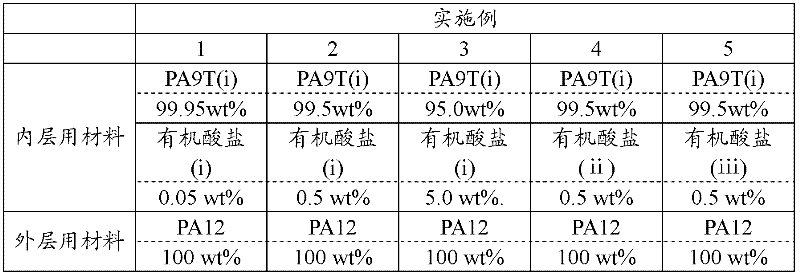

[0089] [Table 1]

[0090]

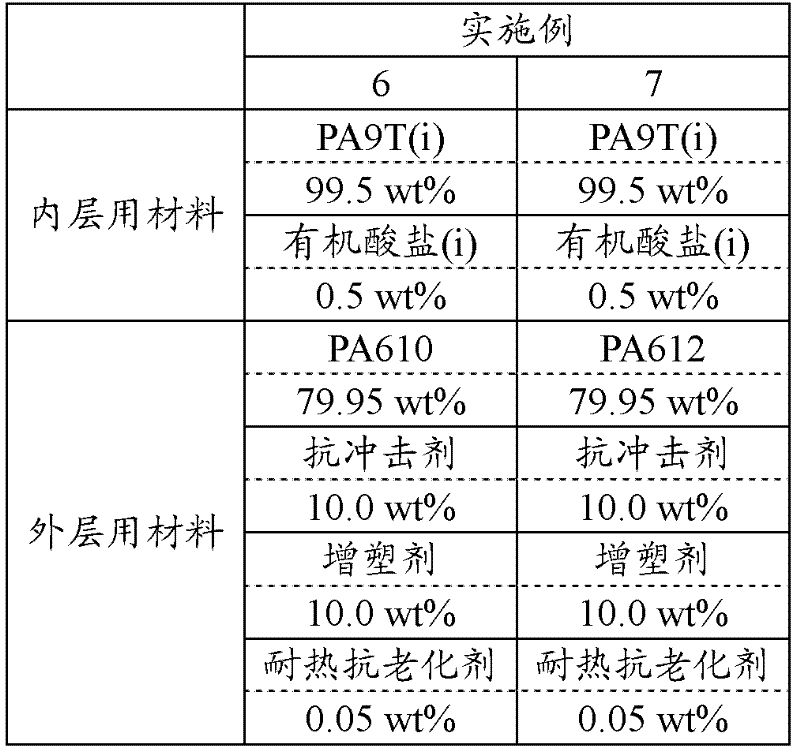

[0091] [Table 2]

[0092]

[0093] [table 3]

[0094]

[0095] [Table 4]

[0096]

[0097] [table 5]

[0098]

[0099] Using the thus-obtained hoses of Examples and Comparative Examples, each property was evaluated according to the following criteria. These results are collectively shown in Tables...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com